Steel powder 3d printing

3D Printing Metal Filaments and Powders

There are two main drivers of whether or not a metal alloy is printed today: printability and demand. Though there are a wide variety of metal 3D printing processes out there, nearly all rely on metal powders. These materials take two forms in printing: raw 3D printing metal powders, or bound powder 3d printing metal filament. As a result, the metal materials printable today are to a large degree constrained by powder availability and whether or not that powder can be effectively bound. Aluminum, as an example, is notoriously difficult to print well and is as a result relatively uncommon.

Metal 3D printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. Harder materials like stainless steels, tool steels, titanium, and others are more difficult to work with and require higher quality tooling, better machines, and more overhead costs. The added natural manufacturing costs adds to the relative value that 3D printing provides, allowing them to cross the "inflection point" at which 3DP becomes valuable. On the other side of the spectrum, materials that are easy and cheap to machine (low grade steel, aluminum), aren't as in demand because it's already easy to make them. This forms a grouping of "common" metal printing materials that are traditionally really hard to work with, made simple by additive instead of subtractive.

What are the most common metals for 3D Printing?

- Stainless Steels (17-4 PH, 316L, 304)

- Tool Steels (h23, A2, D2)

- Specialty Alloys (Inconel, Cobalt Chromium, and others)

- Titanium (Ti64)

- Aluminum (4047, 6061, 7075)

Steel 3D Printing

Steel is the most common metal 3D printing material. Its strength, ability to be turned into 3D printing metal powder, relatively low cost, and post-processability make it a material usable in many applications. Most varieties of steel can be printed: the two most common are stainless steels and tool steels. Not all steels are commonly printed -- Alloy steels, which are the most common to fabricate conventionally, are rarely printed. Due to their lower conventional fabrication costs and inferior material properties, they’re not as valuable of a material to print.

Due to their lower conventional fabrication costs and inferior material properties, they’re not as valuable of a material to print.

Stainless Steels

Stainless steels are strong, stiff steels that possess excellent corrosion resistance due to their significant Chromium content (at least 12%, often up to 18%). They come in two different varieties, austenitic and martensitic.

A stainless steel lattice, printed with a Selective Laser Melting printer. Image from Axom.Austenitic stainless steels are the most common type of stainless steel. They’re corrosion resistant and can be both machined and welded, though they cannot be heat treated. 303 and 304 are the most common types of austenitic stainless steels, and 316L is a variant that maximizes corrosion resistance.

Martensitic stainless steels are much harder than austenitic steels, but more brittle and less corrosion resistant. As a group, they lack the general versatility of austenitic steels -- however, they can be heat treated and precipitation hardened. They’re best when you need a hard and stiff stainless steel. 17-4 PH is a particularly useful type of martensitic stainless steel that can be heat treated to fit a variety of material properties -- it’s also the most common martensitic steel, though others (like 420) are also printed.

They’re best when you need a hard and stiff stainless steel. 17-4 PH is a particularly useful type of martensitic stainless steel that can be heat treated to fit a variety of material properties -- it’s also the most common martensitic steel, though others (like 420) are also printed.

Tool Steels

Tool Steels are named for their central application -- tooling of all varieties. They contain carbide, an extremely hard compound that’s critical to their ability to cut, grind, stamp, mold, or form. Generally, they’re very hard, abrasion resistant, and usable at high temperatures. Tool steels are categorized by the AISI-SAE grading systems, divided into types by function. The three types most commonly metal 3D printed are A series, D series, and H series tool steels.

Tools steels are often uses for stamping, pressing, and other metal forming applications. Image from ultrastamping.A Series tool steels are great general-use tool steels -- they balance wear resistance and toughness and are machinable. There are eight varieties of A Series tool steels, the most common of which is A2. It’s a versatile tool steel often used to make punches and dies, but usable in a wide variety of applications.

There are eight varieties of A Series tool steels, the most common of which is A2. It’s a versatile tool steel often used to make punches and dies, but usable in a wide variety of applications.

D Series tool steels are optimized for wear resistance and hardness. They’re not particularly tough, and only used for cold work applications. The most common variety of D Series tool steel is D2 -- it’s used for all kinds of cutting tools, from blades to industrial cutting tools and even knives.

H Series tool steels cut and shape material at high (or cycling) temperatures. They’re not as wear resistant as A or D Series tool steels at low temperatures, but hold their strength and stiffness well in increased heat. Though there are many types of H-Series tool steel, h23 the most common 3D printed variety. Its mix of excellent toughness, wear resistance, and heat resistance make it a good general use tool steel that’s optimized for use in high temperatures (hot working).

Titanium 3D Printing

While Titanium is by no means a common material to fabricate conventionally, its unique properties and high base cost make it a great candidate for 3D printing. It’s strong, incredibly lightweight, heat and chemical resistant, and can be biocompatible. Though there are a few different types of Titanium that can be printed, one is by far the most common: Titanium 64 (Ti-6Al-4V).

A custom titanium bike part 3D printed with an SLM machine. Image from Spencer WrightTi64 is the most common type of Titanium in both 3D printing and conventional fabrication. It possesses an excellent strength to weight ratio and can be heat treated to further improve strength. The material also excels in adverse environments due to its corrosion and heat resistance. As a result, it’s used heavily in aircraft (missiles, rockets, airplanes) medicine (as orthopedic implants) and other places where high strength to weight ratio is beneficial.

Aluminum 3D Printing

Aluminum is notoriously difficult to print. As a result, it’s a relatively uncommon printing material despite being exceedingly common in conventional fabrication. The varieties that are printed are generally casting grade aluminum, not more common machinable types like 6061 or 7075. These casting grade aluminum alloys all contain significant (up to 12%) Silicon content, and are weaker and less stiff than 6061. It’s not immediately clear when Aluminum will become more readily available as a 3D printing material, but until then materials like steel and titanium achieve similar strength to weight ratios when printed with open cell infill.

As a result, it’s a relatively uncommon printing material despite being exceedingly common in conventional fabrication. The varieties that are printed are generally casting grade aluminum, not more common machinable types like 6061 or 7075. These casting grade aluminum alloys all contain significant (up to 12%) Silicon content, and are weaker and less stiff than 6061. It’s not immediately clear when Aluminum will become more readily available as a 3D printing material, but until then materials like steel and titanium achieve similar strength to weight ratios when printed with open cell infill.

Specialty Alloys

In addition to more common metals, 3D printers can also fabricate parts out of alloys uniquely suited for hostile environments. These “superalloys” -- metals that exhibit high strength, heat resistance, good surface stability, and resistance to corrosion or oxidation -- can be used in a wide variety of high performance applications. Two subgroups are most common: Inconel and Cobalt Chrome.

Inconel

Inconel is the most common and best known proprietary nickel alloy. It’s an extremely strong, stiff, and corrosion resistant material used in places like turbines, engine seals, and rockets. There are two main formulations that are 3D printed: Inconel 718 is stronger and tougher, and Inconel 625 is more heat resistant. Both materials are incredibly expensive to machine conventionally, making 3D printing a cost-effective alternative to fabricating high fidelity parts.

Cobalt Chrome

Cobalt Chromium is a superalloy known for its biocompatibility, high strength to weight ratio, and corrosion resistance -- it’s essentially a higher-grade, more expensive version of Titanium. Like Inconel, it’s used in turbines and other hostile environments. Unlike Inconel, it can be used in medical applications as orthopedic or dental implants.

Looking Forward

The long term success of metal printers hinges to a large degree on their ability to support a wide variety of materials reliably. The current list is short and focused on higher grade materials that are financially beneficial to fabricate now. However, as metal 3D printing matures, expect to see more and cheaper metal 3D printing filaments and powders available across different metal printing platforms. These materials in turn will open up new applications for metal printing, furthering its adoption by the manufacturing masses.

The current list is short and focused on higher grade materials that are financially beneficial to fabricate now. However, as metal 3D printing matures, expect to see more and cheaper metal 3D printing filaments and powders available across different metal printing platforms. These materials in turn will open up new applications for metal printing, furthering its adoption by the manufacturing masses.

Metal Powders for 3D Printing

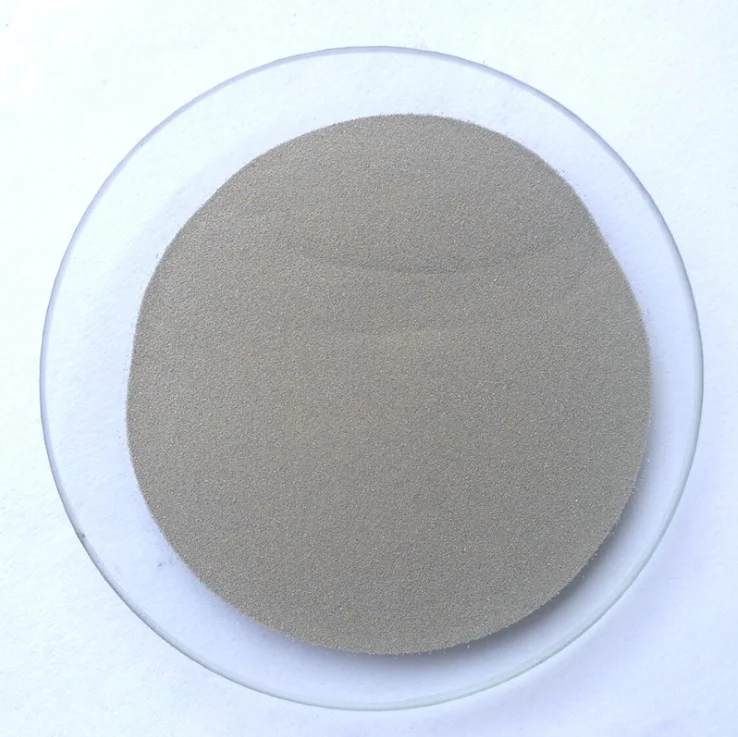

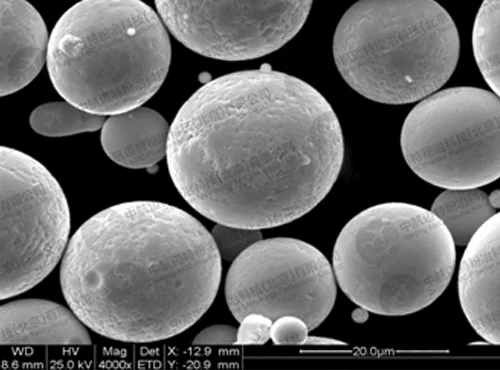

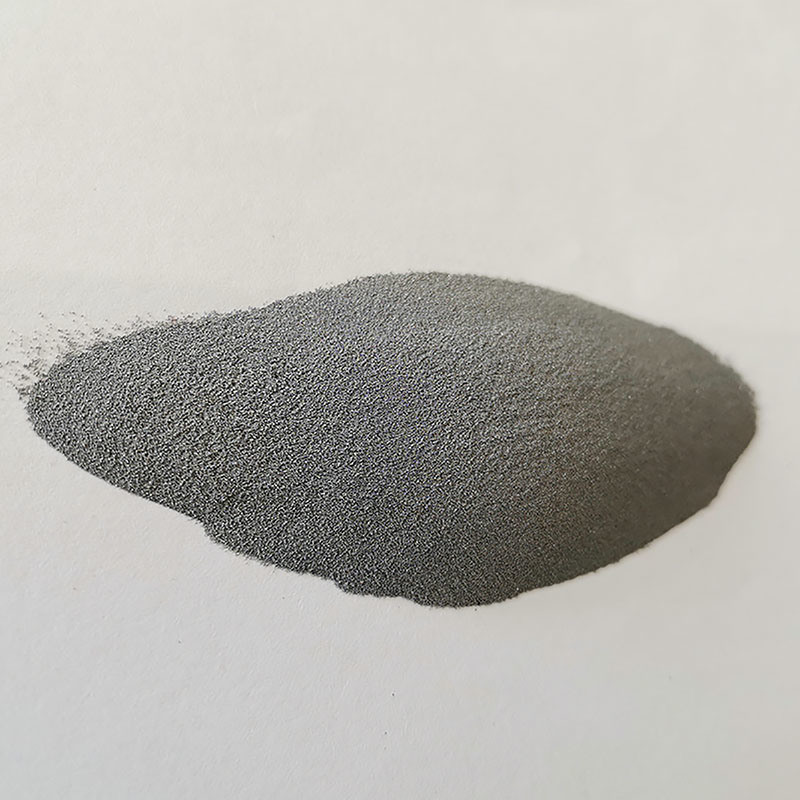

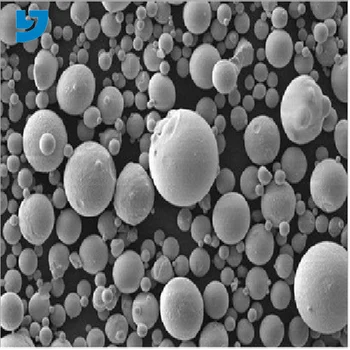

Metal powders are metals that are reduced to fine particles and are the preliminary base materials for most 3D printing processes that produce metallic parts. 3D printing, also known as additive manufacturing (AM), is the manufacturing of parts and products in a layer-by-layer fashion. Both the characteristics of the metal powder and the type of the 3D printing process determine the properties of the end product. Powder characterisation takes place depending on the way it is produced, which may result in different particle morphology and purity.

Here, you can learn about what characterises metal powders, how they are produced, and what 3D printing methods and applications employ such powders.

Characteristics of metal powders

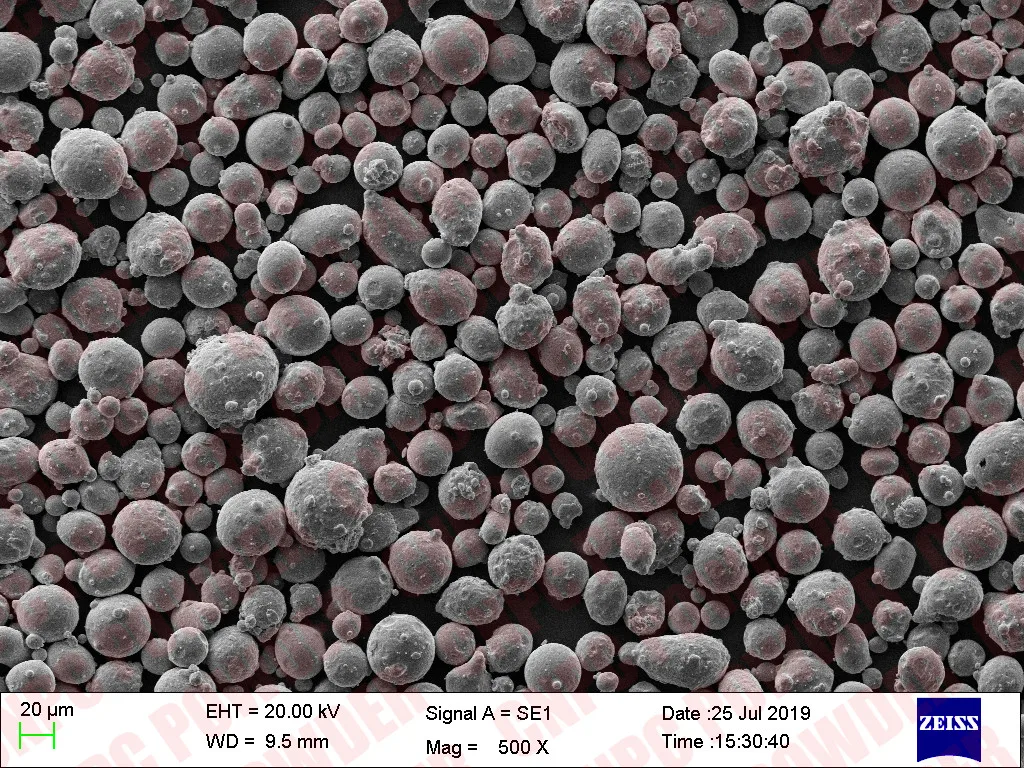

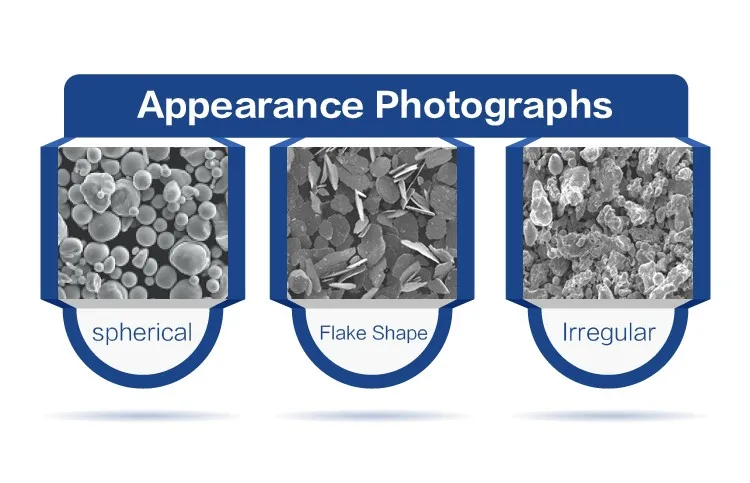

To guarantee accurate reproducibility in metal component production, metal powders have to display consistent characteristics [1]. The primary characteristics are size distribution and morphology. Other technological and physico-chemical characteristics include density, compressibility, sintering ability, chemical composition, green strength, surface area, flowability, and thermal properties [2]. Figure 1 shows the distribution of different metallic materials based on two mechanical properties, yield strength and hardness.

Figure 1: Mechanical properties of metallic materials – minimum values from data sheets. Retrieved from Ref. 3.

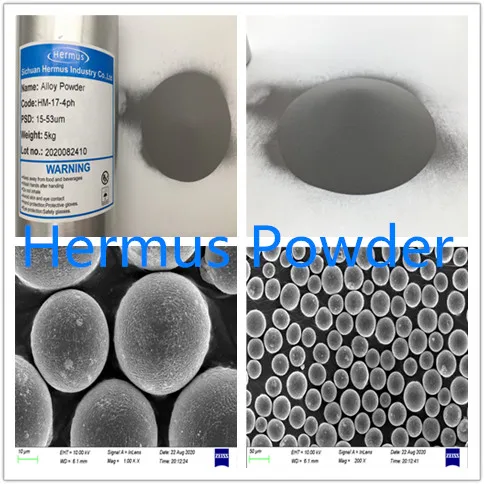

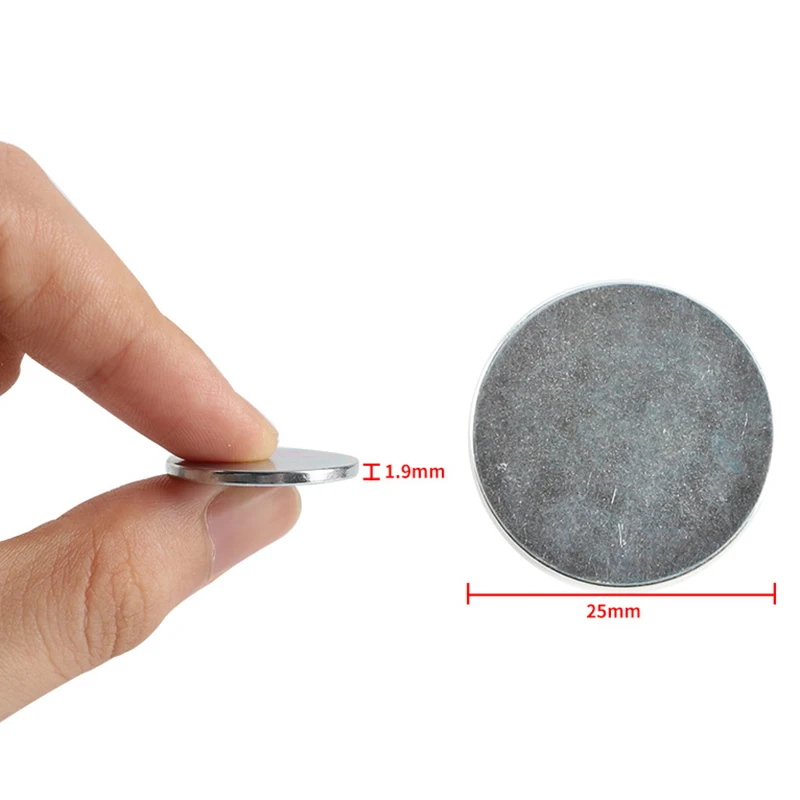

One of the main assumptions for metal powders in 3D printing is that they are nominally spherical and have a certain size distribution that allows them to be well packed, which results in a dense product with good and desired mechanical properties. In other words, the particle size – which determines the smallest possible layer height to achieve – and particle shape, in addition to the powder’s level of purity, play a crucial role in controlling the powder quality.

In other words, the particle size – which determines the smallest possible layer height to achieve – and particle shape, in addition to the powder’s level of purity, play a crucial role in controlling the powder quality.

Production of metal powders for 3D printing

To produce metal powders with the desired characteristics and powder quality and depending on the required properties of the metallic components to be manufactured from the powder, the selection of the powder production process may differ.

Metal powders can be produced using several methods, some of which are solid-state reduction, milling, electrolysis, chemical processes, and atomisation. Yet, because it produces the most geometrically convenient powders for 3D printing, atomisation has been historically regarded as the best method for producing metal powders for AM.

Atomisation can be performed through, but not limited to, three different processes: water atomisation, gas atomisation, and plasma atomisation. Water atomisation, however, results in particles with a highly irregular morphology as the particles solidify faster than their spheroidisation time, which renders the process not suitable for specialised AM [4].

Water atomisation, however, results in particles with a highly irregular morphology as the particles solidify faster than their spheroidisation time, which renders the process not suitable for specialised AM [4].

Gas Atomisation

In this process, the feedstock alloy, usually in ingot form, is melted in a furnace; usually, a vacuum induced melting (VIM) furnace to monitor interstitial elements. The furnace is positioned above the atomisation chamber for direct material discharge into the atomiser. As the melt falls down through the chamber, high-pressure gas jets are sprayed to atomise the material, which solidifies as spherical powder particles, and is collected at the bottom. The gas medium used is usually an inert gas, such as nitrogen or argon, to minimise oxidation and contamination possibilities. Air could also be used as a gas medium. The particle size distribution (0-500 μm) can be modulated to a certain extent by adjusting the ratio of gas to melt flow rate. Some of the powder material produced by gas atomisation are nickel, iron, aluminium, and cobalt.

When processing reactive alloys, like Ti-6Al-4V, there is a high contamination risk if the material gets exposed to the atmosphere or crucible. One way to reduce that risk is by introducing the metal into the atomiser as a rod, melted by a surrounding induction coil prior to entry. This method is called electrode induction melting gas atomisation (EIGA) [4].

Plasma Atomisation

Here, the feedstock is fed into the atomisation chamber in two possible forms, wire or powder form. In the chamber, co-axial plasma torches and gas jets melt and atomise the material at the same time, resulting in extremely spherical powder particles with a relatively finer size distribution (0-200 μm). Titanium is commonly produced by plasma atomisation.

A more specialised method called plasma rotating electrode process (PREP) makes use of a rotating bar instead of a wire as the feed form, whereupon entry to the atomisation chamber, the bar extremity is melted by the plasma torches, and the discharged melt solidifies before reaching the encompassing walls. This process results in powders of high purity, high sphericity, and fine particle sizes (0-100 μm). Titanium and exotic materials can be produced by PREP [4].

This process results in powders of high purity, high sphericity, and fine particle sizes (0-100 μm). Titanium and exotic materials can be produced by PREP [4].

3D Printing with Metal Powders

There is a wide range of powder materials that could be used in 3D printing, and that depends on the desired properties of the end product and the method of printing employed. Some of the common metal powders utilised in AM include alloys of nickel, steel, cobalt, and titanium. In the table below are some of the most common metal powder materials with their 3D printing processing methods and application areas.

| Alloy Material | AM Processing methods | Application Areas | |

| Nickel | Ni 230 | PBF-LB | Aerospace engine components; gas turbine components; high-temperature, corrosion resistant components |

| Ni 625 | PBF-LB | Aerospace engine components; gas turbine components | |

| Ni 718 | PBF-LB, PBF-EB, DED | Aerospace engine components; gas turbine components; oil and gas sensors | |

| Ni 738 | PBF-LB | Turbine engine hot section, blades, heat shields | |

| Steel | h21 | PBF-LB | Aircraft landing gear; hot forging and extrusion dies; helicopter rotor blades; die casting moulds |

| h23 | PBF-LB, DED | Hot work casting dies; hot forging and stamping dies; hot shear blades; plastic injection moulds | |

| 17-4PH | PBF-LB | Aerospace; chemical processing; nuclear and oil/petrochemical refining; metalworking; surgical parts | |

| Cobalt | MM509-A | PBF-LB | Aerospace and IGT engines; nozzle guide vanes; carrier rings |

| ASTM F75 | PBF-LB | Aerospace engine components; gas turbine; medical and dental implants | |

| h288-A | PBF-LB | Transition ducts; combustion cans; spray bars; flame holders; liners | |

| Titanium | Ti-6Al-4V | PBF-LB, EBM | Aerospace and defence; automotive and racing; maritime applications; high-end sports equipment; medical and dental; jewellery and art |

| CP-Ti | BJ, DED, EBM, MIM, SLM | Aerospace materials; automotive; chemical industry; biomedical; dental implants | |

Legend

- BJ: Binder Jetting

- DED: Direct Energy Deposition

- EBM: Electric Beam Melting

- MIM: Metal Injection Moulding

- PBF-LB: Laser Powder Bed Fusion

- PBF-EB: Electron Beam Powder Bed Fusion

- SLM: Selective Laser Melting

[1] J. A. Slotwinski et al., 2014, “Characterization of Metal Powders Used for Additive Manufacturing”, Journal of Research of NIST, 119, pp. 460-93.

A. Slotwinski et al., 2014, “Characterization of Metal Powders Used for Additive Manufacturing”, Journal of Research of NIST, 119, pp. 460-93.

[2] K.S. Narasimhan, M.O.H. Amuda, 2017, “Powder Characterization”, Reference Module in Materials Science and Materials Engineering.

[3] “Metal powders – the raw materials”, n.d., from: https://www.metal-am.com/introduction-to-metal-additive-manufacturing-and-3d-printing/metal-powders-the-raw-materials/

[4] J. Dawes, R. Bowerman, R. Trepleton, 2015, “Introduction to the Additive Manufacturing Powder Metallurgy Supply Chain”, Johnson Matthew Technology Review, 59, (3), 243.

Metal powder for 3d printer: titanium powder production

Metal printing is one of the most promising industries of the future. It allows you to avoid a lot of disadvantages inherent in classical casting or stamping. For the manufacture of the part, a special powder is used, from which the workpiece is obtained. It is he who gives the final product one or another physical property.

It is he who gives the final product one or another physical property.

Main characteristics of metal 3D printing

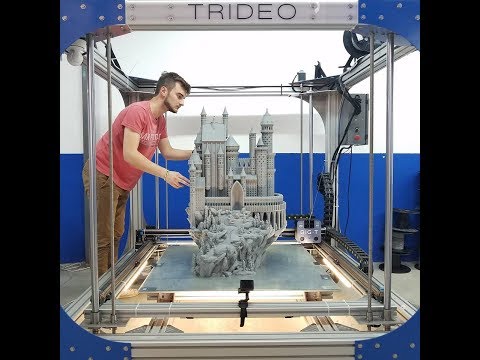

Metal 3D printers are used in large-scale production. They find their application in design offices, engineering shops and research institutes. In civilian areas, metal printers are installed in medical centers.

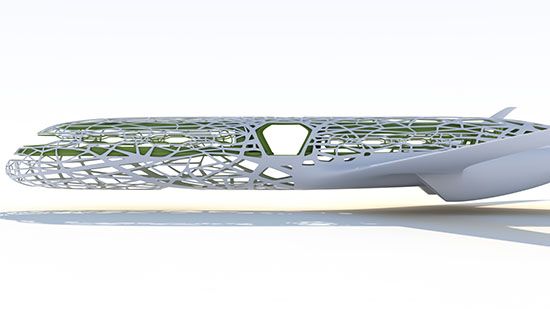

Additive printing technology allows you to make complex interlaced designs in a single piece. For example, in 2020 NASA made a "space fabric". The material resembles chain mail in texture with a very complex internal pattern. The difference between ancient armor and modern material lies in the production technology. Chain mail was woven, linking each link by hand. The space fabric was printed in one pass.

Space cloth

3D printed metal products are valued for their characteristics:

- High strength finished part. Density indicators are 1.5 times higher than in metal casting.

- Complex geometry.

You can print intricate shapes of bizarre geometry. For example, to make a high-strength chain without welding points.

You can print intricate shapes of bizarre geometry. For example, to make a high-strength chain without welding points. - Wide range of alloys and materials. From aluminum to titanium.

- Rough product surface. In some cases, this is a plus, not a minus.

- No tension in the metal, which is almost impossible to achieve with casting.

- Wide range of post-processing.

A separate line is the cost of the finished part. Powder printing does not require special equipment, as, for example, for casting. The desired part is loaded into the program memory, and after a short time it appears from the printer.

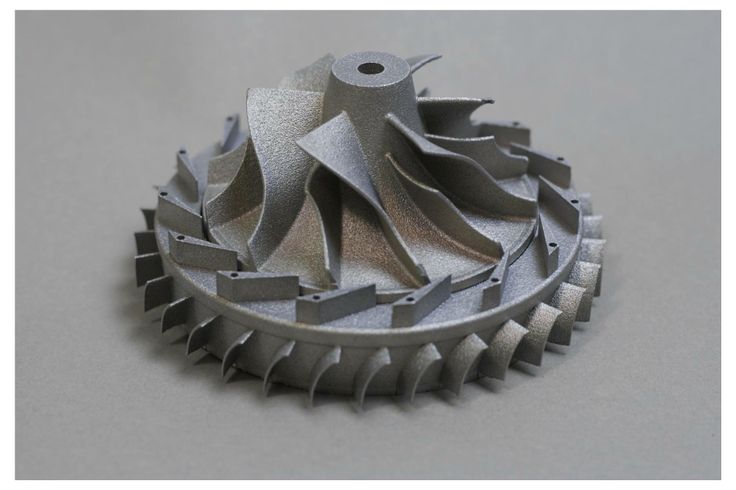

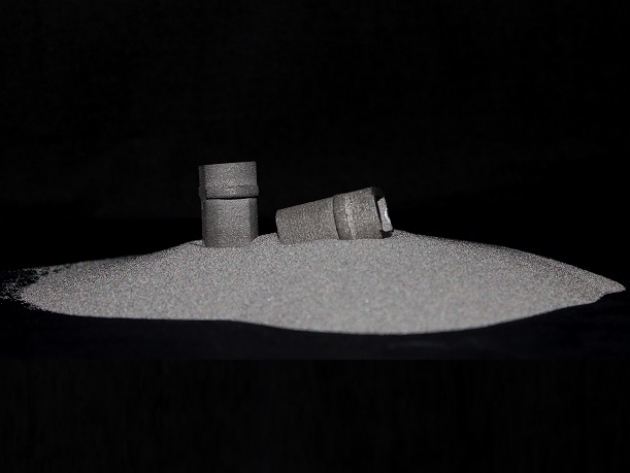

Printing Part

Printing Technology

There are several basic printing technologies:

- SLM is the basic metal powder printing technology. The part is formed by sintering the material in the inner chamber of the printing device under the influence of a laser.

- DMP is almost a complete analogue of the previous technology.

Such a solution can be found in 3D Systems printers.

Such a solution can be found in 3D Systems printers. - EBM is a technology in which the powder is sintered under the action of an electron beam gun.

There is a private variant of SLM called DMLS. The second option implies that the powder particles are heated to lower temperatures. The material does not become liquid.

Help! The SLM printing technology was developed by Wilhelm Meiners, Konrad Wissenbach, as well as Dieter Schwarz and Matthias Fokele. Subsequently, the founder Dieter Schwarz left for SLM Solutions GmbH, which is one of the world leaders in the production of 3D metal printers.

SLM Solutions 3D printer operator

Types of metal powders for 3D printing

There are about 20 most famous metal powder materials that are used for various tasks. For example, a technologist can take a titanium alloy to create the frame of a future assembly, and make the walls and insides of the mechanism from aluminum. Get a strong and lightweight design with the desired performance characteristics.

Get a strong and lightweight design with the desired performance characteristics.

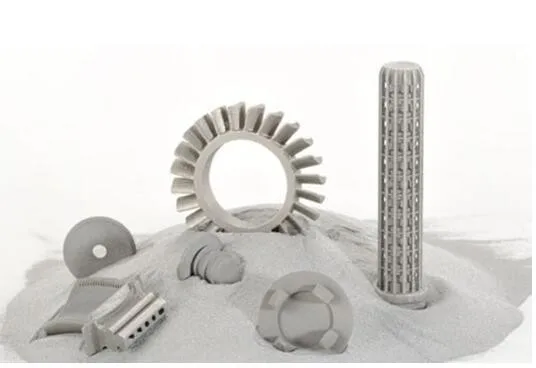

Metal powders are actively used in the aviation, automotive, and aerospace industries. With the help of additive technologies, engineers create complex assemblies and innovative parts. The main types of powders: titanium, steel, aluminum, cobalt-chromium, nickel.

Important! When we say "powder", we mean an alloy based on one of the listed metals.

Titanium powder for 3D printer

The most common alloy is Ti6Al4V. It has excellent performance characteristics. Titanium alloy is rightfully considered one of the strongest and most durable among other metals. The finished product has a density of 4500 kg/m. Tensile strength ratings up to 900 MPa. The maximum temperature is up to +1100 °C. The material is valued for its lightness and reliability. It is often used in the aircraft and space industries.

Steel

Tool steel is used everywhere. The most common alloys: 1.2343, 1.2344, 1.2367, 1.2709. With the help of this material, molds for casting, various tools are made: cutters, measuring dies and tooling. Typically, steel alloys contain from 0.7% carbon. This makes the material more viscous. End products receive increased strength and hardness.

The most common alloys: 1.2343, 1.2344, 1.2367, 1.2709. With the help of this material, molds for casting, various tools are made: cutters, measuring dies and tooling. Typically, steel alloys contain from 0.7% carbon. This makes the material more viscous. End products receive increased strength and hardness.

Aluminum and alloys

This material is considered one of the cheapest lithium alloys on the market. The most common powders are AlSi10Mg, AlSi12. This material has several advantages: high resistance to corrosion, thermal conductivity, fluidity. The alloy is a good conductor of electricity. It is used in the manufacture of overall thin-walled parts.

Cobalt Chromium

CoCr alloy is one of the most common materials used in aircraft and missile applications. The alloy has high mechanical properties. Various components and parts with complex geometry are made from it. Cobalt-chromium alloys are used in the manufacture of clasp prostheses.

Nickel alloys

The main feature of nickel is the ability to dissolve other metals without losing strength. It is this characteristic that makes it one of the most common in various industries. For example, heat-resistant blades for jet engines are made from NiCr alloy. Some nickel alloys are comparable in melting point to titanium powder. Their upper threshold reaches +1100 °C. The most common nickel alloys are Inconel 625, Inconel 718, Inconel 939, Invar 36, NX.

It is this characteristic that makes it one of the most common in various industries. For example, heat-resistant blades for jet engines are made from NiCr alloy. Some nickel alloys are comparable in melting point to titanium powder. Their upper threshold reaches +1100 °C. The most common nickel alloys are Inconel 625, Inconel 718, Inconel 939, Invar 36, NX.

Other alloys and metals

Among other common metals, two more groups can be distinguished:

- Stainless steel alloys. Powders with a chromium content of at least 12%. These include 15-5PH, 17-4PH, AISI 410, AISI 304L, AISI 316L, AISI 904L.

- Non-ferrous alloys. Metal powder with the addition of copper or tin. Such materials include CuSn6, CuSn10.

There are also less demanded alloys, for example, based on tungsten.

Interesting! There are precious metal powders. In particular, Cooksongold created platinum powder for jewelry printing. Finished products receive a 950 test and boast the best mechanical characteristics.

Platinum jewelry

Production of powder for a 3D printer

The cost of manufacturing a material for "refueling" a 3D printer for metal is higher than, for example, a filament or a photopolymer. This explains the price of the finished product. At the factory, the hot melt of metal is "sprayed" with a jet of gas, water or plasma to obtain a powder. This greatly complicates and increases the cost of production.

Interesting! In 2019, a group of Russian scientists from NUST MISiS developed a new method for making titanium and aluminum powder. In its production, a planetary mill is used. They get, as it were, a semi-finished product that reaches the desired mechanical properties already in the printing process.

SLM machine operators use the powder several times. In particular, they recycle marriage, and also re-produce support. And this is about 10% of the total mass of the printed blank. The remains are crushed and processed on special installations - atomizers.

The remains are crushed and processed on special installations - atomizers.

Atomizer

There are a large number of powders based on metal alloys. All of them solve certain problems. It is necessary to select the material based on the physical, mechanical and chemical properties of the final product.

- March 22, 2021

- 3545

Get expert advice

Steel 3D Printing - Quick Guide / Sudo Null IT News0001

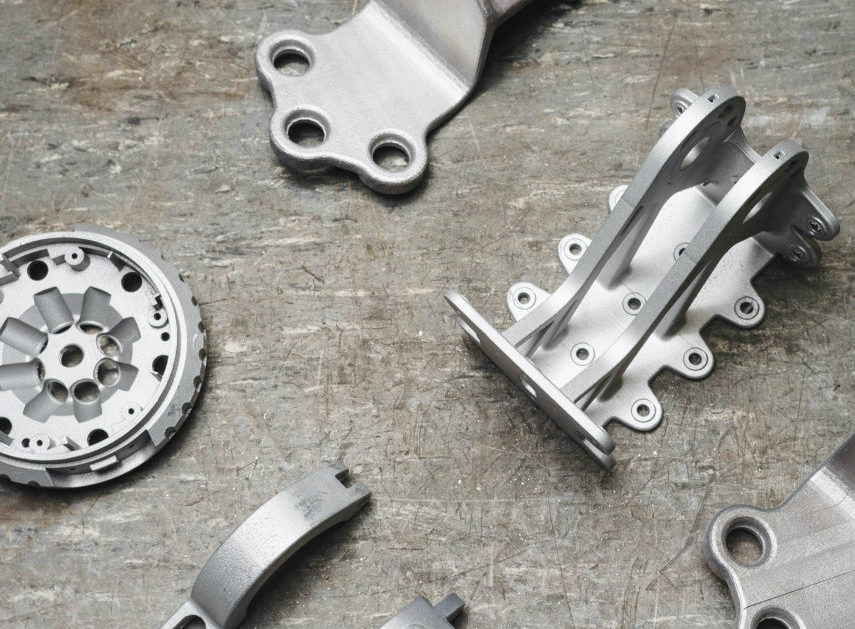

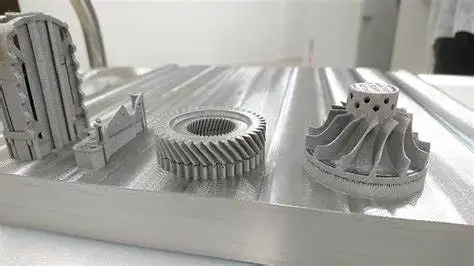

Metal 3D printing using pure steel and alloys produces durable functional parts for mechanical and industrial products.

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts?

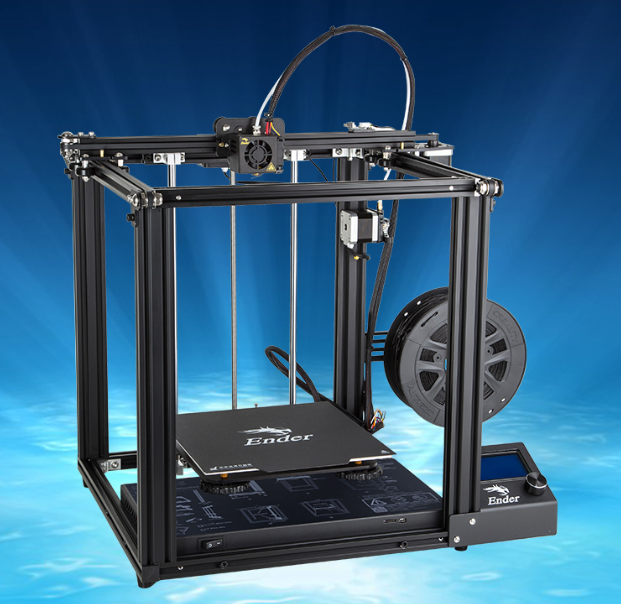

Let's see how a 3D printed steel part revolutionizes manufacturing and opens the door to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

Strength of steel printed parts.

Cast steel part (left), 3D printed version (center). On the right, a fully 3D printed hinge requires no assembly. (Source: Desktop Metal)The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?" ?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes even stronger, than those made in the traditional way. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc.

Parts printed from steel are used in the aerospace industry, for the military, and also, for example, for the manufacture of a footbridge, shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

A 3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts.

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In experiments comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture.

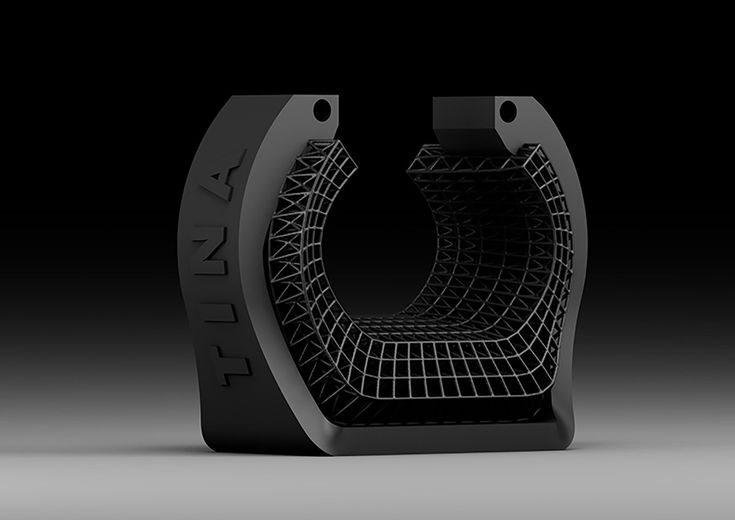

The main advantage of printing with steel is not only its strength, but also the unique ability to create internal channels and lattice fillings in parts, which is impossible using traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength.

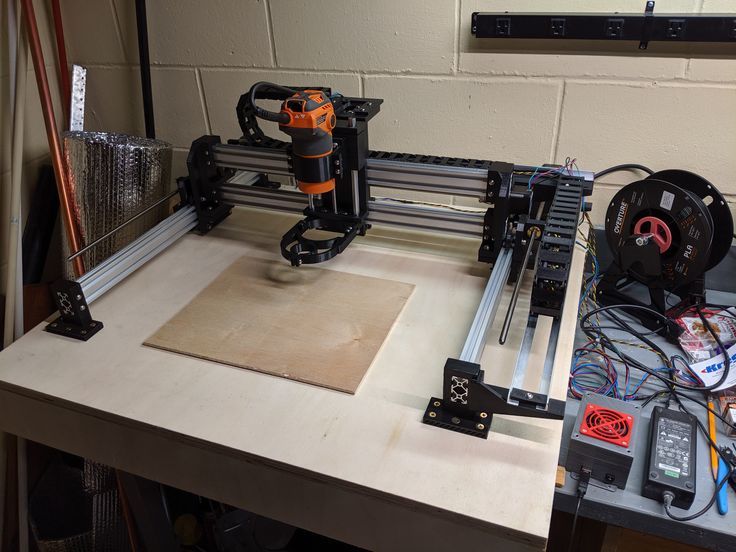

MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D) Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product.

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants.

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc.), then all these parameters can be incorporated into the product at the production stage.

Types of steel for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive) There are thousands of different grades of steels and alloys with different mechanical properties, used in traditional manufacturing but in 3D printing there are only a few dozen of them, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

Among the steel options, the following can be distinguished:

-

Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410).

-

Tool steel (D2, M2, h23, h21, MS1, 1.2709).

-

Low alloy steel (4140).

-

Structural alloyed (20MnCr5).

Recently, unique alloys have been developed specifically for 3D printing, designed to solve the problems that occur with classical production methods.

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to achieve increased corrosion resistance while being easy to machine and polish.

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

How to print with steel

The strength, properties, and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast.

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

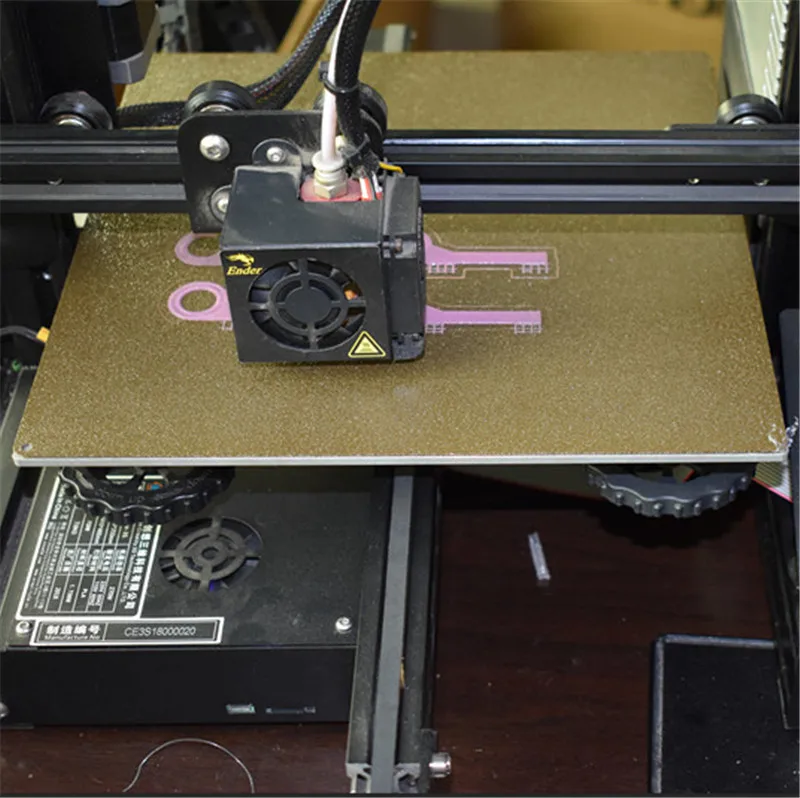

Fused Deposition Printing (FDM)

BCN3D's Epsilon printer extrudes metal filament from stainless steel. as more printer manufacturers certify metallic filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced.

This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced. FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts.

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's 316L Stainless Steel Ultrafuse filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts.

(Source: BCN3D) While 3D printing with metallic materials may not be suitable for demanding applications such as aerospace, the economics of producing simple metal components without critical loads on an affordable FDM printer can outweigh the impossibility of applying them in some areas.

Metal prototype parts and finished parts that will not be subjected to extreme stress are ideal uses for this technology.

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used bonded metal bars that were extruded layer by layer to form a metal part (Source: Desktop Metal)Similar to FDM, Metal mesh deposition method (BMD) or bonded powder extrusion (BPE) is a 3D printing process based on extrusion. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required.

There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel.

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal instruments.

Laser powder sintering.

Laser powder sintering technology uses one or more lasers to melt powdered metal into a desired shape layer by layer (Source: GE Additive) metal printing. This technology is used by 80% of all metal 3D printers on the market.This method uses powerful lasers to selectively sinter metal powder layer by layer.

LPBF 3D printers are available in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods.

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments.

Binder Jetting

Binder Jetting 3D printing technology uses powdered metal and a binder to form metal parts (Sorrce: ExOne) binder, and not with a laser. During post-processing, the binder is removed.Binder application stands out for its high printing speed compared to other 3D printing methods or traditional manufacturing, and metal parts made with this technology have material properties equivalent to those made by metal injection molding.

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels.

Electron Beam Melting (EBM)

(Source: GE Additive)Electron Beam Melting (EBM) is another powder cladding technology. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer.

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries.

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)Cold spray 3D printing is done by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation.

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for crash repairs because the high strength steel substrates in cars can be susceptible to thermal repair methods such as welding.

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

WAAM Steel Parts from MX3D (Source: MX3D) Direct Energy Deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into the power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining.

DED can get such parts much closer to finished than traditional CNC machining.

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost reduction. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field.

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint) Micro scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less).