Med 3d printer

Introduction to Medical 3D Printing and 3D Printers for Healthcare

Personalized, precision medicine is on the rise. New tools and advanced technologies are bringing doctors closer to patients, delivering treatments and devices customized to better serve each unique individual.

Advances in medical 3D printing technology have made tremendous contributions to fields throughout healthcare. For patients, new tools and therapeutic methods developed through 3D printing can bring new degrees of comfort and personalization to treatment. For doctors, this newly accessible technology allows for a greater understanding of complex cases and provides new tools that can ultimately result in a higher standard of care.

From surgical planning models to 3D printed vasculature and bioreactors, read on to discover five ways 3D printing in healthcare is taking off and why many medical professionals are excited about the potential of 3D printing in the medical field. Then, learn about the most popular 3D printers for healthcare and how to choose a solution for specific use cases.

Webinar

Join Formlabs for this introduction to learn best practices for medical 3D printing and see the latest Formlabs Medical ecosystem, including multiple new medical-grade products!

Watch the Webinar Now

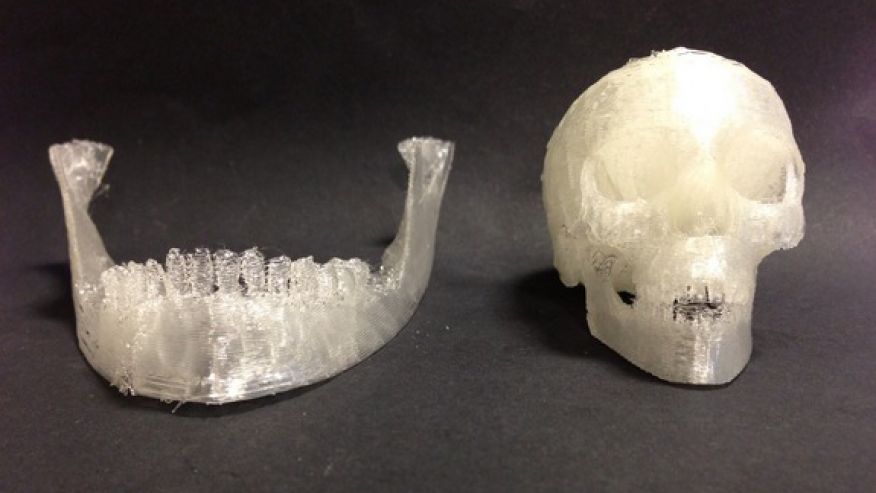

3D printed anatomical models from patient scan data are becoming increasingly useful tools in today’s practice of personalized, precision medicine. As cases become more complex and operating room efficiency becomes more important for routine cases, visual and tactile reference models can enhance understanding and communication within OR teams and with patients.

Healthcare professionals, hospitals, and research organizations across the globe are using 3D printed anatomical models as reference tools for preoperative planning, intraoperative visualization, and sizing or pre-fitting medical equipment for both routine and highly complex procedures that have been documented in hundreds of publications.

Producing patient-specific, tactile reference models from CT and MRI scans is affordable and straightforward with 3D printing. Peer-reviewed literature shows that they provide an additional view that helps physicians prepare better for surgeries, leading to drastically reduced time and cost in the operating room while improving patient satisfaction, lowering anxiety, and reducing recovery time.

Physicians can use patient-specific surgical models to explain the procedure beforehand, improving patient consent and lowering anxiety.

Learning from preoperative models can influence the course of treatment as well. This was true of the experience of Dr. Michael Eames. After replicating a young patient’s forearm bones, Dr. Eames realized the injury differed from what he’d previously thought.

Dr. Eames settled on a new, soft-tissue procedure—one that was much less invasive, decreased rehabilitation time, and produced far less scarring. Using the printed bone replica, Dr. Eames walked the young patient and his parents through the procedure and obtained their consent.

Eames walked the young patient and his parents through the procedure and obtained their consent.

The result? A surgery time of less than 30 minutes, instead of the initially planned surgery of three hours. This difference in surgery time led to an estimated $5,500 in cost avoidance for the hospital and meant the patient would need to spend less recovery time in postoperative care.

In the words of Dr. Alexis Dang, an orthopedic surgeon at the University of California San Francisco (UCSF) and the San Francisco Veteran's Affairs Medical Center: “Every one of our full-time orthopedic surgeons and nearly all of our part-time surgeons have utilized 3D printed models for care of patients at the San Francisco VA. We’ve all seen that 3D printing improves performance on game day.”

New biocompatible medical 3D printing materials have also enabled new surgical tools and techniques to be developed for the express purpose of further improving clinical experience during surgery. These include sterilizable fixation trays, contouring templates, and implant sizing models that can be used to size implants in the OR before the first cut, helping surgeons reduce time and increase accuracy of complex procedures.

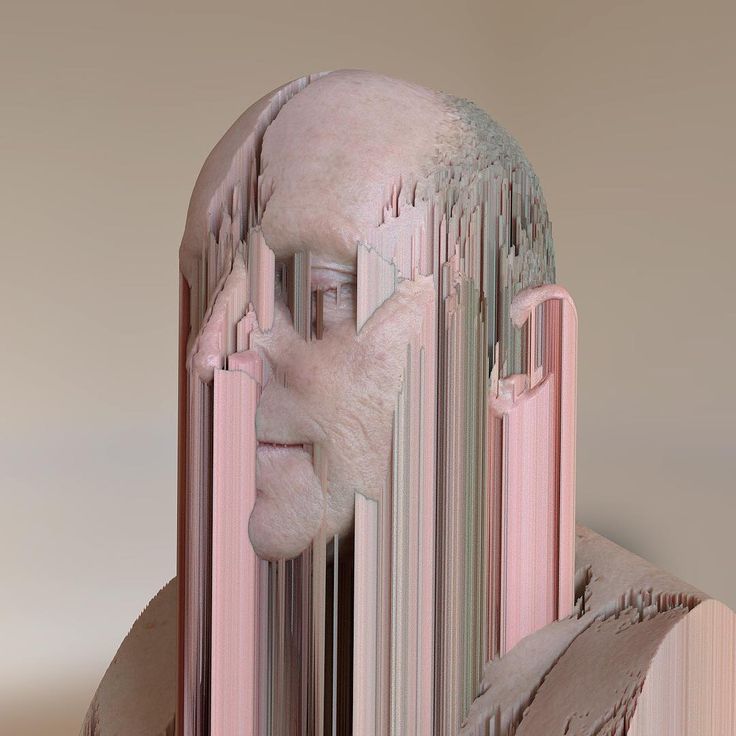

Anatomical model of a hand, including the 'skin' made out of an elastic 3D printing material.

Todd Goldstein, PhD, Instructor at the Feinstein Institute for Medical Research, is unequivocal in his estimation of how central 3D printing technology has become to his department. He estimates that if Northwell uses 3D printed models in 10-15% of its cases, it could save $1,750,000 a year.

“From medical device prototypes, complicated anatomical models for our children’s hospital, to creating training systems, and finally entering the dental clinic with implant surgical guides, [3D printing technology] has increased our capabilities and decreased our costs, all while allowing us to provide tools to treat patients that would be next to impossible to replicate without our go-to SLA 3D printer,” said Goldstein.

White Paper

Download our white paper for a practical walkthrough for physicians and technologists to get started creating 3D printed anatomicals models from patient scans, reviewing best practices for setting up a CT/MRI scan, segmenting datasets, and converting files to a 3D-printable format.

Download the White Paper

White Paper

In this webinar, Dr. Jonathan Morris, co-director of the Anatomic Modeling Laboratory and Neuroradiologist at the Mayo Clinic shares the history of 3D printing in medicine, and examines real-world case studies of how radiologists have successfully introduced 3D printing capabilities and programs into hospitals.

Watch the Webinar Now

3D printing has virtually become a synonym for rapid prototyping. The ease of use and low cost of in-house 3D printing has also revolutionized product development and many manufacturers of medical tools have adopted the technology to produce brand new medical devices and surgical instruments.

Over 90 percent of the top 50 medical device companies use 3D printing to create accurate prototypes of medical devices, jigs and fixtures to simplify testing, as well as directly 3D printing medical devices.

In the words of Alex Drew, a mechanical project engineer at DJO Surgical, a global provider of medical devices. “Before DJO Surgical brought the [Formlabs 3D printer] on board, we relied almost exclusively on outside print vendors for prototypes. Today, we are running four Formlabs machines, and the impact has been profound. Our rate of 3D printing has doubled, cost has been reduced by 70 percent, and the level of print detail allows for clear communication of designs with orthopedic surgeons.”

Medical device companies like Coalesce use 3D printing to create accurate prototypes of medical devices.

3D printing can accelerate the design process by iterating complex designs in days instead of weeks. When Coalesce was tasked to create an inhaler device that can digitally assess an asthma patient’s inspiratory flow profile outsourcing to service providers would have resulted in lengthy lead times for each prototype. Design files would have had to be painstakingly refined through various iterations before being sent off-site to be built.

Instead, desktop SLA 3D printing allowed Coalesce to keep the entire prototyping process in-house. The prototypes were fit for use in clinical studies and looked just like a finished product. In fact, when they showcased the device, their clients mistook the prototype for the final product.

Overall, in-house represented an enormous 80–90% reduction in lead time for prototypes. What’s more, the parts took only eight hours to print and could be finished and painted within a few days, while the same process would have taken a week or two through an external contractor.

White Paper

In this report, learn how Formlabs Medical helps medical device firms bring digital fabrication in-house, and get inspired through the examples of four companies currently creating groundbreaking devices using 3D printing.

Download the White Paper

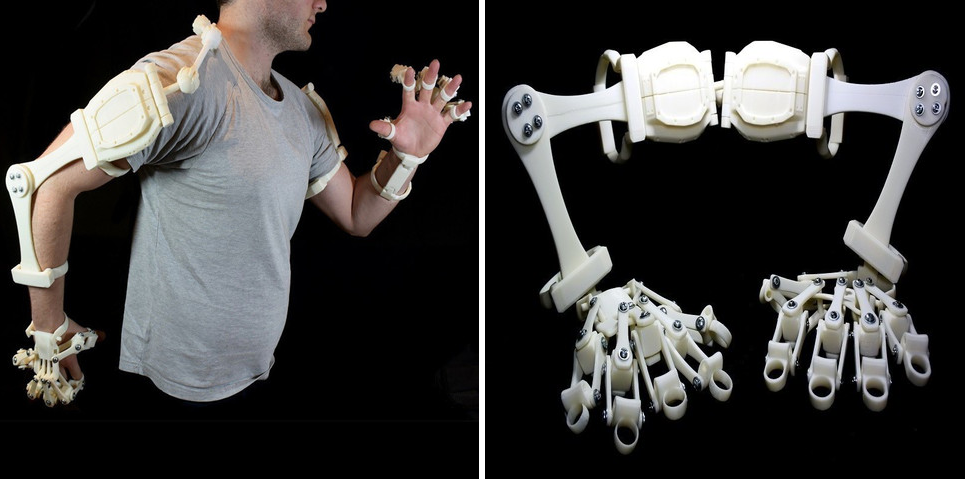

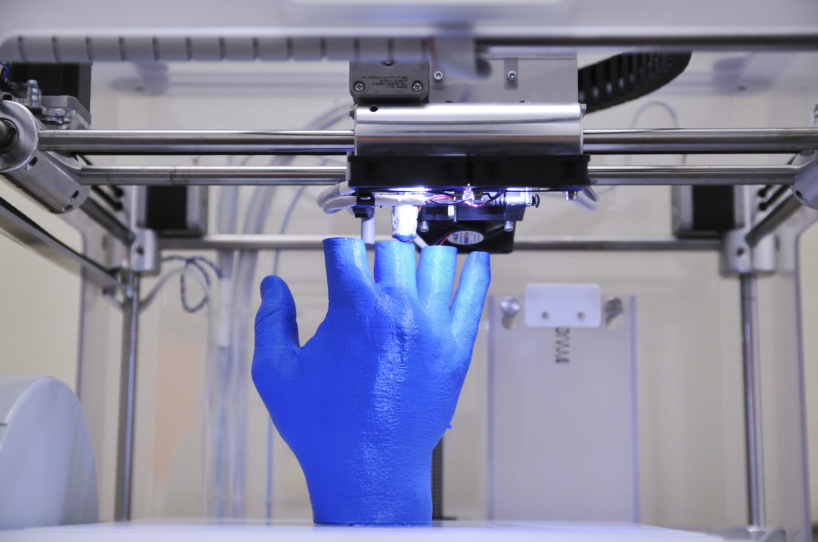

Each year hundreds of thousands of people lose a limb, but only a subset of them get access to a prosthesis to recover its function.

Simple prostheses are only available in a few sizes, so patients must make do with what fits best, while custom-fit bionic devices designed to mimic the motions and grips of real limbs that rely on muscles in a person’s residual limb to control their functions are so expensive that they’re only accessible to patients with the best health insurance in developed countries. This particularly affects prostheses for children. As children grow and get into adventures, they inevitably outgrow their prostheses and require expensive repairs.

The difficulty is the lack of manufacturing processes that can produce custom parts affordably. But increasingly, prosthetists can take advantage of 3D printing’s much-noted design freedom to mitigate these high financial barriers to treatment.

Initiatives such as e-NABLE allow entire communities around the world to form around 3D printed prostheses. They’re driving an independent movement in prosthetic production by sharing information and open-source designs freely online, so patients can get a custom-designed prosthesis that is well-adapted for them for as little as $50.

Other inventors like Lyman Connor, take this one step further. With only a small facility of four desktop 3D printers, Lyman was able to complete and fit his first production prostheses. His ultimate objective? To create a customizable, fully bionic hand to be sold at a fraction of the current tens of thousands of dollars retail price tag for such advanced prostheses.

Elsewhere, researchers at MIT have also identified 3D printing as an optimal means of producing more comfortable prosthesis sockets.

Needless to say, the low cost of producing these prostheses, along with the freedom that comes with custom designs, has proved revelatory. Prostheses made with 3D printing can be turned around in as little as two weeks and then can be trialed and maintained at a much lower cost than their traditional counterparts.

As the costs continue to decrease and material properties improve, 3D printing will undoubtedly play an increasing role in this department of healthcare.

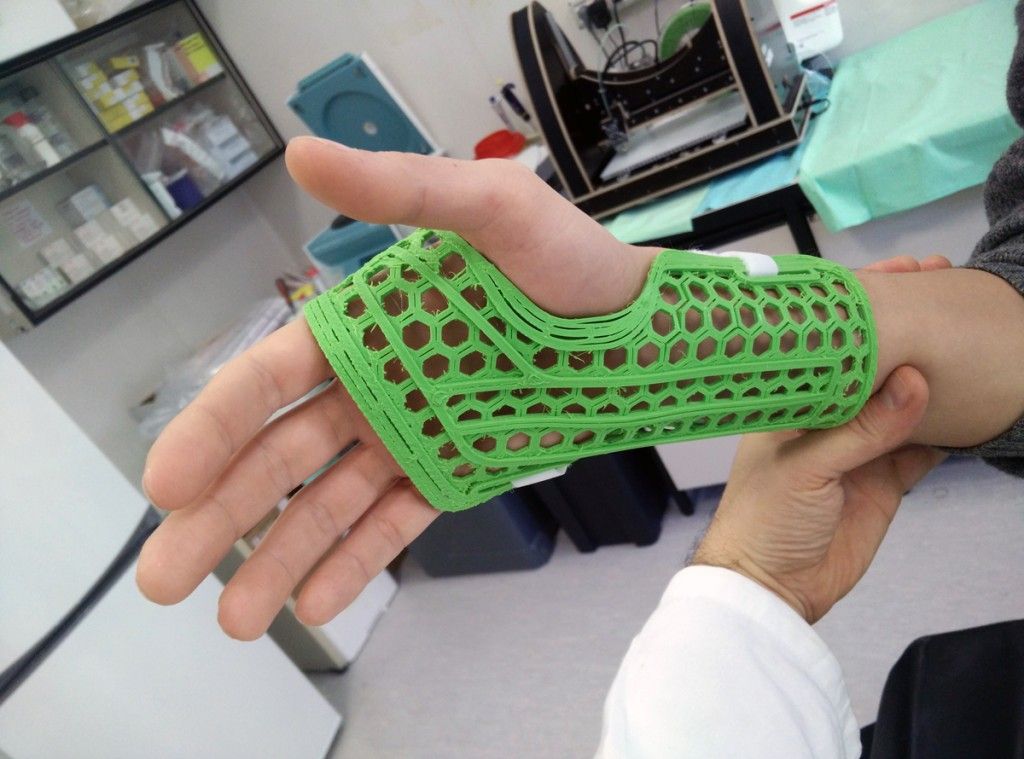

Many of the same high financial barriers to treatment seen in prosthetics are also native to fields such as orthoses and insoles. Like many other patient-specific medical devices, custom orthoses are often inaccessible due to their high cost and take weeks or months to get manufactured. With 3D printing, that no longer needs to be the case.

The example of Matej and his son Nik springs to our mind. Born prematurely in 2011, difficulties during childbirth caused Nik to have cerebral palsy, a condition that affects almost twenty million people worldwide. Matej was inspired by his son’s unwavering will to transcend the limitations of his condition, but he was faced with a choice between a standard, pre-made orthosis that would have been inadequate and uncomfortable for his son, or an expensive custom solution that would take weeks or months to be delivered, only to be made quickly obsolete by a growing child.

He decided to take matters into his own hands and sought out new solutions to achieve this goal. With the freedom offered by digital technologies including 3D scanning and 3D printing, Matej and Nik's physical therapists were able to experiment liberally and develop an entirely new innovative workflow for ankle foot orthoses (AFOs).

With the freedom offered by digital technologies including 3D scanning and 3D printing, Matej and Nik's physical therapists were able to experiment liberally and develop an entirely new innovative workflow for ankle foot orthoses (AFOs).

The resulting custom-made, 3D printed orthosis provided Nik with support, comfort, and correction precisely where it was needed, helping Nik to at last take his first independent steps. This custom orthotic device reprised the highly-adjusted finish of high-end orthotics, at a fraction of the price, and with no further adjustments required.

Professionals around the world are using 3D printing to reinvent patient- and customer-specific insoles and orthoses, as well as a range of other tools for improving physical therapy. In the past, the course of physical therapy using customized tools had proved difficult. Patients often faced long wait times and finished pieces that led to discomfort. 3D printing is on the path to change this status quo. 3D printed insoles and orthoses have proved to be a better fit, led to better therapeutic outcomes, and provided a greater degree of comfort and use for patients.

3D printed insoles and orthoses have proved to be a better fit, led to better therapeutic outcomes, and provided a greater degree of comfort and use for patients.

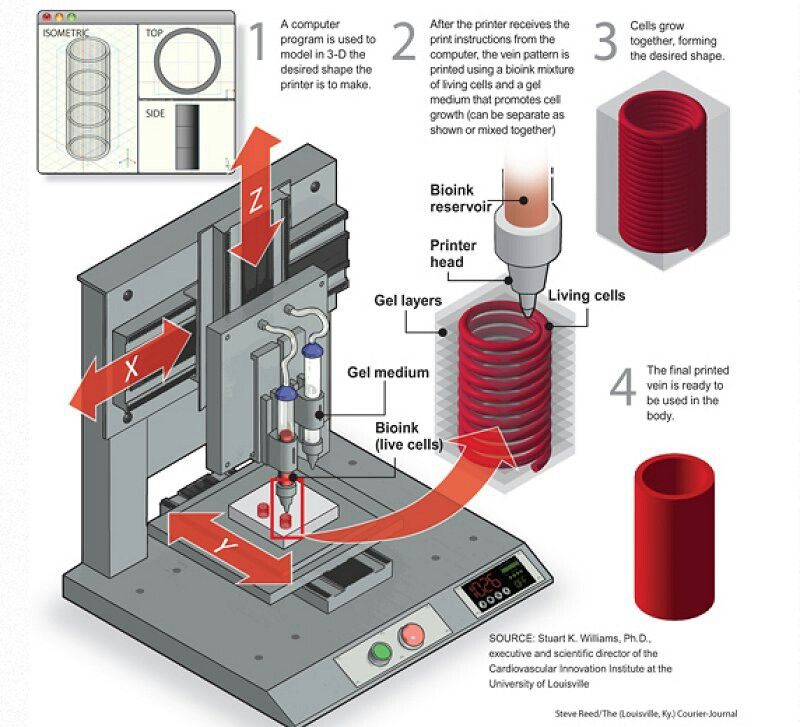

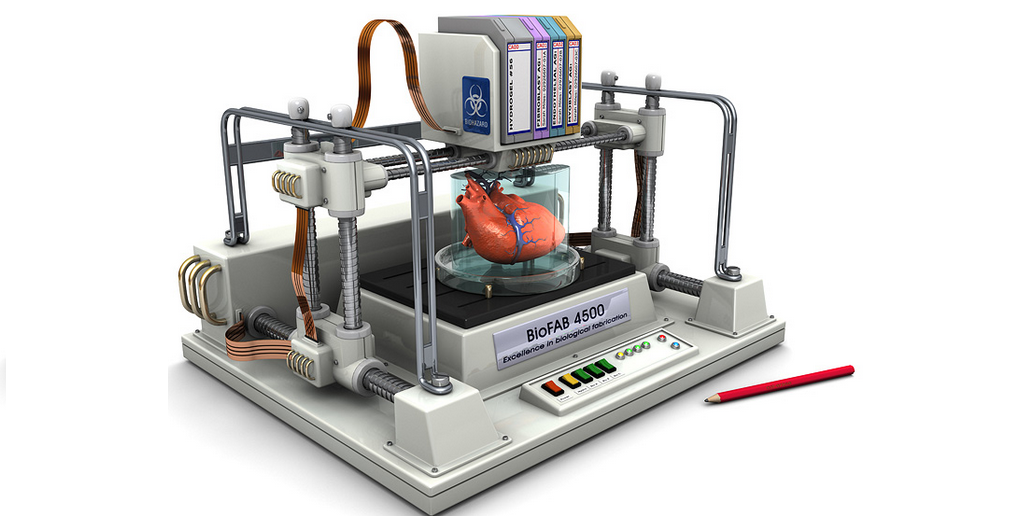

The conventional means of treating patients with grave organ failures currently involve using autografts, a graft of tissue from one point to another of the same individual's body, or organ transplants from a donor. Researchers in the fields of bioprinting and tissue engineering are hoping to soon change that and be able to create tissues, blood vessels, and organs on demand.

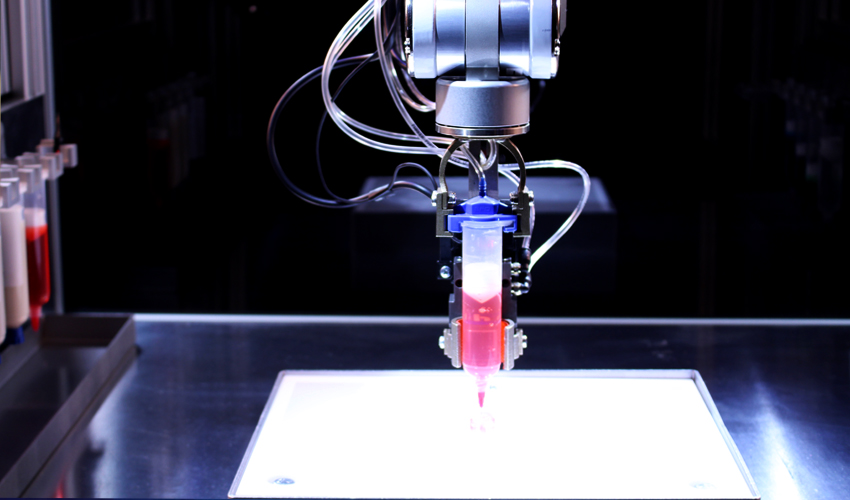

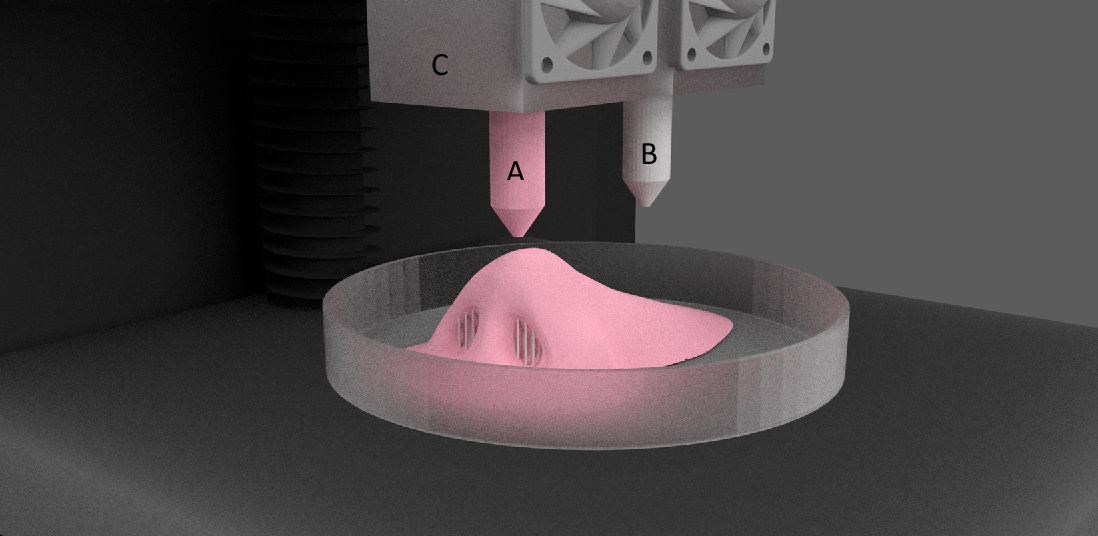

3D bioprinting refers to the use of additive manufacturing processes to deposit materials known as bioinks to create tissue-like structures that can be used in medical fields. Tissue engineering refers to the various evolving technologies, including bioprinting, to grow replacement tissues and organs in the laboratory for use in treating injury and disease.

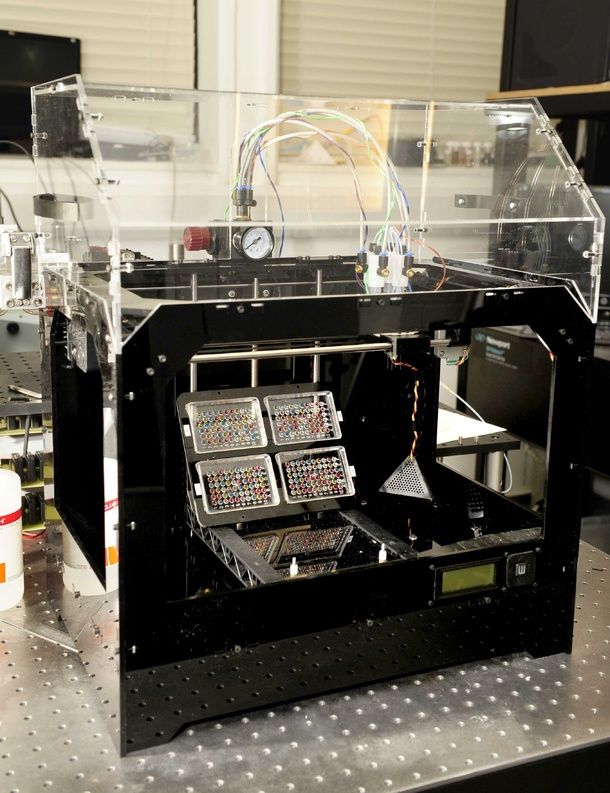

With the help of high-precision 3D printing, researchers like Dr. Sam Pashneh-Tala from the University of Sheffield have brought new possibilities to tissue engineering.

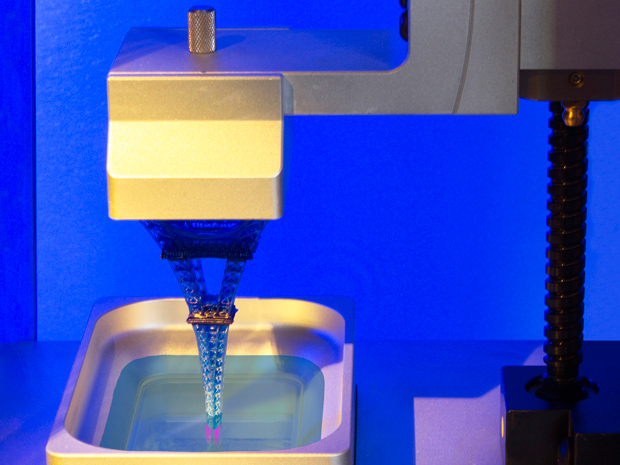

To direct cellular growth so that the required tissue is formed, Dr. Pashneh-Tala grows living cells on a scaffold in the lab, that provides a template of the required shape, size, and geometry. For example, a tubular structure is needed to create a blood vessel for a cardiovascular patient. The cells will multiply and cover the scaffold, taking on its shape. The scaffold then gradually breaks down, leaving the living cells arranged into the shape of the target tissue, that is cultured in a bioreactor, a chamber that contains the developing tissue and can reproduce the internal environment of the body, to acquire mechanical and biological performance of organic tissue.

A 3D printed bioreactor chamber with a tissue-engineered miniature aorta growing inside. The tissue is cultured in the bioreactor to acquire the mechanical and biological performance of organic tissue.

This will empower scientists to create patient-specific vascular graft designs, improved surgical options and provides a unique testing platform for new vascular medical devices for those suffering from cardiovascular disease, that is currently the number one cause of death worldwide. Following that, the ultimate goal is to create blood vessels that are ready to be implanted into the patients. As tissue engineering uses cells that are taken from the patient requiring the treatment, it eliminates the possibility of rejection by the immune system—a major issue in conventional organ transplant procedures today.

Following that, the ultimate goal is to create blood vessels that are ready to be implanted into the patients. As tissue engineering uses cells that are taken from the patient requiring the treatment, it eliminates the possibility of rejection by the immune system—a major issue in conventional organ transplant procedures today.

3D printing has proven capable of responding to the challenges of producing synthetic blood vessels by solving the difficulties of recreating the precise shapes, sizes and geometries of the vessel required. Being able to closely match printed solutions to the specific needs of patients has proved revelatory.

In Dr. Pashneh-Tala’s words: “[Creating blood vessels through 3D printing] offers the potential for improved surgical options and even patient-matched blood vessel designs. Without access to high-precision, affordable 3D printing, creating these shapes would not be possible.”

We have seen exciting breakthroughs in biological materials suitable for use in 3D printers. Scientists are developing new hydrogel materials that have the same consistency as organ tissue that can be found in the human brain and lungs and can be compatible with various 3D printing processes. Scientists are hoping to be able to implant them onto an organ, to act as ‘scaffold’ onto which cells would be encouraged to grow.

Scientists are developing new hydrogel materials that have the same consistency as organ tissue that can be found in the human brain and lungs and can be compatible with various 3D printing processes. Scientists are hoping to be able to implant them onto an organ, to act as ‘scaffold’ onto which cells would be encouraged to grow.

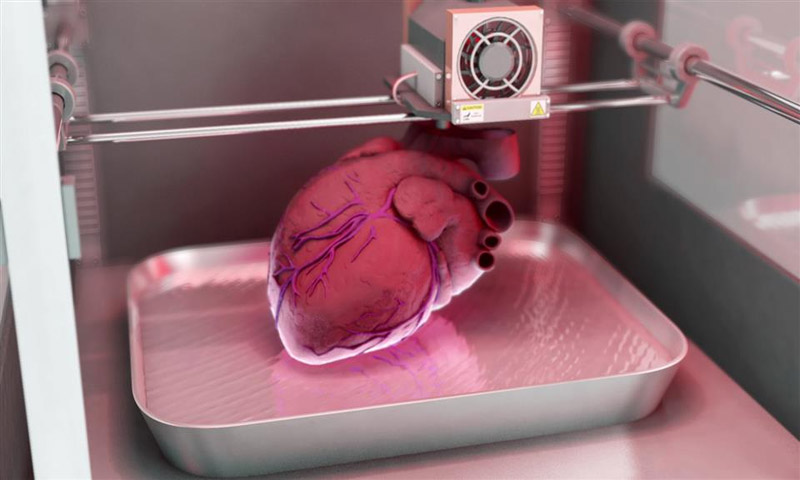

While bioprinting fully functional internal organs such as hearts, kidneys, and livers still sounds futuristic, advancements with hybrid 3D printing techniques are happening at a very rapid rate.

Sooner or later, building biological matter in laboratory printers is expected to lead to the ability to generate new, fully functional 3D printed organs. In April 2019, scientists created the first 3D heart using a patient's biological materials at Tel Aviv University. The tiny replica was created using the patient’s own biological materials, engendering a complete match of the patient’s immunological, cellular, biochemical, and anatomical profile.

"At this stage, our 3D heart is small, the size of a rabbit's heart, but larger human hearts require the same technology," said Professor Tal Dvir.

The first 3D bioprinted heart, created at the University of Tel Aviv.

When it comes to 3D printers for healthcare, not all methods are created equal. It is important to choose the right printing technology for specific use cases.

The most popular medical 3D printing technologies include stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM) for plastic parts, and direct metal laser sintering (DMLS) and selective laser melting (SLM) for metals.

SLA 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization. SLA is one of the most popular processes among medical professionals due to its high resolution, precision, and material versatility.

-

Advantages of SLA

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies. The main benefit of SLA, however, lies in its versatility. SLA resin formulations offer a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA resin formulations offer a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA is a great option for highly detailed anatomical models, medical device prototypes requiring tight tolerances and smooth surfaces, as well as molds, tooling, patterns, and functional end-use parts. SLA also offers the widest selection of biocompatible materials for dental and medical applications. With Draft Resin, the Formlabs SLA printers are also the fastest options for 3D printing large prototypes, up to 10X faster than FDM.

SLA’s wide versatility comes with a slightly higher price tag than FDM, but it is still more affordable than all other 3D printing processes. SLA resin parts also require post-processing after printing, which includes washing the parts and post-curing.

SLA 3D printing offers a wide selection of 3D printing materials, including biocompatible materials, for a variety of medical and dental applications.

Sample part

See and feel Formlabs SLA quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Webinar

Join Formlabs and Nelson Labs for a deep dive into biocompatibility, including an introduction to our new materials and best practices for medical manufacturers from industry experts.

Watch the Webinar Now

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures, making SLS a particularly effective choice for complex mechanical parts.

Its ability to produce parts with excellent mechanical capabilities makes SLS the most common polymer additive manufacturing technology for industrial applications. Depending on the material, SLS nylon parts may also be biocompatible and sterilizable.

-

Advantages of SLS

Since SLS printing doesn’t require dedicated support structures, it’s ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

The most common material for SLS is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt. 3D printed nylon parts can also be biocompatible and not sensitizing, which means that they are ready to wear and safe to use in many contexts.

The combination of low cost per part, high productivity, established materials, and biocompatibility makes SLS a popular choice among medical device developers for functional prototyping, and a cost-effective alternative to injection molding for limited-run or bridge manufacturing.

SLS 3D printers have a higher entry price than FDM or SLA technologies. While nylon is a versatile material, material selection for SLS is also more limited than for FDM and SLA. Parts come out of the printer with a slightly rough surface finish and require media blasting for a smooth finish.

SLS 3D printing is ideal for strong, functional prototypes and end-use parts, such as prosthetics and orthotics.

Sample part

See and feel Formlabs SLS quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

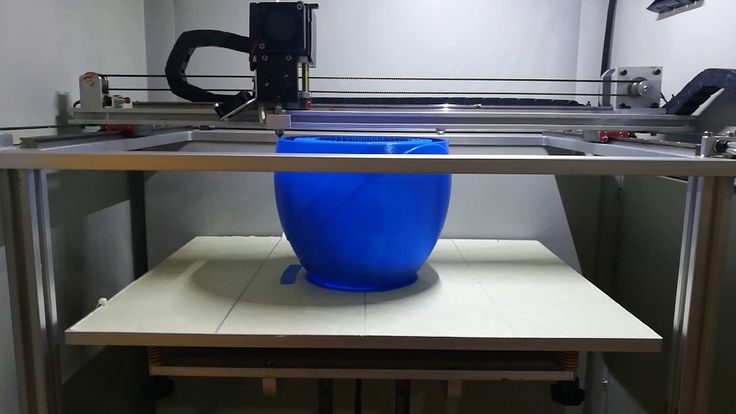

FDM, also known as fused filament fabrication (FFF), is a printing method that builds parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

FDM is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers. Industrial FDM printers are, however, also popular with professionals.

-

Advantages of FDM

FDM works with an array of standard thermoplastics, such as ABS, PLA, and their various blends. This results in a low price of entry and materials. FDM best suits basic proof-of-concept models and the low-cost prototyping of simpler parts. Some FDM materials are also biocompatible.

FDM has the lowest resolution and accuracy when compared to other 3D printing technologies for plastics such as SLA or SLS, which means that it is not the best option for printing complex designs or parts with intricate features, such as anatomical models. Higher-quality finishes require labor-intensive and lengthy chemical and mechanical polishing processes. Some industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics, but they also come at a steep price. When creating large parts, FDM printing also tends to be slower than SLA or SLS.

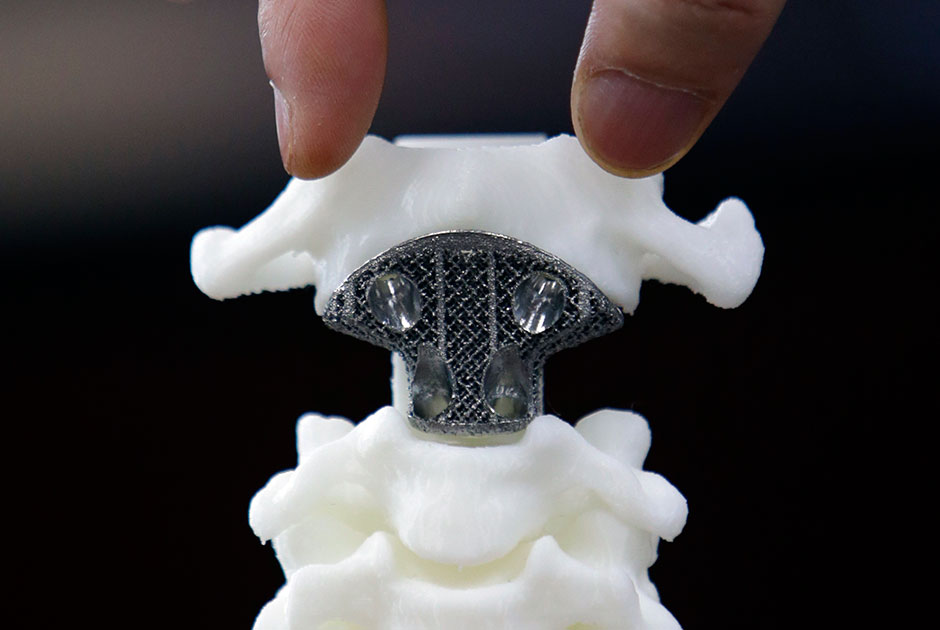

Direct metal laser sintering (DMLS) and selective laser melting (SLM) 3D printers work similarly to SLS printers, but fuse metal powder particles together layer by layer using a laser instead of polymers.

DMLS and SLM 3D printers can create strong, accurate, and complex metal products, making this process ideal for a variety of medical applications.

The biggest advantage of these processes is obviously the materials, as DMLS and SLM 3D printers are capable of producing high-performing end-use medical devices and components from metal. These processes can reproduce complex geometries and the finished products are strong, durable, and biocompatible. They can be used to manufacture generic implants (hips, knees, spine implants, etc.), custom implants for cancer or trauma treatment, dentures, as well as medical and orthopedic technology products.

While the prices of metal 3D printers have also begun to decrease, with costs ranging from $200,000 to $1 million+, these systems are still not accessible to most businesses. Metal 3D printing processes also have an involved and complex workflow.

Alternatively, SLA 3D printing is well-suited for casting workflows that produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

The table below highlights the 3D printing technologies that are best equipped to handle the different medical 3D printing applications.

| Stereolithography (SLA) | Selective Laser Sintering (SLS) | Fused Deposition Modeling (FDM) | Metal 3D Printing (DMLS, SLM) | |

|---|---|---|---|---|

| Build volume | Up to 300 x 335 x 200 mm (desktop and benchtop 3D printers) | Up to 165 x 165 x 300 mm (benchtop industrial 3D printers) | Up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) | Up to 400 x 400 x 400 mm (large industrial DMLS/SLM) |

| Price range | Starting from $3,750 | Starting from $18,500 | Starting from $2,500 | Starting from $200,000 |

| Materials | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, silicone-like, flexible, heat-resistant, rigid), castable, dental, and medical (biocompatible). | Engineering thermoplastics, typically nylon and its composites (nylon is biocompatible + compatible with sterilization). | Standard thermoplastics, such as ABS, PLA, and their various blends. | Stainless steel, tool steel, titanium, cobalt chrome, and aluminum. |

| Ideal applications | Anatomical models, highly detailed prototypes requiring tight tolerances and smooth surfaces; molds, tooling, patterns, functional parts, dental and medical end-use devices. | Complex geometries, functional prototypes, short-run or bridge manufacturing of medical devices, including orthotics and prosthetics. | Basic proof-of-concept models, low-cost prototyping of simple parts. | Strong, durable parts with complex geometries, implants, dentures, medical and orthopedic components out of metal. |

Precise and affordable medical 3D printing processes are democratizing access to the technology, empowering healthcare professionals to develop new clinical solutions and quickly manufacture custom devices, and allowing physicians to deliver new treatments across the globe. As medical 3D printing technologies and materials continue to improve, they will pave the path for personalized care and high-impact medical applications.

As medical 3D printing technologies and materials continue to improve, they will pave the path for personalized care and high-impact medical applications.

Every medical facility should have access to the latest tools to improve care and provide the best patient experience. Get started now or expand your in-house production with Formlabs, a proven, cutting-edge partner in medical 3D printing.

Reach out to our medical experts to learn more about how in-house 3D printing can provide better treatment and supplement your current medical device design and manufacturing workflow.

Contact Our Medical Experts

3D Printing in Medicine | About

Skip to main content

Aims and scope

3D Printing in Medicine publishes 3D printing innovation that impact medicine. Authors can communicate and share Standard Tessellation Language (STL) and related files via the journal. In addition to publishing techniques and trials that will advance medicine with 3D printing, the journal covers "how to" papers to provide a forum for translating applied imaging science.

In addition to publishing techniques and trials that will advance medicine with 3D printing, the journal covers "how to" papers to provide a forum for translating applied imaging science.

Benefits of publishing with BMC

High visibility

3D Printing in Medicine's open access policy allows maximum visibility of articles published in the journal as they are available to a wide, global audience.

Speed of publication

3D Printing in Medicine offers a fast publication schedule whilst maintaining rigorous peer review; all articles must be submitted online, and peer review is managed fully electronically (articles are distributed in PDF form, which is automatically generated from the submitted files). Articles will be published with their final citation after acceptance, in both fully browsable web form, and as a formatted PDF.

Flexibility

Online publication in 3D Printing in Medicine gives you the opportunity to publish large datasets, large numbers of color illustrations and moving pictures, to display data in a form that can be read directly by other software packages so as to allow readers to manipulate the data for themselves, and to create all relevant links (for example, to PubMed, to sequence and other databases, and to other articles).

Promotion and press coverage

Articles published in 3D Printing in Medicine are included in article alerts and regular email updates. Some may be highlighted on 3D Printing in Medicine’s pages and on the BMC homepage.

In addition, articles published in 3D Printing in Medicine may be promoted by press releases to the general or scientific press. These activities increase the exposure and number of accesses for articles published in 3D Printing in Medicine. A list of articles recently press-released by journals published by BMC is available here.

Copyright

As an author of an article published in 3D Printing in Medicine you retain the copyright of your article and you are free to reproduce and disseminate your work (for further details, see the BMC license agreement).

For further information about the advantages of publishing in a journal from BMC, please click here.

Open access

All articles published by 3D Printing in Medicine are made freely and permanently accessible online immediately upon publication, without subscription charges or registration barriers. Further information about open access can be found here.

Further information about open access can be found here.

As authors of articles published in 3D Printing in Medicine you are the copyright holders of your article and have granted to any third party, in advance and in perpetuity, the right to use, reproduce or disseminate your article, according to the BMC license agreement.

For those of you who are US government employees or are prevented from being copyright holders for similar reasons, BMC can accommodate non-standard copyright lines. Please contact us if further information is needed.

Article-processing charges

Open access publishing is not without costs. 3D Printing in Medicine therefore levies an article-processing charge of £1290.00/$1890.00/€1590.00 for each article accepted for publication, plus VAT or local taxes where applicable.

If the corresponding author's institution participates in our open access membership program, some or all of the publication cost may be covered (more details available on the membership page). We routinely waive charges for authors from low-income countries. For other countries, article-processing charge waivers or discounts are granted on a case-by-case basis to authors with insufficient funds. Authors can request a waiver or discount during the submission process. For further details, see our article-processing charge page.

We routinely waive charges for authors from low-income countries. For other countries, article-processing charge waivers or discounts are granted on a case-by-case basis to authors with insufficient funds. Authors can request a waiver or discount during the submission process. For further details, see our article-processing charge page.

Visit Springer Nature’s open access funding & support services for information about research funders and institutions that provide funding for APCs.

Springer Nature offers agreements that enable institutions to cover open access publishing costs. Learn more about our open access agreements to check your eligibility and discover whether this journal is included.

For more information on APCs please see our Journal Pricing FAQs

Indexing services

All articles published in 3D Printing in Medicine are included in:

- WTI Frankfurt eG

- TD Net Discovery Service

- Semantic Scholar

- PubMedCentral

- ProQuest-ExLibris Summon

- ProQuest-ExLibris Primo

- OCLC WorldCat Discovery Service

- Naver

- Institute of Scientific and Technical Information of China

- Google Scholar

- Gale

- EMBASE

- EBSCO Discovery Service

- Dimensions

- DOAJ

- Chinese Academy of Sciences (CAS) - GoOA

- CNKI

The full text of all articles is deposited in digital archives around the world to guarantee long-term digital preservation. You can also access all articles published by BioMed Central on SpringerLink. We are working closely with relevant indexing services such as Web of Science (Clarivate Analytics) to ensure that articles published in 3D Printing in Medicine will be available in their databases when appropriate.

You can also access all articles published by BioMed Central on SpringerLink. We are working closely with relevant indexing services such as Web of Science (Clarivate Analytics) to ensure that articles published in 3D Printing in Medicine will be available in their databases when appropriate.

Peer-review policy

Peer-review is the system used to assess the quality of a manuscript before it is published. Independent researchers in the relevant research area assess submitted manuscripts for originality, validity and significance to help editors determine whether the manuscript should be published in their journal. You can read more about the peer-review process here.

3D Printing in Medicine operates a single-blind peer-review system, where the reviewers are aware of the names and affiliations of the authors, but the reviewer reports provided to authors are anonymous Publication of research articles by 3D Printing in Medicine is dependent primarily on their scientific validity and coherence as judged by our external expert editors and/or peer reviewers, who will also assess whether the writing is comprehensible and whether the work represents a useful contribution to the field.

Submitted manuscripts will generally be reviewed by two to three experts who will be asked to evaluate whether the manuscript is scientifically sound and coherent, whether it duplicates already published work, and whether or not the manuscript is sufficiently clear for publication. Reviewers will also be asked to indicate how interesting and significant the research is. The Editors will reach a decision based on these reports and, where necessary, they will consult with members of the Editorial Board.

Editorial policies

All manuscripts submitted to 3D Printing in Medicine should adhere to BMC's editorial policies.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appeals and complaints

Authors who wish to appeal a rejection or make a complaint should follow the procedure outlined in the BMC Editorial Policies.

Submit manuscript

- Editorial Board

- Manuscript editing services

- Instructions for Editors

- Sign up for article alerts and news from this journal

Annual Journal Metrics

- ISSN: 2365-6271 (electronic)

Medical 3D Printing Application Overview

Contents:

- Medical 3D Printing Equipment Use

- Benefits of using 3D printers

- The main directions of the use of additive technologies in medicine

- Manufacture of surgical and other medical instruments

- Dentistry and prosthetics

- Student education and preparation for surgery

- 3D bioprinting of organs and tissues

- Production of medicines on a 3D printer

- Creating ovaries

- Making a model of the heart of a 4-year-old patient on a three-dimensional printer Zortrax M200

- Creation of a cranial implant

- Use of individual sensors

- Treatment of extensive wounds

- Creation of artificial corneas

- Manufacture of the Volt Bipolar Surgical Forceps for Laparoscopic Operations

- Hip replacement

- Fabrication of dental crowns

- Reconstruction of the auricle (cartilage fabrication)

- Production of dental impressions

- Construction of a medical exoskeleton

- Fabrication of the Cardiovascular Model

- Creation of prostheses

3D Printing in Medicine

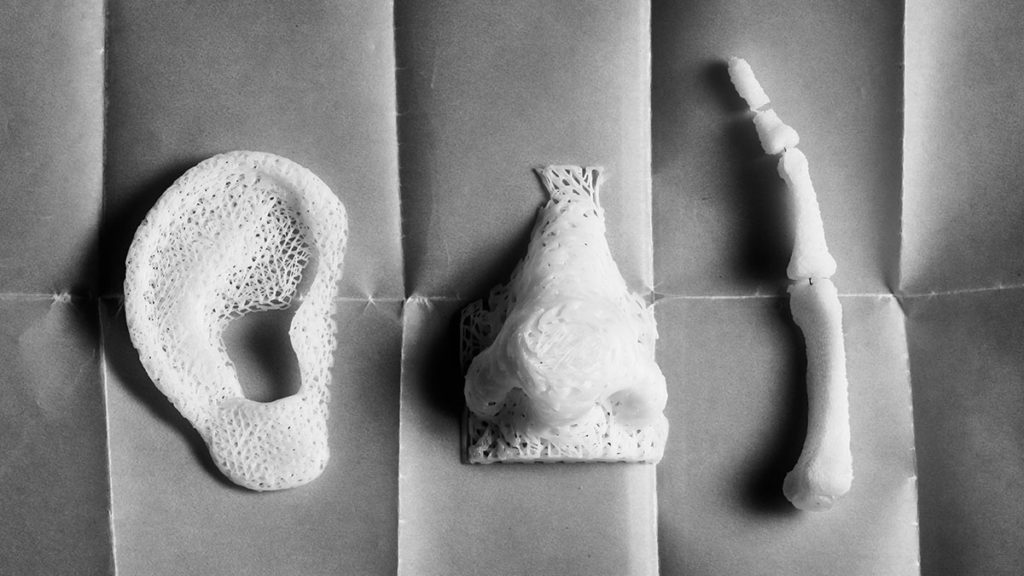

3D printing was first used in the medical field to print dental implants in the early 2000s. Since then, the field of medical application of this electronic technology has expanded significantly and continues to develop. Now with its help, elements of the respiratory tract (nose, etc.) and the skeleton (jaw, joints, etc.), cell cultures, blood vessels, some parts of the eyes, organs (kidneys, bladder, etc.), tissues, medicines are produced. , layouts of biomolecules, bacteria, viruses and more.

Since then, the field of medical application of this electronic technology has expanded significantly and continues to develop. Now with its help, elements of the respiratory tract (nose, etc.) and the skeleton (jaw, joints, etc.), cell cultures, blood vessels, some parts of the eyes, organs (kidneys, bladder, etc.), tissues, medicines are produced. , layouts of biomolecules, bacteria, viruses and more.

Printable 3D files allow users and researchers around the world to share their own scientific developments over the network, discuss interesting cases and the opinions of colleagues. And also independently or jointly with partners to improve three-dimensional prototypes without spending months and years reproducing objects from scratch.

Working on additive projects requires the integration of technologies from different scientific fields, including cell biology, medicine, mathematics, physics, engineering, biomaterials science, and industries.

Advantages of using 3D printers

Medical 3D printing has the following advantages:

- material and labor savings;

- 3D printing of structures of the highest level of complexity, completely similar to prototypes, lightening their weight;

- high print speed;

- high accuracy and detail, taking into account the anatomical parameters of a particular patient;

- a large number of innovative high-tech materials, including a wide range of consumables that are suitable for implantation in the body;

- cost reduction of medical products;

- reduction of production terms and, as a result, timely provision of medical care.

The main areas of application of additive technologies in medicine

The use of 3D printers in medicine can be divided into the following categories:

- Manufacturing of medical instruments.

- Printing of orthopedic products, frameworks and implants.

- Printing of 3D anatomical models for educational purposes and in preparation for operations.

- Creation of organs and tissues.

- Pharmaceutical research.

Manufacture of surgical and other medical instruments

In order to perform surgical interventions with minimal trauma for patients, surgeons try to use personalized instruments that are anatomically suitable for a particular person. 3D printing makes it possible to produce customized instruments and templates for surgery in just a few hours.

Additive technologies allow surgeons to customize finished instruments to the right shape and size for more productive, comfortable and safer work. Dentists have the opportunity to create, for example, personal guiding instruments in front of the patient to protect healthy teeth from damage when installing prostheses.

Dentists have the opportunity to create, for example, personal guiding instruments in front of the patient to protect healthy teeth from damage when installing prostheses.

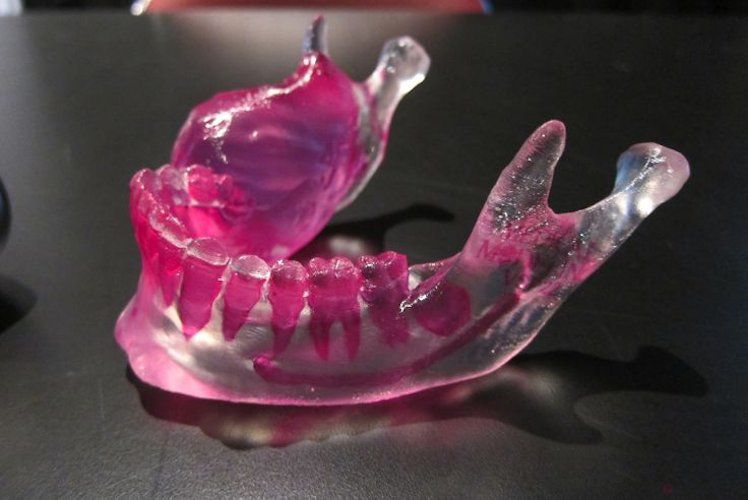

Dentistry and prosthetics

Three-dimensional technologies have become a real breakthrough in the development of the medical products market and the field of dentistry in particular. First of all, they made it possible to scan the oral cavity in a three-dimensional format as accurately and in detail as possible. Secondly, with the help of 3D printing, it is possible to produce dental prostheses in full accordance with the anatomy of patients without additional fitting. A significant reduction in manual labor when working on veneers, bridges and crowns made it possible to expand the list of materials for prosthetics, reduce the required manufacturing tolerances and improve the quality of work in general.

Additive manufacturing is widely used in medicine to design complex individual and serial products: surgical implants, prostheses of any geometry, auxiliary structures, etc. Such structures are made by converting CT, MRI or X-ray images into three-dimensional models for 3D printing devices using specialized software. 3D technologies are especially in demand when it comes to the urgent production of non-standard prostheses and implants. The fact is that standard models often do not correspond to the specifics of the anatomy of patients. For example, neurosurgeons often face such a problem: human skulls have a unique shape, so it is extremely difficult to create a standard cranial implant. Before the advent of three-dimensional technologies and 3D-printed models, doctors finalized and customized implants, sometimes right during the operation. Now you don't need to do this. The most important advantage of printed prostheses is a perfectly precise connection with the body with virtually no risk of rejection.

Such structures are made by converting CT, MRI or X-ray images into three-dimensional models for 3D printing devices using specialized software. 3D technologies are especially in demand when it comes to the urgent production of non-standard prostheses and implants. The fact is that standard models often do not correspond to the specifics of the anatomy of patients. For example, neurosurgeons often face such a problem: human skulls have a unique shape, so it is extremely difficult to create a standard cranial implant. Before the advent of three-dimensional technologies and 3D-printed models, doctors finalized and customized implants, sometimes right during the operation. Now you don't need to do this. The most important advantage of printed prostheses is a perfectly precise connection with the body with virtually no risk of rejection.

Student education and preparation for surgery

3D models are a much better medium for teaching and training medical students than human cadavers. 3D mock-ups are more accessible, and 3D modeling helps to reproduce a wide range of pathologies relevant to the topic under study. For example, neuroanatomical 3D models are very useful for future neurosurgeons, as they provide the most complete picture of the most complex structures of the body, which cannot be achieved by studying two-dimensional images.

3D mock-ups are more accessible, and 3D modeling helps to reproduce a wide range of pathologies relevant to the topic under study. For example, neuroanatomical 3D models are very useful for future neurosurgeons, as they provide the most complete picture of the most complex structures of the body, which cannot be achieved by studying two-dimensional images.

Three-dimensional models printed on a 3D printer based on the results of hardware research allow taking into account the patient's anatomy when rehearsing operations. The use of a tangible three-dimensional model of the patient's organ gives the surgeon the opportunity to more thoroughly study the pathology or simulate surgery, which significantly reduces the risk of medical errors.

Production of organs and tissues by 3D bioprinting

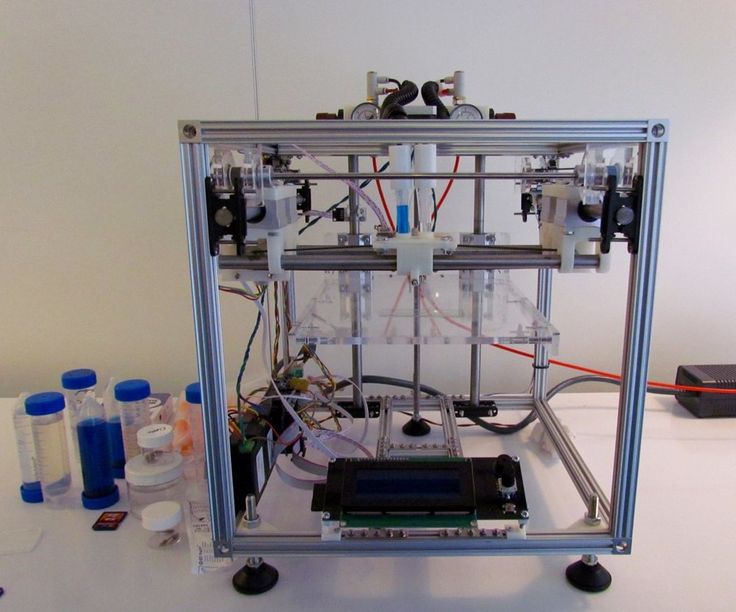

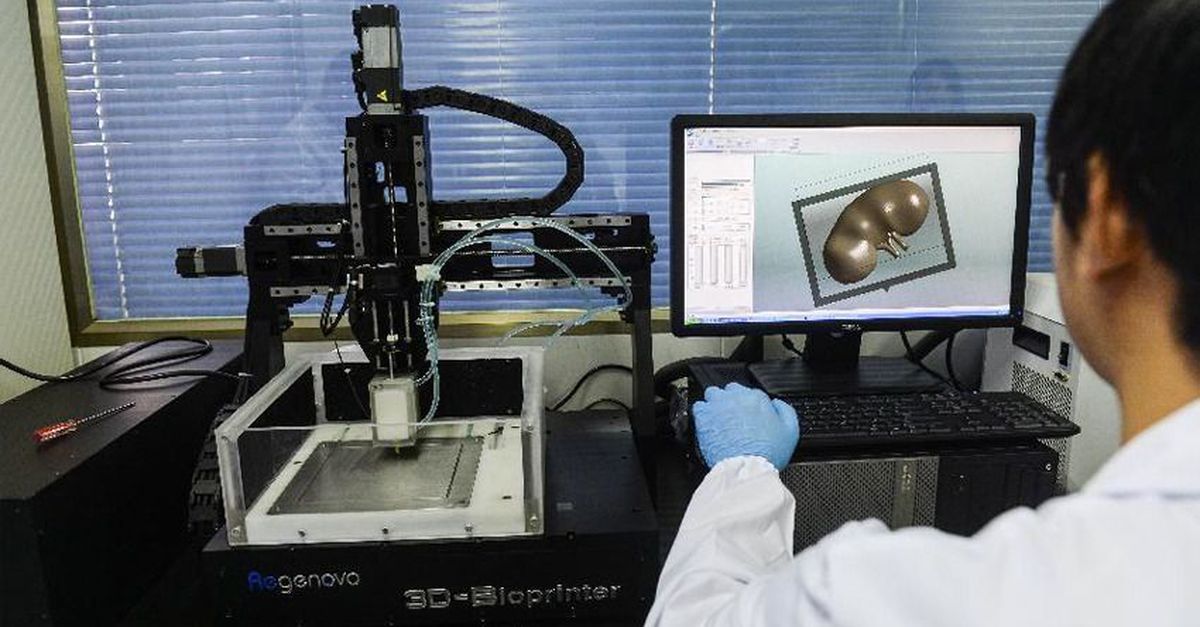

Bioprinting is one of the types of 3D printing in medicine. Instead of metal or plastic, special printers use a syringe dispenser to apply "biological ink" (tissue spheroids), that is, layers of living cells or a structuring base for them, creating an artificial living tissue. For the "printing" of some tissues, stem cells, seaweed or porcine collagen protein are taken.

For the "printing" of some tissues, stem cells, seaweed or porcine collagen protein are taken.

Organic materials obtained in this way are a good alternative to donor tissues and a valuable tool for medical research. They can be used for tissue regeneration, and in the future, for the restoration of organs directly in the patient's body.

3D bioprinting can be done using different technologies: inkjet, laser or extrusion. The most common method is 3D inkjet printing, where multiple printheads can be used to print different types of cells (muscle tissue, blood vessels, organ-specific cells). These cells are essential for building heterocellular organs and tissues.

3D drug production

3D technologies are used in personalized medicine and pharmaceutical research. With the help of 3D printing, you can fully control the dosage of various drugs and the composition of dosage forms with prolonged action and complex release profiles of active substances. Pharmacists have the opportunity to effectively analyze the pharmacogenetic profile of patients and other parameters. For example, gender, age and weight, to determine the optimal dose of drugs and their regimen. Based on the clinical response, the dosage may be adjusted if necessary.

For example, gender, age and weight, to determine the optimal dose of drugs and their regimen. Based on the clinical response, the dosage may be adjusted if necessary.

Additive printing allows the production of personalized medicines according to new formulations, for example, complex multilayer tablets or capsules containing several active ingredients, and many other useful things.

Examples of the use of 3D printers in medicine

Ovarian printing

In 2017, American doctors and scientists at Northwestern University Chicago (USA) developed an artificial ovary that opens up opportunities for the full restoration of female reproductive function. During the study, a 3D-printed ovarian prosthesis was implanted into the body of an infertile laboratory mouse. As a result of the experiment, the “patient” acquired offspring, moreover, the mice turned out to be completely viable and after that they were also able to produce offspring.

It is currently unknown whether such an artificial ovary can be implanted in a woman, as human follicles grow much faster than mouse follicles.

Making a model of the heart of a 4-year-old patient on a Zortrax M200 3D printer

A team of experts from the Department of Pediatric Cardiology and Congenital Heart Diseases, together with colleagues from the Department of Radiology and Cardiac Surgery of the Medical University of Gdansk (Poland), used the Zortrax M200 3D printer to prepare for the execution surgery for the treatment of complex congenital heart disease in a four-year-old patient - tetralogy of Fallot.

The modern method of treating this pathology involves the supply of an artificial valve for implantation to the heart through a special catheter inserted through the femoral vein. This is an extremely complex operation that requires the surgeon to have the most complete and detailed knowledge of the anatomical characteristics of a real patient.

Previously, doctors could only rely on a three-dimensional computer model developed from MRI and CT images. However, these images were not enough to form a complete picture of the state of the organ and the likely problems that could occur during surgery. The use of a highly detailed physical copy of an organ (heart with cells, chambers, ventricles, blood vessels) can play a decisive role in the planning of the operation and be the main factor in its success.

The use of a highly detailed physical copy of an organ (heart with cells, chambers, ventricles, blood vessels) can play a decisive role in the planning of the operation and be the main factor in its success.

The model of the heart was printed in the laboratory in 24 hours. Z-Ultrat material was used for 3D printing of the heart, and Z-Glass material was used for vessels. Operation was successfully completed. The model was then handed over to the University for use as a teaching tool for students.

Creation of a cranial implant

Titanium bone implants are printed in single copies. It is when working with them that the advantages of 3D printers using selective laser melting (SLM) technology are best manifested. This method allows you to print implants of any shape with the highest accuracy in just a few hours.

Using custom sensors

In 2016, scientists from Washington University in St. Louis (USA) conducted a study on the use of flexible and movable silicone custom sensors. They printed three-dimensional copies of scanned models of the hearts of experimental animals and placed sensors around them. Three-dimensional sensors can be removed from the prototype and fixed to the human heart. With their help, you can monitor the work of the heart muscle in order to prevent the occurrence of strokes, heart attacks and other serious diseases. Individual sensors are used so far only outside the body, but scientists suggest that in the future it will be possible to introduce them into the human body.

They printed three-dimensional copies of scanned models of the hearts of experimental animals and placed sensors around them. Three-dimensional sensors can be removed from the prototype and fixed to the human heart. With their help, you can monitor the work of the heart muscle in order to prevent the occurrence of strokes, heart attacks and other serious diseases. Individual sensors are used so far only outside the body, but scientists suggest that in the future it will be possible to introduce them into the human body.

Treatment of extensive wounds

Scientists at the Wake Forest Institute of Regenerative Medicine have developed a mobile 3D printer that can print skin cells grown from patient tissue directly over a wound.

Major burns are traditionally treated by grafting the patient's healthy skin over damaged skin. This method is quite traumatic, in addition, it cannot be applied in the absence of healthy skin on the body.

The ZScanner Z700 handheld scanner, developed by scientists, will determine the depth and size of the wound. Based on this data, 3D bioprinting equipment creates epidermal, dermal and subcutaneous skin cells at appropriate depths, completely covering the wound. The 3D printer consists of an extruder (print head) with eight nozzles with a diameter of 260 microns with independent dispensers, moving along three axes. Especially for this model of a 3D printer, scientists have developed a bioink based on epidermal keratinocytes and autologous dermal fibroblasts in a hydrogel carrier.

Based on this data, 3D bioprinting equipment creates epidermal, dermal and subcutaneous skin cells at appropriate depths, completely covering the wound. The 3D printer consists of an extruder (print head) with eight nozzles with a diameter of 260 microns with independent dispensers, moving along three axes. Especially for this model of a 3D printer, scientists have developed a bioink based on epidermal keratinocytes and autologous dermal fibroblasts in a hydrogel carrier.

Printing of artificial corneas

A group of scientists from the School of Medicine of Kungpuk National University and Pohang University of Science and Technology in South Korea has developed a technology for 3D printing of an artificial cornea from a patient's tissue material (stem cells and decellularized corneal stroma) on a Nano Master SMP-III 3D bioprinter with microextrusion technology. The cornea, made on a 3D printer and filled with biomaterial, is cultivated for four weeks in an incubator at a temperature of 37 degrees.

The resulting material can completely replace the donor cornea. Its main advantage is full compatibility with the patient's tissues. Cellular 3D printing reproduces the natural microenvironment of the eye as closely as possible, allowing for natural transparency. Unlike traditional artificial corneas made of synthetic polymers and recombinant collagen, this material takes root just fine. In addition, its use will help reduce the waiting time for surgery, which is on average 6 years (for example, South Korea).

Manufacture of the Volt Bipolar Surgical Clamp for Laparoscopic Operations

In 2016, Bite developed a miniature 3D printed laparoscopic instrument for clamping and coagulating tissues and vessels, designed for minimally invasive surgery. The clamp has been successfully tested on porcine liver. The design of the instrument allows easy adjustment of the geometry of the tip and shaft, taking into account the anatomy of the patient and the specifics of the surgical intervention.

Hip prosthesis print

Employees of the Institute of Traumatology and Orthopedics. R.R. Vreden, together with colleagues from LETI (St. Petersburg), worked on the design of a titanium prosthesis of the hip joint. First, scientists made a model of the bone out of plastic based on computed tomography. Then the implant was designed and its positioning on the bone was corrected. The next step was planning the operation on a mock-up and, to top it off, printing the prosthesis on a 3D printer. The implant was successfully implanted in a patient with an almost completely destroyed hip joint, as a result of which the person regained the ability to walk independently.

Production of dental crowns

Using the Farsoon FS121M 3D printer, working on SLM technology, allows you to simplify and speed up the printing of dental crowns and other objects of complex shape. The equipment can print 160 metal crowns in just 3 hours. The highest precision of products is achieved through the use of a laser beam with a spot diameter of 40 microns and a fine powder.

Reconstruction of the auricle (cartilage production)

Using the Rokit Dr. 3D printer. Invivo 4D Premium with a syringe dispenser and consumables such as copolymer of glycolic and lactic acids (PLGA) and hydroxyapatite (HAp) can print the flexible structures needed for cartilage reconstruction. This technology is used in reconstructive surgery of the outer ear.

Dental Impression Printing

The Raise3D Pro2 3D printer with FDM technology enables the production of orthodontic dental impressions. The huge advantage of this technique is the reduction of time spent with the patient. A 3D model is created using a volumetric scanner in just 1 minute. On its basis, a plastic prototype is printed, which is used by orthodontists for subsequent work. The technology is widely used by physicians at the French hospital Ortho 34.

Creation of a medical exoskeleton

Specialists from Barlomiej Gaczorek Design Studio have developed a model of a complex supporting exoskeleton for hands and printed its details on a Sinterit Lisa 3D SLS printer. The use of SLS selective sintering technology made it possible to achieve the highest precision of structural elements.

The use of SLS selective sintering technology made it possible to achieve the highest precision of structural elements.

Modeling of the cardiovascular system

In rare forms of cardiovascular diseases, especially in newborns, the risk of making mistakes in the preparation of the therapy regimen is too high, which requires a detailed development of the treatment program. Specialists at the University Clinical Center in Gdansk (Poland) use the Sinterit Lisa SLS printer to work with complex diagnoses. Doctors have created a three-dimensional model of the cardiovascular system, designed for a detailed study of the anomaly and preparation for surgery.

Creation of prostheses

The use of FDM printers is indispensable in situations where it is necessary to facilitate and reduce the cost of manufacturing exclusive prostheses. Canadian designer Albert Fung has developed a 3D digital model of a prosthesis that has become the basis for the production of prosthetic hands for Sierra Leoneans affected by the civil war. Medical specialists in Sierra Lyon modify the CAD model based on the anatomy of each patient and print the products on a Raise3D Pro2 3D printer. Printing of such structures costs only 50 US dollars (for comparison, the cost of prostheses made using other technologies is several thousand dollars).

Medical specialists in Sierra Lyon modify the CAD model based on the anatomy of each patient and print the products on a Raise3D Pro2 3D printer. Printing of such structures costs only 50 US dollars (for comparison, the cost of prostheses made using other technologies is several thousand dollars).

Conclusion

The field of application of 3D printing technology in medicine is full of achievements and is constantly expanding, resembling a real revolution in the field of healthcare. Additive manufacturing methods increase the productivity and cost-effectiveness of doctors' work, open up a lot of new opportunities and reduce waiting times. They allow the production of individual medical products and drugs, improve the quality of patient care, while making medical care more accessible.

3DTool sells trusted brands of 3D scanners and 3D printers for medical use.

Medical 3D Printer | Why doctors need 3D printing

Medical 3D printing and its varieties

3D printer for medicine has taken on a whole new meaning in recent years due to the rapid development of 3D technologies. Now it is a versatile production tool with which you can perform a wide range of diverse tasks. Thus, 3D printing in medicine is actively used for:

Now it is a versatile production tool with which you can perform a wide range of diverse tasks. Thus, 3D printing in medicine is actively used for:

- Creation of living tissues and organs;

- Bone seals;

- Creation of blood vessels;

- Manufacture of biocompatible prostheses;

- Creation of individual implants;

- Manufacture of unique surgical instruments;

- Development and creation of auxiliary devices and much more.

Of course, these are not the only areas in which a 3D printer for medicine is actively used. But it is in these directions that world-class medical organizations are moving. In many large hospitals and laboratories, 3D printing has already become a very common practice. For such organizations, professional equipment is massively purchased, but in this section we want to tell you more about why you need a desktop 3D printer for medicine.

How a 3D printer is used in medicine

When it comes to using 3D technology for medical purposes, many immediately think of 3D printing of organs and other revolutionary projects. However, do not forget that even ordinary FDM and SLA 3D printers can do a good job for the followers of Hippocrates. Here are the areas in which they are useful:

However, do not forget that even ordinary FDM and SLA 3D printers can do a good job for the followers of Hippocrates. Here are the areas in which they are useful:

- Dentistry . The most common medical industry in which 3D printers are massively used. Many photopolymer resins and devices for SLA 3D printing are even adapted to the needs of dentists. To date, using this technique, even full-fledged dental instruments and implants can be created;

- Manufacture of implants . Here we are talking about surgical implants, including metal ones. Of course, making a biocompatible titanium implant would require a professional medical 3D printer, but prototypes and master models are produced using desktop 3D printers;

- Custom medical models . Such models are needed for high-quality medical planning and are most often created on the basis of CT scan data. With their help, it becomes possible to quickly and competently distribute all stages of treatment without disturbing the patient.

Roughly speaking, a doctor can perform an operation without an operation;

Roughly speaking, a doctor can perform an operation without an operation; - Orthopedic corsets . A very common use of 3D printers that requires a 3D scan. Thus, the output is an individual orthopedic corset that fully corresponds to all the anatomical features of the patient.

- Creating tutorial models . A medical 3D printer will also be an excellent companion for medical students and trainees who need to thoroughly study the human anatomy. 3D printing is an economical and efficient way to reproduce anatomical models.

Buy Medical 3D Printer

Of course, we can't say that every doctor or hospital needs a medical 3D printer, but its usefulness for this industry is hard to deny. So, SLA 3D printing is gradually gaining popularity in dentistry circles due to its accuracy and convenience. Our company has also worked on a number of real medical projects using FDM 3D printing and further use of 3D metal printers.