Felix 3d printer review

Felix 3D Printer Review 2022

Considering getting the Felix 3D printer? Here is why you should not buy this particular 3D printer! We reveal some interesting facts about this 3D printer!

By Justin Evans

3.5

See Price

It’s easy to get focus solely on the most recent 3D printer releases, but in doing so, you run the risk of missing out on a little-known diamond in the rough. After all, as printers get more advanced, they tend to prioritize ease of use, which can leave tinkerers unsatisfied and hoping for more of a challenge.

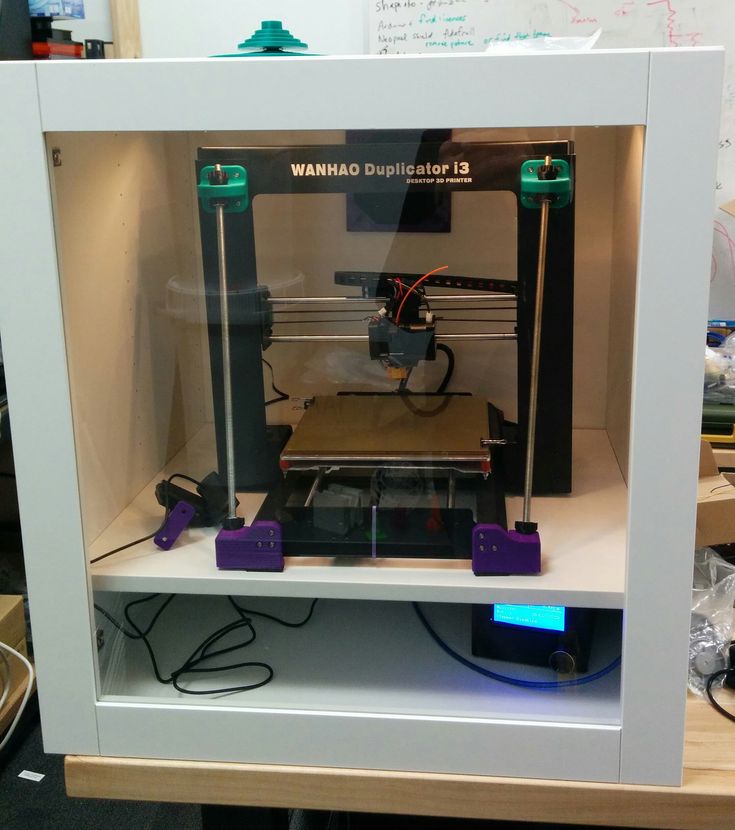

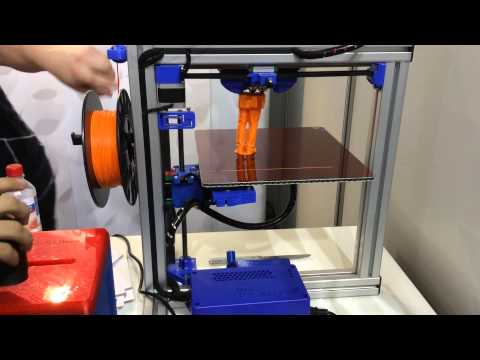

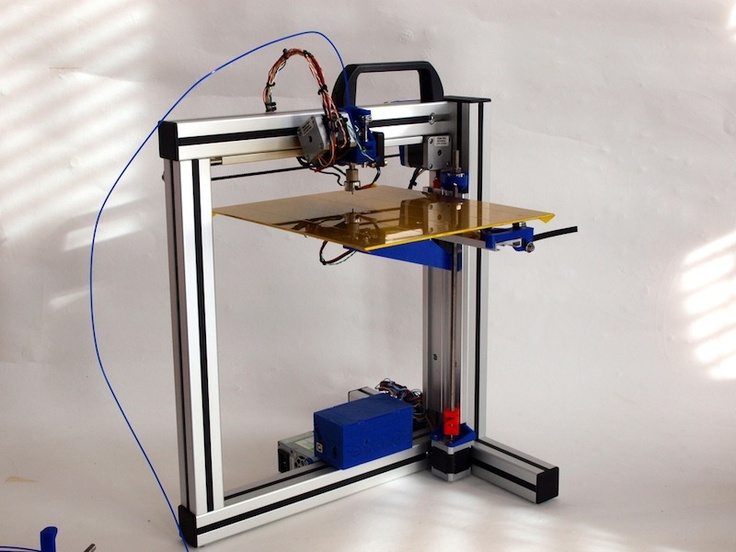

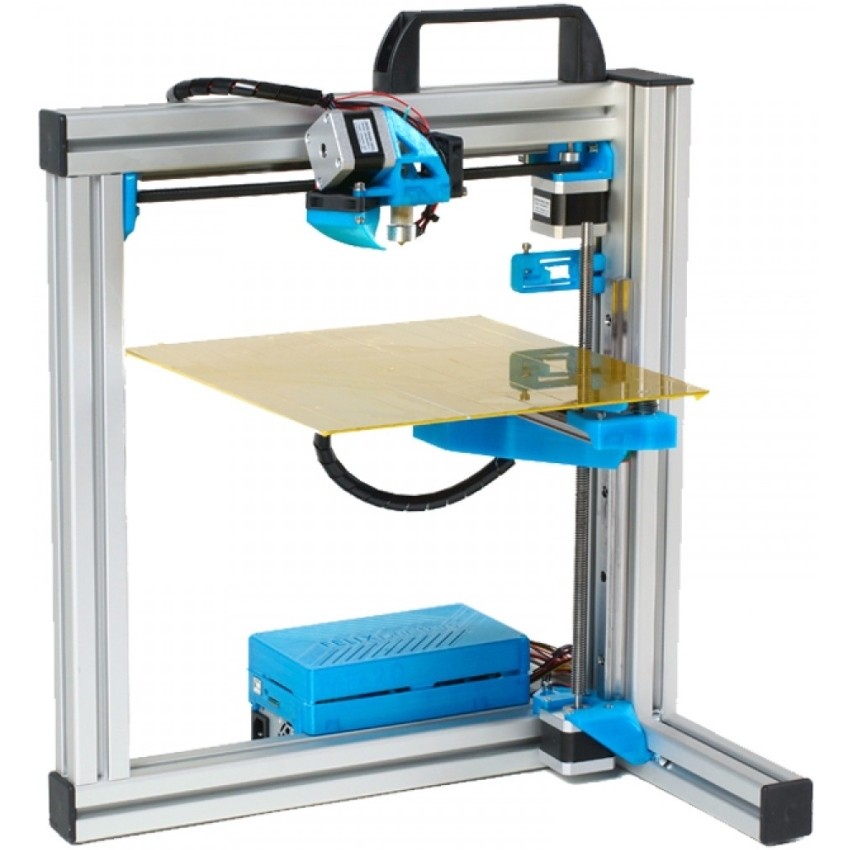

Today, we’re taking a look at the Felix 2.0, a discontinued 3D printer that balances user-friendliness with the capacity for modding and optimization. It’s a little tricky to find these days, but should you even bother? That’s what we’re here to find out.

| Filament Diameter | 1. |

| Extruders | 1 |

| Supported Materials | PLA, ABS, Nylon |

| Connectivity | USB, SD Card |

| Printing Speed | 200mm/s |

| Build Volume | 10 x 8 x 9.2” |

Table of ContentsShow

Design

The Felix 2.0 can be bought either fully assembled, or in kit form, and thanks to its simplistic design, building it shouldn’t take long. Notice how thick those supports are – this helps prevent wobbling and ensures that your extruder points are exactly where it’s supposed to at all times.

There’s another slightly unusual addition here – the carry handle. It’s worth noting that this is a very lightweight printer, so you could move it around if you wanted. That said, we’d recommend just finding a designated area for it so you don’t have to re-level the bed each time.

Users can import models via USB or SD card, but there’s no WiFi support. There is, however, a pretty basic microcontroller you can use to start prints without being connected directly to a PC. These connectivity options are pretty standard for products in this price range, so we can’t complain.

There is, however, a pretty basic microcontroller you can use to start prints without being connected directly to a PC. These connectivity options are pretty standard for products in this price range, so we can’t complain.

Printing

We wouldn’t exactly call this printer a workhorse. Don’t get us wrong: it produces reasonably detailed prints, but the quality could definitely be better. We noticed rough edges and highly defined layers, but this only really caused problems when creating interlocking parts. If you don’t mind a little post-processing, though, this is fine.

There is one positive, though. The Felix 2.0 is very fast, with a maximum speed of 200mm per second. This does contribute somewhat to the low quality, and if you slow it down, you’ll find your prints look a lot better. It really depends on whether you want quality or quantity.

The range of supported materials is a little disappointing. It can use PLA, ABS, or Nylon filament, which wouldn’t be an issue if the Felix 2. 0 was an entry-level printer. At this price, though, it’s a tad underwhelming. At least you can use third-party materials, though.

0 was an entry-level printer. At this price, though, it’s a tad underwhelming. At least you can use third-party materials, though.

Features

Everything about this model is designed to reduce noise when printing. The frame absorbs most of the vibrations, the bearings move almost silently, and the fans are barely audible. This means you can leave something printing overnight without worrying about disturbing other people in your vicinity.

Because the design is so basic, calibration is a snap. The heated bed can be leveled in a matter of minutes, and the included copy of Repetier-host comes with a Felix printer profile already installed. As a result, you can go from building to printing in just a couple of minutes.

The barebones construction also means that this printer is very easy to mod. Want to add new features or upgrade existing components? No problem! You’ll find that it’s very accommodating, and the range of things you can do is limited only by your imagination.

Cost

Now, the price is the Felix 2.0’s biggest problem. Fully assembled models retail for around $1800 and are only available from third-party sellers. Really, for this price, we’d expect to see a little more functionality, but instead, it seems to be targeting intermediate-level users without much to offer them.

You should also consider the fact that the Felix 3.1 is available from the manufacturer for around the same price. The two models share many features, but the later version obviously has some improvements. With this in mind, and given how hard it is to find, the 2.0 becomes much less attractive.

Whichever model you choose, your running costs should be pretty low. The supported materials are all pretty inexpensive. There’s a huge variation in terms of brand pricing, however: while you can find spools of PLA for around $10, more advanced variants can cost far more.

Support

To its credit, Felix has a fairly comprehensive support area. It provides generalized troubleshooting and maintenance guides, plus there’s a forum for users who need more detailed information. You can also submit a support ticket to get technical help straight from the manufacturer.

You can also submit a support ticket to get technical help straight from the manufacturer.

Felix offers a one-year warranty on its printers. Interestingly, the terms don’t say that you have to have bought it directly from Felix, so if you can find a 2.0 from an external supplier, you should still be covered. You will have to provide proof that the product is still less than a year from its purchase date, though.

Really, with how simple this printer is, it’s unlikely you’ll need much help. That said, we’re glad it’s accessible at no extra cost for users who are maybe new to 3D printing and need a little extra support. Of course, the 2.0 is a few years old now, so you may struggle to find users who can help resolve model-specific issues.

Prusa i3 MK2 Review

Felix Pro XL 3D Printer In-Depth Review

ADVERTISEMENT

9. 1Expert Score

1Expert Score

Felix Pro XL 3D printer

Felix Pro XL has a huge build volume, with flexible build plate, and dual extruder printing makes one part of industrial 3D printing. So, the printer has many features to attract professionals in the field of 3D printing worldwide.

Affordability

5

Quality

10

Speed

10

Capability

10

Practicality

10

User Expectations

10

PROS

- Huge Build volume.

- Removable and bendable flexplate.

- Dual extrusion system.

- High-quality surface finish.

- Dimensional accuracy even in intricate parts and functional prototypes.

CONS

- Enclosed print chamber.

- Post processing of part is difficult because cooling takes more time than in any open-body 3D printer.

Print industrial-grade parts using Felix Pro XL with ease. Offering a build volume of 600 x 400 x 600 mm, the printer allows users to create larger ...

Offering a build volume of 600 x 400 x 600 mm, the printer allows users to create larger ...

Add to wishlistAdded to wishlistRemoved from wishlist 0

Add to compare

|

Table of Contents

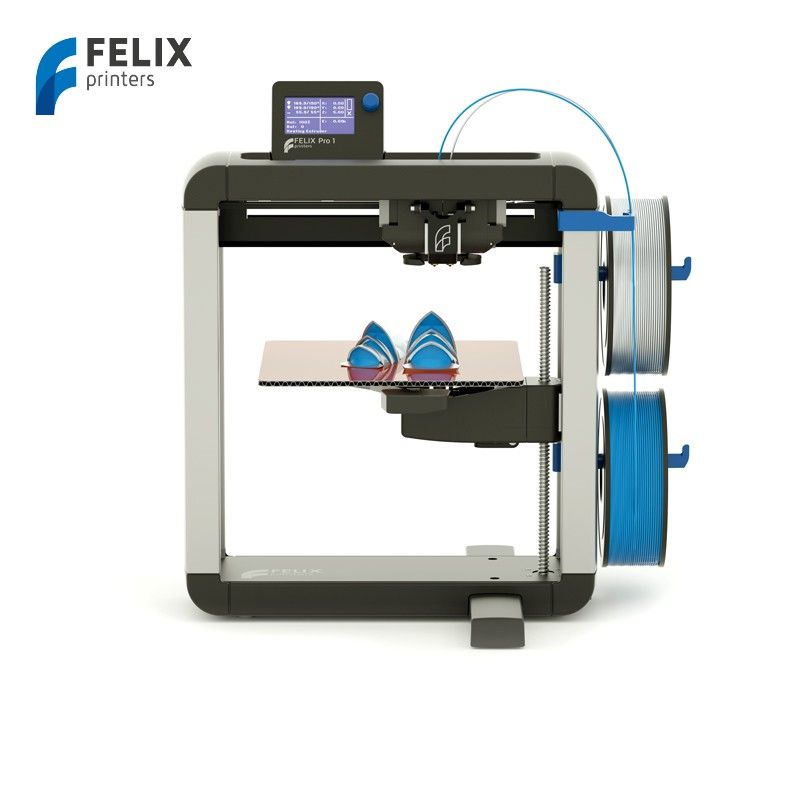

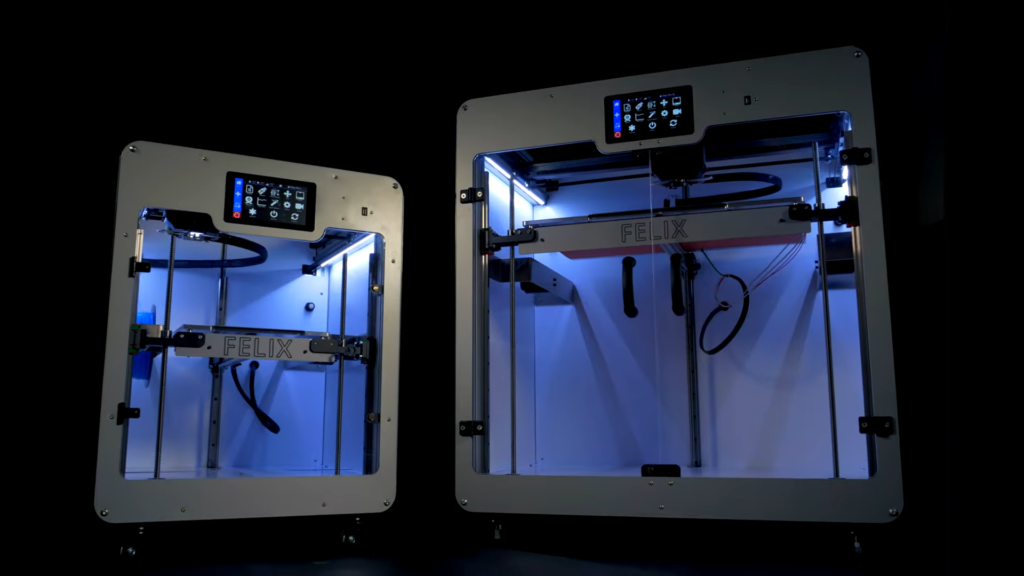

Launched with Felix Pro L, this 3D printer to marks Felix printer’s first steps into the journey of going big.

Both, Pro L and Pro XL are known to offer huge build volumes for printing parts and functional prototypes to their customers.

This article will focus on various characteristics of the Felix Pro XL 3D printer.

The attempt will be to expedite one’s buying decision of a 3D printer in the same price range, by allowing the reader to completely compare in-depth the characteristics of Pro XL. Leaving the reader with an opportunity to use language as a tool for comparing features and specifications and other aspects of this printer with others.

So, the reader of this article can benefit, even by not using the printer, but gaining insights into Felix Pro XL.

The Pro L, as well as the Pro XL, are sleek light silver in color, they come with a touchscreen interface, a glass door that grants one access to the print chamber of the printer, and a glass top.

A lot of such nuances brought in these printers and the difference between Pro L and Pro XL is what one can get to read in this article.

We will start our journey by viewing the Features of the printer.

ADVERTISEMENT

Features

Felix Printers has, after working in the additive manufacturing industry for more than eight years, gained an excellent reputation.

It is known for providing a range of 3D printers in almost all markets. Its desktop 3D printers have been very helpful to education institutions as well as hobbyists.

Whereas its range of intermediate 3D printers has been handy to a lot of intermediate 3D printing technology users.

And by entering in the industrial-grade 3D printers, using Pro L and Pro XL, the company has completed what was incomplete.

Pro XL is the company’s largest offering when it comes to comparing the build volume of its 3D printers. Once this printer was manufactured, it was tested in Belgium, independently.

And the results of these tests approved Felix printers as an accomplished player in the field of manufacturing industrial-grade 3D printers.

There were many features of this 3D printer that were appreciated by the independent tester in Belgium. Those features, alongside other features, are something that we are mentioning and explaining below.

Strong construction

The body of this printer is constructed by a very strong material which ensures the printer does not vibrate during the printing process.

That strong material is none other than Aluminum.

The material provides strength to the overall body of the printer.

Aluminum has a long-standing reputation for getting used in making 3D printer bodies.

And the fact that Felix Printers has chosen it in their largest build volume offering 3D printer shows how the company’s research team is well aware of the industry-standards.

ADVERTISEMENT

Thin print bed

Generally, when you will come across a printer that offers build volume anywhere near 600 mm * 400 mm * 600 mm, the print bed would be thick.

But contradicting that fact, Felix Printers have kept the print bed of Felix Pro XL thin, which is worth observing.

Also, the company must be appreciated for offering this amazing perspective in the field of industrial 3D printers.

If the material has the amount of strength it needs for carrying a part or functional prototype on itself, the printer does not need to have thicker materials in use.

And this perspective was not seen in the world of industrial 3D printers before this company brought a light of focus to it.

Removable and bendable flexplate

Felix Printers should also be appreciated for taking into account the post-processing part of the 3D printing process as important as the pre-processing part.

For how else could they’ve managed to put in a removable bendable flexplate that not only assure a maker that the printed part with a stick to it, but also could be removed with any damage.

The removable bendable flexplate will be very helpful to all the users after having printed a part or functional prototype that is difficult to remove without bending and removing the flexplate.

ADVERTISEMENT

A large touch screen interface

There are two ways to interact with the printer, either with the web or the touch screen.

One can choose according to convenience. Both of these options are very well knitted.

They provide the user with the ease that they need, be it in navigating or choosing the functionality options.

Felix Printers has gone with the recent trend that has made every 3D printer manufacturer put a touch screen interface for increasing user-friendliness in their 3D printers and decreasing human interventions.

Large Build Volume

Parts and functional prototypes of various industries cannot be made using desktop 3D printers.

By offering industrial-level build volume with their printer, Felix Printers have made an important footstep in fulfilling the demands of manufacturers in the field of 3D printing.

Apart from manufacturers, large build volume also makes a printer favorable and gains the liking of professionals.

Felix Pro XL will attract manufacturers of parts and functional prototypes in various industries that require industrial level 3D printing.

Dual Nozzle Direct Drive Extruders

Even when the printer is used for making two similar parts from different materials at the same time, the quality of surface finish is high, so is the detailing.

Overhangs and bridges are almost perfect compared to other 3D printers in the same price range and even above.

This is possible because the printer features dual nozzle direct-drive extruders.

Felix Pro XL is known to produce extremely impressive results when used continuously for hours to 3D print with two different sets of materials.

And in the post-processing, the supporting material is always easy to remove because of its water-soluble nature.

ADVERTISEMENT

Specifications

Credit: felixprinters.comFelix Pro XL has a build size of 600 mm * 400 mm * 600 mm and a build volume of 144 liters.

The filament source of Felix Pro XL is open and one can print using PLA, ABS, PETG, PVA, FLEX, Carbon Fiber, Nylon, Glass, and Wood II.

Brass nozzle diameters with which one can print on Felix Pro XL are 0.35, 0.5, 0.7, and 0.9 mm.

The same set of nozzle diameters can be used while printing with hardened steel material.

One can print parts or functional prototypes with a print speed up to 100 millimeters per second, but the company recommended 60 millimeters per second.

The positioning accuracy of Felix Pro XL in the XY and Z-axis is 0.01 mm.

The layer thickness range that can be observed in parts and functional prototypes printed using this printer is 0.05 mm to 0.35 mm.

The nozzle of this printer can reach up to 275 degrees Celsius of temperature.

The heated bed of the printer is constructed using solid casted and high precision aluminum.

There is a seven-inch long touch screen interface that allows users of the printer to interact and monitor it.

The touch screen interface is compatible with English, German, Dutch, Spanish and other languages.

Felix Pro XL is compatible with Windows as well as Mac operating systems and can be connected using Wi-fi, USB, or LAN.

The printer weighs approximately 80 kilograms.

ADVERTISEMENT

Price

Felix Pro XL is available for $12845.

First Impressions

Credit: felixprinters.comThe printer makes up for a pretty impressive look that lets it stand out when seen with a bunch of other dark-colored 3D printers.

As it has a silver color, glass over the top, in the front.

There is a door that has access to the print chamber of the printer and the right wall of the printer has the filament spool holder.

Whereas the touch screen interface is at the head of the front of the printer.

The rails are not witnessed easily when one looks at the printer from the front, which makes Felix Pro XL look like a neat and clean 3D printer.

Setup

The box of the printer that is delivered at your place has tweezers, USB cable, LAN cable, filament spool holders, spool of PLA filament, and a quick start manual to help you get familiar with various parts of the printer before starting to print with the printer.

Print Type/Cost

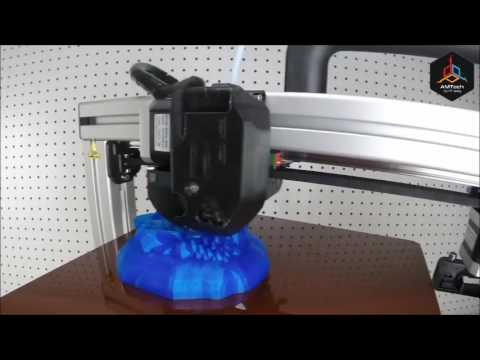

Fused Deposition Melting or Fused Filament Fabrication is the 3D printing technology employed by Felix Pro XL for 3D printing parts and functional prototypes.

And this 3D printing type is very famous in the world of additive manufacturing. So much so that majority of 3D printers are based on this technology.

For the same reason, the cost of 3D printing a part or functional prototype using this technology is lesser than it is with other 3D printing technologies.

Although it should be noted that the cost of 3D printing depends on many factors and can change according to the geometry of the part, the amount of infill needed in it, and the layer resolution as well as the print speed.

ADVERTISEMENT

Print Quality

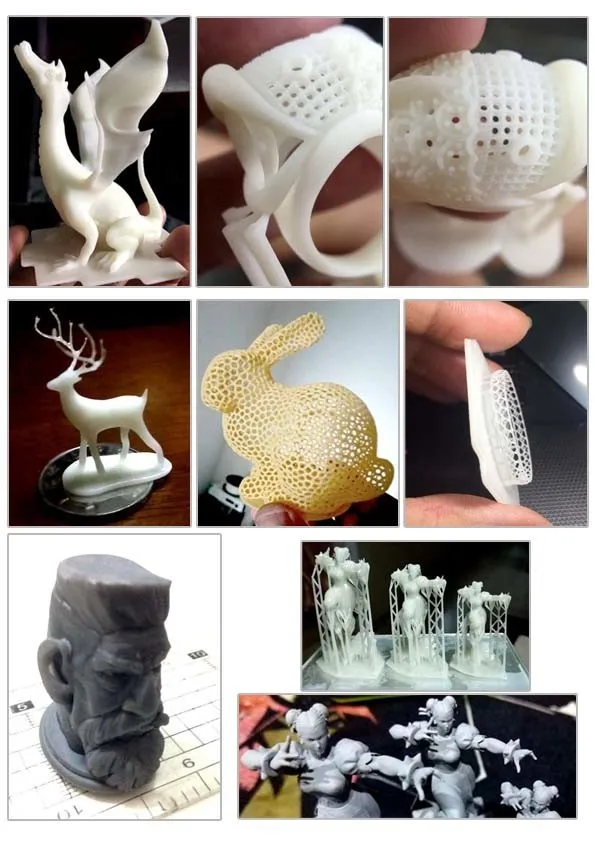

Credit: felixprinters.comExcellent surface finish and intricate detailing is seen on parts or functional prototypes that are manufactured even when the printer works in dual nozzle direct extruder mode.

The layer resolution of the parts or functional prototypes manufactured by the printer is much higher than other printers in the same price range for which Felix printers must be given an immense amount of credit.

Software

Simplify 3D is the recommended software by Felix printers. The download link for all the pre-settings of this software is available from the website of Felix Printers. It is open-source software.

Customer Support

Felix Printers is a company that is known for many things, amongst which customer support is the main reason.

The company provides a warranty in many of its 3D printers and extends lifelong support in case of any technical problem in any of its 3D printers.

One can reach out to the company via call, email, or Skype.

In case of learning in-depth about the company’s printers, one can also take the help of the global community hosted by the printer.

ADVERTISEMENT

Parameters influencing the buying decision

Those parameters that one must look at before buying a 3D printer, to compare it with another are mentioned below.

3D Printer Cost: Expensive enough to say that only professionals in the world of 3D printing will be able to afford it.

3D Print Quality: Extraordinary surface quality of parts and functional prototypes even while printing with dual extruders is achievable using Felix Pro XL.

3D Print Speed: By assuring good quality prints, the manufacturer does not sway away from offering decent print speed in this printer.

3D Printer Capability: One can not only print with the most popular materials, but also with rare materials such as Carbon Fiber on this printer.

3D Printer Practicality: Small business owners and hobbyists would have to think a lot before making such a huge investment in buying this 3D printer.

3D Printer User Expectations: A professional would be happy to acknowledge the presence of such reliable manufacture in his domain.

The Verdict

Felix Pro XL’s price defines a lot about the target audience of the company. At least as much as its build volume does.

Huge build volume, with flexible build plate, and dual extruder printing makes one part of industrial 3D printing.

Whereas the other half is served by the stability instilling aluminum rails, nozzle system, print heads, glass top, intuitive and many languages compatible touch screen interface.

All in all the printer has many features to attract professionals in the field of 3D printing worldwide.

And so, if you are one, do consider this printer before making a buying decision.

Felix Pro 2 3D printer overview

Contents

-

- Mechanics.

- Soft

- Results

- Traditionally a minute of advertising

- Mechanics.

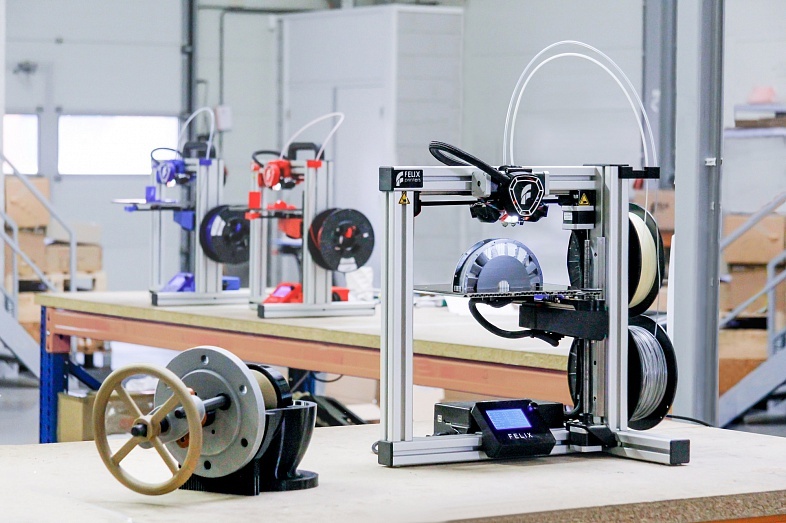

At the end of last year, Tsvetnoy Mir started deliveries of Felix Pro 2 3D printers and now we want to present a review of this updated model from a well-known Dutch manufacturer.

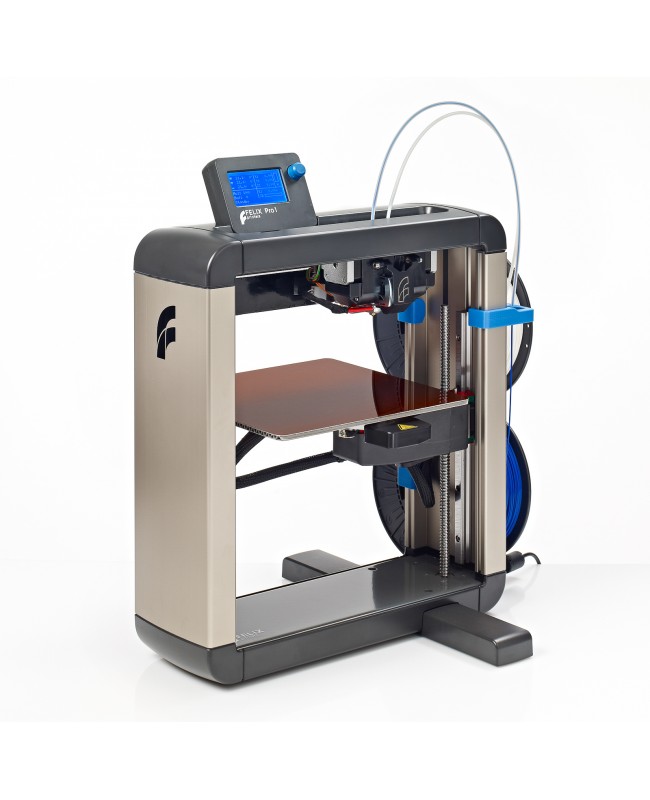

The Felix Pro 2 3D printer is a revised and improved version of the FELIX Pro 1.

- Felix Printers is a Dutch company that specializes in the manufacture of modern 3D printers. Felix printers are easily recognizable by their unique design, these printers are more like a CNC machine than a household appliance for home use, and the company itself positions its devices specifically for professionals, especially the Pro series, which provides great opportunities for advanced users.

The printer is supplied in 2 versions - with a touch, color touchscreen display or with a conventional one. We got the second option.

Mechanics.

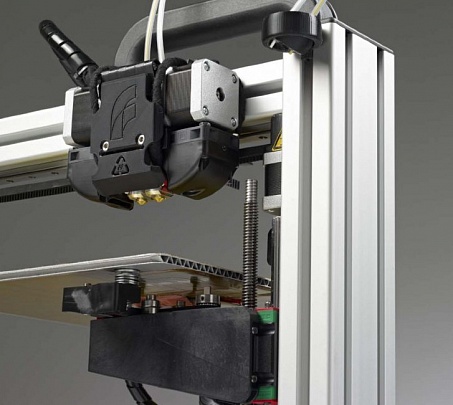

With a close acquaintance, it is noticeable that the printer is thought out to the smallest detail.

Before each print, the printer automatically calibrates the table height. The magnetic auto-calibration system allows you to do this very quickly and accurately.

Now you do not have to align the table for a long time on a piece of paper or a probe.

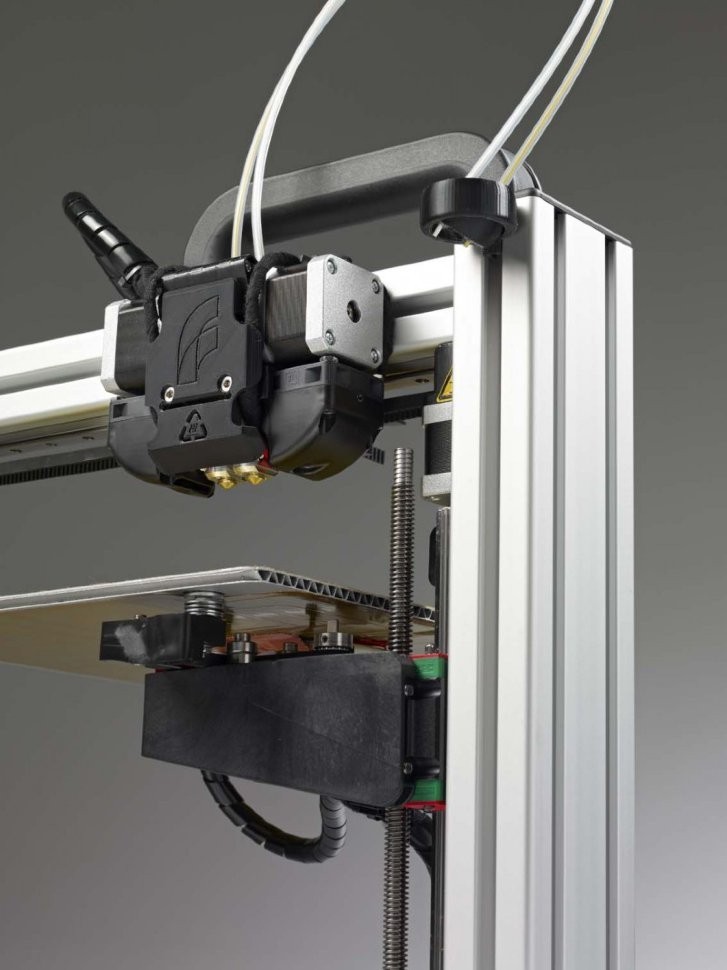

In the updated version, Felix received a simplified extruder with rising (or even more correctly swinging) heads.

Now printing with two heads will become even easier and better.

There is also an interesting possibility of quick replacement of the print head.

The heads are attached with magnets and can be easily removed. Nothing needs to be unscrewed or disassembled (most importantly, do not forget to unload the plastic).

Along the X axis, the head slides along rail guides. This solution allows you to print quickly and accurately despite the impressive weight of the head (after all, there are motors for feeding plastic on the head).

A rail is also installed along the Z axis. The movement of the table occurs along the ball screw, instead of the already familiar trapezoidal screw.

Despite my dislike for designs with a “jump table”, it is worth recognizing that they tried to minimize the weaknesses here.

The table is made of corrugated aluminum panel, the upper plate is 1 mm thick, the lower one is twice as thin, between them is a wavy strip of thin aluminum sheet.

This makes it as light as possible and minimizes thermal deformation when heated.

By the way, the table with the heating element is attached with only 3 magnets. If necessary, it can be quickly removed. You don't have to unscrew any screws or disconnect wires.

Soft

For printing, we used the "native" slicer FelixBuilder 2.1, an annual license for this software comes with the printer, later it can be extended to a perpetual one. (Other free analogues, alas, did not work).

(Other free analogues, alas, did not work).

The profile is used as for Pro 1.

The main plus of the program is, of course, the mass of ready-made profiles for different types of plastic. For beginners, this will be a huge plus.

FelixBuilder refuses to slice some "broken" stl-ki, offering to "cure" them through an online service.

You have to register, download, treat. It's a little annoying.

Of course, you can tell a lot, but the results of printing will be more eloquent than any words.

ESUN PLA layer 0.15.

Of course, I would like more airflow. For small parts, you will either have to lower the speed, or additionally cool the model when printing.

ABS from ESUN, layer 0.15.

Despite the open body of ABS, it is quite possible to print. On small parts, it is worth turning on the blower (in the standard profile for ABS, the blower is turned off), but printing large parts can be problematic.

And of course two-color printing. PLA/PLA, layer 0.15.

Very worthy. There is no mixing of colors, not even small inclusions of another color.

When printing with 2 nozzles, the printer cools the inactive nozzle so that plastic does not ooze out of it. The model, of course, turns out to be of very high quality, but the printing time is not encouraging. A lot of time is spent on cooling-heating nozzles.

And this is how Felix can print after more painstaking adjustment of print settings.

Totals

In principle, the printer turned out to be very worthy. For all my dislike for designs with a "jump table" and even with an open case, he was able to show that with thoughtful attention to detail, such printers can show very good print results.

FELIX Pro 2 clearly demonstrates that manufacturers are trying to make 3D printing more accessible. Many calibrations and settings that may cause difficulties for a novice user are performed automatically here. And the replacement of some components is simplified to the maximum.

And the replacement of some components is simplified to the maximum.

Traditionally a minute of advertising

Buying equipment from our company, you get 10 advantages:

- The ability to use the Trade In program.

- Warranty - 12 months

- Manual in Russian

- Lifetime support

- You buy a 3D printer from an official distributor in Russia

- Free shipping.

- Free training in our office.

- Opportunity to buy a printer on credit through TKS, OTP, Renaissance banks.

- 10% discount on plastic forever.

- An opportunity to get acquainted with the printer in our demo room.

The review was prepared by Anna Panfilova, a 3D printing specialist at Tsvetnoy Mir.

Subscribe to our Facebook and VK groups to keep abreast of the latest events =)

https://www.facebook.com/groups/cvetmir3d/

https://vk.com/cvetmir3d

https://www. youtube.com/channel/UCnfeyFh4TKIVpMCMi1zd0fA

youtube.com/channel/UCnfeyFh4TKIVpMCMi1zd0fA

FELIX Tec 4 single extruder 3D printer

Out of stock

Add to compare

Product added to compare Go

10% discount on materials Free shipping within Russia

202 500 ₽

Notify me of admission

Official distributor

We work directly with manufacturers.

Any form of payment

The opportunity to see the 3D printer in action in our demo room.

Own warranty service

Warranty and post-warranty service for equipment purchased from us.

Permanent 10% discount on consumables

When buying a 3D printer from us,

you get a 10% discount on all consumables.

The FELIX Tec 4 3D printer with a single extruder will expand the possibilities of 3D printing and open up a new field for experimentation.

FELIX works closely with the user community and took into account all the wishes, comments and requests of customers when developing new models.

One of the main advantages of Tec 4 is the integration of automatic calibration through software, as well as the possibility of bump mapping. This feature guarantees a perfect first layer, which in turn is the key to successful printing. Table calibration is semi-automatic with induction sensors and manual wheels for leveling.

This feature guarantees a perfect first layer, which in turn is the key to successful printing. Table calibration is semi-automatic with induction sensors and manual wheels for leveling.

The FELIX Tec 4 is manufactured using high quality components such as solid metal printheads and industrial grade linear guides. A high level of durability ensures reliability, trouble-free printing and long life of the printer.

Thanks to the user-friendly interface, combined with a large LCD display and user-friendly control buttons, it is very easy and quick to start typing.

Felix's new removable print surface is designed to minimize damage to removable prints. After printing, just remove it and bend it a little, the model will peel off in just a second.

Tec 4 allows you to print more than 15 types of materials, such as PLA, PVA, ABS, PETG, PolyFlex, Wood and others.

Rugged, lightweight, open and compact, the FELIX Tec 4 fits neatly into any workspace.

build size

build size