Lead screw pitch 3d printer

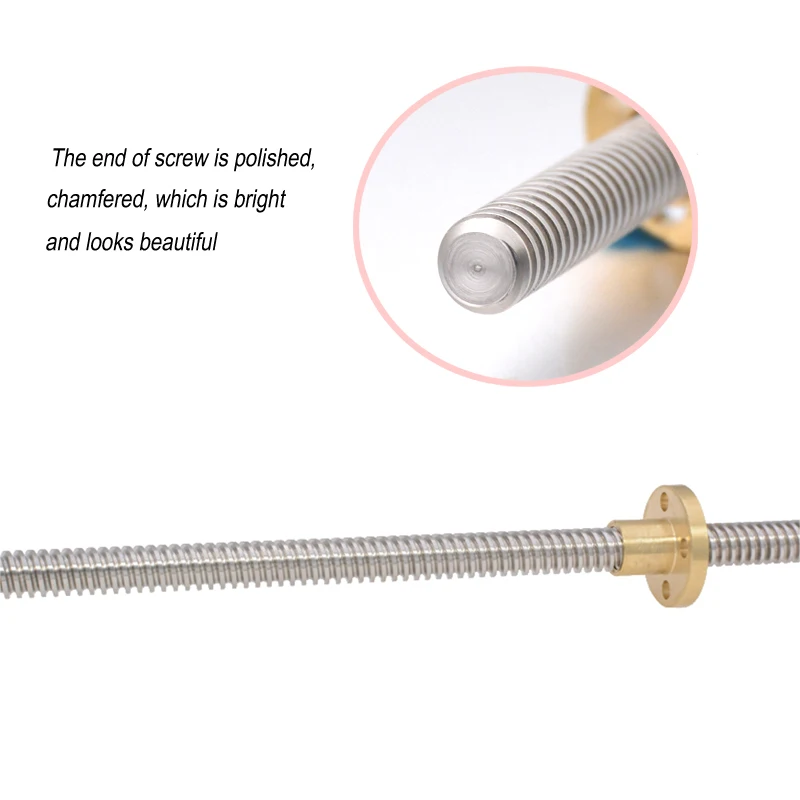

printer building - Choice of lead for lead screw

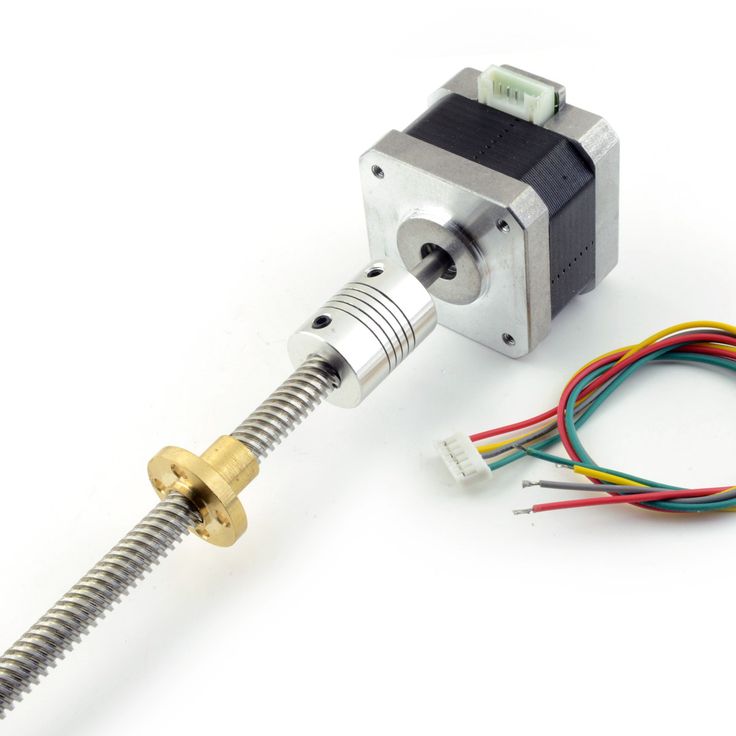

Direct-drive, 8mm-pitch Z-axis screws is a very common configuration. Although it results in low z-axis resolution, apparently it works well enough for most FFF applications.

Like you, I noticed this curious design as soon as I got into 3D printing. Based on normal design principles, the resolution of the Z-axis of most printers is technically inadequate or barely adequate, at least based on normal principles from CNC machines and other motion applications (my background is semiconductor industry robots).

Printers cut a lot of corners for cost reasons. That's why they cost hundreds of dollars instead of many thousands of dollars like CNC machines. My printer, like many others, has 8mm-pitch screws and no gear reduction. Sticking an 8mm-pitch lead-screw directly onto a stepper is simply a cheap and easy design. You could get better resolution with a shallower-pitch leadscrew, or with stepper gearboxes, or with belt-and-pulley reduction. But it would add cost and complexity, and modern stepper drivers help to band-aid the low mechanical resolution.

The divisibility of the layer heights into stepper motor revolutions is not that big of a problem in the context. Z-axis resolution is just plain low, and evenly-dividable layers may or may not make an actual improvement. I think if you are concerned about Z-axis resolution then increasing the mechanical resolution should be a far higher priority than worrying about even divisibility.

It still sort of bothers me that the Z-axis resolution is so low. But we see that printers like mine tend to work fine with the 8mm leadscrews, even in vase mode, and even with auto-bed-leveling. And I never pay attention to "magic" z-axis numbers, either. I'm sure the Trinamic stepper drivers are a big part of the reason it works so well. Sure, I could buy 2mm-pitch lead-screws and nuts to increase my Z-axis resolution by 4X. Or, I could install planetary reducers to increase it 10X. But the problem I would be solving is apparently pretty minor in practice.

But the problem I would be solving is apparently pretty minor in practice.

Also: most of these 8mm-pitch screws are 4-start threads. The reason the pitch is 8mm is partly to do with the lead-angle of the threads, and partly to do with the fact that it's a 4-start thread. The more starts a thread has, the higher the effective pitch; other things being equal, a 2-start thread will have twice the pitch, and a 4-start thread will have 4 times the pitch. So why use multi-start threads, if it reduces resolution? Technically, multi-start threads are better for lead-screw applications because they reduce binding forces. Single-start threads, like the normal UNC threads, are unbalanced, and they "push" from only one part of the diameter, so the nut tends to tilt and bind when loaded axially. This is normally fine for bolts which need to wedge in order to stay tight, but it adds friction and play when operating as a lead-screw. Using 2-start threads, the nut is "pushed" from opposite sides of the diameter, so the nut doesn't have the default tendency to tilt and bind. 3-start threads are even better because the nut is stabilized at 3 points, resisting binding forces from any direction. 4-start threads are better still but maybe a bit overkill. All this is to say that the downsides of the high effective thread pitch are somewhat compensated for by the benefits of using mult-start threads. Switching to a single-start 1mm thread would increase the resolution by 4X but would introduce some other downsides of using single-start threads, which technically could cause some other inefficiencies. It's not practical to make 4-start, 1mm thread or if it were, it wouldn't be a common part and thus probably even more expensive than just using gear reduction.

3-start threads are even better because the nut is stabilized at 3 points, resisting binding forces from any direction. 4-start threads are better still but maybe a bit overkill. All this is to say that the downsides of the high effective thread pitch are somewhat compensated for by the benefits of using mult-start threads. Switching to a single-start 1mm thread would increase the resolution by 4X but would introduce some other downsides of using single-start threads, which technically could cause some other inefficiencies. It's not practical to make 4-start, 1mm thread or if it were, it wouldn't be a common part and thus probably even more expensive than just using gear reduction.

diy 3d printer - Are there practical reasons to NOT use a stepper motor with lead screw for the X and or Y axes?

I am going to answer this as someone who actually did rework their Prusa i3 fleabay clone to use leadscrews for all axes. Before digging into the matter, the backlash issue can be solved easily with spring-loaded brass nuts, kinda like how ballscrews work. That's the simplest problem to solve though as there are a lot of other issues.

That's the simplest problem to solve though as there are a lot of other issues.

Short version / tl;dr

Hardware can't handle that many microsteps.

Crosstalk and motor inductance limit speeds and acceleration.

Print quality suffers in really weird ways because of (2).

Leadscrews are not made for quick movement over extended periods of time and will wear, even with grease.

You'll need additional bearing surfaces to prevent your motors from grinding themselves apart, and to eliminate backlash due to the flex couplings.

The system becomes a lot more prone to highly destructive failure modes.

Long explanations

First

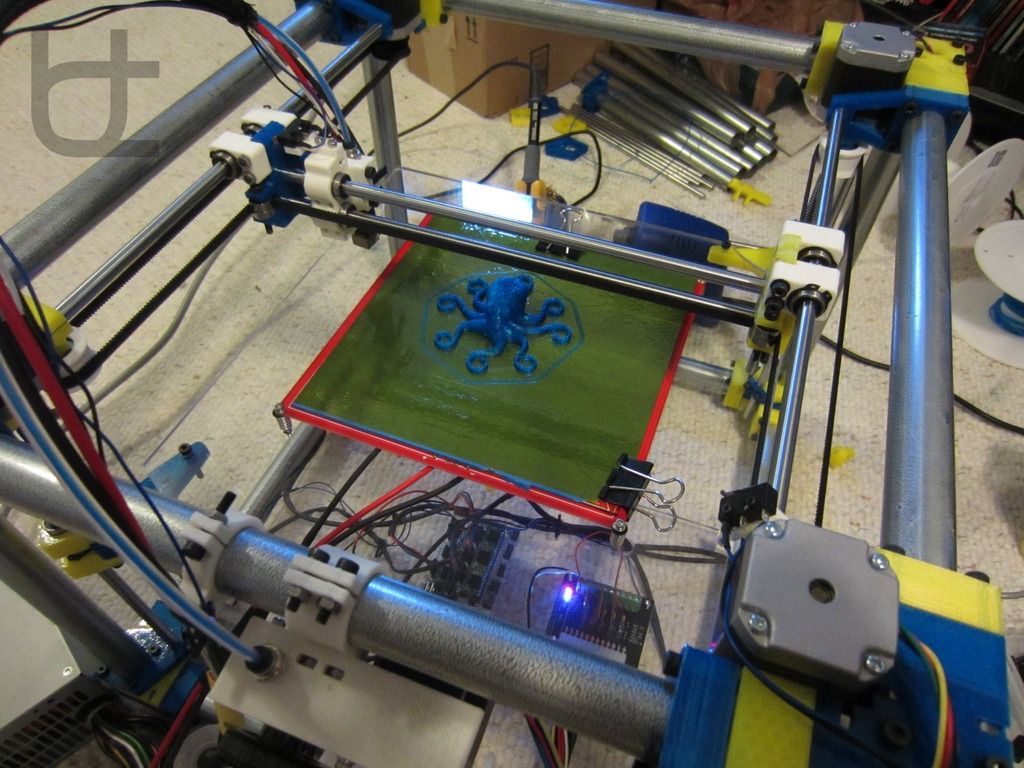

You're going to notice is that you're constrained to horribly, horribly slow movement and acceleration rates. My screws are 8 mm screws, with 8mm pitch. That means it takes 200 steps to travel 8 mm. Multiply by 1/16th microstepping, and that's 3200 microsteps per 8 millimeter of travel. Multiply by whatever speed you're trying to print at, then the number of axes you're using, and you'll find that your RAMPS board starts to stutter on complex moves if you print fast enough.

Multiply by whatever speed you're trying to print at, then the number of axes you're using, and you'll find that your RAMPS board starts to stutter on complex moves if you print fast enough.

Second

You'll quickly hit the inductance limits of your motors. At "standard" power levels (ones that don't fry my knockoff NEMA17 motors), even after switching to 24 V for the entire setup, the fastest I could spin my motors was about 5 revolutions per second, which translates to 16,000 microsteps per second with 8mm pitch screws. For reference that means that under ZERO load, the fastest my N17 w/ 8 mm pitch could travel, is about 40 mm/s.

You're basically running the motor coils at several kilohertz, which means you have to be really careful about keeping your wires separate and shielded to prevent crosstalk, in addition to the fact that as your step frequency goes up, your step torque goes down dramatically. Not only does this limit the weight of the bed that the motor is capable of pushing at a given speed, but you even have to worry about the inertia of the motor and bed much more than with a belt-driven system. So instead of 30 mm/s jerk with 200 mm/s2 acceleration, suddenly you're limited to, say, 5 mm/s jerk and 40 mm/s2 acceleration.

So instead of 30 mm/s jerk with 200 mm/s2 acceleration, suddenly you're limited to, say, 5 mm/s jerk and 40 mm/s2 acceleration.

As mentioned, for best results, the whole system needs to be converted to 24 V, and not all boards are configured for this to be easily done. My cheap RAMPS clone only needed a single diode removed and everything else was fine, but YMMV in this regard.

You could solve this particular problem by gearing the motors down, but at that point you've now introduced a new source of backlash either between the gear teeth or in the belt drive system, and kinda defeated the point.

Third

Due to this effect, is that you run into extrusion pressure artifacts. Basically, the plastic in the nozzle is a fluid, a very viscous one, being forced through a small hole. The fluid pressure will "lag" somewhat behind what the extruder motor thinks is happening.

The end result is that while you're accelerating, the lines you're laying are thinner than they should be, and will be thicker than they should be while decelerating, and you tend to get weird "globs" on each corner when you come to a stop. For me, with a 0.4 mm nozzle, 0.8 mm line width, and 0.2 mm layer height, these artifacts actually completely offset the additional accuracy I was getting with a tightly-coupled leadscrew with spring loaded dual nuts on it. The parts ended up being even less dimensionally accurate than before, with very strange deformities.

For me, with a 0.4 mm nozzle, 0.8 mm line width, and 0.2 mm layer height, these artifacts actually completely offset the additional accuracy I was getting with a tightly-coupled leadscrew with spring loaded dual nuts on it. The parts ended up being even less dimensionally accurate than before, with very strange deformities.

There ARE settings you can use in the firmware to try and combat this specific effect, but the process is tedious and takes a lot of trial-and-error, and recompiling the firmware every 30 seconds is annoying, not to mention the variables are dependent on line width, speed and acceleration settings, and layer height, so you have to recompile your firmware any time you want to change the print quality. Super, super annoying.

Fourth

Leadscrews aren't actually designed for this. The constant back-and-forth motion will wear the brass nuts and even the steel threads of the screws over time. You end up with a black powdery residue on everything underneath the screw, which, in the X axis, typically also means your print. Nobody wants steel powder messing up their layer adhesion.

Nobody wants steel powder messing up their layer adhesion.

In my case I used Superlube, which is a silicone/PTFE grease, to help prevent this problem, but that only works so well when you've got spring-loaded brass nuts. Eventually they push most of the lube out. Additionally, the lube tends to grab and hold any metal powder that does form, accelerating wear in areas that are still lubricated.

Fifth

Bearings. Turns out motors have internal bearings, that generally suck and aren't made for heavy loads in any direction. I found that out when my Y-axis N17 motor failed because the bearing did, and spread powder all over the coils, some of which got pushed through the enamel and shorted the wires out.

Additionally, because tiny amounts of misalignment turn motors into shrapnel in a hurry, you're almost certainly going to be using flex couplings. Flex couplings have a certain amount of yield to them axially, and are primarily designed to be under compression loads, and tend to fail when stretched repeatedly.

For the Z axis this is normally not an issue because the whole system is held down by gravity, but in the X and Y axes, you'll get some weird offsets of even a millimeter or two each time the carriage or bed switches directions. So you'll want to make sure that the motors aren't load bearing themselves, and the screw remains locked relative to the frame while still being able to rotate.

You can accomplish this by having a ring fastened to each end of the leadscrew that either pushes on a thrust bearing or rides in a regular ball bearing. Ideally, you can do both, but this turns into an expensive venture with a whole lot of brackets in odd places that you may not have space for. I ended up losing about 20 mm of bed travel solving this problem.

Sixth

You need to think about what happens when a component fails. For me, it was my endstops. The first failure was from the crosstalk issue I mentioned above. Y-stops triggered, bed started shifting towards the front of the printer over time, and eventually the printer started trying to move the bed through the front of the printer frame.

It was successful.

The second time was simply the endstop switch failing mechanically. Belt travel stops at the pulley. Leadscrews go all the way to the end of the screw, and because they're geared so much lower than belts are, there's a lot more torque involved. I destroyed my printer frame three separate times because of this problem, and once more when the Y-axis flex coupling snapped. This allowed the motor to spin the screw easily in one direction but not in another - which this time forced the print bed backwards instead of forwards, yanking the Y motor through its bracket and the frame again.

Conclusion

X/Y screws are not necessarily a bad idea, simply an expensive and tedious one in 3D printing. They're much better suited to low-feedrate applications like CNC mills, mechanical engravers, and the like. You may notice that even high-accuracy applications like laser printers tend to have belt-fed carriages rather than screw-driven ones. Screws are much better suited to high load, low-speed applications, and printers tend to be the opposite of that.

If you're trying to eliminate backlash due to the belts not being tight enough, as I was, the answer is to make a better printer. I couldn't tighten the belts enough to get my prints accurate before the motors started failing, because I didn't have the motor-end pulley supported by a bearing. Start there, literally just support on either side of the pulley on the motor shaft with a small bearing braced against the frame to take the radial load off the motor. If your belts are stretching too much, use steel-core GT2 belt. If your system is overall just sloppy, build a more robust system. My current project is a Hypercube Evo, and I found a supplier that makes steel-core GT2 belt. I'm going to use that to maximize rigidity in the CoreXY belt system. The frame is made from 30x30 mm T-slot extrusions, with 12 mm Z-axis rods and 10 mm X/Y axis rods. Bigger, more expensive components that are way more robust and will flex much less than the 400 mm long 8 mm rods on my cheapo printer.

Hope this helps. (edited to get my math right on the microsteps)

(edited to get my math right on the microsteps)

Leadscrews: an extended experience of long-term use

Sandbox

So, the printer has already printed enough for me to tell absolutely everything about the screws.

The original idea was that the belts need to be tightened, and the print resolution on them is not very high. Decided to try the screws in connection with this.

First, let's talk about speed. The achieved 100mm/s proved to be unstable. In reality, the initially found 60 mm / s turned out to be reinforced concrete stable. What is most offensive is that the speed cannot be raised even on movements without printing. That is, the printer constantly crawls 60mm / s, regardless of the job. What generates a bunch of snot on the models, the retract does not help much. This is partly a feature of my extruder: the hot zone is quite large, and there is a lot of liquid plastic.

In an attempt to increase speed and to complete the experiment, I had very, VERY thick 60mm NEMA17 sliders:

The idea was simple: larger sliders would give more torque and holding moment, which is so necessary for the lead screws. But in real life, everything turned out to be almost the opposite: it was not possible to get stable 60mm on them. In the course of the experiments, I reached the full step mode of the stepper motor, but this did not help either. In addition, the printer just yelled from resonant phenomena. These engines turned out to have too much magnetic coupling (? I don’t know how to call it correctly), and they do not digest high speeds. As a result, I sent them to supply plastic to another printer.

But in real life, everything turned out to be almost the opposite: it was not possible to get stable 60mm on them. In the course of the experiments, I reached the full step mode of the stepper motor, but this did not help either. In addition, the printer just yelled from resonant phenomena. These engines turned out to have too much magnetic coupling (? I don’t know how to call it correctly), and they do not digest high speeds. As a result, I sent them to supply plastic to another printer.

Speaking of noise... The printer is noticeably louder than it was on the belts. And it's not just the aforementioned resonant phenomena and the 1/4 step mode. The point is the backlash of the nut-lead screw connection. When changing direction, a distinctly audible knock is heard. Sleep next to him is impossible in principle, a knock is heard even behind two closed doors.

Not all is well with the nuts themselves either. If the screw is under the table (as with the Y-axis), then everything is more or less smooth, but if it is above the table, as in the case of the X-axis, then the table will always be strewn with black chips that fall off the nut as it wears out.

Nut play must also be constantly monitored. If the backlash becomes more than 0.1 mm, you can forget about accurate printing. This is due to the fact that a heavy X-carriage (as in my case) after a stop by inertia chooses backlash in the opposite direction. And as a result of this, X-wobbling and Y-wobbling are added to the notorious Z-wobbling characteristic of i3, and any printout turns into something unforgettable in the most terrible sense. Software backlash compensation partly saves, but only up to 0.1 mm. The next step is to replace the nut.

I had some misalignment of the nut with the screw in the X axis, and the nut was eaten very vigorously, in about 400 hours of printing. The slightest unnecessary friction - and wear increases almost exponentially. Here someone described the solution to the backlash problem in the form of 2 nuts and a spring between them (I did not find the link), and so: this is nonsense. Nuts will gobble up even faster than in my case, and even doubly cover everything with bronze chips (this is true for X and Y - axes that constantly rotate). By the way, here is a photo of a new and used nuts:

By the way, here is a photo of a new and used nuts:

Wear visible to the naked eye.

Another non-obvious minus: when the table is parked, and it needs to be pulled out for applying abs-juice or cleaning, you have to tediously turn the screw to do this, while with straps you could just pull the table towards you.

Based on all of the above, I sum up the disappointing result: the screws are not applicable for a 3D printer, except for the Z axis. I'm getting ready to return to the belts. Don't repeat my mistake.

Adios

Subscribe author

Subscribe

Don't want

4

3D printing - threads and screws

First things first: what is the difference between a screw and a thread?

A screw is a fastener used to form a connection that can later be dismantled, while the thread is the main fastener of the screw. In this case, the thread is not only used for screws; they are also present on pipes, in linear drives, worm gears and many other devices.

The common feature of all threads is the way they are formed. Each thread is a continuous spiral groove of a certain cross section, made on the outer or inner side of the cylindrical surface.

In most cases, the cross section or shape is triangular or trapezoidal. Triangular thread forms are primarily used for fasteners (screws), while trapezoidal thread forms, varieties of square threads, are used for power transmission and linear drives on lead screws. To keep things simple, this article only covers triangular shaped threads, but everything applies to both types.

A further level of categorization distinguishes metric threads from inch threads. The former are mainly used in Europe and Asia, while the latter are used in America and the UK. To the untrained eye, they look the same, but the difference exists in the shape of the triangle and the pitch of the spiral curve.

In this article, we will cover the basics of designing and 3D printing screws and threads.

Basic Terms

There are a few terms and concepts that you should be familiar with before you start designing a thread.

External or internal thread : External or external thread exits the cylindrical surface. The female thread is cut on the inner cylindrical surface. For example, bolts have external threads, while nuts have internal threads.

Thread axis : a line through the center of the cylinder on which the thread is to be formed.

Base : the bottom of the groove that runs around the body of the thread.

Comb : The highest point of the thread profile.

Large diameter : The diameter of a cylinder enclosing the top of an external thread or the base of an internal thread. This cylinder is concentric with the axis of the thread.

Minor Diameter : The diameter of a cylinder enclosing the root of a thread on an external thread or the crest of an internal thread. This cylinder is concentric to the thread axis and large diameter. The smaller diameter is also known as the drill diameter when handling internal threads.

This cylinder is concentric to the thread axis and large diameter. The smaller diameter is also known as the drill diameter when handling internal threads.

Pitch : distance between equivalent points on adjacent threads. For example, the distance between two adjacent crests of a triangular thread.

Metric thread: The "M" designation of a metric thread indicates the nominal outside diameter of the thread in millimeters. For example, an M5 thread has a nominal outer diameter of 5 mm. For external threads, the nominal outside diameter is equivalent to the major diameter. For internal threads, the nominal outside diameter can be determined by measuring the minor diameter and referring to the metric thread table.

Inch threads: Inch threads are designated using a number of standards, including the Unified Thread Standard (UTS), which basically refers to standard thread sizes as numbers (eg #4). The two most important measurements in UTS are the major or minor diameter of external or internal threads, respectively, and threads per inch (TPI).

Thread Modeling

Let's look at the process of designing external and internal threads using Fusion 360, which provides a simplified threading feature.

Other CAD programs have tools of varying degrees of similarity. It is important to understand the basics presented in the previous section. With this knowledge, you will be able to use any available modeling tool for 3D modeling.

Let's start with the outer thread of the bolt.

External thread

- Draw a circle with a diameter equal to the largest diameter of the desired thread.

- Create a cylinder by extruding a circle to the desired thread length.

- Go to "Create" and select the "Thread" option.

- Select the newly created cylinder. Make sure "Modeled" is checked. Set the thread type and other thread options. Click OK.

That's it. You have an external thread! To make a good bolt out of it, you need to attach it to the head to your liking.

Now let's create a nut with an internal thread.

Internal thread

- Create a hexagon. For the purposes of this tutorial, just make sure it's larger than the carving you want to create.

- Press it out to the desired height.

- Make a hole in the center by selecting the "Hole" option from the "Create" menu. The hole diameter must match the largest thread diameter.

- Select the inner surface of the newly created hole, go to "Create" and select the "Thread" option.

- Don't forget to check the "Modeled" option. Set the thread size and other parameters. Click OK.

That's it. Your first carvings are ready for 3D printing!

Tips for 3D Printing Threaded Parts

This may seem like a simple task at first glance, but printing threads is not always easy, especially if you need small diameters.

Assume you are using a 0.4 mm nozzle and a 0.2 mm layer height. With this setting, the smallest pitch you can achieve during 3D printing is likely to be around 0.5mm (give or take 0. 1mm). This pitch is suitable for M3 threads and you should have no problem trying to print an internal thread on a relatively large part. This is because your threads will have enough time to cool while the nozzle is in a different location.

1mm). This pitch is suitable for M3 threads and you should have no problem trying to print an internal thread on a relatively large part. This is because your threads will have enough time to cool while the nozzle is in a different location.

Things get interesting if you need an external thread, for example on a screw or bolt. In this case, the nozzle has nowhere else to go, which means that you will probably need additional cooling. Check your 3D printer before you decide to print a lot of thin external threads.

One of the most practical options before starting thread printing is the M10 3D Printed Thread Test. Thanks to this special 3D model, you will be able to check exactly what your 3D printer is capable of.

Settings when 3D printing parts with threads

Below are some general guidelines for setting up your 3D printer when printing threads.

- Make sure your 3D printer is properly calibrated. Extruder calibration is also important.

- Always try to print threads vertically. For best results, the thread axes should be perpendicular to your 3D printer table.

- Print without the calipers, or at least make sure they don't go inside the threads. Otherwise, removing them and maintaining functionality can be a real problem, especially with internal threads.

- If possible, use at least 4 vertical layers or vertical walls at least 2 mm thick. This will ensure the strength of the thread.

- Try to set the filling density to at least 25%.

- Layer height is an important parameter when 3D printing threads. For smooth operation, the layers should be as thin as possible. As a guideline, threads larger than M12 or 1/2" can be successfully printed at 0.2mm, while smaller threads should be printed at thinner layers.

Resume

Even if your first test fails, don't despair! Here are some final tips for 3D printing threads:

- Even if you manage to print beautiful external threads smaller than M6 (6mm in diameter), think twice before using it for heavy duty use.