Tesseract 3d printer

▷ the tesseract 3d models 【 STLFinder 】

The Tesseract

thingiverse

Instructions 1) print the parts 2) pull apart each charger and remove the power plug on the circuit board 3) solder positive and negative wires to the circuit board 4) pass the wires through the hole in the charger 5) place 4 chargers into the...

The Tesseract

sketchfab

No description provided.

The TESSERACT from the Avengers movies

myminifactory

The TESSERACT from the Avengers movies Aka The Infinity Space Stone Here is my take on the Tesseract from the Marvel movies. (MCU) You can watch how I made my own version of this Tesseract prop on YouTube: PropsNstuff Only the num pad and the fan...

The Tesseract (Avengers)

thingiverse

Marvel's cosmic cube from Avengers! Yea...this one sure took a long time to model. ...:p

The Avengers Tesseract

thingiverse

A two part tesseract design. ...print in two pieces and then light it up

The Avengers Tesseract

thingiverse

Marvel's cosmic cube from Avengers!

. .. A two part tesseract design.

Use cristal transparent blue filament PLA. Print in two pieces and then light it up.

Dimensions: 10x10x10cm

Awesome effect! ...;)

.. A two part tesseract design.

Use cristal transparent blue filament PLA. Print in two pieces and then light it up.

Dimensions: 10x10x10cm

Awesome effect! ...;)

The Marvel "Tesseract" Cube from the Avengers movies

thingiverse

The TESSERACT from the Avengers movies Aka The Infinity Space Stone Here is my take on the Tesseract from the Marvel movies. (MCU) You can watch how I made my own version of this Tesseract prop on YouTube: PropsNstuff Only the numpad and the fan part...

Tesseract - The Avengers - Game mesh Low-poly 3D model

cgtrader

The Tesseract appears in: Thor, Captain America: The First Avenger, Iron Man, and The Avengers

Tesseract

thingiverse

not to sure how this will print just wanted to see if i could actully draw this if enyone can print it would love to see the outcome Tesseract

Tesseract

myminifactory

In The Avengers movie, The Tesseract is an ancient Asgardian relic that was mistakenly sent to earth and found by a Viking village who placed it underneath a tree call 'The Tree of Life'. ...But after the second world war, it was found and used to...

...But after the second world war, it was found and used to...

Tesseract Briefcase / Maleta Tesseract

thingiverse

Briefcase used in the movie "The Avengers" to save the Tesseract. Maleta utilizada no filme "Os Vingadores" para guardar o Tesseract. ... Watch here / Assista aqui: https://youtu.be/FzdEJP4EvBc

Tesseract Stand

thingiverse

Display stand designed to hold the Tesseract from the SDCC 2018 Hasbro Marvel Legends Red Skull Exclusive box set. It will wold the Tesseract with or without the clear plastic case it came with. ...

Tesseract casing

thingiverse

This is a prop of the casing of the tesseract, used at the End of the firt Avengers Movie. Wouldn't recommend printing this but you can try.

... Enjoy!

Wouldn't recommend printing this but you can try.

... Enjoy!

Tesseract Marvel Movies

thingiverse

TESSERACT - MARVELMOVIES Just a quick version of the Tesseract Cube from the Marvel Movies Printed without support

tesseract

sketchfab

simple tesseract

Tesseract

thingiverse

tesseract cube

tesseract

sketchfab

its a tesseract

Tesseract

prusaprinters

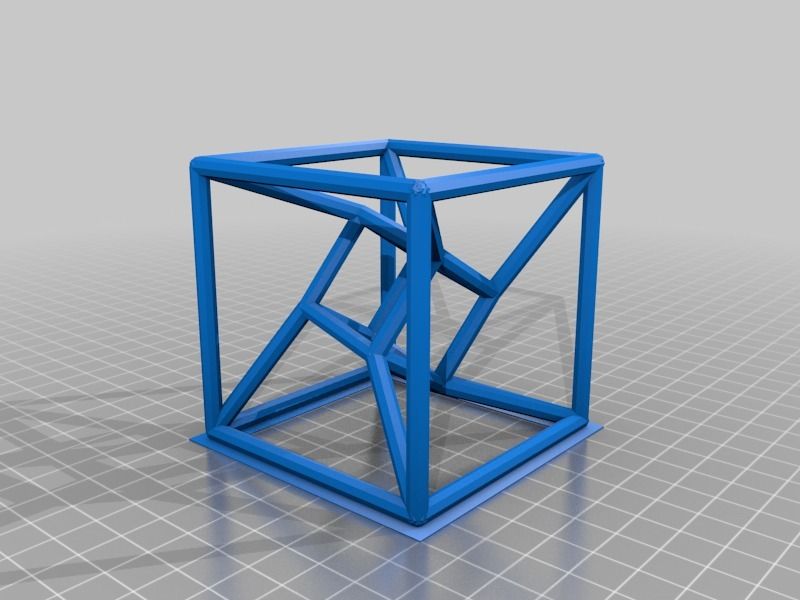

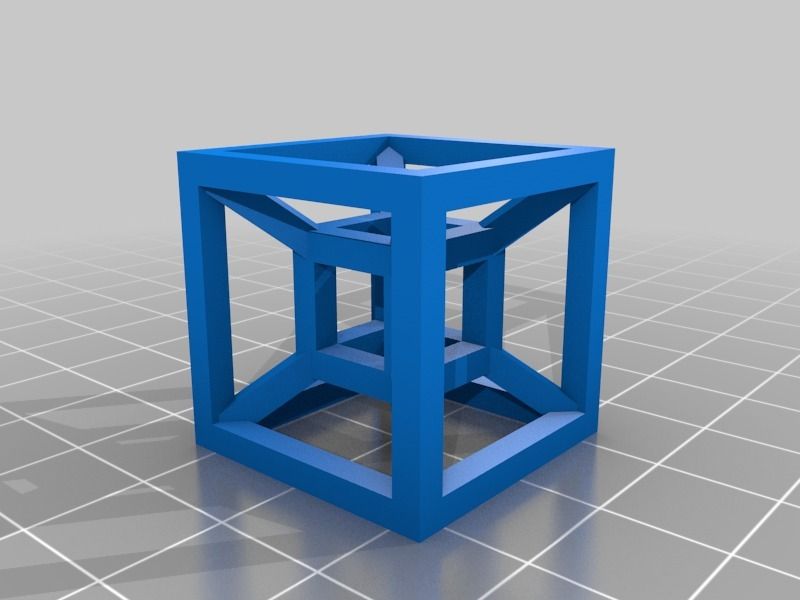

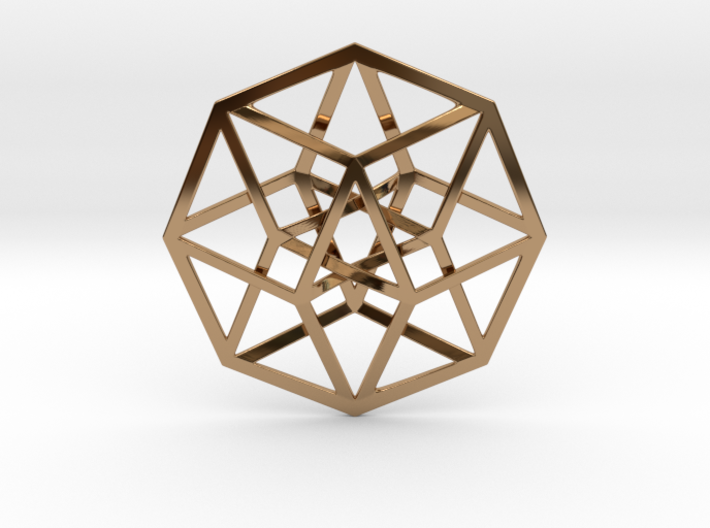

. .. contains 16 vertices, 32 edges, 24 faces, 8 3D faces (cubes). Tesseract is to the cube as the cube is to the square:0D point → 1D line → 2D square → 3D cube → 4D tesseractPrinting tipsUsing some brim is recommended for better adhesion to print bed.

.. contains 16 vertices, 32 edges, 24 faces, 8 3D faces (cubes). Tesseract is to the cube as the cube is to the square:0D point → 1D line → 2D square → 3D cube → 4D tesseractPrinting tipsUsing some brim is recommended for better adhesion to print bed.

Tesseract

thingiverse

A hypercube or tesseract It must be made relatively large ( sides around 1.5" ) because of the size of the supports

Tesseract

thingiverse

This was a study at understanding the transitional shapes created by the vertices of an angular tesseract. I've seen quite a few models of tesseracts, but none of them really focused on this detail. My initial inspiration came from Parametric. ..

..

Tesseract

grabcad

Yesterday I read from it. ...So I made a model just for fun. Who also interesting from this: https://en.wikipedia.org/wiki/Tesseract If you like or download the model, please press the ‘♥’ button.

Tesseract

thingiverse

Angled tesseract with stand for easy 3D printing, requires minimal support, and looks awesome (extra awesome if you spin it). ... *Update* finally reoriented the file so it doesn't need to be rotated to print

Tesseract

thingiverse

I saw a drawing of a tesseract in one of my many books and wondered if I could create it in 3D. ...So I did, and this was the result.

...So I did, and this was the result.

Tesseract

thingiverse

OK, so it's not a pure tesseract. ... But it looks cooler with the additional inner bars. This object was made in Tinkercad. ...Edit it online https://www.tinkercad.com/things/6WZZ8OnN6Oq

Tesseract

pinshape

Model of tesseract (https://en.wikipedia.org/wiki/...) . ...A two part model to avoid to much support material. The CAD model is public in OnShape if you wish to customise it (https://cad.onshape.com/docume...)

Tesseract

thingiverse

it just a Tesseract i made for geometry class.

Tesseract

thingiverse

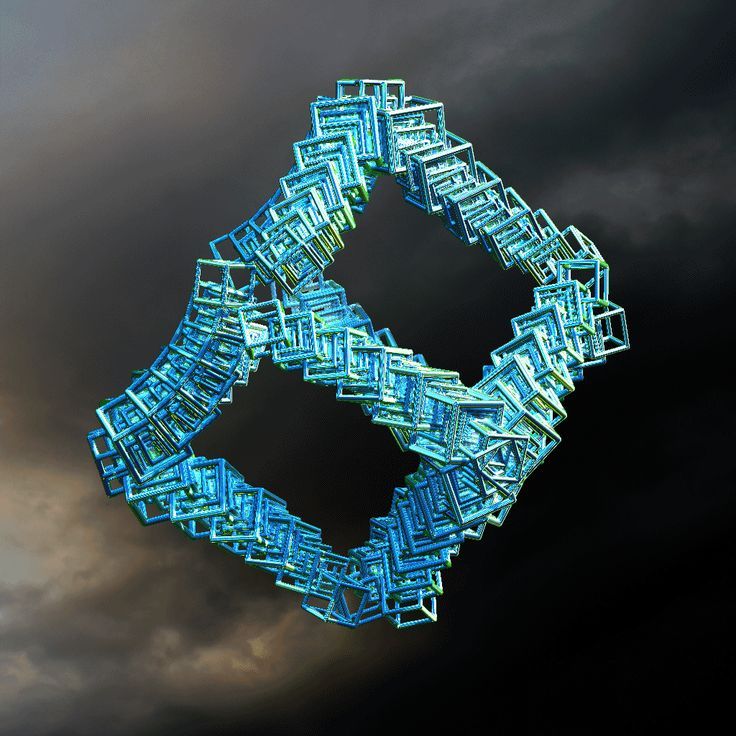

A modified version of a tesseract with increasingly smaller and rotated cubes within a larger cube. I used a for loop to create the multiple sized and rotated cubes. Prints with a LOT of support so try to set settings to least amount of support that...

tesseract

thingiverse

This is a tesseract. A tessaract is a 4-d cube that you sometimes use in math. ... I soon will make another one that is better.

Tesseract

thingiverse

### 4D Hypercube (aka"Tesseract"). ..

..

Tesseract

grabcad

Drag the internal cube and see how the "cylinders" will react.Exercise for demoing Skeleton / Constrains / Flexible assembly

Offering Comprehensive 3D Printing Services to Bring Customer's Ideas into Life

Harsh Sarvaiya, Co-Founder

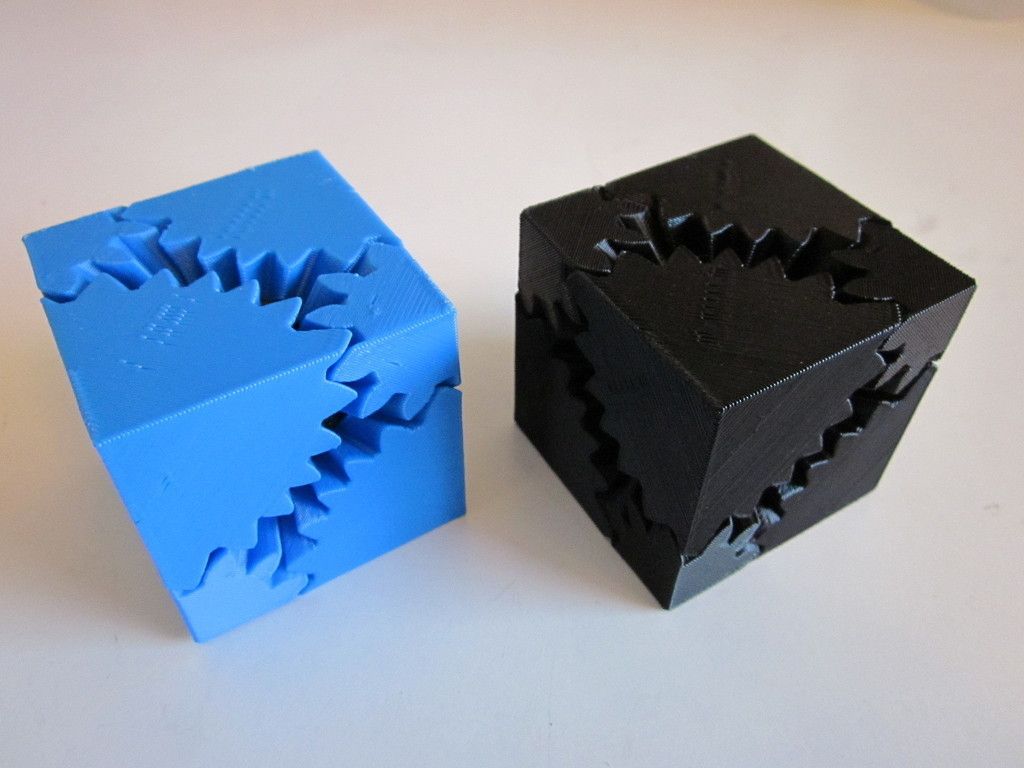

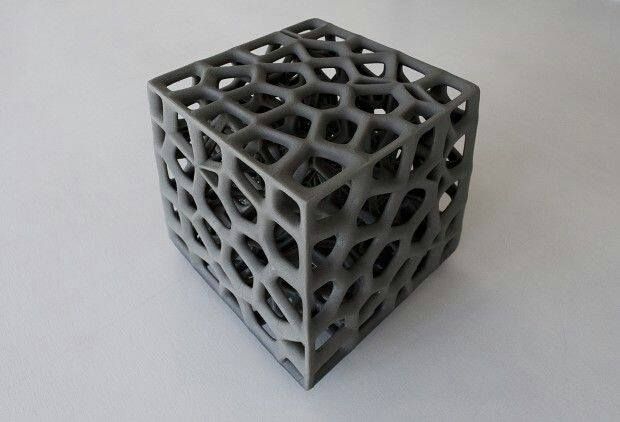

3D Printing is heralding the next industrial revolution and proffers a new opportunity for the businesses to claim stakes in the emerging sector. While the technology is still nascent in India, making motilities into it can bring significant challenges to businesses. Assisting businesses to bout these challenges, and transform their ideas into life is Tesseract, a budding company in the 3D space specializing in design & consultation services. Caned by a team of specialist modellers & designers who are proficient in developing futuristic designs & large complex structures, Tesseract helps customers to redesign/improvise their designs, and make them suitable for 3D printing. Ensuring that materials suit their applications, Tesseract offers 30 different material options in India and utterly gratifies customer’s requirements with accuracy in the nick of time. “We help our customers in designing appropriately and choosing the best technology with superior finish & accuracy at economical prices. We always ensure that we deliver on these commitments & their requirements, and many times, it exceeds their expectations,” says Aman Modi, Co-Founder, Tesseract.

Ensuring that materials suit their applications, Tesseract offers 30 different material options in India and utterly gratifies customer’s requirements with accuracy in the nick of time. “We help our customers in designing appropriately and choosing the best technology with superior finish & accuracy at economical prices. We always ensure that we deliver on these commitments & their requirements, and many times, it exceeds their expectations,” says Aman Modi, Co-Founder, Tesseract.

Holistic Approach

A one-stop-shop, Tesseract expedites its customers in developing products right from market research for product viability, design development/scanning,

prototyping to finally mass manufacturing. The company that specializes in post-production processing and after-sales service, offers all kinds of cutting-edge 3D printing services that include 3D designing, CAD design, 3D scanning, rapid prototyping, filaments & 3D printed gift manufacturing, and more at affordable prices. Through these services, it serves the requirements of diverse industries like Automotive, Defence, General Engineering, Jewellery, Dental, Medical, Consumer Goods, Packaging, Arts, and Education.

Through these services, it serves the requirements of diverse industries like Automotive, Defence, General Engineering, Jewellery, Dental, Medical, Consumer Goods, Packaging, Arts, and Education.

"Tesseract’s design team is equipped to develop futuristic designs, which are challenging/cannot be produced to achieve through traditional techniques"

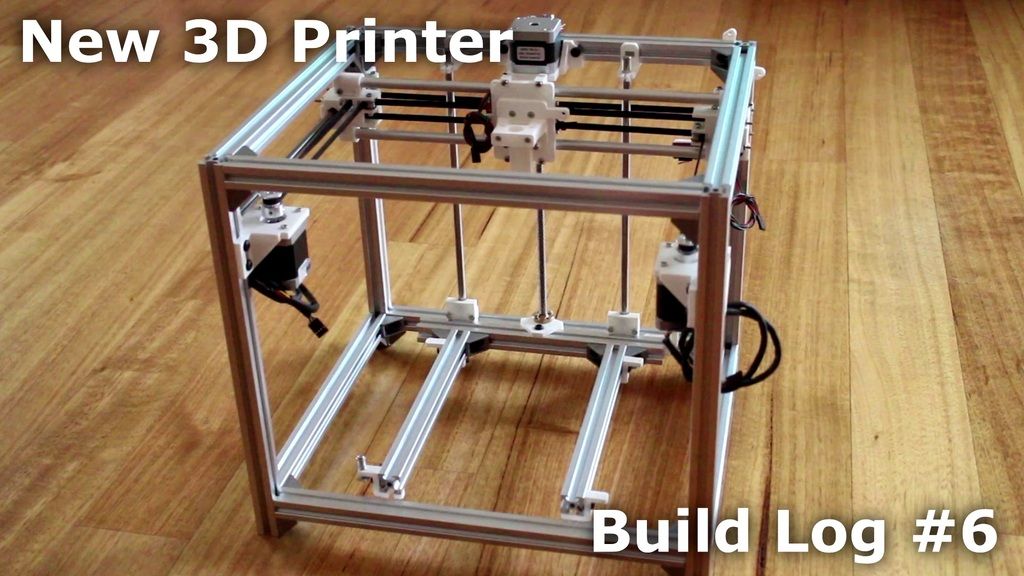

Tesseract’s design team is equipped to develop futuristic designs, which are challenging/cannot be produced to achieve through traditional techniques. For instance, through reverse engineering procedures, it empowers manufacturers to digitize their old parts & design a CAD model of the same for products’ future reproduction. Tesseract’s strong strategic relationships with many of the leading 3D manufacturers in the Netherlands, U.S. and Germany enables it to stay abreast of emerging technologies and introduce them in India to replace & complement traditional operational methods. This also allows it to give large batch manufacturing services and reduce the time & cost of designing new products.

After post-production process, the company’s quality control team ensures that products are delivered only if they are within the parameters defined by the project’s requirements. Moreover, while its swift delivery service assures on-time delivery, its after-sales

service team addresses the customer’s concerns, for instance, if the client is ungratified, it replaces the stock promptly. It’s this holistic approach that thrust Tesseract customers like Minda Corporation, Godrej, Marico, IIT Bombay, DRDO, and Vogo to continue working with it.

Aman Modi, Co-Founder

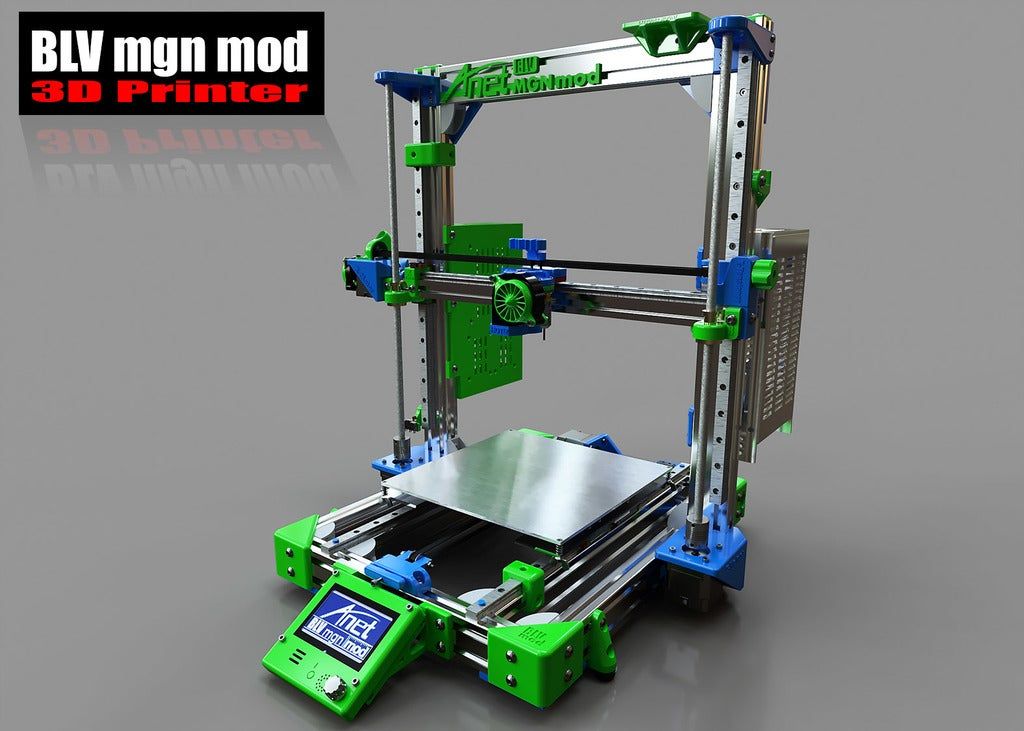

Breaking the Mold

Notwithstanding their well-wishers’ longings, Aman & Harsh Sarvaiya, who are chartered accountants by profession and enthusiastic about bringing 3D printing to the forefront of industry, established Tesseract in 2016. With the duo at its helm, Tesseract’s revenue surged to Rs.3 crore from initial year’s Rs.20 lakh, busting the myth that only engineers can be salutary in the 3D printing industry. The company targets to increase this number by 15 times and become a global company. For that, Tesseract is setting-up cutting-edge 3D print farm equipped with sundry machines by the first quarter of 2019 to provide large batch production & material options at affordable prices. To take-on manufacturing challenges, it’s also expanding its design team to produce designs that can’t be made due to limited manufacturing technologies. “We are also targeting to work with regional players through strategic investments & collaborations to offer better personalized & next door services worldwide,” concludes Harsh.

The company targets to increase this number by 15 times and become a global company. For that, Tesseract is setting-up cutting-edge 3D print farm equipped with sundry machines by the first quarter of 2019 to provide large batch production & material options at affordable prices. To take-on manufacturing challenges, it’s also expanding its design team to produce designs that can’t be made due to limited manufacturing technologies. “We are also targeting to work with regional players through strategic investments & collaborations to offer better personalized & next door services worldwide,” concludes Harsh.

address, phone, opening hours, reviews, rating

Directory of organizations in Krasnoyarsk

4.4 average rating based on 7 reviews.

VK

FB

Telegram

Pin

OK

Contact information

Karla Marksa, office 1 - 95 5th floor (see on the map).

Phones: +7 (965) 899-08-91, +7 (391) 215-49-31, +7 (963) 256-11-12

Opening Hours

Open Now - 03:55 PM

Location Map

Before you go to TESSERACT, check the location of the organization on the map.

Loading map...

Additional information

Website: tesseractcp.ru

Social networks:

- VK: https://vk.com/tesseractcp

.

- Modeling, prototyping

- Jewelry design and modeling

- 3D printing equipment and consumables

Newspapers and Rabochy prospect, 30a st9

3 views

FabLab hangar, center of youth innovative creativity

Address:

-Zatonskaya, 44g

5.0 Current assessment based on 1 review

2 views

3DPoint, 3D scan and 3D printing center

Address:

-Dubrovinsky, 62-1st floor

9000 9000 5.0 5.0 Superior rating based on 5 reviews

9 views

Cube, 3D printing laboratory

Address:

- Krasnodarskaya, 8 - 201 office; 2nd floor

4 views0003

Address:

- Academician Vavilov, 1st 10 - 342 office; 3rd floor

5. 0 Current assessment based on 10 reviews

0 Current assessment based on 10 reviews

2 Views

Inlab, LLC, Center for Youth Innovation Creativity

Addresses:

- Borisova, 14 st7

- Academician Vavilova, 21 - 1st floor

9000

6 views

Promotion, advertising agency

Address:

— Krasnaya Zvezda, 1st 13 — 1st floor

8 views

Gift Workshop, IP Delver S.A.

Address:

-Kutuzova, 96g ST69

4.0 Current assessment based on 3 Reviews

3 Views

Dialog AUTO, LLC

Address:

-Semaphorus, 17a-basement

9000 9000 1.0 Sund-cost rating based on 1 reviews

1 view

Dynasty, jewelry store

Address:

— Lenina, 118

5.0 average rating based on 5 reviews

6 views

Reviews

Read 7 user reviews about TESSERAKT.

View 2 other customer reviews.

Visits to company pages

2 visits to company pages

new materials that change characteristics and shape / Habr

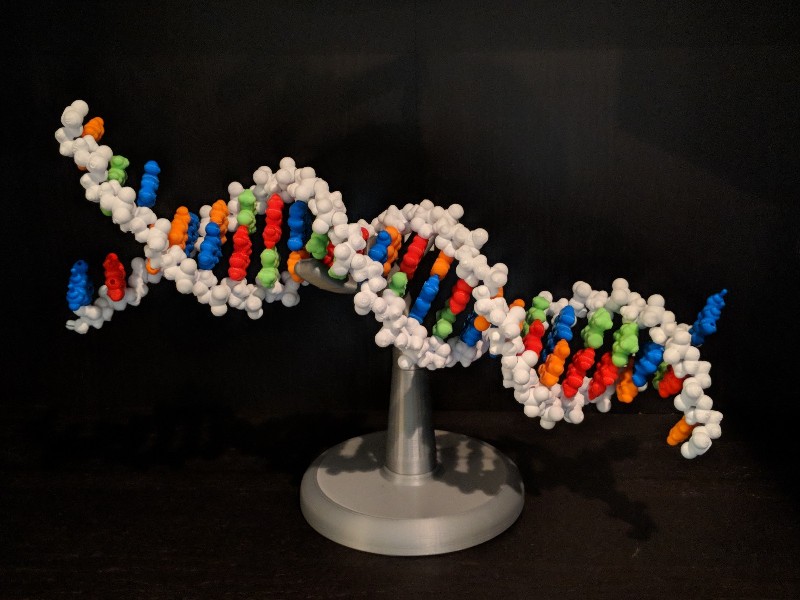

Usually, 4D means a four-dimensional space in which there are four-dimensional objects - tesseract, icositetrachor (has no analogues in the three-dimensional world), and the like. A few years ago, the term 4D began to be used to refer to a special technology for printing objects that change their characteristics over time. Thus, in 4D printing, the “fourth” is not a measurement, but a parameter that is associated with the position (possibly also the function) of an object.

4D printer technology can hardly be called revolutionary compared to conventional 3D printing - the object is created layer by layer in the same way. The most interesting thing happens later, when the finished item begins to change. And here it all depends on what material is used in the printer. Special materials change under the influence of water, heat, light, mechanical stress, and can also be programmed for certain actions.

Special materials change under the influence of water, heat, light, mechanical stress, and can also be programmed for certain actions.

Let's see why 4D printing is needed and what a world looks like built on the basis of things that change their shape and behavior.

Cars of the future

Last year, BMW unveiled what the cars of the future will look like. The concept was not without the use of 4D. As conceived by engineers, the car body consists of movable triangular sections printed on a 4D printer. Such parts will have integrated functionality, which is now achieved by producing different parts and assembling one movement from them.

Thanks to the use of special materials similar in characteristics to carbon fiber, each section will have a programmed function from the moment of production. For example, most of the coverage will serve wheel arches designed for better aerodynamics. During the turn, the triangular sections stretch, and the tires do not rub against the arches.

Visual demonstration of the 4D printed concept car:

Shape change on contact with water

A team of scientists at Harvard University turned their attention to plants that react and change their shape in response to environmental stimuli. Hydrogel composite structures have been developed that change shape when immersed in water.

Orchid flower object printed with hydrogel composite inks containing specifically directed cellulose fibers. To give the wood fibers the desired direction, they were mixed with acrylamide hydrogel. When immersed in water, the resulting substance changes its geometric dimensions in a predetermined way.

Composite ink allows you to obtain products of different shapes. Moreover, it is possible to change the composition of the material to obtain certain properties, such as electrical conductivity or biocompatibility.

Researchers at MIT's Self-Assembly Lab have developed a 2D template that folds into a cube when submerged in water. Self-Assembly Lab prints using the Stratasys Objet260 Connex1 printer, which allows you to work using a variety of materials (including rubber-like and polypropylene).

Self-Assembly Lab prints using the Stratasys Objet260 Connex1 printer, which allows you to work using a variety of materials (including rubber-like and polypropylene).

The laboratory has created a wide variety of products that can independently take the desired shape or self-assemble. They showed laces that lace themselves up and pieces of furniture that unfold themselves.

Space Shield

NASA engineers 4D printed metal fabric to protect satellites from damage and radiation, and to make flexible antennas. The fabric is a kind of "mail", created from pieces of silver and other metals. The material can be repeatedly bent, unfolded, stretched and compressed. Each side of the fabric has its own properties, reflects or absorbs light and heat. Despite being flexible, the fabric is extremely difficult to tear. It is planned that satellites will be packed in protective material before they are launched into space, or spacesuits and habitable modules will be shielded with it.

Technology for the Military

Northwestern University's International Nanotechnology Institute received a five-year grant from the US Department of Defense to develop a 4D printer. The 4D printer will be used for research in chemistry, materials science and defense-related fields. It is assumed that 4D printing will allow the creation of new chemical and biological sensors, designs and materials for microchips.

Progress is currently being held back by the lack of low-cost equipment capable of printing at ultra-high resolution (about 1,000 times thinner than a human hair) from hard materials (metals and semiconductors) and soft materials (eg organics).

The 4D printer will form the basis of a new generation of architectural design tools in which the materials that form the functional components of electronics can be combined with biological objects.

Shape memory

4D printed resin model recovers after deformation.

Back in 2013, researchers at the University of Colorado developed a 4D printing technique by incorporating "shape memory" polymer fibers into composite materials used in traditional 3D printing. Examples of applications of the technology included solar panels that can fold and unfold for transport, vehicle coatings that adapt to the environment, and military uniforms that change camouflage patterns or better protect against gas or shrapnel.

Three years later, a joint team of scientists from the Singapore University of Technology and Design, MIT and the Georgia Institute of Technology developed a new 4D printing method based on exposing photosensitive materials to light. A new printing technique is able to create elements as thick as a human hair.

A photosensitive polymer solution was poured into the printer and the desired object was projected layer by layer, processing the material with ultraviolet light. To test that the polymer is able to recover from deformation, the researchers printed a soft manipulator that is closed when free. With it, scientists were able to successfully capture small objects (such as screws).

With it, scientists were able to successfully capture small objects (such as screws).

Already at this stage, this technology can be adapted for real applications - for example, to create capsules that release substances when the body temperature rises.

Medical Printing

Doctors in northwest China's Shaanxi Province performed a successful and rare tracheal operation using 4D printing technology. Doctors inserted a tubular tracheal stent into the patient to keep her airway open. For the production of the stent, the biomaterial polycaprolactone was used, which dissolves over time - biodegradation in the human body occurs slowly, about 3 years. Doctors pre-determined the dissolution time of the printed stent, and the patient will not need to undergo another operation to remove it.

A similar incident occurred in the USA. Garrett Peterson was born with a malformation of the bronchi - bronchomalacia, when the cartilage is not hard enough. Bronchial ventilation was compromised, and the child spent his entire life in a hospital at the University of Utah on a life-sustaining ventilator.