Ntech 3d printing

Ntech Engineering Solutions - 3D Printing Company in Ahmedabad, Gujarat, India

Ntech Engineering Solutions

GET EXPERT COUNSELLING

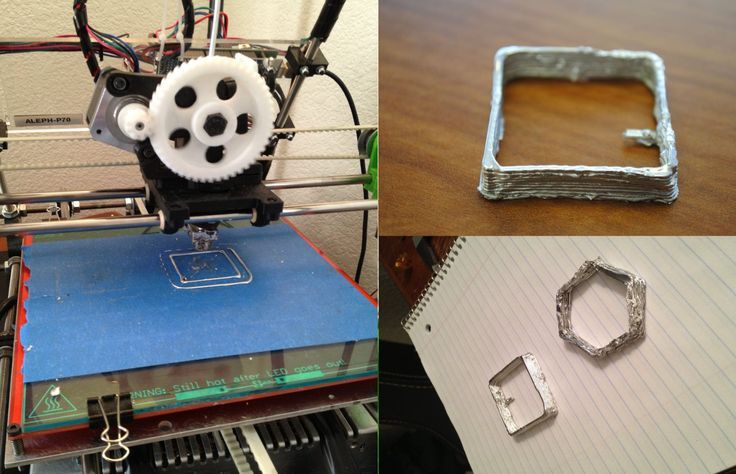

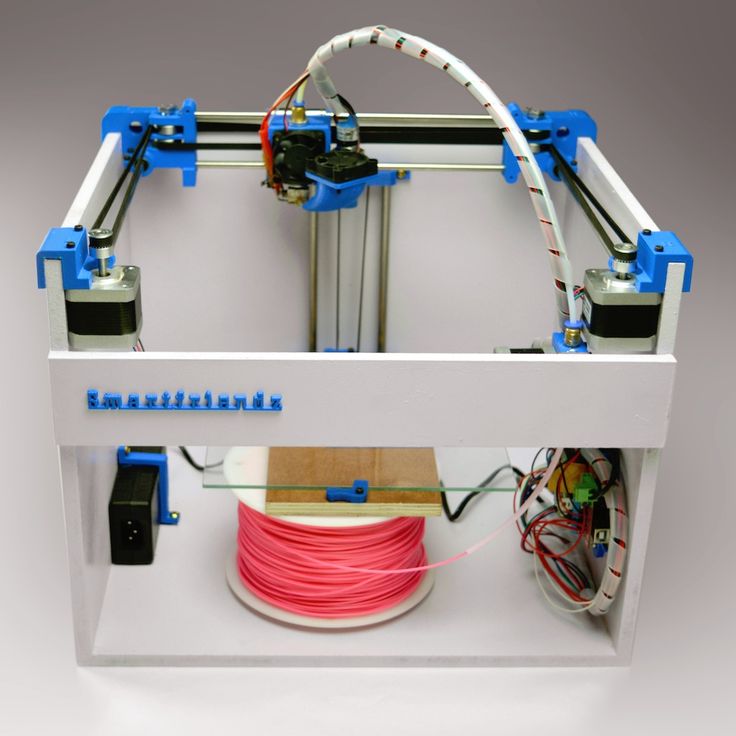

3D PRINTING

Our 3D printing solutions unlocks the door of possibility to consolidate the chain of supply and allow companies to produce lower to mid volumes of parts .

3D LASER SCANNING

Our team of renowned experts of 3D designers produce custom deliverables ranging from point cloud data 3D models, 2D drawings, dimension inspection and RE.

3D PRODUCT DESIGN

By designing your product from the scratch, we can help you get the best ROI from our advanced manufacturing services and ensure that you have the optimum solution to meet the unique requirements.

VACCUM CASTING

From small switchgear parts to large bumpers of automobiles we ensure you to deliver exactly the same product you have desired, NTech has prototyped them all in the last few years.

Get Quote

Estimated quote after discussion.

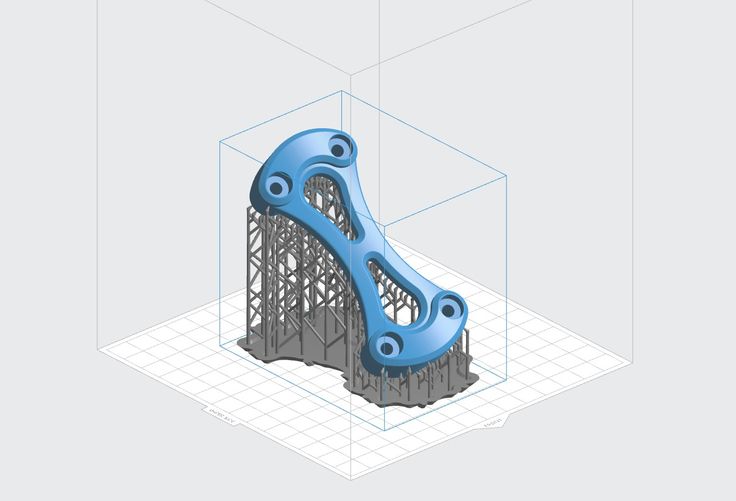

Model Preparation

Send us the part for scanning.

Tech Resources

We scan the part & arrange resources

3D Printing

The part is printed as per the requirement

Packaging

Data delivery and return of part.

Pricing

Meeting Deadlines

Expertise

CONSISTENCY

Standard Pricing

Strict quality control

Professional customer service

Standard Pricing

Strict quality control

Professional customer service

Your satisfaction is our promise

The client sets out with one aim in mind, but this gradually evolves & expands or might change altogether during the 3D design process.

INSIGHT

Gathering apprehension is a foundation path for understanding the hierarchy of need with clients. we understand where the organisation is and where it need to.

CLARITY

Once we get to know the objective of our client we develop an integrated strategy and structural design.

ENABLEMENT

Through the agile methodology we start delivering our service with a clear execution process to ensure that resources are manage appropriately.

Ntech Solutions did a good job in 3D printing my order. They followed up every-time with me for my insightful comments regarding my 3D model. and suggested all necessary improvements and corrected my mistakes because of lack of printing experience.

Jay Patel

They have got a vast knowledge on creating Product Designs, Rapid prototyping systems and also their handling. They were already full with a lot of orders but they managed time and provided us the necessities on time.

Purvesh Simojiya

Excellent very organized, efficient, professional and it was great communicating back & forth. In the end produced a great product in a reasonable price.

Krunal Patel

What is infill in 3D printing?

In 3D printing, infill refers to the structure printed inside the object. The size, shape, pattern, and percentage depends heavily on the design requirements. Higher infill percentage translates to physically stronger 3D printed samples.

Can different infills be chosen for my objects?

Yes, you can opt for different infills for your object. This can be manipulated through different levels in the software. Lower infill percentage can help you to save filament and print time.

How much time does it take to 3D print any object?

The time taken to print any object depends upon the size of the object and settings set for an object. A small object with less dimensions and infills can be printed in less than an hour. Objects with higher dimensions will take several hours to print.

How Does 3D Printing Work?

Here a digital 3D image created on a computer then analyzed & which is divided into layers, as if sliced horizontally or vertically.

Then each slice is produced in succession on the 3D printer, gradually produce a whole object. There are many such alternative processes that can produce an object in this way also.

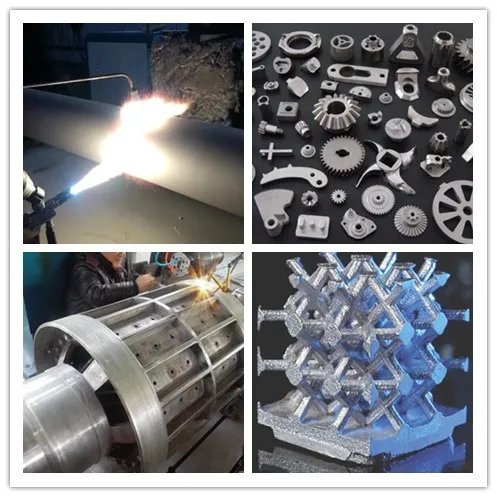

Which Materials Can Be 3D Printed?

ABS is made from petroleum & it is considered to be strong. We use certain experimental materials like mixing wood, metal or nylon particles into PLA plastic. We have certain new 3D printers offer higher temperature build chambers, here where more high-temp materials such as PEEK, ULTEM, PAEK can be used

We have certain new 3D printers offer higher temperature build chambers, here where more high-temp materials such as PEEK, ULTEM, PAEK can be used

How Big An Object Can I 3D Print?

arge projects typically take a long time to complete, often hours or days. Actually it depends on the specific 3D printer you are using. Each one has a max build volume. Typical max size for desktop 3D printers: 150/300 mm P.S. (per side)

3D Printing Brisbane | 3D Printing Services Brisbane

NTech 3D Printing

Our Services

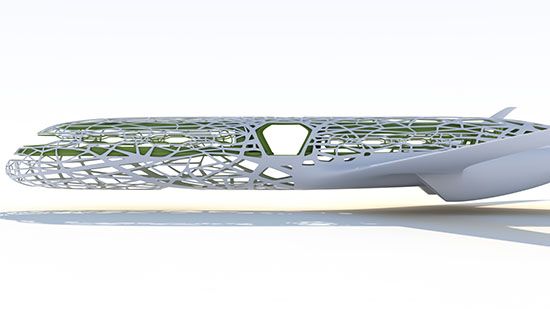

NTech 3D Printing in Brisbane gives you access to FDM 3D Printing and Resin 3D Printing technologies right here in Brisbane to assist you in bringing your ideas to life! 3D Printing is the next generation of manufacturing, often referred to as additive manufacturing. This technique brings lower cost manufacturing into your hands and is often used for prototyping, art, custom items and even end-use products! The potential applications are endless with 3D Printing.

3D printers can be finicky, costly, and sometimes require technical expertise especially if you’re needing reliability and switching materials. We take the pain out of handling the technical nature, upkeep and learning curb of 3D printing so you can solely focus on developing your ideas, prototypes, and products.

Not everyone has 3D CAD design and modelling skills so we also have you covered there, offering 3D CAD design and modelling services which can be created based on your drawings, photos or existing items.There are many material options and considerations when looking to utilise 3D printing however NTech 3D printing Brisbane also has you covered there. You can find all the info you need on the “Service Info and Materials” page.

Whether you need a singular prototype, large 3D prints or bulk 3D printing here in Australia, NTech 3D Printing has the capability. Highly competitive discounting is applied based on the size and type of your order. We can bulk 3D print in materials from PLA and ABS through to high end materials such as Polycarbonate and Nylon which is highly cost effective for small runs or large objects as compared to injection molding or other manufacturing processes.

Get 3D printing today and reach out to us at [email protected]

FDM 3D Printing

The Most Common Form Of 3D Printing In The World With Various Material Choices

3D Design

Parametric 3D CAD Design To Make Your Ideas A Reality

Resin Printing

Ultra high-detail 3D Printing To Bring Your Designs To The Next Level

Printing Consultation

FREE 3D Printing Advice And Consultation To Help Get Your Projects Underway

3D Printer Repair

Fix Up That Troublesome Printer And Get It Printing Like New Again

IMG 3484 1024x768 reduceIMG 3478 1024x768 reduce3D Printed VR Gun2 1 e1558364961961 reduceIMG 3554394 1024x768 Reduce67345441 1118534638342451 7526742155161345745 n 1 reduce65798662 122456629011683 7007715910124937868 n 1 reduce65913065 705411013229302 5752392413902577689 n 1 reduce66288512 1337564389737046 7861314782673757695 n reduceIMG 4975 1024x768 reduceIMG 3943 1024x768 reduceMint Works 1024x768 ruduceIMG 5199 1024x768 reduceOur Benefits

Brisbane Located

Located in the Brisbane area and able to service Australia wide

Affordable

Affordable pricing for consumer and commercial 3D prints

Quick Turnover

Quick turnover on your order regardless of type or size

NTech 3D Printing is the most competitive 3d printing business in Brisbane, offering 3D Printing Australia wide. Capable of producing fast high quality 3D printing and pride ourselves on communication, attention to your specific project and sharing the 3D printing details you need to make the right choices. Whether you have a 3D model ready to go, need your concept designed, or looking into potentially using 3D printing in your application, we’re always willing to go the extra mile.

Capable of producing fast high quality 3D printing and pride ourselves on communication, attention to your specific project and sharing the 3D printing details you need to make the right choices. Whether you have a 3D model ready to go, need your concept designed, or looking into potentially using 3D printing in your application, we’re always willing to go the extra mile.

Get 3D printing today and reach out to us at [email protected]

MICROPRINT, Kostroma — 3d printing studio on Myasnitskaya, 19a on Spravka RU — phones, map, photo, customer reviews and ratings

3d printing studio in Kostroma

Closed Now closed

-

QR code

Rating:

Phone:

- +7 (915) 929-66-66

Address:

Kostroma, Myasnitskaya, 19a 2nd floor

Index:

156000

Region:

Russia, Kostroma region

Site:

- Microprint.

su

su

Category:

Production of plastic products in Kostroma

Opening hours:

| Mon 09:00 - 18:00 (break -) | W 09:00 - 18:00 (break) | CP 09:00 - 18:00 (break) | Th 09:00 - 18:00 (break) | PT 09:00 - 18:00 (break - ) | Sat 09:00 - 15:00 (break - ) |

|---|

QR code with company information

- Contacts

- Map

- About company

- Similar

- Reviews

- Download PDF

- Discovered mistake?

- Is this your company?

-

Map

-

Pictures of

No company photos have been added at the moment.

-

About

3d printing studio “MicroPrint” works in the field of ”Production of plastic products”. On the map of Kostroma you you can see the street and the building at the address: Kostroma, Myasnitskaya, 19a. . Each call to +79159296666 helps to maintain the accuracy and correctness of information about this company.

-

You might be interested

- Imaging

- Jewelry workshops

- Gold (jewelry)

- Jewelers

- Modeling

- Gems

- Wedding rings

- Gold rings

- Silver (jewelry)

- Plastics

- Jewelry design

- Gold jewelry

-

More about the type of activity

-

Additionally, the company is engaged in

Manufacture of plastic products

- Retail

- Manufacturing

- Wholesale

Payment methods

-

On site

- Cash

-

Remote

- By account (for legal entities)

Company categories

- Creation of layouts, prototypes in Kostroma

-

Similar places near

1080m

Intek

Kostroma, Myasnitskaya, 112

1124m

Intek

Kostroma, Myasnitskaya, 112a/1

2793m

Modern packaging technologies

Kostroma, Galichskaya, 126a

3283m

Thermoplastic

Kostroma, Deminskaya, 9

3590m

Ophion

Kostroma, Petra Shcherbina, 23, entrance from the end

3934m

Metaplast

Kostroma, Petra Shcherbina, 23, 2nd floor; end entry

MicroPrint

reviews If you have real experience with this company, then please leave a short review: this will help others navigate among 9companies in this area.

Thank you so much!

No registration required

Add a review

Kostroma Production of plastic products in Kostroma MicroPrint, 3d printing studio

Dynamometer systems - online presentation

Similar presentations:

Transport Process Technology

3D printing and 3D printer

Organization of work and calculation of technical and economic indicators of the part machining section

Lifting machines. (Lecture 4.1.2)

Video card. Types of video cards

Safe work at height

Apple analysis

Well logging

Current and voltage transformers

Transistors

1. By design:

• measuringcomplexes

• monoblock

devices

2. According to the method of installation:

portablestationary

Composition:

• force sensor measuring the transverse

deformation of the polished rod

Composition:

• built-in force sensor (between

rope suspension traverses1) movement, made on the basis of accelerometer

measuring acceleration

portable controller for recording

data and their subsequent storage

on a computer

Software

position sensor that fixes

bottom and top dead points

stroke of the rod

controller that reads

information from sensors and transmits it

to the control center via

telemetry channels

Software

Manufacturer

Naberezhnye

Chelny)

• PAK MIKON-101

NPF Intek

(Ufa)

Stationary system

dynamometer:

Stationary acceleration and load sensor

DPN-T20,

wireless DPNT50

MEGA controller

• PAK MIKON-101-tenzo

• Dynamograph

built-in Mikon802

TNPVO

Siam

(Tomsk)

Dynamography " Dynamograph "Siddos

-Automat 3"

NPP "Grant"

(Ufa)

System

DInamometry

DDS-04

PERSONAL

SUSCOUNTION

11

P

N

Pr

S

Pl

+

+

+

+

+

+

Stationary dynamometer system

(NPF "Intek", Ufa)

Purpose of the system:

Automatic calculation of the actual daily flow rate with 903 downtime, shutdowns and GOR;

· Analysis of the condition of pumping equipment and prompt identification of faults in the form of a dynamometer chart with

in order to reduce operating costs;

Optimization of oil production of marginal wells;

· Control of well operation with rod deep pump

in telemechanics systems;

· Summation of debits and expenses for clusters, brigades,

workshops, fields for automatic control of liquid balance

;

· Visualization and analysis of the technological process for

decision-making by NGDU specialists.

Stationary dynamometer system

(NPF "Intek", Ufa)

Purpose of the system:

· Automatic calculation of the actual daily flow rate

of the well, taking into account downtime, shutdowns and gas factor;

Analysis of the state of pumping equipment and prompt identification of faults in the form of a dynamometer chart with

in order to reduce operating costs;

Optimization of oil production of marginal wells;

· Control of well operation with rod deep pump

in telemechanics systems;

· Summation of debits and expenses for clusters, brigades,

workshops, fields for automatic control of liquid balance

;

Process visualization and analysis for

decision-making by NGDU specialists.

Range of controlled

loads, kN

Range of controlled

displacements

Diameter of the wellhead rod

Range of change

of the number of swings of the balancer,

rpm

Discreteness of control

load

temperature range

for dynamograph

Interface for

data reading

Dynamograph

"SIDDOS-mini 2"

DDS-04

0-200

0-100

500-7500 mm

18-39 mm

2.

5-15

5-15 1-20

20 kgf

400

minus dynamogram

400

minus 14 hour

10 from 14 hour

10 + 50 °C

RS-232

(COM port)

4…20 mA

RS-485

MICON 802

Design of the first version of the position sensor DP-04:

- the moving part is a clamp 1 with

plates fixed on it , on the outer ends of which magnets marked

are rigidly installed 2. For the convenience of setting up the sensor, the length of the plate can be

vary within certain limits;

- the fixed part of the sensor consists of a clamp 1, an angle 2, a cable entry

3 and an electronic module 4 with a marked sensitive plane

5. The clamp is fixed to any structural elements of the gearbox. At

the end of the clamp there is a corner with an electronic module

located on it, which is a cylinder, the upper sensitive

plane 5 of which is marked with black paint. Back side

cylinder has a cable entry.

Movable part

Fixed part

Design of the first version of the position sensor DP-04:

- the movable part consists of two magnets marked with red paint

, which are installed on the inner side of the counterweight

of the pumping unit;

- the fixed part of the sensor consists of corners 1 and 2, cable entry

3, electronic module 4 with a marked sensitive plane 5.