Mojo 3d printer filament

Mojo 3D Printer Review 2022

4.2

See Price

| Printing Area | 127mm x 127mm x 127mm |

| Layer Resolution | 170 microns |

| Supported Filament | ABS, Support Material |

| Connectivity | USB |

| Extruders | 2 (ABS/Support) |

| Weight | 60 lbs |

Table of ContentsShow

Design and Features

Opening the top cover and peering into the belly of the Mojo reveals a professionally engineered machine that even the most stringent designer will find satisfying. The smart positioning of various parts (including the inner brackets for the filament), the quality of said parts, and the clean look of the innards point towards the caliber of the printer in contention here. The configuration is a thing of beauty.

The two-shade gray color of the casing is on the drab side but has the benefit of smooth contours and an uncluttered look. The printing area feels contained and ordered hinting at Stratasys aim to provide an intuitive, easy to use printer free of the tinkering and messiness synonymous with barebones hobbyist alternatives. The Mojo wouldn’t be out of place within the hustle and bustle of a fast-paced professional design studio or prototyping workshop.

The design itself is centered on a fully-enclosed heat regulated chamber supported by a full metal frame and plastic outer casing with a reasonable footprint weighing in at a total of 60 lbs. The heated chamber is vital here because the Mojo only supports ABS filament and as any versed maker will know, temperature and humidity regulation is a core concern when printing with ABS, which is prone to warping.

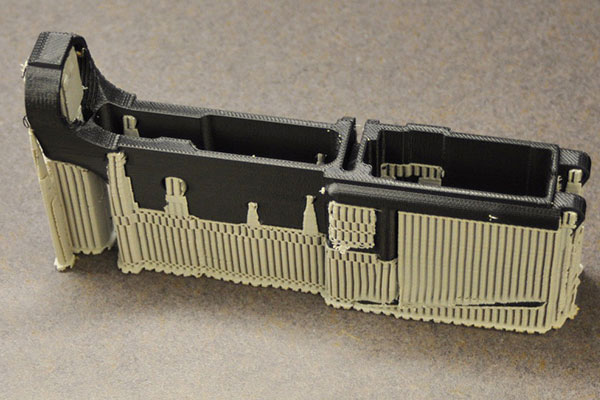

Although the printer has a dual extruder setup that uses Fused Deposition Modeling technology, it differs quite radically from what we’ve come to expect from this duality. Typically, you’d expect two types of filament or at least two different colors of PLA or ABS, but with the Mojo, one extruder is used for ABS, while the other extrudes SR-30 soluble support material. The focus on supports is incredibly important in the systematic quality of the prints.

The focus on supports is incredibly important in the systematic quality of the prints.

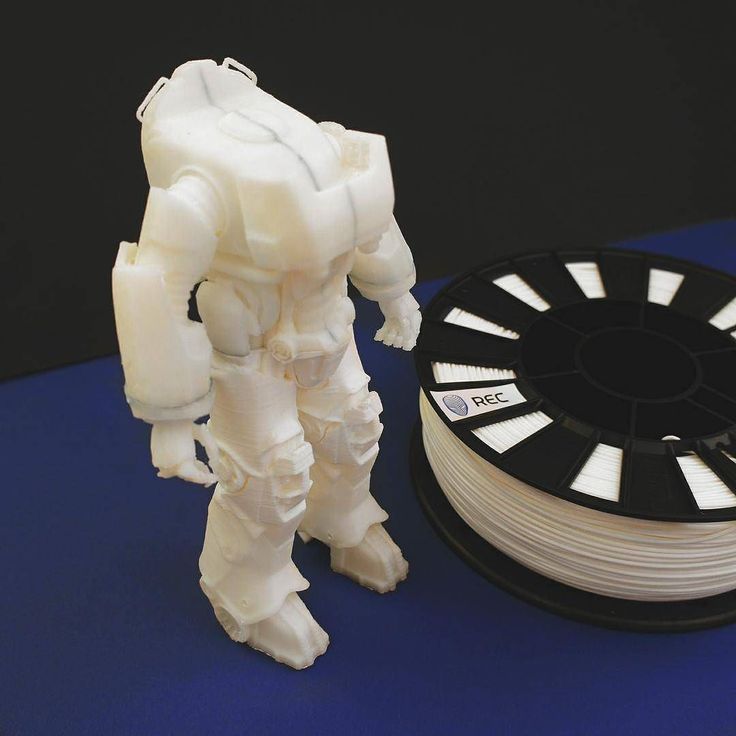

Stratasys has made it so that the Mojo doesn’t just use any run of the mill open source ABS either. The Mojo uses what is termed ABSplus, which is a production-grade thermoplastic that more or less mimics the durability of bonafide production parts with the added benefit of working in unison with the support material to print intricate recesses, cavities, and overhangs.

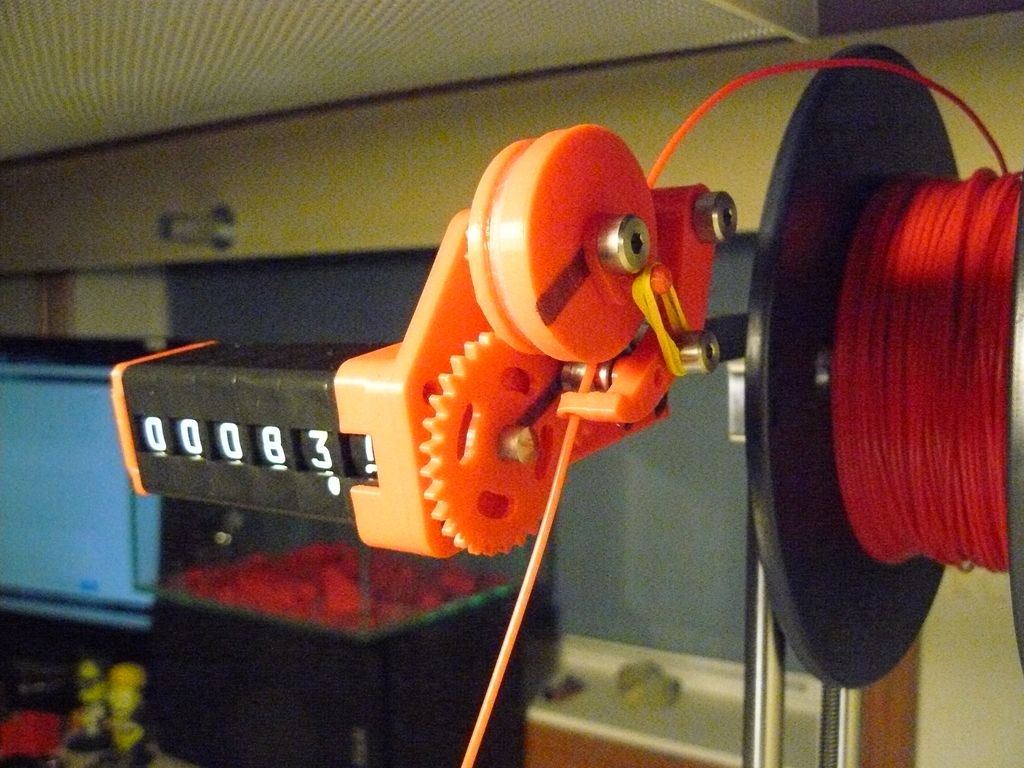

As you’ve probably guessed, Stratasys ships ABSplus in a proprietary filament cartridge coined the QuickPack Print Engine with a capacity of 80 cubic inches available in nine different colors. Not only does the Print Engine contain the ABS, but also a disposable snap-in print head that is ostensibly as easy to switch out as a cartridge on a standard inkjet printer. The new print head with every spool is not just for ease of use, but to keep part quality.

Additionally, a chip is fitted into each Print Engine that communicates to the printer how much filament is left so the printer won’t trigger prints it can’t complete, and each cartridge is foil-wrapped to keep the ABS from going brittle. The Print Engine design is one-time use.

The Print Engine design is one-time use.

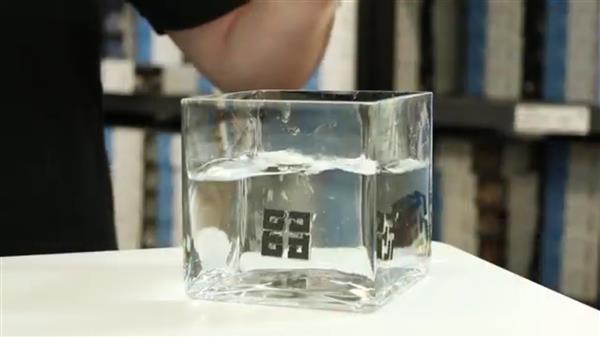

Going back to the support material, Stratasys also ships each Mojo with a WaveWash 5S support cleaning system, which is none other than a bin for cleaning off supports. Just add in an Ecoworks tablet (a dissolving detergent provided by Stratasys), a splash of tap water, turn on the cleaner and it will set the right temperature and amount of swirling to remove the supports without damaging the ABS print.

The Mojo has a comparatively small build area of 127mm x 127mm x 127mm, and the printing process sticks to the tried and trusted Cartesian configuration. The limited size is at odds with the price of the printer, but the truth is that for the majority of prototypes the available surface is more than sufficient. The printer steps up when it comes to the quality of the prints to counterbalance the limited space as we’ll see below.

The Mojo only prints at one layer resolution of 0.17 mm or 170 microns, with only one print speed available. The idea here is to provide detailed prints at every turn at the detriment of a quick test lower resolution print although it isn’t uncommon to see professional grade 3D printers with resolutions as high as 20 microns. Given that Stratasys is flogging the Mojo as a prototyping machine, the attention to detail makes sense but might irk users who desire a little more flexibility.

The idea here is to provide detailed prints at every turn at the detriment of a quick test lower resolution print although it isn’t uncommon to see professional grade 3D printers with resolutions as high as 20 microns. Given that Stratasys is flogging the Mojo as a prototyping machine, the attention to detail makes sense but might irk users who desire a little more flexibility.

The attention to detail also carries over to practicality with features like a set of internal brushes that clean the nozzles and collection bins that pick up any of the excess filament removed by the brushes. In the same vein, the front door has a locking mechanism to ensure the chamber remains at a uniform heat while printing.

As for software, the Mojo comes with the Stratasys Print Wizard utility that resembles a streamlined slicing application that’s intuitive and incredibly easy to use. The Wizard does most of the hard work by scaling STL files to fit the printer, queuing prints if the parts are too large for the build area, and communicates directly with the printer. The only real hands-on aspect is setting up the support style (basic, spare, surround) and orientation, which we found self-explanatory and easy to navigate.

The only real hands-on aspect is setting up the support style (basic, spare, surround) and orientation, which we found self-explanatory and easy to navigate.

We understand that Stratasys is banking on most of the heavy design work being completed in CAD software which is then carried over to Print Wizard for conversion then printing.

Connectivity wise, the Mojo is limited to a USB connection via a PC running Windows 7 or Windows 8.

Assembly

The Mojo ships with the printer itself, one QuickPack Print Engine cartridge of ABSplus and one of SR-30 support material, WaveWash 55 support cleaning system, 24 Ecoworks tablets, a modeling base (read build plate), USB cable, power cord, and official documentation.

For an all-in-one, pre-assembled configuration, two large styrofoam supports on the top and bottom adequately protect the printer. It ships as is with the filament in the brackets and the startup kit sitting on the build plate alongside boxes for the cleaning system. It’s all very minimal in keeping with the functional ethos of the Mojo.

It’s all very minimal in keeping with the functional ethos of the Mojo.

The setup is among the most straightforward we’ve ever encountered. Not only was installing the handful of parts a doddle, but the instructions were concise. We had to remove the cable ties holding the Print Engine cartridges in place, remove the packaging, place them back into the brackets, hook up the print head to the extruder, fit the cleaning brushes inside the chamber by merely putting them on a set on spindles, and finally snap on the modelling plate to the build area. It all took no more than 20 minutes.

The printer auto-calibrates so there’s no wasting time leveling the bed by toying with a set of screws and a piece of leveling paper. From here, we plugged in the power cord, connected the USB cable, and hit the ‘’on’’ button.

Printing

The print quality was nothing short of perfect. Within the space of the seven days we had access to the Mojo, not once did it fail, print blemishes, imperfections, or layering issues. The prints were of the highest quality, systematically. Speed wise, the Mojo isn’t the fastest, but this does mean through and through quality with every print. The support system worked well to ensure each job had the right foundations to come out flawless every time.

The prints were of the highest quality, systematically. Speed wise, the Mojo isn’t the fastest, but this does mean through and through quality with every print. The support system worked well to ensure each job had the right foundations to come out flawless every time.

The small things also made the printing experience that much better. For one, Print Wizard gave spot on estimates for print timings, even providing an exact time for when a project would be finished that it hit without fail. The bins that collect excess filament on the nozzles are excellent for keeping the chamber clean.

Equally, from powering up the Mojo to starting a print job, we are talking less than 15 minutes, and this includes initializing, diagnostics, and heating the chamber. The Mojo is by any standard quick to get going.

The absence of any lingering ABS odor is a nice departure from open-plan 3D printers where you’ll need to crack open a window to be able to breathe comfortably. It’s also inexplicably silent to the point that at times we had to check that it was still printing.

The WaveWash 55 worked well although it does take time to complete a cleaning cycle that can vary from two to five hours depending on the print job in question.

Support

Unfortunately, the Mojo is no longer in production, so any assistance is vendor specific beyond Stratasys offering user guides, videos, and a customer support contact on its website. The Mojo ships with a one-year warranty as standard. The company also still sells the proprietary Print Engine filament.

Verdict

With the Mojo 3D printer, manufacturer Stratasys isn’t holding back: we have here a professional grade device with all the precision, versatility, reliability, and a price tag to match. A hobbyist will shy away at the approximately $10,000 price tag, but professionals will find an affordable printer that gives competitor models with similar qualitative results a run for their money. In other words, for those with a budget to match, they will be hard pressed to find much wrong with the Mojo.

In other words, for those with a budget to match, they will be hard pressed to find much wrong with the Mojo.

Our only real criticism is the ongoing cost of operation; the cartridge design which incorporates a new print head with every Print Engine cartridge doesn’t come cheap. Heavy usage racks up quite the bill sentencing the Mojo to prototyping designers with the financial backing from a profitable company to keep the printer running.

On the flip side, print head failure is the number one cause of issues with 3D printing, and by extension, poor quality prints. In light of this, the additional price does equate to peace of mind and assured printing success.

The Stratasys Mojo Desktop 3D Printer

THE STRATASYS

Bring your Big Ideas to Life

Give your design team a little Mojo with proven Fused Deposition Modeling (FDM) technology and the Mojo 3D Printer. It's as simple to use as an inkjet printer, yet powerful enough to meet the highest 3D printing standards

View Video Request Demo

- Overview

- Key Features

- Advantages

- Materials

- Specifications

- Request a Quote

Discover the Magic of Mojo

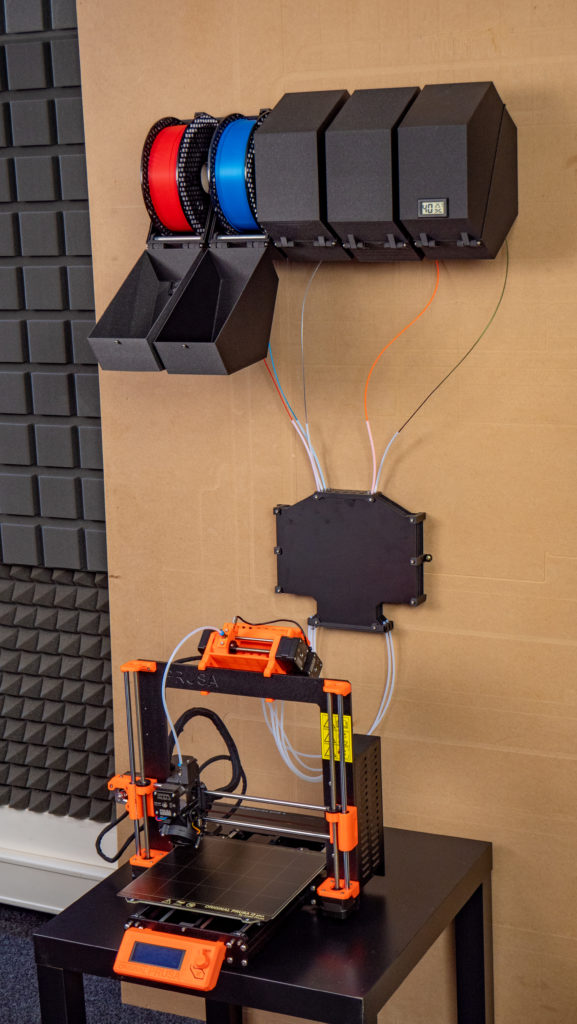

The Mojo 3D Printer from Stratasys brings affordable, professional 3D printing to your design process. Powered by FDM technology, you can trust the Mojo to empower your design creativity. Whether you’re testing for form, fit or function, Mojo works easily with your CAD software- bringing your ideas to life with just the push of a button.

Powered by FDM technology, you can trust the Mojo to empower your design creativity. Whether you’re testing for form, fit or function, Mojo works easily with your CAD software- bringing your ideas to life with just the push of a button.

Explore the Stratasys Mo by watching the video

Affordable, Professional 3D Printing

The Mojo 3D Printer allows you to print professional grade 3D models in ABSplus thermoplastic – at a price lower than other professional 3D printers. Using Stratasys’ Fused Desposition Modeling (FDM) technology , the Mojo achieves excellent accuracy and function, all in one compact unit.

Discover the Magic of Mojo

With the simplicity of a typical inkjet printer, the Mojo makes the transition from 2D to 3D a smooth one. With intuitive 3D Print Wizard Software, easily replaceable material cartridges, and simple post-processing, the Mojo 3D printing process is guaranteed to enhance your application.

An All-In-One Solution

Printer Bundle includes everything you need to start desktop 3D printing:

· The Mojo 3D Printer

· Print Wizard/Control Panel

Software

· WaveWash 55 Cleaning System

· Ivory ABSplus model material

· Support Material

· Ecoworks Tablets

· Modeling bases and more

The Mojo is ideal for printing 3D models that help determine form, fit, and function- everything from ergonomics to design verification. When it’s time to test your concepts, Mojo produces durable ABSplus 3D models that will stand up to testing in their intended environment

SHOP ABSPLUS

Bring Your Ideas to Life

The Mojo from Stratasys is ideal for 3D printing models that help determine form, fit, and function- everything from ergonomics to design verification.

Print models with ABSplus, production-grade thermoplastic that provides your print with durability and a high-quality finish.

Simple Yet Powerful

As one of the smallest industrial 3D printers, the Mojo is the perfect desktop solution for quick prototype prints in both small or large office spaces. The system works as easily as a traditional inkjet printer yet powerful enough to meet and exceed 3D printing standards. Included software allows for real-time status updates and estimated print times allowing your design team to print their ideas efficiently.

Easy to Use

Everything you need to start printing is straight out of the box. Set up is fast and easy- you can be printing your first 3D model in less than an hour.

With the WaveWash 55 Support Cleaning System, removing support material is easy. Featuring a stainless steel carafe, the device dissolves soluble support material quickly and quietly.

Dixon Valve

Manufacturing

View Case Study

Materials

ABSplus

Production-grade thermoplastic ideal for conceptual modeling, prototyping and end-use parts. Get a high-quality finish with matching durability

Get a high-quality finish with matching durability

LEARN MORE

Build Tray Size |

Build Tray Size12.7 x 12.7 x 12.7 cm [5 x 5 x 5 in] |

Layer Thickness |

Layer Thickness0.17 mm [0.007 in] |

Printing Material |

Printing MaterialP430 ABSplus |

Support Material |

Support MaterialSR-30 Soluble |

Workstation Compatibility |

Workstation CompatibilityWindows 7+ |

Printer Size |

Printer Size63 x 45 x 53 cm [25 x 18 x 21 in] |

Printer Weight |

Printer Weight60 lbs [27 kg] |

Stratasys Mojo | 50 factors

smartphones graphics cards wireless headphones CPU

44 points

Stratasys Mojo

Stratasys Mojo

Why is Stratasys Mojo better than others?

- Thickness?

430mm vs 462. 11mm

11mm - USB connectors?

1 vs 0.74

Which comparisons are the most popular?

MakerBot Replicator

vs

Ultimaker

MakerBot Replicator 2

vs

MakerBot Replicator2x

Formlabs Form 1

vs

MakerBot Replicator 2

MakerBot Replicator 2

vs

Ultimaker 2

MakerBot Replicator Mini

vs

Ultimaker 2

MakerBot Replicator

vs

MakerBot Replicator 2

Price Comparison

Components

Production of Accessories

✔Stratasys Mojo

The printer will automatically create the intermediate elements needed to print the product. Extra elements can be easily removed later.

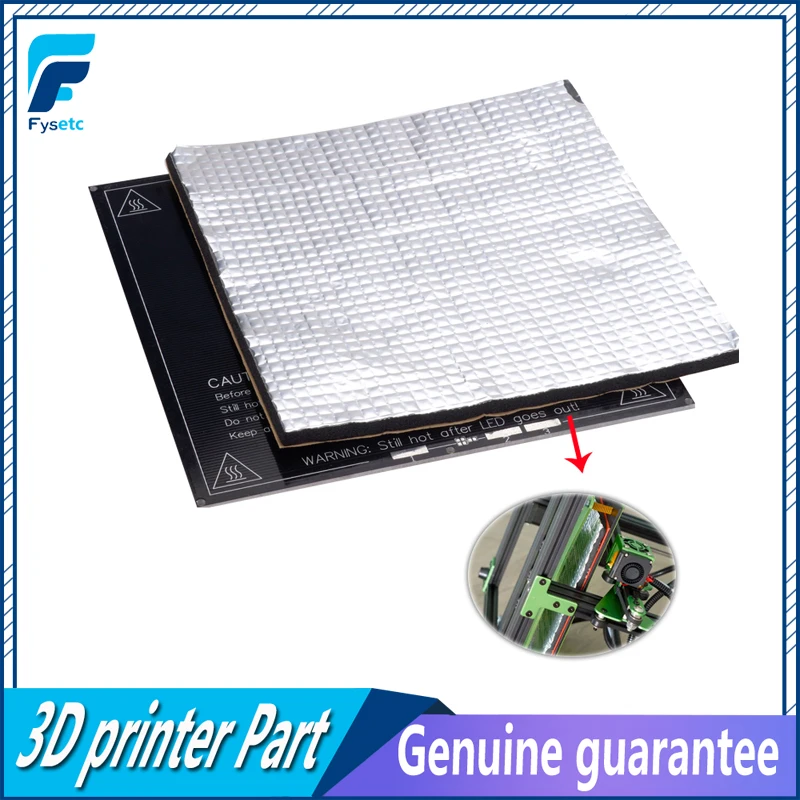

Heated Perforated Bed Available

✖Stratasys Mojo

The Heated Print Bed is designed to keep the bottom of the product warm while the top is being printed. This is necessary for more uniform cooling of the product.

This is necessary for more uniform cooling of the product.

Filament diameter 1.75 mm

✖Stratasys Mojo

The 1.75mm filament is gradually replacing the old 3mm standard. 1.75mm filament is easier to accept by the printer and provides more flexibility in the printing process.

nozzle size

Unknown. Help us offer a price.

The smaller the nozzle, the more detailed the final product. However, if print speed is much more important than detail, large nozzles are preferable.

3D print speed

Unknown. Help us offer a price.

The speed at which 3D objects are printed. Measured in millimeters per second

number of print heads

The more print heads, the more different inks or media types can be used at the same time. The second extruder is required to build the PVA/PLA auxiliary elements around the main ones during printing.

Automatic Platform Calibration

✖Stratasys Mojo

This feature saves time and attempts to set up. However, the level of the perforated platform still needs to be adjusted manually.

Hollow print option available

✖Stratasys Mojo

Hollow print builds a product quickly with minimal materials. With this option you can make drafts before creating solid models, i.e. products for presentation instead of solid functional instances.

Materials

Printing in PLA

✖Stratasys Mojo

Polylactide (PLA) is a popular material in 3D printing because it cools and hardens quickly. Unlike ABS polymer, it is biodegradable and therefore biodegradable.

Prints in full color

✖Stratasys Mojo

These 3D printers, just like conventional 2D printers, mix inks from different cartridges. Combining different inks allows the printer to reproduce the color spectrum so that almost any shade of color can be matched.

Prints in HIPS

✖Stratasys Mojo

The printer is capable of printing in high impact polystyrene (HIPS). HIPS is similar to ABS but uses different solvents (limonene instead of acetone). UPS is easy to paint and glue.

Printing in ABS

✔Stratasys Mojo

The printer prints in ABS (a plastic based on acrylonitrile, butadiene and styrene). It is 30 times stronger than conventional plastic and is most commonly used in 3D printing.

Printed in PVA

✖Stratasys Mojo

Another type of resin used in 3D printing, similar to ABS, is polyvinyl acetate (PVA). It is used to create auxiliary elements for printing, as it can dissolve without a trace.

Prints on paper

✖Stratasys Mojo

The printer is capable of printing on paper. 3D printing in paper involves an additional process: a laser cuts each layer of paper according to a predetermined shape in order to obtain the desired end product. 3D printed paper objects are similar in texture to wood.

3D printed paper objects are similar in texture to wood.

Prints in tree

✖Stratasys Mojo

The printer is capable of printing in tree. Usually, the printing process uses a mixture of wood components and a binder, which, when dried, becomes hard like wood.

number of colors in print

Simultaneous use of various color materials makes it possible to select an exclusive design.

Print sizes

layer thickness

The thinner the print layer, the clearer the design. Layer thickness is often referred to as resolution. Measured in microns.

maximum project size

127 x 127 x 127mm

This is the largest object size that can be output to the printer.

minimum print size

Unknown. Help us offer a price.

This is the smallest volume (cm³) object size that can be output to the printer.

X resolution

Unknown. Help us offer a price.

Maximum possible X-axis resolution, measured in microns.

Y-axis resolution

Unknown. Help us offer a price.

Maximum possible Y-axis resolution, measured in microns.

Z resolution

Unknown. Help us offer a price.

Maximum possible Z-axis resolution, measured in microns.

Connection

has a slot for memory cards

✖Stratasys Mojo

The device has a standard slot for memory cards (SD, MicroSD, etc.), so you can either expand the internal memory with available memory modules, or you can Easily retrieve data such as photos from a memory card.

USB sockets

With more USB sockets, you can connect more devices.

RJ45 ports

Unknown. Help us offer a price.

Help us offer a price.

RJ-45 ports are used for LAN connection. More ports increase the throughput within the network, or provide the ability to connect to multiple local networks. Another advantage: the connection does not disappear in the event of a failure of one of the networks.

has Wi-Fi

✖Stratasys Mojo

The device can connect to Wi-Fi.

Wi-Fi version

Unknown. Help us offer a price.

Wi-Fi versions supported by the device.

Plug and play

✖Stratasys Mojo

The device is set up and ready to use with the supplied software.

Cloud support

✖Stratasys Mojo

Compatibility with Cloud technology enables remote control of devices using smartphones, tablets and other Internet devices.

Functions

Display available

✖Stratasys Mojo

The unit is equipped with an electronic display to present information to the user.

screen size

Unknown. Help us offer a price.

The larger the screen size, the better the user experience.

has a touch screen

✖Stratasys Mojo

You can operate the unit by directly touching objects on the screen with your fingers.

acoustic noise level

Unknown. Help us offer a price.

The device produces acoustic noise during operation. Reducing acoustic noise improves quality.

Non-operating noise level

Unknown. Help us offer a price.

Noise level when not in use.

established designs

Unknown. Help us offer a price.

With 3D designs already installed on the printer, you can start working right away.

Pre-assembled

✔Stratasys Mojo

Since the item is shipped fully assembled, there is no need to build it from parts.

power consumption during operation

Unknown. Help us offer a price.

How much power is consumed by a running device.

Price comparison

Which 3D printers are best?

This page is currently only available in English.

FDM 3D printers, printing technology - 3dprofy

Turch October 21st, 2014

FDM melt modeling technology allows you to create three-dimensional objects through 3D printing. As a consumable, a plastic thread is used, which melts, is fed to the work surface, and de-hardens. This is how the first layer is done, then the process is repeated until a 3D model is created.

Technology features

Building parts based on layers allows you to get parts that have complex geometry and at the same time are distinguished by careful detailing. The only disadvantage of this method is that during melting, the plastic spreads in different directions, which cannot be controlled. Therefore, the models are distinguished by a relief surface, which loses accuracy during processing. On the other hand, only on the basis of this technology it is possible to obtain parts that are strong in terms of mechanical and chemical properties.

3D printer for FDM

Based on this device, you can create models and parts based on thermoplastic, which will be strong and durable. Such printing is considered the only professional one that allows you to reproduce three-dimensional three-dimensional models. All 3D printers have a certain design and consist of several elements.

- The printhead is everything. In this element, the main role is played by a heater, which melts the plastic thread and squeezes it out through a nozzle having a small diameter. The filament feed mechanism is called an extruder, and the heating element is called a hot end. For a 3D printer, the filament can be supplied in two diameters - 1.75 mm and 3.0 mm, while the extruder works only with a certain type of diameter, which must be taken into account when selecting the material.

The thread is fed by a special stepper motor and a system of gears and shafts. And a certain speed is maintained by the controller that controls the engine. The temperature of the hot end is controlled by a thermistor.

- To maintain a certain operating temperature, models are equipped with radiators, a fan, and thermal barriers in the form of gaskets made of substances that have low thermal conductivity. The main requirements for gaskets are the ability to withstand high temperatures, resistance to deformation and the absence of harmful substances in the composition.

- Tubes are installed to reduce friction between the plastic filament and the walls of the heating element.

- The nozzle for the 3D printer must be replaced because its hole is clogged and needs to be cleaned. When choosing, consider the pitch and diameter of the thread.

The desktop is everything

The desktop, or platform, is an important part of the printer. It is on it that the formation of the created model takes place. Most often, the platform consists of two plates on which structural elements are securely attached. The top of the table should spring back to avoid mistakes in the process of creating parts. The platform can be made of glass, acrylic, aluminum. To prevent these materials from sticking to the surface of the desktop, it is perforated or a certain composition is applied to it.

Coating materials are those that provide good adhesion and are able to withstand the temperature of the molten thread when the first layers are applied. Capron is often used as a covering material, which is a thin film of polyamide and can withstand temperatures up to 4000 C. In 3D printers, capron is used in the form of a self-adhesive tape that has a width of 5-200 mm. Its segments cover the working surface. Another popular material for FDM printers is blue polypropylene tape, which is highly heat resistant.

Despite the wide choice of materials, very often they do not adhere well to the surface. To achieve better grip, the platform is heated - for this, the lower part of the working table is equipped with an electric heater. By heating, the temperature gradient between the layers can be further reduced, since the layers can be deformed when they collide with air. 3D printing requires the head and worktable to be in motion. For this, special mechanisms are used that ensure the movement and accuracy of this process.

What about the temperature?

A feature of the 3D printer is that as soon as a layer is created, it immediately undergoes deformation. To avoid this, supporting supports and structures are used. The second way to solve this problem is to ensure that the plastic hardens quickly through fan cooling. That is why FDM printing is considered dual: on the one hand, you need to instantly cool the plastic that comes out of the nozzle, on the other hand, you need to take your time and do the work evenly to avoid technical deformations.

An important technical role is played by the frame, on which all the elements of the printer are located. Often it is created from an inexpensive aluminum profile or ordinary threaded rods. Sometimes the frame is made of plexiglass, plywood, but it is difficult to talk about the durability of such products.

Control electronics of the 3D printer

All printer components are controlled by the controller, which receives the program in the form of a special code. When generated, it describes the future model. Most of the controllers work on the Arduino platform, which has an open architecture and program code. Special modules are used to manage printer devices and receive data. Some 3D printers are controlled by a computer, some models have a control panel - it allows you to fully control the printing process. The controller itself and the print head are connected by wires. The printer is powered by power, and since printing takes quite a long time, it is very important to keep it running smoothly.

Popular printers for FDM technology

The Mojo is one of the most popular printers, because it is compact and easy to use, capable of printing models in excellent quality and with clear detail.