3D printing sunglasses

Trends in the eyewear industry in 2023

3D Learning Hub

See all categories

Contents:

- Introduction

- Why is 3D printing a great technology for the eyewear industry?

- Best 3D printed glasses projects

- How to create your 3D printed glasses with Sculpteo?

Introduction

Why is 3D printing a great technology for the eyewear industry?

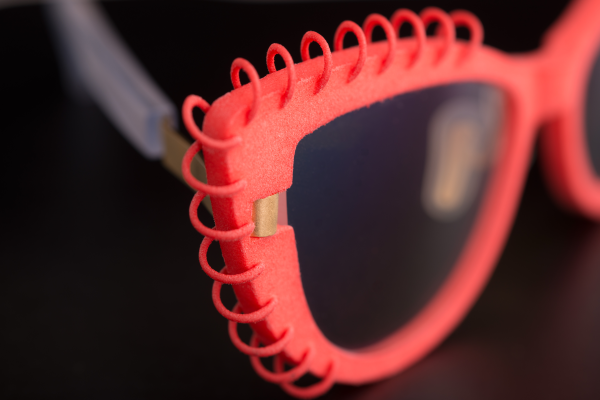

3D printing brings unlimited possibilities of designs

There is a simple sentence that clearly defines the whole potential of 3D printing when it comes to creation and design: “The only limit is your own imagination”. Indeed, this technology allows you to create extremely complex structures, and in some cases, designs that you could not even make come true without 3D printing due to traditional manufacturing constraints.

In the eyewear industry, this technology has been used more and more to create 3D printed glasses since it opens a broad range of possibilities to create 3D printed glasses frames totally custom-made. You can easily create either simple and complex designs.

Custom-made 3D printed glasses are more comfortable

For the person wearing glasses, choosing the right pair is not an easy task. Finding comfortable glasses with good design takes time. Also, the limited choices of design, in some cases, lead the wearer to sacrifice the design above their own comfort. Thanks to this cutting-edge technology, 3D printed glasses can be customized to fit the individual’s needs. It gives the wearer a feeling of comfort and at the same time a cool style.

Besides offering freedom of designs and shapes, 3D printing uses less material to produce glasses frames. Additive manufacturing also offers new opportunities, it is actually a great way to improve your product thanks to new designs and new materials: lighter 3D printed glasses frames can be made thanks to 3D printable frames.

Additive manufacturing also offers new opportunities, it is actually a great way to improve your product thanks to new designs and new materials: lighter 3D printed glasses frames can be made thanks to 3D printable frames.

With 3D printing, you can produce high-quality glasses

When it comes to choosing glasses, quality of the material, resistance and durability are the main elements that need to be taken into account. To produce the same quality of glasses, Polyamide 12, known as Nylon, is commonly used to 3D print glasses frame. This material has the expected properties, being resistant, durable and offers great freedom for design. Thus, thanks to 3D printing you can create high-quality 3D printed glasses. For the moment, companies 3D print frames, but soon, it could even become possible for you to 3D print lenses for your glasses

Build your brand thanks to 3D printing

3D printing helps you get ahead of your competitors, by getting a much more efficient manufacturing process. Moreover, using additive manufacturing is the perfect way to build your brand and your DNA. Using 3D printing, combines aesthetics and innovation, pushing your company to a brand new level.

Moreover, using additive manufacturing is the perfect way to build your brand and your DNA. Using 3D printing, combines aesthetics and innovation, pushing your company to a brand new level.

Optimize your supply-chain

If you want to use additive manufacturing to create finished 3D printed glasses, then, this technology will help you optimize your whole production process. Indeed, using additive manufacturing also means reducing your stock. With traditional manufacturing techniques, you need to build your stock, but with 3D printing: you avoid waste, you can produce your parts when you need them!

Best 3D printed glasses projects

3D printed glasses have been around for years and many companies started to adopt this innovation to improve their design. Here are some 3D printed glasses manufacturers that adopted this technology to improve their products, or their manufacturing process.

Netlooks

Sculpteo recently partnered with Netlooks, a company precisely at crossroads of technology and craftsmanship. This eyewear company is now making the most of the advantages of 3D printing.

This eyewear company is now making the most of the advantages of 3D printing.

In the beginning, Netlooks was handling everything in-house: customers just had to choose the eyewear, get a face scan, and try a test model, before getting the final handmade product. But here is the problem, per store, more than 200 testing models were required, involving more than 1000 hours of work and a dozen craftsmen dedicated to creating them. That is precisely where 3D printing appeared to be the best solution for Netlooks, to create their test eyewear models and scale their business growth! The final product is still handcrafted, but 3D scanning helps to create 3D models, and 3D printed glasses helps to ensure that the eyewear frames are perfectly adapted to the customer’s morphology.

Monoqool

Aiming to bring innovation to the fashion industry, Monoqool manufactures its own 3D printed glasses. In its new Slider Collection, this Danish-based eyewear company creates ultra-thin and lightweight glasses thanks to 3D printing. In this case, additive manufacturing is used to improve the product, not to create extravagant designs and collections. These glasses frames are simple and feature screwless hinges.

In this case, additive manufacturing is used to improve the product, not to create extravagant designs and collections. These glasses frames are simple and feature screwless hinges.

October71

Creating 3D printed eyewear made in France! October71 uses our online 3D printing service to create ultra-light glasses. According to its founder Christophe Mouty, 3D printing for optics is a way to make light products, actually 30% lighter than acetate or plastic on average), but also very robust, customizable eyeglasses and sunglasses. It definitely helps optimize the supply chain of a eyewear manufacturer.

Oxydo

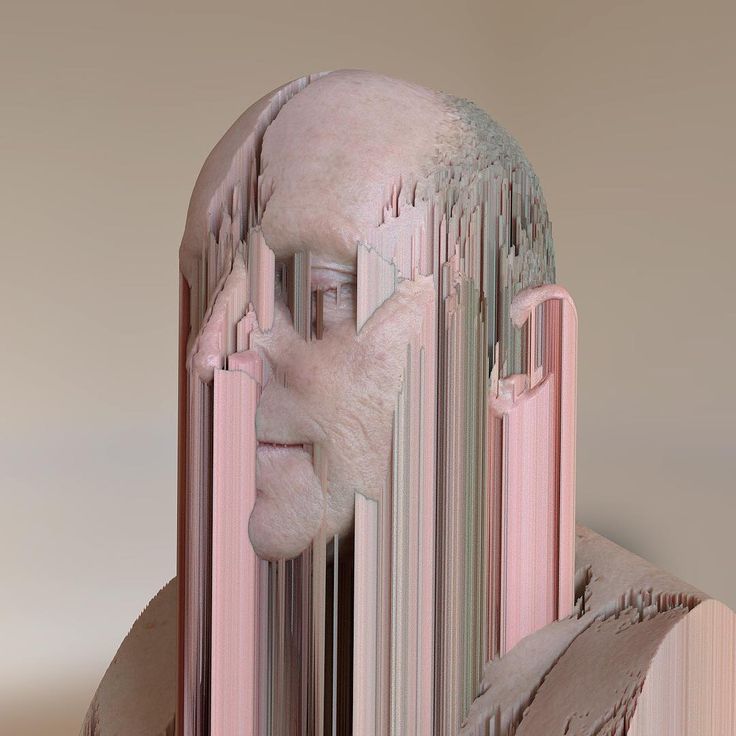

Oxydo is another brand, creating what they call “wearable sculptures”. This company is pushing the limits of creativity, using 3D technology to develop their impressive products. Colorful and original 3D printed sunglasses, with architectural forms and a lot of details.

Hoet

Additive manufacturing also allows for fancy possibilities. Hoet is a Belgian eyewear design company. Their goal is clearly to use 3D printing technology in order to experiment and find new designs. These glasses are another proof that additive manufacturing is able to create end products with great quality.

Their goal is clearly to use 3D printing technology in order to experiment and find new designs. These glasses are another proof that additive manufacturing is able to create end products with great quality.

Protos Eyewear

Another eyewear company that adopts this cutting-edge technology to create 3D printed glasses that really fit you. Protos Eyewear is using 3D printing at a more complex level than the previous brands: Protos created a software that allows them to alter the design of glasses to fit your facial structure. Using hypoallergenic bioplastics, Protos Eyewear creates innovative designs that are impossible to replicate using a traditional manufacturing process.

How to create your 3D printed glasses with Sculpteo?

Manufacturing eyewear is not an easy thing to do, but 3D printing can help you with the manufacturing process, for rapid prototyping for example, but also for the production of your finished eyewear product. At Sculpteo, we help you give life to your 3D design in a few clicks.

Choose the best materials

Each project you develop has its own needs. This means, each project will need a different 3D printing material, different material properties, and a different finished look.

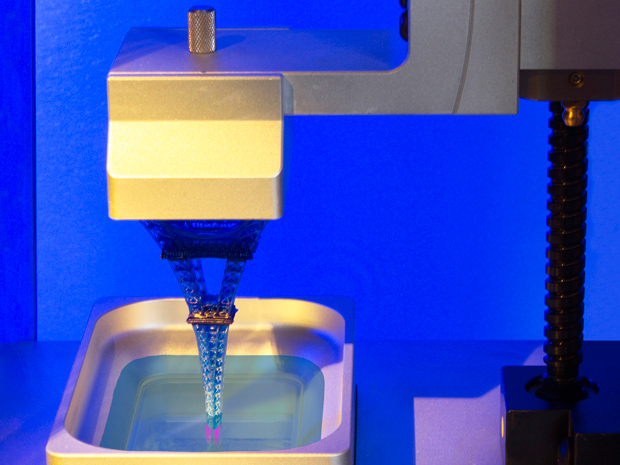

So what material will be the best option in order to develop your 3D printed eyeglasses? For a reliable and economical project, the best choice will be to use a powder bed fusion technology, Selective Laser Sintering (SLS), which offers you possibilities to print using various of our plastic materials such as Nylon PA12, or Multi Jet Fusion PA12 and make the most of great finishes for your 3D printed glasses, or 3D printed sunglasses.

You could go even further by developing glasses made using plastic and metal 3D printing: technology such as binder jetting could be used to add details and some jewelry to your creations. Additive manufacturing offers new opportunities, impossible to reach with traditional manufacturing techniques.

The perfect finish for your 3D printed glasses

You are now ready to 3D print your own glasses, but we have one more tip for you. Indeed, to help you get the best finished product, we recommend you to add the Color touch finish to your 3D printed glasses. This finish is available on our online 3D printing service thanks to the DyeMansion technology and will optimize the final look of your glasses by giving them a satin look. At Sculpteo, we already 3D printed luxury sunglasses with this finish. They have been used daily for more than two years now, and their colors are still UV-stable and brilliant.

Indeed, to help you get the best finished product, we recommend you to add the Color touch finish to your 3D printed glasses. This finish is available on our online 3D printing service thanks to the DyeMansion technology and will optimize the final look of your glasses by giving them a satin look. At Sculpteo, we already 3D printed luxury sunglasses with this finish. They have been used daily for more than two years now, and their colors are still UV-stable and brilliant.

Check out the color touch finish page to get more information about the DyeMansion technology and the colors available for your 3D printed glasses.

So, do you have any idea in mind about your own 3D printed glasses design? Print your own glasses right now by uploading your 3D file. Make the most of our professional 3D printers and receive your parts in a few days! From rapid prototyping to production, additive manufacturing will help you give life to your 3D design.

Is it possible to 3D print glasses?

How do you print 3D glasses?

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

Sunglasses best 3D printer models・Cults

Eiffel Tower inspired glasses

€3.75

tropical holiday Cookie Cutter 0299

€3.50

STARERS Glasses for masses

Free

glasses version 1

Free

Avocado lamp

€0.50

They Live Ghoul

€15

SKULL PUNK

€3.71

Raccoon Sunglasses Holder

€0.93

bear + breakfast Hank Design

Free

Sunglasses shelf - glasses resting ledge organizer - hook usefull key holder - ray ban pilot parker- - file for 3D printing

€2

8 Bit Shutter Shades Retro Sunglasses 1980s Gamer Costume

€0. 92

92

glasses legs with inverted hinge

Free

Fox Sunglasses Holder

€0.93

Pineapple and sunglasses Stl File

€3.25 -50% €1.62

truck dashboard organizer for commercial vehicles

€0.75

LoveGlasses

€0.75

catch-all tray sunglasses shaped

Free

Simple Sunglasses Clip

€0.88

Ray Ban bridge 4105 size 50

€10

Sunglasses Crocs Pin

€1.20

Flat Mount Sunglasses Clip

Free

Chicco Nextfit carseat sunglasses clip

Free

ST Patrick Beard and sunglasses Stl File

€3. -50% €1.62 25

25

Unicorn sunglasses Stl File

€3.25 -50% €1.62

Sunglasses COOKIE CUTTER - SUMMER TROPICAL COOKIE CUTTER STL FILE

€2.32

Backpacker

Free

Dog wearing sunglasses

€1.02

Bunny sunglasses Stl File

€3.25 -50% €1.62

Oakley over the top glasses

€4

Cool cocker keychain

€0. 75

75

Polestar 2 Glasses holder

€3.14

Glasses nose bridge pad replacement

Free

Glasses

€0.62

firstborn with sunglasses

Free

Ney years 2023 glasses

Free

Sunglasses Stl File

€3.25 -50% €1.62

Sunglasses Holder - expandable and modular

Free

ARGENTINA CAMPEONES DEL MUNDO MESSI anteojos glasses new year party

€3.53

2023 sunglasses design

Free

Poochie the little poodle dog 80’

€2

heads caps 3D print model

€44

mini sunglasses

Free

tiki cup with sunglasses

€0. 99

99

Smart Box top case articulated magic box

€0.75

Willy Wonka sunglasses

€2.58

3D Bulldog Head

€1.53

Sunglasses Emoji Pendant/Keychain

Free

Oculular Pressure Magnifier (Lens-less)

Free

👓 Best files for 3D printing glasses and sunglasses・Cults

👓 Best files for 3D printing glasses and sunglasses

Download 3D files for glasses

Designers from the Cults community have come up with all kinds of glasses. Of course, there are sunglasses and 3D printed glasses, but you will also find fancy glasses for various events or to create cosplay costumes!

Popularity Rating

Sunglasses

Free

VirtualTryOn.

fr Eyeglass frame (flat)

fr Eyeglass frame (flat) Free

Harry Potter Glasses

Free

Nose pad for mask - COVID

Free

Glasses

Free

Universal Glasses Stand

Free

VirtualTryOn.fr - 3D Printing Glasses - Steve

Free

VirtualTryOn.com - 3D Printing Glasses - Steve v2 - VTO

Free

Sunglasses

Free

Glasses / Sunglasses

Free

VirtualTryOn.fr Eyeglass frame

Free

VirtualTryOn.fr - Glasses 3D printing - Low Paulie

Free

Glasses COVID-19

Free

Pencil Case triangle

Free

POP Glasses

Free

Eyeglasses wall mount holder

Free

Bre got glasses?

Free

CUSTOMIZABLE 3D VTO PRINTING GLASSES

Free

Luna Lovegood Glasses

Free

SpecStand (Short) Eyeglasses/Sunglasses Stand

Free

Car Sunglasses Glasses/Card/Ticket Clips Holder

Free

VirtualTryOn.

co.uk - 3D Eyewear - Enio

co.uk - 3D Eyewear - Enio Free

Thug Life Glasses - Dual Color

Free

PLASIL 2 Glasses Stand

Free

3DBK Frames

Free

Tiki Sunglass Holder

Free

Nose Glasses Support

Free

Sunglass holder

1,87 €

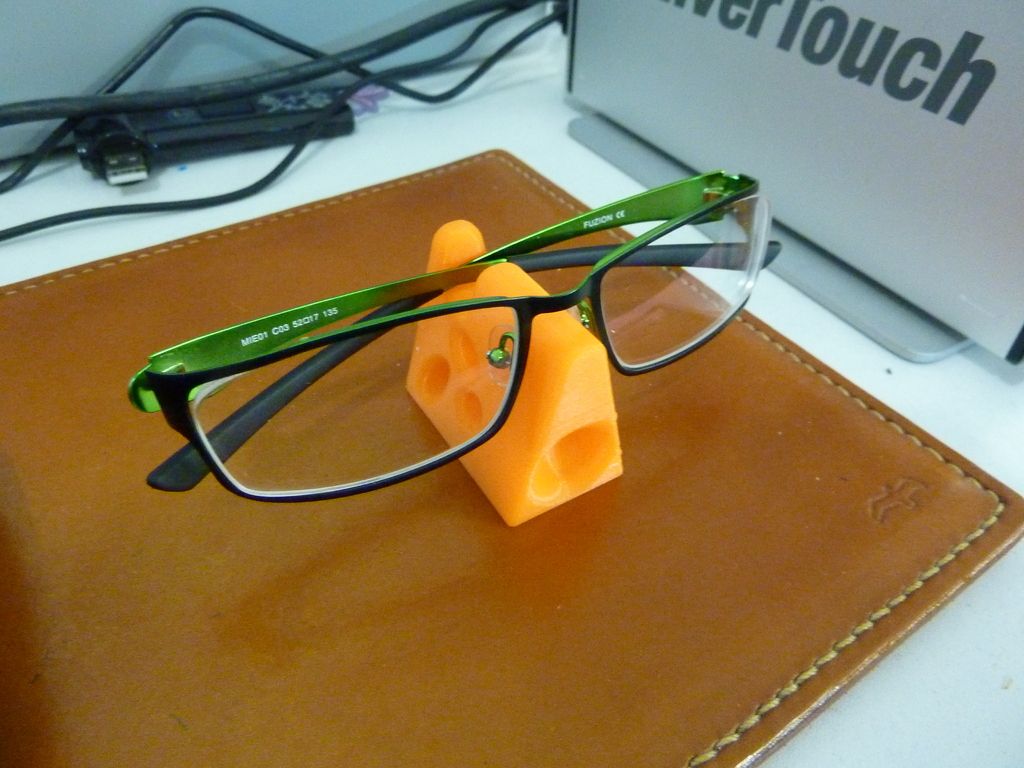

Funny Nose Glasses Stand

Free

Melon Shades

Free

Sunglasses

Free

RhinoGlass

Free

3d printable Glasses

Free

Modular Glasses Stand

Free

Face Mask Pozicer-Prevents fogging of glasses

Free

Operating theater glasses 2h Covid 19

Free

Glasses case (rework of Jasoncanning design)

Free

modular glasses

Free

Spectacle holder

2 €

Jaa's Steampunk Glasses v 1.

0

0 Free

Anti Fog Clip For Surgical Mask

Free

Lashes Glasses

Free

DIY Video Glasses for Raspberry Pi

Free

Eye glasses holder

Free

Sunglasses V2

Free

2020 Silly New Year Glasses with dual extruder option

Free

Sunglasses #2

Free

Spectacle/glass holder (OpenSCAD project)

Free

Modular Glasses Stand

Universal Glasses Stand

Pencil case triangle

CUSTOMIZABLE 3D VTO PRINTING GLASSES

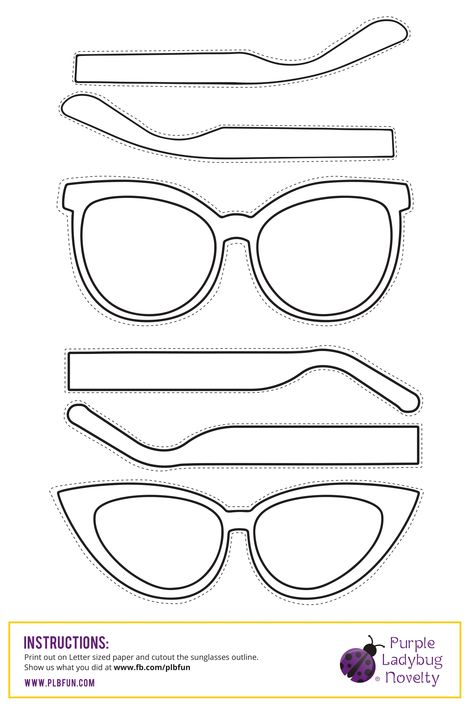

Discover our selection of best 3d files for 3d printers to make glasses or sunglasses . All these STL files are easily 3D printed so you just need to download them, warm up your 3D printer and of course add glasses. This collection has been created by selecting the best creations from 3D Object Libraries **Cults .

All these STL files are easily 3D printed so you just need to download them, warm up your 3D printer and of course add glasses. This collection has been created by selecting the best creations from 3D Object Libraries **Cults .

That's the beauty of 3D printing, you can create everyday items right at home and they're functional. In this case, for **3D printing glasses , even the mechanism for closing the temples can now be printed. In addition to the functional aspect, there is an aesthetic aspect and the big advantage of this 3D technology is the ability of to personalize your glasses thanks to 3D printing.

Glasses customization includes the ability to adapt the size to your face and skull shape , as well as select recycled and recyclable materials such as bioplastic PLA. There are also 3D printing materials that can replicate the look of wood or even bronze!

Needless to warn you that you must be very careful with your eyes and that glasses and sunglasses remain medical supplies. Therefore, it is up to your doctor, ophthalmologist or optometrist to advise you before using these glasses!

Therefore, it is up to your doctor, ophthalmologist or optometrist to advise you before using these glasses!

HOW TO GET CUSTOMIZED PRODUCTION AND ATTRACT NEW CUSTOMERS

You are here

Home

The events of recent years: the pandemic, the difficult geopolitical situation, the unstable exchange rate of the ruble have had a negative impact on many areas of business in Russia. The optical accessory industry is no exception. Some companies operating in this industry have come to the need for rapid import substitution and development of their own production facilities. In this they are helped by additive technologies. Installing a 3D printer allows you to set up the production of frames on your site in the shortest possible time, eliminate intermediaries and the risks associated with delivery from abroad.

The frame printing method has significant advantages over standardized manufacturing.

- Production customization: the client himself chooses the design and color of the frame. When milling, this is extremely difficult to implement, since a separate control program must be written for each model.

- The ability to create both piece products and a series of frames with any number of units.

- Production speed: designing an individual 3D model and printing it takes no more than 2 hours.

In addition, the use of additive technologies can solve the problem of storing unrealized balances. In mass production, up to 40% of finished frames end up in the warehouses of the company or its distributors. In the case of custom-made frames, the need for both storage facilities and transport logistics disappears.

World experience in the use of additive technologies in the production of frames

Adidas launched its first 3D printed sunglasses last year in partnership with Marcolin Grou. The goggles weigh 20 grams and have a flexible structure that provides maximum ventilation. They are suitable for almost any sport, from running and cycling to tennis and golf.

The goggles weigh 20 grams and have a flexible structure that provides maximum ventilation. They are suitable for almost any sport, from running and cycling to tennis and golf.

The glasses combine aesthetics and functionality, and their geometry, weight and volume fully meet the requirements for sports accessories. Thanks to special contact points on the bridge of the nose and temples, they do not cause discomfort during prolonged wear, for example, during competitions.

Printed frames are increasingly used in the creation of designer glasses. One of the most striking examples is the collection of accessories designed by Brazilian designer Edward Beiner for his US boutiques. The glasses are made in Germany, and the frames are printed from plastic by a company specializing in the production of parts for aircraft. Points are presented in 12 style solutions.

The choice of 3D printing made it possible to create lightweight models of glasses while fully preserving their technical properties. For wearers, this means increased wearing comfort and longer product life. At the same time, technologies make it possible to instantly change the design and color of the frame according to customer requests.

For wearers, this means increased wearing comfort and longer product life. At the same time, technologies make it possible to instantly change the design and color of the frame according to customer requests.

The German company You Mawo prints glasses that are sold in stores located in 15 countries around the world. The company initiated a life cycle analysis of optical accessories from production to the point of use to assess their environmental impact. Testing took place on 18 parameters, which included toxicity to humans, climate change, ozone depletion, depletion of water resources. As a result, printed frames performed significantly better in all categories than conventional frames.

In particular, it was found that the manufacture of frames by 3D printing reduces the carbon footprint by 58%. They also leave 80% less waste than acetate frames.

Russian experience in the production of frames using 3D printing

To organize our own production of designer custom frames - a customer addressed us with such a request. After analyzing the market, he saw a growing demand for accessories, the appearance of which would be chosen by the users themselves. Previously, the company used the traditional method of making frames, which was suitable for creating series of the same color and geometry. But it was unprofitable to make custom-made piece products with it.

After analyzing the market, he saw a growing demand for accessories, the appearance of which would be chosen by the users themselves. Previously, the company used the traditional method of making frames, which was suitable for creating series of the same color and geometry. But it was unprofitable to make custom-made piece products with it.

To implement the task, we proposed to print frames using SLS technology. With its help, you can quickly create a product with a design at the request of the client, as well as paint it in any color.

The result of the introduction of 3D printing was:

- obtaining a sustainable competitive advantage for the company: so far, single manufacturers provide the opportunity to order a customized frame;

- faster production times: printing takes less time than milling or casting, which means it is more cost-effective;

- improvement of technical characteristics: the weight of the printed frame starts from 10 grams, which is 30% less than analogues created in the traditional way.

At the same time, it is quite durable and suitable for long-term operation;

At the same time, it is quite durable and suitable for long-term operation; - saving raw materials and no waste: only as much material is used during printing as required for a particular frame,

- an increase in the average check: despite the fact that the cost of a printed frame is higher than a regular one, users are willing to pay extra for uniqueness. In this case, the value of an exclusive accessory significantly outweighs its price.

Additional advantages in the production of frames by the additive method are provided by the use of the latest post-processing system using AMT technology. It allows to achieve the quality of products, similar to injection molding. The PostPro3D installation performs automatic surface smoothing, which significantly reduces processing time and improves its quality. Frames processed in this way have a perfectly flat and smooth surface. In addition, they can be washed.

The pilot project fully met the customer's expectations.