Australian geographic 3d printer

3D-printed apartments provide cosy home for frogs

By Australian Geographic • September 23, 2021

Image credit: Rod Shannon

Reading Time: 2 Minutes • Print this page

With a mini pool and snacks, it’s no surprise frogs have taken to these apartments.

When Rod Shannon spotted a big green tree frog struggling to find shade around his home in central Queensland he wanted to help. So, he printed some 3D apartments.

“I’d often find ‘Fatty Croak’ baking in the late afternoon summer sun, and I’d taken to placing a wet cloth over her to stop the sun a bit. I thought it might be an interesting project to experiment with my fledgling skills at 3D modelling and design.

“When I built the very first apartment in late 2020, I then found that three frogs immediately tried to move into it overnight, and so I progressively printed a series of additional apartments to cater.”

(Image credit: Rod Shannon)Officially dubbed the ‘Fatty Croak Apartments’ after Rod’s first and favourite visitor, the apartments are decked out with a pool (mug of water) and some delicious mealworm treats.

“The bathing mug is on a patio outside one door to our house, and sits on a ledge just beside the external door to our cold room.”

With just three key pieces – a base, lid and balcony, which can be interchanged and added to to create more appartments – Rod has constructed a comfy home for frogs.

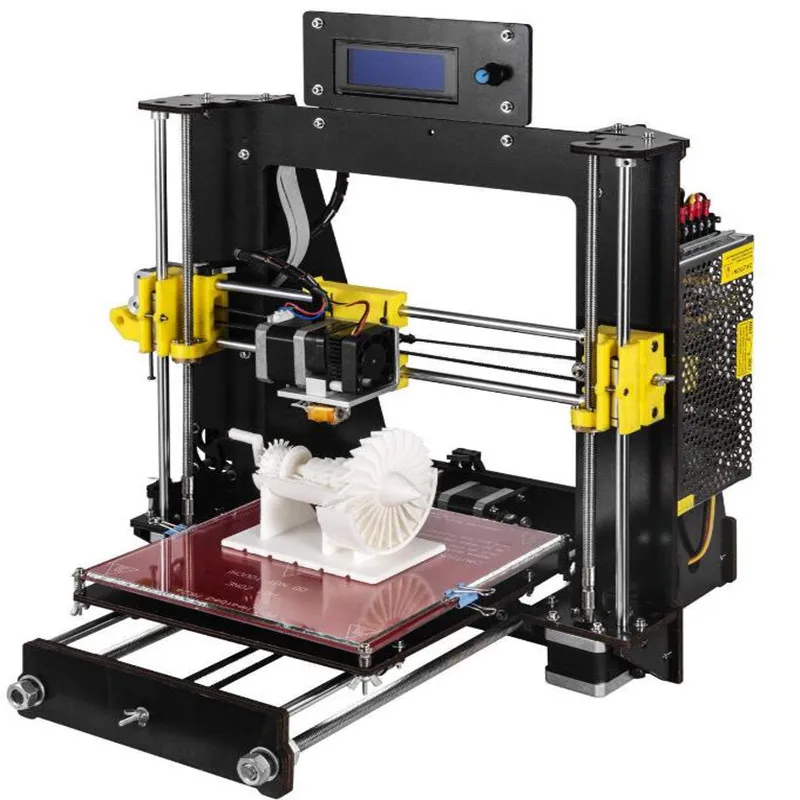

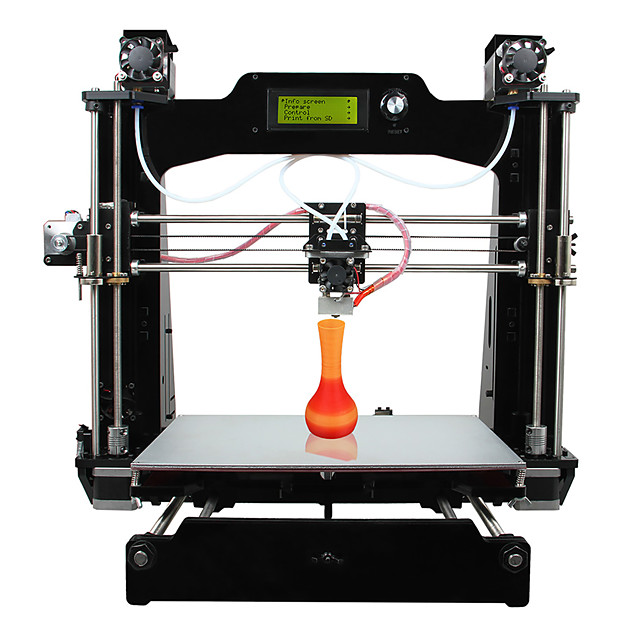

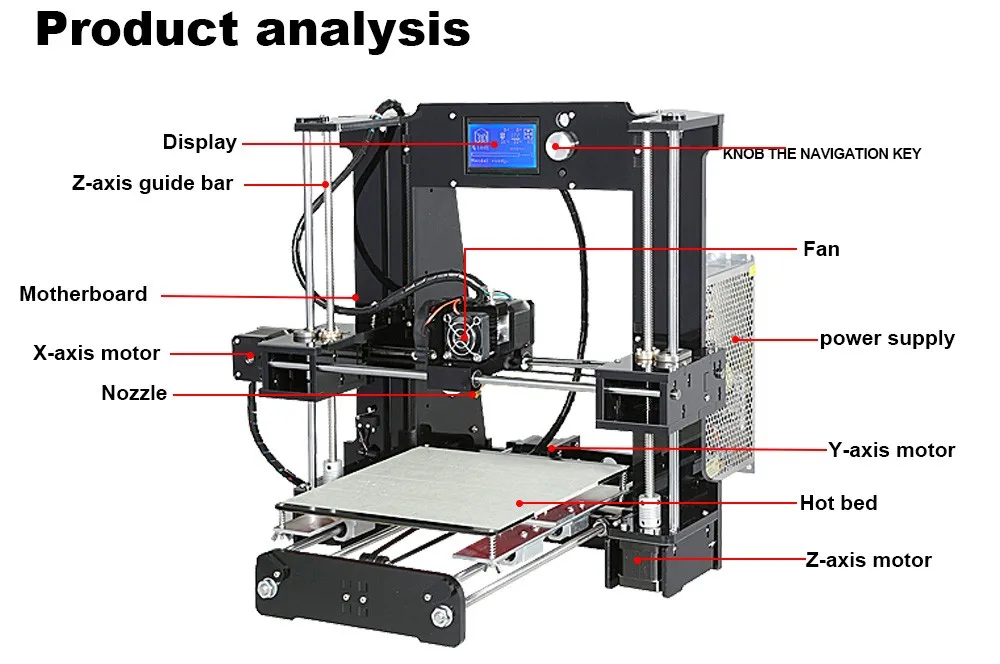

The apartments are made out of a plant-based plastic, designed with Rhino 3D and printed with a Flashforge Creator Pro. Once they’re printed, Rod sands them with fine paper to remove any sharp edges and soaks them in rainwater.

Related: A guide to making a frog hotel with frog expert Jodi Rowley

Rod’s 3D design for frog apartments. (Image credit: Rod Shannon)“I’ve made these apartment designs from scratch; basically took the largest frog I could find, and measured what sort of space they would need to feel secure, but also have room.

“Not sure I’ve dialled the apartment size in just right, as they keep getting fatter, but it would be very simple to make apartment bases taller. ”

”

Do frogs have an apartment colour preference? Rod thinks so.

“There is an idea that in the first apartments there was a colour preference for the two blue apartments.

“In this newest version of the apartment stack there is a single blue apartment, and as we are now in the active months, I plan to start rotating the apartments around to see if the blue theory holds any credence.

“At present, the blue apartment is the easiest to reach from the bathing mug, but I won’t be surprised if Fatty Croak doesn’t choose to return to the blue apartment anyway when I rotate it around.”

TAGS Australian frogsfrog apartmentsFrogIDfrogs

Issue 172 Out Now

By subscribing you become an AG Society member, helping us to raise funds for conservation and adventure projects.

Subscribe

Australian Geographic acknowledges the First Nations people of Australia as traditional custodians, and pay our respects to Elders past and present, and their stories and journeys that have lead us to where we are today.

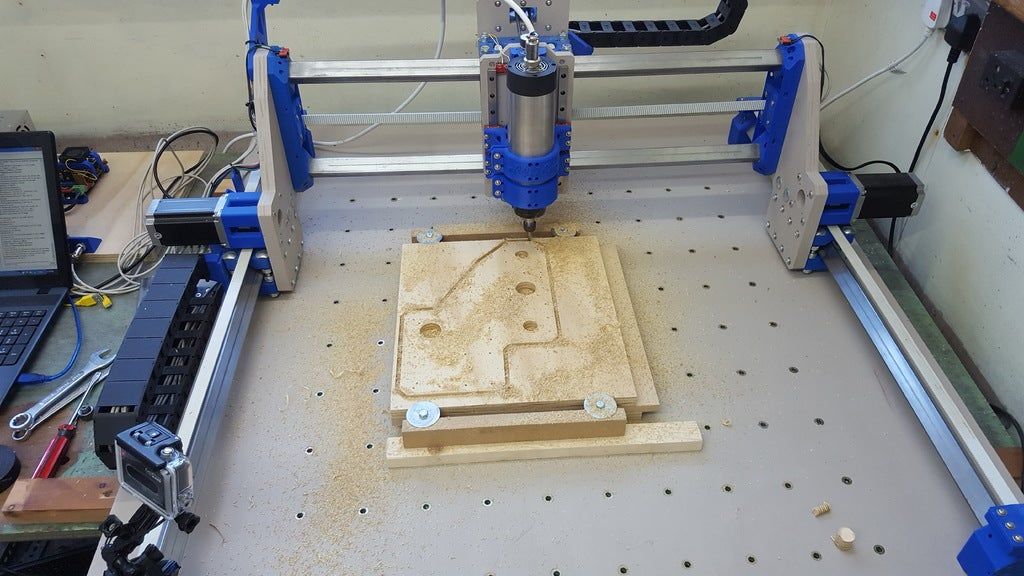

How to print maps, terrains and landscapes on a 3D printer

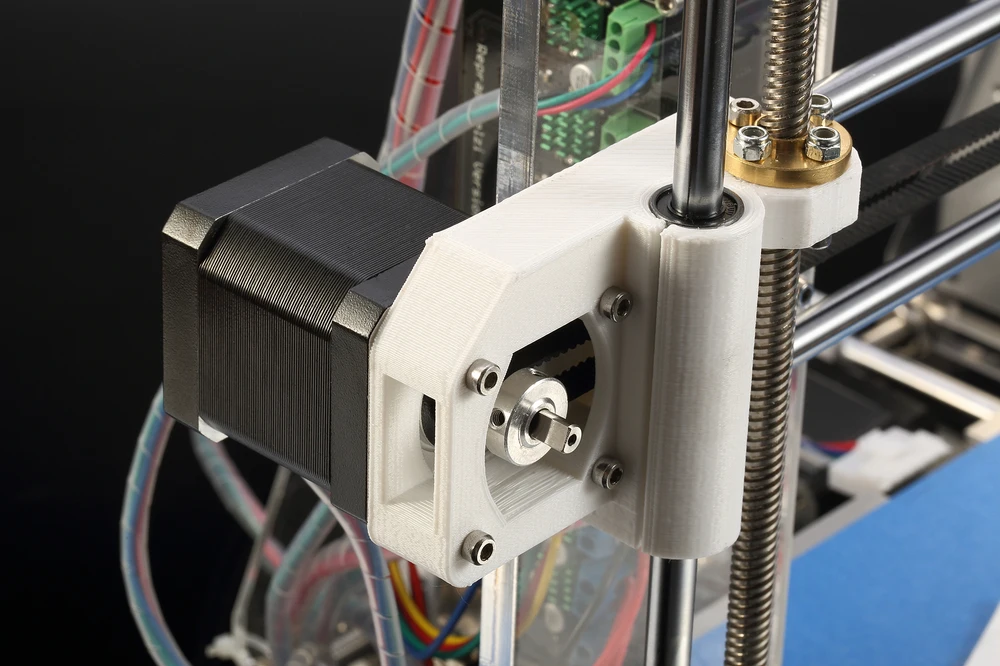

From time to time, every 3D printer owner is asked the same question: “Why is the printer really good and useful? I cannot imagine what would I use it for.” I did not find a satisfactory answer to this simple question at first, because I don’t consider printing figures and statues as the right example. That’s why every time the 3D printing technology is applied in practical use, I’m excited! Today, I’ll show you how to print a 3D map, that can serve in a number of situations not only using our Original Prusa i3 MK3 printer. How about a plastic model of terrain for school education, a small-scale version of a national park, a model that shows the overview of a real-world race track, or perhaps a tiny version of a mountain you climbed in the past. Thanks to these models, we can see the landscape from a bird’s eye view. Input data will be topographic maps that are most interesting for 3D printing purposes.

Models based on maps can be divided into two groups:

- Printing a terrain model – ideal for mountain ranges, volcanoes or abysses.

So where there are well-known elevations.

So where there are well-known elevations. - Printing a terrain model including buildings – ideal for cities and areas with buildings.

Terrain models

A 3D terrain model (without buildings) can be obtained simply and for free with the Terrain2STL web application.

- Find a place on the map. Rugged terrain works the best.

- On the Location tab, press Center to View. This will show a selection rectangle on the map.

- On the Model Details tab, adjust the size of the selected area by moving the Box Size slider. The selection can be moved in the map. If the resulting model is very flat, it is possible to scale it on the Z axis. This is done in the Model Details by using the Vertical Scaling slider. However, keep in mind that the resulting model will differ from reality.

- On the Water and Base Settings tab, set the desired model base height.

- Press the Generate Model button. Then click the Download button and download the model.

Does a square or rectangular shape feel way too ordinary? Let’s take a look at how to work with some more complex shapes. Naturally, one of the basic ideas is to use borders of existing countries. For the sample print, I chose the Czech Republic – the home of Prusa Research. A good start is to successfully obtain the STL terrain model from the previous step. However, the disadvantage of the Terrain2STL application is that it is not possible to change the shape of the selection. So, if you want to work with a larger area, you will need to cut the STL model first using a 3D editor and then work with it. This is because the Tinkercad software we want to use limits the size of the imported file to 25MB. A better solution is to use a similar tool like Terrain2STL. The TouchTerrain project allows you to select any aspect ratio on the map. I recommend aligning the map, for example, in the upper left corner for a simpler placement of the shape for the cutout.

I recommend aligning the map, for example, in the upper left corner for a simpler placement of the shape for the cutout.

How to do it:

- Find and download the desired shape in .SVG format. Ideally, it should be on a white or transparent background. To make searching easier, I recommend adding the keyword “silhouette“.

- In a web browser, open the Tinkercad tool and sign in (or create a free account).

- Create a new design by pressing the Create new design button.

- Create a block (use the “Box” tool on the right) and change the dimensions so it stretches across the entire Workplane.

- Import the downloaded .SVG file with the shape using the Import button in the top right corner. When the import is complete, the image is automatically converted to a 3D object. Change the shape type to “Hole“.

- Click the object with the right mouse button and first adjust its height in the Z-axis so that it is higher than the block.

Then, adjust the size of the model by dragging any corner to fit the block. To keep the aspect ratio hold the Shift key.

Then, adjust the size of the model by dragging any corner to fit the block. To keep the aspect ratio hold the Shift key. - Now select both objects (Ctrl + A), group them with the Group button (Ctrl + G) and change to the “Hole” type. This creates a negative shape, which then cuts the terrain.

- Import the terrain model using the Import button in the top right corner and wait for it to finish.

- Adjust the size of the terrain model and place it in the right place in relation to the carved shape.

- Deselect the selection of objects by pressing the mouse outside the print area.

- Export the object using the Export button in the top right corner of the .STL format.

- The model is ready to be sliced, for example, in Slic3r, where it can be scaled in the Z-axis if needed for better terrain visualization.

Download link: The Czech Republic 3D terrain model on PrusaPrinters

City model with terrainIn this case, the procedure is a little more complex than the terrain itself and more tools need to be used. To get the model, we use the CADMAPPER web tool, which uses freely available maps from OpenStreetMap as a source. The tool allows you to download a 3D model up to 1 km² area for free. Larger areas are paid. In most cases, 1 km² is perfectly fine. By covering the entire print area (25 x 21 cm), we get the ideal scale for the model (approximately 1: 4000 to 1: 5000).

To get the model, we use the CADMAPPER web tool, which uses freely available maps from OpenStreetMap as a source. The tool allows you to download a 3D model up to 1 km² area for free. Larger areas are paid. In most cases, 1 km² is perfectly fine. By covering the entire print area (25 x 21 cm), we get the ideal scale for the model (approximately 1: 4000 to 1: 5000).

- Open CADMAPPER tool in the browser and click Create a map.

- Select the desired area up to 1 km² (or larger and buy the model).

- Select the output format for SketchUp 2015+.

- Include Topography and 3D Buildings in the output model and choose the height of buildings for which the height in the map is not defined.

- Press the Create button to start generating.

- Press the Download button to download a generated zip file that contains the .SKP file.

The downloaded file is not yet fully prepared for slicing. What we need to do is to create an object under the terrain. In addition, we can simply change the height of buildings in this tool, especially those that have a default value from CADMAPPER. We will use SketchUp Pro for editing, which is free to download in the trial version.

What we need to do is to create an object under the terrain. In addition, we can simply change the height of buildings in this tool, especially those that have a default value from CADMAPPER. We will use SketchUp Pro for editing, which is free to download in the trial version.

Eneroth Terrain Volume extension is useful when you want to create a solid object under the terrain easily. Download this extension as well.

Add extensions using the Window -> Extension Manager. Press the Install Extension button and select the downloaded file from the previous step.

Now we have everything ready and we can start editing the model.

- Run SketchUp, open the downloaded file from CADMAPPER (File -> Open).

- On the right side of the application window, expand the Layers section and remove all layers except buildings, topography and Layer0. Press the “Delete content” icon. The content of the deleted layers is not easily printable, that’s why we’re deleting them.

However, you can play around with the content of deleted layers and see if something interesting comes out of it – we won’t be using them in our guide, though.

However, you can play around with the content of deleted layers and see if something interesting comes out of it – we won’t be using them in our guide, though. - Click anywhere on the terrain to select it. In the top menu of the app select Extensions menu -> Eneroth Terrain Volume. This creates a solid object under the terrain.

- If you want to change the height of the base or buildings, you must explode the model (select the whole model, right mouse button, Explode option), and then the Push / Pull tool to increase or decrease the height of the buildings or the base under the model.

- Export the model using File -> Export -> 3D Model.

The file is now ready for 3D printing. Open it in the Slic3r PE and adjust the size to fit the print area. For an area of 1 km², the approximately square shape of the model is reduced to about 20% of the original size. So we get the model on a scale of cca 1: 5000. We recommend a PLA material and a layer height 0. 15mm.

15mm.

1:5000

1:2500

1:1000

Download link: Prague Castle area on PrusaPrinters

Preparing the model for printing and correct orientationUse Slic3r PE or your favorite slicer tool to generate the gcode file.

Terrain models with at least one straight edge can be printed in two ways, either horizontally or vertically. Each of these orientations has its pros and cons and for each model, it is necessary to decide which orientation to choose. Let’s look at the main differences.

The horizontal positionThis position is natural in the real world. In this position, we are able to print almost any model. In the Z-axis, however, we are limited by the height of the layer. The lowest height of the extruded material is about 0.05mm and the most commonly used nozzle diameter is 0.4mm. The relatively large diameter of the nozzle alone causes “drops” on the peaks. The nozzle diameter also affects edge sharpness.

We recommend selecting a layer height of 0.15mm and a 15% to 20% infill.

Pros:

- you can print almost any model

- there are horizontal lines on the model that represent contour lines (some may consider this a con)

Cons:

- infill is necessary (longer printing time)

- drops on peaks

- there may be strings between the peaks/buildings

In the vertical position, the biggest advantage is that no “drops” of material on the peaks will be created, and the peaks will be smoother. This makes the surface more detailed and looks much better. The vertical orientation is suitable for models where there are no areas that make an angle with the print area less than about 45°. Supports for such models is not a solution we would recommend.

Vertical orientation is also not suitable for printing city-building models, because almost every building would have a perimeter wall parallel to the print surface and therefore the model would be non-printable without supports.

With vertical orientation, it is advisable to choose the most suitable area on which the model will be placed. Choose the one that will touch the bed with the largest possible area. Use the Place on the face button to rotate the model.

We recommend selecting a layer height of 0.15mm and a 0% infill. Infill is not needed in most cases. The printing time will be almost half and you save some material. For best results, use PLA filament.

Pros:

- print without support and infill

- there is no stringing between peaks

- the terrain looks smoother than the horizontal print position

Cons:

- can not be used to print city models

- there’s a chance that it will become loose and that the print will fail

The difference of print in horizontal and vertical orientation is shown in the pictures below.

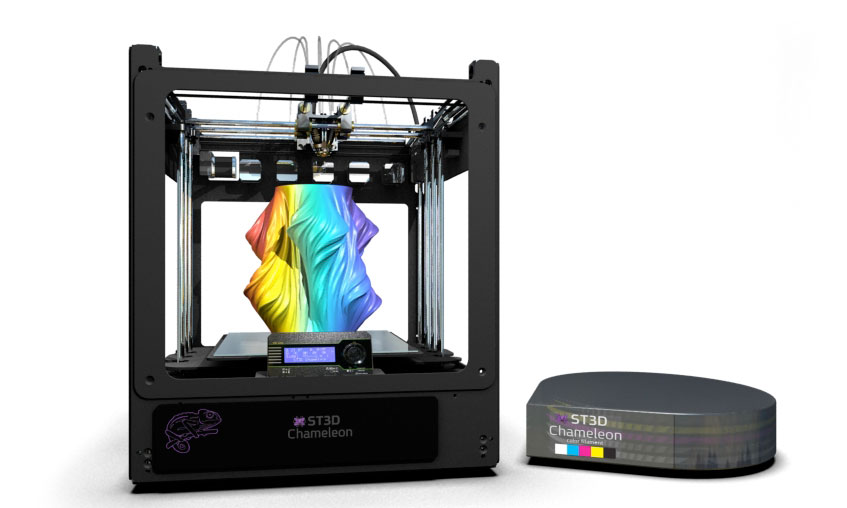

Our tips for color models:

- Use ColorPrint to change the color of the filament depending on the altitude.

Learn how to use ColorPrint in this article.

Learn how to use ColorPrint in this article. - Print the model with a single filament and paint it afterward. It depends only on your imagination.

- If you already have Original Prusa Multi Material Upgrade 2.0, you can try to create a color model to distinguish terrain, buildings, waterways and roads.

Feel free to experiment, try various changes and edits, and don’t forget to share the results in our forum.

The Masters Movement, IP Litigation and Law Reform

October 2019

Author: ), Brisbane, Australia

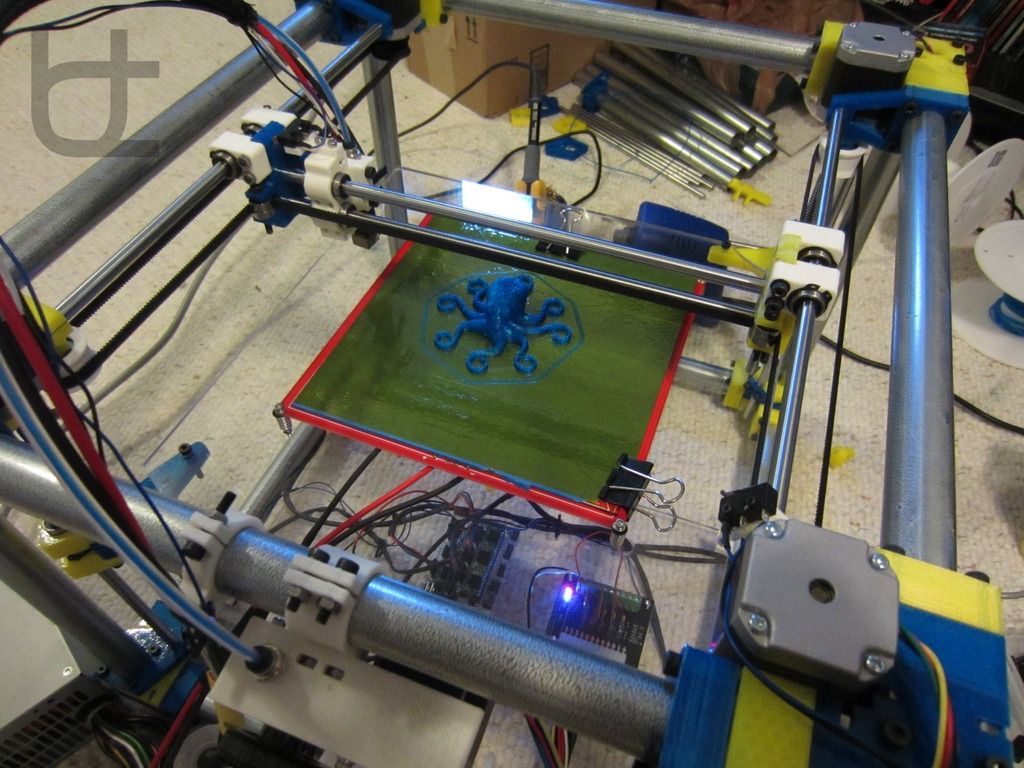

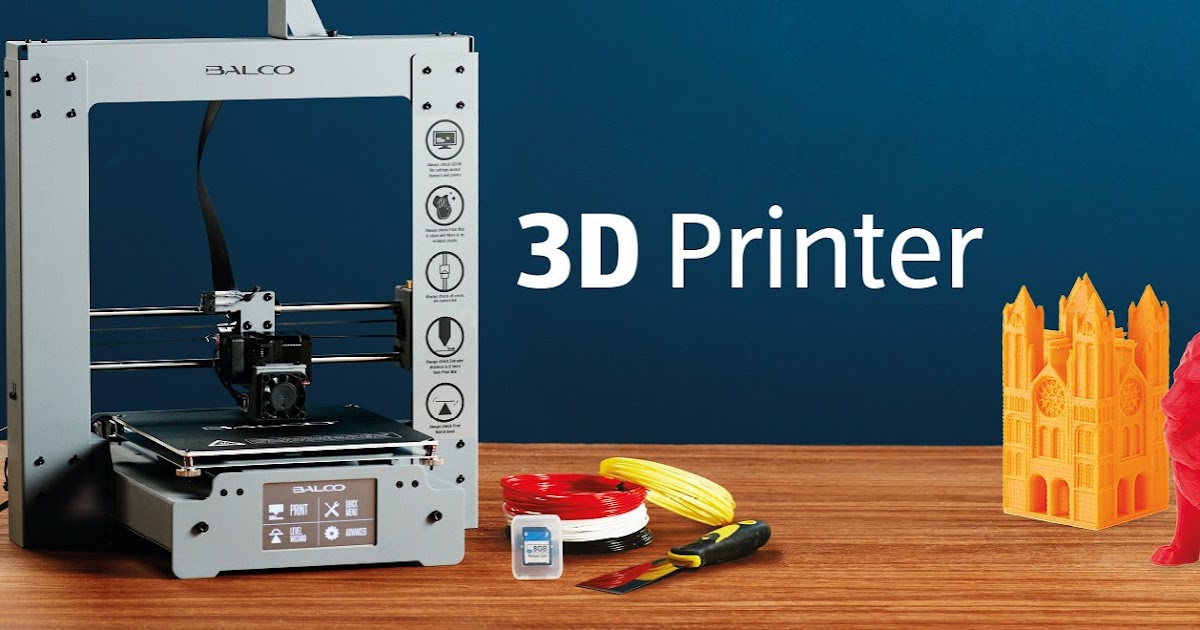

3D printing is an industry based on the principle of additive manufacturing (as opposed to the subtractive manufacturing principle that underlies the traditional manufacturing industry). 3D printing is also associated with the Craftsmen Movement, a social movement whose main idea is to develop designs for various products and share them.

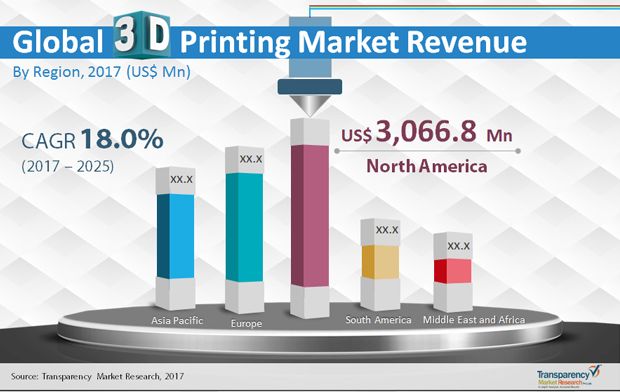

Currently, the development of 3D printing is in a transitional phase. While the consumer “3D printing revolution” has failed, other varieties and categories of 3D printing have seen growth. (Photo courtesy of Queensland University of Technology)

While the consumer “3D printing revolution” has failed, other varieties and categories of 3D printing have seen growth. (Photo courtesy of Queensland University of Technology) 3D printing is currently in transition. The consumer "3D printing revolution", which aimed to have a 3D printer in every home, has failed. MakerBot, a pioneer in 3D printing, is having trouble with its changing approach to intellectual property (IP) issues, disrupting its ties to the open source software community, and the user audience turned away from it. As former MakerBot CEO Bre Pettis said in an interview, "The open source community has kicked us out of their paradise." As a result, MakerBot was acquired by Stratasys, a leader in the 3D printing industry, which restructured and repurposed it.

Some other key players also went bankrupt. In particular, TechShop, a membership-funded and open-to-all network of studio-workshops for home craftsmen, went bankrupt. Maker Media, which publishes Make magazine and hosts craft festivals in the United States, has gone under external control. Make magazine founder Dale Doherty is trying to revitalize his project with a new structure he created called Make Community LLC.

Make magazine founder Dale Doherty is trying to revitalize his project with a new structure he created called Make Community LLC.

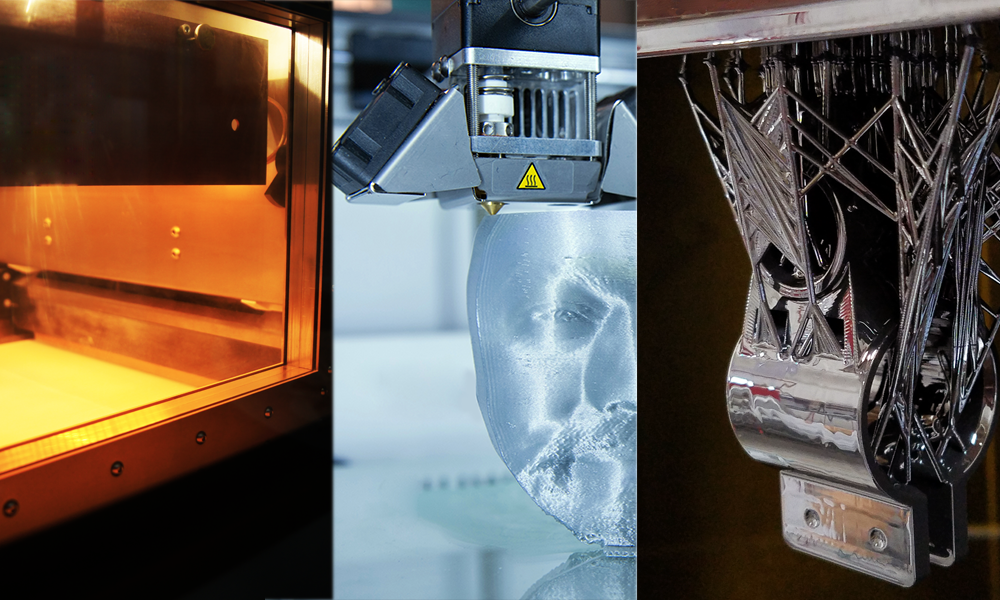

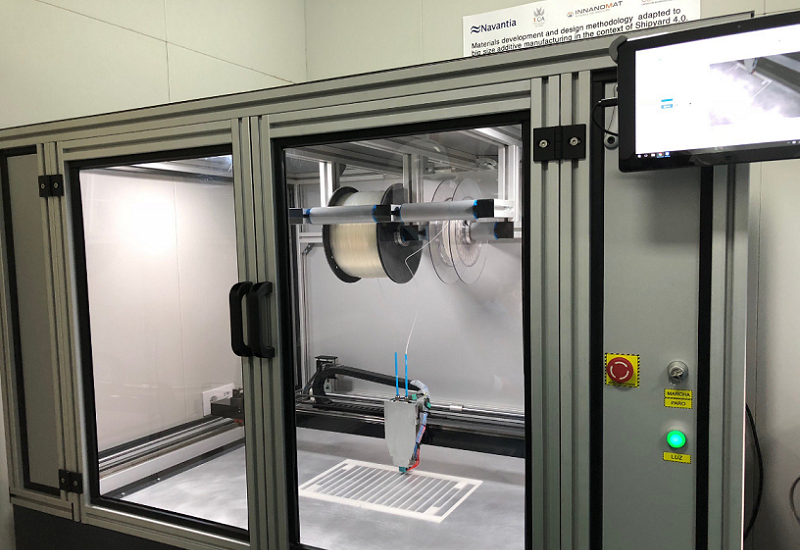

Industrial 3D printing continues to grow

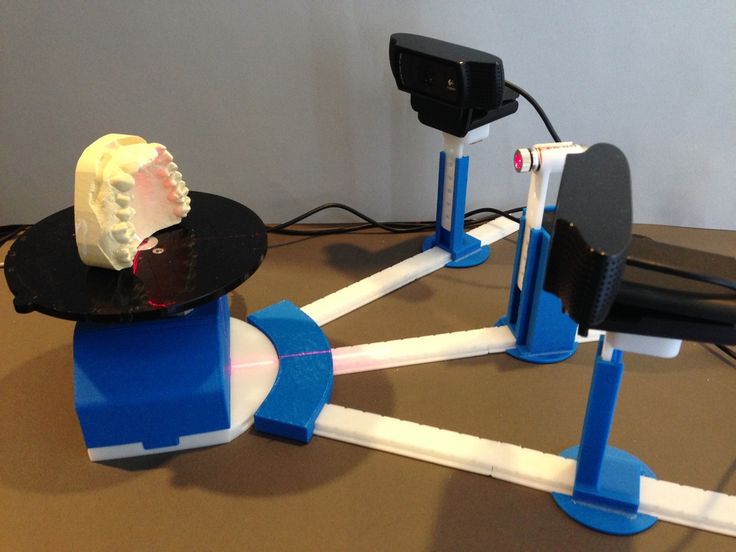

Although personal 3D printing has not developed as expected, there has been growth in a number of other forms and categories of 3D printing. Along with robotics and big data, 3D printing has become one of the promising technologies in the manufacturing industry. Companies specializing in information technology and design are working to improve the way 3D printing is used. Significant investments, especially from transport companies, have been attracted by the technology of 3D printing of metal products. In addition, there have been large-scale experiments related to the application of 3D printing in the healthcare sector, including 3D printing in dentistry, 3D printing in medicine, and bioprinting.

As technology improves and develops, there have been several cases of lawsuits being filed in the courts, as well as certain political developments regarding the regulation of the 3D printing industry. Our recently published book 3D Printing and Beyond explores some of the major developments in IC and 3D printing. In particular, it analyzes the issues of 3D printing in relation to areas such as copyright law, trademark law, patent law, and trade secrets (as well as some of the broader issues related to the regulation of 3D printing). In addition, the book highlights the use of open licensing mechanisms in the field of 3D printing.

Our recently published book 3D Printing and Beyond explores some of the major developments in IC and 3D printing. In particular, it analyzes the issues of 3D printing in relation to areas such as copyright law, trademark law, patent law, and trade secrets (as well as some of the broader issues related to the regulation of 3D printing). In addition, the book highlights the use of open licensing mechanisms in the field of 3D printing.

3D printing and copyright law

A few years ago, there was a panic that the widespread use of 3D printing would lead to a wave of large-scale infringements of authors' rights, similar to the situation that arose with the advent of the Napster file-sharing network . Although such fears have not yet materialized, there have been various conflicts related to copyright and 3D printing. For example, Augustana College (United States) objected to 3D scanning of Michelangelo's statues, even though they were not subject to copyright protection and were clearly in the public domain. The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

3D printing was also subject to the on-demand removal of content under the Digital Millennium Copyright Act (USA). Shapeways and a number of other 3D printing firms have raised concerns about the implications of this regime for online platforms and 3D printing intermediaries.

In addition, discussions took place on issues related to the use of technical protection measures in the context of copyright law and 3D printing. For example, the US Copyright Office has confirmed a limited technical protection exception for 3D printing stocks.

3D printing and design law

Developments in 3D printing have also raised the issue of product repair rights.

Efforts have been made across the European Union to recognize the right to repair in order to support consumer rights and develop a circular economy. In this regard, one of the important factors in achieving changes in the behavior of companies and consumers has become the European Greening Directive (Directive 2009/125/EC).

In July 2019, the United States Federal Trade Commission held a Hearing on "Can't be Repaired: A Workshop on Product Repair Restrictions." Significant differences remain between IP owners and right-to-repair advocates in the United States. Presidential candidate Elizabeth Warren has called for legislation to secure the right to repair for the benefit of farmers in the agricultural regions of the United States.

Significant and first-of-its-kind litigation in Australia regarding right to repair under Design Law ( GM Global Technology Operations LLC v S . . - S - Auto Parts Pty Ltd [2019] FCA 97). The Australian Treasury is considering policy options regarding the practice of sharing vehicle repair information.

Australian Capital Territory (ACT) Consumer Affairs Minister Shane Rettenbury called for recognition of the right to repair from the rostrum of the Consumer Affairs Forum, which includes ministers from both Australia and New Zealand. Federal Minister Michael Succar asked the Australian Productivity Commission to look into the matter.

Calls for right-to-repair laws, both at the provincial and federal levels, are also being heard in Canada. As Laura Tribe, Executive Director of Open Media, noted in this regard, “We are committed to ensuring that people have the opportunity to be the real owners of the products they own. ”

”

3D printing and trademark law

3D printing also brings uncertainty to trademark law and related legal regimes, including product substitution, identity rights, commercial use of characters, and trade dress. The legal conflict surrounding Katy Perry's trademark application for the "shark on the left" image provides some insight into some of the issues that arise in this regard.

Regarding bioprinting, Advanced Solutions Life Sciences sued Biobots Inc. Due to the alleged violation of its trademark rights ( Advanced Solutions Life Sciences , LLC V BIOBIOTS Inc 15 May 201111111111111. Advanced Solutions Life Sciences owns and uses the registered trademark Bioassemblybot for 3D bioprinting and tissue growth.

3D Printing and Patent Law

According to the 2015 WIPO Global Intellectual Property Report, Revolutionary Innovation and Economic Growth, 3D printing patent applications are on the rise. Some industrial 3D printing companies, including 3D Systems and Stratasys, have managed to build large 3D printing patent portfolios. Large industrial companies, including GE and Siemens, have also accumulated significant patent assets in 3D printing and additive manufacturing. Information technology companies, including Hewlett Packard and Autodesk, also play an important role in the 3D printing industry.

Some industrial 3D printing companies, including 3D Systems and Stratasys, have managed to build large 3D printing patent portfolios. Large industrial companies, including GE and Siemens, have also accumulated significant patent assets in 3D printing and additive manufacturing. Information technology companies, including Hewlett Packard and Autodesk, also play an important role in the 3D printing industry.

With the growing commercial importance of 3D printing in the manufacturing industry, there have been a significant number of litigations related to 3D printing of metal products. In July 2018, as part of the “Desktop Metal Inc.” v. Markforged, Inc. and Matiu Parangi (2018 Case No. 1:18-CV-10524), a federal jury found that Markforged Inc. did not infringe two patents owned by rival Desktop Metal Inc. (See Desktop Metal Inc. v. Markforged, Inc. and Matiu Parangi (2018) 2018 WL 4007724 (Massachusetts District Court, jury verdict). In this regard, the CEO of Markforged Inc. .” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs. " For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

" For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

In 2018 (after the above verdict) Desktop Metal Inc. and Markforged Inc. entered into a confidential financial agreement that settled all other litigation between them. However, in 2019 Markforged Inc. filed another lawsuit against Desktop Metal Inc. due to the fact that, according to her, the latter violated that part of the agreement, which concerned non-disclosure of negative information.

3D printing and trade secrets

In addition, the first litigation regarding 3D printing and trade secret legislation took place. In 2016, Florida-based 3D printing startup Magic Leap filed a lawsuit in federal court for the Northern District of California against two of its former employees for misappropriation of trade secret information within the meaning of Trade Secret Protection Act (“ Magic Leap Inc . " v Bradski et al (2017) case no. 5:16-cvb-02852). In early 2017, a judge granted the defendants' request to stay the case, stating that Magic Leap had failed to provide "a reasonable degree of specificity" to the disclosure of alleged trade secrets. Subsequently, the judge allowed Magic Leap to amend the text of its submission. In August 2017, the parties entered into a “confidential agreement” in connection with this issue. In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

" v Bradski et al (2017) case no. 5:16-cvb-02852). In early 2017, a judge granted the defendants' request to stay the case, stating that Magic Leap had failed to provide "a reasonable degree of specificity" to the disclosure of alleged trade secrets. Subsequently, the judge allowed Magic Leap to amend the text of its submission. In August 2017, the parties entered into a “confidential agreement” in connection with this issue. In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

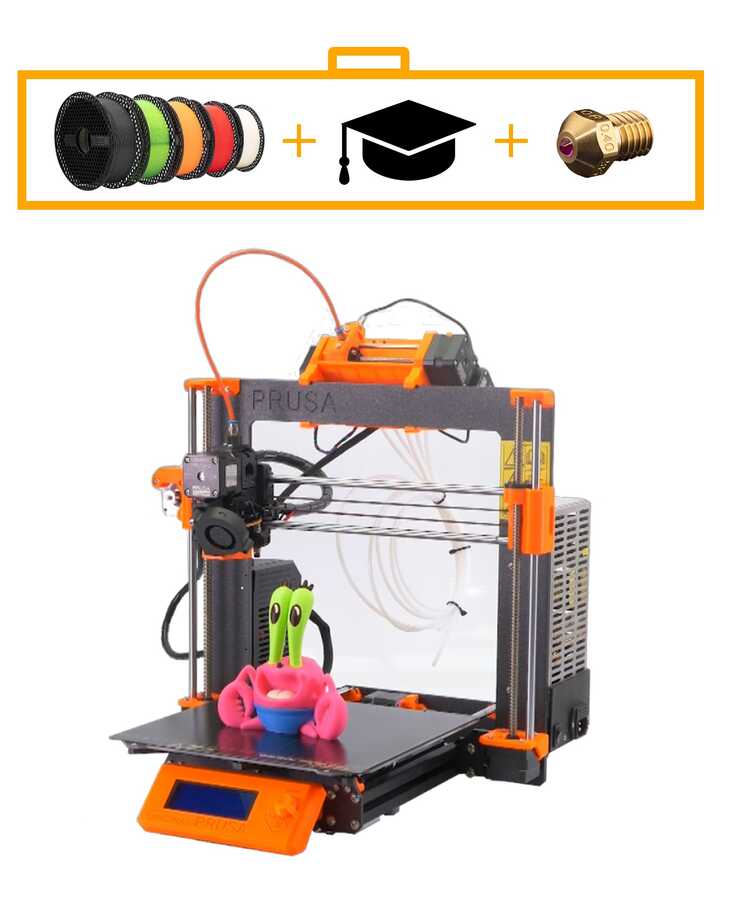

3D printing and open licensing

In addition to proprietary IP protections, 3D printing has a widespread practice of open licensing. Companies with a free distribution philosophy include Prusa Research (Czech Republic), Shapeways (Netherlands-US) and Ultimaker (Netherlands). Members of the Craft Movement used open licensing mechanisms to share and distribute 3D printing files. As noted in The State of the Commons 2017, the Thingiverse platform was one of the most popular platforms using Creative Commons licenses.

Companies with a free distribution philosophy include Prusa Research (Czech Republic), Shapeways (Netherlands-US) and Ultimaker (Netherlands). Members of the Craft Movement used open licensing mechanisms to share and distribute 3D printing files. As noted in The State of the Commons 2017, the Thingiverse platform was one of the most popular platforms using Creative Commons licenses.

Other issues arising from the development of 3D printing

In addition to IP issues, the development of 3D printing also raises a number of other legal, ethical and regulatory issues. In healthcare, regulators have faced challenges with personalized medicine. The United States Food and Drug Administration and the Australian Health Products Administration held consultations on the development of a balanced set of regulations for medical 3D printing and bioprinting. The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing.

Litigation regarding 3D printing of firearms is also ongoing in the United States. Several state attorneys general have sued the current administration to obstruct an agreement between the federal government and Defense Distributed. Several criminal cases have been filed in Australia, the United Kingdom, the United States and Japan in connection with attempts to 3D print firearms. Legislators are debating the feasibility of criminalizing crimes related to possession of digital blueprints for 3D printed firearms.

Several state attorneys general have sued the current administration to obstruct an agreement between the federal government and Defense Distributed. Several criminal cases have been filed in Australia, the United Kingdom, the United States and Japan in connection with attempts to 3D print firearms. Legislators are debating the feasibility of criminalizing crimes related to possession of digital blueprints for 3D printed firearms.

Footnotes

* Dr. Matthew Rimmer is Head of the KTU Research Program on Intellectual Property Law and Innovation and is involved in the KTU Research Center for Electronic Media, the KTU Australian Health Law Research Center and the KTU Research Program in International Law and global governance. In addition, he is a Senior Research Fellow at the Australian IP and 3D Printing Research Council Innovation Project. Dr. Rimmer is the author of numerous publications on copyright and information technology, patent law and biotechnology, access to medicines, anonymous packaging of tobacco products, IP and climate change, and IP of indigenous peoples. His current research interests include IP, Creative Industries and 3D Printing; IP and Public Health; and IP and Trade, including the Trans-Pacific Partnership, the Transatlantic Trade and Investment Partnership and the Agreement on Trade in Services. His work is held in the SSRN Abstracts and Bepress Selected Works archives and funded by the Australian Research Council.

His current research interests include IP, Creative Industries and 3D Printing; IP and Public Health; and IP and Trade, including the Trans-Pacific Partnership, the Transatlantic Trade and Investment Partnership and the Agreement on Trade in Services. His work is held in the SSRN Abstracts and Bepress Selected Works archives and funded by the Australian Research Council.

Related Links

- Read more about 3D printing and IP Litigation

INTAMSYS

INTAMSYS

High performance FDM 3D printers INTAMSYS (China). Functional engineering materials PEEK, PEKK, ULTEM, etc.

Z-axis - the exclusive distributor of Intamsys in the territory of the Russian Federation and the countries of the customs union

Go to catalog

INTAMSYS funmat pro 410

INTAMSYS FUNMAT PRO 410 is an industrial 3D printer for additive manufacturing, equipped with a double extruder and a large print chamber.

Go to catalog

INTAMSYS funmat PRO 610HT

INTAMSYS FUNMAT PRO 610HT is the latest model in the INTAMSYS FUNMAT 3D printer series. It is an industrial high performance printer designed for testing functional parts in critical environments and for low volume production.

It is an industrial high performance printer designed for testing functional parts in critical environments and for low volume production.

Go to catalog

INTAMSYS FUNMAT HT

INTAMSYS FUNMAT HT is a compact industrial 3D printer for printing prototypes, functional parts and structural elements. Printing with engineering plastics.

Go to catalog

Z-axis Company -

Master distributor of INTAMSYS in Russia and CIS countries

INTAMSYS TECHNOLOGIES (China) is a leading global manufacturer of industrial FDM 3D printers and consumables - engineering plastics (ULTEM, PEEK, PC, etc.) for 3D printing of functional products and prototyping.

The high popularity of the INTAMSYS brand is confirmed by the wide geography of equipment installations in China, Europe and the USA, including world famous companies: Apple, Airbus, HP, Bosch, GE, Mitsubishi, Siemens, Nissan, FORD, etc.

In Russia, among the users of INTAMSYS printers are research institutes, nuclear scientists, equipment manufacturers for the petrochemical industry, UAV manufacturers, the automotive industry, leading technical universities and other organizations.

After manufacturers of 3D printers from the US and Europe have joined the embargo on the supply of equipment to the Russian Federation, we suggest that Russian companies consider purchasing INTAMSYS TECHNOLOGIES printers, which, in terms of their technical characteristics, are not inferior to Western models and are not subject to US sanctions and EU.

discover the best high temperature fdm 3D printers

Complete solutions from prototyping to small batch production of functional products

610 x 508 x 508MM PRINT AREA

300°C CHAMBER HEAT TEMPERATURE

500°C HIGH TEMPERATURE EXTRUDER

305 x 305 x 406MM PRINT BUILD AREA

90°C CHAMBER HEATING TEMPERATURE

160°C TABLE HEATING TEMPERATURE

500°C HIGH TEMPERATURE EXTRUDER

260 x 260 x 260MM PRINT BUILD AREA

90°C CHAMBER HEATING TEMPERATURE

160°C TABLE HEATING TEMPERATURE

450°C HIGH TEMPERATURE EXTRUDER

INDUSTRIAL-GRADE DESKTOP 3D PRINTER - NEW

Independent dual extruder (IDEX) is ideal for a variety of printing modes, including dual material printing.