3D printing for surgery

Can 3D Printing Improve Your Medical Care? > News > Yale Medicine

So, you’re worried about getting, let’s say, a knee replacement. Will it be difficult? Will it hurt?

These are good questions. Every patient’s body is unique, and even the best surgeons do a bit of educated guessing to try to place a new knee as perfectly as possible. If the placement is even a bit off, there could be extra pain and stiffness, and it could take longer to recover.

But, what if, before your operation, your surgeon could make an exact replica of the parts of your knee—that’s your knee, as measured by your MRI and CT scan? Then, what if the surgeon could use it to plan the operation in advance and ensure precise placement of the new parts, which in turn means you’d have less pain, a speedy recovery, and a new knee that is just as good as the original? Better, actually.

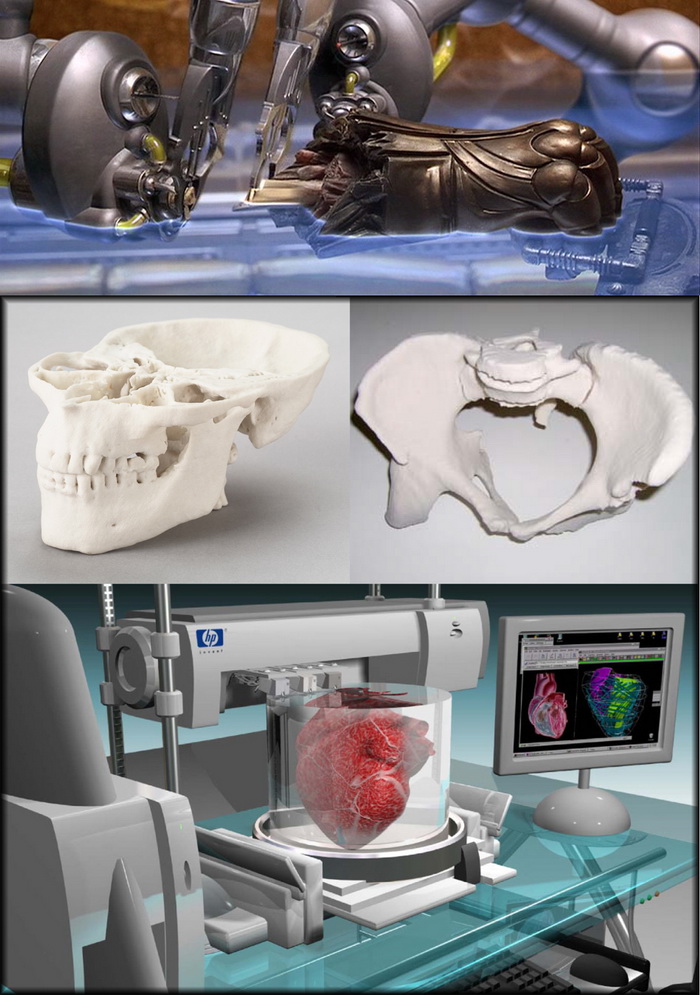

That future is here. Some Yale Medicine surgeons now routinely use 3D printing (essentially producing a solid, three-dimensional object from a virtual digital model) to plan surgeries, design tools specific to an upcoming surgery and that particular patient’s anatomy, and even to print some of the parts used to replace defective ones in the body.

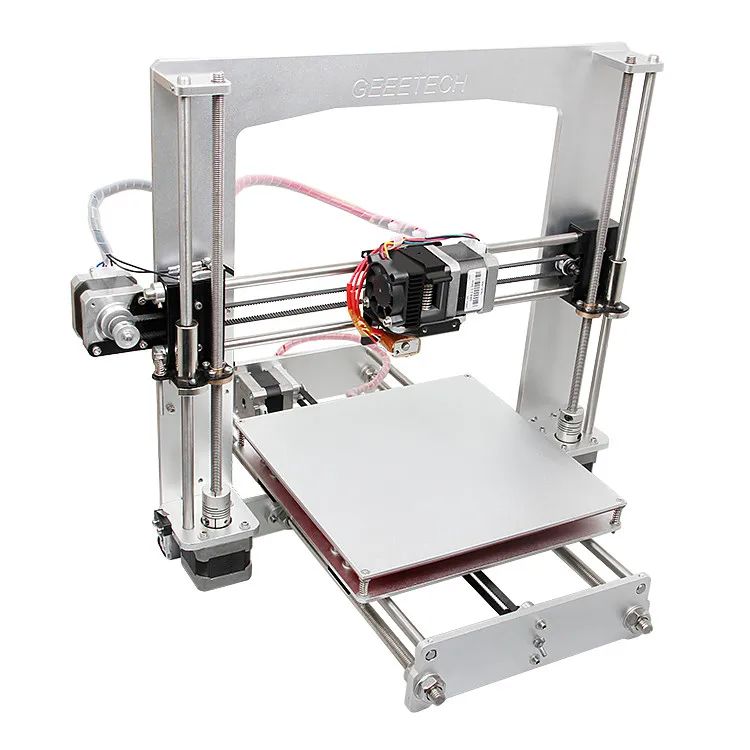

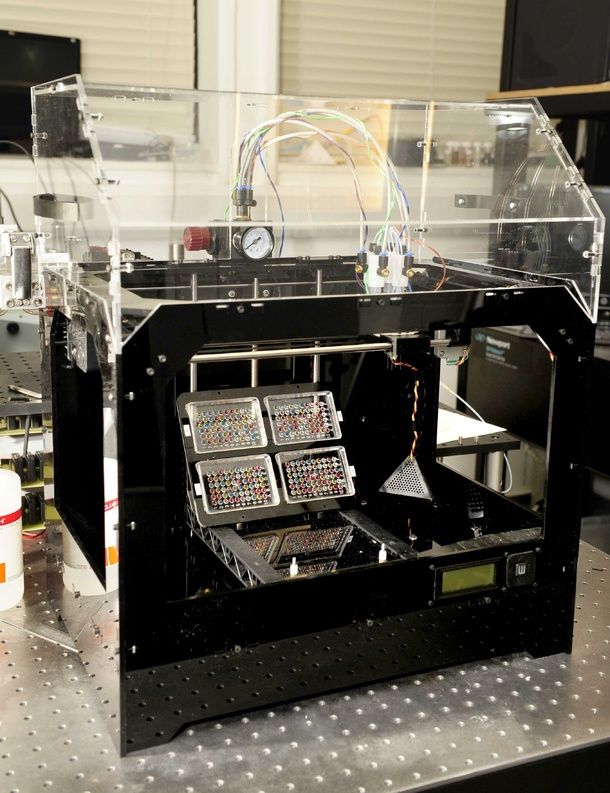

Daniel Wiznia, MD, a Yale Medicine orthopedic surgeon, is seeing significant improvements in his knee replacement patients since he started using 3D printing to plan their operations. He is one of several doctors who make regular use of a 3D printer at the Yale School of Engineering & Applied Science, a MakerBot machine that looks something like a microwave oven.

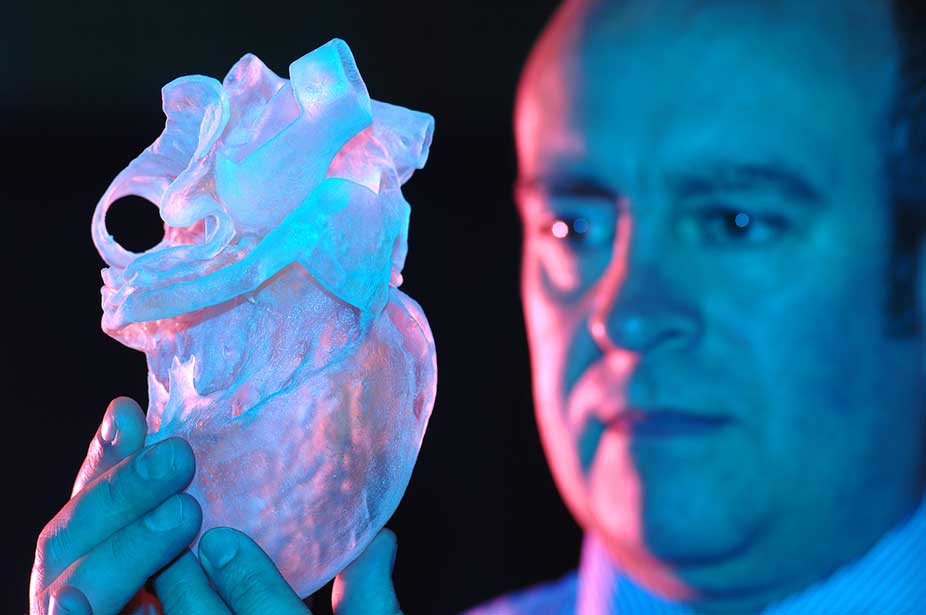

Vincent Wilczynski, deputy dean of the school and director of the Yale Center for Engineering Innovation & Design, remembers one of the first doctors who visited the lab several years ago, who used a printer to make a model of a 20-year-old patient’s knee tumor. “He printed the tumor every time the patient came in to get scanned, so the patient could hold the 3D model in his hands and feel how it was shrinking,” Wilczynski says.

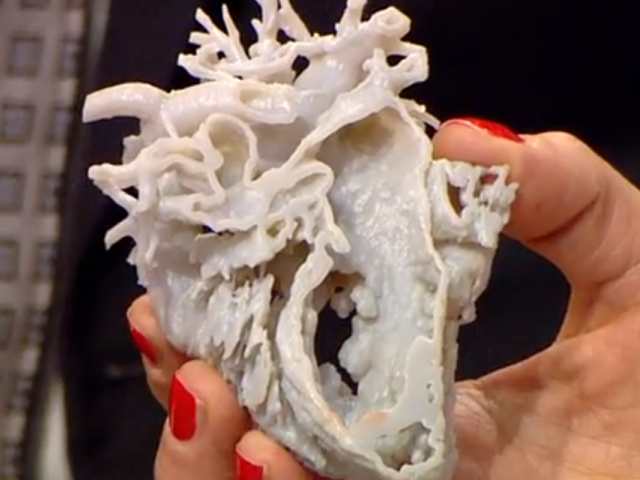

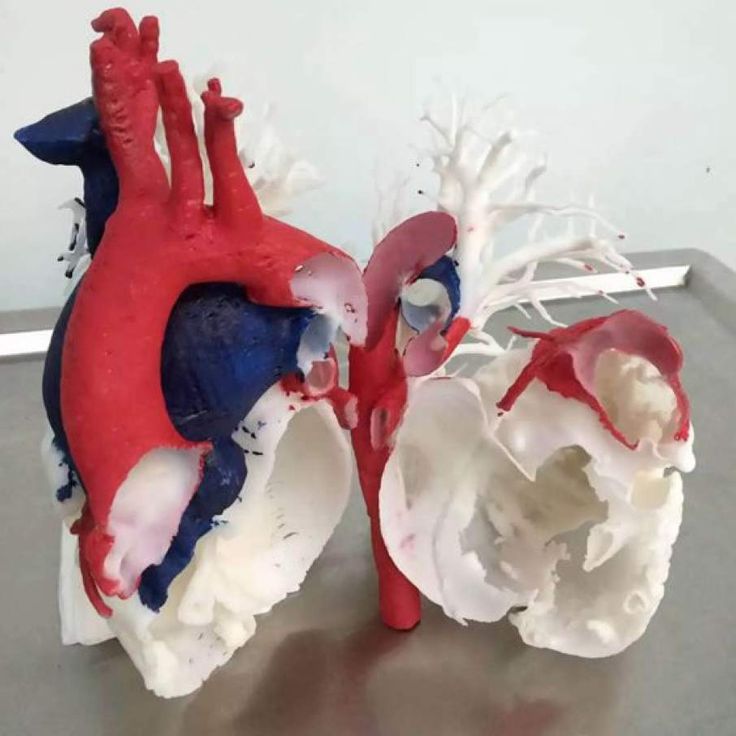

There is more to come. Researchers are exploring ways to use 3D printing to make patient-specific transplant organs and eyes capable of translating light into electrical signals. While practical use of these things is still years away, researchers recently printed the world’s first 3D vascularized, engineered heart, using a patient’s own cells and biological materials.

While practical use of these things is still years away, researchers recently printed the world’s first 3D vascularized, engineered heart, using a patient’s own cells and biological materials.

Here are a few ways some Yale Medicine doctors are using 3D printing in patient care right now.

Easier, speedier knee replacement recovery

If you are having a knee replacement, 3D printing can make your surgery smoother, lessen the pain (which can be significant after knee surgery), and contribute to a quicker knee replacement recovery, Dr. Wiznia says. With this technology, your new knee can be implanted more accurately, leading to better biomechanics so the knee feels more natural when you move, with less wear on the implant, he adds.

“It’s a matter of precision,” Dr. Wiznia says, explaining that it lowers the risk of error compared to the traditional placement of a new knee. Following a 3D-printed model with cutting guides allows the surgeon to conduct surgery without significant positioning errors, he says.

When he is planning a surgery, Dr. Wiznia feeds data from the patient’s MRI into a computer program, allowing him to use software to plan where he wants to place the new knee, how he wants it to fit on the bone, the sizes of the implants and how the knee should bend kinematically. Then, he converts the information into a format that can be fed into a 3D printer so it will custom print surgical instruments. “The beautiful thing is, you don’t have to cut as much when you do the operation,” he says. “I use smaller incisions, because I’ve already modeled how to position the implants. There is less stretching of the ligaments and soft tissue, so there is less pain, blood loss, and length of stay in the hospital.”

He predicts knees implanted this way will have a longer life span. He also says pre-planning with 3D printing allows him to shave as much as 20 to 25 minutes off the time it takes to perform a knee operation. For the patient, this means less anesthesia, fewer blood transfusions, and less tourniquet time, he says.

Planning operations with life-sized hand models

You slip on an ice patch and fall on your wrist, or you get mad and punch a wall. You can break a bone in your hand that way. Adnan Prsic, MD, a hand surgeon, decided it would be easier to fix this type of injury by first printing out a life-size model of your hand to better see what he and his residents will be working with. He has done this so many times he has amassed a collection of printed hands he keeps in a box in his office. Made of silicone, some are complete with "bones" inside made of varying types of plastics. If you bend a knuckle in one of these hands, you’ll hear a soft click (much like the legs in an old Barbie doll body). Dr. Prsic might “break” a bone inside the hand to simulate an injury.

Dr. Prsic is using 3D-printed hands in two ways. One is to help surgeons practice an especially complex hand surgery so they can better anticipate challenges. The second is to teach medical residents their craft—hand surgeons operate on small areas, so precision is key to sparing bone. He is collaborating on this with plastic surgeon Albert Woo, MD, from the Alpert Medical School at Brown University.

He is collaborating on this with plastic surgeon Albert Woo, MD, from the Alpert Medical School at Brown University.

Other hand specialists have tried similar things with high-end 3D printers, but Dr. Prsic wants the capability to be available to anyone. So, he is making hands on the inexpensive MakerBot machine; he says each costs about $30, compared to $150 to make a hand on a more sophisticated machine. Inspired to become a hand surgeon in his native Bosnia, where he saw people come out of war with terrible hand injuries, Dr. Prsic says one of his future goals is to provide a model for inexpensive prosthetic hands that will be affordable for people in developing countries. He and Yale Medicine colleague James Clune, MD, are working on this together.

Easing anxiety when a birth defect is diagnosed

The more you can understand about a birth defect while the baby is in utero, the better you will be prepared to treat it, says Mert Ozan Bahtiyar, MD, director of the Yale Medicine Fetal Care Center. While it’s not currently possible to print out a model of a problem deep inside the body, like a heart defect, he envisions using 3D models of such problems as cleft palates and hand deformities. He believes these could be helpful psychologically to expectant parents.

While it’s not currently possible to print out a model of a problem deep inside the body, like a heart defect, he envisions using 3D models of such problems as cleft palates and hand deformities. He believes these could be helpful psychologically to expectant parents.

He also has printed a placenta to show prospective mothers who he treats with twin-to-twin transfusion syndrome, a condition characterized by an imbalance in blood flow due to placental vessel connections. “I show them what the surface of the placenta looks like and talk about how the procedure is done."

Producing these 3D parts for expectant parents is more difficult than creating models of hands or hips. Doctors use ultrasounds when they perform imaging for pregnant women because it does not harm the unborn baby. But software to convert ultrasound to a 3D-printable file format isn’t as readily available as it is for CT scans. So, Dr. Bahtiyar is working with Xenophon Papademetris, PhD, professor of Radiology & Biomedical Imaging and Biomedical Engineering at Yale School of Medicine, and Praneeth Sadda, a Yale medical student, to develop what he needs. His ultimate goal is to keep a 3D printer in his office so he can print out pictures during patient visits.

His ultimate goal is to keep a 3D printer in his office so he can print out pictures during patient visits.

“When I diagnose a fetal anomaly, the next step is counseling parents about how it will look,” says Dr. Bahtiyar, explaining that a 3D print is more powerful than an ultrasound, which provides a picture in two-dimensional black and white, with fields of gray. “I don’t think it will change the way we treat these problems. But pregnancy is not only the physical part, it is emotional as well, so maybe this will help a patient’s psyche. Maybe if they touch it, feel like it’s there, it makes them less anxious. It takes away the surprise.”

Restoring or adjusting to fix a face

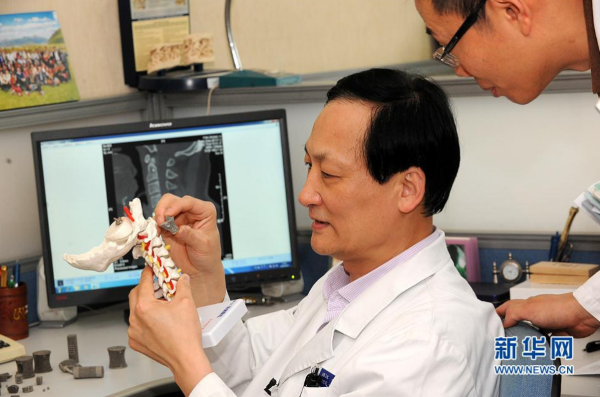

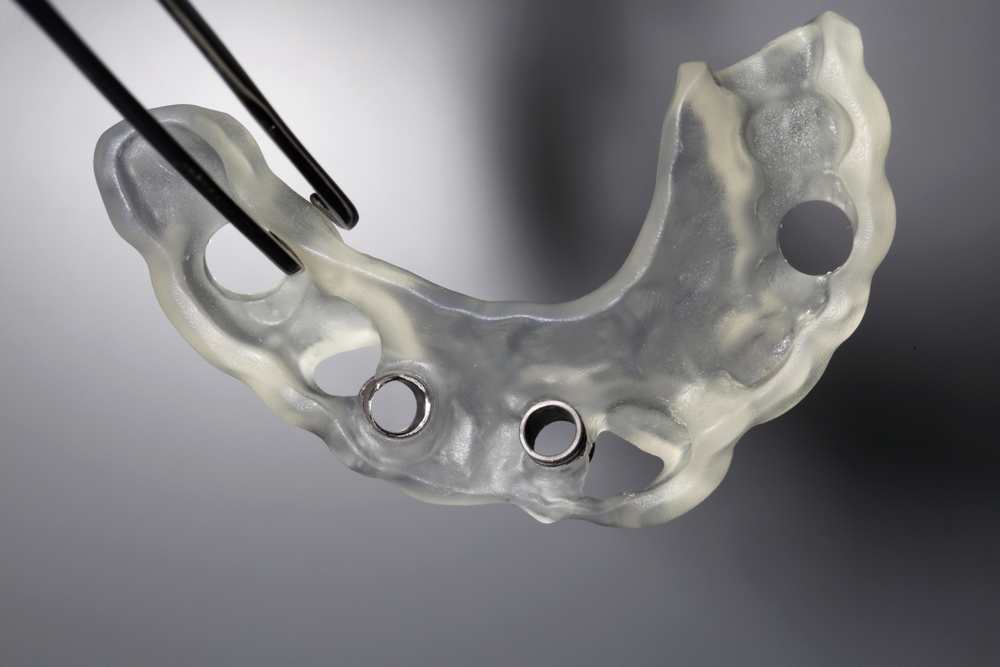

Sometimes plastic surgeons are called upon to reposition a nose or create a stronger jaw, either for cosmetic purposes or to improve function. Besides repositioning parts of the face, their work may include facial reconstruction surgery and bone manipulation. Derek Steinbacher, DMD, MD, plastic surgeon and director of craniofacial medicine for Yale Medicine, has a varied collection of skulls, faces, and cutting guides, along with other 3D prints. A leading expert in the use of 3D imaging and printing in plastic surgery, he uses these techniques to aid in his treatment of complex cases such as rebuilding sections of the face or skull, treating congenital skull abnormalities, and nasal, orthognathic, and facial aesthetics.

A leading expert in the use of 3D imaging and printing in plastic surgery, he uses these techniques to aid in his treatment of complex cases such as rebuilding sections of the face or skull, treating congenital skull abnormalities, and nasal, orthognathic, and facial aesthetics.

He has been using 3D printing routinely since he arrived at Yale almost nine years ago, and has used it for almost 2,000 cases. He says it has revolutionized these surgeries, taking the process from “eyeballing intraoperatively” to a high level of planned precision that makes his work far more efficient, reproducible, and accurate.

The first step in bony 3D planning and printing is for the patient to have a CT scan of the area where he will operate. “That is converted to a virtual 3D image that can be manipulated—like an architect who builds something by first working with a 3D model in digital space,” Dr. Steinbacher explains. “In our case, we analyze and manipulate the 3D anatomy and gain insight into the patient’s diagnosis, walk through possible reconstructive scenarios, choose the final plan, and then print models and guides. ”

”

Rhinoplasty (plastic surgery on the nose) is one operation where the approach is especially useful. “We look at a patient’s pre-existing nose, and we can see whether it is pointing left or right, or if it is somehow asymmetric. Then we manipulate it on the computer. There is some aesthetic and artistic preference that goes into it,” he says. “I also have to consider function.”

Dr. Steinbacher says, “it is possible from the 3D image to print a model of their nose or face with the actual expected post-op results.” He works closely with companies that specialize in this type of 3D printing. He has also printed actual parts to use as permanent implants in a new face, and plates that can be used to help move a jaw. Or, “if there is a tumor in the lower jaw, you can see exactly where that tumor is,” he says. He compares that with the opposite side of the face to see how he will reconstruct it once the tumor is removed.

Making complex operations for kids safer

A 3D model has prompted David Frumberg, MD, a pediatric orthopedic surgeon, to completely change the direction of a surgery that he has planned. Dr. Frumberg performs complicated surgeries for young children with such problems as limb and spinal deformities, as well as those with a variety of congenital or acquired conditions. He has used X-rays, CT scans, and MRI imaging to assess deformities and injuries and to plan an operation ahead of time, but he says 3D prints provide the most useful information.

Dr. Frumberg performs complicated surgeries for young children with such problems as limb and spinal deformities, as well as those with a variety of congenital or acquired conditions. He has used X-rays, CT scans, and MRI imaging to assess deformities and injuries and to plan an operation ahead of time, but he says 3D prints provide the most useful information.

“A life-size model of the actual bones that I can hold in my hand—there is something about it that changes everything,” he says. When he is planning a foot surgery, he is able to orient the model foot in different directions. “I can see what would happen if I shift one thing—or cut it one way as opposed to another during the surgery.”

Using a 3D-printed model was especially helpful when Dr. Frumberg performed foot and ankle surgery on a young girl from outside the U.S. with a rare congenital disorder that caused extreme abnormalities in her limb alignment. The girl did not have access to proper medical care as a child, and because doctors normally would have treated the issues when she was a toddler, there was no clear roadmap, he says. “If you are doing a surgery at this level of complexity, and you really need to know where all the bones are and maybe even practice, there is no better way.”

“If you are doing a surgery at this level of complexity, and you really need to know where all the bones are and maybe even practice, there is no better way.”

Dr. Frumberg says the models also seem to help children and families feel better about their procedures. When he was preparing to do a complicated operation on another girl’s foot, he showed her a 3D model he had printed, and drew on it with a Sharpie to show the various cuts he would make. “She was excited for the surgery after we did that,” Dr. Frumberg said. Later, he said, one of his medical students made a small 3D print of the model into a keychain she could keep.

Read more Yale Medicine newsRelated Specialists

The clinical use of 3D printing in surgery

Review

. 2018 Sep;70(3):381-388.

doi: 10.1007/s13304-018-0586-5. Epub 2018 Aug 30.

Luigi Pugliese 1 , Stefania Marconi 2 , Erika Negrello 2 , Valeria Mauri 2 , Andrea Peri 3 , Virginia Gallo 3 , Ferdinando Auricchio 2 , Andrea Pietrabissa 3

Affiliations

Affiliations

- 1 Department of Surgery, Fondazione IRCCS Policlinico San Matteo, Pavia, Italy. [email protected].

- 2 Department of Civil Engineering and Architecture, University of Pavia, Pavia, Italy.

- 3 Department of Surgery, Fondazione IRCCS Policlinico San Matteo, Pavia, Italy.

- PMID: 30167991

- DOI: 10.1007/s13304-018-0586-5

Review

Luigi Pugliese et al. Updates Surg. 2018 Sep.

. 2018 Sep;70(3):381-388.

doi: 10.1007/s13304-018-0586-5. Epub 2018 Aug 30.

Authors

Luigi Pugliese 1 , Stefania Marconi 2 , Erika Negrello 2 , Valeria Mauri 2 , Andrea Peri 3 , Virginia Gallo 3 , Ferdinando Auricchio 2 , Andrea Pietrabissa 3

Affiliations

- 1 Department of Surgery, Fondazione IRCCS Policlinico San Matteo, Pavia, Italy.

[email protected].

[email protected]. - 2 Department of Civil Engineering and Architecture, University of Pavia, Pavia, Italy.

- 3 Department of Surgery, Fondazione IRCCS Policlinico San Matteo, Pavia, Italy.

- PMID: 30167991

- DOI: 10.1007/s13304-018-0586-5

Abstract

The use of 3D printing is gaining considerable success in many medical fields including surgery. Here, the technology was introduced for increasing the level of anatomical understanding thanks to the inherent characteristics of 3D printed models: these are highly accurate and customized reproductions, being obtained from own radiological imaging of patients, and are solid graspable objects allowing for free manipulation on part of the user. The resulting tactile feedbacks significantly help the comprehension of anatomical details, especially the spatial relations between structures. In this regard, they proved to be more effective than conventional 2D imaging and 3D virtual models. To date, an increasing number of applications have been successfully tested in many surgical disciplines, extending the range of possible uses to pre-operative planning, counselling with patients, education of students and residents, surgical training, intraoperative navigation and others; in recent years, 3D printing was also employed for creating surgical tools and reproducing anatomical parts to be used, respectively, as templates or guides for specific tasks of the surgery and individualized implantable materials in reconstructive procedures. Future expectations concern on one side the reduction of manufacturing costs and time to further increase the accessibility of 3D printing, while on the other the development of novel techniques and materials suitable for 3D printing of biological structures by which recreating the architecture and functionality of real human organs and tissues.

The resulting tactile feedbacks significantly help the comprehension of anatomical details, especially the spatial relations between structures. In this regard, they proved to be more effective than conventional 2D imaging and 3D virtual models. To date, an increasing number of applications have been successfully tested in many surgical disciplines, extending the range of possible uses to pre-operative planning, counselling with patients, education of students and residents, surgical training, intraoperative navigation and others; in recent years, 3D printing was also employed for creating surgical tools and reproducing anatomical parts to be used, respectively, as templates or guides for specific tasks of the surgery and individualized implantable materials in reconstructive procedures. Future expectations concern on one side the reduction of manufacturing costs and time to further increase the accessibility of 3D printing, while on the other the development of novel techniques and materials suitable for 3D printing of biological structures by which recreating the architecture and functionality of real human organs and tissues.

Keywords: 3D printing; Anatomy; Model; Surgery; Technology.

Similar articles

-

Value of 3D printing for the comprehension of surgical anatomy.

Marconi S, Pugliese L, Botti M, Peri A, Cavazzi E, Latteri S, Auricchio F, Pietrabissa A. Marconi S, et al. Surg Endosc. 2017 Oct;31(10):4102-4110. doi: 10.1007/s00464-017-5457-5. Epub 2017 Mar 9. Surg Endosc. 2017. PMID: 28281114

-

3D-printing techniques in a medical setting: a systematic literature review.

Tack P, Victor J, Gemmel P, Annemans L. Tack P, et al. Biomed Eng Online. 2016 Oct 21;15(1):115. doi: 10.1186/s12938-016-0236-4. Biomed Eng Online. 2016.

PMID: 27769304 Free PMC article. Review.

PMID: 27769304 Free PMC article. Review. -

Current Use of Three-dimensional Model Technology in Urology: A Road Map for Personalised Surgical Planning.

Porpiglia F, Amparore D, Checcucci E, Autorino R, Manfredi M, Iannizzi G, Fiori C; for ESUT Research Group. Porpiglia F, et al. Eur Urol Focus. 2018 Sep;4(5):652-656. doi: 10.1016/j.euf.2018.09.012. Epub 2018 Oct 4. Eur Urol Focus. 2018. PMID: 30293946 Review.

-

Three-dimensional Printing and Augmented Reality: Enhanced Precision for Robotic Assisted Partial Nephrectomy.

Wake N, Bjurlin MA, Rostami P, Chandarana H, Huang WC. Wake N, et al. Urology. 2018 Jun;116:227-228. doi: 10.1016/j.urology.2017.12.038. Epub 2018 May 22. Urology. 2018. PMID: 29801927

-

Creation of a novel simulator for minimally invasive neurosurgery: fusion of 3D printing and special effects.

Weinstock P, Rehder R, Prabhu SP, Forbes PW, Roussin CJ, Cohen AR. Weinstock P, et al. J Neurosurg Pediatr. 2017 Jul;20(1):1-9. doi: 10.3171/2017.1.PEDS16568. Epub 2017 Apr 25. J Neurosurg Pediatr. 2017. PMID: 28438070

See all similar articles

Cited by

-

Does using 3D printed models for pre-operative planning improve surgical outcomes of foot and ankle fracture fixation? A systematic review and meta-analysis.

Wood L, Ahmed Z. Wood L, et al. Eur J Trauma Emerg Surg. 2022 Nov 24. doi: 10.1007/s00068-022-02176-7. Online ahead of print. Eur J Trauma Emerg Surg. 2022. PMID: 36418394 Review.

-

Three-dimensional printing and 3D slicer powerful tools in understanding and treating neurosurgical diseases.

You Y, Niu Y, Sun F, Huang S, Ding P, Wang X, Zhang X, Zhang J. You Y, et al. Front Surg. 2022 Oct 14;9:1030081. doi: 10.3389/fsurg.2022.1030081. eCollection 2022. Front Surg. 2022. PMID: 36311943 Free PMC article. Review.

-

Implementation of an In-House 3D Manufacturing Unit in a Public Hospital's Radiology Department.

García RI, Jauregui I, Del Amo C, Gandiaga A, Rodriguez O, Margallo L, Voces R, Martin N, Gallego I, Minguez R, Eguiraun H. García RI, et al. Healthcare (Basel). 2022 Sep 16;10(9):1791. doi: 10.3390/healthcare10091791. Healthcare (Basel). 2022. PMID: 36141403 Free PMC article.

-

3D printing in the planning and teaching of endovascular procedures.

Stana J, Grab M, Kargl R, Tsilimparis N.

Stana J, et al. Radiologie (Heidelb). 2022 Sep 16. doi: 10.1007/s00117-022-01047-x. Online ahead of print. Radiologie (Heidelb). 2022. PMID: 36112173 Review. English.

Stana J, et al. Radiologie (Heidelb). 2022 Sep 16. doi: 10.1007/s00117-022-01047-x. Online ahead of print. Radiologie (Heidelb). 2022. PMID: 36112173 Review. English. -

A survey regarding the organizational aspects and quality systems of in-house 3D printing in oral and maxillofacial surgery in Germany.

Zeller AN, Goetze E, Thiem DGE, Bartella AK, Seifert L, Beiglboeck FM, Kröplin J, Hoffmann J, Pabst A. Zeller AN, et al. Oral Maxillofac Surg. 2022 Aug 22. doi: 10.1007/s10006-022-01109-3. Online ahead of print. Oral Maxillofac Surg. 2022. PMID: 35989406

See all "Cited by" articles

References

-

- Korean J Radiol. 2016 Mar-Apr;17(2):182-97 - PubMed

-

- Surg Radiol Anat.

2016 Apr;38(3):361-7 - PubMed

2016 Apr;38(3):361-7 - PubMed

- Surg Radiol Anat.

-

- J Surg Educ. 2016 Mar-Apr;73(2):264-9 - PubMed

-

- Anat Sci Educ. 2016 May 6;9(3):213-21 - PubMed

-

- BMJ Simul Technol Enhanc Learn. 2018 Jan;4(1):27-40 - PubMed

Publication types

MeSH terms

3D printing for surgical planning

Why surgeons need 3D printing | Examples in Russia | Veterinary operations | Choosing a 3D printer

How 3D printing helps surgeons

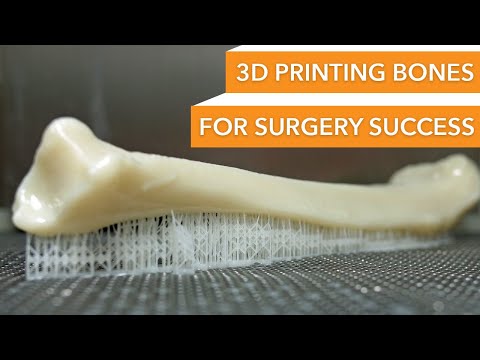

Comprehensive preparation for surgery is one of the most important criteria for its success. Modern 3D printing makes it possible to produce high-precision surgical models from various materials based on computed tomography data from real patients. With their help, surgeons can simulate the upcoming operation, try out different approaches and scenarios, test tools, and calculate timing.

Modern 3D printing makes it possible to produce high-precision surgical models from various materials based on computed tomography data from real patients. With their help, surgeons can simulate the upcoming operation, try out different approaches and scenarios, test tools, and calculate timing.

Operation planning stages using a 3D printed bone model.

There are a number of reasons why 3D printing is an effective and profitable tool for surgeons.

You know what to do. The surgeon uses a model obtained from a tomography of a real patient. With its help, you can accurately plan each stage of the operation, find solutions for complex and non-standard tasks, and distribute roles. No surprises during the actual operation.

You save time. Preparation can significantly reduce the time of the actual operation. Doctors spend less energy, patients are under anesthesia for a shorter period, which positively affects the results of operations. The patient needs a shorter period of rehabilitation.

You save money. A qualified doctor is a valuable resource that costs money to use. By reducing the operation time, you save the surgeon's time and the hospital's money. It also reduces the cost of the rest of the staff, anesthesia, electricity.

Surgical model of the pelvis and x-ray after the operation.

The increasing use of 3D printed models in the work of surgeons is driving the emergence of additive centers that specialize in the production of such products to order. Hospitals and private clinics that are unable to purchase their own 3D printer turn to such companies to print samples based on CT scans.

Russian experience of using 3D printing in surgery

Privolzhsky Federal Medical Research Center uses 3D printing for preoperative planning for severe deformities of the human skeletal bones. Doctors create accurate models of bones using a 3D powder printer. Computed tomography data serve as the basis for the development of a 3D bone model.

X-ray of the bone to be corrected and the process of simulating the upcoming operation.

The model of the damaged bone allows developing an individual operation for high-precision correction of the deformity, determining the required size and position of the fixators, and reducing the time of the surgical intervention.

More about the experience of Nizhny Novgorod doctors >>

At Tyumen State University , problematic parts of organs and bone structures of patients are printed to order. The resulting models are sent to doctors for preoperative study, surgery planning and implant manufacturing.

The process of preparing patient tomography data for 3D printing.

Upon admission, the patient undergoes a standard cone beam tomography, the data files are transferred to the university, where they are processed and a model is created for printing on a 3D printer. Material - plastic. With the help of such models, the doctor can more accurately examine the problem area, see convenient accesses and order an exact implant for surgery.

“By the fall of 2016, we successfully operated on three patients using this technology,” says Dmitry Shcherbakov, the leading operating otorhinolaryngologist in Tyumen. “The technology implemented at Tyumen State University allows us to take a completely new look at pathologies and more accurately plan operations in the facial skull, as well as obtain a material that is completely suitable for the size of a bone defect.”

3D printing and veterinary surgeries

Veterinarians use 3D printing to prepare complex surgeries. For example, Cornell University (USA) uses the results of tomography to make exact copies of bone structures.

Model of a dog paw joint created to simulate surgery.

This model was used to treat a puppy named Becca, whose CT scan showed a deformity of the paw bones. The veterinarians knew that surgery would be required and wanted to train on a 3D printed replica of the joint. “During the operation, we clearly knew what to do and how to do it,” says Dr. Ursula Krotczek. “This significantly reduced the time that Becca was under anesthesia, which greatly increased the chances of a successful operation.

Ursula Krotczek. “This significantly reduced the time that Becca was under anesthesia, which greatly increased the chances of a successful operation.

Australian veterinarians are taking the power of 3D printing even further. They not only train on 3D printed samples, but also make surgical templates and implants. In addition, 3D modeling helps visualize the problem and the need for surgery to concerned owners.

— Take, for example, a dog with a joint injury. A CT scan or X-ray will reveal the problem, but it will be difficult to explain it to the owners with the help of a picture alone, says clinic owner Charles Kunz. “With the help of a physical sample, we can clearly demonstrate what the essence of the damage is and how we plan to fix it.

Video: how Australian veterinarians are using 3D printing.Selecting a 3D Printer for Printing Surgical Models

Surgeons have multiple 3D printing technologies and a variety of materials at their disposal. The choice of a specific model of a 3D printer depends on the requirements for the resulting model and the budget. With the help of 3D printing, you can create both relatively rough plastic models and high-precision surgical models from special polymer materials (including elastic, colored, transparent).

The choice of a specific model of a 3D printer depends on the requirements for the resulting model and the budget. With the help of 3D printing, you can create both relatively rough plastic models and high-precision surgical models from special polymer materials (including elastic, colored, transparent).

Want to learn more about 3D surgical printing? Globatek.3D specialists will help you in choosing the right equipment, calculate the cost of manufacturing models and answer all your questions.

Get advice on choosing a medical 3D printer

Globatek.3D is a leading provider of professional 3D printing and non-contact measurement solutions. If your business is planning to purchase a 3D printer or 3D scanner, call 8 800 333-12-82 and our experts will help you choose the right solution.

new advances in surgical simulation

Implementation stories

Medicine

Author: Aleksey Chekhovich

Author: Aleksey Chekhovich

High-precision models for training specialists in the field of surgery | Comments of hospital surgeons | Sharebot 3D printers are reliable tools for innovation

Undoubtedly, 3D printing is one of the most advanced technologies of our era and, probably, in a few decades, these years will be remembered as the period of its formation. This is one of the most promising and revolutionary technologies that is used in various fields, in particular, in healthcare. Therefore, it is worth clarifying a few questions. For example, how can 3D printers contribute to the development of medicine and healthcare in general?

This is one of the most promising and revolutionary technologies that is used in various fields, in particular, in healthcare. Therefore, it is worth clarifying a few questions. For example, how can 3D printers contribute to the development of medicine and healthcare in general?

A good example is the unique project of the General Surgery Department of the Sacra Famiglia Fatebenefratelli Hospital in Erba (Lombardy, Italy), where, using the Sharebot 3D printer, it was possible to recreate real anatomical organs and structures to simulate basic surgical interventions, such as video laparoscopic cholecystectomy.

Meet sharebot.ru : all about innovative 3D solutions to optimize your business. Catalog of 3D printers based on the most popular additive technologies, tasks and applications, success stories, promotions, videos and other useful materials!

Liver and gallbladder segment models printed on a Sharebot 43 FDM printer

In collaboration with Sharebot, an experimental model of a segment of the liver and gallbladder was created using a special material (LAY-FOMM) produced in the form of a plastic thread. After immersion in water, this material, thanks to its two-component composition (rubber and PVA-based soluble part), becomes similar to organic tissues, which also allows surgical sutures to be applied. It was found that the degree of extensibility in combination with residual moisture after immersion in water is similar to organic counterparts.

After immersion in water, this material, thanks to its two-component composition (rubber and PVA-based soluble part), becomes similar to organic tissues, which also allows surgical sutures to be applied. It was found that the degree of extensibility in combination with residual moisture after immersion in water is similar to organic counterparts.

iQB Technologies experts recommend the article: Additive technologies in medicine: how to reduce risks to patients' health

Is your healthcare facility interested in implementing 3D technologies? Order free test services 3D printing and 3D scanning!

Leave a request

High-precision surgical training models

Thus, the surgeons of the hospital were able to reproduce the video laparoscopic cholecystectomy directly on the printed models. In practice, this involves removing the gallbladder without damaging the liver tissue. Performing surgery on a model pelvis (laparoscopic simulator) allows surgeons to master the correct technique, as well as experiment with new non-invasive methods of removal.

Pelvic Surgery Simulator

By simulating important surgeries on high-precision 3D-printed anatomical models, it has been possible to make a big step in the field of medical technology, which undoubtedly increases the chances of patients recovering with similar interventions.

We are interested in 3D printing in terms of practical training of a new generation of surgeons based on more advanced and accurate models.

Specialists of the General Surgery Department of the Sacra Famiglia Fatebenefratelli Hospital

Comments of the surgeons of the hospital

The peculiarity of the model developed by us is that there are two holes between the liver and the gallbladder, which make it possible to completely empty the gallbladder in order to then fill it with a colored liquid to simulate bile. Due to its elasticity, the liver is also used to develop the technical possibilities of applying laparoscopic and traditional sutures.

In each model, the liver and gallbladder are directly connected by supporting structures. Using a raft (a horizontal mesh of plastic located at the base of the model) and supports, we developed a model of the gallbladder, in which they, simulating the liver bed, allow us to model the plane of the liver section. This model includes only the gallbladder and saves consumables, which speeds up the 3D printing process.

Anatomical base with liver made of PLA plastic

We also reduced the space between the support and the gallbladder to make the area between them more complex and realistic. For more efficient placement inside the pelvis model (laparoscopic simulator), we created an anatomical base with a liver made of PLA plastic. It contains a soft sponge that mimics a real liver, into which a component of a 3D model of the gallbladder made of LAY-FOMM, an easy-to-use filament, has been inserted through the valve. This rigid model allows quick and easy replacement of LAY-FOMM gallbladder models.

Finally, we created an ellipsoidal cylindrical model with a vertical hole, which makes it possible to simulate intestinal sutures and anastomoses. 3D printing of this model does not require much time and money.

Models for testing intestinal sutures

We believe that this technology opens up diverse and broad possibilities. We intend to create models of other organs for high-precision simulation of a number of important surgical interventions. To do this, we need to learn how to perform 3D printing based on DICOM files in particularly complex or atypical cases sometimes encountered in clinical practice. In general, 3D printing with LAY-FOMM interested us in terms of technical perspectives and, most importantly, the practical training of a new generation of surgeons based on more advanced and accurate models.

Specialists of the Department of General Surgery

iQB Technologies Experts Recommend Article: 3D Printed Prostheses Transform Patients' Lives

Sharebot 3D Printers - Reliable Tools for Innovation

Fatebfratelli hospital staff use a Sharebot 43 compact professional 3D printer equipped with two autonomous extruders. The device allows you to print products of the most complex geometry with soluble supports. In addition, a system of mirroring and duplication is available when printing. The flexible printer platform maintains a temperature of 120°C, and the maximum heating temperature of the extruders reaches 300°C, which allows the use of technical and professional materials that meet a wide variety of physical, chemical and mechanical conditions, including high or low temperature, the presence of oil and gasoline, as well as impact and friction.

The device allows you to print products of the most complex geometry with soluble supports. In addition, a system of mirroring and duplication is available when printing. The flexible printer platform maintains a temperature of 120°C, and the maximum heating temperature of the extruders reaches 300°C, which allows the use of technical and professional materials that meet a wide variety of physical, chemical and mechanical conditions, including high or low temperature, the presence of oil and gasoline, as well as impact and friction.

Printing process on Sharebot 43

The collaboration between Sharebot and the Department of General Surgery at the Fatebenefratelli Hospital in Erba has demonstrated the importance of introducing 3D printing, which opens up the possibility of creating new types of models and high-precision surgical simulators. This area is just one of the possible directions for the development of technology. Whether it's recreating organs for experimentation or printing implantable prostheses, 3D technology is becoming a key tool for medical innovation.