Makerbot 3d printer pla filament

MakerBot 3D Printing Filament | MatterHackers

Rigorously tested for quality, and optimized for Method Printers.

Guides & Articles

How To Succeed When 3D Printing With PLA Filament

Discover the best practices for 3D printing with PLA filament - from finding the right temperature, to which surfaces to 3D print on, this step-by-step guide will help you succeed with 3D printing PLA.

How To Succeed When Printing With ABS

ABS filament is a versatile material that's a great option for when you need your 3D-printed parts to be strong and heat-resistant. Learn how to print this material like a Pro in this in-depth guide.

How to Succeed when 3D Printing with PETG Filament

This in-depth guide provides everything you need to succeed when printing with PETG filament. Embrace the fantastic properties of durable and easy to print, PETG filament!

How to Succeed with 3D Printing Metal on a Desktop 3D Printer

The time is here to explore easy and affordable metal 3D printing. 3D printing with real metal on a desktop 3D printer is now possible using Ultrafuse Metal 3D printing filament from BASF Forward AM.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When Printing With Flexible Filament

Let’s take a look at what makes flexible filaments easier to print and how you can add flexible filament to your 3D printing material toolbox.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

How to Succeed When 3D Printing with MH Build Resin

Make SLA resin 3D printing easier with this helpful detailed article on how to successfully fine-tune photopolymer resin to your 3D printer.

How To Succeed: 3D Printing with Nylon and Nylon Composites

Nylon and nylon composites perform exceptionally well in a variety of uses, it just takes a gentler touch to print it successfully.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

MakerBot PLA Filament Bundle - Large - Buy 9, Get 10-Pack

by Makerbot

Save 0% Save %

Original price $430. 00 - Original price $430.00

00 - Original price $430.00

Original price

$430.00

$430.00 - $430.00

Current price $430.00

| /

SKU MP06572

Availability In Stock

QUESTIONS & ANSWERS

- Description

- Shipping & Returns

- Price Match

Description

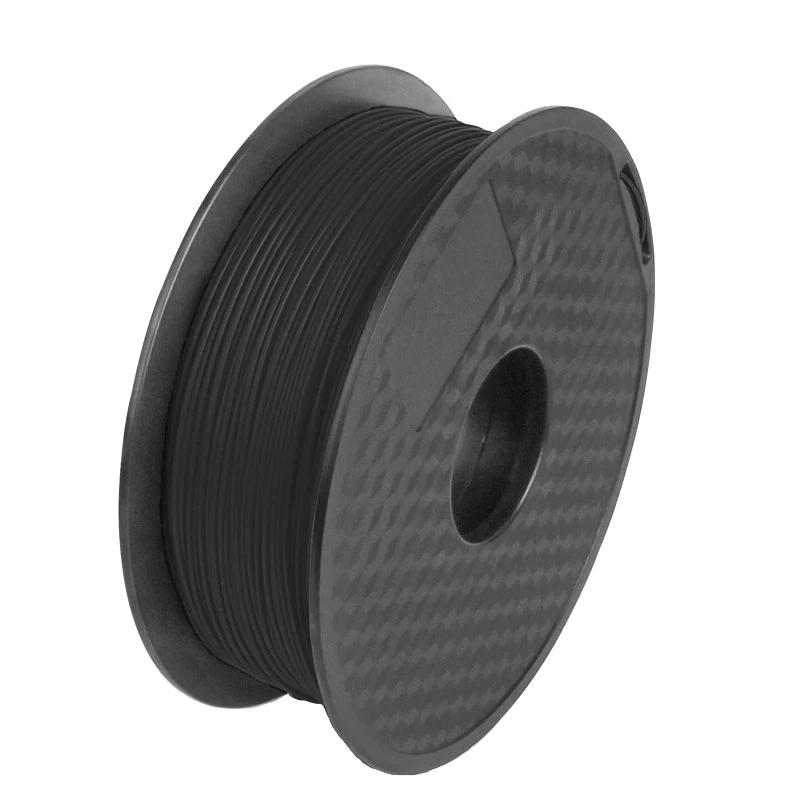

MAKERBOT PLA 10-PACK

Get ten Large Spools of MakerBot PLA Filament for the price of nine! Filament Starter Packs include one large spool in each of the following True colors: Red, Orange, Yellow, Green, Blue, Purple, White, Warm Gray, Cool Gray, and Black.

MakerBot PLA Filament is the best and most consistent filament optimized for use with Replicator+ as well as MakerBot's 5th Generation Line of 3D Printers. These size spools are for use in the MakerBot Replicator+, Replicator Desktop 3D Printer (5th Gen), the MakerBot Replicator Z18 3D Printer, or the MakerBot Replicator 2 Desktop 3D Printer.

All MakerBot Filament is manufactured to produce the highest quality 3D prints and is trusted by leading companies and institutions the world over, thanks to state-of-the-art filament manufacturing and quality control standards.

FEATURES

- When used with MakerBot Replicator 3D Printers, PLA Filament helps produce higher-quality prints, reduce filament problems, and minimize downtime.

- Compared to ABS, PLA demonstrates much less part warping and curling and, for this reason, can be successfully printed without a heated build plate.

- Details such as sharp corners and edges print well and PLA printed objects will generally have a glossier look and feel.

- MakerBot PLA Filament is optimized for Grip Surface adhesion on the MakerBot Replicator+ and the MakerBot Replicator Mini+.

- MakerBot PLA Filament also adheres well to acrylic and MakerBot Build Plate Tape on the MakerBot Replicator (5th Gen) and older models.

WHAT'S INCLUDED:

- 10 Large PLA Material Spools (Assorted Colors)

Shipping & Returns

Order Confirmation:

As soon as you place your order, you will receive an order confirmation e-mail. This means that we have received your order in our system and pre-authorized your credit card for the purchase. As soon as we receive your order, we automatically reach out to our suppliers to confirm that it is in stock and available for immediate shipment. If your item is on backorder or unavailable, we will void the pre-authorization and reach out to you via e-mail. If your item(s) are available for immediate shipment (within 5 business days), we will process the charges and submit the order for shipment.

Order Shipment:

If your order is in stock and we process the charges to your credit card, it will ship within five business days from the date of your order. We will send you tracking information within 24 hours of your order leaving the warehouse to the e-mail address you provided when checking out. If you do not receive tracking information from us within six business days of your order, feel free to follow up with us at [email protected].

Cancellations & Refunds/Returns:

Before accepting a return on a product that isn't functioning as it should, Project 3D Printers reserves the right to exhaust any and all means to resolve and/or repair the malfunction through technical support and replacement parts provided by both the manufacturer and Project 3D Printers. No return will be accepted without reasonable attempts to resolve the issue(s) first. All returned products must be returned within 10 days of date of purchase.

Project 3D Printers enforces a strict "No Returns Accepted" policy for opened and/or partially used products, including filament, resin, or any consumable of any size and weight that has been used or opened from its factory and vacuum seal. Only products and consumables that are unused, and in brand new factory condition are eligible for return to the manufacturer of origin within 10 days of the purchase date.

Only products and consumables that are unused, and in brand new factory condition are eligible for return to the manufacturer of origin within 10 days of the purchase date.

If a product is found to be non-functional or defective, the product must be returned with its full original contents within 10 days of the delivery date for inspection of the non-functionality. If the product is found to be defective or non-functional a full-refund will be given, not including return shipping at the customer's expense.

All orders cancelled after 48 hours are subject to a $20 administration fee, whether or not your order has shipped. If you order has shipped, you (the buyer) will also be responsible for actual return shipping charges. Refunds will only be issued to the original credit card that you use when placing your order. Buyer is responsible for and pays a 20% restocking of the value of the returned item(s). Buyer pays all shipping fees for the returned item(s).

Customs Fees, Tariffs, Duty Fees and Import Taxes:

Only customers are responsible for their local import taxes, tariffs, duty fees and import taxes incurred during shipping. To know about your customs import duties please contact your local customs office with this details (HS Code :8477 Product description: 3d printer or 3d printer kit). If the tax amount is high, we can provide assistance to reduce it.

To know about your customs import duties please contact your local customs office with this details (HS Code :8477 Product description: 3d printer or 3d printer kit). If the tax amount is high, we can provide assistance to reduce it.

Price Match

We work very hard to ensure that we offer the absolute best prices online. If you find another online store that offers a lower price than us within six months of your purchase date please let us know and we will refund your original payment for the difference. We want you to feel confident that you are getting the absolute best price for the product you are ordering. If you find that our own website has a lower price for the same item you have ordered within six months of your purchase date will refund the difference as well.

To request your partial refund simply e-mail us a link to the same product on our website, or on our competitors website within six months from the date of your order and we will process the credit accordingly.

Our 100% Price Guarantee has some limitations:

- You must purchase the item from our website before requesting your Price Match Guarantee

- Promotions such as rebates and buy one, get one free offers are not eligible

- The item must be in stock on the competitors website

- The competitor must be an online store, they may not have a retail location

- The website can not be a discounter or auction website (ie; eBay, overstock, etc..)

- The competitor must be an Authorized Retailer of the product in question

- The Price Match Guarantee includes the item price and the shipping charges, it excludes sales tax

Techno Print 3D Company

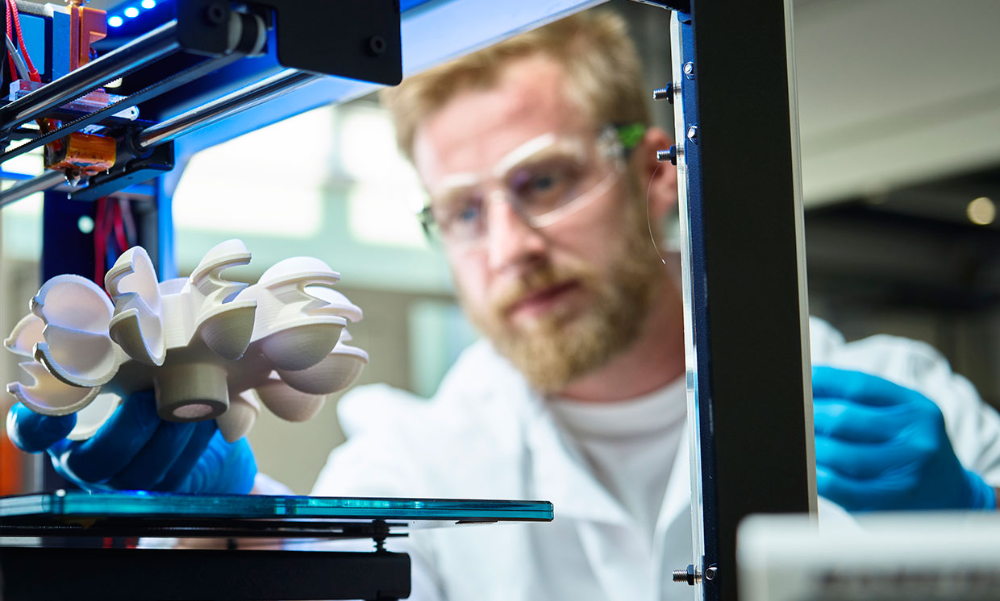

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

If you want to understand how this is done correctly, then read this article. Aceto Read more→

MakerBot Replicator 2 3D printer from the manufacturer MakerBot Industries, LLC The MakerBot Replicator 2 personal 3D printer has a high print resolution of 100 microns, which puts it in line with expensive professional 3D printers. The device can create 3D models with dimensions of 285x153x155 mm with high print speed: 50 mm/s without losing the quality of printed objects. The printer is equipped with a heated platform, which eliminates plastic slip and layer deformation.

About the MakerBot Replicator 2

Rugged steel housing ensures durability.

MakerBot is the benchmark for desktop 3D printers. The main model of the company has undergone many changes, constantly undergoing modernization of both functional features and appearance. MakerBot Replicator 2 should not be considered a household printer, because it is not. This device is aimed at the more advanced users, or at least those who are willing to delve into the intricacies of the 3D printing process and be rewarded with high quality prints and rich functionality.

This device is aimed at the more advanced users, or at least those who are willing to delve into the intricacies of the 3D printing process and be rewarded with high quality prints and rich functionality.

Design

MakerBot Replicator 2 3D Printer

The exterior design of the Replicator 2 is hardly classic. It would be more correct to be “original”, because it was the “replicators” (including their heterogeneous predecessors, the MakerBot Thing-O-Matic and MakerBot Cupcake printers) that made the open case with cutouts in the facing panels a kind of standard that gave rise to a myriad of imitations and outright clones. The cutouts serve a strictly practical purpose, facilitating access to the build platform from all sides and, last but not least, providing good ventilation and fast cooling when printing with PLA.

The printer frame is made of powder-coated steel and PVC cladding panels. The guides are made of aluminium, while the bearings are made of cermet based on oil-impregnated bronze. In general, the developers have put a lot of effort into ensuring the durability of the device. True, the metal frame is not to everyone's taste, because the wood used in the early models of the printer tends to absorb vibrations more effectively.

In general, the developers have put a lot of effort into ensuring the durability of the device. True, the metal frame is not to everyone's taste, because the wood used in the early models of the printer tends to absorb vibrations more effectively.

Unlike some earlier versions, the Replicator 2 uses only one extruder, but the size of the working area has been significantly increased and is 285x153x155mm. Note that some confusion is possible: the latest model of the fifth generation is again called the Replicator. This device can be considered a further development of the described Replicator 2 model, which, according to the new nomenclature, should be attributed to the fourth generation. At the moment, the fourth and fifth generation models are sold in parallel, having certain differences in the configurations of the build areas, electronic filling, and some other points.

Acrylic worktable excellent for PLA printing

Since “replicators” have traditionally been designed primarily for PLA printing, the Replicator 2 does not have a heated bed. Actually, polylactide is the only type of consumable that is officially supported by this device. By the way, there is a printer variant called the Replicator 2X (“X” stands for “experimental”), in which MakerBot re-tested printing with ABS plastic, including a heated platform in the design, removable panels that cover openings in the cladding panels, and returning printing with two extruders . This option is also on sale, but is intended for professional users. The removable table of the Replicator 2 is made of acrylic, which is an excellent base for models made of PLA plastic.

Actually, polylactide is the only type of consumable that is officially supported by this device. By the way, there is a printer variant called the Replicator 2X (“X” stands for “experimental”), in which MakerBot re-tested printing with ABS plastic, including a heated platform in the design, removable panels that cover openings in the cladding panels, and returning printing with two extruders . This option is also on sale, but is intended for professional users. The removable table of the Replicator 2 is made of acrylic, which is an excellent base for models made of PLA plastic.

Printing

Replicator 2 3D printer extruder

Printing is done using a single extruder and a 0.4mm nozzle. With a minimum layer thickness of 100 µm and a positioning accuracy of 11 µm along the X and Y axes and 2.5 µm along the Z axis, very high-quality models are obtained, allowing the Replicator 2 to be put in the class of semi-professional printers.

As already mentioned, the detachable work table is made of acrylic. This option has been so successful that most users do not even resort to additional means of holding the model in place, such as duct tape. On the contrary, the addition of tape can worsen the adhesion of the polylactide compared to printing on a bare bed. You just need to make sure that the platform is free of dust and grease before printing.

This option has been so successful that most users do not even resort to additional means of holding the model in place, such as duct tape. On the contrary, the addition of tape can worsen the adhesion of the polylactide compared to printing on a bare bed. You just need to make sure that the platform is free of dust and grease before printing.

The choice of colors of the branded plastic thread is quite rich, including 26 options, of which 7 are translucent. In addition, the Replicator 2 uses quite standard spools and the usual 1.75mm filament diameter, which allows you to use "non-native" materials, although at your own risk.

Inexpensive variants from the same Chinese manufacturers often suffer from rather poor performance. It is not uncommon for a filament to have an oval cross section, which, coupled with a frankly rather weak pulling mechanism, can lead to loss of adhesion and clogging of the extruder. A particularly unpleasant surprise can be the instability of the filament shape - printing can start quite normally, but end up crashing in the middle of the process with the loss of an unfinished model. It is worth paying attention to the packaging: coils sold without vacuum packaging inevitably collect dust, whose accumulation in the extruder again does not promise anything good.

It is worth paying attention to the packaging: coils sold without vacuum packaging inevitably collect dust, whose accumulation in the extruder again does not promise anything good.

The Replicator 2 has been used successfully with sandstone and wood simulants.

In addition to potential savings, the use of standard spools provides the ability to print materials not originally intended by the printer's designers. For example, the Replicator 2 prints quite successfully with resin wood and sandstone simulants, known as LAYWOO-D3 and Laybrick, from the German manufacturer Orbi-Tech. True, to print with these materials, you will have to make some changes to the printer settings. For example, LAYWOO-D3 is preferably printed at a nozzle temperature of about 215-210°C (standard temperature for PLA printing is 230°C) and with the fan turned off, usually cooling freshly applied PLA layers. In the case of Laybrick, an extrusion temperature of 165-190°C for smooth surfaces and 210°C with fan running for a rough outer layer.

Printing with ABS is theoretically impractical due to the lack of platform heating, but there is evidence of successful printing of small models. The greatest difficulty is preventing ABS plastic from slipping, but the savvy of 3D craftsmen suggested the option of replacing the desktop with a glass one and using hairspray as glue. However, the printing of large models is doomed to twisting of the deposited layers and deformation of the model during shrinkage.

Fairly good results can be achieved with nylon, although the lack of a heated bed also makes the process much more difficult. Specially designed options such as Taulman 618 and 645 are recommended.

All in all, the Replicator 2 allows you to let your imagination run wild and experiment with many materials beyond the standard PLA.

Software

The Replicator 2 software caused quite a stir. The fact is that the company used a closed code. The proprietary program was called MakerWare. Actually, "closeness" touched the design of the entire printer, for the first time since the founding of the company, which built its business on the use of designs and developments in the public domain. Most outraged was the legendary founder of the open source printer project, called RepRap, Josef Prusa, who caught MakerBot in the commercial use of his ideas. Traditionally, RepRap developments are intended for use by enthusiasts, and if for commercial use, then with the concomitant provision of improvements to the public domain. But to some extent, MakerBot can be understood: the latest models have undergone such significant changes that their manufacture by improvised means is unlikely. The addition of proprietary software was only the final touch in the "closing" of design features.

Most outraged was the legendary founder of the open source printer project, called RepRap, Josef Prusa, who caught MakerBot in the commercial use of his ideas. Traditionally, RepRap developments are intended for use by enthusiasts, and if for commercial use, then with the concomitant provision of improvements to the public domain. But to some extent, MakerBot can be understood: the latest models have undergone such significant changes that their manufacture by improvised means is unlikely. The addition of proprietary software was only the final touch in the "closing" of design features.

MakerWare - MakerBot Replicator 2 Proprietary Software

In terms of functionality, MakerWare is practically the same as the previously used open source programs Skeinforge and Repetier-Host, except that the interface has changed. The program is compatible with Windows 7 and 8, Mac OS X and Linux and is able to work with STL, OBJ and THING files.

What is alarming is the lack of full control of the printer via a computer connection. The Replicator 2 is equipped with a very user-friendly LCD control module that exclusively performs operations such as platform calibration or plastic loading. If the module breaks, the user can use the remaining plastic on the spool, but then the printer will have to be returned for repair. One computer is not enough. On the other hand, while the module is working, you can use the SD card reader to print offline, without fear of print failures due to a computer freeze or a cable break due to a toothy pet.

The Replicator 2 is equipped with a very user-friendly LCD control module that exclusively performs operations such as platform calibration or plastic loading. If the module breaks, the user can use the remaining plastic on the spool, but then the printer will have to be returned for repair. One computer is not enough. On the other hand, while the module is working, you can use the SD card reader to print offline, without fear of print failures due to a computer freeze or a cable break due to a toothy pet.

Summary

Replicator 2 with Heated Bed by BC Technological Solutions

One of the most successful and sought after 3D printer models on the market. The model has undergone many changes aimed at optimizing performance and increasing durability, and at the same time received a stylish and strict exterior design, befitting a high-tech gadget. Perhaps the only serious drawback of the printer can be considered a fairly high cost compared to competitors or previous models.