Mojo 3d printers

Mojo 3D Printer Review 2022

4.2

See Price

| Printing Area | 127mm x 127mm x 127mm |

| Layer Resolution | 170 microns |

| Supported Filament | ABS, Support Material |

| Connectivity | USB |

| Extruders | 2 (ABS/Support) |

| Weight | 60 lbs |

Table of ContentsShow

Design and Features

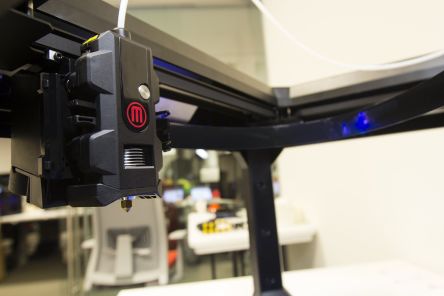

Opening the top cover and peering into the belly of the Mojo reveals a professionally engineered machine that even the most stringent designer will find satisfying. The smart positioning of various parts (including the inner brackets for the filament), the quality of said parts, and the clean look of the innards point towards the caliber of the printer in contention here. The configuration is a thing of beauty.

The two-shade gray color of the casing is on the drab side but has the benefit of smooth contours and an uncluttered look. The printing area feels contained and ordered hinting at Stratasys aim to provide an intuitive, easy to use printer free of the tinkering and messiness synonymous with barebones hobbyist alternatives. The Mojo wouldn’t be out of place within the hustle and bustle of a fast-paced professional design studio or prototyping workshop.

The design itself is centered on a fully-enclosed heat regulated chamber supported by a full metal frame and plastic outer casing with a reasonable footprint weighing in at a total of 60 lbs. The heated chamber is vital here because the Mojo only supports ABS filament and as any versed maker will know, temperature and humidity regulation is a core concern when printing with ABS, which is prone to warping.

Although the printer has a dual extruder setup that uses Fused Deposition Modeling technology, it differs quite radically from what we’ve come to expect from this duality. Typically, you’d expect two types of filament or at least two different colors of PLA or ABS, but with the Mojo, one extruder is used for ABS, while the other extrudes SR-30 soluble support material. The focus on supports is incredibly important in the systematic quality of the prints.

The focus on supports is incredibly important in the systematic quality of the prints.

Stratasys has made it so that the Mojo doesn’t just use any run of the mill open source ABS either. The Mojo uses what is termed ABSplus, which is a production-grade thermoplastic that more or less mimics the durability of bonafide production parts with the added benefit of working in unison with the support material to print intricate recesses, cavities, and overhangs.

As you’ve probably guessed, Stratasys ships ABSplus in a proprietary filament cartridge coined the QuickPack Print Engine with a capacity of 80 cubic inches available in nine different colors. Not only does the Print Engine contain the ABS, but also a disposable snap-in print head that is ostensibly as easy to switch out as a cartridge on a standard inkjet printer. The new print head with every spool is not just for ease of use, but to keep part quality.

Additionally, a chip is fitted into each Print Engine that communicates to the printer how much filament is left so the printer won’t trigger prints it can’t complete, and each cartridge is foil-wrapped to keep the ABS from going brittle. The Print Engine design is one-time use.

The Print Engine design is one-time use.

Going back to the support material, Stratasys also ships each Mojo with a WaveWash 5S support cleaning system, which is none other than a bin for cleaning off supports. Just add in an Ecoworks tablet (a dissolving detergent provided by Stratasys), a splash of tap water, turn on the cleaner and it will set the right temperature and amount of swirling to remove the supports without damaging the ABS print.

The Mojo has a comparatively small build area of 127mm x 127mm x 127mm, and the printing process sticks to the tried and trusted Cartesian configuration. The limited size is at odds with the price of the printer, but the truth is that for the majority of prototypes the available surface is more than sufficient. The printer steps up when it comes to the quality of the prints to counterbalance the limited space as we’ll see below.

The Mojo only prints at one layer resolution of 0.17 mm or 170 microns, with only one print speed available. The idea here is to provide detailed prints at every turn at the detriment of a quick test lower resolution print although it isn’t uncommon to see professional grade 3D printers with resolutions as high as 20 microns. Given that Stratasys is flogging the Mojo as a prototyping machine, the attention to detail makes sense but might irk users who desire a little more flexibility.

The idea here is to provide detailed prints at every turn at the detriment of a quick test lower resolution print although it isn’t uncommon to see professional grade 3D printers with resolutions as high as 20 microns. Given that Stratasys is flogging the Mojo as a prototyping machine, the attention to detail makes sense but might irk users who desire a little more flexibility.

The attention to detail also carries over to practicality with features like a set of internal brushes that clean the nozzles and collection bins that pick up any of the excess filament removed by the brushes. In the same vein, the front door has a locking mechanism to ensure the chamber remains at a uniform heat while printing.

As for software, the Mojo comes with the Stratasys Print Wizard utility that resembles a streamlined slicing application that’s intuitive and incredibly easy to use. The Wizard does most of the hard work by scaling STL files to fit the printer, queuing prints if the parts are too large for the build area, and communicates directly with the printer. The only real hands-on aspect is setting up the support style (basic, spare, surround) and orientation, which we found self-explanatory and easy to navigate.

The only real hands-on aspect is setting up the support style (basic, spare, surround) and orientation, which we found self-explanatory and easy to navigate.

We understand that Stratasys is banking on most of the heavy design work being completed in CAD software which is then carried over to Print Wizard for conversion then printing.

Connectivity wise, the Mojo is limited to a USB connection via a PC running Windows 7 or Windows 8.

Assembly

The Mojo ships with the printer itself, one QuickPack Print Engine cartridge of ABSplus and one of SR-30 support material, WaveWash 55 support cleaning system, 24 Ecoworks tablets, a modeling base (read build plate), USB cable, power cord, and official documentation.

For an all-in-one, pre-assembled configuration, two large styrofoam supports on the top and bottom adequately protect the printer. It ships as is with the filament in the brackets and the startup kit sitting on the build plate alongside boxes for the cleaning system. It’s all very minimal in keeping with the functional ethos of the Mojo.

It’s all very minimal in keeping with the functional ethos of the Mojo.

The setup is among the most straightforward we’ve ever encountered. Not only was installing the handful of parts a doddle, but the instructions were concise. We had to remove the cable ties holding the Print Engine cartridges in place, remove the packaging, place them back into the brackets, hook up the print head to the extruder, fit the cleaning brushes inside the chamber by merely putting them on a set on spindles, and finally snap on the modelling plate to the build area. It all took no more than 20 minutes.

The printer auto-calibrates so there’s no wasting time leveling the bed by toying with a set of screws and a piece of leveling paper. From here, we plugged in the power cord, connected the USB cable, and hit the ‘’on’’ button.

Printing

The print quality was nothing short of perfect. Within the space of the seven days we had access to the Mojo, not once did it fail, print blemishes, imperfections, or layering issues. The prints were of the highest quality, systematically. Speed wise, the Mojo isn’t the fastest, but this does mean through and through quality with every print. The support system worked well to ensure each job had the right foundations to come out flawless every time.

The prints were of the highest quality, systematically. Speed wise, the Mojo isn’t the fastest, but this does mean through and through quality with every print. The support system worked well to ensure each job had the right foundations to come out flawless every time.

The small things also made the printing experience that much better. For one, Print Wizard gave spot on estimates for print timings, even providing an exact time for when a project would be finished that it hit without fail. The bins that collect excess filament on the nozzles are excellent for keeping the chamber clean.

Equally, from powering up the Mojo to starting a print job, we are talking less than 15 minutes, and this includes initializing, diagnostics, and heating the chamber. The Mojo is by any standard quick to get going.

The absence of any lingering ABS odor is a nice departure from open-plan 3D printers where you’ll need to crack open a window to be able to breathe comfortably. It’s also inexplicably silent to the point that at times we had to check that it was still printing.

The WaveWash 55 worked well although it does take time to complete a cleaning cycle that can vary from two to five hours depending on the print job in question.

Support

Unfortunately, the Mojo is no longer in production, so any assistance is vendor specific beyond Stratasys offering user guides, videos, and a customer support contact on its website. The Mojo ships with a one-year warranty as standard. The company also still sells the proprietary Print Engine filament.

Verdict

With the Mojo 3D printer, manufacturer Stratasys isn’t holding back: we have here a professional grade device with all the precision, versatility, reliability, and a price tag to match. A hobbyist will shy away at the approximately $10,000 price tag, but professionals will find an affordable printer that gives competitor models with similar qualitative results a run for their money. In other words, for those with a budget to match, they will be hard pressed to find much wrong with the Mojo.

In other words, for those with a budget to match, they will be hard pressed to find much wrong with the Mojo.

Our only real criticism is the ongoing cost of operation; the cartridge design which incorporates a new print head with every Print Engine cartridge doesn’t come cheap. Heavy usage racks up quite the bill sentencing the Mojo to prototyping designers with the financial backing from a profitable company to keep the printer running.

On the flip side, print head failure is the number one cause of issues with 3D printing, and by extension, poor quality prints. In light of this, the additional price does equate to peace of mind and assured printing success.

The Stratasys Mojo Desktop 3D Printer

THE STRATASYS

Bring your Big Ideas to Life

Give your design team a little Mojo with proven Fused Deposition Modeling (FDM) technology and the Mojo 3D Printer. It's as simple to use as an inkjet printer, yet powerful enough to meet the highest 3D printing standards

View Video Request Demo

- Overview

- Key Features

- Advantages

- Materials

- Specifications

- Request a Quote

Discover the Magic of Mojo

The Mojo 3D Printer from Stratasys brings affordable, professional 3D printing to your design process. Powered by FDM technology, you can trust the Mojo to empower your design creativity. Whether you’re testing for form, fit or function, Mojo works easily with your CAD software- bringing your ideas to life with just the push of a button.

Powered by FDM technology, you can trust the Mojo to empower your design creativity. Whether you’re testing for form, fit or function, Mojo works easily with your CAD software- bringing your ideas to life with just the push of a button.

Explore the Stratasys Mo by watching the video

Affordable, Professional 3D Printing

The Mojo 3D Printer allows you to print professional grade 3D models in ABSplus thermoplastic – at a price lower than other professional 3D printers. Using Stratasys’ Fused Desposition Modeling (FDM) technology , the Mojo achieves excellent accuracy and function, all in one compact unit.

Discover the Magic of Mojo

With the simplicity of a typical inkjet printer, the Mojo makes the transition from 2D to 3D a smooth one. With intuitive 3D Print Wizard Software, easily replaceable material cartridges, and simple post-processing, the Mojo 3D printing process is guaranteed to enhance your application.

An All-In-One Solution

Printer Bundle includes everything you need to start desktop 3D printing:

· The Mojo 3D Printer

· Print Wizard/Control Panel

Software

· WaveWash 55 Cleaning System

· Ivory ABSplus model material

· Support Material

· Ecoworks Tablets

· Modeling bases and more

The Mojo is ideal for printing 3D models that help determine form, fit, and function- everything from ergonomics to design verification. When it’s time to test your concepts, Mojo produces durable ABSplus 3D models that will stand up to testing in their intended environment

SHOP ABSPLUS

Bring Your Ideas to Life

The Mojo from Stratasys is ideal for 3D printing models that help determine form, fit, and function- everything from ergonomics to design verification.

Print models with ABSplus, production-grade thermoplastic that provides your print with durability and a high-quality finish.

Simple Yet Powerful

As one of the smallest industrial 3D printers, the Mojo is the perfect desktop solution for quick prototype prints in both small or large office spaces. The system works as easily as a traditional inkjet printer yet powerful enough to meet and exceed 3D printing standards. Included software allows for real-time status updates and estimated print times allowing your design team to print their ideas efficiently.

The system works as easily as a traditional inkjet printer yet powerful enough to meet and exceed 3D printing standards. Included software allows for real-time status updates and estimated print times allowing your design team to print their ideas efficiently.

Easy to Use

Everything you need to start printing is straight out of the box. Set up is fast and easy- you can be printing your first 3D model in less than an hour.

With the WaveWash 55 Support Cleaning System, removing support material is easy. Featuring a stainless steel carafe, the device dissolves soluble support material quickly and quietly.

Materials

ABSplus

Production-grade thermoplastic ideal for conceptual modeling, prototyping and end-use parts. Get a high-quality finish with matching durability

LEARN MORE

Build Tray Size | Build Tray Size12.7 x 12.7 x 12.7 cm [5 x 5 x 5 in] |

Layer Thickness | Layer Thickness0. 17 mm [0.007 in] 17 mm [0.007 in] |

Printing Material | Printing MaterialP430 ABSplus |

Support Material | Support MaterialSR-30 Soluble |

Workstation Compatibility | Workstation CompatibilityWindows 7+ |

Printer Size | Printer Size63 x 45 x 53 cm [25 x 18 x 21 in] |

Printer Weight | Printer Weight60 lbs [27 kg] |

Stratasys Mojo

3D printerMojo makes 3D printing accessible to everyone

The Mojo 3D printer makes 3D printing accessible like never before.

- Desktop Prototyping System allows you to quickly create accurate and reliable functional models and prototypes right on your desktop.

- The size of the working area of 127x127x127 mm is often sufficient for creating product prototypes in various industries.

Out of production

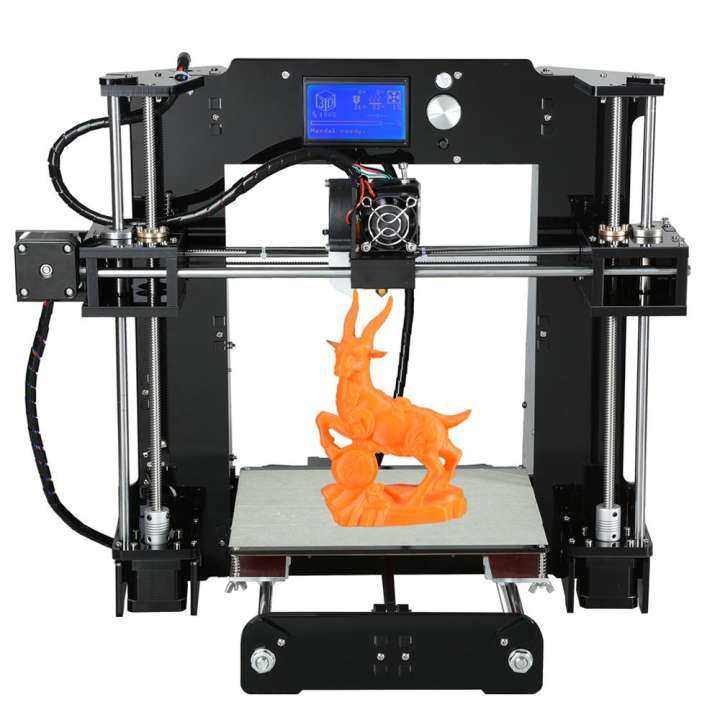

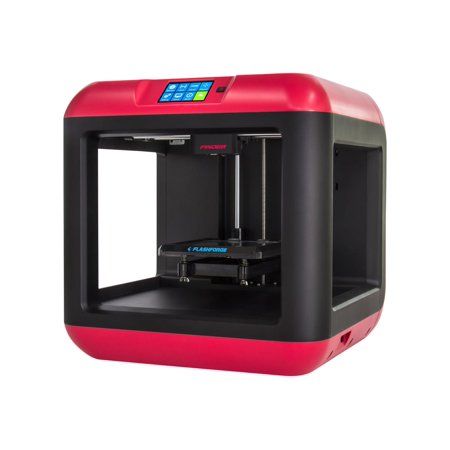

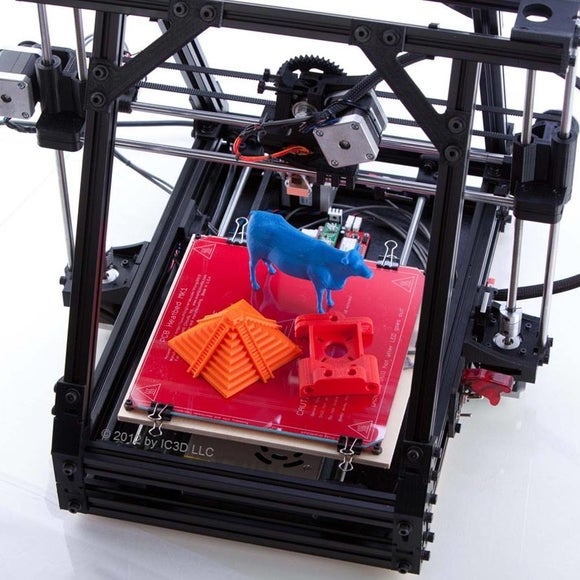

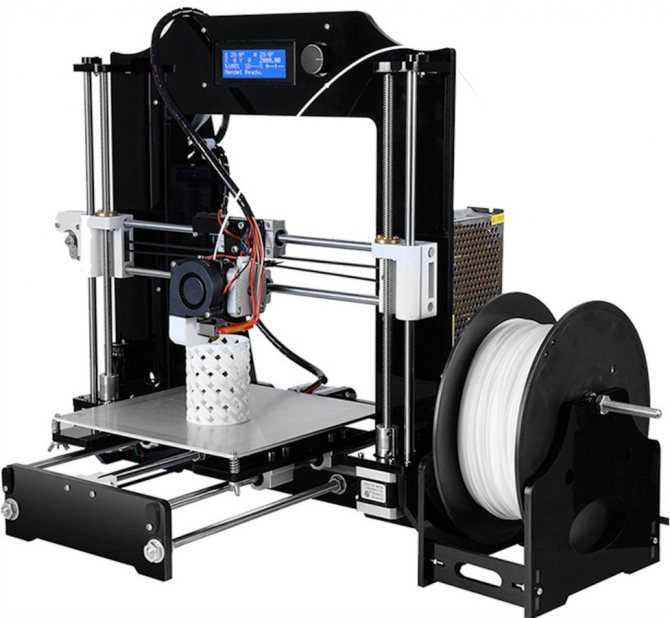

Modern analogues

Affordable 3D printing right from your desktop

Cost-effective 3D printing with the Mojo printer can dramatically improve your workflow. You can create reliable 3D models right on your desktop. Each new version of the design appears in your material quickly and conveniently. There is no need to wait in line for a shared printer or wait for your models to arrive from a service bureau.

You can create reliable 3D models right on your desktop. Each new version of the design appears in your material quickly and conveniently. There is no need to wait in line for a shared printer or wait for your models to arrive from a service bureau.

Accurate models made of durable ABS plastic

It's impossible to describe your idea in many words or two-dimensional pictures, it's as clear as it becomes when looking at the model in three dimensions from different angles.

Mojo is ideal for printing 3D models, which allows you to determine the shape, assembly and functionality of the future part. Mojo reproduces the models in durable ABS plastic, so they can even be tested directly in real life conditions.

Speed up the development process

All companies want to get their product to market as early as possible. The Mojo 3D Printer will help you complete your project as quickly as possible by the predetermined deadline. Mojo fits seamlessly into your current development workflow. With the Print Wizard software, your CAD files are automatically prepared for 3D printing. All you need is to press the "Print" button and start creating functional prototypes.

With the Print Wizard software, your CAD files are automatically prepared for 3D printing. All you need is to press the "Print" button and start creating functional prototypes.

Specifications

| Mojo | |

| Dimensions, mm | 630x450x530 |

| Working area, mm | 127x127x127 |

| Weight kg | 27 |

| Material | P430 ivory, white, black, grey, red, green, blue, yellow, peach |

| Layer thickness | 0.170 |

| Remove support | Solution bath |

| Power supply | 220-240V, 60Hz, |

| Compliance | CE/ELT/RoHS/WEEE |

| LAN | TCP/IP 100/10baseT |

| Operating system | Windows XP/Windows7 |

Materials

Model Materials

The Mojo 3D Printer can produce prototypes and end products from the following industrial grade thermoplastics:

- ABS Plus is a high strength thermoplastic.

Colors: ivory, white, black, grey, red, green, blue, yellow, peach.

Colors: ivory, white, black, grey, red, green, blue, yellow, peach.

Support material

- Soluble SR-30

Software

Print Wizard and Control Panel Software

Using the Mojo desktop 3D printer is very easy with the Print Wizard software . The software easily prepares CAD files for 3D printing, automatically generates support material geometry, and makes recommendations to improve your workflow.

PrintWizard provides:

- 3D preview of the model or models to be printed

- Intuitive and flexible detail scaling

- 3D orientation preview and easy modification

- Automatic placement in real time, for optimum filling of the cooking chamber

- Sketches for STL files

Mojo Software Control Panel displays the real-time status of the 3D printer. The graphic display shows:

- Print jobs

- Estimated print time

- Model and support material levels

- System ready

Touch 3D Printer This is an extruder-type printer (an extruder is a machine for softening (plasticizing) materials and shaping them by forcing through a profiling tool (the so-called extrusion head), the cross section of which corresponds to the configuration of the product).

Price from £1999 to £2495. More details CB printerPortable printer. Will fire models up to 20 x 26 x 18 cm albeit slowly at 100mm/min. Two nozzles are available in 0.3mm and 0.5mm. These machines have been available since summer 2012.

Price £ 1200. Read more

File2Part GutenbergOnly a prototype so far, so excuse the photo, but the model is listed for innovation and coolness: File2Part Gutenberg is the first full color printer for the hobbyist. Future plans include the use of chemicals in inkjet printing before plastic processing, which will give the product a variety of flexibility, all within a single printer model. The machine is able to create things up to 13.6 x 13.6 x13.6 cm.

More Formlabs Form-1 A highly anticipated stereolithography printer for beginner hobbyists.

Priced at $3299 (£2050). Read more The most famous printer for hobbyists. The model's dual extruder prints in two colors but cannot mix them. The maximum build size is 28.5 x 15.5 x 15.3 cm.

Price $2199 (£1370). Read more Objet Connex 350This is a Bugatti Veyron desktop 3D printer priced at just under £100,000. What makes Connex really special is that it can jet two materials at the same time, which means you can mix colors, although the choice of colored resins is limited. One object can have 14 levels of flexibility. Assembly size 34.2 x 43.2 x 20 cm.

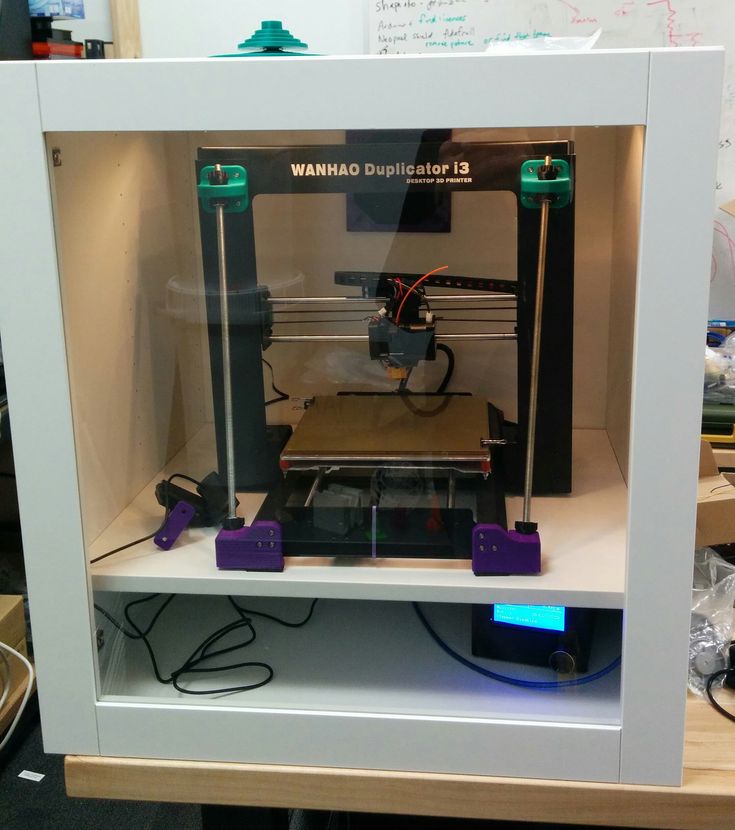

Read more here and here Printrbot jr Budget model 3D printer around 300 pounds: the device works with low melting temperatures. The model is made of wood. There is a portable version for those looking to save space, although it costs more because it runs on batteries.

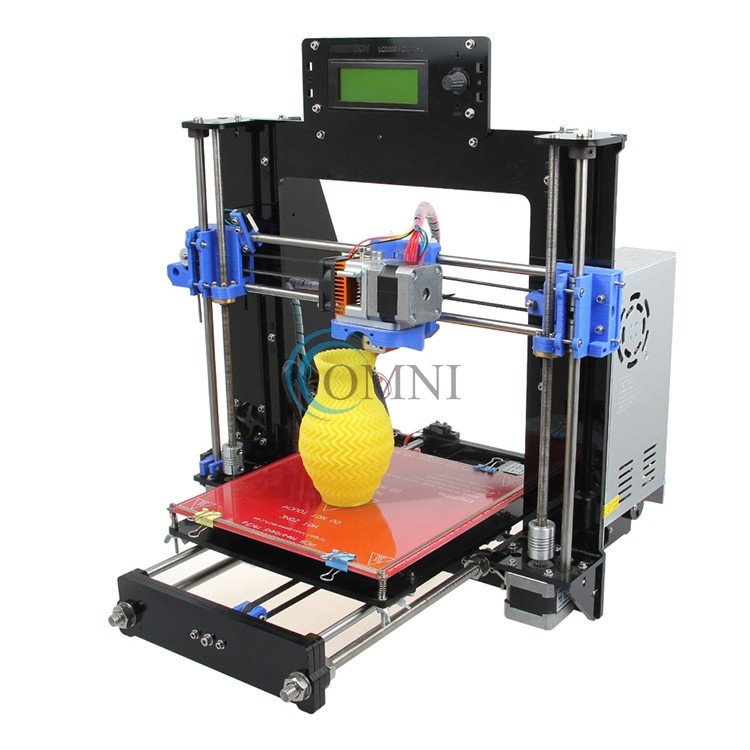

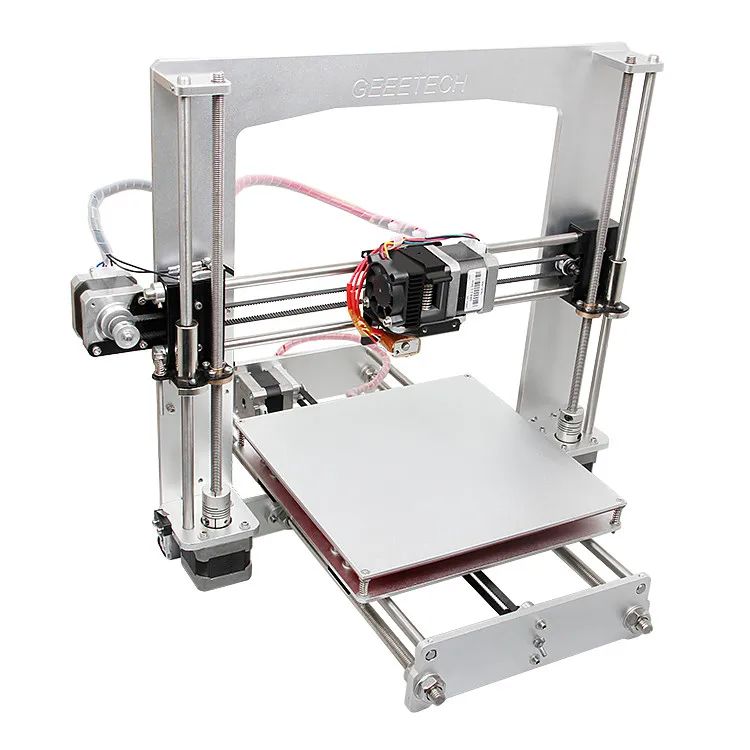

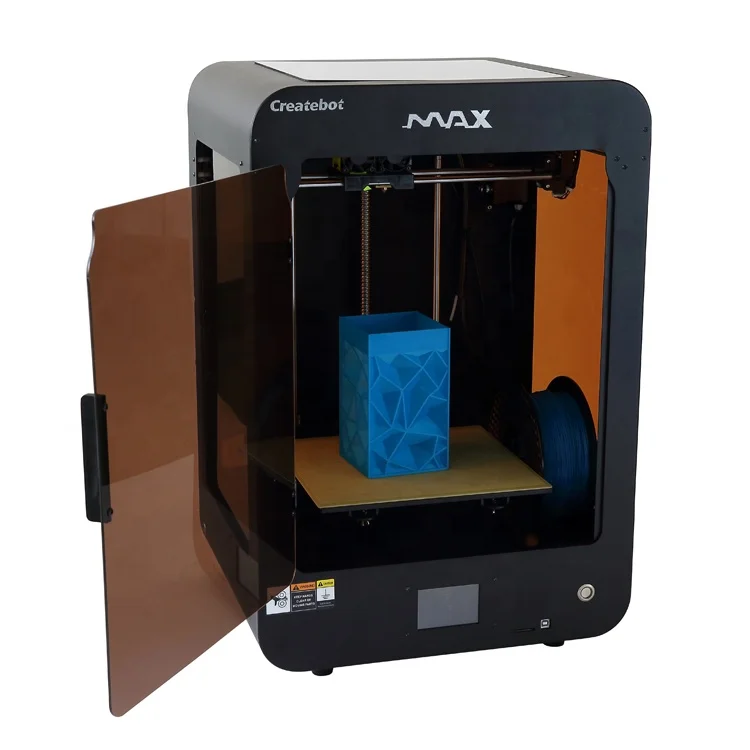

Price $449 (£280). Read more Stratasys Mojo 3D PrinterThis device is out of reach for hobbyists as it is an industrial printer. The print resolution is 0.17 mm and the maximum object size is 12.7 x 12.7 x 12.7 cm.

Price £7,920. More here and here Sumpod BasicTheBritish Arduino-based printer is sold as a complete set with an unpainted wood frame, or much more expensive with an aluminum one. Build speed isn't great, but for an inexpensive entry into the market for someone with decent engineering skills, this is a great place to start.

Price £300 (per set). Read more Up! 3D Plus One of the simplest 3D printers, but steel and quite reliable. It is possible to build objects with a layer thickness of 0. |

Files are printed from a flash drive, and there is also a touch interface. The device has an exceptionally large printable area of 27.5x 27.5x 21 cm.

Files are printed from a flash drive, and there is also a touch interface. The device has an exceptionally large printable area of 27.5x 27.5x 21 cm.  Product measures 12.5 x 12.5 x 16.5 cm.

Product measures 12.5 x 12.5 x 16.5 cm.  One can only guess what you would like to produce if, say, you took it on a plane as hand luggage. The maximum assembly size is 11.4 x 14 x 10.2 cm.

One can only guess what you would like to produce if, say, you took it on a plane as hand luggage. The maximum assembly size is 11.4 x 14 x 10.2 cm.