3D printing prices uk

3DPRINTUK | Pricing Structure | Low Cost 3D Printing

Pricing Structure

Full visibility of our pricing structure and price breaks.

Overview

On this page you will find everything you will ever need to know about our pricing structure. We’ve tried to keep it a simple as possible but if there is anything that you feel has not be answered please let us know.

Click on any of the links below to jump to the relevant section.

1. Pricing Structure

2. Price Estimators

3. Our Services

1.1 XYZ Bounding

Box

1.2 Offset

Pricing

1.3 Dynamic Pricing

2.1 Estimators

3.1 Express

Printing

3.2 Economy

4. Finishing

5. Production Runs

4.1 Polishing

4.2 Dyeing

Carbon Black

5.1 Production

Runs

5.2 Price Breaks

6. Other

6.1 Postage

6.2 Trade Accounts

6.3 Minimum

Order

6.4 Minimum

Part Cost

6.5 Students

XYZ Bounding Box

1. Pricing Structure

Our original and main pricing structure. This is calculated by multiplying the X,Y and Z dimensions of the STL file to get the number of cubic centimetres for the imaginary box that your part would fit into. This is then multipled by the Economy or Express XYZ rates to give you a price.

With this pricing structure you are able to nest as many parts into the same STL file as you like – this can bring your costs right down.

It is easy to calculate the price for your prints using our free app before you have a printable file.

NB – an additional 1mm bounding box is added to the total dimensions to cover the space between the other orders in the printer.

Minimum part costs apply (see below)

Orientation of your parts can massively affect the price too, so be sure to take it into account!

This pricing model is used for larger but lower density parts and only accounts for about 5% of quotes. To calculate the price of parts this way we offset the surface of the model by 3mm and calculate the amount of material taken by this new volume. This is then multiplied by the Economy or Express offset rates to give you a price.

To calculate the price of parts this way we offset the surface of the model by 3mm and calculate the amount of material taken by this new volume. This is then multiplied by the Economy or Express offset rates to give you a price.

A minimum hole of 50mm is required if hollowing parts.

You cannot nest parts with the offset pricing.

New to 2022, we have launched a dynamic pricing structure exclusively to MJF. This pricing structure takes in all aspects of the file uploaded and generates a price based on multiple calculations of the geometries. Sadly there are too many factors to explain it simply, but it works out more efficiently for both parties in terms of cost savings on the vast majority of models.

Nesting is not recommended for Dynamic pricing.

2. Price Estimators

Our low volume pricing estimator shows the point at which injection moulding becomes a more suitable method of production based on the quantity you require and the size of your part. If you’ve previously had a quote for injection moulding, enter the details in the estimator below and see how much additive manufacture can save you in part costs.

If you’ve previously had a quote for injection moulding, enter the details in the estimator below and see how much additive manufacture can save you in part costs.

Our XYZ price estimator will allow you to work out the cost of your 3D prints through us before you have the CAD data to print from. This will help with budgeting for your project from the start. By simply inputting the X, Y and Z dimensions, you are able to get a guide price for your part(s).

We have a handy app for price estimation – it’s free and easy to use. It can calculate the price of your 3D print without the requirement for an STL file. This means you can find out how much your parts will cost before you even start your CAD.

The App does not work for the Offset Pricing model.

3. Our Services

SLS Nylon PA12 (PA2200)

XYZ 18p per cm3 / OFFSET 60p per cm3

Our Selective Laser Sintering Express lead time is where your order joins the front of the queue. The lead time is normally 2-4 working days before dispatch. 95% of orders are ready in 2 working days, however we state 2-4 to cover any issues during printing or post processing.

95% of orders are ready in 2 working days, however we state 2-4 to cover any issues during printing or post processing.

Please also note that if you require Polishing, Dyeing or Shotpeening finishing processes, it adds a day to the overall turnaround time.

The finish and quality are identical to the Economy Service.

Lead times are not guaranteed, and are only estimates. Orders are not refundable once they are loaded onto the printer.

Price breaks apply

XYZ 11p per cm3 / OFFSET 30p per cm3

Our Selective Laser Sintering Economy lead time is where your order joins the back of the queue. The lead time is normally 7-12 working days before dispatch. As with the Express service, if you require Polishing, Dyeing or Shotpeening finishing processes it adds a day to the overall turnaround time.

The finish and quality are identical to the Express Service.

Lead times are not guaranteed, and are only estimates. Orders are not refundable once they are loaded onto the printer.

Price breaks apply

SLS Felxible (PEBA 2301)

XYZ 18p per cm3

Please note that we do not offer an Express service with this material.

We only offer our SLS Flexible material with an Economy lead time, whereby your order joins the back of the queue for this service. The lead time is normally 7-12 working days before dispatch. If you require your flexible parts to be coloured using our Dyeing service, this can add a day to the overall turnaround time.

Lead times are not guaranteed, and are only estimates. Orders are not refundable once they are loaded onto the printer.

Price breaks apply

MJF Nylon PA12

DYNAMIC PRICING (NEW BETA)

Our MJF Express lead time is where your order joins the front of the queue. The lead time is normally 2-4 working days before dispatch. 95% of orders are ready in 2 working days, however we state 2-4 to cover any issues during print or post processing.

Please also note that if you require Polishing, Dyeing or Shotpeening finishing processes, it adds a day to the overall turnaround time.

The finish and quality are identical to the Economy Service.

Lead times are not guaranteed, and are only estimates. Orders are not refundable once they are loaded onto the printer.

Price breaks apply

DYNAMIC PRICING (NEW BETA)

Our MJF Economy lead time is where your order joins the back of the queue. The lead time is normally 7-12 working days before dispatch. Please also note that if you require Polishing, Dyeing or Shotpeening finishing processes, it adds a day to the overall turnaround time.

The finish and quality are identical to the Express Service.

Lead times are not guaranteed, and are only estimates. Orders are not refundable once they are loaded onto the printer.

Price breaks apply

4. Finishing

Our vibro polishing service is optional and offered free of charge, but please be aware that it can add a day onto the lead time for your part(s).

More info about polishing can be found here.

Our vibro polishing service is optional and offered free of charge, but please be aware that it can add a day onto the lead time for your part(s).

More info about polishing can be found here.

Shot peened

We offer a high quality shot peening service for black parts. The shot peening service is charged at 5% extra. We do not offer this service for white parts.

More info about shot peening can be found here.

5. Production Runs

We specialise in production runs here and offer price breaks on batch production. These include a reducing minimum part cost as well as an increasing percentage discount per unit. For up to date price breaks please see the Price Breaks below.

The discounts can be seen on our production runs page as well as a handy interactive graph where you can compare your injection moulding costs with our additive manufacturing prices.

Production Run Samples

We recommend that you print a test sample before going ahead with your full production run. These usually fall way under our minimum print order. If you are happy with that test sample and you order a production run over £500, we will refund the price of your test print that fell under our minimum order. This means that your test samples will be free of charge.

This means that your test samples will be free of charge.

Our innovative pricing structure integrates more aggressive price breaks than ever before, and ensures you get the very best value for money from whether you select the express or the economy service.

Price breaks can be given in three different ways. Please note that they work independently from each other and cannot be combined, however, our quoting tool will automatically default to the cheapest one.

Value price breaks – discounts given to the total value of the part

Quantity Price breaks – given to the quantity of the same STL ordered

Minimum part cost – Given to the value of the minimum part cost as the quantity of STL files increases (only applicable if parts are below the minimum part cost)

The Value price breaks are as follows:

£2000+

| Part Value | Percentage Discount |

|---|---|

| £200+ | 5% |

| £2000+ | 10% |

The Quantity price breaks are as follows:

| Number of units | Percentage Discount |

|---|---|

| 1+ | 0% |

| 2+ | 5% |

| 10+ | 10% |

| 50+ | 15% |

| 100+ | 20% |

| 250+ | 25% |

| 1000+ | 30% |

The Minimum part cost price breaks are as follows:

10000+

| Number of units | Economy – Minimum Part Cost | Express – Minimum Part Cost |

|---|---|---|

| 1+ | £1. 00 00 | £2.00 |

| 50+ | £0.75 | £1.50 |

| 100+ | £0.60 | £1.20 |

| 200+ | £0.50 | £1.00 |

| 500+ | £0.45 | £0.90 |

| 1000+ | £0.40 | £0.80 |

| 2500+ | £0.35 | £0.70 |

| 5000+ | £0.30 | £0.60 |

| 7500+ | £0.25 | £0.50 |

| 10000+ | £0.20 | £0.40 |

NOTE: These discount options are independent of each other and our quote system will automatically default to the cheapest of the three. Minimum part cost discount only applies to parts with an XYZ price that is less than that of the minimum part cost.

6. Other

Our standard postage rates are as follows:

Economy postage £6 – First Class Recorded

Express postage £12 – Next Day before 1pm Recorded

For orders valued over £1000 – Royal Mail 1st Class Recorded £10 + VAT

For an additional charge we can arrange for (call for more info):

Pre 9am Delivery

Guaranteed Saturday Delivery

All couriers are booked by the client for collection during our working hours only.

We do offer trade accounts for regular customers who have a monthly spend of £1,000 + vat or more. This will allow you to be invoiced on 30 day terms rather than having to pay by card. Please enquire if you think you qualify!

We have a minimum order of £40 + vat per order. The minimum order applies to the order as a whole, not per part on the order. This means that if your part(s) come to below the minimum order, you can up the quantities or add more files to make up the difference.

The minimum order does not include shipping.

There is a minimum part cost per part on the STL file. This starts from £1, but drops down to as little as 25p per part depending on the number of parts ordered. The minimum part cost is not an additional charge per body on an STL, rather an average cost per body on an STL file – if the average cost of a body drops below the minimum part cost, the price will default to the minimum part cost x the number of bodies on the STL file. We often have to manually review orders like this due to file quality.

The price drops in accordance with the number of STL files ordered, not the number of parts on an STL file. This means that if you are looking to order a batch of the same items, it is best to upload a single part and up the quantity rather than a single STL file with an array of items on it.

Students get a 20% off discount. To get this please upload your files through the website using your university address and then send it to manual review once you have received your quote. You may be asked to send in your photo ID.

The discount cannot be used in conjunction with any other discounts.

Contact

Call: 0208 692 5208

Email:

General Enquiries - [email protected]

OFFICE HOURS:

Mon-Friday 9.00am - 5.00pm

Daily cut off for new orders: 3.00pm

WE ARE SOCIAL

SEARCH

Search for:Unit D9

Leyton Industrial Village

Argall Avenue

London

E10 7QP

NEWSLETTER

Sign up to our Newsletter for the latest

service updates and special offers

OUR PRICING APP

GENERAL

SERVICES

3D PRINTING

PRICING

ABOUT US

Cost of 3D Printing | 3D Printing Service | Blog

What is the cost of 3D printing and what factors go into that cost

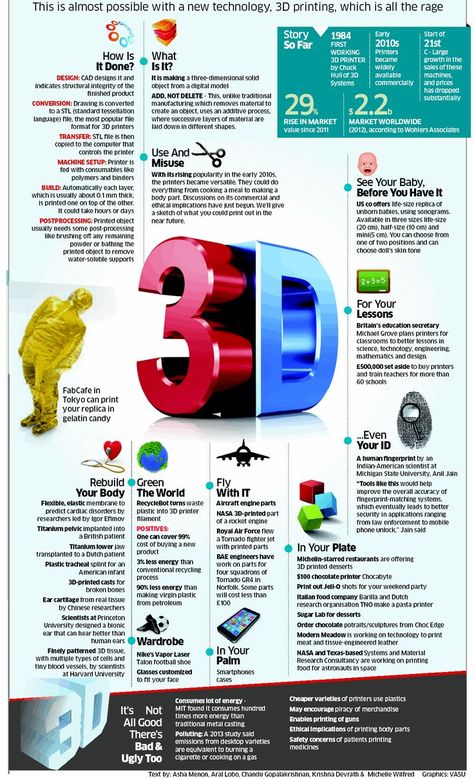

The cost of 3D printing is something that a lot of people are curious about. How much does it cost to get a 3D printer? What are the costs associated with using a 3D printer? In this blog post, we'll take a look at the cost of 3D printing and what factors influence the price. We'll also discuss the different types of 3D printers and their respective prices. By the end of this post, you'll have a good understanding of how much it costs to use a 3D printer.

How much does it cost to get a 3D printer? What are the costs associated with using a 3D printer? In this blog post, we'll take a look at the cost of 3D printing and what factors influence the price. We'll also discuss the different types of 3D printers and their respective prices. By the end of this post, you'll have a good understanding of how much it costs to use a 3D printer.

3D printing is the process of creating a three-dimensional product from a digital file. It includes material dimensions, model complexity and labour costs which impact the cost.

In addition 3d printing services London cost more than some entry-level 3D printers. The print price will vary depending on the number of sheets that must be printed before an object is put out.

3D printing material cost

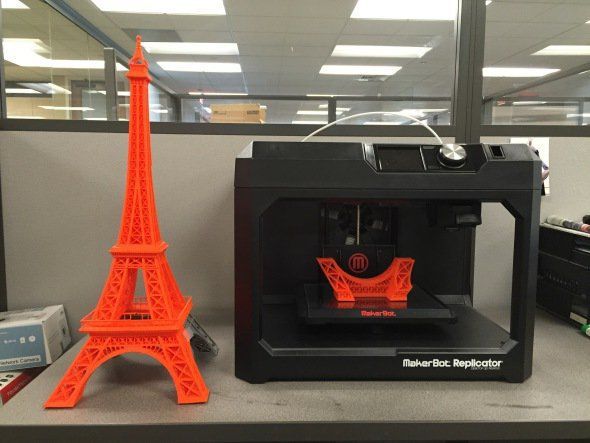

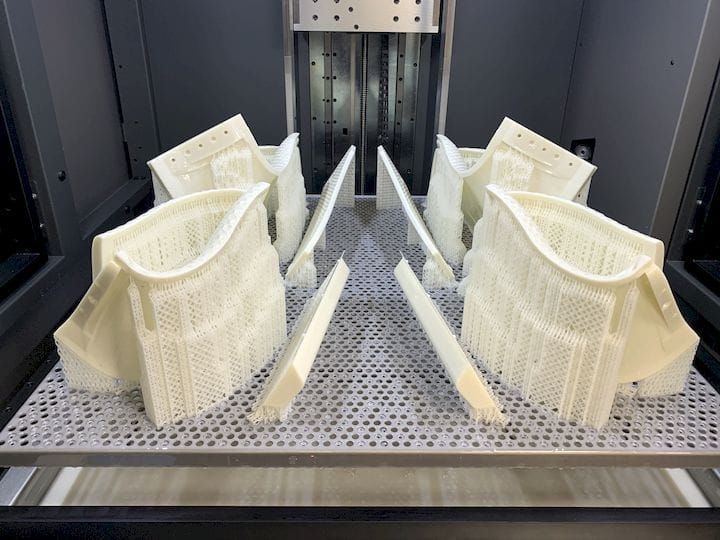

[image from 3dgbire.com]Cost of 3D printing parts is based on how much material your print job will need. The material prices range from £50 per kg to £100 per kilogram.

The material cost of 3-D printing is usually between 20%-75% of the total printed material expense, depending on what you are printing. You can save money on material price by printing a large material volume. For example, if you print a material that is 50x50x50 cm the cost per material will be lower than printing one that's 10x10x4cm.

3D printing post-processing costs

Processing for 3-D printing refers to the process of removing support material and sanding, finishing and painting the print to achieve the desired look and feel.

As is with material cost post-processing greatly depends on print geometry and print size. For example, if you print a small object then there will be less work required in post-processing than when printing a 50x50x100 cm print job.

3D printing prices

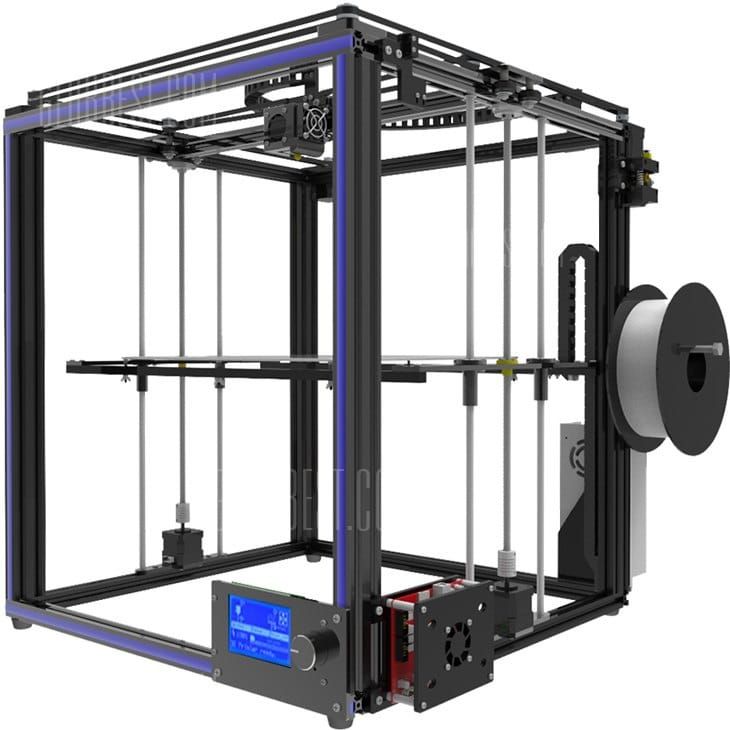

In order for 3D printing to work efficiently, a printer will be required to be supplied with 3D printing machinery and printers. FDM 3D prints are cost savings due to very low cost and cheap filament and software fees. The bigger the print the less fuel you need and the greater you can cost.

The bigger the print the less fuel you need and the greater you can cost.

Different brands have different costs of their filaments – sometimes the pricing helps improve the quality of the final product. It's necessary to consider energy consumption as well as time for prints. Usually, a 3D printer requires the same energy as a fridge.

Cheaper machinery with components of lower quality may need replacement more often, while costly professional printers will last longer.

3D print cost

The print price will vary depending on the number of sheets that must be printed before an object is put out. The print cost can range from £4 to £20 for FFF print, while SLA print prices are around £6-8 per square millimetre.

Multicolour print costs are rather high due to the fact that every colour requires a separate print run, which makes 3D printing expensive.

3D printing services quantity price breaks

Professional services are always more costly than the hardware itself, but they are also worth it if you want your project done in time and at a high quality.

If you love DIY and want to print something personal. In this case, do it yourself and print a 3D print from home. In addition, there are quantity-based price breaks. For example, if you print ten or more of the same object, then its cost per print will be much cheaper than having to print only one of them.

3D printing services minimum part cost?

It's worth noting that not all print services have minimum part cost. If you are lucky, some print providers allow you to print just one print.

There are different methods of 3D printing available depending on the size, accuracy and speed requirements of your print job.

This can be done on several different print types, with colour options available. If you need something 3D printed for your project, business or personal use speak to our team of print experts today at print for business 3d printing on demand.

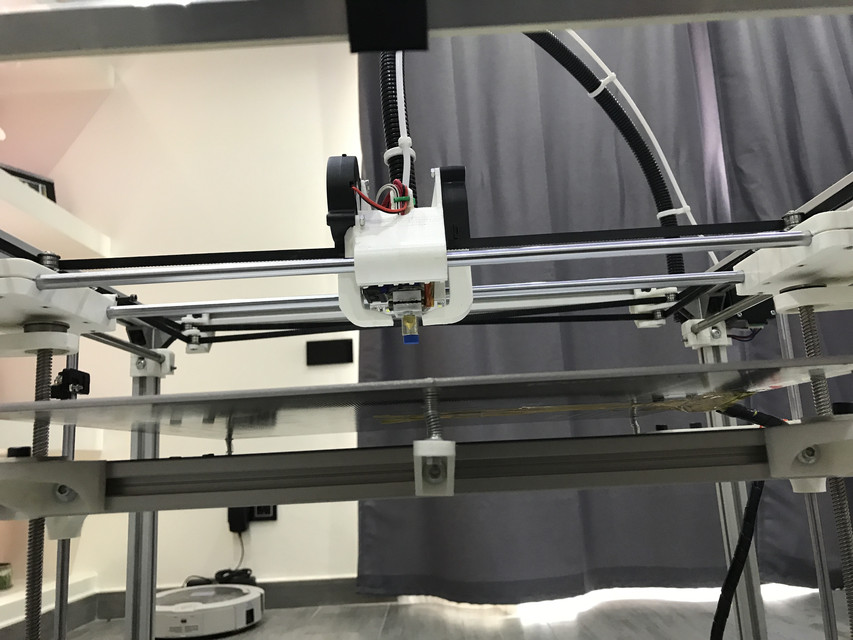

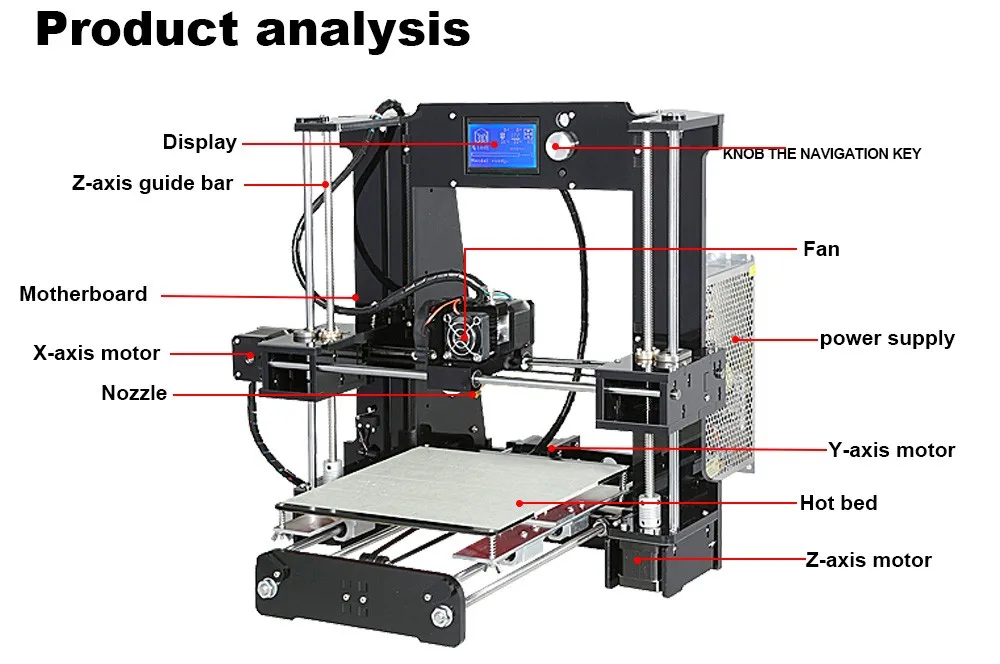

Pricing for Fused Deposition Modeling (FDM)

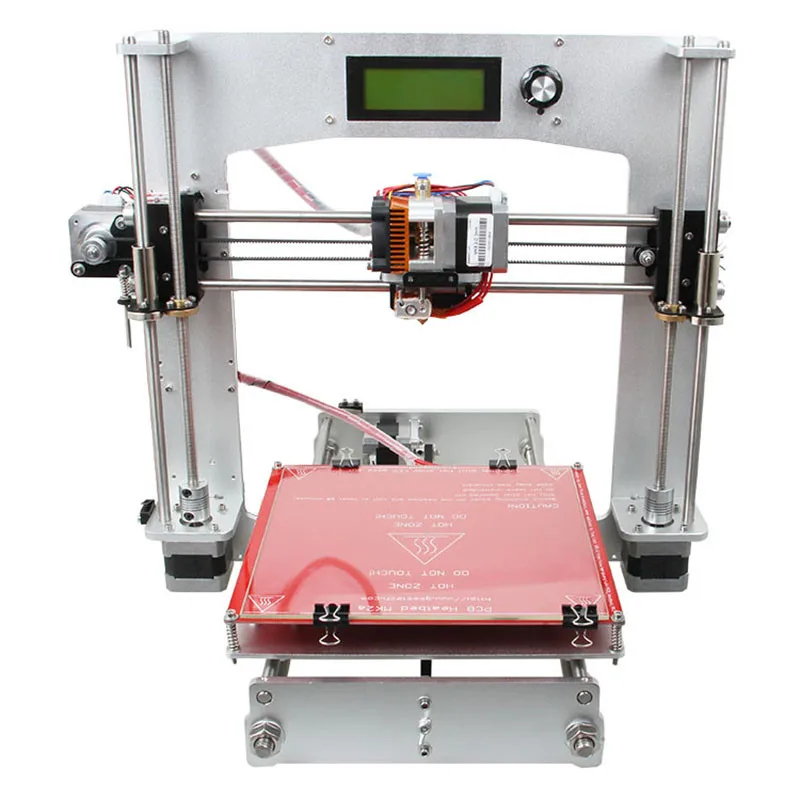

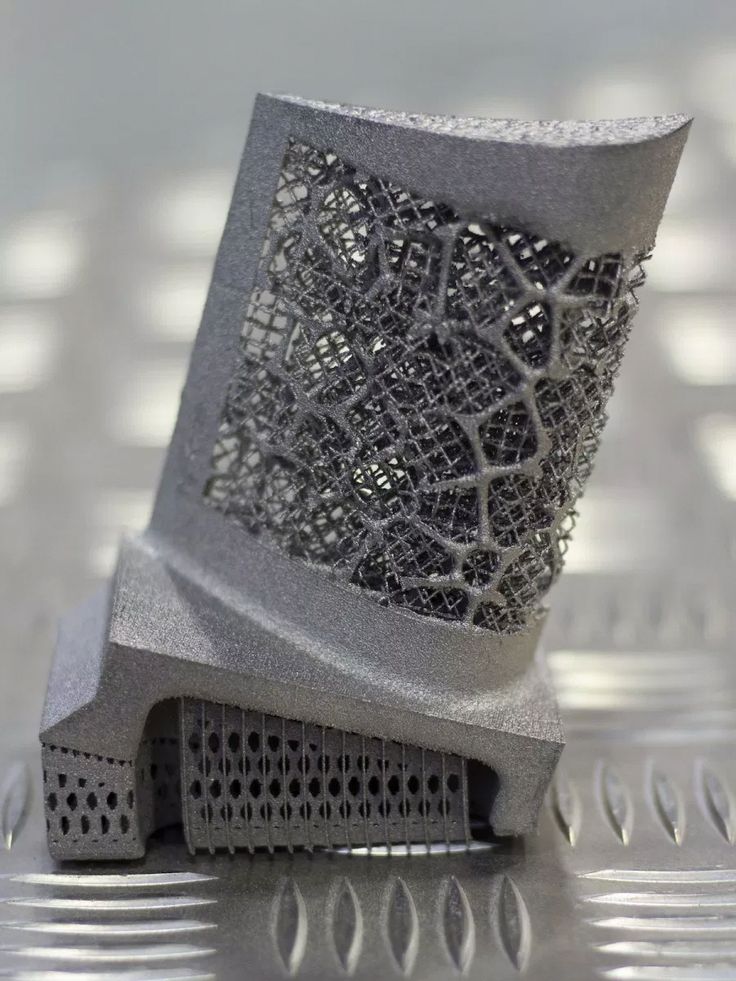

[image from markforged.com]The pricing structure focuses on two fundamental costs: volume for the material used and the time needed for an FDM 3D printer to print the part.

We use machine learning algorithms to update our pricing formula constantly ensuring more exact prices every day. The price is extremely fast due to the low computational processing power required when running the formula compared with simulating the build process.

Longer print runs require longer machine time which is measured by the machine's depreciation time. We also measure failure rates for FDM printing per hour rather than per project.

The longer the time of completion the more likely it is for problems resulting. The length of material required to 3D print a part is, therefore, neither equal nor proportional to the volume of the part.

What is Fused Deposition Modeling ( FDM )

This is an additive process used for making objects from 3mm to 20 mm thick layer thickness.

An object printed this way is affordable, with layers as thin as 100 microns without any loss in stability or strength. This technology works well with PLA, ABS, PET-G and carbon fiber material.

Fused deposition modelling is the best print technology for engineers due to its high print speed, economical print cost and high print output.

Pricing for selective laser sintering (SLS)

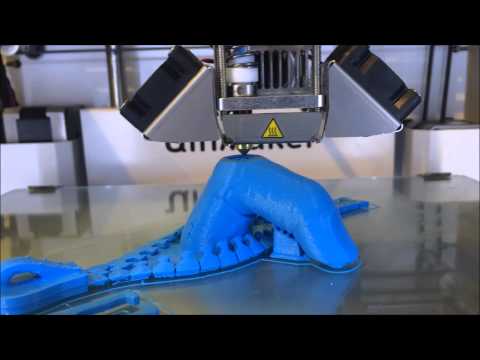

[image from formlabs.com]The volume of a boundary box of a 2D file is the length x length x height of the object. It is used here for referencing part numbers in the case of the SLS.

The parts can be separated by up to 1mm when printing so we provide 0.5 mm of space. The density of boundary boxes is multiplied by 0.00011 as we charge 11 pence per cm2 for SLS 3D Printing.

The majority of the price for SLS printing is PA12 nylon based powder. The amount of information required for a large print run is not comparable. Even when it is small the amount needed for three-dimensional pictures will not be sufficient.

What is Stereolithography (SLA)

This process builds up objects one layer at a time using laser beams to cure liquid photo-resin into a solid form.

A key advantage of SLA print is that it generates very accurate parts with smooth surfaces, making it the better choice for complex designs with small features where FDM print can't match SLA resolution.

Low costs make this print technology affordable for both large and small manufacturers who can use it to produce various parts directly from computer data files or CAD software. This 3D printing method has excellent accuracy which creates smooth and accurate print surfaces with fine surface quality and smooth finish.

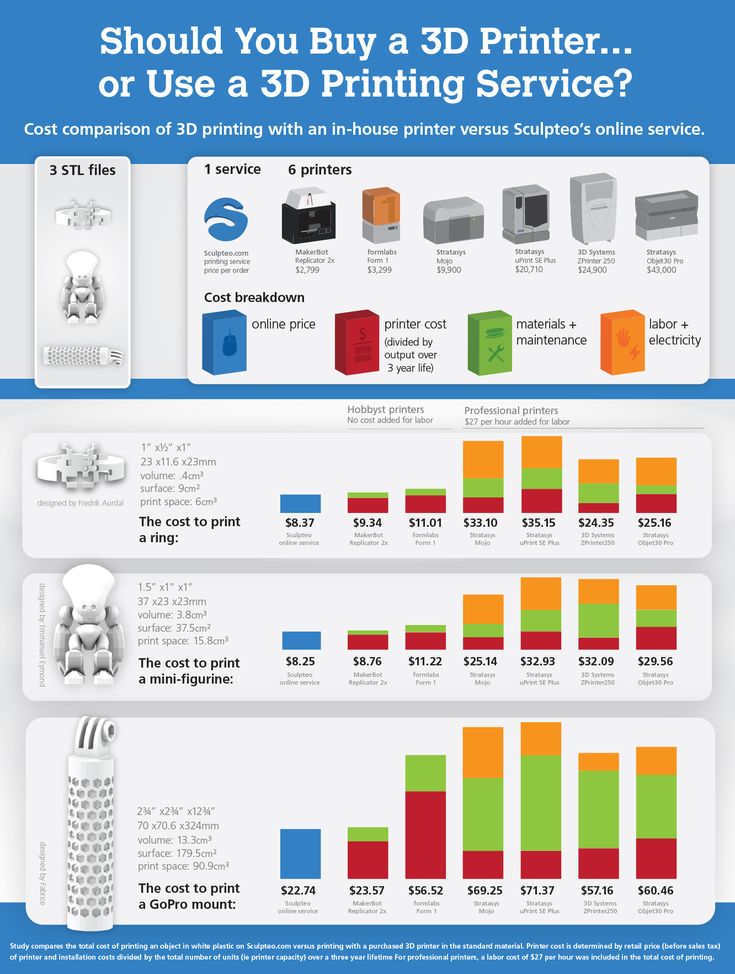

Outsourced production vs. In-house 3D printing

Bureaus usually have several 3D printing processes in-house such as :

Stereolithography [SLA],

Selective Laser Sintering [SLS],

Fused Deposition Modeling [FDM] ,

Binder Jetting [BJT] ,

Digital Light Processing [DLP],

HP Multi Jet Fusion [MJF]

Outsourcing's downsides are mainly cost and lead times. With the increased demand and increase in production outsourcing increasingly become costly. Desktops and benchtops can use the same amounts of capacity as the business wants and scale production by adding additional units as demand goes without any significant investment in a 3D printer.

Serviced offices can still supplement this flexible workflow for larger components or unconventional materials, offering value-added services such as design or advanced finishing. For example, you may print parts across different materials simultaneously.

Free quotes for 3D printing

We at 3DMitech LTD provide you with free quotes for all your prototyping requirements including product modelling or low-rate production needs that will suit small budgets through our Instant Quote online system.

We have a number of 3D printers that meet your budget and efficiency requirements for low volume print runs.

All you need is to upload your design files and place an order. No matter how cheap the service is, we promise top quality print service.

Why is 3D printing so expensive?

3D printing is expensive due to many factors mentioned previously such as labour costs post-processing costs or overhead costs.

All these industrial machines are capable and expensive 3d printers. In addition, they have to add additional profits to this burden. Is a cheap 3D printer a good idea for beginners?

In addition, they have to add additional profits to this burden. Is a cheap 3D printer a good idea for beginners?

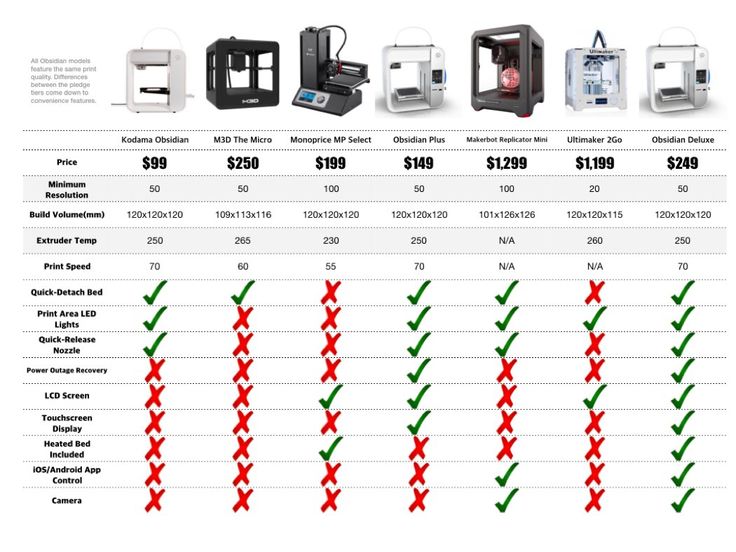

Remember that with manufacturers like Makerbot or Flashforge with almost no print overhead, print time is the only limiting factor. If print time is not an issue for you and print quality is most important, then why go for low-cost printers?

The cheapest 3D printer will probably be relatively slow which increases print costs due to an increase in printing time.

This means adding more machines if you want to cover workflows of multiple users, increasing maintenance costs even further.

The increased print time may eventually lead to huge credit losses since long waiting times could mean losing your client's interest forever.

Considerations beyond direct costs

3D printing simplifies traditional prototyping and production workflows. It helps you save time and surpasses your competitors.

Finding and fixing design flaws early helps avoid expensive design modifications and tooling changes in production.

The production of high-tech prototypes and parts gives you more options when you communicate with your customer's suppliers and others. Create parts in-house means you will not need to give to third parties intellectual properties reducing risks such as leaks or IP thefts.

Using quality components reduces the risk of IP theft or letting IP info gets lost. Having prototype parts can aid you in designing the product for multiple customers at once.

You can print a cheaper prototype that lets you reduce development costs. You will be able to control the production of plastic parts from one single source. This means all your components are optimized allowing for less need for post-processing and reducing time wastage during assembly.

Type of material (Print quality)

It really depends on what materials you use and what you want to save money on 3d printing. Thermoplastics and resin are the most popular material options.

It's important to know the difference between a few popular 3D printing materials before you start your project. Thermoplastics and resin are both great options for those who want an affordable product with some flexibility in design, but they have their own unique pros and cons that will depend on what kind of object you're making!

Thermoplastics and resin are both great options for those who want an affordable product with some flexibility in design, but they have their own unique pros and cons that will depend on what kind of object you're making!

Plastic 3D printer costs

The three most known 3-D Plastic Manufacturing Technologies currently available are fused deposition modelling (FDM), stereolithography (SLA) and selective laser sintering (SLS). SLS are the most economically efficient procedure to produce large volumes in high-quality functional parts.

Resine printing SLA offers higher resolutions, good quality and a wide range of 3D models. Material is slightly more pricey. The difference quickly subsides when you print complex designs or higher batches due to the less labour-intensive post-processing process.

Materials and consumables

Measure material cost and calculate the amount of 3D printed materials needed to create a part.

Measuring to emptied waste. Some 3D printers only use proprietary materials and therefore limit your options for third-party materials. Measurably the cost of material as the cost of hardware decreases as production grows, the cost flattens.

Some 3D printers only use proprietary materials and therefore limit your options for third-party materials. Measurably the cost of material as the cost of hardware decreases as production grows, the cost flattens.

Make sure to clarify your needs for the given part as costs for consumables can fluctuate. Material measurement by calculating the size of the waste is required and how much consumable is required for part production.

Measure costs by determining the requisite material for the production of a given object.

Equipment ownership

3D printing machines have seen a huge reduction in ownership and maintenance costs recently. The increased productivity of your 3D machines and efficient use of them means lower investment costs.

The use of print management software reduces print time by up to 10 times. It reduces the need for human intervention in print operations, reducing labour costs. 3D print management services are being adopted globally so you can have quick access to machines anywhere in the world.

The increased performance means lower maintenance costs.

Labor

Professional desktop 3D printer models are generally optimized for ease of use. DIY printers and hobby printers sometimes need more tweaking to set settings. Regular maintenance on traditionally produced industrial machines may need to deal with expensive maintenance tasks.

Post processes vary by the process but often involve scrubbing sections and removing support or waste material. FDM parts may need lengthy manual post-processing to improve high quality and remove layers.

There are solutions to automate this task, so Formlabs Form Wash and Form Cure simplify the washing and post-treatment workflow for SLA printers.

Post-processing

After 3D printing, the resulting print should be cured cleaner and polished before being considered useable. That is if printing companies are concerned about the Quality of their products.The result must be cleaned and polished.

Leave your files and print them out but nothing quick.

Cost of buying and running a 3D printer

3D printers can cost as much as $90 to $1150,000 according to the technology used. This adds in some respects to the time required to 3D print.

If your 3D model takes about four hours of print that is when you pay $0.81 per day to account for machine maintenance.

The cost for 3d printing depends on the printer's cost and the amount of time spent printing anything. For example, a $3000 3D printer for two years would have costs of $1.21/hr.

Manpower costs

He estimated that work on his single 3d print varies between 0.8 Dollars for Mk3.60 USD per hour. It is not expensive to prepare small models downloaded from the Internet but most models need more difficult printing preparation.

Even a relatively simple technical part will take several hours to draw and thus significantly increases the price. Even trimming alone can take an extra 30 minutes – e.g. preparation of support for SLA printing using manual support might take a bit longer

Profit margin

Profit margin can be between 80% of materials cost. Profit margins will be much lower when you add labour and overhead expenses. This is also a base price/minimum fee that is included if printed printing costs are fewer than a given amount.

Profit margins will be much lower when you add labour and overhead expenses. This is also a base price/minimum fee that is included if printed printing costs are fewer than a given amount.

It wouldn't feel right for a company to 3D printer something for $3. Either you add more quantity or pay the base price of about $30-$90. Even at the most automation 3D. Printing service there are still employees involved, even if a. High automation.

conclusion

The material size and complexity of the 3D model will determine how much material is needed to print it. The time, cost, energy consumption for printing are also factors in determining price.

Printing services can be more expensive than entry-level printers because they have long lead times with their machines.

Looking for a 3d printing service in Plymouth? We offer the best 3d printing services in the area. Our expert team of designers and engineers have years of experience in 3d printing, and can help you bring your ideas to life with customized printing solutions. Whether you need a prototype for an upcoming project, or want to create custom 3d models, we have the tools and expertise to get the job done. So why wait? Contact us today and start exploring the endless possibilities of 3d printing.

Whether you need a prototype for an upcoming project, or want to create custom 3d models, we have the tools and expertise to get the job done. So why wait? Contact us today and start exploring the endless possibilities of 3d printing.

Research shows that the UK 3D printing market could be £2.9 billion in the future Kids toys.

According to OnePoll, over 5 million adults are willing to spend around £500 on a 3D printer if it's easy to use. About 49 live in the UKmillion adults (ONS data). If 1.8% of residents are willing to spend about £500 on a 3D printer, then the UK 3D printing market will be worth £2.9 billion.

However, there are some doubts about the practical value of a 3D printer, as 4 out of 10 people admitted that they had no idea what to do with it.

Chris Elsworthy, CEO of the Robox company, said: “3D printing has already made its mark on the world of technology. As far as the average person is concerned, we still have a long way to go.”

“We found that the British are becoming more and more interested in new technologies, but as with any unfamiliar subject, it takes time for them to understand what a home 3D printer can be useful for. ”

”

"The consumer is unlikely to be able to use most existing printers: they are too expensive, difficult to manage and too large to put on the table."

"On the other hand, we've learned that more and more people want a printer that's relatively inexpensive, nice looking, and easy to use."

In a study of 1,000 people, it turned out that many would like to get creative and print something unusual. A third of those surveyed said they would rather use homemade items such as pipe brackets, holders and doorknobs instead of going to the store to get them.

In addition, a quarter of the respondents admitted that they do not have time to run around the shops in search of gifts for friends and relatives, and they think that a hand-made gift will make an equally pleasant impression.

One fifth of the respondents liked the idea of printing their own case for their phone or tablet. The same number of people would 3D-print a kitchen and print coffee cups, knives, and utensils.

Other uses for 3D printing include picture holders, photo frames, baby shower favors, and all sorts of designer items, including jewelry and belt buckles. All this encourages you to think about buying a 3D printer if it becomes affordable and inexpensive. By the way, some people would also like to save money on children's toys by printing Lego bricks, action figures and lost parts from different games.

Elsworthy said: “The bottom line is that the possibilities of 3D printing are endless, because you can design or replicate any product from the comfort of your home.”

“We've already received a lot of inquiries from local schools whose students dream of seeing Robox in action. Children are always interested in new technologies. In addition, it is easy for them to explain what and how they can print.

Robox 3D 3D Printer Coming to the UK and US Markets Early 2014 Costing £849pounds / 1364 dollars. The developers position it as a “plug and print” device, which even a beginner can figure out how to manage. This is a stylish 3D printer that is equipped with a revolutionary "FFF based dual nozzle print head". One nozzle is designed for printing surfaces with fine details, while the other is for fast filling. Robox is also equipped with an automatic print platform leveling system, a closed feedback circuit and an extrusion system with double pinch rollers.

This is a stylish 3D printer that is equipped with a revolutionary "FFF based dual nozzle print head". One nozzle is designed for printing surfaces with fine details, while the other is for fast filling. Robox is also equipped with an automatic print platform leveling system, a closed feedback circuit and an extrusion system with double pinch rollers.

“3D printing is the future, as it will allow many people to educate themselves. The results of this study are incredible, as they prove that people are already interested in 3D printers, although they do not yet have the opportunity to buy them,” said Elsworthy.

The survey also found that men are twice as interested in buying a 3D printer than women, indicating their penchant for all sorts of technical innovations.

It is not surprising that teenagers are also tempted to print things at home, while those aged 18-44 are more interested in mastering new technology than those who are 15-16 years old.

Interestingly, only 12 percent of those surveyed “do not know” what a 3D printer is.

TOP 10 3D PRINTER APPLICATIONS

- Home items

- Spare parts, fasteners and tools

- Gifts and souvenirs for friends and family

- Decorations for Christmas

- Gadget accessories

- Kitchen utensils

- Jewelry and fashion accessories

- Children's toys

- Office Consumables

- Party & Wedding Favors

Article prepared for 3DTODAY.ru

plastic for 3D printer England

Plastic Esun

Plastic SEM

Plastic Bestfilament

PRINTPRODUCT

Plac

FILAMNO

products, corresponding to your corresponding ones.

Our 3DMall online store offers a wide selection of filaments for any model of 3D prototyping equipment, in particular, you can buy plastic for a 3D printer made in England at the best price in Moscow. Among our suppliers are leading manufacturing companies offering products of decent quality that have passed all stages of certification. You can order plastic for a 3D printer made in England in any required quantity, in an extensive color palette and with delivery in Russia.

You can order plastic for a 3D printer made in England in any required quantity, in an extensive color palette and with delivery in Russia.

Read more…

Our website presents a huge range of equipment for 3D scanning and 3D printing, as well as consumables for printers. Leading brands are engaged in the production of materials for 3D printing. In an extensive catalog you will find plastic for 3D printers from both domestic and foreign manufacturers. Among our trusted and reliable suppliers, who treat their work with skill and responsibility, are English manufacturers.

How to choose plastic for 3D printing?

When choosing filaments for 3D equipment, it is important to familiarize yourself with their technical and physical parameters. On our site there is a huge selection of plastic for 3D printers (England), the quality of which is always on top, but when buying, pay attention to the characteristics of your 3D printer and its compatibility with consumables.

There are many types of additive manufacturing plastics, here are the most common materials:

- ABS. Most often, this type of filament is chosen for 3D printing. Its main advantages are enviable strength characteristics and high heat resistance. Many items used in everyday life are made from ABS plastic, in particular, car components, technical parts, toys. The material requires a high melting point to work with. When heated, plastic for a 3D printer (England) can emit an unpleasant odor with toxins, so work should be done in a well-ventilated area.

- PLA. Plastic lends itself perfectly to low heat, and the surface of the products is smooth and shiny. Among the advantages is the environmental friendliness of the material, even when heated, it does not emit toxins and odor. But PLA plastic has a significant drawback - a short service life of the resulting models. Products can last no more than 2 years under normal conditions at a temperature of about 25 degrees.

Learn more