Metal 3d printing india

Metal 3D Printing Technology | Rapid DMLS

The revolutionary technology that lets you materialize any complex mechanical component.

Speak to our Additive Manufacturing experts to find out how we can help.

The revolutionary technology that lets you materialize any complex mechanical component.

Speak to our Additive Manufacturing experts to find out how we can help.

Book a Free Call

Metal 3D Printing in Brief

Metal 3D Printing in Brief

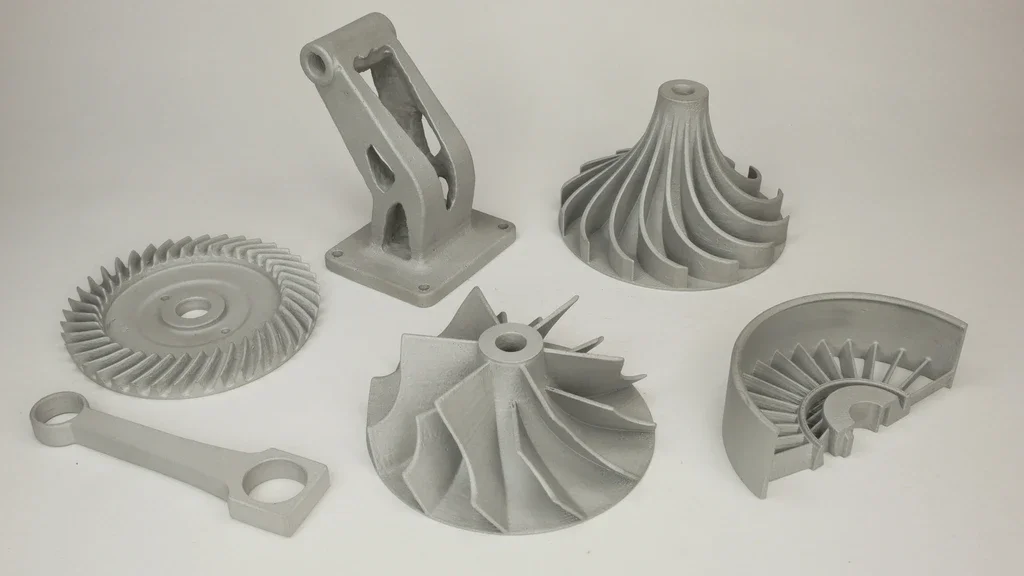

Metal 3D printing or Metal Additive Manufacturing is a revolutionary technology which produces components directly from 3D CAD data. The 3D CAD data is cut into numerous sections, and these sections are printed one over the other to get the final component.

A major advantage of the technology is to produce parts with complex geometries which are difficult to manufacture through conventional techniques. 3D Printing offers the flexibility to design parts for their functionality rather than designing the parts for their manufacturability.

Metal 3D printing is used to manufacture one off prototypes, small batch production parts, series production parts and die and mould repair. Different Metal AM methods such as Powder Bed Melting, Binder Jetting and Direct Energy Deposition have their own advantages.

At Rapid DMLS, we use the most popular technique of Direct Metal Laser Sintering which yields the best part properties and has the ability to produce complex geometries.

Metal 3D printing or Metal Additive Manufacturing is a revolutionary technology which produces components directly from 3D CAD data. The 3D CAD data is cut into numerous sections, and these sections are printed one over the other to get the final component.

A major advantage of the technology is to produce parts with complex geometries which are difficult to manufacture through conventional techniques. 3D Printing offers the flexibility to design parts for their functionality rather than designing the parts for their manufacturability.

3D Printing offers the flexibility to design parts for their functionality rather than designing the parts for their manufacturability.

Metal 3D printing is used to manufacture one off prototypes, small batch production parts, series production parts and die and mould repair. Different Metal AM methods such as Powder Bed Melting, Binder Jetting and Direct Energy Deposition have their own advantages.At Rapid DMLS, we use the most popular technique of Direct Metal Laser Sintering which yields the best part properties and has the ability to produce complex geometries.

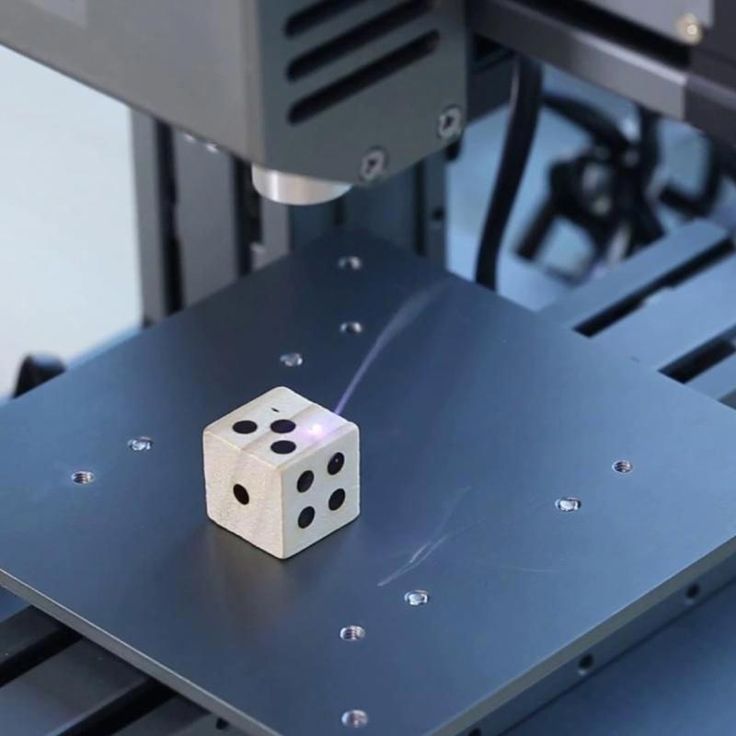

How DMLS Works

How DMLS Works

How We Can Help You with DMLS

How We Can Help You with DMLS

Pre Processing

Pre Processing

- Part Feasibility: Not every part is suited for Additive Manufacturing. Based on the part quantity, size, complexity and material, we suggest whether going additive is the best option.

- Reverse Engineering: When you want to print a part, but do not have the necessary drawings and details, we can generate the 3D models using CMM machines and Laser Scanning.

- Design for Additive Manufacturing: Not every pre-existing design can be printed right away. We optimise your design to make it print-friendly by reducing the mass while retaining the same strength.

- Data Preparation: Once your 3D Cad data is received, we decide the best printing orientation and assign suitable support structures to ensure a successful build with best part quality.

- Part Feasibility: Not every part is suited for Additive Manufacturing.

Based on the part quantity, size, complexity and material, we suggest whether going additive is the best option.

Based on the part quantity, size, complexity and material, we suggest whether going additive is the best option.

- Reverse Engineering: When you want to print a part, but do not have the necessary drawings and details, we can generate the 3D models using CMM machines and Laser Scanning.

- Design for Additive Manufacturing: Not every pre-existing design can be printed right away. We optimise your design to make it print-friendly by reducing the mass while retaining the same strength.

- Data Preparation: Once your 3D Cad data is received, we decide the best printing orientation and assign suitable support structures to ensure a successful build with best part quality.

3D Printing

3D Printing

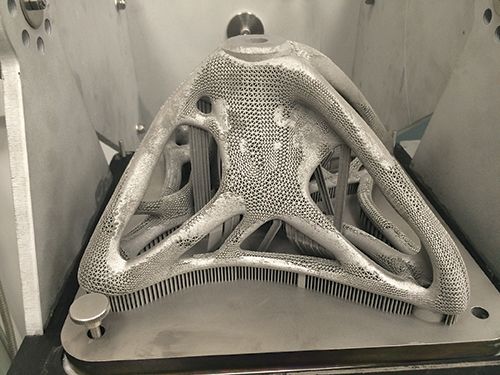

- The analysed CAD data is sliced into numerous layers and the corresponding process parameters are set to get high quality surface finish and part properties.

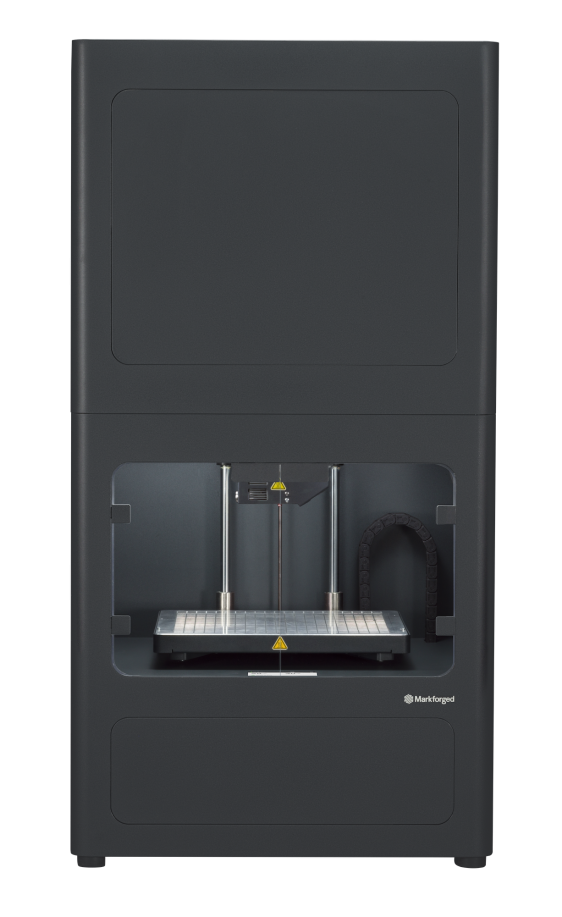

- We use an EOS M280 Direct Metal Laser Sintering machine with a build envelope of 250mm x 250mm x 300mm equipped with a 400W Laser.

- To prevent oxidation, the build chamber is filled with inert gas and the oxygen content in the chamber is maintained at less than 0.1%.

- The parts are built on a pre-heated metal substrate which keeps going down by a layer thickness after each layer is printed, until the final layer is printed.

- Once printing is done, the part is allowed to cool down for a short period and the parts are unloaded for further post-processing.

- The analysed CAD data is sliced into numerous layers and the corresponding process parameters are set to get high quality surface finish and part properties.

- We use an EOS M280 Direct Metal Laser Sintering machine with a build envelope of 250mm x 250mm x 300mm equipped with a 400W Laser.

- To prevent oxidation, the build chamber is filled with inert gas and the oxygen content in the chamber is maintained at less than 0.1%.

- The parts are built on a pre-heated metal substrate which keeps going down by a layer thickness after each layer is printed, until the final layer is printed.

- Once printing is done, the part is allowed to cool down for a short period and the parts are unloaded for further post-processing.

Post Processing

Post Processing

- Depowdering: To ensure all the powder is removed from the printed part.

- Heat Treatment: For stress relieving and improving mechanical properties.

- Wire EDM: To cut-off part from the build plate.

- CNC Machining: For support removal and maintaining high tolerance dimensions.

- Surface Finishing: To get the desired finish on the part.

- Dimensional Inspection: To verify if the dimensions are as per the model and drawing.

- Structural Inspection: To verify if there are any cracks or internal defects in the part.

- Depowdering: To ensure all the powder is removed from the printed part.

- Heat Treatment: For stress relieving and improving mechanical properties.

- Wire EDM: To cut-off part from the build plate.

- CNC Machining: For support removal and maintaining high tolerance dimensions.

- Surface Finishing: To get the desired finish on the part.

- Dimensional Inspection: To verify if the dimensions are as per the model and drawing.

- Structural Inspection: To verify if there are any cracks or internal defects in the part.

Benefits of Metal 3D Printing

Benefits of Metal 3D Printing

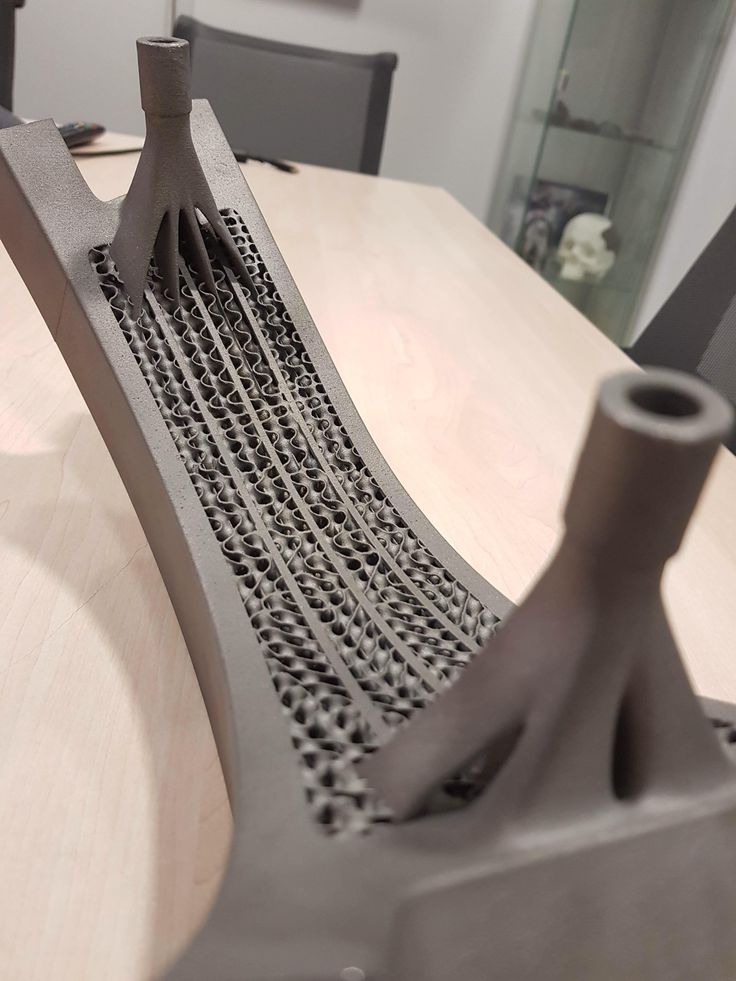

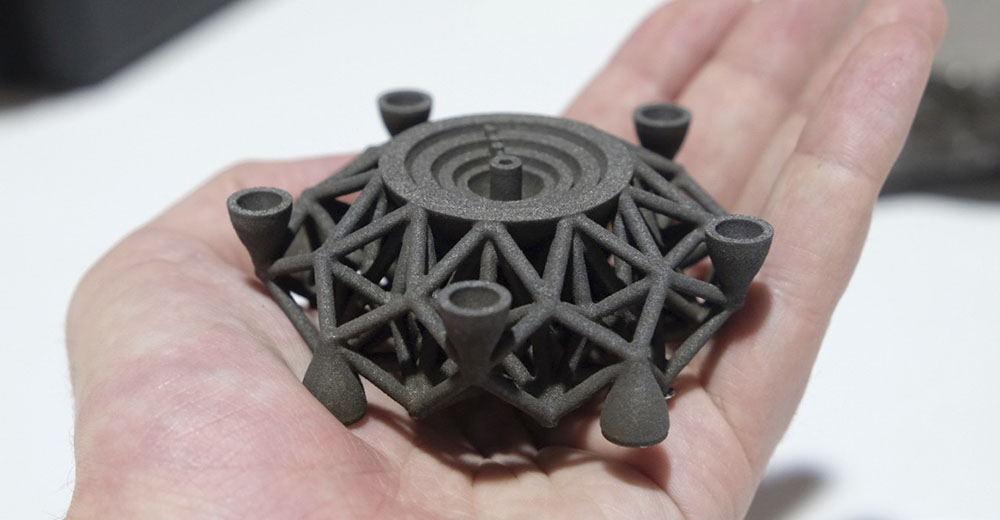

Weight Reduction

Topology optimised part with 35% reduced weight compared to a traditional design.

Improved Functional Performance

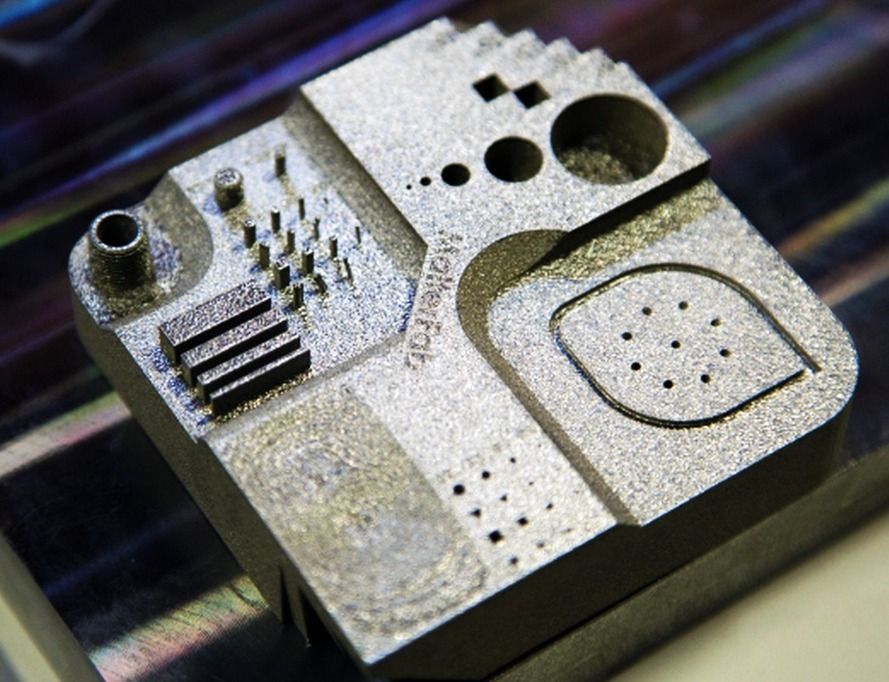

Tooling insert with conformal cooling used in Injection Moulding for faster cycle time.

Mass Customization

Parts with minute design changes printed in a single build to validate the design.

Weight Reduction

Topology optimised part with 35% reduced weight compared to a traditional design.

Improved Functional Performance

Tooling insert with conformal cooling used in Injection Moulding for faster cycle time.

Mass Customization

Parts with minute design changes printed in a single build to validate the design.

Quick Batch Production

Multiple parts printed in one shot for faster lead times and tool less production.

Improved Freedom of Design

A manifold designed for lesser fluid resistance which increases the working efficiency.

Part Consolidation

A highly complex design of Fuel Injector and Swirler redesigned and built as a single piece.

Quick Batch Production

Multiple parts printed in one shot for faster lead times and tool less production.

Improved Freedom of Design

A manifold designed for lesser fluid resistance which increases the working efficiency.

Part Consolidation

A highly complex design of Fuel Injector and Swirler redesigned and built as a single piece.

Common Material Grades Available in DMLS

Common Material Grades Available in DMLS

Stainless Steel

- Corrosion Resistant

- Ductile

- Good Machinability

Wide range of applications in food industry, surgical tools, watches and jewellery.

Aluminium Alloys

- Good Thermal Prop

- Strength & Hardness

- Good Machinability

Wide range of applications in prototype parts, automotive and aircraft interiors.

Nickel Alloys

- Heat Resistant

- Corrosion Resistant

- Performs Even at 700° C

Wide range of applications in aircraft, space and turbine components.

Tool Steels

- Good Thermal Conductivity

- Easily Machinable

- Hardenable Upto 55 HRC

Wide range of applications in tooling and series production parts.

Titanium Alloys

- Light Weight with Strength

- Bioadhesion

- Corrosion Resistant

Wide range of applications in biomedical, aerospace and motor sport industries.

Stainless Steel

- Corrosion Resistant

- Ductile

- Good Machinability

Wide range of applications in food industry, surgical tools, watches and jewellery.

Aluminium Alloys

- Good Thermal Prop

- Strength & Hardness

- Good Machinability

Wide range of applications in prototype parts, automotive and aircraft interiors.

Nickel Alloys

- Heat Resistant

- Corrosion Resistant

- Performs Even at 700° C

Wide range of applications in aircraft, space and turbine components.

Tool Steels

- Good Thermal Conductivity

- Easily Machinable

- Hardenable Upto 55 HRC

Wide range of applications in tooling and series production parts.

Titanium Alloys

- Light Weight with Strength

- Bioadhesion

- Corrosion Resistant

Wide range of applications in biomedical, aerospace and motor sport industries.

Industries & Usage

Industries & Usage

Aerospace

Parts ranging from cabin interiors to complex engine components are now manufactured using Metal 3D Printing. By providing lightweight structures with improved functional performance, AM contributes to the technical improvement of the aerospace industry by reducing material costs, fuel costs and CO2 emissions.

Defence

The strength of a nation is often measured by its defence capability. By using DfaM with Metal 3D Printing, innovative products can be manufactured. By adopting topology optimisation during design stage and then manufacturing through metal 3d printing, the weight of devices carried by soldiers on their back can be reduced.

Aerospace

Parts ranging from cabin interiors to complex engine components are now manufactured using Metal 3D Printing. By providing lightweight structures with improved functional performance, AM contributes to the technical improvement of the aerospace industry by reducing material costs, fuel costs and CO2 emissions.

Defence

The strength of a nation is often measured by its defence capability. By using DfaM with Metal 3D Printing, innovative products can be manufactured. By adopting topology optimisation during design stage and then manufacturing through metal 3d printing, the weight of devices carried by soldiers on their back can be reduced.

Space

The heavier the weight of launch vehicle, more fuel is required and therefore, more cost. With the help of metal 3D printing, weight of the launch vehicle can be decreased drastically. High performance alloys like Inconel which are difficult to machine and find application in rocket engines, are processed much easily through 3d printing.

Automotive

Although the Auto industry needs parts in high quantities, AM has applications for Automotive. When developing a new product, all the design variants can be printed and the best among them can be chosen. With the entry of electric vehicles, ergonomic and lightweight parts can be manufactured which increases the efficiency of the vehicle.

Space

The heavier the weight of launch vehicle, more fuel is required and therefore, more cost. With the help of metal 3D printing, weight of the launch vehicle can be decreased drastically. High performance alloys like Inconel which are difficult to machine and find application in rocket engines, are processed much easily through 3d printing.

Automotive

Although the Auto industry needs parts in high quantities, AM has applications for Automotive. When developing a new product, all the design variants can be printed and the best among them can be chosen. With the entry of electric vehicles, ergonomic and lightweight parts can be manufactured which increases the efficiency of the vehicle.

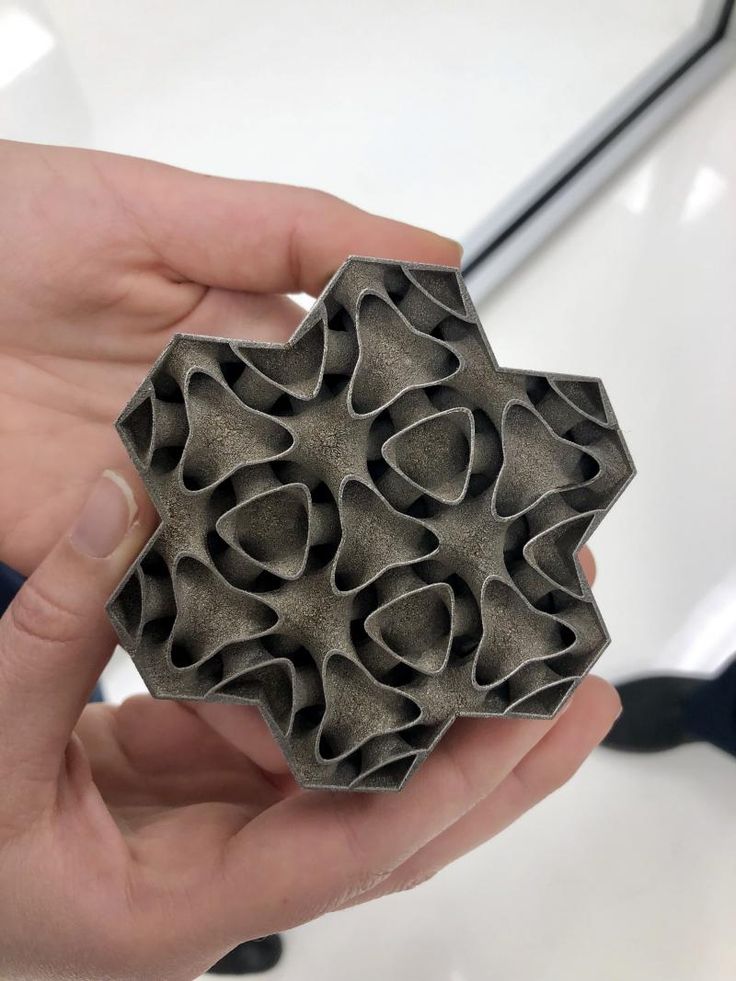

Tooling

Unlike straight cooling channels achieved by drilling, AM produces optimized cooling channels that closely conform to the surface of the mold cavity. This enables for faster heat transfer between the injected material and cooling fluid, resulting in rapid uniform cooling of the injected part, thereby reducing the cycle time and producing better quality parts.

General Engineering

Most of the engineering components can be made feasible for Metal 3D printing. Custom jigs and fixtures can be additively manufactured in a very short lead time. General engineering applications includes prototype parts, small batch production parts as well as custom made parts used to improve an existing process.

Tooling

Unlike straight cooling channels achieved by drilling, AM produces optimized cooling channels that closely conform to the surface of the mold cavity. This enables for faster heat transfer between the injected material and cooling fluid, resulting in rapid uniform cooling of the injected part, thereby reducing the cycle time and producing better quality parts.

General Engineering

Most of the engineering components can be made feasible for Metal 3D printing. Custom jigs and fixtures can be additively manufactured in a very short lead time. General engineering applications includes prototype parts, small batch production parts as well as custom made parts used to improve an existing process.

Medical

Surgical tools made in stainless steel are now manufactured using 3d printing. A proto sample is made through metal AM and then tested for its performance. In trauma cases where implants are needed due to bone damage, metal printing produces custom implant specific to each patient which reduces the possibility of a re-surgery.

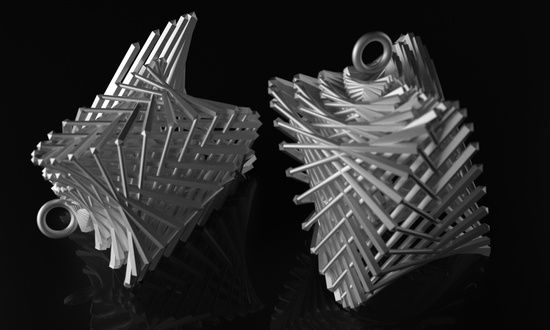

Art

With the way we are evolving, everything will be customised for everybody. Additive manufacturing for artistic items unveils huge potential due to freedom for complex design and customization it can offer. Comprising from customised watches, jewellery to ancient art, the art and fashion world can use 3d printing for their every need.

Medical

Surgical tools made in stainless steel are now manufactured using 3d printing. A proto sample is made through metal AM and then tested for its performance. In trauma cases where implants are needed due to bone damage, metal printing produces custom implant specific to each patient which reduces the possibility of a re-surgery.

Art

With the way we are evolving, everything will be customised for everybody. Additive manufacturing for artistic items unveils huge potential due to freedom for complex design and customization it can offer. Comprising from customised watches, jewellery to ancient art, the art and fashion world can use 3d printing for their every need.

Research & Development

Research & Development

New Material Development

Out of the plethora of metal alloys available in bar stock form, only around 8 to 10 metal grades are currently available for DMLS. Based on your specification, we can get powders of a certain alloy made through Gas Atomisation. This powder then undergoes extensive research at our facility.

Parameter Optimization

Based on your application and requirement, we optimize the process parameters for desired part properties. Requirements could be a better surface finish, higher productivity or a mixture of both. Our R&D activity includes experimenting these parameters and testing it for the desired output.

Our R&D activity includes experimenting these parameters and testing it for the desired output.

New Material Development

Out of the plethora of metal alloys available in bar stock form, only around 8 to 10 metal grades are currently available for DMLS. Based on your specification, we can get powders of a certain alloy made through Gas Atomisation. This powder then undergoes extensive research at our facility.

Parameter Optimization

Based on your application and requirement, we optimize the process parameters for desired part properties. Requirements could be a better surface finish, higher productivity or a mixture of both. Our R&D activity includes experimenting these parameters and testing it for the desired output.

General FAQs

General FAQs

What is the difference between the PBF processes DMLS, SLM and DMP?

Direct Metal Laser Sintering (DMLS), Selective laser Melting(SLM) and Direct Metal Printing(DMP) are all the same. It is basically Powder Bed Melting process using a laser source. Different Machine Manufacturers use different names to promote their brand.

It is basically Powder Bed Melting process using a laser source. Different Machine Manufacturers use different names to promote their brand.

What is the biggest size that can be printed on your machine?

Our machine has a build volume of 250mm x 250mm x 300mm in the x,y and z directions respectively. So, any component within that envelope can be built. However, bigger parts can be cut into sections and these printed sections can be joined through welding to get the final product.

Can we print 2 different alloys together?

Since it is a Powder Bed process, it is currently impossible to print 2 different alloys simultaneously. However, we can print with a certain alloy up to some height, and then continue printing with a different alloy from that height.

Is the powder scrapped after use? What is the material wastage?

The virgin powder after its first use goes through a sieving process to separate condensate material from the good powder. The condensate is scrapped and the sieved powder is used for the next build. A ball –park value for material wastage can be taken as 5% of the part weight.

The condensate is scrapped and the sieved powder is used for the next build. A ball –park value for material wastage can be taken as 5% of the part weight.

What is the difference between the PBF processes DMLS, SLM and DMP?

Direct Metal Laser Sintering (DMLS), Selective laser Melting(SLM) and Direct Metal Printing(DMP) are all the same. It is basically Powder Bed Melting process using a laser source. Different Machine Manufacturers use different names to promote their brand.

What is the biggest size that can be printed on your machine?

Our machine has a build volume of 250mm x 250mm x 300mm in the x,y and z directions respectively. So, any component within that envelope can be built. However, bigger parts can be cut into sections and these printed sections can be joined through welding to get the final product.

Can we print 2 different alloys together?

Since it is a Powder Bed process, it is currently impossible to print 2 different alloys simultaneously. However, we can print with a certain alloy up to some height, and then continue printing with a different alloy from that height.

However, we can print with a certain alloy up to some height, and then continue printing with a different alloy from that height.

Is the powder scrapped after use? What is the material wastage?

The virgin powder after its first use goes through a sieving process to separate condensate material from the good powder. The condensate is scrapped and the sieved powder is used for the next build. A ball –park value for material wastage can be taken as 5% of the part weight.

Speak to Our Additive Manufacturing Experts

Our experts are here to help you create complex mechanical components using DMLS technology. Book a free call below with our experts to find out how you can make the best use of Metal 3D Printing.

Speak to Our Additive Manufacturing Experts

Our experts are here to help you create complex mechanical components using DMLS technology. Book a free call below with our experts to find out how you can make the best use of Metal 3D Printing.

Metal 3D Printing Gallery - Rapid DMLS

Bracket in Aluminium AlSi 10Mg- Part Name: Bracket

- Material: Aluminium AlSi10Mg

Why 3D Printing: To counter the long waiting time for imports of spare parts for the MIG and Sukhoi Aircrafts, this part was 3d printed and was supplied in a week’s time.

Brackets in Stainless Steel 316L- Part Name: Brackets

- Material: Stainless Steel 316L

Why 3D Printing: To demonstrate that the Strength to Weight ratio of a 3D printed part is superior to that of a CNC machined part.

Combustion Chamber in Inconel 718- Part Name: Combustion Chamber

- Material: Inconel 718

Why 3D Printing: To realise a monolithic design with reduced weight.

- Part Name: Conformal Cooled Insert

- Material: Maraging Steel 300

Why 3D Printing: The designed cooling channels can be manufactured only through 3D printing. The cooling channels are designed so that the pressure die casting cycle time reduces thereby increasing the process productivity.

Customized Wheels in Aluminium AlSi10Mg- Part Name: Custom Wheels

- Material: Aluminium AlSi10Mg

Why 3D Printing: Mass Customisation. 3 unique designs were printed together at once and the best performing design was selected.

Deform Nuts in Stainless Steel 316L- Part Name: Deform Nuts

- Material: Stainless Steel 316L

Why 3D Printing: The design is not made for functionality rather than design for manufacturability. Due to the ductility of 316L, the nuts deform as per the functionality under the given loads.

Due to the ductility of 316L, the nuts deform as per the functionality under the given loads.

- Part Name: Heat Exchanger

- Material: Aluminium AlSi10Mg

Why 3D Printing: The convoluted interior profiles achieved through 3D printing increases the surface area for heat transfer which expedites the cooling process.

HP NGV Stator in Inconel 718- HP Nozzle Guide Vane

- Material: Inconel 718

Why 3D Printing: The part has numerous cooling holes which can be achieved directly through 3D printing, unlike the traditional process with multiple operations.

Impeller in Stainless Steel 17 4PH- Part Name: Impeller

- Material: Stainless Steel 17-4PH

Why 3D Printing: Weight of the impeller is reduced without compromising on the strength and functionality.

- Part Name: Jet Engine Prototype

- Material: Stainless Steel 316L

Why 3D Printing: To show that however complicated the parts are, the entire assembly can be manufactured with faster timelines.

Manifold in Stainless Steel 17 - 4PH- Part Name: Hydraulic Manifold

- Material: Stainless Steel 17-4PH

Why 3D Printing: The additive design increases the efficiency of the manifold by reducing the pressure losses of the fluids.

Octopus in Stainless Steel 17 - 4PH- Part Name: Octopus

- Material: Stainless Steel 17-4PH

Why 3D Printing: The entire part is as-built and not assembled. The tentacles of the octopus are free to move which shows the freedom of design involved in the process.

The tentacles of the octopus are free to move which shows the freedom of design involved in the process.

- Part Name: Range Detector

- Material: Aluminium AlSi10Mg

Why 3D Printing: Parts with small batch quantity and complex profiles are best suited for 3D printing.

Wave Guide in Aluminium AlSi10Mg- Part Name: Wave Guide

- Material: Aluminium AlSi10Mg

Why 3D Printing: It is printed as a monolithic piece, instead of the earlier conventional designs which needed numerous parts to be fastened together to constitute the main part.

Government of India develops 3D printing policy for local firms to take them to new global market

The global AM market is expected to reach $34. 8 billion by 2024 and , according to India's Ministry of Information Technology, it will grow at a CAGR of 23.2 percent.

8 billion by 2024 and , according to India's Ministry of Information Technology, it will grow at a CAGR of 23.2 percent.

Looking to the emerging global market, the Ministry of Electronics and Information Technology (MeitY) will soon develop a policy to promote industrial-scale 3D printing and help domestic companies "overcome technical and economic barriers" to they could create support and support facilities for world leaders in technology such as the US and China.

The policy will help create an "enabling ecosystem for the design, development and deployment" of 3D printing and additive manufacturing, the government told The Indian Express.

“3D printing and the viable industry around it is basically additive manufacturing, where companies produce certain products for projects where there are very specific requirements, such as the Ministry of Electronics and Information Technology, etc.” - said a senior official at the Ministry of Information Technology.

A draft policy paper on this subject will be sent out to experts in the field shortly for their input on the way forward. 3D printing or additive manufacturing uses computer-aided design to create prototypes or working models of objects by laying down successive layers of materials such as plastic, resin, thermoplastic, metal, fiber, or ceramic. With software, the model to be printed is first designed by the computer and then issues instructions to the 3D printer.

“So it's not just the manufacturing aspect, but also the design and software. Politics will seek to embrace both sides. When it comes to software, we have an advantage. The idea is to develop in this direction,” the official said.

According to the draft policy, the central government will also seek to encourage market leaders to establish global bases for 3D manufacturing in India, as well as discourage the import of printed materials for domestic use.

“One of the main applications of such products is in medicine and related fields. The problem is the lack of standards as 3D printing is a very niche and new field. There are no global standards for qualification and certification. So that will be a key issue,” another official said.

The problem is the lack of standards as 3D printing is a very niche and new field. There are no global standards for qualification and certification. So that will be a key issue,” another official said.

Other key businesses include the manufacture of automobiles and ancillary automotive parts such as engines, interiors and exteriors of luxury vehicles or chassis, complex brackets and turbine blades

.

“This can find applications in consumer electronics, circuit boards, clothing, toys and jewelry. Only after we get some feedback from experts both in India and around the world can we start to identify industries where this can be more viable and beneficial than others,” the official said.

Asia is the world leader in 3D printing, with China accounting for about 50 percent of its market, followed by Japan at 30 percent and South Korea at 10 percent. But on a global scale, the United States remains the leader with a market share of more than 35%.

“In most places inland we are in the research and development phase. There is interest, but it is at a very early stage. It has not yet been adapted for strategic industrial integration in sectors such as aerospace, where maximum precision is required,” one official said. Another key challenge is to persuade industry and ministries to push for its implementation in their sectors, one official said.

There is interest, but it is at a very early stage. It has not yet been adapted for strategic industrial integration in sectors such as aerospace, where maximum precision is required,” one official said. Another key challenge is to persuade industry and ministries to push for its implementation in their sectors, one official said.

“Any new technology that is not easy to understand has a hard time. In our first meetings on this topic, there were many objections about whether this technology would undermine the jobs of highly skilled workers in the medical equipment or aerospace technology sectors. 3D printing may not lead to an increase in net employment, but we can promote this technology,” the official said.

Source: https://www.amchronicle.com/news/govt-readies-3d-printing-policy-for-local-firms-to-join-new-global-market/

TRUMPF partners with Indian family company Magod Laser to promote 3D printing

Photo courtesy of TRUMPF

Indian family company Magod Laser has joined forces with TRUMPF, one of the world's largest machine tool suppliers and manufacturers of metal 3D printing systems, to promote 3D printing technology in the Indian continent.

Inspiration from the USA

The story began in 1991 in the USA, where Swami Magod, the current Managing Director of Magod Laser, received his Master's degree in Industrial Engineering. After graduating from university, he continued to work in the USA for several years, and it was here that he first became acquainted with laser technology and heard the name TRUMPF. After gaining extensive experience in the field of laser cutting, he returned to India with the clear goal of saving clients time and cost in sheet metal cutting.

Magoda Laser

Magod Laser headquarters in Bangalore / Image provided: Trumpf

Magod Laser, founded in Bangalore, is a synonym for the use of Laser Power technology for industrial . It was the first company in South India to use lasers for sheet metal cutting. With the ultimate goal of making sheet metal cutting faster and more affordable for customers, the company has managed to capture a huge share of the Indian market.:quality(80)/images.vogel.de/vogelonline/bdb/1491000/1491076/original.jpg)

Today, Magod Laser has a total of 25 TRUMPF machines - and is a leader in the development of additive manufacturing in India.

Poppage into additive production

Magod Lasers now uses TRMPF additive production systems, such as TruPrint 1000 / Image Credit: Trumpf 9000 9000 9000

with the existing preference towards TRUMPF and with positive experience with this , Magod Laser purchased the necessary equipment and decided to plunge into additive manufacturing.

Swamy came up with the idea when one of her clients asked the team to weld parts with a laser. Swami explained, “Two of our clients have already used 3D printing and they asked us to laser weld parts together. I realized it was time to print the metal parts myself.”

TRUMPF supplied the necessary equipment in the form of a TruPrint 1000 and Swamy introduced a combined process that took full advantage of the company's expertise. According to Swamy, “There is a limit to the size of parts in 3D printing, so we offer a combination of additive manufacturing and laser welding. To make larger parts, we just weld a few small parts.”

To make larger parts, we just weld a few small parts.”

A major problem in the Indian AM market is a lack of technology awareness, but Magod Laser is confident of success. Many companies have reportedly already expressed interest in testing technologies spanning industries from aviation to medical devices.

Above: Swami Magod and his brother Rajendra at their factory in Bangalore / Image credit: TRUMPF

Of course, there are many good reasons to adopt additive manufacturing. The technology opens up previously impossible geometries, paving the way for users to refine and improve their parts. The production of implants for medical purposes is just one example: 3D printed implants are more durable and more successfully fuse with healthy bone tissue. Another advantage of additive manufacturing is that it only applies material where it is really needed, so 3D printed parts are lighter. What's more, any excess powder can be recycled and reused - a much more cost-effective and sustainable approach than traditional processes where up to 80 percent of the material ends up wasted.

Hands-on experimentation is key

Magod's customers share Magod Laser's enthusiasm for experimenting with different geometries and materials in developing new parts. Magod engineers also make prototypes for companies considering 3D printing their own parts.

Capture the Initiative

Magod Lasers invests in the development of its employees / Image credit: TRUMPF

Educating potential customers and promoting 3D printing in India is an important step and Magod Laser believes it will take the lead. Magod Laser is always happy when potential customers and long-term partners can visit their manufacturing facilities to see 3D printing technology in action. He continues: “We are always on the lookout for new technologies to add to our portfolio because learning new things is a key part of our corporate ethos. We take the professional development of our employees seriously.