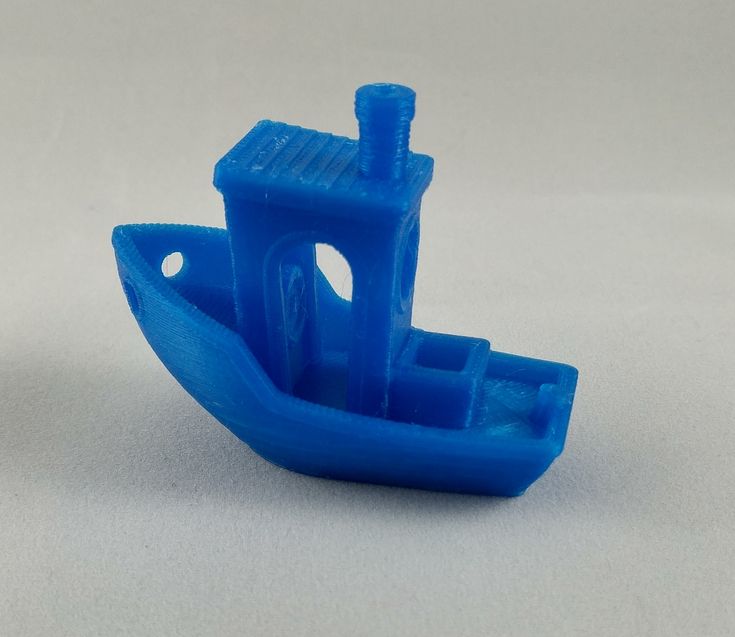

Benchy 3d printer

The 3D Benchy 'torture test' that pushes 3D printers to the limit

0Shares

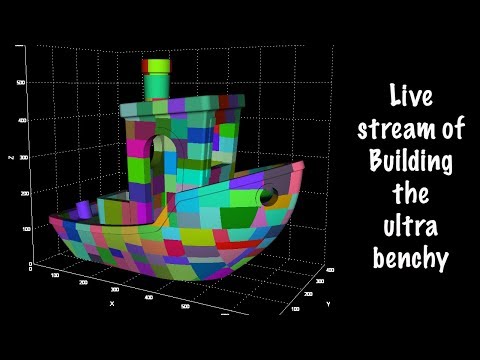

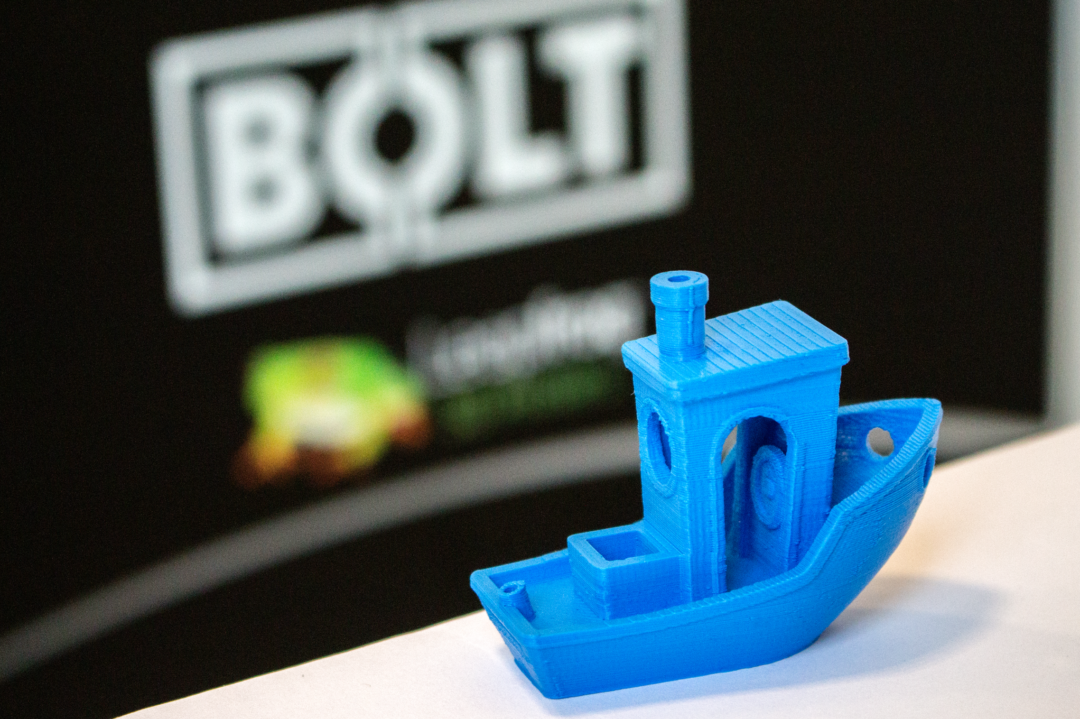

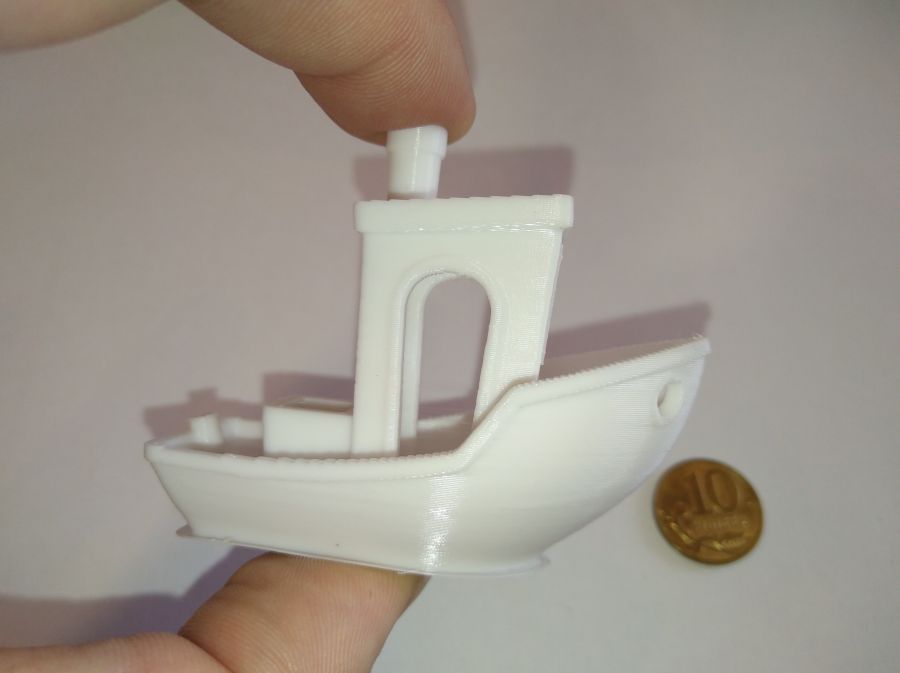

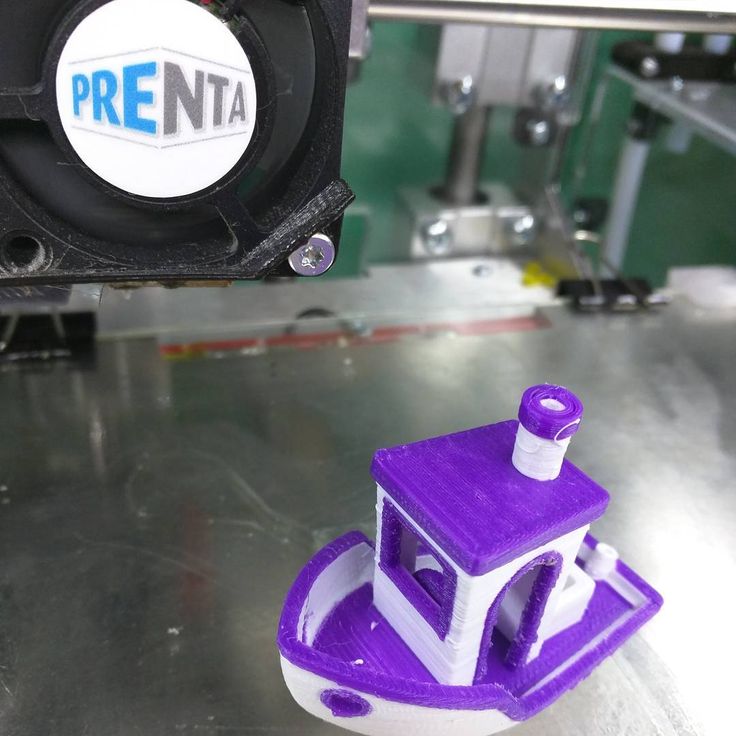

New to the world of 3D printing? Or wondering why people keep printing little boats on their 3D printers? The 3D Benchy is ‘the jolly 3D printing torture-test’ designed by Swedish 3D technology reseller Creative Tools.

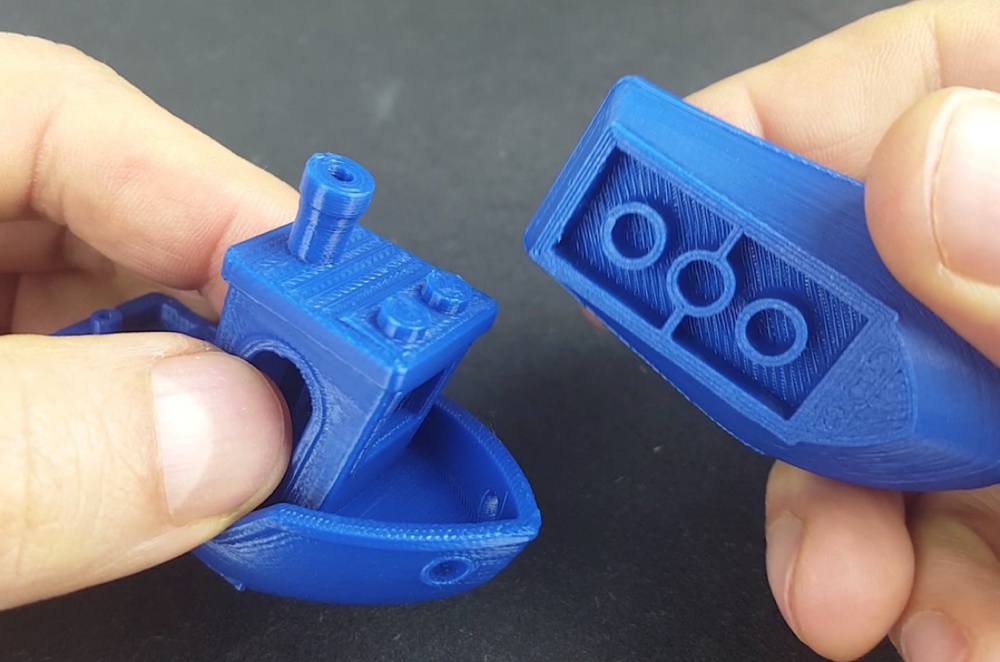

The name ‘Benchy’ is short for benchmark. This little boat is designed with geometric features, such as the portholes and an open cabin, that provide a challenge to 3D printers. When using a new filament, or 3D printer, the 3D Benchy can be used to see how they measure up. On setup, they can also highlight problems that may be occurring in the software commands sent to a 3D printer, or the filament.

Layer separation and ‘delamination’

If layers of extruded plastic aren’t sticking properly, the issue could be that the layers are too thick, or extrusion temperature is too cold. Both issues can be easily solved in the software used to program a 3D printer.

Spaghetti-ing

The dreaded (and occasionally comical) spaghetti-ing effect of a 3D print occurs when layers become completely delaminated, but the 3D printer continues printing. It can be caused by the same settings as above, but if it’s persistent it can be a fault with a 3D printer part.

A 3D Benchy boat with some spaghetti-ing on the hull. This is the result of an experiment using 2 different colored filaments, which is an extra challenge to extrusion. Photo via: 3DBenchy on FlickrStringing/webbing to make ‘hairy’ prints

This is when thin strings of plastic build up in areas of the object that should be empty.

Enabling filament retraction can solve this problem. Retraction ensures that the 3D printer’s extruder doesn’t let the filament spill over between one section and another. Retraction on – the filament returns into the extruder in-between sections so it is not still melting out of the print head.

A hairy 3D Benchy with some layer delimitation on the hull. Photo via: wizardru.net

Photo via: wizardru.netRough surface blobs

This is a problem that may be solved by turning retraction off. If a 3D printed object doesn’t have any spaces in it, e.g. portholes and cabins, in some cases, it is better to turn retraction off so that the extruder isn’t resetting itself between every layer, meaning it can print more smoothly.

Surface blobs on a 3D print. Photo via: Simplify3DInfill settings

Infill is the interior structure of a 3D print. An ability to set this percentage is one of the things that makes 3D printed objects so light and efficient from a materials usuage perspective. The part of an object you don’t see doesn’t need to be solid, so a 3D printer creates it as a kind of waffle structure instead.

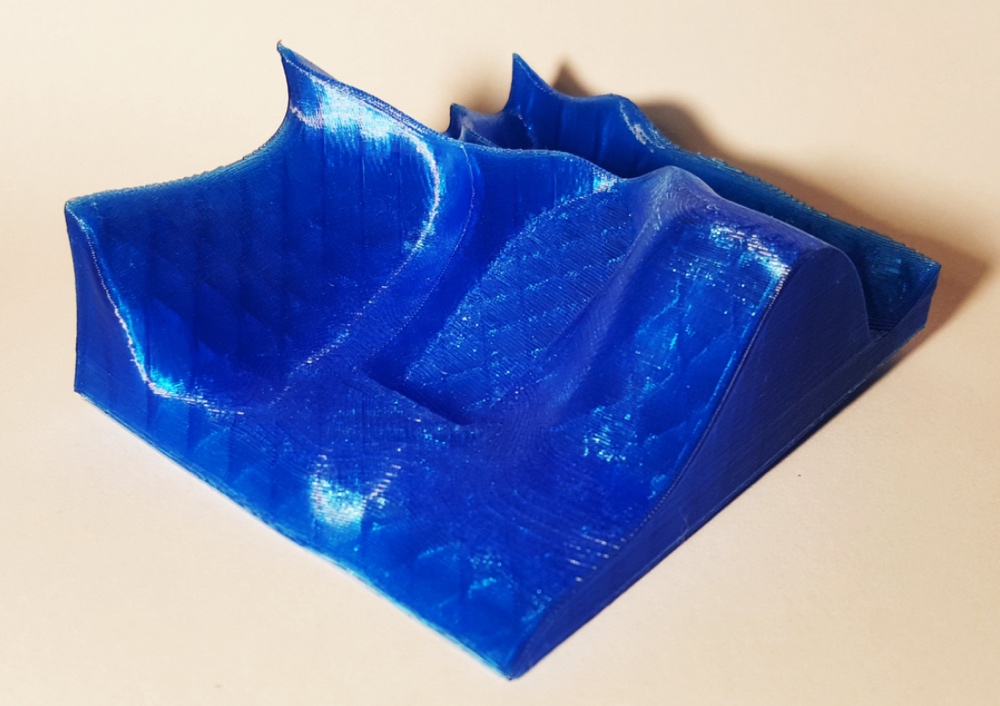

Waffle-like infill of an incomplete boat. Photo via: madprinter.orgThe solid layers is an object’s exterior, i.e. the visible part of an object. Imbalance between the infill and solid layers can create holes or gaps in an object.

Available for everyone

Licensed under the Creative Commons Act, Creative Tools encourage 3D printer users to download, distribute and remix the 3D Benchy .stl file as much as they please. The license even allows users to sell their 3D printed Benchy creations, as the site stipulates: ‘you own them!’

A devoted Flickr photo archive tracks the different 3D prints and designs of the boat in photos submitted by the 3D printing community.

From left to right: 3D Benchy smoke plume design by AKIRA, boat stand by Tomáš Vít, and a LEGO compatible boat by Creative Tools. Photos via: 3DBenchy on FlickrFailure is a badge of honor

YouTuber Vicky Somma, (TGAW on YouTube) who 3D Printing Industry interviewed for global 3D printing day, has turned the iconic boat design into a badge of honor for 3D printing beginners, and frustrated veterans alike.

From Failure Comes Knowledge Maker Coin by Vicky Somma Photo via: VickyTGAW on ThingiverseThe From Failure Comes Knowledge Maker Coin celebrates the idea that failures are part of the process of 3D printing, and features a Benchy boat with the infamous ‘spaghetti-ing’ effect on top.

In 3D Printing Nerd’s video ‘My Top 5 3D Printer Tips After Getting Your First #3DPrinter’, Joel Telling also lists failure as an important part of the process. Essentially, it means that you are learning and experimenting.

Other tips, and a preview of people’s first 3D prints can be found in our Welcome New Makers article, from the beginning of 2017.

Joel Telling’s ‘Top 5 3D Printer Tips After Getting Your First #3DPrinter’ Screenshots via: 3D Printing Nerd on YouTubeAny 3D Printing Industry readers making remixes of the 3D Benchy design can send them to us via email, or tweet photos to us on Twitter.

The 3D Printing Industry Awards for innovation are now open for nominations.

Featured image shows Neon 3D Benchy boats by Javen Wilson of Mosaic Manufacturing Photo via: 3D Benchy on Flickr

Tags 3D Benchy 3D printing community 3D printing Nerd 3D printing newcomers beginners benchmark Benchy boat Creative Tools Joel Telling makers new makers TGAW TouTUbers Vicky Somma

Beau Jackson

Benchy best STL files for 3D printing・Cults

calibration cube 20x20x20 xyz

Free

Battle Benchy

Free

MSE Benchy / Mouse Droid Benchy

Free

Benchy with waves

Free

An Epic Story of Benchy

Free

3DFlagchy - Flag for #3DBenchy

Free

Space Shuttle Benchy

Free

3DBenchyboi

Free

20mm Benchy Test Cube

Free

Cristmas Benchy

Free

test part

Free

The Deep Benchy

€19. 21

21

Reconstructed Benchy from 3D scan

Free

Benchy

Free

Benchy plastic bottle rescue

Free

Benchy Holder

Free

Benchy Diorama Set #1

Free

Designer Benchy

Free

Benchy Tap Extender

Free

Fishing boat (Bathtube/Pond)

€0.50

Benchy Waves

Free

Benchy Gatling Guns

Free

Broken 3D Benchy ship

Free

Naboo Starfighter Benchy

€4. 66

66

3D Rocket Benchy

Free

bubble benchy

€1.45

DRAGON BENCHY, ARTICULATING

€1.52

1U Mechanical Keyboard Keycap of SpaceX Starlink Dish - new and old

€0.50

Fred the Frog Bench(y)press (i dont workout)

Free

Formula 1 Benchy

Free

f1 benchy

Free

Pepito, the benchmark Goldfish.

Free

Toucan test print

Free

Benchy Boat

€0.50

benchy rack

Free

Kenji the print-in-place benchy robot

Free

Pink Lamborghini

€0. 62

62

GodziBenchy

Free

Custom Benchy Design in Designspark Mechanical by W3DE Studio

Free

GodziBenchy

Free

Filament Calibration Cylinder

Free

4 x Gear Spinner Torture tests!

€0.52

Circular maze

Free

Gear Spinner Torture Test

Free

Benchy Thousand Sunny ( One Piece )

€3

Test Tube Rack

€0.62

benchomer

Free

Scentbird Cologne Rack

€0.95

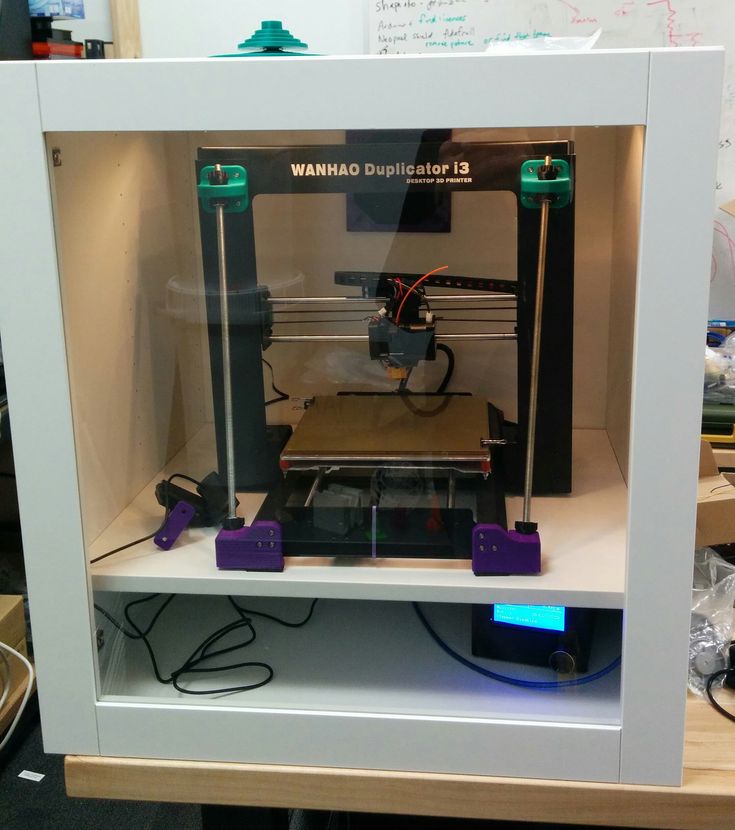

Desktop 3D printers for the home

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix FlashForge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao FlashForge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN iBridger Peopoly snapmaker Voltera Voxelab ZENIT

Delivery

Assembled printer Assembly kit

Application

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm

75 mm 2.85 mm 3.00 mm

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH)

Number of extruders (print heads)

Heating table

Yes Not

Wi-Fi or other wireless network

Yes Not

Country of origin

China Russia USA Taiwan Hong Kong

Netherlands Poland

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Peopoly |

| On order/Transit | On request |

| Construction area size | 527x296x550 mm |

| Country of origin | Hong Kong |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

| Construction area size | 255x210x210 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 134x75x130 mm |

| Country of origin | Taiwan |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 197 x 122 x 245 mm (print volume 5. 9 l) 9 l) |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 165x72x180 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 198 × 123 × 210 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | FlashForge |

| On order/Transit | Goods on the way |

| Construction area size | 200*200*250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | QIDI |

| On order/Transit | Goods on the way |

| Construction area size | 270 x 200 x 200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to Compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 200x125x220 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods on the way |

| Construction area size | 192 x 120 x 200 mm |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 218 x 123 x 235 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Flash Forge |

| On order/Transit | Goods on the way |

| Construction area size | 200x148x150 mm |

| Number of extruders (print heads) | 2 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | QIDI |

| On order/Transit | Goods on the way |

| Construction area size | 300 x 250 x 300 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

You can buy a 3D printer capable of printing small models and prototyping of medium complexity today at the price of an entry-level laptop. The price of PLA or ABS plastic, which acts as a consumable, also no longer seems exorbitant. In a word, if you have long dreamed of getting to know the world of 3D printing and joining the ranks of makers, the right moment has come!

To save you time and make it easier to select equipment, we have collected in one section all desktop 3D printers optimized for home and office use. These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models.

8 nuances worth paying attention to

Sooner or later, everyone will learn about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

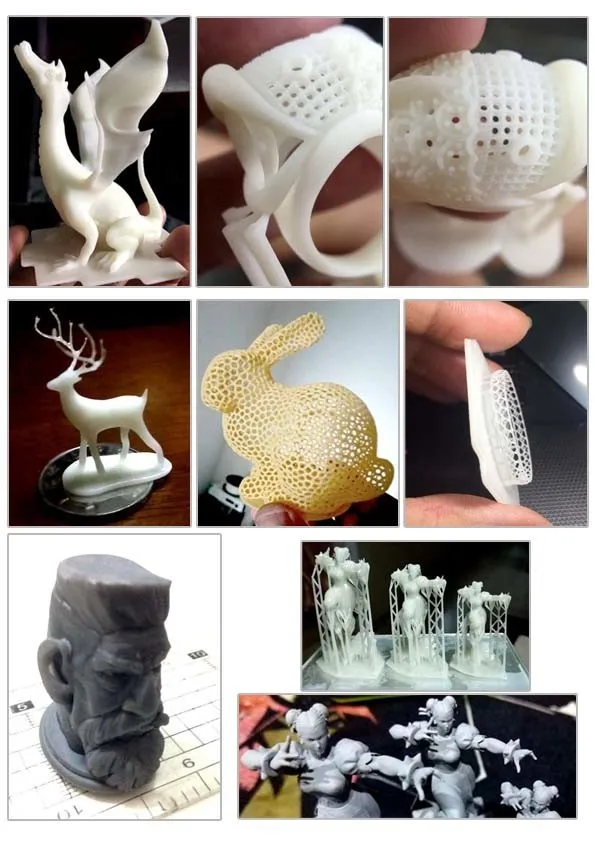

Tip 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs.

This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

They have their pros and cons. But most of them have advantages over moving table printer circuits.

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0.3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0.1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Nuance 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials.

This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.