All metal 3d printer kickstarter

The All-Metal 3D Printer by Snapmaker — Kickstarter

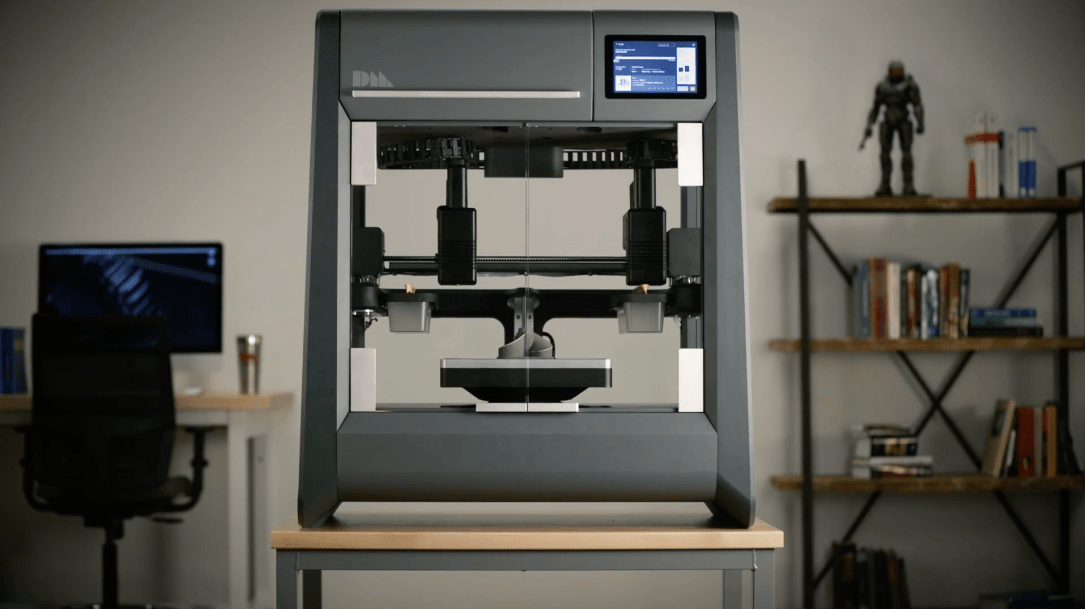

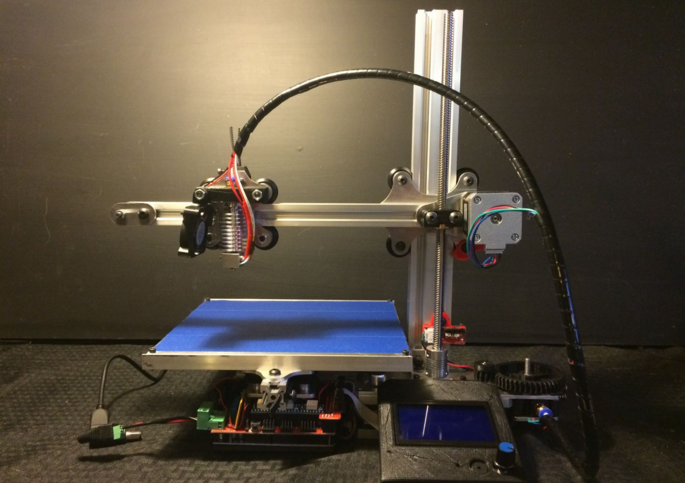

3D printers are amazing. Unfortunately, they used to be hulking, complicated, expensive, and with limited functions. We’ve been hearing about and experiencing the pain of setting up the difficult-to-use DIY 3D printer kit and being limited by the standard plug-and-play 3D printer. We are hoping to change that. So we came up with an idea: create an all-metal 3D printer, which is easy-to-use for beginners, expandable for makers, and truly affordable for everyone.

That’s why we designed Snapmaker to be all-metal and all-in-one.

After many stages of analyzing the mechanical design and making prototypes, we’ve developed the Snapmaker 3D Printer to provide an enjoyable user experience. Moreover, It's also a desktop makerspace, a combination of 3D printer, laser engraver, and CNC machine with interchangeable heads. We can't wait to share it with the Kickstarter community and have you help nurture this unique machine with us.

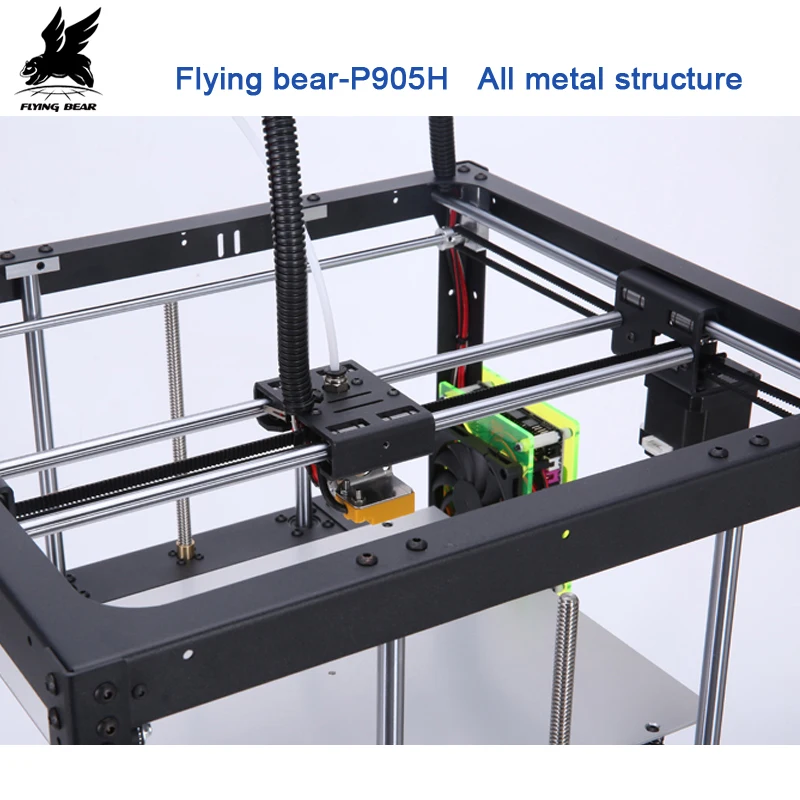

Snapmaker is entirely made of metal, ensuring a high quality and reliable 3D printing experience. Along with a rock-solid aluminum alloys frame, all major components are CNC machined. It uses the precision acme lead screw as a drive mechanism to boost the precision and capacity. The all-metal build also translates into a premium industrial outlook.

Snapmaker has an innovative modular design, which enables a flat-packed and low-cost shipping, quick assembly, strong expandability and manufacturing cost reduction. In particular, we designed a new type of linear module, which can be used in any of x, y, z direction and performs high precision linear motion.

The key to high precision is the combination of a streamlined structure, CNC precision parts, and an improved mechanical design. Snapmaker is capable of high quality printing with excellent details.

You'll need an HTML5 capable browser to see this content.Replay with sound

Play with

sound

A timelapsed video of Snapmaker 3D printing a vase (L 64. 5 x W 64.5 x H 80.0mm). We used 1.75mm PLA filament and 0.2mm layer height. It took approximately 1 hour and 19 minutes.

5 x W 64.5 x H 80.0mm). We used 1.75mm PLA filament and 0.2mm layer height. It took approximately 1 hour and 19 minutes.

High resolution 3D printing is now an affordable reality with Snapmaker. It prints at a resolution as fine as a $1000 3D printer does, while at a fraction of the cost.

Snapmaker comes with a very friendly newbie software experience in Snap3D. Simply drag and drop a print file onto it or add other print files to make multiple items at a time. Besides the Snap3D, you are free to use other slicer software that you prefer.

With movable and intuitive touchscreen, you can check and control various settings in your hand, such as homing, loading the filament, etc. The 3.2-inch color touchscreen enables you own a standalone 3D printer that is capable of handling your 3D printing workflow from start to finish.

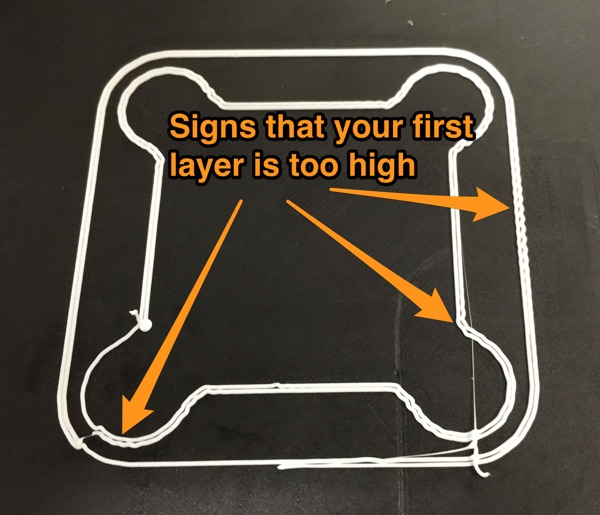

Unlike most traditional 3D printers, Snapmaker never needs leveling. The ingenious design ensures a completely level print platform. Simply set the Z-axis offset with a piece of paper and Snap3D, and then enjoy the 3D printing.

No more hassle of prying loose your print from the print bed! Snapmaker comes with a hassle-free and reusable platform sticker, offering better results than traditional blue painter’s tape and glue sticks. Prints stick well on the printing sticker base and are easy to remove whencompleted.

Have you ever tried to assemble a 3D printer in 10 minutes? With Snapmaker, now you can! It creates an easy setup of 10 parts in only 10 minutes. Do not hesitate, and try it yourself. It’s cool!

You'll need an HTML5 capable browser to see this content.Replay with sound

Play with

sound

Snapmaker can be easily transformed into a laser engraver using the add-on 500mW laser module. You can laser engrave images and logos on wood, bamboo, leather, plastic, fabric, paper and other soft surfaces. Now, customize your wallets, coasters, leather iPad cases, jeans, and more!

You'll need an HTML5 capable browser to see this content.Replay with sound

Play with

sound

[A timelapsed video of carving the Superman logo on bamboo. It took approximately 1 hour.]

It took approximately 1 hour.]

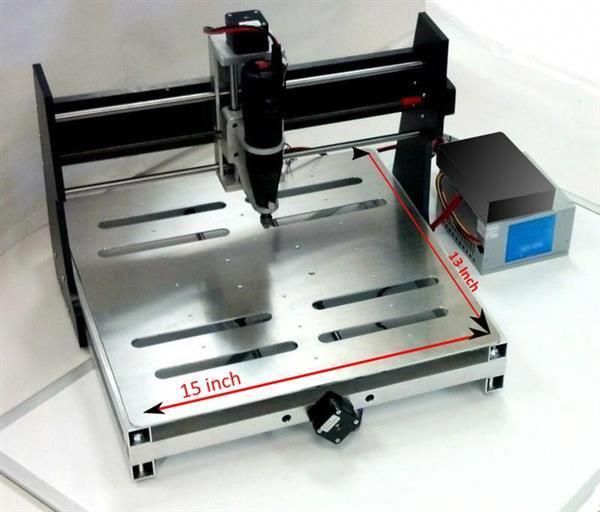

You can do CNC carving on wood, PCB and acrylic using the add-on CNC module (spindle speed: 2,000 - 7,000 RPM). The interchangeable modules equip you with more creative power from 3D printing to 3D carving. Instead of purchasing three machines costing around $500 per piece, now you can use one compact and reliable machine, saving your money and desktop space.

Isn’t it incredible! The Snapmaker 3D Printer surely will be a game changer. High quality, reliable, versatile, and affordable. To own an equivalent printer on the market would cost significantly more. But, now you can get it for a pledge that starts at only $199. Making all of this was a big challenge, a challenge we won by using all-metal & modular design and previous work experience in engineering and manufacturing.

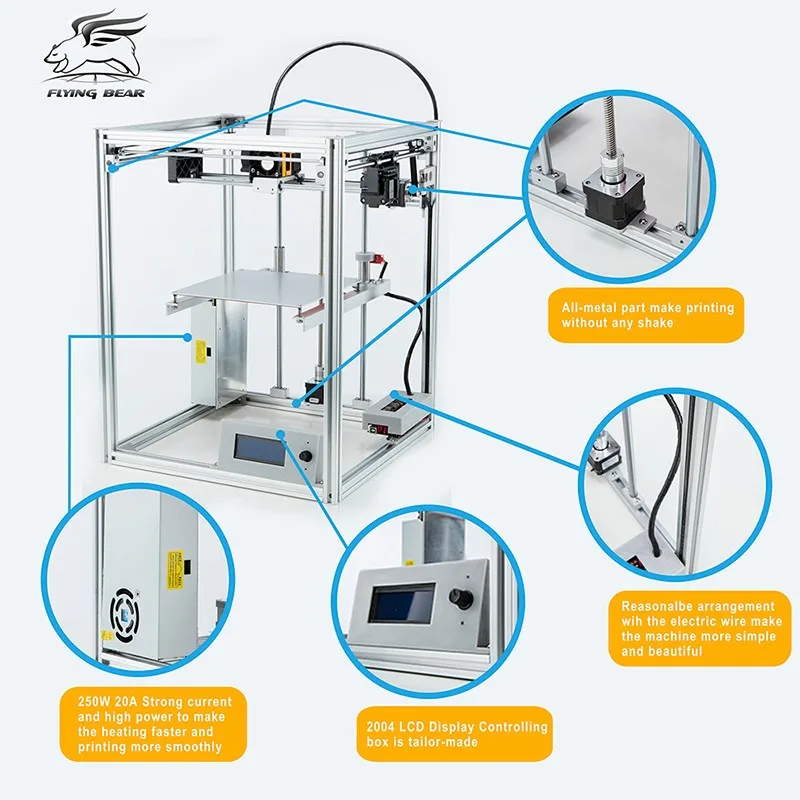

Use All-Metal Design

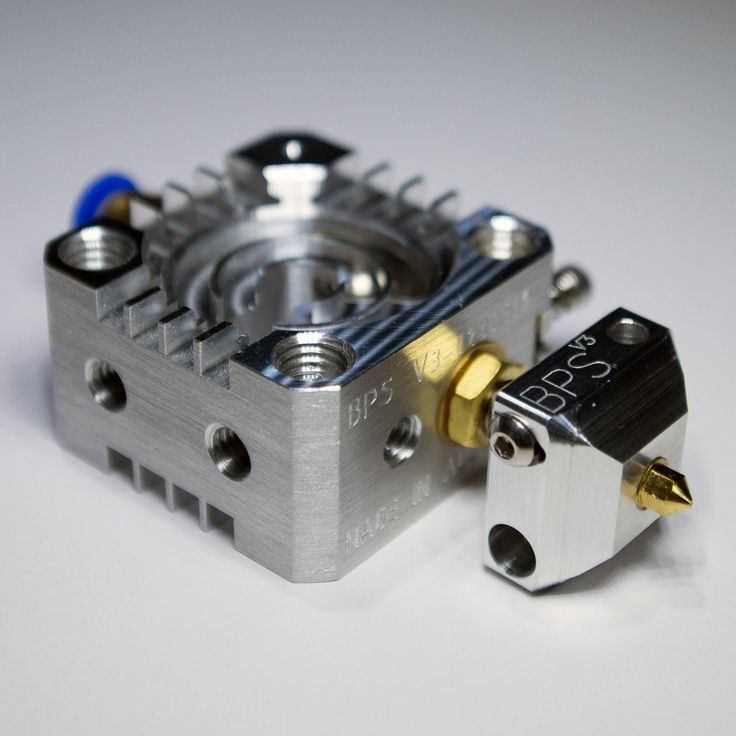

When it comes to 3D printers, reliability is the issue that people care about the most. Snapmaker owes its reliability to an all-metal design. It uses a solid aluminum alloys construction, an all-metal hot end and precision acme lead screws, giving it precision print quality and consistent performance.

In general, higher strength and precision designs can be achieved with aluminum alloys. The body of the linear module is made of extruded aluminum alloys, making it extremely rigid and durable. It has over 10 times better tolerances than plastic, and also better performance than sheet metal. Regarding the motion system, we use lead screws instead of belts and pulleys to achieve higher accuracy and durability.

Regarding the motion system, we use lead screws instead of belts and pulleys to achieve higher accuracy and durability.

Use Modular Design

We not only love 3D printing, but also have a great interest in a number of creative designs. In fact, there are lots of like-minded people who want to create more than 3D printing. We found that all 3D printer, laser engraver and cnc carving machine require a three-axis linear motion system to work. So we combined them into one machine that performs all functions.

Snapmaker is built to be versatile from the very beginning we designed it. It is a compact desktop makerspace: a combination of 3D printer, laser engraver, and CNC carving machine. Its versatility is achieved by using interchangeable heads, modular connectors (RJ25 and RJ45 jacks), and modified firmware that enables three applications of 3D printing, laser engraving and CNC carving.

Work Experience in Engineering & Manufacturing

To enhance product quality while reducing manufacturing costs at the same time, the usual method is to use dies and molds for mass production. It is exactly the way we made the all-metal Snapmaker affordable. Clearly, we can expect a lower cost per unit if we make them in higher volume. Meanwhile, we are able to sell our printers in high volume by hitting a very affordable price point.

It is exactly the way we made the all-metal Snapmaker affordable. Clearly, we can expect a lower cost per unit if we make them in higher volume. Meanwhile, we are able to sell our printers in high volume by hitting a very affordable price point.

Replay with sound

Play with

sound

Generally, making a die or mold is costly. We have been taking this issue under consideration throughout the design process and finally found a great solution: using modular design and designing all three linear modules (the most important and expensive parts) to be identical so that all of them can be made with the same dies. It not only cuts dies costs, but also allows for making linear modules in higher volume. Decreasing the overall manufacturing cost eventually enables us to offer the all-metal Snapmaker at a truly affordable price.

Besides, we control manufacturing risks and costs by selecting popular 6061 and 6063 aluminum alloys raw materials. They not only have good mechanical properties but also are relatively easy to ensure a stable supply. Moreover, we use many common components in making Snapmaker, such as using 42 stepper motors and T8 acme lead screws.

They not only have good mechanical properties but also are relatively easy to ensure a stable supply. Moreover, we use many common components in making Snapmaker, such as using 42 stepper motors and T8 acme lead screws.

Snapmaker is a tech startup team based in Shenzhen & Walnut, CA. We are passionate engineers and designers with working experience in the fields of aviation, robotics and 3D printing. We enjoy creating products that can let you enjoy the innovative technologies in daily life. We’ve been working hard to make the Snapmaker 3D Printer a reality. Moreover, there are numerous amazing partners we’ve worked with for video filming, manufacturing, shipping, etc. We want to give a huge thanks to all supporters, backers and team members!

Product Development and Manufacturing

Daniel has a unique vision of product design and strategy. Tinker and Otoko complete detailed design and communicate with suppliers. All the three of them are experienced engineers and responsible for the design, development and manufacturing of Snapmaker..jpg)

Website, Community and Marketing

David builds and maintains our website. Jade handles Snapmaker’s community management, content operation, etc. Marx handles the market’s research and outreach.

Software and Electronics

Walker works together with Noah to develop our slicer software Snap3D. Paladin is responsible for electronics design, testing and manufacturing.

The Affordable All-Metal 3D Printer by Kodama, Inc. » FAQ — Kickstarter

Share this project

Done

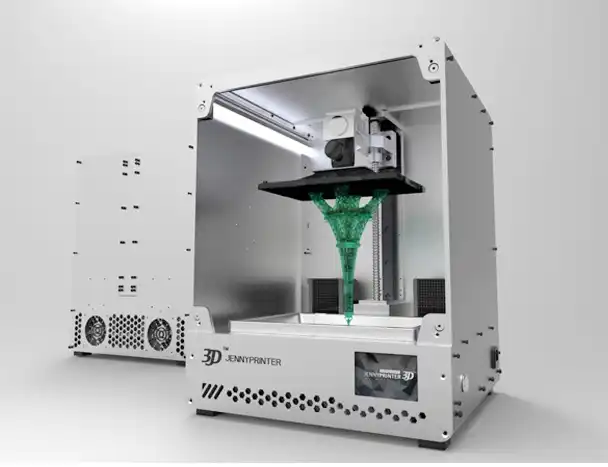

Made of industrial-grade parts. Transforms into a laser engraver in 60 seconds. Trinus is the professional 3D printer you can afford.

Created by

Kodama, Inc.

Kodama, Inc.

Frequently Asked Questions

- ASSEMBLY: How long does it take to assemble Trinus?

We gave our set to someone with no technical experience and she assembled it in 30 minutes. The printer comes in 11 major units and all you need to do is screw them in place.

Last updated:

- ASSEMBLY: How often should I calibrate the system?

We avoided using belts and low-quality parts in order to give Trinus a high degree of precision and reliability. It is designed to only need calibration the first time you use it.

Last updated:

- ASSEMBLY: How long does it takes to replace the 3D Printer head with the Laser Engraver?

It takes just a minute and four screws to add on the Laser Engraver head. Protection glasses are mandatory while using the active laser.

Last updated:

- FILAMENT: What is filament size that comes with Trinus?

Trinus uses 1.75mm filament.

Last updated:

- FILAMENT: What filament can I use with Trinus 3D Printer?

Trinus has been tested and works flawlessly with PLA, ABS, wood, aluminum, bronze, PC, flex and many other filaments.

Last updated:

- FILAMENT: Do I have to exclusively use Polymaker filament with Trinus?

We tested all of the filament brands available to us, and you are free to use any filament brand on the market. We equipped Trinus with a high-quality extruder that can handle a wide range of filaments.

Last updated:

- SOFTWARE: Can I use other software for slicing and printing?

Yes, Trinus is compatible with most available slicing codes (gCode).

Last updated:

- PARTS: What’s the maximum temperature of the hotend?

The hotend reaches 255 degrees Celsius.

Last updated:

- LASER: Can I use Laser Engraver to cut materials?

Laser head on Trinus is not powerful enough to cut materials but engrave on wood, leather or other similar materials.

Last updated:

- PRINT VOLUME: What is Trinus print volume?

120 x 125 x 125mm (4.9 x 4.7 x 4.9in)

Last updated:

- RESOLUTION: I wonder what is XY resolution of Trinus?

XYZ axis resolution are identically 2.5um

Last updated:

- Do you offer any warranty?

Yes we will offer 1 year limited warranty.

Last updated:

Don't see the answer to your question? Ask the project creator directly.

Ask a question

Snapmaker All-Metal 3D Printer 3D printer launched on Kickstarter

Turn your desktop into a workshop! Successfully launched on Kickstarter and raised more than 1 million dollars Snapmaker multifunction device project: 3D printer, CNC machine and laser engraver.

Snapmaker is made entirely of metal, guaranteeing the highest quality and reliability of 3D printing. Snapmaker is capable of high quality printing with excellent detail.

Equipped with a color touch screen. Have you ever tried to build a 3D printer in 10 minutes? With Snapmaker, now you can! This creates an easy 10-piece setup in just 10 minutes. nine0005

All-metal

Snapmaker is made entirely of metal for high quality and reliable 3D printing. Along with the massive aluminum alloy frame, all major components are CNC machined. It uses a precision lead screw as the drive mechanism to improve accuracy and productivity. The all-steel construction also translates into a premium industrial outlook.

High Precision

The key to high precision is the combination of a streamlined structure, precise CNC parts and improved mechanical design. Snapmaker is capable of high quality printing with excellent detail. nine0005

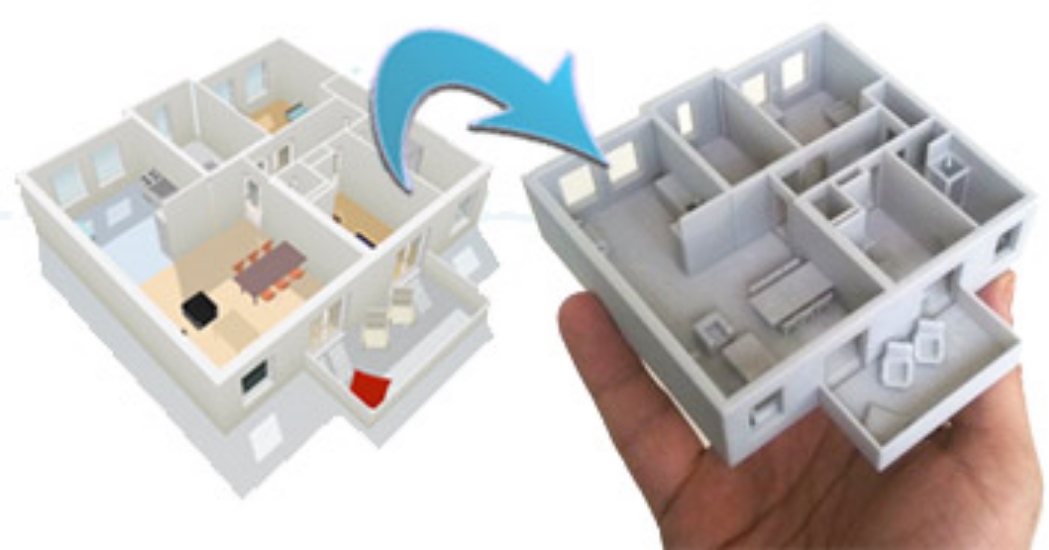

High resolution

Timelapse video of Snapmaker 3D printing vase (L 64. 5 x W 64.5 x H 80.0 mm). We used 1.75mm thick PLA filament and 0.2mm layer height. It took about 1 hour 19 minutes. High resolution 3D printing is now an affordable reality with Snapmaker. It prints at a resolution as thin as a $1,000 3D printer, albeit at a fraction of the cost.

5 x W 64.5 x H 80.0 mm). We used 1.75mm thick PLA filament and 0.2mm layer height. It took about 1 hour 19 minutes. High resolution 3D printing is now an affordable reality with Snapmaker. It prints at a resolution as thin as a $1,000 3D printer, albeit at a fraction of the cost.

Easy to use

Snapmaker comes with very user friendly software for beginners. Simply drag and drop a print file onto it or add other print files to make multiple models at once. Apart from Snap3D, you can use other software and slicers that you prefer. nine0005

Color touch screen

With an intuitive touch screen, you can check and control various printing parameters such as homing, filament loading, etc. The 3.2 inch color touch screen allows you to have a standalone 3D printer capable of processing your 3D -Print workflow from start to finish.

Calibration and alignment

Unlike most traditional 3D printers, the Snapmaker never needs alignment. The original design provides a fully printable platform. Just set the Z offset with a sheet of paper and Snap3D and then enjoy 3D printing. nine0005

Just set the Z offset with a sheet of paper and Snap3D and then enjoy 3D printing. nine0005

Easy to assemble

Have you ever tried to assemble a 3D printer in 10 minutes? With Snapmaker, now you can! This creates an easy 10-piece setup in just 10 minutes.

| Stock | Out of production |

| Printable area | 160 x 160 x 155 |

| Consumables | PLA |

| Layer thickness | 0.10-0.40 (100-400 µm) |

| Heated table | No |

| Print speed | up to 30 cm3/h |

| Connection method | USB, WiFi |

| Warranty | nine0043 1 year|

| Number of heads | 1 |

| Country of origin | US |

| Software | Repetier-Host, Slic3r, Cura, Simplyfy3D |

Who creates the best work as a 3D printer client?・Cults

The BLU-5 is one of the most affordable desktop 3D printers we've ever made. It offers the largest print area of any TwoTrees 3D printer, the most consistent performance, and is suitable for users of all skill levels. nine0113 Its all-metal base and frame provide durable performance. Simple, elegant design combined with outstanding performance makes the BLU-5 a toy for DIY enthusiasts, as well as a professional printing machine for designers and factories.

It offers the largest print area of any TwoTrees 3D printer, the most consistent performance, and is suitable for users of all skill levels. nine0113 Its all-metal base and frame provide durable performance. Simple, elegant design combined with outstanding performance makes the BLU-5 a toy for DIY enthusiasts, as well as a professional printing machine for designers and factories.

Here is a video review made by Aurora Tech, you can search for other video reviews of the BLU-5 printer on Youtube (formerly known as BLUER Plus).

90% pre-assembled, easy to install

BLU-5 comes with 90% pre-assembled parts that require minimal installation. Most installations can be easily done with hex wrenches.

To ensure that users receive devices without printing problems, each device is assembled for a 3D cube printing test prior to shipment. Few factories test the print before shipping as it is time consuming and labor intensive.

Few factories test the print before shipping as it is time consuming and labor intensive.

90% Finished Desktop 3D Printer

Smart 3D Touch Sensor and Auto Leveling

The BLU-5 also has a built-in 3D touch sensor that allows the printer to check if the print platform is level and make adjustments if necessary.

After checking that each part is installed correctly, alignment is recommended and required before printing. The alignment and leveling function in Tool Settings (on the touch screen) allows you to move the nozzle and 3D touch sensor around multiple points and register the position of each one. If the distance between the dot, nozzle and print bed differs from other dots, the software automatically starts the alignment process. nine0005

Built-in 3D touch sensor

Large print area for more options

Compared to other TwoTrees consumer 3D printers, BLU-5 is the largest 3D printer with 300*300*400mm print area. It is also one of the best large-scale 3D printers available in the consumer market. The print size of 300*300*400mm provides enough space for most DIY projects and allows users to complete printing of multiple models in one print. If you're not sure what size you need, the BLU-5 is a good budget option if you take everything into account. nine0005

It is also one of the best large-scale 3D printers available in the consumer market. The print size of 300*300*400mm provides enough space for most DIY projects and allows users to complete printing of multiple models in one print. If you're not sure what size you need, the BLU-5 is a good budget option if you take everything into account. nine0005

Large 3D Printer

Patent Development: Automatic Space Adjustment Function

The basic working principle of FDM 3D printing requires that the print head and print bed move in sync with the design file. Since 3D printing is extremely demanding on precision, any imperceptible defect can cause the print to fail or become distorted.

Patented auto-spacer kit with spring kits greatly reduces motion-induced vibration for high precision and smooth printing. nine0005

Auto interval function

Quiet operation: TMC2209 mute driver

One of the main disadvantages of using FDM 3D printers is annoying noise.

The TMC2209 mute driver reduces running motor noise and makes 3D printing an enjoyable experience.

Dual Z-Axis and Synchronous Belt

Instead of a single Z-axis lead screw, the BLU-5 uses two lead screws with a synchronous belt for smoother movement and faster response. nine0113 This unique setting effectively reduces vibration and improves print accuracy and speed.

Z Axis Twin Guide Screws

Transparent Dual Stage Extruder

Compared to 3D printers with single stage extruders, the BLU-5 uses dual stage extruders to provide greater stretching force to achieve more stable and smooth extrusion.

Transparent housing allows users to observe and control the entire process with the naked eye. nine0005

Packed PEI greenhouse

Although the PEI greenhouse is a basic accessory for 3D printers, users usually have to pay extra for it from most vendors.

To provide users with a print-ready desktop 3D printer, a PEI greenhouse is included with the BLU-5 printers.

Thanks to its resilient and wear-resistant surface, you can easily remove printed patterns.

RJ45 jack

Instead of using other connectors, the BLU-5 uses the common RJ45 interface for connection, which is much more readily available in local stores and easier for users to find replacements on demand. nine0113 RJ45 is also more reliable and efficient in signal transmission.

RJ45 jack

Filament running out detection function and printing resume when power on

It is quite normal when filaments run out during printing, and restarting wastes a lot of time and money on filaments. To solve this problem, all TwoTrees 3D printers are equipped with an intelligent low filament sensor and a restart function.

Whether printing is interrupted due to a power failure or a broken filament, the printer will resume printing at the exact layer or position where it left off. nine0005

Thread flow detection

- X and Y belt tensioner allows users to make proper adjustments without the need for additional tools.

- Removable motherboard service cover makes motherboard replacement much more convenient.

- The 4.3-inch touch screen control panel provides a clear, simple interface and fast response to every touch.

- All-metal base and frame make the 3D printing machine strong and durable for long-term use. nine0198

Click to use promo code

(coupon code automatically added at checkout).

Established in 2017 as a manufacturer of 3D printer accessories, TwoTrees is fast becoming one of the most trusted companies in the world in developing, manufacturing and marketing desktop FDM 3D printers. In addition, TwoTrees is the pioneer of self-developed laser engraving machines in China. Today, our business includes FDM 3D printers, filaments, resins, as well as laser engraving machines and related accessories that have a global reach. nine0113 With R&D teams and a dedicated experimental studio, we promise to always maintain a customer-oriented concept to provide more cost-effective innovative products.