Mimaki 3d color printer

Mimaki 3D printer | MIMAKI

SCROLL

Superior 3D print results

compared with conventional methods

Mimaki offers the world's first 3D printer

with 10 million colors

and UV-curable inkjet printing

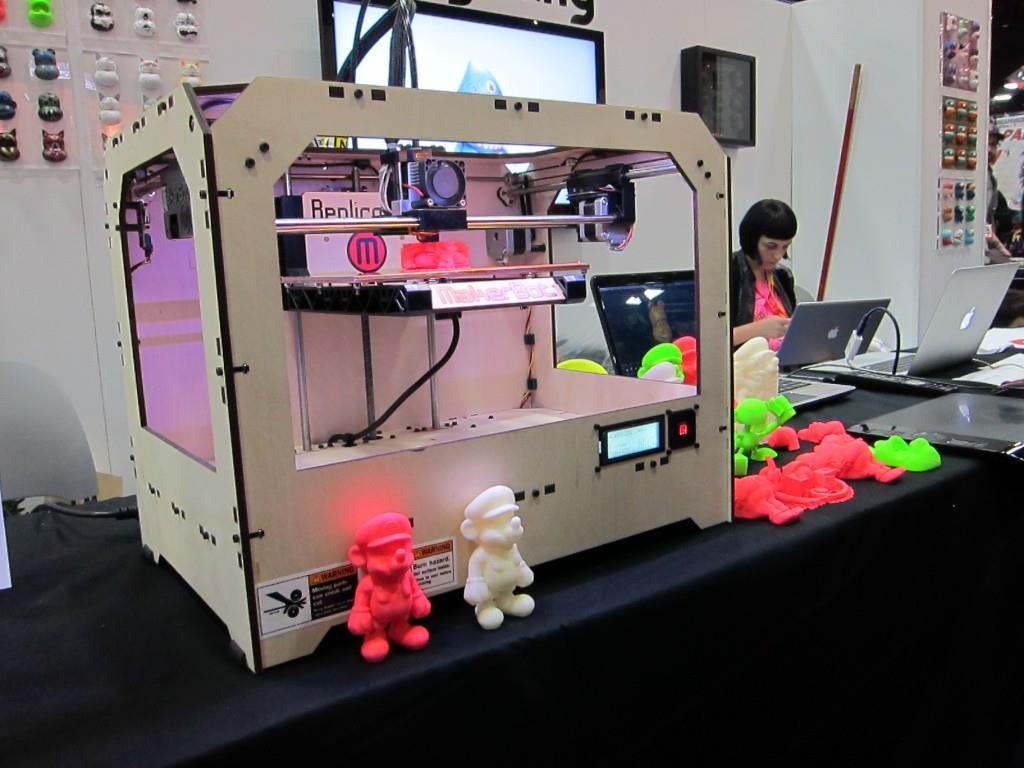

The 3D printer market growth continues to spread globally upon commencing from North America and Europe and its application is mainly entered in manufacturing industry and then penetrating to education, construction and medical business segment.

Mimaki 3D printer [3DUJ-553] has achieved the full color modeling with the capability of world first (*1) over 10 million colors based on our developed technology of 2D inkjet printers of professionals use.

We will propose a new business utilizing [3DUJ-553] as its having rich color expression is better suited to create a final product such as real object sign or building model, of which an extra coloring has been difficult after the completion of modeling.

Mimaki proposal for Sign Graphics market

Object signage by 3D printer is considerably effective to be remarked and understood easily with its presence by the combination of realistic 3 dimensional motif and 2D image.

[3DUJ-553] can express by more than 10 million different full colors and as well enhance the color reproducibility with the color adjustment employing the color profiles.

Mimaki proposal for Industrial Products market

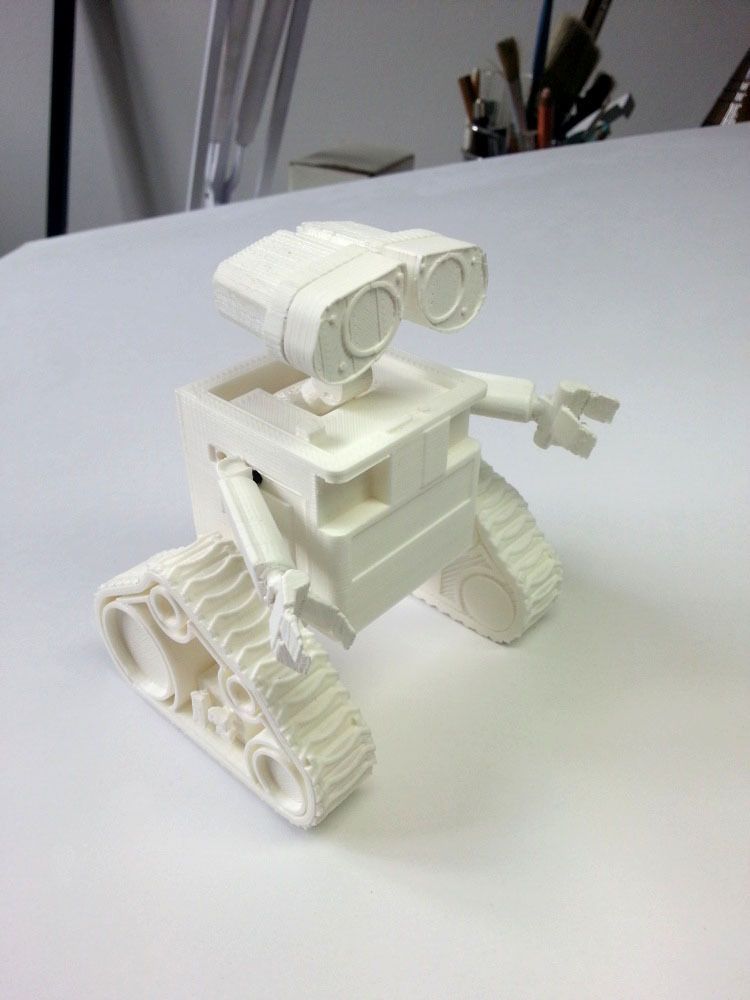

Mimaki 3D printer, [3DUJ-553] can satisfy professionals exacting requirement to make full color and fine modeling of strong preference into the details and final products, for example, figure, 3D map and mock-up. And post processing like over coating and attachment of screws are also applicable.

Features of Mimaki 3D printer

Features of Mimaki 3D printer

Features of Mimaki 3D printer

Beautiful color expression

Beautiful color expression

Elaborate modeling expression

Elaborate modeling expression

Ink property

Ink property

Specifications

Specifications

USER STORIES

USER STORIES

Features of Mimaki 3D printer

Beautiful color expression

Elaborate modeling expression

Ink property

Specifications

USER STORIES

Sample gallery

Sample gallery

Sample gallery

Inquiry

Mimaki full color 3D printer [3DUJ-553] applied the UV curable inkjet system utilized Mimaki's original technology, which was amassed in our development and manufacturing for inkjet printers of professional use during a long period.

To learn more about our products, specifications and quotation, please contact below.

Inquiry contact form

*1: Survey as of August, 2017 by Mimaki Engineering

We use cookies in order to offer you a better experience in our website. By your continuation of browsing, we will regard that you have agreed to the use of cookies. More info

3DUJ-553 - Mimaki Europe

The world’s first full-color 3D UV-curable inkjet printer

With the Mimaki 3DUJ-553 UV LED printing solution we introduced a brand new approach to 3D printing. This is the world’s first 3D printer with over 10 million colours, enabling the production of 3D objects, eliminating the time-consuming finishing and the risk of damaging small detailed parts.

|

|

|

|

|

|

|

|

|

|

|

Applications

Prototypes, tools (making industry), architecture models, offshore & ship presentation models, toys, 3D art, 3D signing, accessories and more.

Previous Next

Specifications of 3DUJ-553

| Item | 3DUJ-553 | |

| Modelling method | UV curable inkjet | |

| Available colour number | Full colour/More than 10 million different colours | |

| Print head | On-demand piezoelectric print head (8 heads inline) | |

| Ink | Type | Modelling ink MH-100(C,M,Y,K, White, Clear) Support material ink SW-100 |

| Colour | C,M,Y,K, White, Clear, Support material | |

| Tank volume | C,M,Y,K:3L White, Clear, Support material 5L | |

| Supply style | Pump C,M,Y,K:1L bottle White, Clear, Support material 4.  8L bottle 8L bottle | |

| Available modelling area (W×D×H) | 508×508×305mm (20x20x12in) | |

| Minimum layer pitch | 20㎛ | |

| Modelling time (Modelling 100×100×100mm(W×D×H) object) | High speed mode: 14.4 hours 600x300x600dpi (42㎛) Standard mode: 17.0 hours 600x300x800dpi (32 ㎛) High definition mode: 25.7 hours 600x300x1270dpi (22 ㎛) | |

| 3D data format | STL, OBJ, VRML, PLY, 3MF | |

| Software (Standard accessories) | Layout software (Mimaki 3D Link) | |

| Interface | Ethernet 1000BASE-TX | |

| Power | Single phase AC 100-120V/220-240V±10% 50/60Hz±1Hz | |

| Safety standard | VCCI Class A/FCC Class A/ Compliant with UL60950, ETL / CE Marking (EMC, Low Voltage Directive)/CB Report/ RoHS/REACH | |

| Outside dimensions (W×D×H) | 2. 250×1.500×1.550 mm (88,6×59,1×61,0 inch) 250×1.500×1.550 mm (88,6×59,1×61,0 inch) | |

| Weight | 600 kg (1.322,8 lb) (mounted ink weight incl.) | |

* Specifications, designs and dimensions stated in this list may be subject to change without notice due to technical improvement etc.

Supplies for 3DUJ-553

| Supplies | Type | Quantity |

| Ink | MH-100 (CMKY) | 1L bottle |

| MH-100 White | 4,8L bottle | |

| MH-100 Clear | ||

| Support material | SW-100 |

Features of 3DUJ-553

More than 10 million colours

With its UV LED curing method, the 3DUJ-553 is able to print objects layer by layer applying UV ink using CMYK, white and clear at a layer thickness of 22, 32 or 42 microns, producing a finished object of exquisite quality. UV LED curing also applies minimal heat to the object. The printer exhibits fast start-up times and minimal power usage, reducing the overall running costs.

UV LED curing also applies minimal heat to the object. The printer exhibits fast start-up times and minimal power usage, reducing the overall running costs.

Colour profiles

The 3DUJ-553 is the world’s first 3D printer to take advantage of colour profiles. This means not only accurate colour from the printer but also allows the development of proofing profiles for accurate viewing of colour on a calibrated monitor. This ensures accurate colour simulation before printing even begins, saving time and reducing waste.

By implementing a color proofing profile created by [MPM3] (option) to Adobe Photoshop, the colour can be simulated and checked on your monitor. The colours of the final printed object will be realistic and will approach the colours that were displayed on your monitor. By using proofing profiles, reduction of colour adjusting is a huge benefit saving your precious time. Just print your coloured object in one “shot”.

UV Inkjet method

UV curable ink is hardened with UV light. Mimaki’s technology involves laying down successive layers of UV curable ink, one on top of the other, until the desired model is completed.

Mimaki’s technology involves laying down successive layers of UV curable ink, one on top of the other, until the desired model is completed.

Lamination and colour fixing

3D data is sliced and printing starts simultaneously for ink and support material until the model is completed.

Add translucency with clear ink

Using clear ink adds an additional effect to 3D printed objects, especially if the object is illuminated. The combination of clear and CMYK inks opens the door to increased designer creativity.

Excellent post-process performance

The inks used by the 3DUJ-553 contain an acrylic resin that produces hardness equivalent to ABS plastic. This means that overcoating, drilling and attachment of screws can be accomplished without damaging the object. It also adds superior weather resistance, surface smoothness and strength to the object.

Water-soluble support material

The 3DUJ-553 uses a water-soluble support structure which can be washed away with water. Removal of the support material using water, enables highly detailed models to be created without damaging the objects during this removal process.

Stable operation

Continuous ink flow is made possible by using an ink sub-tank installed in the print head. This prevents pigment deposits, air bubbles and ensures ink is emitted correctly. Additionally, this prevents missing nozzles and maintains a stable print environment and keeps the up-time of the printer extremely high.

Camera for monitoring of modelling status

The 3DUJ-553 has a monitoring camera that enables users to remotely observe the modelling status.

Downloads

Brochure

One Pager

Product video

Here you will find some Frequently Asked Questions about the 3DUJ-553.

Please contact us through our contact form (above request info button) if you would like to receive more information about our 3D printer.

Specifications of Mimaki 3D printer

What is the printing method?

UV curable inkjet printing. The printed layers of UV curable acrylic resin inks create an object.

What material is used to create an object?

Mimaki genuine acrylic resin ink.

Is the support material necessary for creating an object?

Yes, Mimaki 3D printer uses the support material.

Is it possible to reuse the support material?

No, it is not possible.

What is the layering pitch?

High speed mode: 42 μm, Standard mode: 32 μm, High definition mode: 20 μm

Is the ink reusable when the modeling is failed?

No, it is not reusable.

What is the expiry of ink?

It is about one year after manufacturing.

Is it available to execute multiple data of modeling?

It is available to have modeling by locating the multiple data by layout software.

Software

Is the software developed by Mimaki?

Layout software is developed by Mimaki.

Layout software: [Mimaki 3D Link]

Is [Mimaki 3D Link] an optional software?

No, it is bundled to the printer.

What is the availabe 3D data format?

It is STL, OBJ, VRML, PLY and 3MF.

Is it possible to create a 3D data by [Mimaki 3D Link]?

No, it is not possible.

3D model

What is the available size of modeling?

The available modeling area is X=508 mm (20 in), Y=508 mm (20 in) and Z=305 mm (12 in).

As modeling is including the support material area, the modeling size will be varied depending on its shape.

Is it possible to make an object hollow?

Yes it is possible depending on the data.

How much weight will it be while modeling with the size of 500 x 500 x 300mm?

When the modeling is made in cuboid, it will weigh 80 kg approx.

Mimaki Announces 10 Million Color Desktop Color 3D Printer

News

Mimaki has announced the 3DUJ-2207 color photopolymer 3D printer, which fits on a tabletop and is capable of reproducing over ten million colors.

Mimaki is a well-known manufacturer of office equipment, but the Japanese company entered the market of additive technologies quite recently, three years ago. More precisely, she not so much entered as kicked open the door, immediately releasing a full-fledged 3DUJ-553 color 3D printer ( in illustration below ), which relies on photopolymer resin deposition technology and offers full color reproduction in advanced CMYK+W autotype with over ten million shades. Before Mimaki, only Stratasys Corporation could boast of such equipment with its line of 3D printers using PolyJet technology, which includes color options.

Before Mimaki, only Stratasys Corporation could boast of such equipment with its line of 3D printers using PolyJet technology, which includes color options.

Just six months after the premiere, the heads of 3D Systems and its 3D printers turned pale at the same time when the new 3DUJ-553 pushed the gypsum additive systems of the American company into the arsenal of i.materialise, one of the leading additive online services, which appreciated the opportunity 3D prints of whistles and gnomes in higher resolution and richer colors.

But so far we've only been talking about large-scale additive systems with price tags measured in hundreds of thousands of dollars. And now Mimaki has gone ahead, announcing a conditionally desktop system (after all, 140 kilos and almost a meter in height), completely similar in capabilities to older brothers, with the exception of two factors - the size of the construction area, reduced from 508x508x305 to 203x203x76 mm, and the cost .

The 3DUJ-2207 3D printer is tentatively valued at about forty thousand euros, which is about five times cheaper than 3DUJ-553 - the amount is still considerable, but much more acceptable for small, medium-sized businesses and rich Pinocchio. In addition, a new 3D printer will not have to allocate a separate workshop or evict the mother-in-law. The closest competitor is the Stratasys J55 system, announced this spring - also quite compact, but about twice as expensive (about $ 100 thousand) and reproducing "only" half a million shades.

“Here at Mimaki, we never stop developing breakthrough technologies and constantly challenge ourselves to look even further, constantly looking for ways to accelerate the adoption of additive technologies and the development of the industry as a whole. Our new 3DUJ-2207 3D printer is a prime example of this. We have already raised the bar in 3D printing with the release of the world's first 3D printer with over ten million colors, and now with the launch of our new 3D printer 3DUJ-2207, we are bringing the same palette to many new customers, which, in turn, means new applications and faster adoption of 3D printing technology in general,” said Danna Drion, Senior Marketing Manager at Mimaki Europe.

So far, the new system is being demonstrated at the online exhibition Formnext Connect, but the developers promise to release the 3DUJ-2207 for sale as early as January next year. Additional information is available on the official Mimaki website at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected]

Even more interesting articles

eight

Subscribe to the author

Subscribe

Don't want

The F2 Gigantry system will allow manufacturing companies, in particular aerospace companies, to...

Read more

5

Subscribe to the author

Subscribe

Don't want

Anodizing is a process aimed at creating protective oxide layers on the surfaces of products. ..

..

Read more

83

Subscribe to the author

Subscribe

Don't want

Collaboration 3D

We are pleased to present you our joint development with Speci...

Read more

3D printer Mimaki 3DUJ-553 - Studia3D

3D printer Mimaki 3DUJ-553

12000000.00 ₽

Available for pre-order

-

Description

General Information

The Mimaki 3DUJ-553 3D Printer is the world's first 10 million+ color printer with the company's professional 2D inkjet technology.

Mimaki 3DUJ-553 with its rich palette is suitable for creating final products - models of real objects or buildings. Mimaki 3DUJ-553

3D printer adopts UV ink curing method for inkjet printing. Modeling is done with UV inks (C, M, Y, K, white, transparent) and includes printing, curing and overlay layer by layer. The color is not applied during the final processing, but is modeled using color inks, which ensures a subtle reproduction of the entire palette of colors. Color ink modeling (CMYK, white, transparent) covers 84% of the Fogra 39 color gamutL and 90% SWOP gamma. When modeling with color ink with a high degree of transparency, external light is reflected from the surface of the white ink layer, which gives good color modeling against the background of the white layer.

The color is not applied during the final processing, but is modeled using color inks, which ensures a subtle reproduction of the entire palette of colors. Color ink modeling (CMYK, white, transparent) covers 84% of the Fogra 39 color gamutL and 90% SWOP gamma. When modeling with color ink with a high degree of transparency, external light is reflected from the surface of the white ink layer, which gives good color modeling against the background of the white layer.

With original waveform control technology and high-precision ejection technology, the placement of ink droplets in the 3D printer has achieved its goal. This high precision makes it possible to create complex modeling objects focused on detailed finishing.

A water-soluble substance is used as a support material. The substrate is easily washed off, soaking in water. This excludes damage to the object (scratches, cracks) that can occur when cutting or tearing off the substrate from the object.

The Mimaki 3DUJ-553 3D printer uses ink curing by UV irradiation. The UV LEDs of the light source have almost no thermal effect on the object, and no start-up time is required for illumination. Long service life and energy saving can reduce operating costs. The Mimaki 3DUJ-553

The UV LEDs of the light source have almost no thermal effect on the object, and no start-up time is required for illumination. Long service life and energy saving can reduce operating costs. The Mimaki 3DUJ-553

is the world's first inkjet 3D printer equipped with an ink circulation print head. Stable ink ejection of the print head prevents ink pigment from settling. The ink circulation system removes air bubbles that cause clogged nozzles, maintaining optimal ink spatter.

The printer is equipped with a video camera that allows the user to monitor the status of the printer and print. This eliminates the overspending of material for modeling.Characteristics:

Manufacturer: Mimaki

Type: UV

Purpose: 3D printing

Printing type: color

Printing technology: UV curing inkjet

Printing speed: 10.8 cc/s

Number of colors: 6

Print resolution : 600 x 300 x 1270 DPI

Color scheme: C M Y K Wh Cl

Materials used: UV ink

Workspace size: 508 x 508 x 305 mm

Interface: Ethernet

Electrical requirements: 100-120V/220-240V, 50/60Hz

Software: Layout software (Mimaki 3D Link)

Dimensions: 2130 x 1335 x 1320 mm

Weight: 590 kg (with ink) -

Parts

Product features

Weight 550kg Dimensions 213 × 133.

Learn more