New method of 3d printing

New volumetric 3D printing method relies on light-converting nanoparticles

0Shares

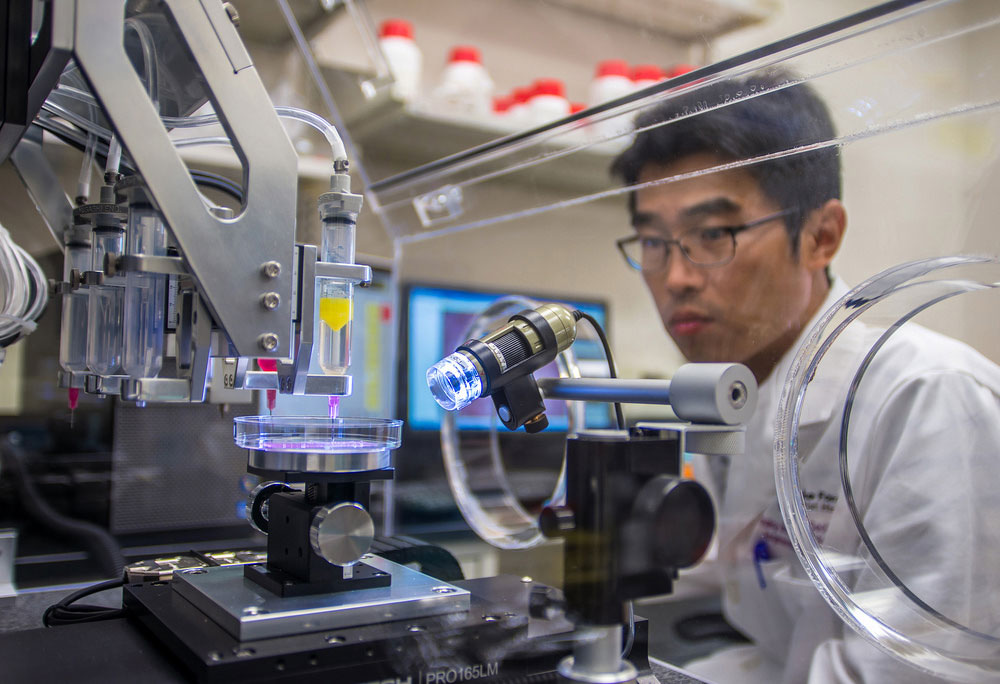

Researchers from Stanford University and Harvard University have developed a new method of volumetric 3D printing capable of fabricating resin parts without the need for any support structures.

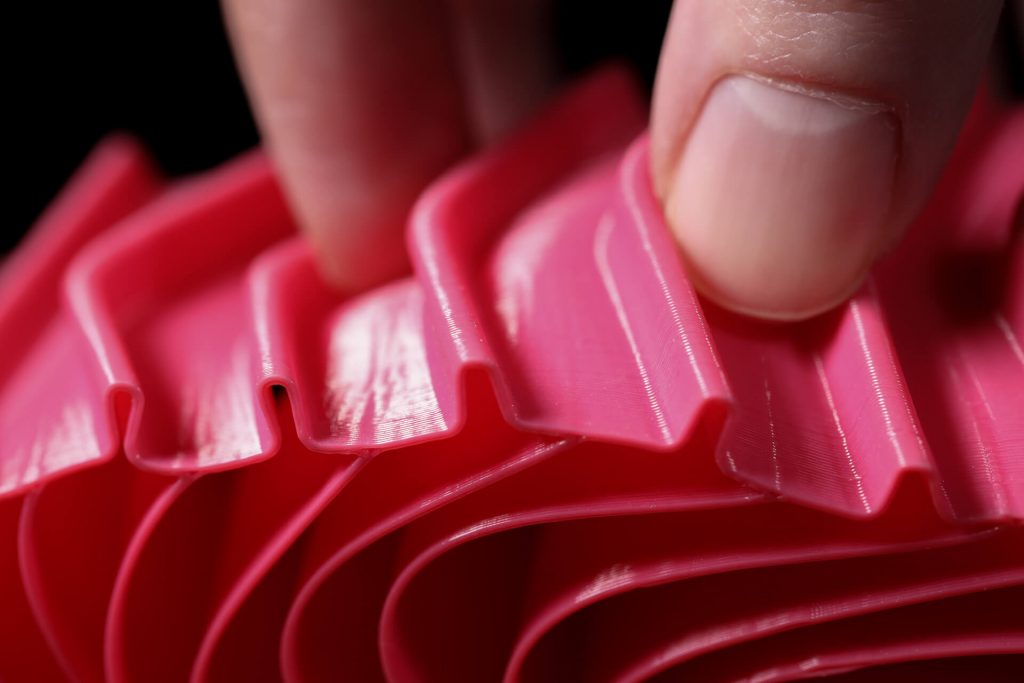

The approach relies on a nanoparticle-laden resin material that only hardens when it’s blasted with a very focused laser spot. By varying the focus of the laser throughout the resin vat, the researchers have made it possible to print at any point in the pool of resin, not just at the surface layer.

As such, the novel 3D printer doesn’t necessarily need to print objects from the bottom-up on a layer-by-layer basis, paving the way for abstract geometries that can be ‘added to’ from virtually any direction.

“Because our resin is self-supporting during the printing process, we don’t need to print any supports, making post-processing of the parts much simpler,” says Dan Congreve, co-author of the study. “Because we aren’t confined to this layer-by-layer process, we can print structures such as overhangs which are traditionally challenging. This is a brand-new technology, and we are just starting to scratch the surface of what it’s capable of.”

Light-converting nanoparticles for 3D printing

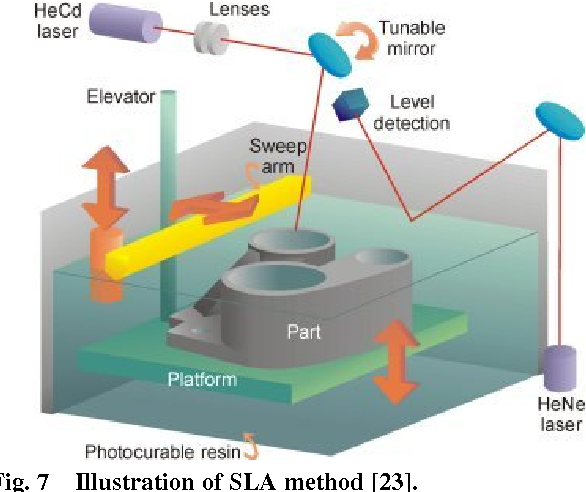

On first inspection, the Stanford 3D printing method looks a lot like conventional stereolithography (SLA). A laser beam is directed at resin in a vat, which cures when it’s exposed to blue light. However, the team didn’t just use a standard blue laser as this would cure the resin along the entire length of the penetrating beam.

Instead, they leveraged a special resin containing light-converting nanoparticles just 80nm in diameter. The nanoparticles are designed to convert red light into blue light when a critical energy threshold is hit, which can only be achieved when the laser is at maximum focus. As such, the technique utilizes a standard red laser instead, with a mechanism for diluting and focusing that red laser.

As such, the technique utilizes a standard red laser instead, with a mechanism for diluting and focusing that red laser.

The novel setup eliminates the need to cure exclusively at the surface layer, making it possible to cure individual points in a resin vat by only focusing the red laser at the desired XYZ coordinates. The team states that one or more lasers can be rotated around the vat to print volumetrically from virtually every direction at the same time, enabling any geometry without supports.

The point of maximum focus is where the resin turns red light into blue light, curing the material. Image via Stanford University.Triplet fusion upconversion

The mechanism for transforming one wavelength of light into another is called triplet fusion upconversion and it’s Congreve’s specialism.

“I got interested in this upconversion technique back in grad school,” he adds. “It has all sorts of interesting applications in solar, bio, and now this 3D printing. Our real specialty is in the nanomaterials themselves – engineering them to emit the right wavelength of light, to emit it efficiently, and to be dispersed in resin.”

Our real specialty is in the nanomaterials themselves – engineering them to emit the right wavelength of light, to emit it efficiently, and to be dispersed in resin.”

To formulate the special resin mix, the team turned the active upconversion molecules into nanoscale droplets and coated them in a shielding silica layer. The resulting nanocapsules were distributed throughout the resin matrix to form the final light-converting composite.

“Figuring out how to make the nanocapsules robust was not trivial – a 3D-printing resin is actually pretty harsh,” said Tracy Schloemer, one of the lead authors of the study. “And if those nanocapsules start falling apart, your ability to do upconversion goes away. All your contents spill out and you can’t get those molecular collisions that you need.”

The researchers are currently in the process of exploring other applications for the light-converting nanocapsules. Potential use cases include more efficient solar panels, whereby low-energy light can be converted into a wavelength that solar cells can more easily capture. They can also be used to study biological models that use light to power chemical reactions.

They can also be used to study biological models that use light to power chemical reactions.

Further details of the study can be found in the paper titled ‘Triplet fusion upconversion nanocapsules for volumetric 3D printing’.

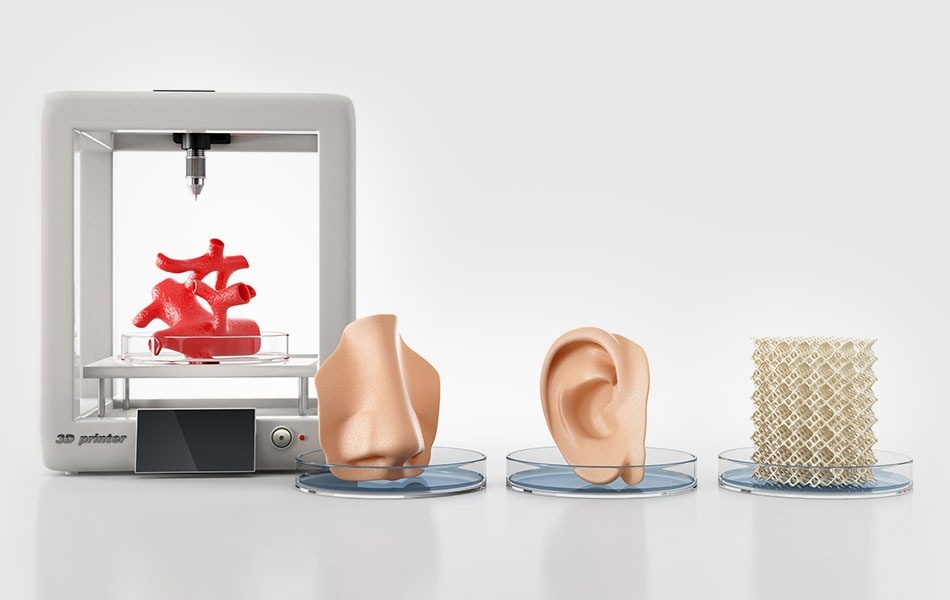

Despite the novelty of their 3D printer, the Stanford researchers aren’t the first to explore the concept of volumetric 3D printing. A research team from Utrecht University recently successfully fabricated working livers using a newly developed ultrafast volumetric 3D bioprinting method. Printed in less than 20 seconds, the liver units were able to perform key toxin elimination processes mimicking those that natural livers perform in our bodies, and could open new opportunities for regenerative medicine and personalized drug testing.

Elsewhere, a research team led by University College London (UCL) recently used volumetric 3D printing to fabricate drug-loaded tablets within a matter of seconds, reportedly for the first time. The team successfully produced paracetamol-loaded tablets within 17 seconds, which is significantly faster than current methods used to print pharmaceuticals within research and some clinical settings.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a tiny resin benchy 3D printed by the Stanford researchers. Photo via Dan Congreve.

Tags Dan Congreve Harvard University Stanford University Tracy Schloemer

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

A new technique for 3D printing

Engineers at Stanford and Harvard have laid the groundwork for a new system for 3D printing that doesn’t require that an object be printed from the bottom up.

By Laura Castañón

While 3D printing techniques have advanced significantly in the last decade, the technology continues to face a fundamental limitation: objects must be built up layer by layer. But what if they didn’t have to be?

A boat figurine produced by a new 3D printing process that makes it possible to print an object within a volume of resin – like an action figure floating in the center of a block of Jell-O – rather than having to build the object layer by layer. (Image credit: Dan Congreve)

Dan Congreve, an assistant professor of electrical engineering at Stanford and former Rowland Fellow at the Rowland Institute at Harvard University, and his colleagues have developed a way to print 3D objects within a stationary volume of resin. The printed object is fully supported by the thick resin – imagine an action figure floating in the center of a block of Jell-O – so it can be added to from any angle. This removes the need for the support structures typically required for creating complex designs with more standard printing methods. The new 3D printing system, which was recently published in Nature, could make it easier to print increasingly intricate designs while saving time and material.

The new 3D printing system, which was recently published in Nature, could make it easier to print increasingly intricate designs while saving time and material.

“The ability to do this volumetric printing enables you to print objects that were previously very difficult,” said Congreve. “It’s a very exciting opportunity for three-dimensional printing going forward.”

Printing with light

At its surface, the technique seems relatively straightforward: The researchers focused a laser through a lens and shone it into a gelatinous resin that hardens when exposed to blue light. But Congreve and his colleagues couldn’t simply use a blue laser – the resin would cure along the entire length of the beam. Instead, they used a red light and some cleverly designed nanomaterials scattered throughout resin to create blue light at only the precise focal point of the laser. By shifting the laser around the container of resin, they were able to create detailed, support-free prints.

Changing the contents of the nanocapsules controls the power of red light required to cure the resin and allows for different types of volumetric printing. Two types of printing shown here: scanning and tracing an image using a high-powered laser (on left) and projecting an image all at once using a low-powered LED (on right). (Image credit: Dan Congreve/Tracy H. Schloemer/Arynn O. Gallegos)

Congreve’s lab specializes in converting one wavelength of light to another using a method called triplet fusion upconversion. With the right molecules in close proximity to each other, the researchers can create a chain of energy transfers that, for example, turn low-energy red photons into high-energy blue ones.

“I got interested in this upconversion technique back in grad school,” Congreve said. “It has all sorts of interesting applications in solar, bio, and now this 3D printing. Our real specialty is in the nanomaterials themselves – engineering them to emit the right wavelength of light, to emit it efficiently, and to be dispersed in resin. ”

”

Through a series of steps (which included sending some of their materials for a spin in a Vitamix blender), Congreve and his colleagues were able to form the necessary upconversion molecules into distinct nanoscale droplets and coat them in a protective silica shell. Then they distributed the resulting nanocapsules, each of which is 1000 times smaller than the width of a human hair, throughout the resin.

“Figuring out how to make the nanocapsules robust was not trivial – a 3D-printing resin is actually pretty harsh,” said Tracy Schloemer, a postdoctoral researcher in Congreve’s lab and one of the lead authors on the paper. “And if those nanocapsules start falling apart, your ability to do upconversion goes away. All your contents spill out and you can’t get those molecular collisions that you need.”

Next steps for light-converting nanocapsules

The researchers are currently working on ways to refine their 3D-printing technique. They are investigating the possibility of printing multiple points at the same time, which would speed up the process considerably, as well as printing at higher resolutions and smaller scales.

Congreve is also exploring other opportunities to put the upconverting nanocapsules to use. They may be able to help improve the efficiency of solar panels, for example, by converting unusable low-energy light into wavelengths the solar cells can collect. Or they could be used to help researchers more precisely study biological models that can be triggered with light or even, in the future, deliver localized treatments.

“You could penetrate tissue with infrared light and then turn that infrared light into high-energy light with this upconversion technique to, for example, drive a chemical reaction,” said Congreve. “Our ability to control materials at the nanoscale gives us a lot of really cool opportunities to solve challenging problems that are otherwise difficult to approach.”

Additional Stanford co-authors of this research are postdoctoral scholar Tracy Schloemer; former visiting researcher Michael Seitz; and graduate student Arynn Gallegos. Other co-authors, including a co-lead author, are from the Rowland Institute at Harvard University.

This research was funded by the Rowland Institute at Harvard University, the Harvard PSE Accelerator Fund, the Gordon and Betty Moore Foundation, an Arnold O. Beckman Postdoctoral Fellowship, the Swiss National Science Foundation, the National Science Foundation, and a Stanford Graduate Fellowship in Science & Engineering (a Scott A. and Geraldine D. Macomber Fellowship).

| 3DNews Technologies and IT market. News printers, print servers, scanners, copiers... A new 3D printing method makes models... The most interesting in the reviews 02/04/2019 [10:48], Konstantin Khodakovsky 3D printers are becoming more and more affordable and widespread. There is a whole range of technologies for recreating a three-dimensional model in a material: this is the extrusion method by applying strips of molten plastic, and the photopolymer method using pixel-by-pixel or layer-by-layer solidification of the material, and laser powder baking, and lamination. A new technology created by Californian technologists takes a completely different approach and produces an immediate whole structure by projecting light onto a container with a translucent polymer resin that hardens under the influence of radiation. She was nicknamed the "replicator" in honor of the device from the Star Trek saga, capable of materializing almost any inanimate object. The new development really takes science fiction one step closer to reality. "This is an exciting achievement for rapidly prototyping fairly small and transparent parts," said chemist Joseph DeSimone of the University of North Carolina at Chapel Hill. Electrical engineer Hayden Taylor of the University of California at Berkeley explained that the printer described in Science magazine resembles a CT scan in reverse. The development team, on the other hand, used a 3D computer model of the object to create projections from different angles. Then they made a cylindrical container filled with acrylate rotate in sync with a conventional digital projector, which emits the appropriate flat images at the right time. “As the container rotates, the amount of light each dot receives can be controlled individually. If the luminous flux exceeds a certain value, the liquid solidifies" ," Hayden Taylor explained. This chemical is an ester of acrylic acid and is characterized by a tendency to polymerize: once the number of absorbed photons reaches a certain threshold, the resin molecules join in chains, forming a hard translucent plastic. The remaining liquid is then removed. Speaking about the speed of the experimental prototype, the copy of Auguste Rodin's sculpture "The Thinker" shown in the attached video, a few centimeters high, took about two minutes to print. According to Mr. Taylor, this method outperforms existing ones not only in printing speed and smoother surfaces (although it doesn't seem to be doing very well when it comes to rendering details), but also in the ability to print over existing objects to create a new part or kind of shell. Scientists suggest that the method can be used to create medical or optical components. Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: https://3dnews.ru/982188 Headings: News Hardware, printers, print servers, scanners, copiers, MFPs, electronics design and manufacture, Tags: 3d printer, 3d printing, polymer, development ← В past To the future → |

A new method of 3D printing of metal products will speed up production by 10 times

Stories

Stories

Daria Sidorova

Editor of the History Department.

Darya Sidorova

A new metal 3D printing technology has been developed that could completely change the way large industrial products like airplanes and cars are made. It will help reduce not only the cost of mass production, but also its carbon footprint.

Daria Sidorova

Since the 1980s, 3D printing, also called additive manufacturing, has been used to make small plastic parts and prototypes. Metal printing is a newer technology. Its main task is to speed up and reduce the cost of creating large automotive and other parts compared to traditional methods.

Current metal 3D printing technology melts a thin layer of metal powder using a laser and then welds it to the bottom layer. As the layers accumulate and the object grows, the digital design gradually takes shape.

Read on the topic: Rostec company received a license for serial 3D printing of aircraft components

However, this is an extremely slow process. Even with multiple lasers, this method is not fast enough to produce auto parts and consumer electronics in large volumes.

Even with multiple lasers, this method is not fast enough to produce auto parts and consumer electronics in large volumes.

However, the industry seems to have finally made a breakthrough. Startup Seurat Technologies (named after the artist Georges Seurat, who studied the science of light and developed the pointillism style) proposes to speed up the process by splitting a single powerful laser beam into 2.3 million beams of light.

30 kW laser power, can be controlled with high resolution images that can be programmed to block or let light through individual pixels.

Each one defines its own laser spot, so the system can instantly weld a large area of metal powder. Thanks to this, multi-layered objects take shape 10 times faster than with the current method.

“And this is not even the beginning of what we are capable of,” says James DeMuth, CEO and co-founder of Seurat Technologies. According to him, the company's technology will completely replace 3D printing, like a printing press - a pen and paper.

If Seurat Technologies' method is suitable for large-scale production, supply chains will also be affected. In the United States, for example, parts can be produced in-house on demand at low-cost "printing stations."

Technology history and company plans

As DeMuth writes in his blog, the concept of laser beam pixelization originated more than a decade ago at the Livermore National Laboratory of the US Department of Energy. DeMuth and his colleagues were working on a completely different problem - energy fusion.

Their task was to develop a reaction chamber capable of withstanding the extreme temperature fluctuations that occur during laser power generation. Through trial and error, they adapted the method already developed in the Livermore Laboratories for other purposes.

By 2015, DeMuth and another founder of Seurat Technologies, Eric Toomre, proved that the technology could also be used for 3D metal printing. And in January 2016, the company licensed it.

And in January 2016, the company licensed it.

Seurat Technologies has now closed deals with seven of the world's largest automotive, aerospace, energy and industrial companies to commercialize the technology this year.

The startup raised $78 million in funding, and its latest investors are Xerox Ventures and SIP Global Partners. Previous investments in Seurat Technologies include Capricorn Technology Impact Fund, DENSO, True Ventures, GM Ventures, Porsche Automobil Holding SE, Siemens Energy and Maniv Mobility.

Source.

Cover photo: MarinaGrigorivna / Shutterstock

- 3D printing

- Industry

- Startup

- Technology

Found a typo? Select the text and press Ctrl + Enter

Related materials

- one Do you want to build a 3D printing business? Here's what to know

- 2 95% cheaper: what is the effectiveness of 3D printing for modern business

- 3 MPEI will print airplanes: young scientists presented an innovative 3D printer

- four 3D common sense: why do companies introduce additive technologies?

- 5 Create what no one has created.

Learn more

But one way or another, all these methods are related to additive manufacturing, that is, they are associated with the sequential, layer by layer, creation of a figure. A separate group are milling machines, laser engravers and cutters.

But one way or another, all these methods are related to additive manufacturing, that is, they are associated with the sequential, layer by layer, creation of a figure. A separate group are milling machines, laser engravers and cutters.  In tomographs, an x-ray tube rotates around the patient, taking images of sections of the internal organs of the body. These projections are then used by a computer to create a three-dimensional image.

In tomographs, an x-ray tube rotates around the patient, taking images of sections of the internal organs of the body. These projections are then used by a computer to create a three-dimensional image.