Form1 3d printer for sale

Form 1 + 3D Printer Review 2022

4.6

See Price

In a departure from the widely used FDM technology found in the majority of consumer 3D printers, Formlabs jumps off the bandwagon to offer a small form factor desktop SLA printer at a fraction of the usual cost.

On the back of a tremendously successful Kickstarter crowdfunding campaign that raised an eye-watering $3 million in the space of few months, the Form 1 and its advanced version, the Form 1 +, strives to bring the precision-oriented SLA technique to the masses.

How does it rival the standard FDM design and has Formlabs succeed in its mission to bring professional-grade quality free of the variable quality of other low-cost 3D printers to the average maker? Let’s find out.

| Printing Area | 125 mm x 125 mm x 165 mm |

| Layer Resolution | 25, 50, and 100 microns |

| Supported Filament | Liquid Plastic Resin |

| Technology | SLA |

| Software | PreForm |

Table of ContentsShow

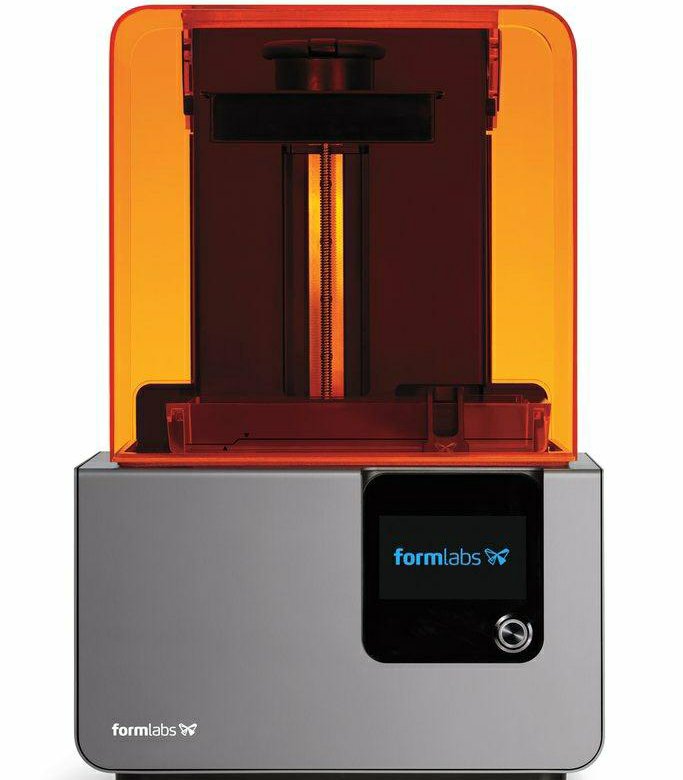

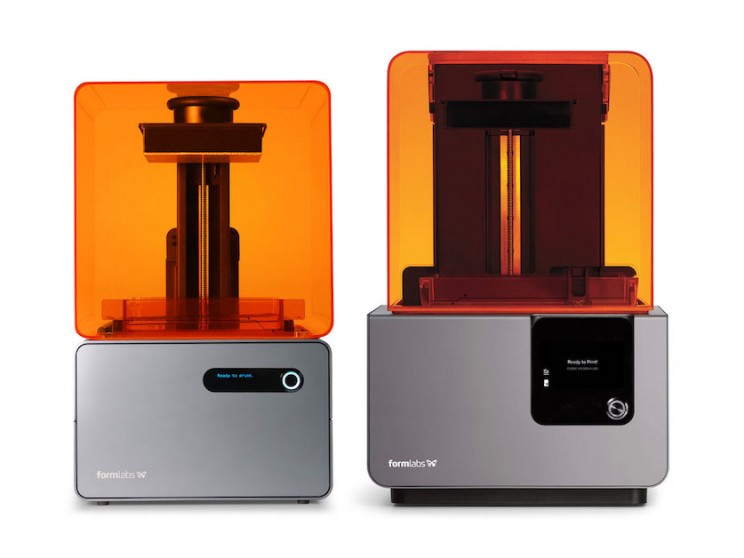

Design and Features

Most striking is the orange acrylic cover that sits above a glossy grey base with soft contours, an efficient closed look, and a definite nod towards Formlab investing considerable time and money into generating a visually enticing device. The Form 1 + is well constructed with an intelligent design from the placement of the different components, the latched removable inverted build plate, and functional resin reservoir.

It’s easy to forget that the Form 1 + is supposed to sit alongside entry-level pre-assembled 3D printers due to how good it looks. It oozes precision and professionalism with an almost otherworldly attraction that drew us inexplicably to this machine. The total weight of 18 lbs is worth noting as it ensures the printer stands firmly on any surface with a robust set of low-profile feet.

As mentioned above it uses SLA tech, or inverted stereolithography, which involves a UV laser that cures or hardens a light-sensitive liquid plastic resin layer by layer into a solid object. The galvanometer-directed UV laser effectively draws on the surface of the liquid resin causing it to harden. Delving a little deeper the process centers on a process called photopolymerization, whereby molecules are fused and solidified when in contact with light to create polymers.

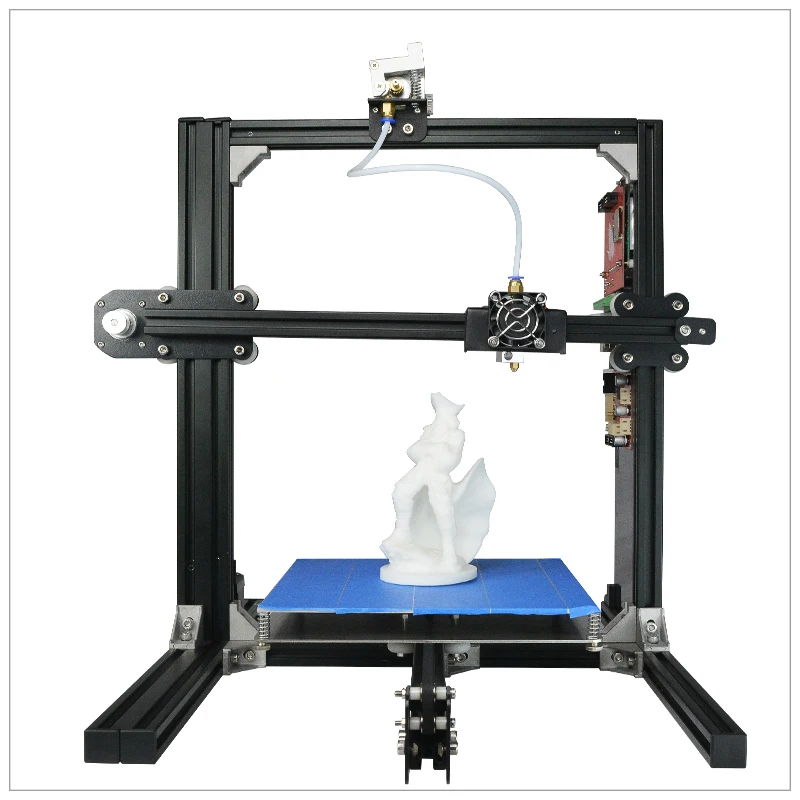

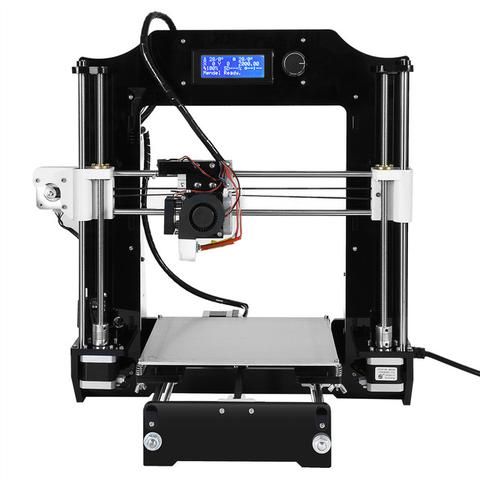

As you can see, this is miles away from the, at times, slapdash FDM technique, where plastic is melted then extruded layer by layer to create a printed model. Consequently, SLA usually carries with it a non-negligible price tag, if only for the equipment itself, but also for the actual liquid resin.

But the jump in price is also synonymous with a massive leap in quality as well. The results are incomparable to standard FDM tech, and if you were to put two identical models made via each of the technologies alongside one another, you’d be amazed by how much better the SLA printer performed.

The benefits don’t stop there, SLA is all but silent and long are the days of abrasive mechanical ear sores emanating from an FDM printer three rooms away. Equally, it is arguably safer due to only reaching temperatures ranging from 18 to 28 degrees centigrade compared to the standard 100 + degrees recorded during the operation of conventional 3D printers.

Now, to jump back to the hinged orange casing mentioned previously, it serves a fundamental purposes as it blocks outside light from infiltrating the closed chamber and spoiling the resin as well as looking pretty cool.

The Form 1 + packs a decent build area of 125 mm x 125 mm x 165 mm that is somewhat constrained by the incremental cost of SLA printing. The build volume took a hit to make the printer cost-effective. It’s smaller than most similarly priced FDM equivalents, but the upside is much better precision and detail.

At this point in our review, we would usually dive into extruder specifics, but as the Form 1 + doesn’t have one we jump to layer resolutions that range from an ultra-precise 25 to 100 microns alongside a minimum feature size of 300 microns (i.e., features of a model).

As for the resin itself, it is made of acrylate-based materials with an NPCA HMIS health safety rating of 2 (read moderately hazardous) and is produced exclusively by Formlabs and is, as expected, pretty expensive at around $150 for 500 mL, but much cheaper than the resin used for professional-grade machines. The standard resin is engineered for high-resolution details as well as strength and durability. Formlabs offers a range of colors and finishes alongside castable and flexible resins. Third-party resins aren’t supported and unfortunately won’t work with the Form 1 +.

Formlabs offers a range of colors and finishes alongside castable and flexible resins. Third-party resins aren’t supported and unfortunately won’t work with the Form 1 +.

Formlabs believes in simplicity and no more so than in the controls on the Form 1 +, which is nothing more than a one-button control panel with monochromatic LCD.

Otherwise, connectivity is limited to USB-to-PC via Formlabs slicing/preparation software dubbed PreForm with inbuilt tools for orientation, rotation, scaling, duplication, support generation and placement, density and geometry options, monitoring and print time estimates, and STL/OBJ file support (pulled from any 3D CAD software) converted to FORM for the Form 1+ to read. PreForm is compatible with both Windows and MacOS.

PreForm is easy to use, intuitive, and definitely among the best proprietary forced usage software we’ve come across in our years of 3D printing.

Assembly

The Form 1 + comes amply protected in a package of suspended cardboard inserts holding the printer in place, edge protectors, and protective tape. Unpacking involves removing the printer while being careful not to damage the packaging as it is designed for reuse when transporting the Form 1 +.

Unpacking involves removing the printer while being careful not to damage the packaging as it is designed for reuse when transporting the Form 1 +.

The package includes the Form 1 +, USB cable, power cord, power adapter, official documentation, quick start guide, safety guide, a 1L bottle of resin, and a Form Finishing Kit (setup guide, rinse bucket, rinse basket, tray, scraper, squeeze bottle, tweezers, absorbent pad, and disposable nitrile gloves).

The Form 1 + comes pre-assembled, and we mean genuinely, pre-assembled. No messing around fitting extruders, build plates, or filament spools. Due to the SLA tech, there’s no bed leveling or calibration either. It is functional straight out of the box.

Setup couldn’t be easier: remove the plastic protective layer from the resin tank paying attention not to smudge the bottom or top, plug in the power cord to the adapter and socket, connect the USB cable to the printer then PC, and finally switch on the Form 1 + via the button next to the display screen.

Print preparation is limited to filling the resin tank with liquid resin up to the marked line. Gloves are recommended which is a slight inconvenience, but otherwise, the process couldn’t be more straightforward.

Printing

For someone accustomed to FDM printers, the Form 1 + was a revelation. The quality of the prints can only be described as outstanding to the point that we’re genuinely dreading going back to FDM models.

The quality of the precision allows finite details on models to be abundantly apparent and not merely a blotched mesh of vaguely resembling filament that is so often the case with FDM. Every model we printed came out great with more detail than we are accustomed to in consumer/prosumer 3D prints.

The whole setup, slicing, and print initiation setup was also a pleasure and a world away from the overly complicated procedure usually associated with SLA style 3D printing. We did not once face any issues or failed prints at all.

The printer is also reasonably fast, and the revised Form 1 + is up to 50 times faster due to an improved UV laser and optics.

The finishing kit is also excellently designed with brackets to fit the detached build plate while you scrape off the model and an efficient rinse basket. The supports were easy enough to remove with a little force; a sure sign they were doing their job during the printing process.

The one real issue we had with the Form 1 +, but that comes with the SLA territory, was how meticulous we had to be in keeping the device clean. Any stray finger marks or blemishes on the resin tank meant cleaning it from top to bottom or risk ruining the curing process due to the precision of the optics, mirrors, and UV laser.

Support

Although Formlabs has technically stopped producing the Form 1 + in favor of the Form 2, they stay committed to providing expert after-sales support as well as a free one-year warranty, manning a repairs and servicing team, and providing educational resources from articles to videos by way of webinars and troubleshooting guides on its website.

Verdict

The Form 1 + takes the precision and quality of professional SLA printers, miniaturizes it, simplifies the printing process, and produces high-resolution prints with a nearly perfect finish. If you want something different to the standard FDM design, then the Form 1 + offers the ideal all-in-one package to get your feet wet.

If you want something different to the standard FDM design, then the Form 1 + offers the ideal all-in-one package to get your feet wet.

Although the ongoing cost of resupplying the resin tank can prove costly overtime, the Form 1 + uses resin sparingly, and we were surprised by how many models we were able to pump out with the stock 1L bottle. The long term cost is worth keeping in mind, but not a deal breaker in our book.

The cost of the resin means you won’t use it to create and experiment with test models. We see it more as finishing tool for low tolerance prototyping and models for casting.

The price tag hovers around the $3000 mark so this printer isn’t necessarily within the realm of the novice or first-time buyer, but veterans on the lookout for a new addition to their collection will find a lot of joy in the Form 1 +.

Formlabs 3D Printing Materials Library

Advanced 3D printing materials designed to deliver beautiful results.

Need help selecting the right material from our catalog? Try our interactive material wizard.

Recommend Me a Material

Explore Libraries

General Purpose

Outstanding performance. Excellent detail.

Custom-formulated to deliver the highest-quality output, our Standard Resins capture astonishing detail without sacrificing strength.

Learn More

Engineering Resins

Functional prototyping materials.

Our library of versatile, reliable Engineering Resins is formulated to help you reduce costs, iterate faster, and bring better experiences to market.

Learn More

Dental Resins

Professional materials for digital dentistry.

Formlabs Dental Resins enable high precision, low-cost digital production of a range of dental products in-house, including surgical guides, orthodontic models, retainers, and aligners.

Learn More

Jewelry Resins

High-detail materials for jewelry design and clean investment casting.

Prototype impressive concept models and manufacture distinctive pieces with sharp resolution and the best surface finish on the market, from idea to fitting to casting.

Learn More

Medical Resins

3D Printing Materials for Healthcare.

Access a library of over 20 materials available on one powerful desktop 3D printer, the Form 3B+. Our technology has been validated in FDA-cleared workflows and we develop and manufacture our own biocompatible materials in an ISO 13485 certified facility.

Learn More

Production-Ready Materials for the Fuse 1 generation printers.

Balancing strength and detail, our powders for selective laser sintering (SLS) are highly capable materials for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

Learn More

SAMPLE REQUEST

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Material Selector

Our interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of materials.

Recommend Me a Material

Data Sheets

Download safety and technical data sheets for all Formlabs materials.

Handling & Safety

Handling & Safety

Resin should be handled with care. Proper handling will ensure safe printing and efficient use. Our resins have been designed to be similar or safer to handle as other household chemicals or adhesives. Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

The Safety Data Sheets (SDS) are up to date for every resin product and follow the latest government guidelines. Always consult the SDS as the primary source of information to understand safety and handling of Formlabs materials. For more information about handling resin, learn more tips for resin maintenance in our Help Center.

For more information about handling resin, learn more tips for resin maintenance in our Help Center.

Technical Data

Technical Data

Plastics are complex materials, and finding the right one for your specific application requires balancing multiple attributes. Our library of resins is ideal for product development, rapid prototyping, and a variety of specialized applications. Download our Technical Data Sheets to explore the mechanical properties of each material.

Material

– Select –BioMed AmberBioMed BlackBioMed ClearBioMed WhiteBlackCastableCastable WaxCastable Wax 40CeramicClearColor BaseColor PigmentsCustom TrayDental LT ClearDental LT Clear V2Dental SGDigital DenturesDraftDurableESDElasticElastic 50AFlexibleFlexible 80AFull Materials LibraryGreyGrey ProHigh TempIBTModelModel V3Nylon 11Nylon 11 CFNylon 12Nylon 12 GFPU Rigid 1000PU Rigid 650Permanent CrownReboundRigid 10KRigid 4000Soft TissueSurgical GuideTemporary CBToughTough 1500Tough 2000White

Language

– Select –BulgarianChineseCroatianCzechDanishDutchEnglishEstonianFinnishFrenchGermanGreekHungarianIrishItalianJapaneseKoreanLatvianLithuanianMalteseNorwegianPolishPortugueseRomanianRussianSlovakSlovenianSpanishSwedishTurkish

Technical Data Sheets

There is no technical data sheet available for the chosen material.

Safety Data Sheets

There is no safety data sheet available for the chosen material.

Formlabs Form 1+ 3D printer in Moscow

Out of production

Add to compare

Item added to compare Go

Free shipping within Russia

Exchange of old equipment for a new one with a surcharge. Detailed information is available on the page or from our managers.

Official distributor

We work directly with manufacturers.

Any form of payment

The opportunity to see the 3D printer in action in our demo room.

Own warranty service

Warranty and post-warranty service of equipment purchased from us.

Permanent 10% discount on consumables

When you buy a 3D printer from us,

, you get a 10% discount on all consumables.

The Formlabs For 1+ 3D printer uses laser stereolithography technology. This means that the objects on it are made from thin layers of resin, which are processed by a laser, which ensures an accuracy of up to 25 microns. The surfaces of the finished models are smooth, they do not need processing.

For management, proprietary software is used. It allows you to adjust the print size and layer thickness. Also, the program will inform you in advance how much time and material will be required to manufacture the object.

Extraction of small models is carried out with a scraper. After printing, the object must be degreased by immersing it in alcohol.

After printing, the object must be degreased by immersing it in alcohol.

| Formlabs Form 1+ 3D printer | 1 piece |

| Set for work with printed objects | 1 piece |

Payment and delivery

Delivery scale

Delivery to all regions of Russia and countries of the Customs Union.

Free shipping

When you buy a 3D printer (except assembly kits) you get free shipping.

Cash

In our store you can pay for your order in cash.

Online payment on site

You can pay for orders with a bank card on the website of our online store.

Similar Items

Free Shipping

Add to Compare

Item added to compare Go

Out of stock

Formlabs Form 3 3D Printer 3D printers

Free shipping

Add to compare

Item added to compare Go

Out of stock

Phrozen Sonic Mini 3D Printer 3D printers

Free shipping

Add to compare

Item added to compare Go

Out of production

Phrozen Shuffle 4K 3D Printer 3D printers

Formlabs Form 1+ 3D Printer (SLA)

Form 1 + Printer from Formlabs, which uses laser stereolithography instead of extrusion - the layering of molten plastic - the object is formed by the thinnest layers of resin, photopolymerized under the action of a laser, which ensures the highest printing accuracy at 25 microns. Projects are very smooth with little need for post-processing, and thanks to the high print quality, you can create a model that matches the digital sample down to the smallest detail.

Projects are very smooth with little need for post-processing, and thanks to the high print quality, you can create a model that matches the digital sample down to the smallest detail.

Technical features:

Another feature of the Form 1+ is the ability to print parts with so-called "hanging parts" that extruder (FDM) printers rarely can offer. (Print without support)

Changes in Formlabs Form 1+ compared to the first version of the 3D printer:

- Print speed increased by 2 times

- 2nd generation laser, laser power increased by 4 times

- Print quality improved

Installation:

The Form 1+ is the simplest printer in the world in terms of setup and connection. You connect it via USB to a computer, select the desired file in the program and then send it for printing. The file is being downloaded to the printer, at this time the cable must not be pulled out, otherwise printing will not start.