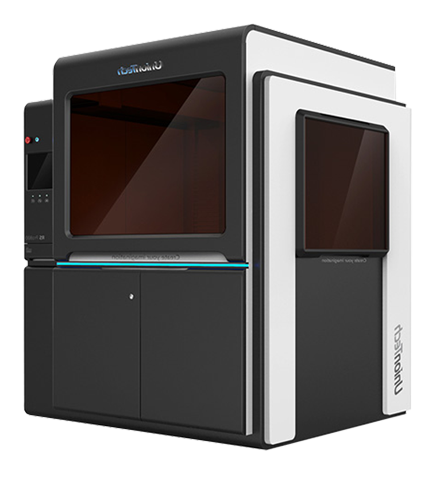

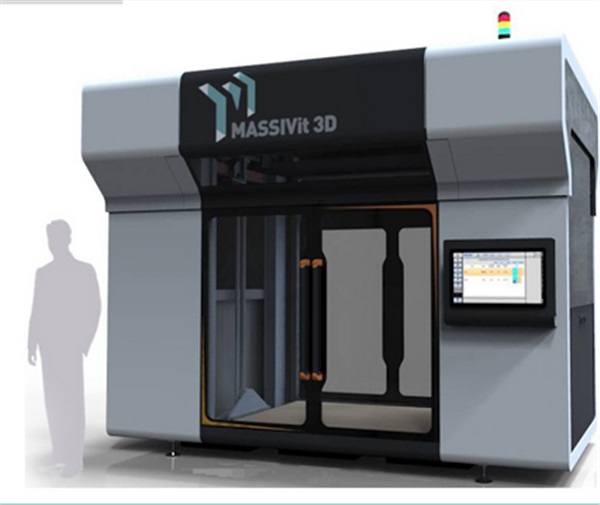

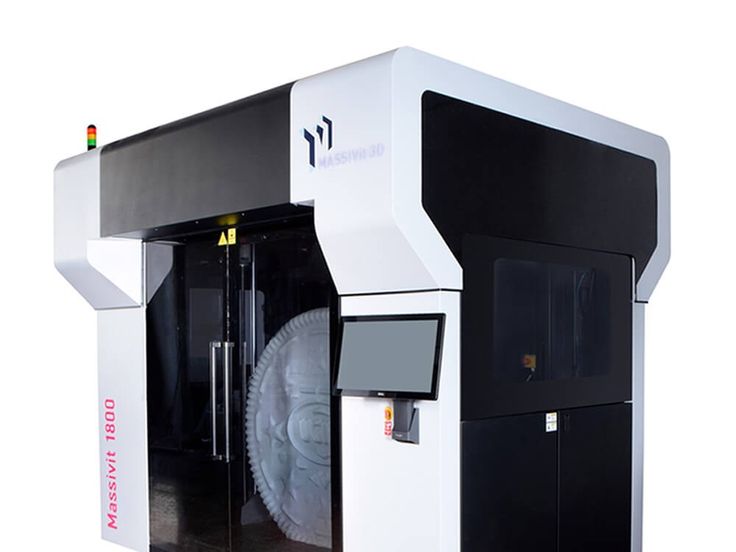

Massivit 1800 3d printer

About | Massivit 3D

Transforming Manufacturing of Large Parts

Massivit 3D Printing Technologies Ltd. is a pioneer of large format 3D printing solutions for the Engineering, Visual Communications, Entertainment, Academia, Interior Design, and Architectural markets. Leveraging its proprietary Gel Dispensing Printing (GDP) technology, the company’s solutions enable rapid and cost-effective production of scale 1 models and parts.

Founded in 2013 by a team of recognized industry experts, Massivit 3D is headquartered in Lod, Israel and provides its worldwide community with end-to-end services supported through an extensive dealer network.

Read more about Massivit 3d | Hebrew

OUR

valuesINNOVATION. We continually develop innovative, large additive manufacturing systems as well as brand new applications that grow our customers’ businesses in exciting new ways.

PASSION. It’s exciting to be able to shift the paradigm across multiple industries such as Engineering, Visual Communicaitons, Entertainment, and Academia. We’re passionate about bringing to market fresh and cost-effective fabrication methods and applications, with a solid track record of 57 patent assets.

SIMPLICITY. Large format 3D printing is not only digital, but in our case, intuitive and easy to learn. A friendly user interface, simple operation, and truly outstanding customer services make a difference.

PARTNERSHIP. Supporting our customers’ ambition to make 3D printing a profitable dimension of their business is key. Through fast-turnaround solutions, intuitive technology, training & support and industry leading expertise – we support customer success every step of the way.

OUR

TeamDreaming big

We are a young company building on a rich legacy of industry innovation. Founded by Gershon Miller, Moshe Uzan and Igor Yakubov, pioneers in wide format printing & 3D printing, Massivit 3D is rapidly expanding the possibilities of large format 3D printing across multiple industries.

Founded by Gershon Miller, Moshe Uzan and Igor Yakubov, pioneers in wide format printing & 3D printing, Massivit 3D is rapidly expanding the possibilities of large format 3D printing across multiple industries.

Our team of visionary co-founders and printing innovators is breaking new ground with revolutionary products and applications. As our customers make the exciting leap into digital, large format 3D printing, we’re supporting them every step of the way.

The leading team

Yaron Yecheskel

Chairman

Yaron Yecheskel

Chairman

Yaron Yecheskel is the founder and CEO of Opal Family Office – which provides financial strategy and management for family wealth. Previously, Yaron served as Manager of a private banking branch of Ubank, which is a part of the FIBI banking group, and as VP Marketing and Sales of a portfolio management company and a mutual fund company. Yaron holds a bachelor’s and master’s degree in Business Administration with a specialization in Finance and Capital Markets. He holds an investment advisor and investment portfolio manager license, issued by the Israeli Securities Authority. Yaron leads the controlling group of Massivit 3D and has served as Director of the company’s Board of Directors since 2016. In recent years, Yaron has greatly assisted in raising Massivit 3D’s capital and led the company to a successful IPO in the Tel Aviv Stock Exchange in 2021.

He holds an investment advisor and investment portfolio manager license, issued by the Israeli Securities Authority. Yaron leads the controlling group of Massivit 3D and has served as Director of the company’s Board of Directors since 2016. In recent years, Yaron has greatly assisted in raising Massivit 3D’s capital and led the company to a successful IPO in the Tel Aviv Stock Exchange in 2021.

Yaron Yecheskel

Chairman

Yaron Yecheskel is the founder and CEO of Opal Family Office – which provides financial strategy and management for family wealth. Previously, Yaron served as Manager of a private banking branch of Ubank, which is a part of the FIBI banking group, and as VP Marketing and Sales of a portfolio management company and a mutual fund company. Yaron holds a bachelor’s and master’s degree in Business Administration with a specialization in Finance and Capital Markets. He holds an investment advisor and investment portfolio manager license, issued by the Israeli Securities Authority. Yaron leads the controlling group of Massivit 3D and has served as Director of the company’s Board of Directors since 2016. In recent years, Yaron has greatly assisted in raising Massivit 3D’s capital and led the company to a successful IPO in the Tel Aviv Stock Exchange in 2021.

Yaron leads the controlling group of Massivit 3D and has served as Director of the company’s Board of Directors since 2016. In recent years, Yaron has greatly assisted in raising Massivit 3D’s capital and led the company to a successful IPO in the Tel Aviv Stock Exchange in 2021.

Erez Zimerman

CEO

Erez Zimerman

CEO

Erez Zimerman served as VP Global Sales at Massivit 3D for three years before being appointed CEO. He has a successful track record in sales & marketing and vast experience in multi-disciplinary systems. Before joining Massivit 3D, Erez served as VP Marketing & Business Development at Matan Digital Printers, which was acquired by EFI. Prior to Matan, Erez worked at Objet Geometries (which later merged with Stratasys) as Asia Pacific Marketing Manager and Product Manager. Erez also worked at Scitex Vision serving in various management positions both in R&D and Marketing. Erez holds a BSc in Electrical Engineering and an MBA from Bar Ilan University, Israel.

Erez Zimerman

CEO

Erez Zimerman served as VP Global Sales at Massivit 3D for three years before being appointed CEO. He has a successful track record in sales & marketing and vast experience in multi-disciplinary systems. Before joining Massivit 3D, Erez served as VP Marketing & Business Development at Matan Digital Printers, which was acquired by EFI. Prior to Matan, Erez worked at Objet Geometries (which later merged with Stratasys) as Asia Pacific Marketing Manager and Product Manager. Erez also worked at Scitex Vision serving in various management positions both in R&D and Marketing. Erez holds a BSc in Electrical Engineering and an MBA from Bar Ilan University, Israel.

Gershon Miller

Co-Founder & Chief Innovation Officer

Gershon Miller

Co-Founder & Chief Innovation Officer

A serial innovator and entrepreneur, Gershon founded Idanit, a pioneering developer of large format digital printing solutions. In 1998, Idanit was sold to Scitex Corporation where it was rebranded as Scitex Vision, and later sold to HP. Mr. Miller was the co-founder of Objet Ltd, a developer and manufacturer of 3D printers. In 2012 Objet merged with Stratasys, to become the leading 3D printing company (traded on NASDAQ under “SSYS”). He holds an BSc in Electro optics from The Jerusalem College of Technology in Israel.

In 1998, Idanit was sold to Scitex Corporation where it was rebranded as Scitex Vision, and later sold to HP. Mr. Miller was the co-founder of Objet Ltd, a developer and manufacturer of 3D printers. In 2012 Objet merged with Stratasys, to become the leading 3D printing company (traded on NASDAQ under “SSYS”). He holds an BSc in Electro optics from The Jerusalem College of Technology in Israel.

Gershon Miller

Co-Founder & Chief Innovation Officer

A serial innovator and entrepreneur, Gershon founded Idanit, a pioneering developer of large format digital printing solutions. In 1998, Idanit was sold to Scitex Corporation where it was rebranded as Scitex Vision, and later sold to HP. Mr. Miller was the co-founder of Objet Ltd, a developer and manufacturer of 3D printers. In 2012 Objet merged with Stratasys, to become the leading 3D printing company (traded on NASDAQ under “SSYS”). He holds an BSc in Electro optics from The Jerusalem College of Technology in Israel.

Igor Yakubov

Co-Founder & VP R&D

Igor Yakubov

Co-Founder & VP R&D

Igor began his career as a programmer at Idanit, before gaining promotion to HP Scitex R&D Application & Color Group Manager where he led a group comprising 60 people covering all products. In 2011 Igor moved to AdOM, where he headed up software and algorithm development for analyzing 3D imaging files in a company offering advanced treatments for the retina. With extensive experience of multi-disciplinary products, Igor holds an MSc in physics from Makhachkala University, Russia. Igor also serves as a Director on the Massivit 3D board.

In 2011 Igor moved to AdOM, where he headed up software and algorithm development for analyzing 3D imaging files in a company offering advanced treatments for the retina. With extensive experience of multi-disciplinary products, Igor holds an MSc in physics from Makhachkala University, Russia. Igor also serves as a Director on the Massivit 3D board.

Igor Yakubov

Co-Founder & VP R&D

Igor began his career as a programmer at Idanit, before gaining promotion to HP Scitex R&D Application & Color Group Manager where he led a group comprising 60 people covering all products. In 2011 Igor moved to AdOM, where he headed up software and algorithm development for analyzing 3D imaging files in a company offering advanced treatments for the retina. With extensive experience of multi-disciplinary products, Igor holds an MSc in physics from Makhachkala University, Russia. Igor also serves as a Director on the Massivit 3D board.

Moshe Uzan

Co-Founder & COO

Moshe Uzan

Co-Founder & COO

A specialist in innovative multi-disciplinary printing systems, Moshe Uzan has built a distinguished career in the large format digital printing industry. One of the first members of Scitex Vision, Moshe subsequently became R&D manager of the drum machines product line at HP, including leading the development of the company’s ~1$ billion-generating Turbojet project line. He holds a BSc in Electronics Engineering from Ben Gurion University in Israel.

One of the first members of Scitex Vision, Moshe subsequently became R&D manager of the drum machines product line at HP, including leading the development of the company’s ~1$ billion-generating Turbojet project line. He holds a BSc in Electronics Engineering from Ben Gurion University in Israel.

Moshe Uzan

Co-Founder & COO

A specialist in innovative multi-disciplinary printing systems, Moshe Uzan has built a distinguished career in the large format digital printing industry. One of the first members of Scitex Vision, Moshe subsequently became R&D manager of the drum machines product line at HP, including leading the development of the company’s ~1$ billion-generating Turbojet project line. He holds a BSc in Electronics Engineering from Ben Gurion University in Israel.

Dana Erez

General Counsel and Company Secretary

Dana Erez

General Counsel and Company Secretary

Dana Erez

General Counsel and Company Secretary

Avi Cohen

VP Global Sales

Avi Cohen

VP Global Sales

Avi Cohen’s career started in sales, marketing, and high-level management positions in various companies, his over 20-year association with the additive manufacturing sector beginning in 1999 when he joined Stratasys (formally Objet). At Stratasys for 16 years, Cohen became Director of Healthcare Sales and Marketing, focusing his expertise on evangelizing about 3D printing technology, with a special concern for the medical and dental sectors. Cohen comes to Massivit after a 5-year stint as the Vice President at XJet Ltd a position he took up after moving on from Stratasys in 2015, and over two years at Nano Fabrica (acquired by Nano Dimension). Working at the forefront of the digital manufacturing revolution, Avi Cohen commands the respect of the entire international 3D printing community, and he is recognized as a strategically astute technology leader.

At Stratasys for 16 years, Cohen became Director of Healthcare Sales and Marketing, focusing his expertise on evangelizing about 3D printing technology, with a special concern for the medical and dental sectors. Cohen comes to Massivit after a 5-year stint as the Vice President at XJet Ltd a position he took up after moving on from Stratasys in 2015, and over two years at Nano Fabrica (acquired by Nano Dimension). Working at the forefront of the digital manufacturing revolution, Avi Cohen commands the respect of the entire international 3D printing community, and he is recognized as a strategically astute technology leader.

Avi Cohen

VP Global Sales

Avi Cohen’s career started in sales, marketing, and high-level management positions in various companies, his over 20-year association with the additive manufacturing sector beginning in 1999 when he joined Stratasys (formally Objet). At Stratasys for 16 years, Cohen became Director of Healthcare Sales and Marketing, focusing his expertise on evangelizing about 3D printing technology, with a special concern for the medical and dental sectors. Cohen comes to Massivit after a 5-year stint as the Vice President at XJet Ltd a position he took up after moving on from Stratasys in 2015, and over two years at Nano Fabrica (acquired by Nano Dimension). Working at the forefront of the digital manufacturing revolution, Avi Cohen commands the respect of the entire international 3D printing community, and he is recognized as a strategically astute technology leader.

Cohen comes to Massivit after a 5-year stint as the Vice President at XJet Ltd a position he took up after moving on from Stratasys in 2015, and over two years at Nano Fabrica (acquired by Nano Dimension). Working at the forefront of the digital manufacturing revolution, Avi Cohen commands the respect of the entire international 3D printing community, and he is recognized as a strategically astute technology leader.

Hadar Friedland

VP HR

Hadar Friedland

VP HR

Hadar Friedland

VP HR

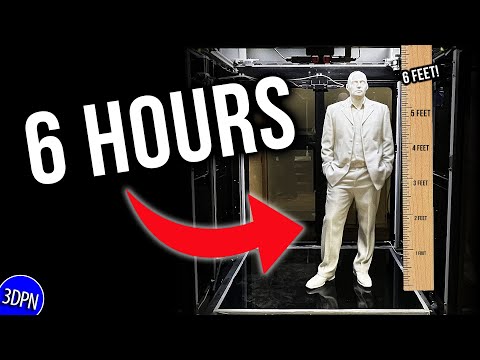

Massivit 1800 3D Printer In-Depth Review

ADVERTISEMENT

7.2Expert Score

Massivit 1800 3D Printer

This machine is a very large format 3D printer and offers a very unique extrusion technology, similar to FFF, but not exactly the same.

Affordability

3

Quality

9

Speed

8

Capability

8

Practicality

8

User Expectations

7

PROS

- Users can print two different objects parallelly

- The print speed is fast

- Massivit is accurate and can create complex designs without the hassle

- One can print support free models, even for non-vertical walls and ceilings

CONS

- It is very expensive

- Prints in only its proprietary material

- Very huge in size

Do you believe that ‘bigger is better’? If yes, do check the Massivit 1800 3D printer designed to offer enhanced performance to industries looking . ..

..

Add to wishlistAdded to wishlistRemoved from wishlist 0

Add to compare

|

Table of Contents

Industrial 3D printers are becoming more and more popular. There was a time the technology was limited to a few hands. However, fast forward today, it isn’t very uncommon to own an industrial-grade 3D printer for big businesses.

There was a time the technology was limited to a few hands. However, fast forward today, it isn’t very uncommon to own an industrial-grade 3D printer for big businesses.

There still are concerns with price and affordability, however, the machine does promises to repay the invested amount sooner than ever. With so many applications and innovative technologies, 3D printers are becoming capable and enhanced.

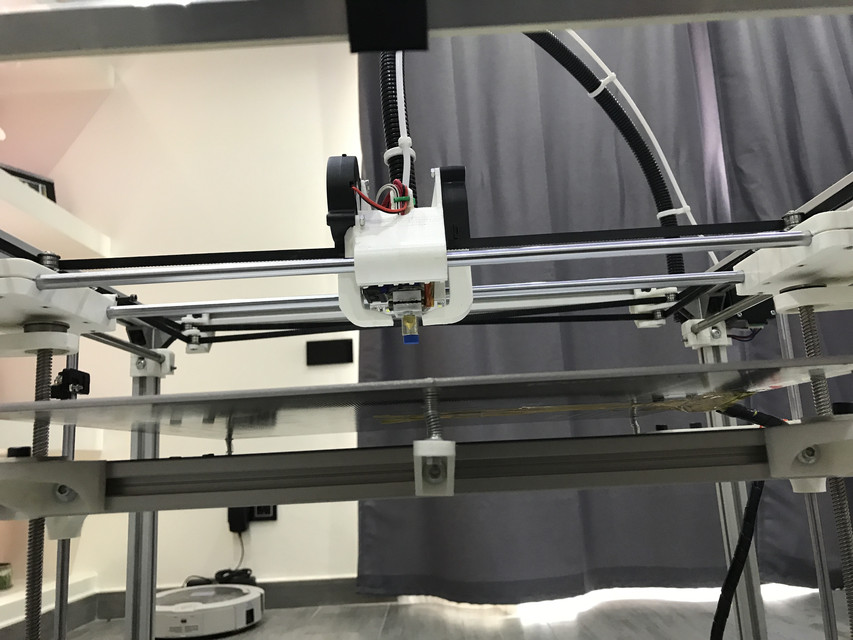

One such example is Massivit 1800 3D printer. This machine is a very large format 3D printer and offers a very unique extrusion technology, similar to FFF, but not exactly the same.

What makes Massivit a lot different from other large-format 3D printers is its speed. The manufacturer claims this machine to be the fastest one. There is one more difference between other industrial grand printers and this one.

Credit: 3dprint.comMost of the 3D printers manufactured for businesses are driven towards engineering uses. However, this one is, by far the only 3D printer primarily designed for display type applications.

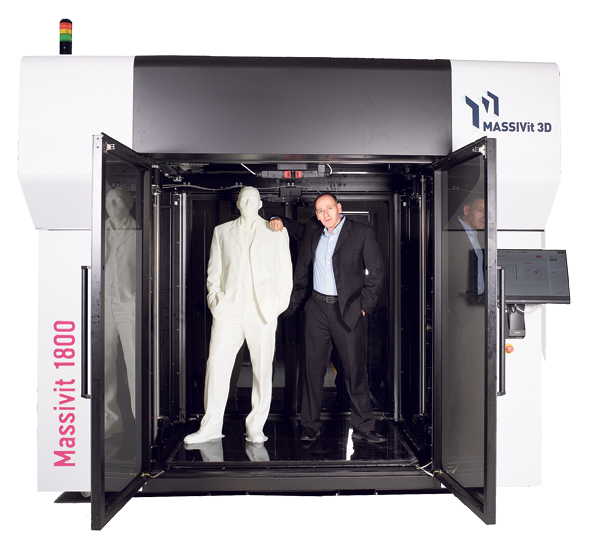

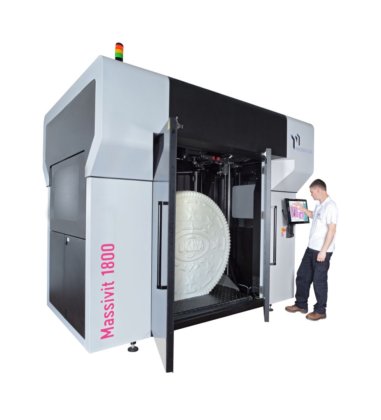

You can imagine large-sized sculptures getting ready in a matter of hours using this amazing 3D printer. It is well equipped with all the necessary features to create life-sized plastic figures.

How about the massive chess pieces? In short, you can expect to 3D print 1.8m high models when printing with this 3D printer. One can also attach different 3D printed pieces to create even bigger size figurines, larger than the print volume of Massivit 1800.

So, why not go through various benefits and limitations of this 3D printer and find out what all features it entails for its users. Read the complete Massivit 1800 review to know what the machine is capable of. Plus, it would help you make an informed decision.

ADVERTISEMENT

Features

The design of the 3D printer is focused on attracting the display market. Massivit 1800 was put to test in 2015 at a customer site. Later, in 2016, the machine display was arranged after which its features and specifications gathered huge acclaim from the users around the world.

Later, in 2016, the machine display was arranged after which its features and specifications gathered huge acclaim from the users around the world.

According to the statements made by the manufacturer, Massivit is not very different from the wide-format graphics, printers. However, it is much more enhanced and has the ability to mesmerizing and attractive 3D printed sign as well as display projects.

The results from the 3D Printer, if properly utilized could go way beyond the output achieved from any 2D large format printing solutions. Hence, the 3D printer has features that could help users create engaging and eye-catching signs than ever.

Here are a few of the features of the machine that you must know:

Large Format Design

The 3D printer is massive, one of the largest 3D printers for application within the display niche. It can produce life-size models. You can create signs, boards, sculptures, figurines, and many attractive designs. To further scale the size of the models, you can even connect the various printed parts together to produce massive 3D models.

ADVERTISEMENT

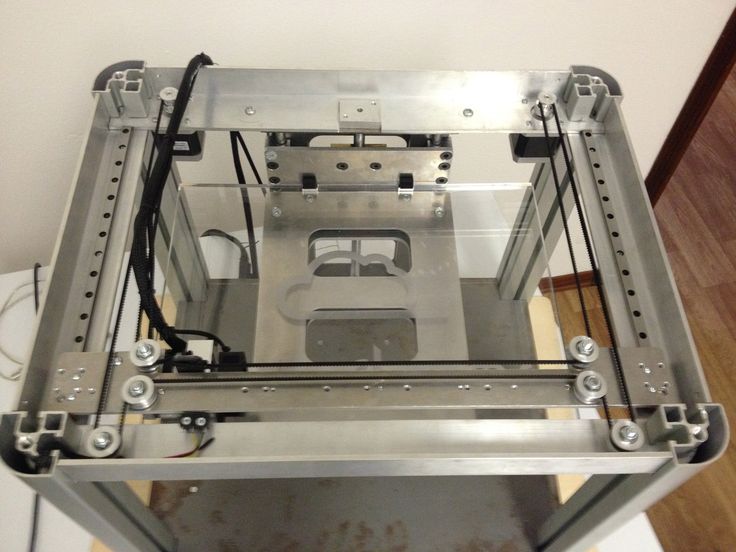

Closed Frame

Massivit has a closed frame. This helps in maintaining the consistent temperature inside the print area. Hence, increasing the precision and accuracy of the models. That is why printing such huge models isn’t a problem.

Sturdy Body

The metal frame provides the 3D printer a very sturdy look and feel. And, the best part is that the 3D printing can go at a smooth pace without any vibrations even at a higher print rate. This again is a very important feature making the printer capable of printing precisely along with high accuracy.

Dual Process

This is something that is a very unique and beneficial feature. Massivit could help users print two different objects parallelly at the same time. This means that the printer can produce more models in half of the time.

Isn’t that really captivating for users who are always in a hurry to get their work done in the least possible time?

Low Material Consumption

Once again, the manufacturer has thought about a lot of aspects when creating this amazing industrial-grade 3D printer, helping users keep the cost of material as low as possible. And, this is done using a design that enables support of less 3D printing.

And, this is done using a design that enables support of less 3D printing.

That also makes the printing task easier and hassle-free. Plus, one does not need to get rid of support after the printing completes. A huge plus for the users, isn’t it?

ADVERTISEMENT

Unique Material

The team has come up with a unique material to make 3D printing, a breeze for its users. To do so, it has designed this unique material that is sensitive to a particular UV wave.

Hence, it solidifies fast and hence, adds on to the fast speed of the 3D printer. Thus, making the 3D printer an apt solution for fast manufacturing.

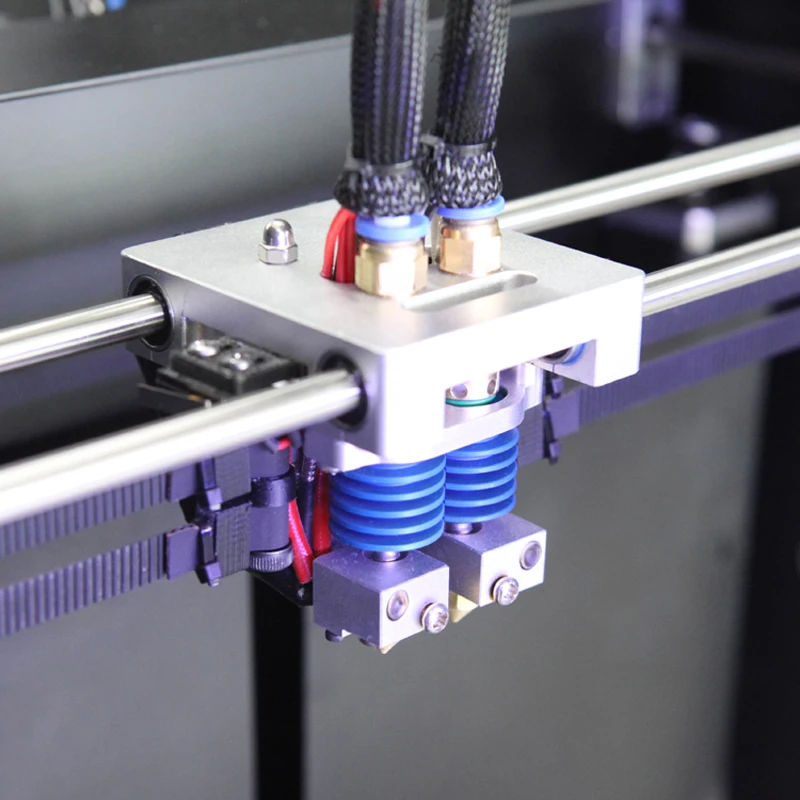

Dual Print Head

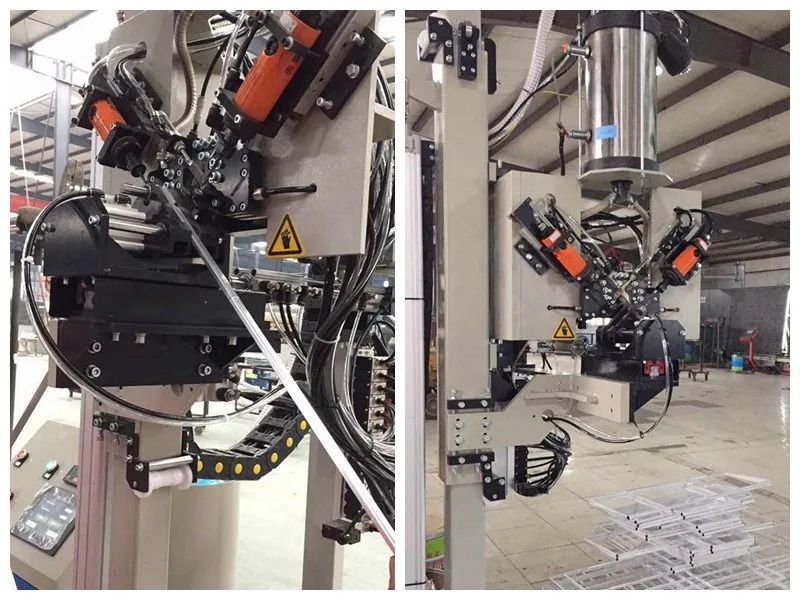

There could be one or two print head and it could further be scaled as well, as needed. Hence, providing users with more options and better capabilities.

Touchscreen Print Control

A huge touchscreen print control reciprocating the size of the machine is installed on the side of the machine. It helps manage the settings of the prints right from the printer itself.

Hence, there is no need to look for a connection to the computer or laptop when starting or changing the settings of the print.

Vacuum Print Table

Once again a unique feature that allows this 3D printer to offer unmatched printing results. Vacuum print table with linear printing adds more advantages for the users.

There are various other features that make this 3D printer the best choice for those working for display models. One can even create non-vertical ceilings as well as walls without support material.

This is because of the gel-based material that isn’t too running and sets easily. Overall, Massivit has many features that can help industries create unimaginable designs, not possible through any traditional method, especially at this speed.

ADVERTISEMENT

Specifications

As you would expect from an industrial-grade 3D printer, Massivit has a huge footprint. It is 1200 × 1500 × 1800 mm in size and offers 145cm x 111cm x 180cm of maximum print volume. Massivit weighs 2500 kgs. And, that is massive as the name suggests.

It is 1200 × 1500 × 1800 mm in size and offers 145cm x 111cm x 180cm of maximum print volume. Massivit weighs 2500 kgs. And, that is massive as the name suggests.

The 3D printer can have one, two, or even more print heads as per the requirement. An ability to scale provides users with options to go for better print output, depending on their specific needs.

Talking about the speed, the 3D Printer is very fast. You can run the machine at a maximum linear speed of 300mm/sec. The Z-axis per hour is also very impressive and counts for 35cm/hour.

There are two settings for print quality. One can choose between normal and high-quality 3D printing. It has a vacuum print table with linear printing abilities. Moreover, touch control access helps in preparing this 3D printer as a standalone working companion for businesses.

Not to forget, it also allows for remote control using a tablet. That creates more room for the flexible handling of the 3D printer. Massivit does add a lot of unique and astonishing features for its customers.

Price

The cost of the twin-engine version of Massivit is £300,000. The single-engine version costs a few bucks less. However, it still is expensive. But what could you expect from an industrial-grade printer that could allow you to print models of your size?

Although it may feel like a huge price to pay, for the right application, it is worth every penny.

ADVERTISEMENT

First Impressions

Credit: 3dprint.comIntroducing yourself to such a huge 3D printer than handles life-size models would certainly be a different experience. And, the manufacturer ensures that users feel comfortable when handling this massive machine.

It is a completely assembled machine. Hence, you must prepare a space for the same when ordering the 3D printer. You may want to fix it right away to the designated place. As moving it more often won’t be feasible at all.

Setup

Like most of the industrial-grade 3D printer, this one also cannot be installed all by yourself. Hence, the manufacturer provides installing and onsite training to every customer.

Hence, the manufacturer provides installing and onsite training to every customer.

Sometimes, it does it directly and other times, it manages to help customers through its distributors. Mostly depending on the location of the customer.

However, with touchscreen control along with the vacuum print plate, the training does not take much time. It is easy to handle and provides users with a hassle-free workflow.

Printing Type/Cost

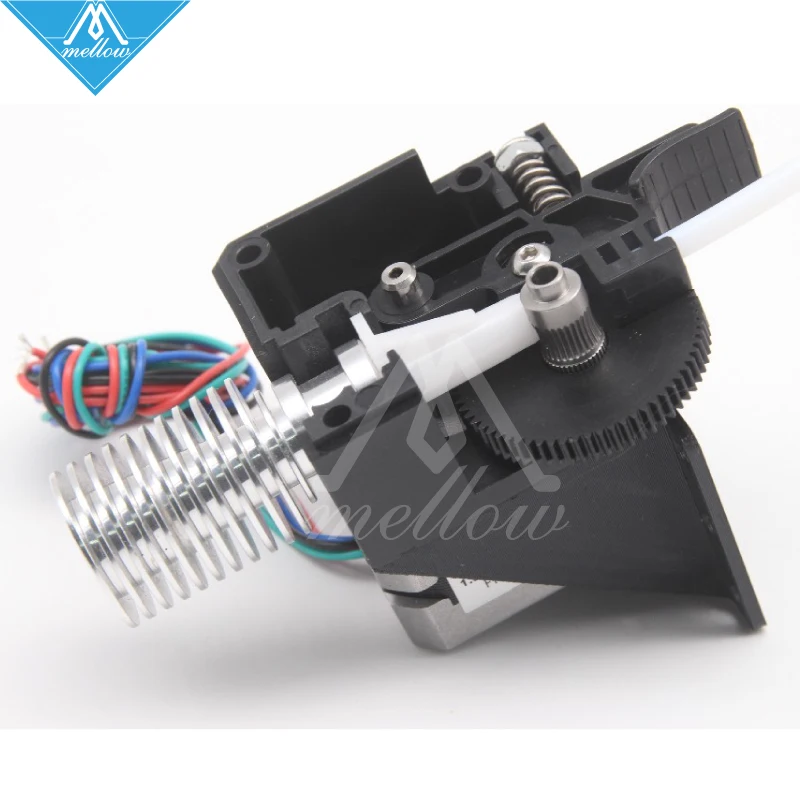

The 3D printer isn’t a usual FFF machine. However, manages to apply a completely different technique that does take its motivation from the FFF 3D printing process. Massivit is based on GDP, also known as Gel Dispensing Printing, a proprietary technology of the manufacturer. Like FDM printers, this machine also has a support plate. And, it moves down in a similar fashion too after each layer is extruded.

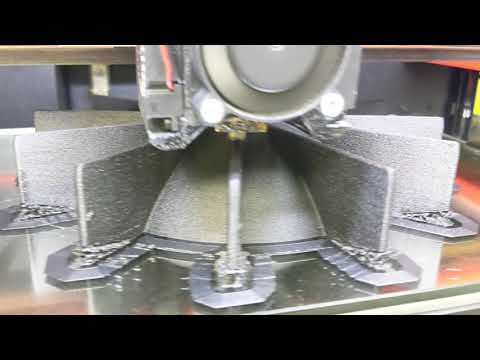

However, the layers aren’t set by cooling those down. However, the material is in gel form and it needs particular UV waves for setting it down. This special material, called Dimengel photopolymer white plastic, is photosensitive and requires the UV waves for hardening.

This special material, called Dimengel photopolymer white plastic, is photosensitive and requires the UV waves for hardening.

The price of printing would depend upon a lot of factors including the material cost, design complexity, and various other parameters. However, the good news is that the gel material isn’t very runny and sets faster. Hence, one does not require support material even when printing angles. This certainly reduces the printing cost by eliminating the expense invested in the support material.

ADVERTISEMENT

Print Quality

Credit: stackpathcdn.comYou can expect the print quality to be exemplary. Without a pinch of doubt, you can create amazing finishes and complex designs without needing support.

Software

Massive Smart Pro is the proprietary software that comes integrated with this 3D printer. It is compatible with windows and is very intuitive. It allows for great detailing of the input file for letting users print huge models.

Customer Service

The manufacturer is very precise about its customer experience and offers huge support to the users. It even manages the initial training and installation, either directly or through its distributors.

Alongside this, it is very easy to reach the technical team in need of issues related to the 3D printer. The manufacturer also takes care of the maintenance. Hence, allowing users to sit back and relax while enjoying every perk of 3D printing.

Parameters Influencing the Buying Decision

Before you decide to buy this 3D printer, you must look for the right reasons. Verifying various factors, you can take an informed decision. So, here is what you must expect from Massivit 1800 3D printer.

3D Printer Cost: It is a very expensive industrial-grade 3D printer. Hence, not suitable for commercial use.

3D Print quality: You can expect this 3D Printer to offer high-quality prints. It comes in two print modes, one is normal, while another is high print quality. In both these modes, you can achieve great details, with fewer differences.

In both these modes, you can achieve great details, with fewer differences.

3D Print speed: As claimed by the manufacturer, it is one of the fastest printing large format printers. Because the gel-based material sets faster, the printer is capable of completing the job in comparatively less time.

3D Printer capability: Massivit 1800 can print non-vertical walls without support. And, there are many fantastic things one can achieve with this 3D printer. It provides accurate and precise printing. Plus, one can even sand the models after printing to further smoothen the surface.

3D Printer Practicality: Focused on helping the display industry, the printer allows for printing unimaginable designs. One can print signboards, figurines, sculptures, non-vertical walls, and ceiling for decoration.

3D Printer User expectations: It does serve user expectations well.

The Verdict

Overall, Massivit 1800 is a very accurate machine with competitive fast speed providing great results to the user. Plus, the support free printing of life-size models makes this 3D printer one of the most efficient options out there.

Plus, the support free printing of life-size models makes this 3D printer one of the most efficient options out there.

Massivit 1800

3D printing

At the end of 2016, a Massivit1800 3D printer from Massivit3D, unique in its technical characteristics, appeared at our production site. After half a year of work and a number of successful orders, we are very happy to share the results with the 3DToday community.

Background: Massivit3D was founded in Israel in 2013 by professionals who previously worked for world-famous companies such as Hewlett-Packard, Stratasys and Scitex Vision Ltd. During the first years of the company's work, 25 Massivit1800 3D printers were installed and put into operation around the world and the number of orders is constantly growing.

So what is the Massivit1800 3D printer? This is a huge machine with a working area of 1.2 x 1.5 x 1.8 m. Unlike previously known printers for 3D printing large objects, the main advantage of the Massivit1800 3D printer is speed. The development of Massivit3D specialists allows you to print large-scale products at a speed of 35 cm per hour along the Z axis (in height).

The development of Massivit3D specialists allows you to print large-scale products at a speed of 35 cm per hour along the Z axis (in height).

Massivit3D independently developed and patented a special 3D printing technology called Gel Dispensed Printing (GDP). At the heart of the GDP process is the combination of a highly viscous unique photopolymer gel and optimized support structure placement.

The principle of GDP technology is similar to that used in FDM systems, but in GDP the nozzle extrudes a liquid photosensitive material, which is cured by UV lamps located above the printheads. Thus, layering and curing is very fast. Due to the curing speed in the Massivit1800 printer, there is no need to apply supports for horizontal surfaces, which saves material and time and was previously beyond the power of similar 3D printing technologies.

An outstanding advantage of Massivit1800 3D printer is the presence of two independent printheads, so that within the working area it is possible to simultaneously print two different products or two parts of one object, which allows you to create shapes over 3 meters in size with subsequent gluing.

In addition to the above-mentioned advantages, Massivita has one more important thing - the simplicity of the post-processing process. Frozen in layers, dimengel lends itself perfectly to grinding and has excellent susceptibility to staining and paintwork.

Of the projects that we have implemented in six months, most of all I would like to share a model of a kinetic helicopter for a state enterprise. This model was ordered to us for the international exhibition HeliRussia.

Recently, our main project has been the preparation for the international exhibition EXPO2017 in Astana, the capital of Kazakhstan. We took part in the production of 12 stands for the Energy Best Practices Area pavilion. Thanks to Massivite, we were able to significantly accelerate the progress of work on some of those that required large-scale printing

For example, for ABB Solar Impulse we printed a globe for the stand. The size of the globe is 60 cm in diameter

, printing time 5 hours, surface preparation and painting 3 days.

For Andrytz Hydro we printed windmill and fish blades (Turbine size 1.5m, 2.5m,3.5m, 12 fish ranging in size from 25cm to 50cm, printing time for all elements 3 days, surface preparation and painting 5 days)

We also printed blades for the Rainmaker stand on Massivite.

For the stand of the Global Hymalayan Expedition, we created a mock-up of the Himalayan mountains, 4x1 m. mountain coloring. We printed the buildings from plaster on Projet660.

We will be happy to answer your questions

Follow author

Follow

Don't want

31

More interesting articles

eight

Subscribe to the author

Subscribe

Don't want

Introduction

So, good day to all! This is my second post. ..

..

Read more

dagov

Loading

11/08/2017

195

Subscribe to the author

Subscribe

Don't want to

Loading

04.02.2016

76228

158

Follow author

Subscribe

Don't want

Everyone knows about the rollback, but few understand where to start to manage it properly....

Read more

Massivit 1800. Think big!

You are here

Home

At the end of 2016, a Massivit 1800 3D printer from Massivit 3D, unique in its technical characteristics, appeared at our production site.

After six months of work and a number of successful orders, we are very pleased to share the results with the readers of the Additive Technologies magazine.

Background: Massivit 3D was founded in Israel in 2013 by professionals who previously worked for world-famous companies such as Hewlett Packard, Stratasys and Scitex Vision Ltd. During the first years of the company's operation, 25 Massivit 1800 3D printers were installed and put into operation around the world, and the number of orders is constantly growing.

So what is the Massivit 1800 3D printer? This is a huge machine with a working area of 1.2 × 1.5 × 1.8 m. Unlike previously known printers for 3D printing large objects, the main advantage of the Massivit 1800 3D printer is speed. The development of Massivit 3D specialists allows you to print large-scale products at a speed of 35 cm per hour along the Z axis (in height).

Massivit 3D independently developed and patented a special 3D printing technology called Gel Dispensed Printing (GDP). At the heart of the GDP process is a combination of a highly viscous unique photopolymer gel and optimized support structure placement.

At the heart of the GDP process is a combination of a highly viscous unique photopolymer gel and optimized support structure placement.

The principle of GDP technology is similar to that used in FDM systems, but in GDP the nozzle extrudes a liquid light-sensitive material, which solidifies under the influence of UV lamps located above the print heads. Thus, layering and curing is very fast. Due to the fast curing speed of the Massivit 1800 printer, there is no need to apply supports for horizontal surfaces, which saves material and time and was previously beyond the power of similar 3D printing technologies.

The outstanding advantage of this Massivit 1800 3D printer is the presence of two independent print heads, so that within the working area it is possible to simultaneously print two different products or two parts of one object, which allows you to create shapes larger than 3 meters with subsequent gluing.

In addition to the above-mentioned advantages, "Massivita" has one more thing, and not least - the simplicity of the post-processing process. Frozen in layers, dimengel lends itself perfectly to grinding and has excellent susceptibility to staining and paint coatings.

Frozen in layers, dimengel lends itself perfectly to grinding and has excellent susceptibility to staining and paint coatings.

Our main project this year was the preparation for the international exhibition EXPO 2017 in Astana, the capital of Kazakhstan. We took part in the production of 12 stands for the Energy Best Practices Area pavilion. Thanks to Massivite, we were able to significantly speed up the progress of work on some projects that require large-scale printing.

For Andrytz Hydro, we printed windmill and fish blades (turbine sizes 1.5 m, 2.5 m, 3.5 m, 12 fish ranging in size from 25 cm to 50 cm, printing time for all elements 3 days, surface preparation and painting - 5 days).

For the Global Hymalayan Expedition booth, we created a mock-up of the Himalayan mountains measuring 4×1 m. We completed this work in five weeks, of which a week was spent on printing, two weeks on filling with two-component polyurethane, gluing, sanding, puttying, and another two weeks on painstaking mountain coloring. We printed the buildings from gypsum on the Projet 660.

We printed the buildings from gypsum on the Projet 660.

Efficiency in fulfilling orders in the advertising business is sometimes a priority in our fast-paced times. Massivit 1800 is undoubtedly the answer to the challenges of the 3D printing and advertising industry. If high-quality large-scale work is required and it is needed “yesterday”, then Massivit 1800 will surpass in speed of its execution any of the existing production methods. ■

- Large fleet of professional 3d equipment:

- 3d printing

- 3d modeling

- 3d scan

— Direct sales of 3d equipment and consumables

— Creation of content for augmented and virtual reality

— Digital solutions Kolpakova, house 2, building 13, floor 5

Phone: +7 495 212 07 01

www.3d.ru, e-mail: [email protected]

Other materials:

- Solving unsolvable problems

- Import substitution and 3d printing: a simple connection between complex things

- Continue building a subsistence economy or five reasons to choose manufacturing outsourcing

- LASERTEC 30 SLM.

Learn more

24 × 59.06 × 70.87 in

24 × 59.06 × 70.87 in