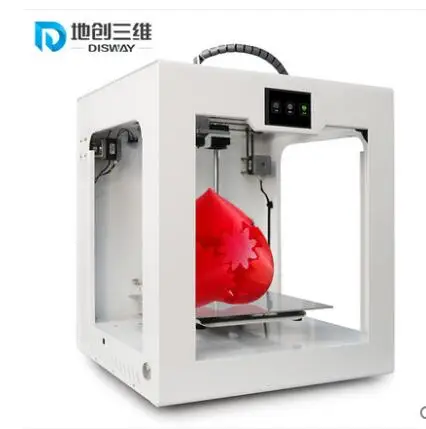

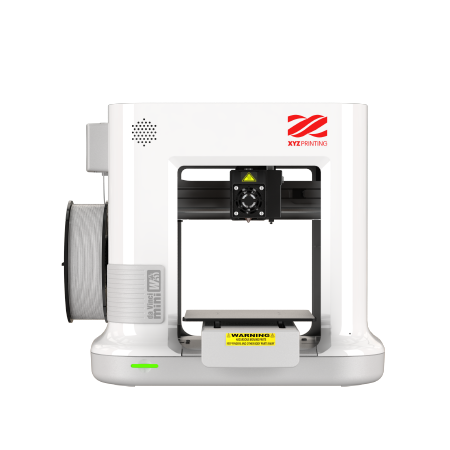

Da vinci mini 3d printer parts

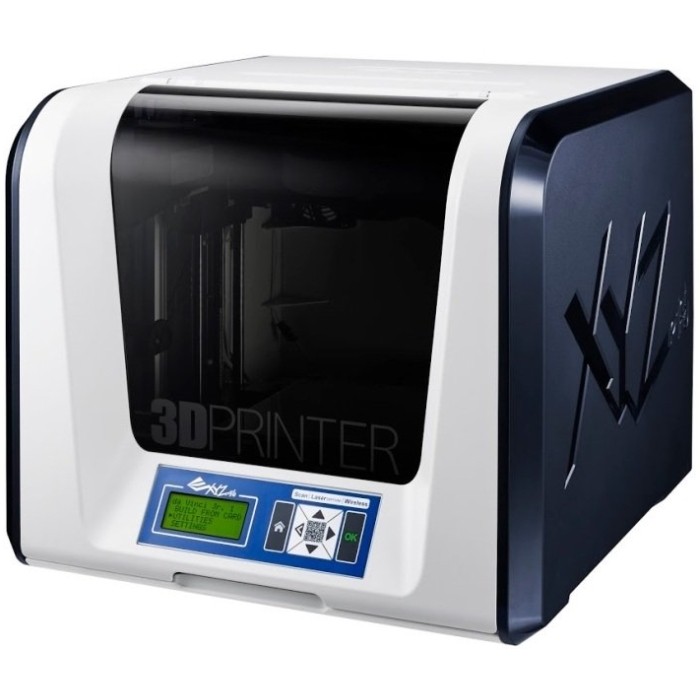

XYZ da Vinci Mini 3D Printer

The da Vinci Mini offers a perfect entry point for beginners and students to explore 3D printing, thanks to simplified controls and a user-friendly workflow process.

- One touch button process for quick 3D printing

- Auto calibration provides instant bed leveling

- Small footprint, yet robust build volume

- Bundled with XYZmaker and XYZware

- Built-in Wi-Fi for connecting to the home, office, or classroom

- Accommodates safe, non-toxic PLA filament

Read the full description below

Notes from the Workshop:

With the XYZprinting STEAM program, students and beginners can quickly get acclimated to 3D printing in science, technology, engineering, math, and the arts.

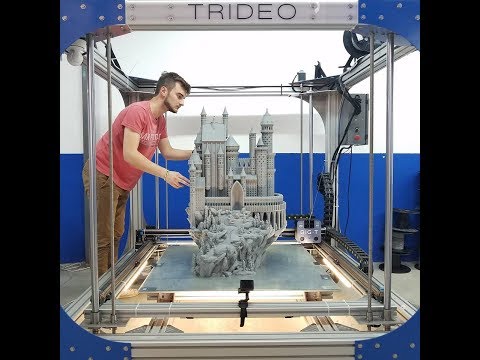

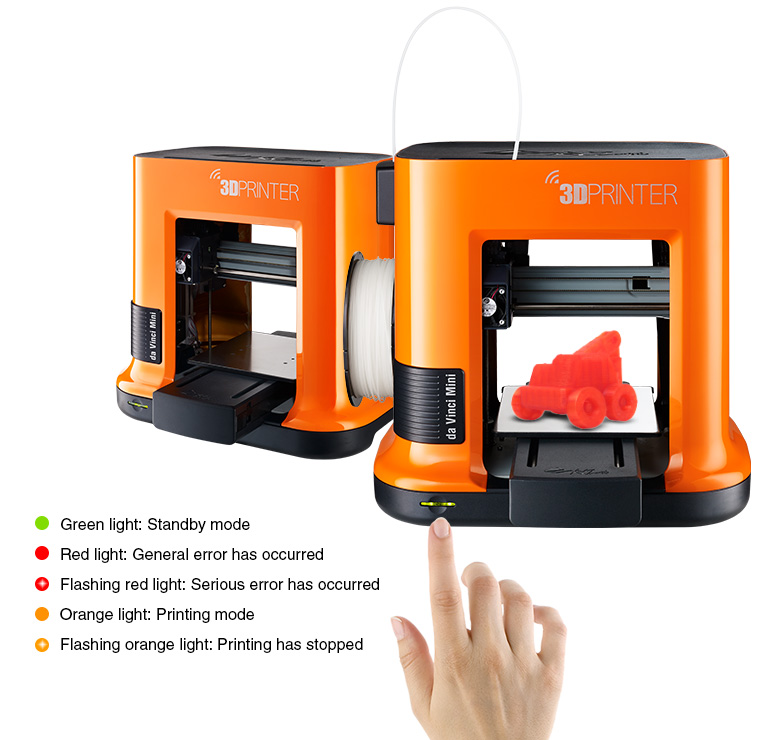

XYZprinting’s da Vinci Mini is part of its Beginning line of products, ideal for young makers, students, and part-time hobbyists who require an easy and affordable way to get started with 3D printing. Using a seamless, one-touch control process, the da Vinci Mini features an automatic filament loading system, color coded indicator lights, and a simplified overall workflow for beginners. With its intuitive auto-calibration system, the da Vinci Mini performs instant bed leveling prior to each 3D print. It can connect wirelessly to computers in homes, offices, and classrooms, reducing the need for USB cable clutter.

Made with a rigid plastic housing and supported by steel components, the da Vinci Mini 3D printer offers a stable, vibration-free extrusion process in order to ensure accuracy. The aluminum build plate helps promote surface adhesion in order to prevent warping and curling. All of the printer’s precision components have been carefully designed to ensure consistent and trouble-free 3D printing.

The da Vinci Mini’s build area measures 5.9” x 5.9” x 5.9”, allowing it to work with objects such as toys, small prototypes, jewelry, and more. The external drive system pushes filament toward the single extruder hot end, simplifying the process for beginners. The color coded LED interface changes according to the 3D printing conditions, providing a new way for users to interpret heating, printing, or potential filament feeding issues.

The color coded LED interface changes according to the 3D printing conditions, providing a new way for users to interpret heating, printing, or potential filament feeding issues.

Important information about print material (filament) – again, in a positive way

- To be noted if print material is limited (e.g. only custom PLA spools).

- To be noted if the variety of print materials is impressive.

Anything else notable

- The da Vinci Mini 3D printer uses proprietary filament rolls from XYZprinting, making them safe for younger consumers, students, and casual hobbyists.

- XYZprinting PLA filaments are non-toxic and free of heavy metals; extensively tested for safe and reliable 3D printing.

- XYZmaker and XYZware are bundled with the da Vinci Mini, providing streamlined 3D modeling and slicing capabilities that are easy and intuitive for classrooms.

- Can go into more technical information about the print chamber size, extruder model or temperatures, print bed material.

Feel free to include actual specs (e.g. 17 microns, 12”, etc.)

Feel free to include actual specs (e.g. 17 microns, 12”, etc.)

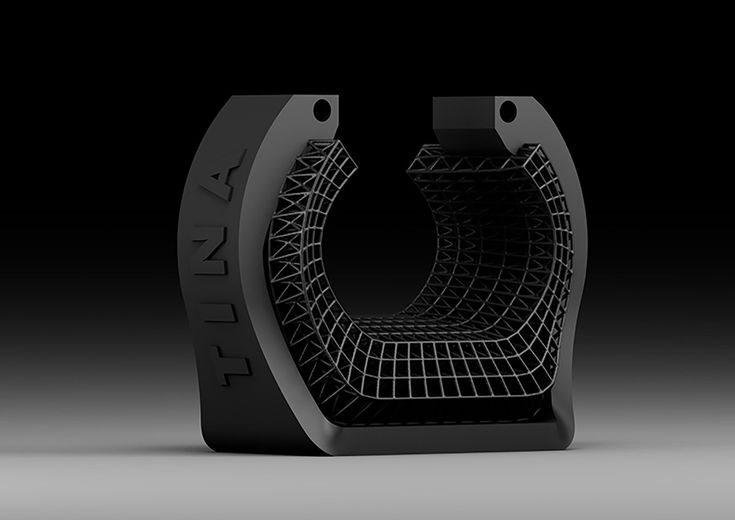

The da Vinci Mini 3D printer is capable of printing between 100 micron (0.1 mm) and 400 micron (0.4 mm). Users should be aware that the finer the resolution, the slower the overall print speed.

The da Vinci Mini is available in two colors, orange and black, and red/yellow/blue. The red, yellow, blue color scheme is designed to complement the atmosphere of younger classrooms.

XYZprinting is a leading provider of affordable desktop 3D printers for homes, offices, and schools. Backed by a variety of 3D printers and accessories, the company strives to make 3D printing affordable and accessible to the masses.

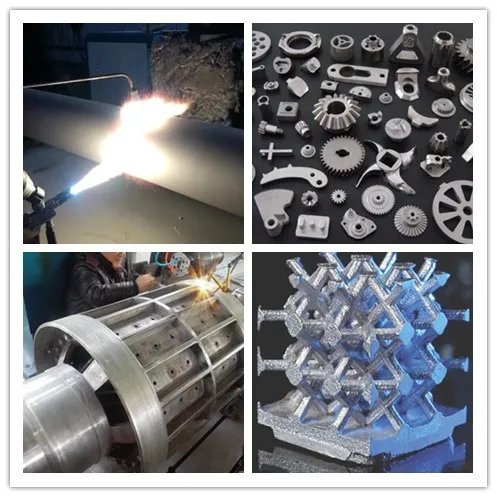

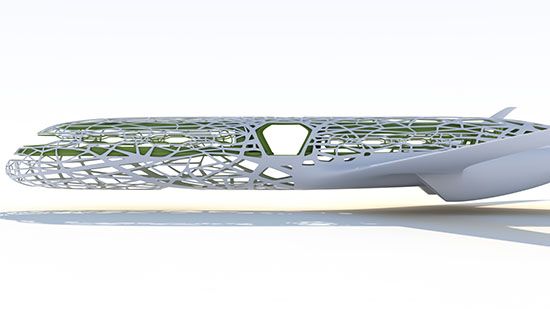

| Technique | Additive Manufacturing |

|---|---|

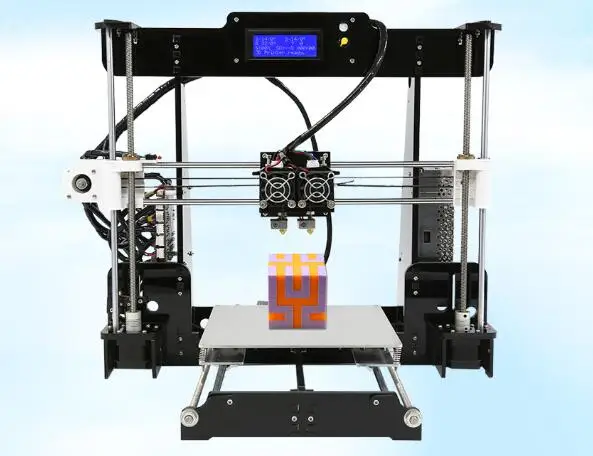

| Printer Type | FDM (Fused Deposition Modeling) |

| Filament Compatibility | PLA (Polyactic Acid) |

| Construction | Plastic, Aluminum |

| Printer Weight | 22. 7 lbs 7 lbs |

| External Dimensions | 20” x 18” x 15.5” (508 mm x 457 mm x 394 mm) |

| Print Bed | Aluminum Plate |

|---|---|

| Print Bed Max Temp | Non-Heated |

| Extruder Configuration | Single Extruder |

| Extruder Max Temp | 230 Degrees Celsius (446 Degrees Fahrenheit) |

| Motor | NEMA |

| Build Area | 5.9” x 5.9” x 5.9” (150 mm x 150 mm x 150 mm) |

|---|---|

| Build Volume (Approximate) | 205 cubic inches (3.36 Liters) |

| Layer Thickness Minimum | 100 microns (.1 mm) (Variable) |

| Layer Thickness Maximum | 400 Microns (.4mm) (Variable) |

| Input File Type | .STL |

|---|---|

| System Compatibility | Windows |

| Software Compatibility | XYZ Maker, XYZWare, XYZ printing STEAM |

| Power Compatibility | 100 – 240 VAC, 50 – 60hz |

|---|---|

| Manufactured In | Thailand |

Vendor: XYZ Printing

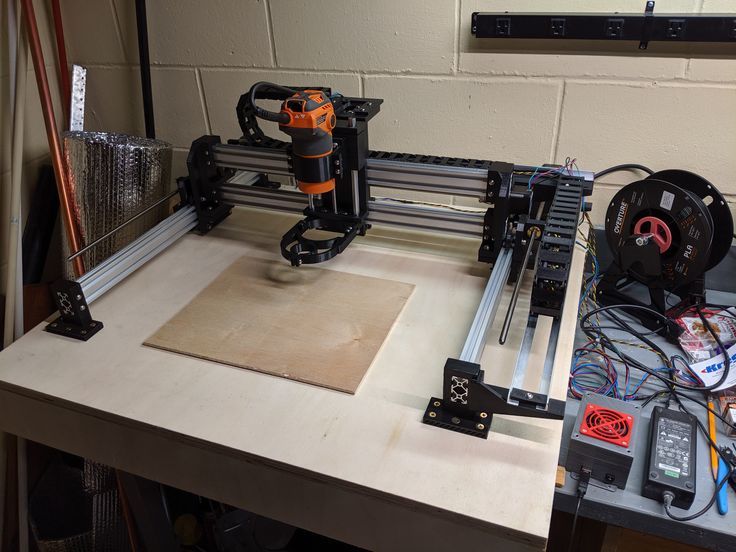

3D printer spare parts

-

Da Vinci Junior Back Quick Coupling

£6. 00

00 -

Replacement UP! Nozzle – 3D printer Parts

£21.60 -

Print Bed Tape for the Da Vinci Junior

£10.50 -

NFC Open Smart Tag

£72.00 -

UP Box FFC extruder Cable

£28.20 -

Da Vinci Junior 0.3mm print head upgrade

£84.00 -

PTFE tubing 1m of 2mm ID 4mm OD

£5.10 -

LokBuild print surface

£7.80–

£17.58 -

XYZ Da Vinci 1.0 Extruder printhead

£96.00 -

Tiertime Nozzle Heater V5

£100.80 -

Brass Cetus Nozzle

£13.20 -

Da Vinci Pro 0.4mm Printhead

£99.96 -

Da Vinci Color Inkjet Cartridge Yellow

£66.60 -

Da Vinci Color Inkjet Cartridge Black

£66.60 -

Da Vinci Color Inkjet Cartridge Magenta

£66. 60

60 -

Da Vinci Color Inkjet Cartridge Cyan

£66.60 -

Da Vinci Pro Laser Engraver head

£170.40 -

Print Bed Tape for the Da Vinci Pro

£15.24 -

Da Vinci Junior quick release printhead

£78.00 -

BCN3D e3D hotends

£96.00–

£170.40 -

Da Vinci Idler roller support

£8.94 -

Hepa Filter for UP box and Up Mini 2

£18.00 -

Tiertime Extruder Motor Assembly

£26.40 -

Replacement Tiertime Steel UP Nozzle

£21.60 -

ABS Extruder for UP300 and Upbox Plus

£199.20 -

UPBox Perf Board

£33.60 -

Da Vinci Mini Quick Release Print head

£99.96 -

BCN3D Endstop Z

£4.50 -

PTFE tubing 1m of 2mm ID 3mm OD

£5. 10

10 -

XYZ Da Vinci 1.0 Print bed

£66.00 -

Da Vinci Pro Back Quick Coupling

£8.10 -

Quality LM8UU linear bearings

£7.20

3D printing products

Showing 1–32 of 120 results

Sort by popularitySort by average ratingSort by latestSort by price: low to highSort by price: high to lowTestimonials

Was having problems calibrating my printer until I contacted iDig3DPrinting. They responded quickly and provided great technical documentation that I couldn’t find anywhere else. Thanks!!

Allen

Fantastic service. Goods received within 24 hours of placing order. Will be purchasing more stuff. Would definitely recommend.

Janice

Great service, very quick to answer queries and resolve any problems. Reliable and affordable

.

Adam

First class service and support, purchased some spare parts for my printer and they were glad to help with an unrelated problem I was having with the printer, even though it was not supplied by iDig , I would recommend them without hesitation.

Ed

Have had a lot a of problems setting up a 3d printer at our school, idig3d printing contacted me through a forum and have been brilliant ,giving advice and guidance. Thank you

Claudia

Answers to maintenance questions

General maintenance and printer maintenance questions.

This tag is for general service and printer maintenance questions.

This may include general items such as motor and rods, or maintenance questions for specific printer models.

- Ender 3D Pro Stepper Motor Shaft Length The feed motor on my replacement extruder started to cut filament but was not feeding properly. I order a REDREX Tech full metal extruder with two gears to eliminate…

- Ender 3 plate damage Just received Ender-3 a week ago. This is my first 3D printer. On the 5th print, the object eventually tore off the surface of the build plate so that it could no longer be used.

…

… - How to check the belts on the Ender 3 3D printer? I need to check the belts on my Ender 3 to make sure they are properly installed, functioning and not damaged. How should I do it?

- Polyurethane and steel timing belts? Has anyone tried steel-reinforced polyurethane timing belts? If so, how do they compare to rubber?

- Print head cable, is there such a thing? As the printer ages, the constant movement of the print head wears out the conductors inside the cable. Create all sorts of fun debugging scripts. Is there such a thing as a cable...

- Suitable Z-Axis Lead Screw Lubricant I need to lubricate the lead screw for my 3D printer. I plan to use this lubricant. I want to know if this will work. There are several others such as silicone grease, lithium grease and…

- Removing Stubborn Partial Clogs After Printing Nylon My Prusa i3 MK3S was partially clogged the last time I printed with nylon.

Although I've experienced blockages and partial blockages before, all the usual tricks I've tried don't work this time...

Although I've experienced blockages and partial blockages before, all the usual tricks I've tried don't work this time... - Elegoo Saturn Screen Protector? Can I cut out the iPad screen protector and stick it on top of my Elegoo Saturn to protect the LCD from scratches or resin leaks/drops? Or will it damage the prints? Additional…

- When changing the FEP, do I have to pierce it first or just screw through it? I am about to do my first FEP change on my Elegoo Saturn. The manufacturer has a video on how to replace it showing how they insert the FEP into the gasket frame and then just screw it in...

- Screen stays black on new Ender 3 V2 after power up I finally decided to buy Ender 3 v2. It arrived today, and a few hours later, making sure everything was in order, I tried to turn it on and make a test print... I was disappointed to see…

- Correct belt tension for Ender 3 v2 Y-axis belt just broke on my Ender 3 v2.

I believe it was too tight from the factory. When I first assembled the printer, I noticed that the Y-axis tensioner was almost fully tightened. Self…

I believe it was too tight from the factory. When I first assembled the printer, I noticed that the Y-axis tensioner was almost fully tightened. Self… - Quantitative measurement of nozzle wear Is there a quantitative measurement of nozzle wear? What steps are you taking to measure this, if so? I have several digital calipers but I don't have much confidence...

- E3D V6 nozzle trapped in heater block The 0.4mm brass nozzle in my Prusa i3 MK3 is worn out - the extrusion hole is noticeably larger than the replacement nozzles I have to install. So I'm trying to change the nozzle. Unfortunately, the nozzle…

- How do I replace the nozzle in my hotend assembly? What should I take care of in order to correctly replace the nozzle of the hotend assembly? What data, precautions, tools, steps and checks are important for nozzle replacement? The procedure seems simple, but…

- Cons of UV Printing I was curious about the various UV/Laser printers on the market (or coming up) that use liquid resin.

I've seen Pegasus Touch, Form1 and Carbon3D samples as examples...

I've seen Pegasus Touch, Form1 and Carbon3D samples as examples... - How to Identify Nozzle Wear E3D-Online and Make Magazine have written about the potential damage printing carbon fiber and glow-in-the-dark filaments can do to your printer's nozzle. What I can't seem to find...

- What is the best way to clean the platen after printing? I sometimes had problems with excess filament sticking to the platen. There are ways to prevent this, but sometimes even these precautions are not enough. So…

- Springs for tensioning the V rollers? I've just been troubleshooting the V-rollers on my Ender 3 and have started checking the installation of the eccentric nut. It's hard to get perfect tension without over-tensioning...

- Linear rail maintenance I have linear rails on my delta printer and one of them (rail+block) started to creak while printing. I thought of these reasons: 1) the rails are not well lubricated, they always.

..

.. - Does it matter what FEP film you use for the SLA printer? I have a mini Phrozen Sonic printer and of course I will eventually need to replace the FEP film with a resin vat. Is there anything I need to consider when purchasing a replacement...

- What should buildtak(knock off) cleanup use? My printer came with a BuildTak knockdown similar to build surface. How can I clean it? I don't want to hurt him.

- How do I clean/prepare a flexible/magnetic mat (eg Ender 5) compared to a glass table? I started printing about a month ago on an Ender 5 (using mostly PLA, but recently also PETG) and it looks like it's time for a more thorough cleaning of the print bed than I usually do...

- resin SLA? As far as I know the resin trays have a teflon coating which allows prints to stick to the mounting plate more easily than the resin tray, but that teflon coating over time... to help with sticking to the table on my heated table.

Are there any signs that would lead me to believe that I need to change the film? …

Are there any signs that would lead me to believe that I need to change the film? … - Replacing bearings with dry bushings When I bought my Chinese made Anet A8 printer, it comes with linear bearings in the form of ball bearings for 8mm guide rods. Pulling the parts out of the box and…

- Insulate the hotend on the Makerbot Smart Extruder Simple question: how do you re-insulate MakerBot Smart Extruders? Background: I work in a library. We recently replaced the MakerBot (extruder connection problems accompanied by…

- Hot end cleaning tips [Makerbot Replicator v2] My Makerbot Replicator V2 keeps jamming. Usually when I go to use it after it's been off for a few hours, the filament gets stuck and I have to take off the front...

- What is the best way to clean PETG residue from PEI magnetic steel sheet? I have a MK3 with magnetic PEI and some PETG residue stuck to the surface. How can I remove it? Does acetone work? Thanks

- How do I know when to replace my SLA tray? How do you know when your SLA print tray has lost its non-stick coating? Are there any visible or verifiable signs that you can use to tell it's time to…

- Da Vinci Jr.

Has anyone disassembled the nozzle of da Vinci Jr.'s 3D printer? The first time I tried to clean the nozzle after it got stuck, I broke the filament just before it was...

Has anyone disassembled the nozzle of da Vinci Jr.'s 3D printer? The first time I tried to clean the nozzle after it got stuck, I broke the filament just before it was... - How long does the MakerBot grip surface last? Now I've done some prints on my MakerBot Replicator+ and I'm curious if anyone else knows what is the typical lifespan for a grip surface tape? In the past…

- The z-axis is difficult to move in some areas - what could be the disadvantages, how can they be improved? I have a z-axis which schematically follows the same principle as the makerbot one (threaded rod and two drive rods with linear ball bearings carrying the level). This is from the old…

- Pre-extrusion, extruder code help? I'm not sure what this code is doing..... I recently bought a titan extruder that needs to be calibrated with my printer (417 micro steps http://wiki.e3d-online…

- What to look for after 3D extraction long-term storage printer I have a homemade Mendel Reprap style 3D printer.

I didn't use it for a while after moving in, but I want to use it again. What should I pay attention to before calibrating…

I didn't use it for a while after moving in, but I want to use it again. What should I pay attention to before calibrating… - How can I keep my extruder head from clogging? When using a thermoplastic MDF printer with a 0.4 mm extruder nozzle, I often have problems with nozzle clogging. I'm not sure what's causing the blockage, but my guess is...

- Soft little top layers? I just added a fan to my printer because very small layers seem to come out really bad. For example, a 5 mm thick PLA cube, which is the top level of the test mold,…

- Do stepper motors require maintenance? I have had my printer for almost a year now. Is there anything I should do to service engines?

- How do I get consistent and accurate thermocouple readings? I switched to a Mk9 dual extruder and it had thermocouples installed instead of the thermistors I had before. No matter what I did with the thermocouples, the temperature indicated is.

..

.. - How do I prevent the platen tape from sticking to the filament? A few months ago I made a test print of a small cogwheel (~1.5" in diameter) with a hole in the center. The filament (ABS) stuck to the print bed on the first try...

- Filament pulls out at an angle One of my printer's nozzles has the filament coming out at a 45 degree angle. This appears to be causing issues with table adhesion and overall quality. What caused this problem? How do I…

- How do I clean the extruder when changing materials? I often change the print media, such as ABS/PLA/Wood/Flex, What is the best way for me to clean the extruder in between so as not to contaminate the next print?

Smeg frying pan instruction manual CKFF2401RDM

smeg CKFF2401RDM Cookware Frying pan

Use and maintenance

When using for the first time, remove all packaging and wash with soapy water. Boil some water in a bowl and then dry it. Lubricate with edible oil or fat. When using aluminum non-stick cookware, there is no need to use oils or fats for cooking. Do not use cooking oil sprays, as they may leave residue that could alter the non-stick properties. Use a heat source that matches the bottom of the cookware. Place the pot on medium heat. Avoid burning fatty foods. Do not use sharp metal utensils and do not cut food inside the utensils, so as not to damage the non-stick layer. Use wooden, plastic or silicone utensils. Store your cookware carefully to protect the non-stick coating. Make sure the handle is tight before use and check it periodically as it may loosen over time.

Boil some water in a bowl and then dry it. Lubricate with edible oil or fat. When using aluminum non-stick cookware, there is no need to use oils or fats for cooking. Do not use cooking oil sprays, as they may leave residue that could alter the non-stick properties. Use a heat source that matches the bottom of the cookware. Place the pot on medium heat. Avoid burning fatty foods. Do not use sharp metal utensils and do not cut food inside the utensils, so as not to damage the non-stick layer. Use wooden, plastic or silicone utensils. Store your cookware carefully to protect the non-stick coating. Make sure the handle is tight before use and check it periodically as it may loosen over time.

Lid

Raise the lid to avoid escaping steam or oil splashes. Be careful when installing the steam valve so as not to burn yourself. It is recommended to place the steam valve away from the side from which you have to handle the dishes. If the glass has been impacted, it may be damaged and crack during cooking. Be especially careful when using and storing glass lids. Avoid rapid cooling with cold water. Do not use if cap is cracked or scratched as it may break suddenly during use. The lid is equipped with a metal handle. Therefore, when handling it, you should wear kitchen gloves. Products and lids can be used in the oven up to 250°C/480F°. They are equipped with steel handles and buttons. Therefore, when handling them, you must wear kitchen gloves.

Be especially careful when using and storing glass lids. Avoid rapid cooling with cold water. Do not use if cap is cracked or scratched as it may break suddenly during use. The lid is equipped with a metal handle. Therefore, when handling it, you should wear kitchen gloves. Products and lids can be used in the oven up to 250°C/480F°. They are equipped with steel handles and buttons. Therefore, when handling them, you must wear kitchen gloves.

Cleaning

We recommend washing the dishes by hand using a sponge (non-abrasive/non-metallic) and liquid detergent. Do not use powders or oven cleaners. If you use a dishwasher, we recommend that you do not use aggressive detergents and use Eco low temperature cycles. The use of the dishwasher does not affect the characteristics of the dishes, but it may change their original color. The use of softened water in the dishwasher can accelerate corrosion/wear on bare aluminum components. The use of oils or fats together with high temperatures can cause visible stains, especially on light-colored finishes. If steel parts turn yellow over time or are exposed to high temperatures, for example in the oven, it is recommended to use special steel cleaning creams. For safety reasons and for best results, we recommend using Smeg CREMA INOX polishing cream. Contact an authorized service center to see if it is available in your country.

If steel parts turn yellow over time or are exposed to high temperatures, for example in the oven, it is recommended to use special steel cleaning creams. For safety reasons and for best results, we recommend using Smeg CREMA INOX polishing cream. Contact an authorized service center to see if it is available in your country.

Warning

Do not overheat empty cookware. In this case, remove the dishes and ventilate the room. Never leave cooking food unattended. Do not allow food to dry out completely. Keep hot dishes out of the reach of children. Allow the dishes to cool before cleaning. When using cookware on glass-ceramic hobs (resistive, induction or halogen), make sure that the bottom of the cookware and the glass-ceramic surface are clean, as dirt residues can scratch the surface of the hobs. Do not move the cookware on the hob; lift it up to avoid scratching the hob. When using a frying pan, make sure it is cold and dry and not near water sources before adding oil. Top with oil, leaving at least 5 cm/2 inches from the top edge of the pan to leave enough room after adding food. Do not use plastic utensils: Some plastic materials can melt easily in hot oil. Avoid contact of water with hot oil. Do not use water to cool cookware that has been used for frying. Do not clean the appliance while frying food. If the oil catches fire, do not use water to extinguish it. The use of water may further spread the burning oil. The best way to put out a fire is to use a fire extinguisher or a metal lid. Some cookware (especially if it has a small bottom) may be unstable when used on gas hob stands. Always carefully place them on the supports.

Top with oil, leaving at least 5 cm/2 inches from the top edge of the pan to leave enough room after adding food. Do not use plastic utensils: Some plastic materials can melt easily in hot oil. Avoid contact of water with hot oil. Do not use water to cool cookware that has been used for frying. Do not clean the appliance while frying food. If the oil catches fire, do not use water to extinguish it. The use of water may further spread the burning oil. The best way to put out a fire is to use a fire extinguisher or a metal lid. Some cookware (especially if it has a small bottom) may be unstable when used on gas hob stands. Always carefully place them on the supports.

When using on induction cookers

Never preheat an empty pan as it can heat up very quickly and damage the non-stick coating. When using dishes after washing, make sure the bottom outer surface is dry. The special shape of the bottom means that the cookware can hold water droplets, which are subsequently released as steam when heated.