Chicago 3d printing expo

3D Printing & Additive Manufacturing Event

North America’s largest and most influential Additive Manufacturing event.

May 2 - 4, 2023

McCormick Place

Chicago, IL

people

Why Attend

What makes the largest and most influential additive manufacturing event in North America a can’t miss experience in 2022.

event

Event Features

Find out what makes RAPID + TCT next level in 2022.

devices

Digital Experience

RAPID + TCT 2022 – Now Streaming

RAPID + TCT 2022 in One Word: Wow!

Join us as we revisit the excitement and innovation that made RAPID + TCT 2022 so remarkable.

Learn More

Watch the Keynotes On Demand

-

Barbara Humpton Siemens USA

-

Caralynn Collens, MD Dimension Inx

View More

Access On Demand Content!

Login to the RAPID + TCT 2022 Digital Experience to access livestreamed Keynotes, Thought Leadership Panels, Industry Partner Presentations, SME Technical Community Presentations, and recorded conference content!

Login Now

Explore the NEW Conference and Event Preview

Look what’s waiting for you in Detroit… 400+ exhibiting companies, keynote presentations, thought leadership panel discussions, new product previews, networking and so much more!

The Rapid + TCT Experience

Event and Industry News

-

June 22, 2022

You can rest assured that you held a great event when both the exhibitors and attendees offered thanks and words of praise.

That is exactly what I heard throughout RAPID + TCT 2022, and in the week that followed.

That is exactly what I heard throughout RAPID + TCT 2022, and in the week that followed. -

June 2, 2022

SME and the Rapid News Group welcomed thousands of members of the Additive Manufacturing (AM) community back for another successful installment of the industry’s largest and most influential event, RAPID + TCT 2022, May 17-19 at Huntington Place in Detroit.

-

May 20, 2022

RAPID + TCT 2022 has officially kicked off—this time returning to its roots at Huntington Place in Detroit!

Membership Has Its Advantages

With an All-Access pass to RAPID + TCT, you'll receive a free 1-year SME membership! SME members can connect with peers, gain knowledge related to manufacturing technology and trends, solve problems and participate in leadership opportunities.

Get Your All-Access Pass

View More News

RAPID + TCT 2022 On Demand

RAPID + TCT 2022 is now streaming! 130+ sessions from over 200 speakers, 400+ exhibitors, and thousands of additive manufacturing thought leaders, conversations, and explorers - all in one place & available on your time. Get access today!

Get access today!

Learn More

RAPID + TCT Event Overview

For more than 30 years, RAPID + TCT has defined the crucial role of additive manufacturing and empowered the establishment of an industry that continues to conceive, test, improve and manufacture new products at a faster, more cost-efficient pace. The two industry leaders in 3D-technology events, SME and Rapid News Publications, have teamed up to produce the annual RAPID + TCT event, which takes place May 2-4, 2023 in Chicago, IL.

Known worldwide as North America’s most important and largest additive manufacturing event, RAPID + TCT provides everything you need to know about the latest 3D-technologies, all under one roof. It is where you will witness groundbreaking product announcements, experience hands-on exhibits, learn real-world additive manufacturing solutions from the industry’s most respected experts and network with thousands of industry peers. At the RAPID + TCT conference, over 100 industry leaders go beyond the hype to bring you real-world solutions to advance your manufacturing processes.

At the RAPID + TCT conference, over 100 industry leaders go beyond the hype to bring you real-world solutions to advance your manufacturing processes.

Meet our Industry Partners!

The following organizations are critical to the future success of the additive manufacturing industry and we are thrilled that they have joined this collaborative effort that aims to foster industry standardization, thought leadership and growth.

RAPID + TCT 2023

May 2-4, 2023

McCormick Place

Chicago, IL

Register Now

Event Hours

Tuesday May 17: 9am - 5pm

Wednesday May 18: 9am – 5pm

Thursday May 19: 9am – 3pm

Exhibit Hall Hours

Tuesday May 17: 10am - 5pm

Wednesday May 18: 10am – 5pm

Thursday May 19: 10am – 3pm

About SME and Rapid News Publications

The two leaders in additive manufacturing, SME and owner of the TCT Group, Rapid News Publications, joined forces in 2016 to produce the RAPID + TCT event, combining decades of 3D-technology insights and experience.

SME is the definitive industry source for 3D-technology knowledge, experience, education, and connections. With a community of over 200,000 people, we are fully committed to the advancement and increased adoption of additive manufacturing technology. We also attract students to exciting careers in manufacturing through contests, design challenges, and dynamic hands-on experiences.

SME’s Additive Manufacturing Community provides access to experts, connecting you to the world-class knowledge that is advancing the manufacturing industry. Technical papers, conference presentations, industry news, videos and webinars keep you on the leading edge of development while preparing you for what’s next. Our certifications and training courses empower you to take that next step in your career. And our events give you access to the connections and knowledge you need to create your additive manufacturing success story.

No matter where you are on your journey in additive manufacturing – simply exploring the possibilities, designing new innovations or facing the challenges of scaling up production, SME is your resource every step of the way.

RAPID + TCT Event Advisors

RAPID +TCT Event Advisors are pivotal in assisting SME and TCT with developing and implementing the RAPID + TCT event. This advisory team represents a broad base of the AM industry to help us build a world-class event and conference that educates and inspires all participants, no matter the stage of their career or the size of their business.

The RAPID + TCT Event Advisors provide input on industry trends, technological advances and the future of AM. They also recommend industry thought leaders to present in various areas of the event.

Meet the Event Advisors

Membership Has Its Advantages

SME members can connect with peers, gain knowledge related to manufacturing technology and trends, solve problems and participate in leadership opportunities. Plus, with an All-Access pass to RAPID + TCT, you’ll receive a free 1-year membership! Enjoy all the benefits of membership, including a monthly subscription to our highly respected Manufacturing Engineering magazine, customized research assistance, local chapter engagement, online networking, and discounts on conferences and trade shows, and more.

Renishaw unveiled a new metal 3D printer at IMTS and plans to bring 3D printing to the industrial level

Mark Saunders, Renishaw's Global Solutions Centers Director: additive technology. Canada, the UK, India and Shanghai have Renishaw solution centers everywhere, and this year the company will open them in Chicago and elsewhere.

Renishaw is currently in the process of launching its latest RenAM 500M and is taking orders for it at this show in Chicago. The metal powder 3D laser printer will ship by the end of the year. “This machine is really focused on industrial applications,” adds Saunders.

"The difference between [it and] other printers is that it has an integrated powder handling function." Watching the relatively compact machine at Renishaw's booth is an opportunity to see the technology in action. The powder handling system is sealed to create a stable processing environment and facilitate cleaning. RenAM's control system was impressive enough for many attendees to be the topic of several informal dinner conversations.

"Powder management is important in terms of automation because it saves labor costs, but it's also important in terms of product quality." The RenAM system eliminates exposure to oxygen during the recycle cycle, and the sealed environment is also "good for health and safety [because] hand processing metal powder is definitely not something you want to do yourself."

Saunders says "it has more automation, plus it has features like higher laser power, making it more productive" than previous models, and allows it to handle "tricky" materials with high melting point.

Given that the assembly environment in the chamber is stable, "it allows the processing of reactive substances." Oxidation can weaken the metal part if processed under standard conditions. Renishaw RenAM can flush oxygen from the build chamber to prevent this.

Bringing 3D printing to the industrial level

Sanders recently gave a talk on the road to industrialization, during which he explains Renishaw's vision as follows:

“I think our vision is that additive manufacturing (3D printing) ) is going to take its place as the main production process in the next few years to create cutting-edge parts. ”

”

However, he warns against deceit and adds,

"This technology is not going to take over the world at all, but all this, of course, has great potential to destroy not only production, but also products and markets."

This destruction will take place by "allowing innovation in geometry, in the development of materials used, to create new products that are of great value to customers and therefore to the manufacturers of these products."

Saunders also believes that 3D printing will "destroy business models as well." In addition to allowing mass customization, additive manufacturing also allows production to be spread out. This means that businesses can "change supply chains and possibly mix individual products in markets."

He goes on and says, "we're going to have an interesting period over the next few years as these effects show up."

More knowledge from manufacturers is needed to take full advantage of additive manufacturing. Further in his presentation, Saunders introduced the concept of a manufacturing process pyramid and described it: “Four levels of additive technology: from rapid prototypes for development to design for additive technology (DfAM). ”

”

As the user moves up the steps of the pyramid, there is not only an involvement in the development, but also a vision of greater value in the product. On a lower level, "the advantage is that additive manufacturing is a repeatable process," says Saunders.

"At the next level, direct part replacement, [additive manufacturing] can reuse materials and take into account different business models." For example, moving products closer to the customer and restructuring the supply chain in the event of technical upgrades or replacement parts.

The next step is the consolidation of parts, ie. reducing the number of components in a piece or removing seams. As an example, when used to make microwave guides, additive manufacturing can improve performance, as removing individual components can eliminate back reflections, and therefore improve performance. Additive technology may allow mechanisms to be incorporated into a product. At the top rung “a load of possibilities begins to emerge”. For example, gaining the ability to create lightweight parts using complex internal geometry that is not possible to create with traditional manufacturing methods. “Another important argument is topological optimization,” continues Saunders, for example transforming part geometry in a biologically or biomimetic way, which can also improve performance.

For example, gaining the ability to create lightweight parts using complex internal geometry that is not possible to create with traditional manufacturing methods. “Another important argument is topological optimization,” continues Saunders, for example transforming part geometry in a biologically or biomimetic way, which can also improve performance.

3D printing can also be used to increase the surface area of a component, for example by adding lattice structures to hip cups to encourage bone ingrowth, or to make it easier to connect separate parts. Heat transfer is another area where surface area is critical: for this purpose, additive manufacturing can be used in the manufacture of engine components.

In his talk, Saunders gives an example of how designing for additive manufacturing can reduce the weight of a part from 4.6 kg to 0.4 kg, saving 9one%. An intermediate tailoring step for AM can lead to issues such as changes to the part's desired characteristics (such as stiffness), so designing for AM must take into account such processes, "AM is not an island," says Saunders.

3D printing and end users

What about the specific end users using the 3D printing solutions offered by Renishaw? It is becoming increasingly common that most of these users have non-disclosure agreements. This is standard practice these days. And at the same time, it is a disappointment for 3D printing companies that want to show the world their technology in action. However, the fact that so many businesses believe that 3D printing gives them a competitive advantage worthy of the mystery is a testament to the industry's maturity

"The Solutions center model is highly confidential, where we work on very sensitive points in the product development cycle." Saunders says, "companies won't let us talk about it until they're ready."

One company that Renishaw talked about earlier is the Robot Bike Company. They partnered with Renishaw to build custom bikes.

Robot Bike Co. uses additive technologies to produce "bespoke bikes" that take into account the riding style and physical characteristics of the owners. This can be done "at no extra cost compared to mass-producing identical bikes" and allows manufacturers to add value to the product.

This can be done "at no extra cost compared to mass-producing identical bikes" and allows manufacturers to add value to the product.

“We work with companies in obvious areas such as aerospace, where we know additive technology has taken root. In addition, we are starting to work with automotive and consumer electronics, motorsports and oil and gas companies.”

Renishaw has also been involved in several Innovate UK projects with HiETA Technologies Ltd. "They're developing things like heat exchangers," the potential for more surface area for heat dissipation, making AM "a very promising area."

Visitors to the IMTS international show can see the RenAM 500M at booth E-5509 in the lakeside building. If you are impressed and have $650,000 (about £430,000), then you can even place an order.

London 3D PrintShow. Is the industry a goldmine or a ghost hunt? / Habr

There are lyrical heroes, and there are commercial cynics. I am from the clan of the second, dark .

I am from the clan of the second, dark .

RepRap's open paradigm - gave the world the opportunity to assemble a 3D printer on its own, without waiting for corporate products, however dark quickly realized and are trying to make a business of various sizes based on it.

Like moths to the light - they fly to the heady phrase "Welcome to the 3D era" .

I was able to observe a meeting of designated moths of various calibers for two whole days in London at 3D Printshow 2014, perhaps the largest world show in the context of 3D printing technologies.

Under the cut you will find:

- UNOBJECTIVE review of exhibitors

- DISCUSSION about the advisability of entering the 3D industry for entrepreneurs

- Some robots, PRINTBOTS

- Arduino COMPETITOR spy photos

- 3D light erotic

So, let's begin.

After the previous show in New York, 3D PRINTSHOW in London seemed like a breakthrough.

Either the organization and activity of participants is much higher here, or the industry as a whole has grown over the past year and was ready to show finished products at a fairly high level, but the desire to ask the question “Is that all?” - this time it wasn't.

Below is a panoramic photo of the exhibition hall.

The stands of Autodesk, 3DFUEL, Makerbot can be called visual dominants of the show.

And if everything is clear with AutoDesk (100% successful company), with the Americans - too (they were bought for an indecently large amount of money for the industry), then here is the value for the market of a very difficult to use scanner FUEL 3D with the unsympathetic results of a tedious 3D scan - the second year remains a mystery to me.

It was MAD at the entrance to the exhibition hall.

People with bulging eyes tried to draw something in the air with melting and almost instantly hardening plastic.

This 3D Doodle deftly “clung” to the 3D industry, one of the few who could ride the success in this extremely difficult, in my opinion, market.

Makerbot was a traditionally delicious American booth. In contrast to the 3D models, which are standard for exhibitions of this format, which have set the teeth on edge, he presented cute printouts from licensed files developed by the company's designers.

I will single out the Z18 model separately.

You will be surprised, but this is the TOP of sales in the company, and by no means personal computers and mini.

So the guys from BEST FILAMENT (Lyosha, hi), who have taken on the distribution of such a product in Russia, are probably POSSIBLY on the right track.

Personally, I LOVED the presence of WORKING food printing machines at the exhibition (there were none in New York).

There were also at least 4 manufacturers here:

But "broke" all DOVETAILED , target printer for molecular cuisine (Vitya Polyakov, hello!).

Can print berries, fruits with completely unusual flavors. It is loaded with syrups of all stripes:

The abundance of printers "for geeks and for hippies" was pleasing to the eye, but on the other hand hinted at the absence of serious breakthroughs in technology. The job of changing the printer went outward, not inward.

The job of changing the printer went outward, not inward.

Wifi modules, LCD screens, built-in webcams, multi-colored or super-transparent futuristic colors - these are all add-ons, but NOT qualitative changes.

You don’t need to get upset, in principle, you can be glad that 3D printers are becoming different from each other and attractive to different buyers.

Before running to the manufacturers (DO NOT CONFUSE WITH PACKERS) PLA, ABS plastic (this was one of the business tasks at the exhibition), I hung out at booth bq .

News from manufacturers Witbox - it turned out to be a lot MORE than I expected.

- The Spaniards made an awesome signature Teflon touch coating for 3D printer platforms.

Now is the time when PLA plastics with different properties are becoming more and more. Delamination, fuzzy fixation on the platform, is a problem known to many 3D printers. Methacrylate platforms hold generally well, but often require blue 3M wide tape and lose flatness during use. Glass platforms do not have the disadvantages of the former, but without 3D varnish or other "shamanism" they also do not always take off.

Glass platforms do not have the disadvantages of the former, but without 3D varnish or other "shamanism" they also do not always take off.

bq-shnoe cover is mounted on top of the table (be it Witbox, Prusa i3 Hephestos or any other 3D printer with a comparable print area), it lasts long and comfortably.The SWEETEST news regarding bq's new pre-release products had to be blurted out at the request of the company's marketing department. Here: who managed - he ate. Now be quiet. Shhhh... Official releases will be out within a month

After bq passed by booth Ultimaker (Vlad, hello to you):

The booth is objectively nice and big (albeit without new products), but when I saw the dampened platform of the demonstration 3D printer, I thought: “Guys, you need bq teflon...”

A long fairy tale It affects, but the work is done slowly.

Finally, I got to plastic .Theses-trends regarding consumption for FDM printers, highlighted during the study of the stands of the participants - are as follows:

- Eco-friendly, non-toxic

- FUCK Chine

- Variety

The serious focus of manufacturers on PLA speaks in favor of the first point.

I found several samples of ABS at the exhibition, including unexpectedly in granules, but they are clearly not a trend maker:

FUCK Chine-ness Each of the manufacturers reacted absolutely calmly, paternally, to the mention of Chinese manufacturers.

“The technological gap in this segment is very large,” they say.

“To make plastic of our level they are objectively beyond their power.”When we mentioned Russian production, they simply couldn't hide their smiles.

"Production? In Russia? You don't seem to have been to a REAL PLA PRODUCTION. If they were, they wouldn't ask such a question."For what I bought - for that I sold. Thanks to my partner's communication skills for these insights.

Variety . Here - even the manufacturers of consumables think more NOT in the context of colors, but in the context of applicability.

Personally, I was put in (among other things) - a chair assembled from small elastic fragments:Watch:

And .

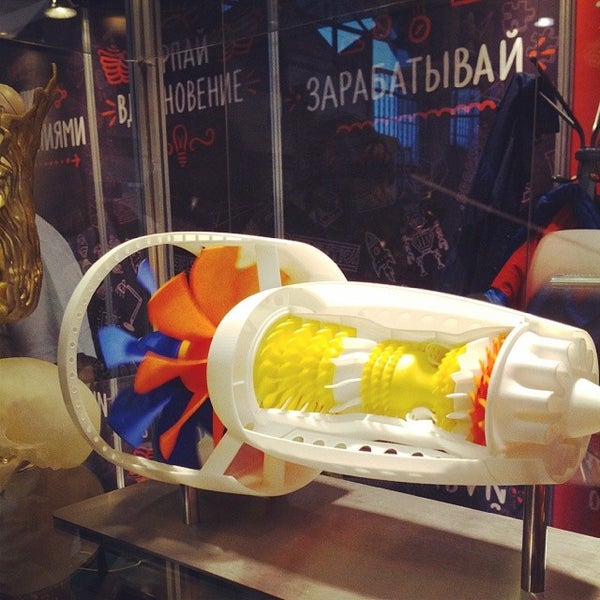

.. sneakers, no fools:

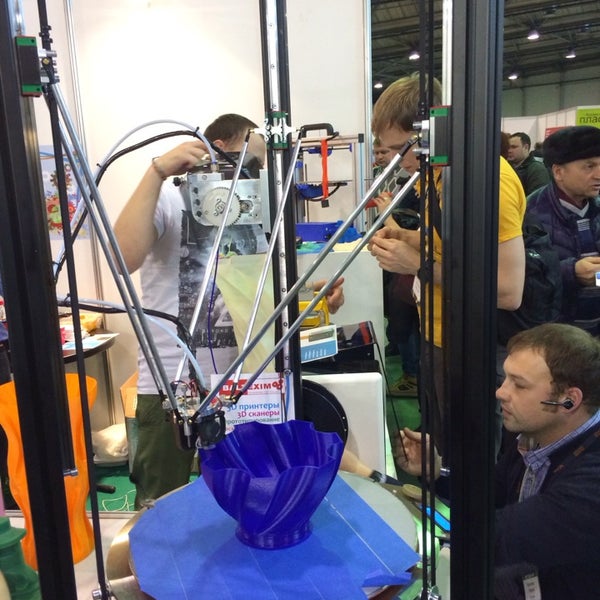

.. sneakers, no fools: Having run large printers :

printers for printing:and renowned 2D player Roland:

I, as if rooted to the spot, stood in front of this:

Eye-stopper worked reliably, and after watching the video to the end, and then glancing at what happened: my3Dtwin .

The mechanics are not as simple as they seem.

Photographing takes place in a bright arena (details can be seen on the video). You are being photographed by an INCORRECTLY large number of 2D cameras at the same time.

The result is approximately THIS number of shots:Then - partly programmatically, partly manually, all these images are formed into a 3D file (STL extension).

Next choice - you can either order a figurine in the right size, or buy this file and print it in any online printing service: 3Dtwins , Shapeways - in the world, 3D.ru (Seryozh, hello), 3D -printus (Konstantin, you are THE BEST) in Russia.

Now I look like this on the files after scanning:

Let's see what the final result will be after 3D printing.

Let's compare, I intend to lay out when ready.In general, the review of large strokes can be considered complete.

I publish robots:and printbots (printed on a personal 3D printer):

Many class photos from the exhibition can be found in an official photograph:

* * *

Postpartian Office7

More than three intensive months of work in the industry have passed since my last post on Habré.

What can be said here.

Rookies who run into the industry, COOL.

The market is overheated by media, but there is NO real demand that can make so many people/companies' businesses profitable.

Any serious projects: Online platforms, Industrial 3D printing, Professional distribution are far from being independent profitable projects. They can exist on venture investments, or are financed by donor businesses.

Learn more