Micro 3d printing

Micro 3D printers and micro AM (µAM)

What is micro 3D printing?

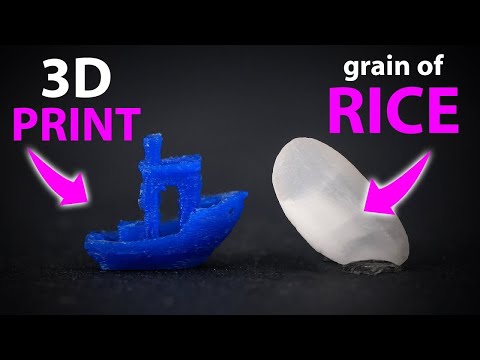

Micro 3D printing is the practice of 3D printing parts with micro-sized features. Spanning multiple technologies including microstereolithography and micro laser sintering, micro 3D printing requires the use of micro 3D printers capable of achieving incredibly fine resolutions — sometimes below the micron/micrometer (μm) level.

Micro 3D printed parts by Incus. Source: IncusAlso known as 3D microfabrication, micromanufacturing, or micro additive manufacturing (µAM), micro 3D printing may be considered a form of microfabrication, a catch-all term that also includes micromachining and semiconductor manufacturing processes like ion etching. Micro 3D printing is a comparatively new technology and is only now offering an alternative to these established processes.

A small number of micro-precision 3D printing technologies, such as two-photon polymerization, are also forms of nanofabrication technology since they can produce incredibly small structures with features measurable in nanometers (units one thousand times smaller than a micron).

This guide covers all the main micro 3D printing technologies and their applications, in addition to providing an overview of the market’s leading µAM systems.

Micro 3D printing technologies

Micro laser sintering

At the macro level, selective laser sintering (SLS) is a form of metal additive manufacturing in which a computer-controlled laser beam sinters particles of metal powder to make a 3D shape. A moving platform allows the printer to move from one 2D layer to the next.

Some micro 3D printers use micro laser sintering, a form of high-precision metal 3D printing, to make very fine-featured metal structures. The technology is similar to SLS, but with up to three main differences: a smaller laser spot size, a platform that can move in smaller increments and therefore produce thinner layers, and powders with a small-diameter particle size.

The ability to produce micro metal parts makes micro laser sintering particularly useful in areas like semiconductor production, aerospace, and watchmaking.

Microstereolithography

Microstereolithography or micro SLA is a form of stereolithography adapted for micro 3D printing. Like SLA, the high precision micro 3D printing technology uses a photosensitive polymer resin which is selectively cured, layer by layer, using a high-precision light source such as a laser.

A related technology is projection microstereolithography (PµSL), which uses UV projections instead of a laser and can cure entire 2D layers at once. In this way, PµSL resembles the macro 3D printing process of digital light processing (DLP) as much as stereolithography.

Micro SLA produces micro parts that may be used in industries such as medicine, while clear resin parts can be used in areas like microfluidics and microoptics.

Two-photon polymerization

A form of multiphoton lithography, two-photon polymerization (2PP) is a maskless direct laser writing technology capable of achieving incredibly high resolution, often well below the micron level.

The 2PP process works a bit like SLA and other photopolymerization processes, only with a much more localized area of polymerization. During the process, a photoinitiator molecule within a photoresist absorbs two photons simultaneously. This initiates polymerization around a laser beam spot, creating a single voxel. This nanofabrication process is repeated until a 3D shape is built out of multiple voxels.

Materials for two-photon polymerization include acrylic and epoxy resins, and applications include medical microdevices, microoptics, and material engineering.

Other µAM technologies

Novel methods of microfabrication are constantly in development. Some less common micro-precision 3D printing technologies include:

- Electrochemical deposition

- Nano ink jetting

- Glass micro 3D printing

- Metal lithography

The best micro 3D printers in 2022

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| Microlight3D | µFAB-3D | ⌀ 16 x 6 mm | France | $ 120,000100 000 €106,445 £17,886,720 ¥ | Quote |

| Incus | Hammer Lab35 | 89.6 × 56 × 120 mm3.53 × 2.2 × 4.72 in | Austria | $ 277,000235 000 €245,710 £41,288,512 ¥ | Quote |

| Femtika | Laser Nanofactory | – | Lithuania | $ 415,000350 000 €368,122 £61,858,240 ¥ | Quote |

| 3D MicroPrint | DMP60 series | ⌀ 60 x 30 mm | Germany | upon request | Quote |

| BMF | microArch P130 | 4 × 3 × 10 mm0.16 × 0.12 × 0.39 in | United States | upon request | Quote |

| Exaddon | CERES | ⌀ 1 x 1 mm | Switzerland | upon request | Quote |

| FEMTOprint | FEMTOprint Platform | – | Switzerland | upon request | Quote |

| Fabrica Group | FABRICA 2. 0 0 | 50 × 50 × 100 mm1.97 × 1.97 × 3.94 in | Israel | upon request | Quote |

| Multiphoton Optics | MPO100 TPP | 100 × 100 × 100 mm3.94 × 3.94 × 3.94 in | Germany | upon request | Quote |

| Nanogrande | MPL-1 | – | Canada | upon request | Quote |

| Nanoscribe | Quantum X shape | – | Germany | upon request | Quote |

| UpNano | NanoOne | 120 × 100 × 40 mm4.72 × 3.94 × 1.57 in | Austria | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Material | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Microlight3D | µFAB-3D | ⌀ 16 x 6 mm | Bio-ink/organic | France | $ 120,000100 000 €106,445 £17,886,720 ¥ | Get a quote |

| Incus | Hammer Lab35 | 89.6 × 56 × 120 mm3.53 × 2.2 × 4.72 in | Metal | Austria | $ 277,000235 000 €245,710 £41,288,512 ¥ | Get a quote |

| Femtika | Laser Nanofactory | – | – | Lithuania | $ 415,000350 000 €368,122 £61,858,240 ¥ | Get a quote |

| 3D MicroPrint | DMP60 series | ⌀ 60 x 30 mm | Metal | Germany | upon request | Get a quote |

| BMF | microArch P130 | 4 × 3 × 10 mm0.16 × 0.12 × 0.39 in | – | United States | upon request | Get a quote |

| Exaddon | CERES | ⌀ 1 x 1 mm | Metal | Switzerland | upon request | Get a quote |

| FEMTOprint | FEMTOprint Platform | – | – | Switzerland | upon request | Get a quote |

| Fabrica Group | FABRICA 2. 0 0 | 50 × 50 × 100 mm1.97 × 1.97 × 3.94 in | Ceramic | Israel | upon request | Get a quote |

| Multiphoton Optics | MPO100 TPP | 100 × 100 × 100 mm3.94 × 3.94 × 3.94 in | – | Germany | upon request | Get a quote |

| Nanogrande | MPL-1 | – | Metal | Canada | upon request | Get a quote |

| Nanoscribe | Quantum X shape | – | – | Germany | upon request | Get a quote |

| UpNano | NanoOne | 120 × 100 × 40 mm4.72 × 3.94 × 1.57 in | – | Austria | upon request | Get a quote |

Overview of the best micro 3D printers in 2022

Femtika is a Lithuanian company spun off from the Vilnius University Laser Research Center that specializes in hybrid nanofabrication systems.

The Femtika Laser Nanofactory is a hybrid additive and subtractive nanofabrication machine that combines multiphoton polymerization with selective laser etching and laser ablation. Its main advantages are multimaterial fabrication — of, for example, etched glass microchannels with printed polymer nano filters — and support-free printing.

Its main advantages are multimaterial fabrication — of, for example, etched glass microchannels with printed polymer nano filters — and support-free printing.

Femtika’s hybrid system is designed for industrial nanofabrication R&D in areas like biotech, medicine, microoptics, and photonics, as well as for academic research.

Contact manufacturer Get a quote Add to comparison

Multiphoton Optics, a subsidiary of Heidelberg Instruments Mikrotechnik based in Germany, is a two-photon polymerization specialist.

The company’s Multiphoton Optics MPO100 nanofabrication printer provides sub-micron resolution and is designed for polymer printing on substrates of various shapes and materials, including active devices like LEDs. The system is also capable of laser ablation.

Built for academic and industrial users, the MPO100 has applications in microoptics, photonics, micromechanics, and biomedicine.

Contact manufacturer Get a quote Add to comparison

German company Nanoscribe is a nanofabrication specialist that has developed technology based on two-photon lithography.

The Nanoscribe Quantum X nanofabrication printer combines two-photon lithography with grayscale lithography, providing sub-micron resolution and precise voxel control.

The system can fabricate biomedical components and bioinspired microenvironments suitable for cell studies, as well as lab-on-a-chip structures for the study of neuronal networks, cell growth, migration, or stem cell differentiation. Other printable parts include microscale biomedical instruments (e.g. microneedles), microfluidic systems, and photonic interconnects.

Contact manufacturer Get a quote Add to comparison

Austria’s UpNano is a two-photon polymerization company that has developed two versions of its nanofabrication micro 3D printing system.

The UpNano NanoOne is a 2PP printer with an especially high throughput of up to 200 cubic millimeters per hour and a resolution of 0.17 microns. The system is suited to tasks in microoptics, microfluidics, micromechanics, and medical engineering.

UpNano has also developed the NanoOne Bio, a micro 3D bioprinter that can print a gelatin-based hydrogel to make structures that mimic the microenvironment of cells.

Contact manufacturer Get a quote Add to comparison

French company MicroLight 3D makes two-photon polymerization 3D printers compatible with polymers and biomaterials, building on 15 years of research at the University of Grenoble Alpes (UGA).

The company’s µFAB-3D is a 2PP nanofabrication system with a resolution of 0.2 microns, enabling the printing of microstructures and nanostructures with very smooth surfaces that do not require post-processing. It is available as a basic model or as a customized system with user-specific features.

The µFAB-3D can be used in areas like microoptics, microfluidics, cell biology, and metamaterials.

Contact manufacturer Get a quote Add to comparison

Canadian microfabrication specialist Nanogrande is one of a handful of companies making 3D printing technology for micro metal parts.

The Nanogrande MPL-1 uses a patented form of laser sintering technology that Nanogrande calls Power Layering Technology.

Compatible with several metals including titanium, platinum, and gold, the micro 3D printer is suitable for applications in watchmaking, jewelry making, electronics, and mold tooling.

Contact manufacturer Get a quote Add to comparison

Switzerland’s FEMTOprint is a company unique in its goal of creating micro 3D printers capable of fabricating glass microdevices.

The FEMTOPRINT platform uses a light source to modify the refractive index and density of the material, enabling the production of sub-micron glass structures usable in fields like microoptics, microfluidics, electronics, and micromolding.

FEMTOprint offers microdevice R&D, prototyping, and production services, in addition to selling its micro 3D printing platform to academic and industrial users.

Contact manufacturer Get a quote Add to comparison

Exaddon, based in Switzerland, is a metal micro 3D printing company spun off from biotech company Cytosurge AG.

The Exaddon CERES uses electrochemical deposition (an ion tip pushes out tiny quantities of ion ink which are transformed into solid metal by a reduction reaction) to fabricate parts at sub-micron resolution. The machine can also locate substrates with sub-micron accuracy to enable direct printing onto other micro components.

The ability of the CERES to print onto substrates is useful in brain-machine interfaces, semiconductor surface modification, and in high-frequency communications components, e.g. microneedles on a chip.

Contact manufacturer Get a quote Add to comparison

Based in Israel, micro AM company Fabrica Group (ex Nanofabrica) has developed its own Micro Adaptive Projection technology, a form of micro digital light processing (DLP).

The company’s 3D printing system, the FABRICA 2.0, moves its build plate through a vat of photosensitive resin in increments of 1 micron, while the XY accuracy of its projection system is also 1 micron. Materials include an ABS-like resin and a ceramic-filled resin.

A relatively large build volume allows for the simultaneous microfabrication of many micro parts, allowing users to use the FABRICA 2.0 for prototyping or mass production.

Contact manufacturer Get a quote Add to comparison

Boston Micro Fabrication, a micro 3D printing company based in Massachusetts, develops 3D printing hardware and provides micro AM services.

The company’s BMF microArch P130 uses a DLP-like technology called Projection Micro Stereolithography (PµSL) and offers an optical resolution of 2 microns. It is compatible with BMF materials — including a high-temp resin and a biocompatible resin — and third-party materials. The microArch S130 offers a larger build envelope.

BMF’s micro-precision 3D printer has uses in electronics, microfluidics, medical device production, and elsewhere.

Contact manufacturer Get a quote Add to comparison

Germany’s 3D MicroPrint was founded via a collaboration between EOS and 3D-Micromac and focuses on micro laser sintering for the microfabrication of metal parts.

The 3D MicroPrint DMP60 series comprises three micro laser sintering systems: the DMP60 (nonreactive materials), the DMP63 (nonreactive and reactive; high-power laser option), and the DMP64 (highest resolution). The machines use an infrared fiber laser and an inert argon atmosphere.

3D MicroPrint says its systems are typically used by those in medicine, automotive, aerospace, semiconductor and MEMS production, energy and chemical, watchmaking, and jewelry making.

Contact manufacturer Get a quote Add to comparison

Incus, an offshoot of ceramic 3D printing company Lithoz based in Austria, is a metal 3D printing company that has developed a technology called Lithography-based Metal Manufacturing (LMM).

LMM, a photopolymerization process in which metal powder is dispersed throughout a photosensitive resin and selectively polymerized by a light source, is the foundation of the plug-and-play Incus Hammer printer. With part and material quality comparable to metal injection molding (even without post-processing), the Hammer offers wide material compatibility and industrial scalability.

Incus says its 3D printer — which can print non-flowable and non-weldable metals, including titanium and precious metals — has applications in aerospace, energy, medical, automotive, and jewelry making.

Contact manufacturer Get a quote Add to comparison

Micro 3D printing applications

Microfabrication and nanofabrication applications span a range of industries and areas of research, from electronics to lab-on-a-chip microfluidics.

Electronics

Miniaturization and lightweighting are a high priority in the electronics industry, and micro 3D printing enables the production of tiny electronics components like micro antennae, RF devices, and electrical contacts.

Some micro 3D printers can also print directly onto substrates such as LEDs and photodiodes, reducing the need for the assembly of micro components.

Aerospace & automotive

Micro 3D printing technology is becoming more commonplace in both the aerospace and automotive industries, where micro and nanoscale components have many uses.

One area of µAM receiving a lot of attention is the development and production of novel sensors that can detect pressure, temperature, and humidity — all of which require control and monitoring within vehicles.

Medical

The medical and healthcare sector can benefit from the use of microfabrication systems, both in clinical and research settings.

Many microoptics and microfluidics applications overlap with medicine, while microfabrication is also being used to develop micro drug delivery devices and biomedical instruments like microneedles and microporous membranes. Other medical applications include cell-sized micro-robots.

Metamaterials

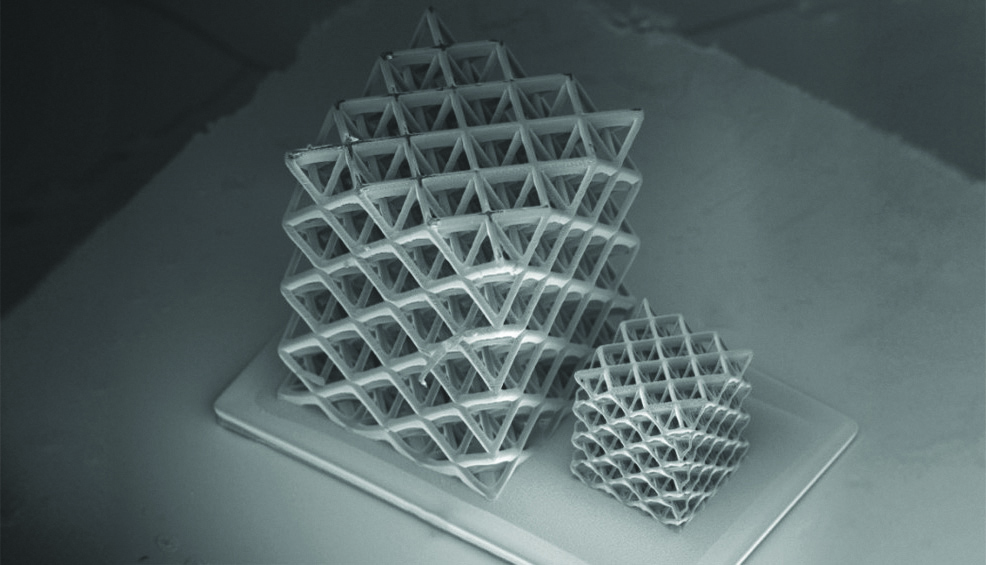

A key application for microfabrication is the development and production of meta-materials or microstructures.

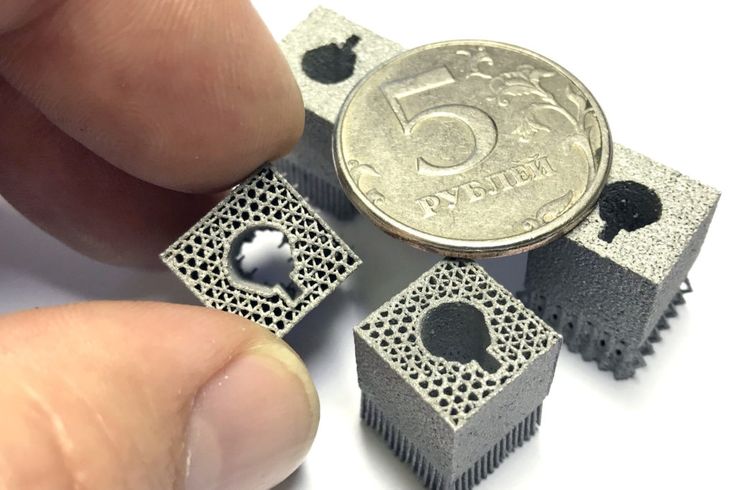

3D printed metamaterials are microstructures with highly sophisticated internal patterns that affect the physical behavior — the elasticity and resistance, for example — of the structure as a whole. These patterns, which can be generated automatically using topology optimization software, often take the form of lattices.

These patterns, which can be generated automatically using topology optimization software, often take the form of lattices.

Printed metamaterials are used in mechanical engineering, aerospace, sound insulation, and other areas.

Metamaterial structure 3D printed with Nanoscribe systems by T. Frenzel at the Karlsruhe Institute of Technology. Source: NanoscribeMicrooptics

Microfabrication technologies that produce finely detailed and smooth-surfaced polymer structures are often suitable for the production of microoptics: optical systems typically measuring between a micron and a millimeter in size.

3D printed microoptics include micro-lenses, micro-prisms, compound lens systems, metalenses, and freeform optics. These can be used in optical telecom equipment, consumer electronics, and material processing equipment.

Freeform fiber-to-chip coupler 3D printed with Nanoscribe’s Photonic Professional GT by H. Gehring, W. Hartmann, W. Pernice et al. , University of Münster. Source: Nanoscribe

, University of Münster. Source: NanoscribeMicrofluidics

Microfluidics is a field of science focused on the manipulation of tiny quantities of fluids, usually through precisely engineered channels. It has practical applications in areas like lab-on-a-chip technology, inkjet printing, and micro-thermal technologies.

Micro 3D printers can be used to fabricate microfluidic systems comprising extremely narrow fluid channels — which can be printed either directly or as masters (printing the would-be hollow area and molding around it) — as well as other microfluidic elements such as filters, nozzles, and capillary pumps.

Micro 3D printing vs comparable technologies

Micro 3D printing may be seen as an alternative to more established microfabrication processes like CNC micromachining and micro injection molding. However, these micro-precision technologies work in different ways and have different strengths and weaknesses.

CNC micromachining

CNC machining is a manufacturing process in which a cutting tool removes material from a workpiece according to computer instructions. Most CNC machines have minimal tolerances of around 50 microns, but CNC micromachining allows for much greater precision.

Many micro CNC machines (usually 5-axis machining centers, wire EDM, or sinker EDM machines) are capable of achieving tolerances below one micron, making micromachined parts comparable in scale to parts printed using micro 3D printers.

Advantages of CNC micromachining include a wide range of material options, especially metals, and the ability to machine micro features on macro parts.

Common micromachined parts include miniature gears, fiber optic components, waveguides for microwaves, microfluidic systems, micro components for medical monitoring equipment, and micro molds.

Micro injection molding

Micro injection molding or micromolding is a manufacturing process used to create very small molded thermoplastic parts with micron tolerances.

Like macro injection molding, the micromolding process involves forcing molten material into a metal mold (which may be produced using micro 3D printing, CNC micromachining, or another microfabrication process).

Although limited to thermoplastics, micromolding is a highly valuable process for fabricating large quantities of identical parts, with a far better production rate than micro 3D printing or CNC micromachining.

The micro injection molding process is widely used for the production of tiny items like microfluidic systems, miniature gears, micro fasteners and connectors, two-shot micro molded parts, and insert molded micro parts.

Micro injection molding can work in tandem with micro 3D printing, with the latter able to produce micro tooling. Small-batch 3D printed tooling can even be printed in non-metal materials using, for example, 2PP or micro SLA printers.

Future possibilities for micro 3D printing

Higher resolutions, new material options, and broader commercial availability are just some of the factors creating new possibilities for micro 3D printing.

Improvements in the technology will open up new possibilities such as 3D printed micro tooling with a lifespan of 1,000+ shots, smaller components for wearable electronics, improved biomedical devices, and faster micro-scale prototyping.

Swiss company Exaddon believes micro 3D printing will play a crucial role in the production of microscale high-frequency communication components for 6G networks, helping to create a “game-changing data transportation infrastructure.”

FAQ

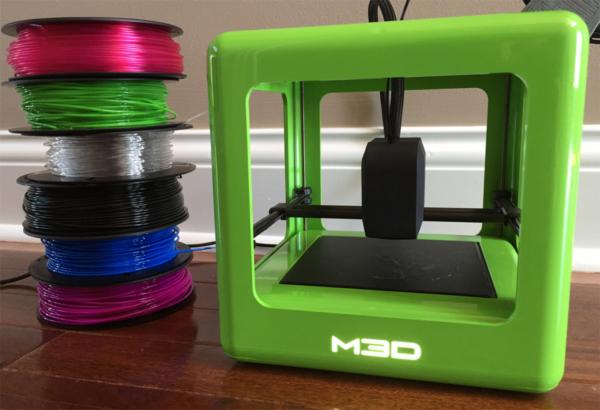

Can regular 3D printers be adapted for micro 3D printing?

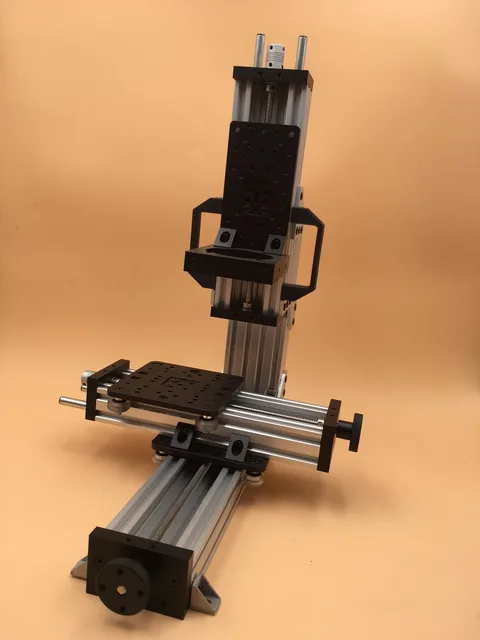

The minimum feature size of macro 3D printers is limited by hardware such as stepper motors (and how finely they can move a build platform or printhead) and lasers (and the size of the laser spot).

Micro-precision 3D printers typically contain highly engineered pieces of hardware designed specifically for the fabrication of microscale parts; their function cannot be replicated by macro 3D printing hardware.

What is microfabrication and what is nanofabrication?

Microfabrication is a generic term for manufacturing processes (micro 3D printing, micromachining, etc.) capable of producing microscale parts, i.e. those measurable on the micron scale. Nanofabrication is another catch-all term, but for manufacturing processes that can produce nanoscale parts, i.e. those measuring well below 1 micron.

Can micro 3D printing be combined with other technologies?

Some micro 3D printers, such as the Femtika Laser Nanofactory, are hybrid systems that can perform substractive microfabrication processes like etching. Others are capable of printing directly onto substrates such as microscale parts that have been made using other manufacturing processes.

Micro 3D printing can also be used to make tiny molds or patterns for use in micro injection molding.

Boston Micro Fabrication - Micro-Precision 3D Printers

ULTRA-HIGH RESOLUTION, ACCURACY, AND PRECISION

Boston Micro Fabrication is the world leader in micro-precision manufacturing solutions based on Projection Micro Stereolithography (PµSL) technology. Many leading companies worldwide are adopting PµSL to 3D print true microstructures with ultra-high printing resolution (2µm~50µm) and printing tolerance (+/- 10µm ~ +/- 25µm).

Many leading companies worldwide are adopting PµSL to 3D print true microstructures with ultra-high printing resolution (2µm~50µm) and printing tolerance (+/- 10µm ~ +/- 25µm).

Micro-precision 3D printing is the optimal manufacturing process for various use cases across a wide variety of industries. BMF empowers companies with complete design freedom to enable the creation of geometries that can be manufactured no other way. The combination of ultra-high resolution, accuracy, and precision allows for more intricate, exact, and replicable parts, at scale and tolerances that match those of micro injection molded parts.

Learn More

Our Capabilities

News

Accelerating Prototyping and Design Testing with Micro 3D Printing

Learn how Tessy Plastics uses Projection Micro Stereolithography to optimize the design on a minimally invasive surgical tool for one of their largest customers.

Read More

Our Products

Build Size

- 100 × 100 × 75mm

- 100 x 100 x 50mm

- 19.2 × 10.8 × 45mm

- 3.84 × 2.16 × 10mm

- 48 × 27 × 50mm

- 50 × 50 × 10mm

- 50 x 50 x 50mm

- 94 × 52 × 45mm

Layer Thickness

- 10μm~40μm

- 10μm~50μm

- 5μm~20μm

Optical Resolution

- 10μm

- 25μm

- 2μm

Printing Material

- Ceramic

- Photosensitive Resin

Clear Filters

Request a Benchmark Part

We’d be happy to manufacture a benchmark part so you can assess our quality.

Request a Benchmark part

News • November 29, 2022

BMF CEO John Kawola on the new microArch S350, the company's new 25µm resolution printer

“Really good surface finish and really good performance, which we believe, from a part quality point of view, is better than the rest of the market.” John Kawola, CEO of BMF, told TCT at Formnext 2022 in Frankfurt.

The company’s new system, the microArch S350, is the latest addition to the line-up of industrial grade micro-precision 3D printers. The S350 offers a 25µm resolution and has the highest throughput in the BMF portfolio.

Read More

The quality and accuracy of BMF PµSL parts is very unique, and truly mimic expensive micro molded parts, and now we can have parts ready for test within 1-2 days rather than 1-2 months, as well as reducing the huge costs associated with tooling manufacture and reworking as the new products evolve.

We can also explore designs previously out of reach due to manufacturing limitations. Our main focus is to lift our prototyping capabilities to the highest possible level, both in quality and speed. BMF will help us accomplish that.

– Sally van der Most, DSS Manager, Sonion NL

We chose BMF’s microArch 3D Printer due to its ability to replicate critical micro features. Their unique Projection Micro Stereolithography (PµSL) technology prints 3D parts with ultra-high resolution and accuracy, which is key to our business. This is the first 3D printer we’ve encountered that can print micro-precision parts, with the dimensional accuracy and precision that our customers require at this stage of product development. We have put the BMF parts through the same rigorous CT scanning inspection process of our micro molded components and were amazed that dimensionally the parts fell within the tolerances required.

Our customers have been equally amazed.

– Donna Bibber, VP of Business Development, Isometric Micro Molding, Inc.

We have been looking for some time for a machine that can reliably produce parts in this size range as we were at the limits of other machines or would have to sink cost into other manufacturing methods- typical micro injection molding or other micro machining activity that can be expensive and prohibitive to R&D iterations. The ability to rapidly produce these types of parts combined with an open ecosystem is unmatched.

– Sam Wilson, STORM Lab UK, Institute of Robotics and Autonomous Sensing, University of Leeds

The parts say it all. The first time you see a part from a BMF printer you will be amazed. 3D printing, until now, has never been able to produce parts of such precision, and accuracy.

Being able to capture thin walls and fine features at this scale and resolution, with unmatched reliability, is unprecedented from any 3D printing technology. This will absolutely usher in new industries, that have previously ignored 3D printing, to the world of rapid design iteration.

– James Grimm, Senior Business Development Manager, Empire Group

December 6, 2022 • Additive Manufacturing

Read MoreSeptember 21, 2022 • Press Release

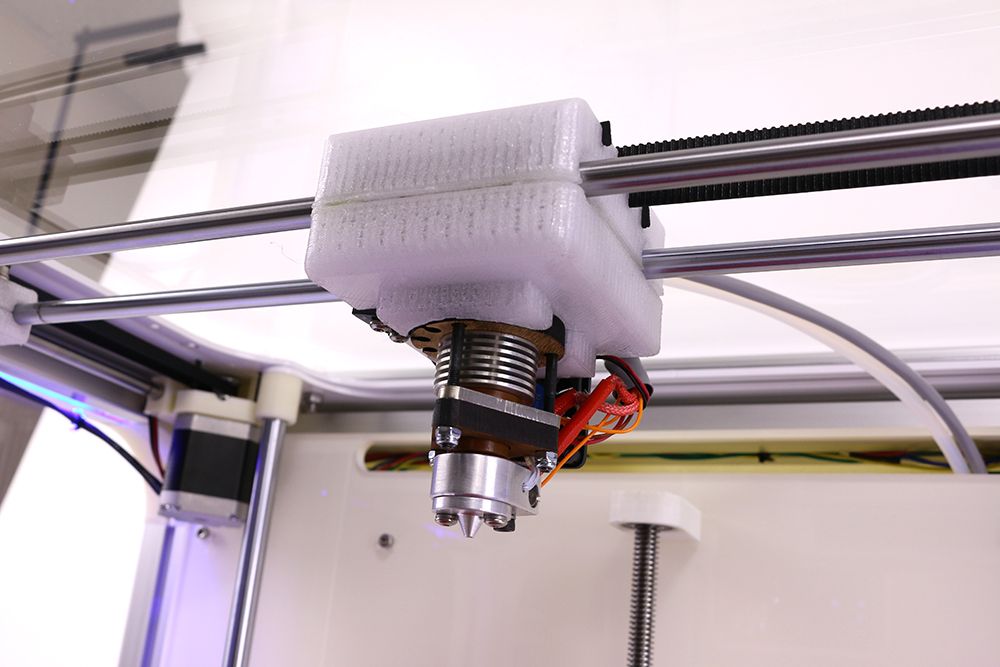

Read ArticleMicro 3D printing (FDM) At the tip of a tweezer

Hello, dear friends! I am with you, Anatoly Yunakh, and this is the workshop “Spotlight 8 kW”.

Today we have a very unusual 3D printing - micro 3D printing. And it will be produced not on a photopolymer, that is, SLA printer, but on a conventional FDM. What is needed for this and how you can repeat the same 3D printing, I will tell in this article. Let's start printing.

And it will be produced not on a photopolymer, that is, SLA printer, but on a conventional FDM. What is needed for this and how you can repeat the same 3D printing, I will tell in this article. Let's start printing.

For microprinting, I stocked up on a 0.15mm micronozzle from TriangleLabs. Please note that even in the description for these nozzles it is written that they are experimental. The holes are almost invisible, although they are there. nine0003

I also bought a 0.1 mm sapphire die. But about it in the next article. She really needs a different approach.

First - replace the nozzles. To do this, you don’t need so many tools: a simple key, I have 17, preferably with thin sponges, so as not to damage the heating element and close it;

socket for your nozzles, I have 7 mm;

the thinnest 0.05 mm stylus.

I want to note that it is a very convenient tool for setting up the table, it's a pity that the probes are mainly sold in sets, but if there are several nozzles, then buying a set is advisable. nine0003

nine0003

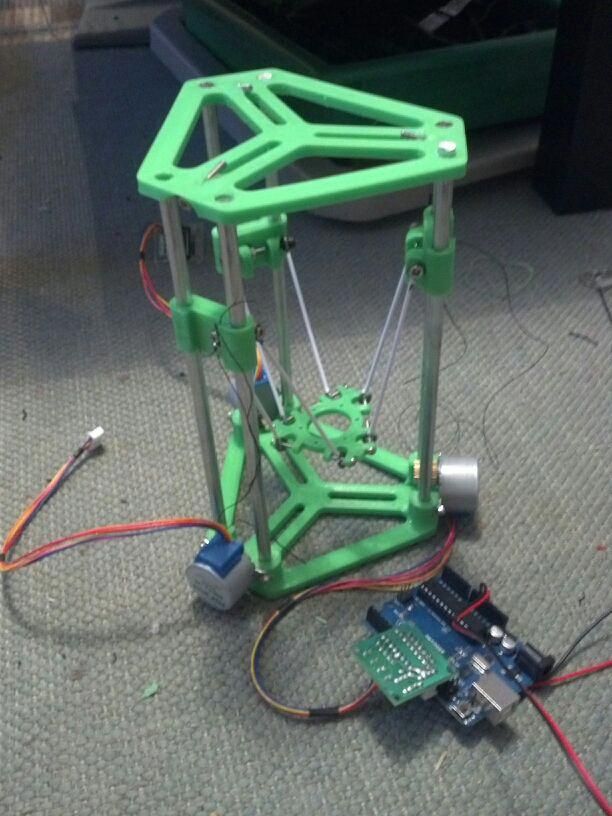

I will be glad to present you the printer that we will torture - Ulti Steel. An overview of it can be viewed here: https://www.youtube.com/watch?v=Ki3ODdg21Is

Let's start replacing the nozzle. I understand that common truths will be spoken now, but not only seasoned gurus read this information, so be patient. The first thing is, of course, we warm up the hot end to the operating temperature, hold the cube with a key and unscrew the nozzle itself with the end head.

If everything is done correctly, it should come off quite easily, so as not to suffer, unscrew it further by hand. nine0003

Most importantly, do it quickly and don't burn yourself. We twist the new nozzle also hot. Here you need to turn even faster. We bait, and then we twist and tighten, not forgetting to hold the block with a key.

Well, now the most dreary part is the table calibration. First of all, we press the table with screws to the very bottom and send the table home, and then we set up the table corner by corner.

Ulti Steel has only three mounting points and the table is set up perfectly. Since the first layer is 0.05 mm, we take a 0.05 mm probe, after which we must try to make it so that it cannot go between the tip of the nozzle and the table. nine0003

Now I'll show you in the picture. I know, I'm just "Infographic God." Yellow color - nozzle, black color - probe, blue - table. As you can see, the probe, as it were, touches the nozzles. But there must be a distance between the table and the nozzle.

And if the probe passes under the nozzle, then this is not true.

Next we need to take the model, we'll take a look at our alma mater on Thingiverse. Baby Yoda is perfect. We reduce the dimensions by 10 times, along the Z axis from 90 mm to 9 mm, I think that's enough for a start.

Printing time is quite interesting, only 15 minutes. This is good, you do not have to sit for days and wait until the sample is printed. Finished and start printing. I left the settings for the first print the same as I usually print with a 0. 4 nozzle. nine0003

4 nozzle. nine0003

For printing all the details I used ABS plastic from Filamentarno.

Honestly, when I saw this figurine for the first time, my reaction was something like this: “The bird pooped”.

Well, don't get upset, let's print another model. The most boring event is to wait while the printer prints during microprinting (photo - side view of the print).

I did not lower the print speeds for this printer. We get the printed model. We remove a whole bunch of supports, for this size there was a whole bunch. nine0003

But in reality, all the support can fit on a coin, that's how much plastic you need to spend on useless parts. It can be seen from the printed part that due to the fact that I forgot to set the retracts, according to the new diameter, it almost did not turn on, and the whole part was covered in snot.

Supports come off very easily. But, in principle, all the shoals are exactly the same as most beginners. Incorrectly configured retract, insufficient airflow, incorrectly set speeds. But, the experience is cool! When you can, looking at the detail, say what specifically is incorrectly configured. Yes, you won’t drink away the experience, but you will greatly dilute it. nine0003

But, the experience is cool! When you can, looking at the detail, say what specifically is incorrectly configured. Yes, you won’t drink away the experience, but you will greatly dilute it. nine0003

And right after this not-so-pretty print, we launch a new one. We look at the photo.

Next, I printed the dragon. The quality is just bomb. In reality, he looks quite tiny.

Next Pikachu, there are traces of decent plastic overheating on the ears, but the print quality is just on top.

As for overheating, here you have to shamanize with airflow, although this will not save you much. All this is due to the fact that the nozzles have a plane at the exit from the working hole and with small movements, the heat from the nozzle tip is still transferred to the print material. For such a small caliber, heavier artillery must be connected. nine0003

In front of you on the left is a nozzle with a working diameter of 0.15 mm, as you can see, the flat edges are almost twice as wide as the hole. And on the right, this is already a sapphire die, the outlet diameter is 0.1 mm.

And on the right, this is already a sapphire die, the outlet diameter is 0.1 mm.

But we will fight them next time. The reason is simple, with such a small diameter, there are already other laws of physics. Of course, I joked about the laws, but the requirements for settings, as well as for plastic, are simply Spartan. But at the moment I want to draw your attention to the rounding of the die tip, as we understand, the smaller the contact area, the less heat is transferred to the part. nine0003

For the technical experiment, I took a classic test cube in reduced dimensions by 2 times.

As you can see, all the edges and all the letters are printed just gorgeous. But you don’t find it, it’s somehow small for such a nozzle. Oh what a play on words. You just have no idea how tiny he looks in reality. I remind you that I printed all models with a height of 0.05 mm.

Why I am developing the topic of microprinting. In principle, this is selfish interest. I have repeatedly faced the fact that I refused clients, because they brought me too small details that I would not have printed with classic nozzles of 0.3-0.4 mm. Physically, I would not print. For example, even if you buy an expensive sapphire die, you can recoup it in about 2-5 orders, but apart from those who usually consider the order price per gram. nine0003

I have repeatedly faced the fact that I refused clients, because they brought me too small details that I would not have printed with classic nozzles of 0.3-0.4 mm. Physically, I would not print. For example, even if you buy an expensive sapphire die, you can recoup it in about 2-5 orders, but apart from those who usually consider the order price per gram. nine0003

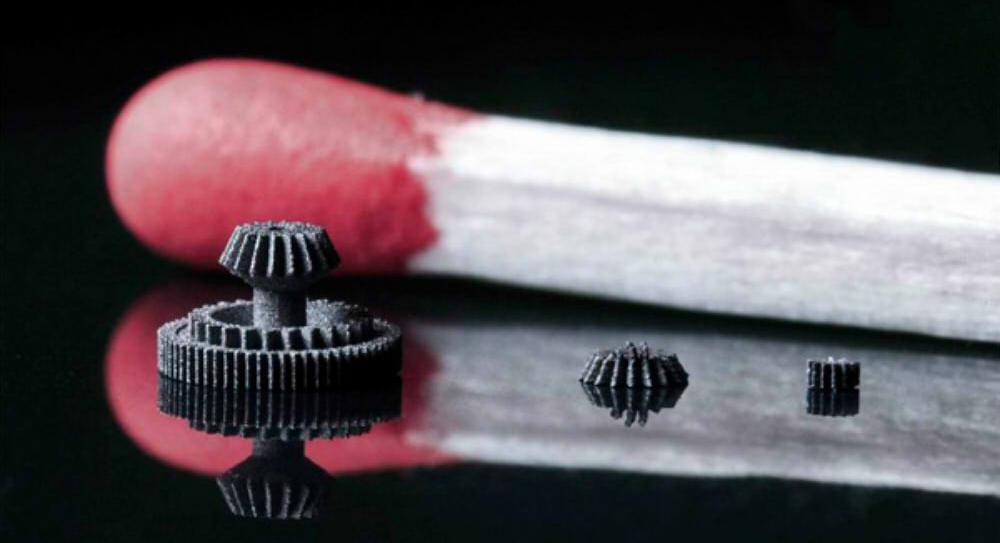

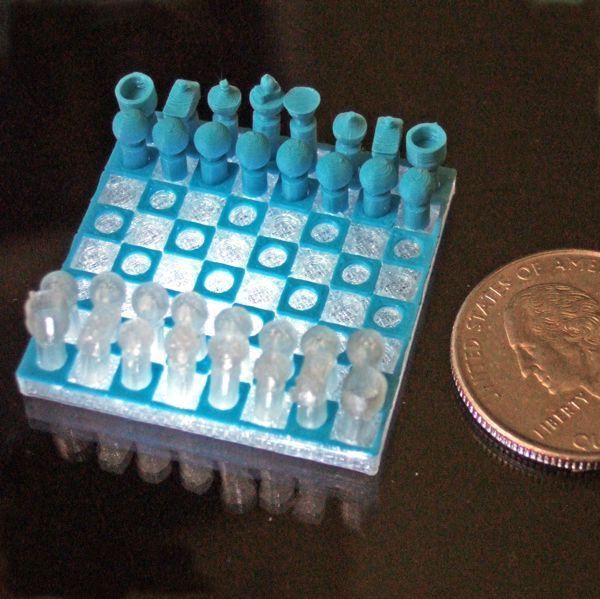

For example, we will print gears with a diameter of 5, 8 and 10 mm and for scale here the gear in the original size of 24 mm.

A couple more gears so you can see what actually happened.

I printed specially with a different number of teeth. This pair of gears turned out to be absolutely efficient, but the rest are in question.

I would say that it is suitable for all kinds of dioramas and other things, but for work, specifically these models are hardly suitable. Too large nozzles for such parts. nine0003

And here is a comparison of printed gears with an ordinary five-ruble coin.

This picture is perfect for preview.

I'll try to sum up the intermediate results. What do you need to start microprinting. The first is, of course, a printer that can produce such a print quality and such a microstep, first of all. The second is the nozzles themselves or the sapphire die. The third is the settings, it's really sad, then I will give out the main patterns. Fourth - direct hands and a lot of patience, because in order to achieve at least some sane results, you need a whole lot of patience. nine0003

And it took me a whole week to get out of the quality of the “Pooping Bird” level to what you see now on the screen.

Good adhesive that can be applied thinly, ideally spray.

At worst, a hard glue stick. But, here I would also think a thousand times before taking it, for example, the same kalyaka-malyaka, because she gives details from the table very reluctantly, and our details are very small and fragile. Therefore, my choice falls on glue spray. Nozzles must be from a good manufacturer for something like this to come to you. nine0003

Nozzles must be from a good manufacturer for something like this to come to you. nine0003

Not like that.

Now about the slicer settings, please note that microprinting is very picky about plastic flow, so the print temperature should be higher. But at the same time, you must understand that by increasing the temperature it will be necessary to deal with influxes and snot, and fight with airflow. I have already found a golden mean for myself. That's about 5 degrees below the maximum print temperature I normally print at. With a nozzle of 0.4 I have ABS 245 degrees.

For micro nozzle - 240 degrees. Retract 1-1.5 mm. Table - 110.

This is just the first article on microprinting. And there will be more.

Now let's summarize. So, in general, what is this article for? Everything is very simple. There are SLA printers, that is, photopolymers, and of course, no one can compare with them in terms of detailing. This is amazing technology. But there is one but. For an artist, this type of print is simply gorgeous, it is wonderful, just super. But let's say, for the same technique, we need to know the physical properties of the material with which we will print. "And what? A photopolymer resin that has unknown physical properties?” Well, for the most part, yes, I don't know. It is necessary to try several compositions in order to understand which of the compositions will give the most optimal and desired result. nine0003

For an artist, this type of print is simply gorgeous, it is wonderful, just super. But let's say, for the same technique, we need to know the physical properties of the material with which we will print. "And what? A photopolymer resin that has unknown physical properties?” Well, for the most part, yes, I don't know. It is necessary to try several compositions in order to understand which of the compositions will give the most optimal and desired result. nine0003

Please note that SLA printers, photopolymers, after the printer prints the model, you do not get the finished part, you only get the blank. It will need to be washed with alcohol, and then treated with ultraviolet light to harden the part. And at the same time, I repeat, there are a huge number of types of resins, there are no tests. You need to focus only on what the manufacturer himself writes, but paper will endure everything, you can write anything.

Therefore, in my opinion, it is better to print an artist on an SLA printer, that is, there is no physical activity, the main thing is beauty and detail, so it’s there, in that steppe. If we are talking about technical details, then of course, it is better to choose an ordinary FDM printer. nine0003

If we are talking about technical details, then of course, it is better to choose an ordinary FDM printer. nine0003

That's it, my dear friends. I hope this article was useful for you. Anatoly Yunakh was with you.

Microprint video link: https://www.youtube.com/watch?v=YljgJaKkYKc&feature=youtu.be

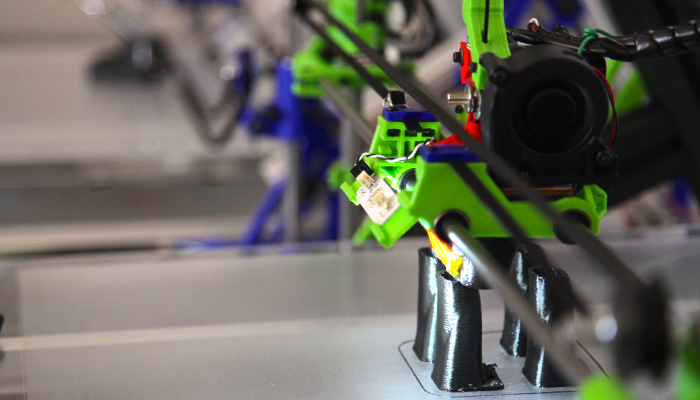

Industrial micro 3D printing | Top Machine

Contents

Introduction

When there is a need to quickly create products or components that have a complex structure and small dimensions, traditional methods impose great restrictions on this process. In the field of medicine, microelectronics, and scientific research, in addition to the small dimensions of products, their accuracy also plays an important role. Such products require very precise processing, which will provide the necessary structure and surface quality, which is quite an expensive process. nine0003

The development of additive technologies makes it possible to solve the problems of producing high-precision parts that have a lower cost and fast manufacturing time. The unique micro-3D printing technology was developed in the US by Boston Micro Fabrication, founded by MIT professor Dr. Nick Fang and serial entrepreneur Dr. Xiaoning He.

The unique micro-3D printing technology was developed in the US by Boston Micro Fabrication, founded by MIT professor Dr. Nick Fang and serial entrepreneur Dr. Xiaoning He.

Technology

Fig. 1 (Schematic diagram of BMF technology)

The process of creating high-precision parts on BMF 3D printers is based on projection microstreolithography (Pμsl) technology. Based on the principles of stereolithography, this method allows rapid photopolymerization of the entire photopolymer layer using ultraviolet radiation with microscale resolution. This makes it possible to achieve ultra-high precision and resolution of products, the production of which is not available with other technologies.

Using the additive manufacturing of polymers and composites, BMF can produce industrial parts to high tolerances (minimum print resolution 2 µm and tolerance +/- 10 µm). The printing technology from BMF matches the quality of high-resolution micro-injection molding and CNC micro-machining. nine0003

nine0003

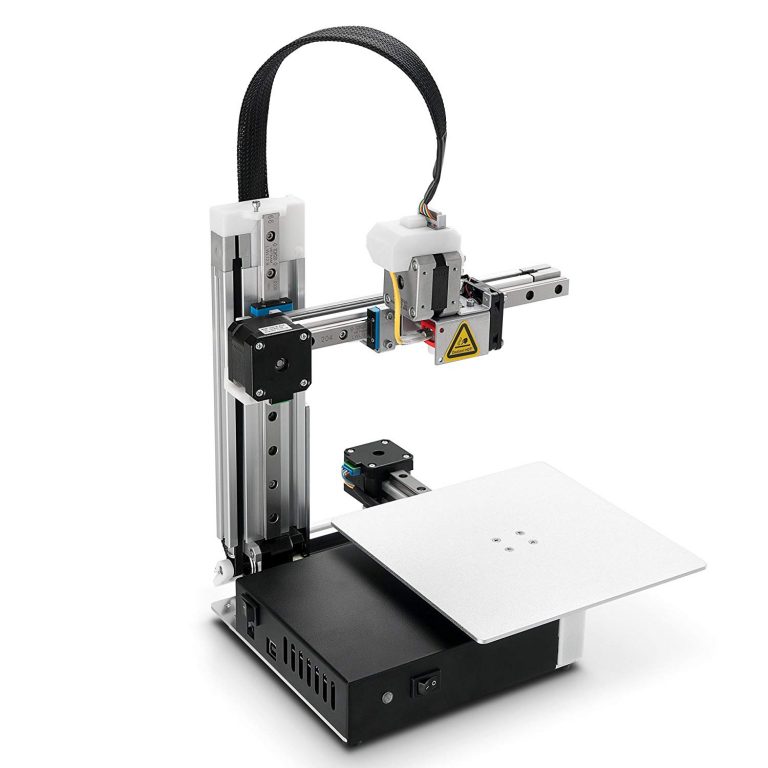

Equipment description

Boston Micro Fabrication 3D printers are divided according to the optical resolution along the X, Y axes: Series 2, 10 and 25 µm. The microArch™ series is the first commercial high-resolution 3D microfabrication equipment based on PμSL (projection microstereolithography) technology.

An updated and newest addition to the BMF 3D printer line, the microArch S240 is based on the innovative PROJECTION MICRO STEREOLITHOGRAPHY (PμSL) technology, which allows rapid photopolymerization of a layer of liquid polymer using a flash of ultraviolet light with microscale resolution. nine0003

BMF microArch S240 3D printer

The BMF3D microArch S240 is a high-precision micro-3D 3D printer designed for low-volume production of micro-parts. The advanced roller system distributes layers in seconds, resulting in 10 times faster print speeds than other models. It features the largest displacement of any previous model, as well as compatibility with industrial materials, composites, ceramics, and polymers with viscosities up to 20,000 cP. nine0003

nine0003

General specifications

| BMF microArch S240 | Meaning |

|---|---|

| Print Technology | PμSL (Projection Micro Stereolithography) |

| Light source | UV LED |

| Radiation wavelength | 405 nm |

| Media | Photosensitive resins, ceramics |

| Input data file format | STL |

| Optical resolution | 10 µm |

| Printable area | Mode 1: 19.2×10.8×75 mm Mode 2: 100×100×75 mm Mode 3: 100×100×75 mm |

| Layer thickness | 10-40 µm | nine0165

| Surface roughness | 0.4-0.8 µm Ra (top) 1.5-2.5 µm Ra (side) |

| Tolerance | +/- 25 µm |

| Power supply | 2 kW |

| Printer dimensions | 650(L) × 700(W) × 790(H) mm |

| Printer weight | 130 kg | nine0165

| Voltage | 110-220V |

| Certification | CE |

A video showing the presentation of this printer is available here

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).