Make your own 3d printer kit

The 10 Best DIY 3D Printer Kits 2022 (Starting at $150!)

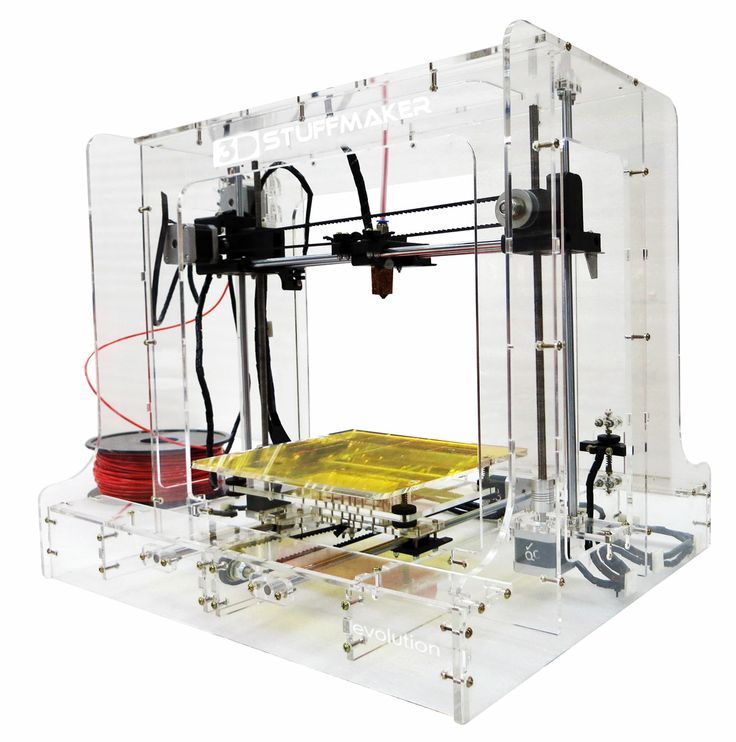

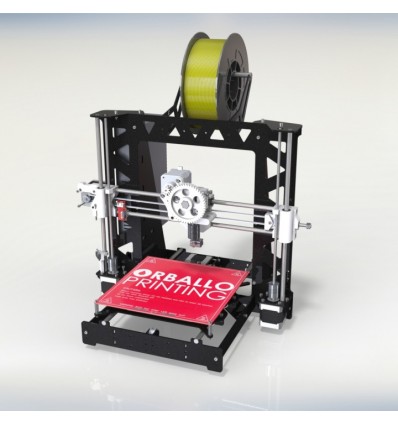

Increasingly, makers are turning away from desktop FDM 3D printers, preferring to buy a cheap 3D printer kit and build their own DIY 3D printer from scratch. Some of these are RepRap 3D printer kits, and some are specially designed kits.

The 3D printer kit revolution has reduced prices, led to a number of key breakthroughs, and has made 3D printing more accessible than ever before.

Great Ender 3 Alternative

Amazon here

Best Budget 3D Printer

Amazon here

Best 3D Printer Kit Overall

Buy pre-assembled here

These 3D printer kits can take just a few minutes to assemble, or take hours or even days. They can also vary greatly in price, print accuracy, maximum build and print speed. Some even use technologies other than fused deposition modeling — you can now buy DIY SLS 3D printers and SLA 3D printers.

| 3D printer kit name and brand | Build Volume (mm) | Price | Where to purchase for best price | Alternative Purchase Option |

|---|---|---|---|---|

| Creality Ender 3 | 220 x 220 x 250 | $189 | Creality Store here | Amazon here |

| Prusa Mini | 180 x 180 x 180 | $399 | Prusa Store here | |

| Creality Ender 3 V2 | 220 x 220 x 250 | $279 | Creality Store here | Amazon here |

| Creality Ender 5 | 220 x 220 x 300 | $349 | Amazon here | |

| Flsun QQ-S | 255 x 255 x 360 | $369 | Amazon here | |

| Tronxy X5SA Pro | 330 x 330 x 400 | $399 | Amazon here | |

| Anycubic Vyper | 245 x 245 x 260 | $429 | Anycubic here | Amazon here |

| Creality CR-10 / V3 | 300 x 300 x 400 | $369 / $459 | Creality here | Amazon here |

| Prusa i3 MK3S | 250 x 210 x 210 | $749 / $999 | Kit available available on Prusa Store here | Fully assembled on Prusa Store here |

| Peopoly Moai | 130 x 130 x 180 | $1,295 | Matterhackers here |

Advantages of DIY 3D printers

- Open source: Most homemade 3D printers are also open source 3D printers, meaning they can be tinkered with, upgraded, and modded freely with the creators’ permission. Many Creality, Prusa and Anet printers are open source, as well as desktop 3D printers like BCN3D and Ultimaker printers.

- Open build areas: 3D printer kits rarely feature closed chambers or enclosures as standard. This would affect the printing of filaments like Nylon or PEEK, but is less of an issue for standard filaments like PLA or PETG.

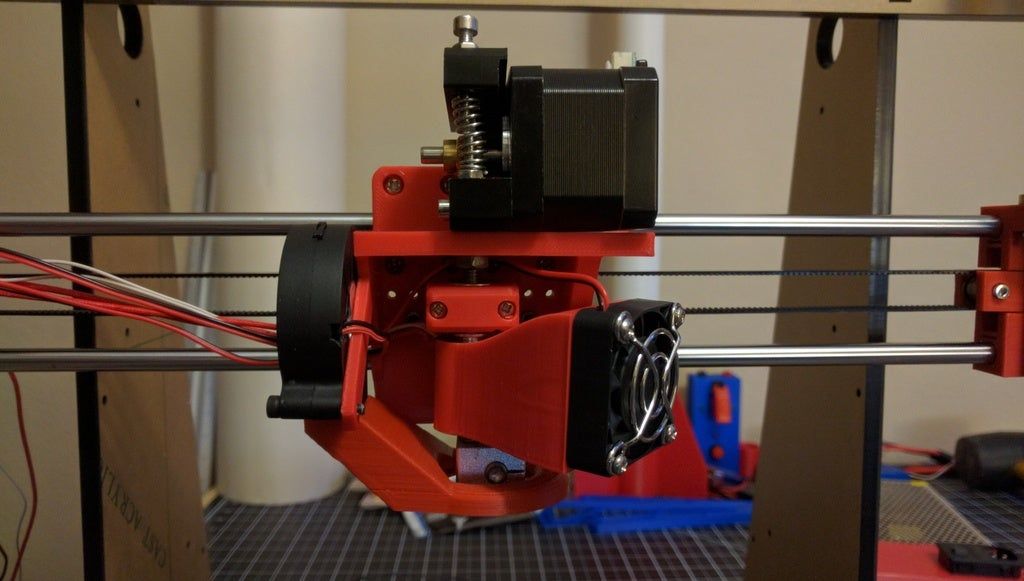

- Easily upgradable parts: DIY 3D printer owners are frequently switching out parts, such as nozzles, hot ends and extruders for better quality parts.

- Lower price: For the quality and size, you get a better deal if you build your own 3D printer.

- Larger build volume: The open build area means that you can have a larger 3D printer build area for the same size, neglecting the need for an enclosing frame.

Therefore, low cost kits like the Creality CR-10 can have huge build volumes.

Therefore, low cost kits like the Creality CR-10 can have huge build volumes.

Build your own 3D printer: what makes a good DIY 3D printer?

We used several criteria to determine which 3D printer kit made it into our ranking:

- Cheap DIY 3D printer kits: We only included FDM 3D printer kits under $1,500. The printers are listed in price order, cheapest first.

- Print quality

- It it easy to build your own 3D printer: Not everyone is a technology wizard. Therefore, any kit that can be assembled quickly, easily, and is simple to operate, is at an advantage.

The best 3D printer kits

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

1. Creality Ender 3

- Price: $189 — Available on Creality Store here / Available on Amazon here

- Build volume: 220 x 220 x 250 mm

The original Ender 3 is still one of the most popular 3D printer kits in the world, more than three years after it was originally released. The low price, great build area, and reliability have cemented the Ender 3 as one of the best 3D printer kits around.

The low price, great build area, and reliability have cemented the Ender 3 as one of the best 3D printer kits around.

The reliability is a major selling point in such a cheap 3D printer kit. Whereas most DIY printers in this price range are plagued by issues caused by low-quality parts, the Ender 3 is dependable and consistent, partly due to its upgraded extruder to prevent clogging or poor extrusion.

The resume printing function is useful if you’re prone to power cuts or want to print for several days straight and don’t want to risk a huge ruined print, and the Ender 3 is fairly quick to assemble, and shouldn’t take more than an hour or so.

However, it doesn’t feature auto-leveling — you’ll need to install a BLTouch or similar kit for that.

Best Budget 3D Printer

Creality Ender 3 3D Printer

The best budget 3D printer kit around - and the best-selling, too. If you have the budget, pick up the V2 or V2 Neo version, or even the Ender 3 S1 if you prefer a direct drive extruder.

Creality hereAmazon here

We earn a commission if you make a purchase, at no additional cost to you.

2. Prusa Mini — Great Prusa 3D printer kit

- Price: $399 — Available on Prusa Store here

- Print volume: 180 x 180 x 180 mm

- Print speed: up to 200mm/s

The Mini 3D printer version of the wildly successful Prusa MK3S, the Mini retains the 0.05mm layer precision and can still calibrate itself, but costs less than half of the i3 MK3S. With the Mini, you can build your own 3D printer — and one with Prusa-level reliability! — for just $349.

It’s more compact, with a smaller build volume, and features removable spring steel sheets that make removing finished prints extremely easy — just flex the build plate and prints will come off with ease.

The extruder cannot reach the same temperatures during printing as the MK3S, though you can still print a number of tougher filaments like ABS, PETG, ASA and flexible filaments. The Mini retains the fast 200mm/s max printing speed, and can be upgraded to feature a filament sensor.

The Mini retains the fast 200mm/s max printing speed, and can be upgraded to feature a filament sensor.

Overall, it’s another reliable 3D printer by the trusted Prusa brand who have proven over the years that their printers are some of the best 3D printer kits around. If you have the money, go for the MK3S, but for those on a budget, the Mini does a great job.

Best Mini 3D Printer Kit

3. Creality Ender 3 V2 — Best DIY 3D Printer Under $300

- Price: $279 — Available on Creality Store here / Available on Amazon here

- Build volume: 220 x 220 x 250 mm

Building on the success of the Ender 3 and improving and fixing its few flaws, the Ender 3 V2, while the same size build volume, is a much enhanced DIY 3D printer.

The upgraded motherboard makes the printer quieter than ever, and the extra power makes for a much more stable and precise printing experience.

Read more: the quiet 3D printer buyer’s guide

The upgraded extruder is also a great touch. It’s easier to load and feed filament into via the rotary knob, ideal for PLA and flexible filaments. The large 4.3-inch screen makes the interface more intuitive, and the Ender 3 V2 is really easy to use overall.

It’s easier to load and feed filament into via the rotary knob, ideal for PLA and flexible filaments. The large 4.3-inch screen makes the interface more intuitive, and the Ender 3 V2 is really easy to use overall.

Another extra is the carborundum glass platform, which can heat up faster than ever and improves adhesion so you can be sure of a great first layer. Overall, if you have the extra $100 to spare, consider going for the Ender 3 V2 over the original.

Top Pick

Creality Ender 3 V2

$279.99

Upgraded version of the original Ender 3 with a number of key quality-of-life improvements.

Creality Store hereAmazon here

We earn a commission if you make a purchase, at no additional cost to you.

4. Creality Ender 5 — The Best DIY 3D printer under $500

- Price: $349 — Available on Amazon here

- Print volume: 220 x 220 x 300 mm

Another Creality kit, the Ender 5 is another great 3D printer you can build at home. The Ender 5 is $100 more expensive, but boasts a number of improvements that make the extra money seem worth it.

The Ender 5 is $100 more expensive, but boasts a number of improvements that make the extra money seem worth it.

Firstly, it can print taller prints than the Ender 3 — 300 mm high rather than 250 — important if you print tall structures like tall vases or monument 3D models. The structure is also stronger, having adopted a cube shape like the Tronxy X5SA which helps with stability, reducing vibrations or movements from external events, and improving part surface finish and quality.

Moreover, the minimum layer height of 50 microns is extraordinary for such a cheap machine. Review after review repeats how crisp the surface finish of their prints look with the Ender 5, so it’s fair to say the Ender 5 is a smash hit.

- For an extra $50 you can upgrade to the Ender 5 Pro printer kit, at $399. It’s available to buy here.

Note: while the Ender 5 can be tweaked to increase print speed without a noticeable loss in print quality, we recommend you don’t get too extravagant with this. Stick with 60 mm/s or below for models with intricate parts — it’s worth a bit of extra printing time to guarantee crisp prints.

Stick with 60 mm/s or below for models with intricate parts — it’s worth a bit of extra printing time to guarantee crisp prints.

5. FLSUN QQ-S — Great Delta DIY 3D printer

- Price: $369 — Available on Amazon worldwide here

- Print volume: 255 x 255 x 360 mm

- Print speed: up to 300mm/s

One of the best DIY delta 3D printer machines out there, the Flsun QQ-S features notable improvements on the original Flsun QQ. It comes 90% assembled, so though technically still a 3D printer kit it will take under an hour to get up and running.

- We were lucky enough to test the FLSUN QQ-S, make sure to also check out our FLSUN QQ-S review.

Not only does it have a fantastic build volume for the price — especially the ability to print tall parts! — but it also comes with an upgraded lattice glass print bed, allowing for faster heating up to 100C in under 5 minutes, less warping and better adhesion during 3D printing. This is perfect for materials such as ABS filament, which are known to warp significantly under the wrong conditions.

Another advantage that beginners will enjoy is that as delta 3D printers don’t move the print bed — the print head does all the moving — the printer only needs to be auto-leveled once. It comes with a titan extruder, and can print with common printing materials like PLA and ABS, PVA, and HIPS for supports, as well as wood-filled filaments and flexible filaments.

It’s accurate, too, able to print at up to 50 microns. Overall, it’s a fantastic delta 3D printer kit that prints accurately, and super fast — it even made it into our fastest 3D printer ranking. It’s also one of the easiest DIY 3D printers to build, coming almost fully assembled — you just need to attach the gears and rods to hold the structure up, and then attach the extruder and filament holder.

Best Delta 3D Printer Kit

FLSUN QQ-S-PRO Pre-assembled Delta 3D Printer

$399.00

Amazon here

We earn a commission if you make a purchase, at no additional cost to you.

12/17/2022 07:50 am GMT

6. Tronxy X5SA Pro — Huge Self-Assemble 3D printer

- Price: $399 — Available on Amazon here

- Build volume: 330 x 330 x 400 mm

Kit 3D printer kings Tronxy showed humility and dedication to improve the X5SA Pro, fixing a number of small issues that affected the original. The X5SA Pro addresses the X-axis issues and has made it more stable, and upgraded the materials forming the printer kit’s structure. Now on the X5SA Pro, most of the printer is made from aluminum and is heavier and more stable, reducing vibrations and generally improving print performance.

As for the X5SA’s specs, it’s a large 3D printer DIY kit with similar printing sizes to the Creality CR-10, and boasts a 330 x 330 x 400 build volume. It claims increased precision vs the original Tronxy X5SA, and has a maximum accuracy of 125 microns. It’s impressive, reliable and one of the best cheap 3D printers you can get with such a large size — so those with big 3D printing ideas will enjoy both this and the Creality CR-10.

It’s impressive, reliable and one of the best cheap 3D printers you can get with such a large size — so those with big 3D printing ideas will enjoy both this and the Creality CR-10.

It’ll probably take you around four hours to build this printer kit, but it’ll be worth it once you start printing!

Big 3D Printer Kit

TRONXY X5SA PRO 3D Printer with Glass Bed Upgrade

Amazon here

We earn a commission if you make a purchase, at no additional cost to you.

7. Anycubic Vyper

- Price: $429 — Available on Anycubic store here / Available on Amazon here

- Build volume: 245 x 245 x 245 mm

A key feature on the Anycubic Vyper missing from many printers in this price range is that the Vyper self-levels. This is a huge relief for busy makers who would rather not re-level their printer every few prints, and who just want to get to the fun part — printing! The 16-point bed leveling process accounts for differences between the nozzle and bed and can be done in just one click.

The 32-bit motherboard is beefed up compared to previous Anycubic 3D printer kits, offering silent printing and improved stability. We tested the Anycubic Vyper and found it to be consistent in printing, easy to operate with the 4.3-inch touchscreen, and it was incredibly easy to assemble — we built it in 10-15 minutes.

The new PEI spring steel magnetic print bed can be lifted off the platform easily for easy removal of your finished parts, and is designed to be scratch and heat resistant and to work well with standard filaments such as PLA, ABS, PETG, and TPU.

The Vyper also features an innovative new two-fan dual cooling system, cooling down parts quicker and enabling faster printing without causing errors — the Vyper can comfortably print at 100mm/s.

Great Ender 3 Alternative

8. Creality CR-10 / V3

- Price: $369 / $459 — Available on Amazon here / Available on Creality Store here

- Print volume: 300 x 300 x 400 mm

The Creality CR-10 has a passionate group of supporters who hail it as the best DIY 3D printer kit in its price range. Manufactured by Creality, the CR-10 is a fantastic 3D printer build kit that can be built within 45 minutes.

Manufactured by Creality, the CR-10 is a fantastic 3D printer build kit that can be built within 45 minutes.

The Creality CR-10 has an accuracy and print volume which is competitive with printers 5 times more expensive. With it’s minimum layer thickness of 0.05mm and fantastic 300 x 300 x 400 mm build volume, the Creality CR-10 is a great printer for just $370. It’s easy to use, making it the perfect 3D printer for beginners.

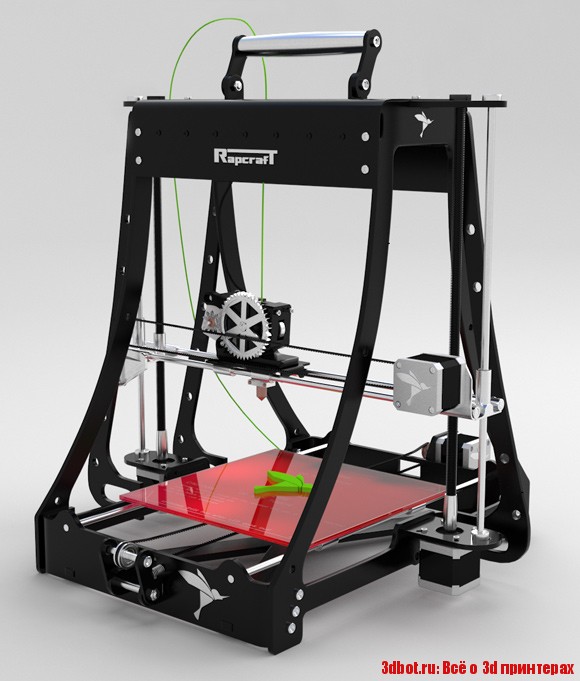

9. Prusa i3 MK3S — best 3D printer kit

- Price: $749 as a kit — Available on the Prusa store here / $999 fully assembled — Available on the Prusa store here

- Build volume: 250 x 210 x 210 mm

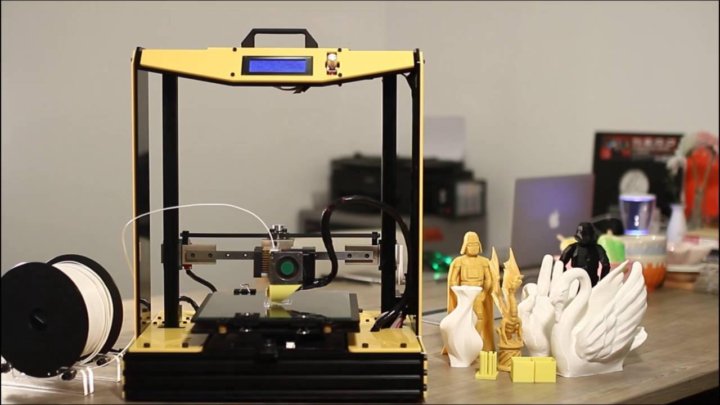

The Prusa i3 is known as the undeniable king of DIY 3D printer kits. These RepRap kits are fantastic, sporting an impressive print volume of 250 x 210 x 210 mm, and being able to print at speeds up to 200mm/s! It’s also accurate, durable and a complete workhorse, with layer heights from 0. 05 mm and a bendable print surface to make removing finished prints as easy as possible.

05 mm and a bendable print surface to make removing finished prints as easy as possible.

Accessible via USB stick or by SD card, the Prusa i3 MK3 kits are designed to be simple to use as well as effective. With layer resolutions up to 50 microns, the Prusa i3 homemade 3D printer is so effective that it outperforms far more expensive 3D printers. It can print tougher filaments than more expensive printers too, with a Bondtech extruder that can reach temperatures of up to 300C, making printing Polycarbonate, ABS, Nylon, and other difficult filaments no problem.

Additionally, you can print up to 5 colors simultaneously with your Prusa if you purchase their multi-material upgrade kit, costing $300. This makes colorful model printing a breeze, and opens up for far more extravagant printing projects.

The Prusa, with Multi Material Upgrade kit, allowing it to print multiple colors simultaneously. We explain this in our color 3D printer guide.- With a Multi Material Upgrade kit, it can also print multiple colors.

We explain more in our color 3D printer buyer’s guide.

We explain more in our color 3D printer buyer’s guide. - You can buy the Multi Material Upgrade Kit 2.0 here.

You can choose to either assemble the kit yourself or buy the printer pre-assembled, though this costs a few hundred dollars more. Overall, the Prusa remains the undisputed king of DIY 3D printer kits, with its competitors needing to do a lot of catching up to dethrone it.

Best 3D Printer Kit Overall

Original Prusa i3 MK3S+ kit

The best 3D printer kit of all time. If you have $1,000, this is some of the best value you can get.

Buy as a kit hereBuy pre-assembled here

We earn a commission if you make a purchase, at no additional cost to you.

10. Peopoly Moai SLA Kit — Homemade resin 3D printer kit

- Price: $1,295 — Available on Matterhackers here

- Build volume: 130 x 130 x 180 mm

The only resin 3D printer featured in our 3D printer kit guide, the Peopoly Moai is an incredible feat of engineering. It’s huge, offers incredible accuracy and precision, and best of all, you can build your own 3D printer at home from scratch.

It’s huge, offers incredible accuracy and precision, and best of all, you can build your own 3D printer at home from scratch.

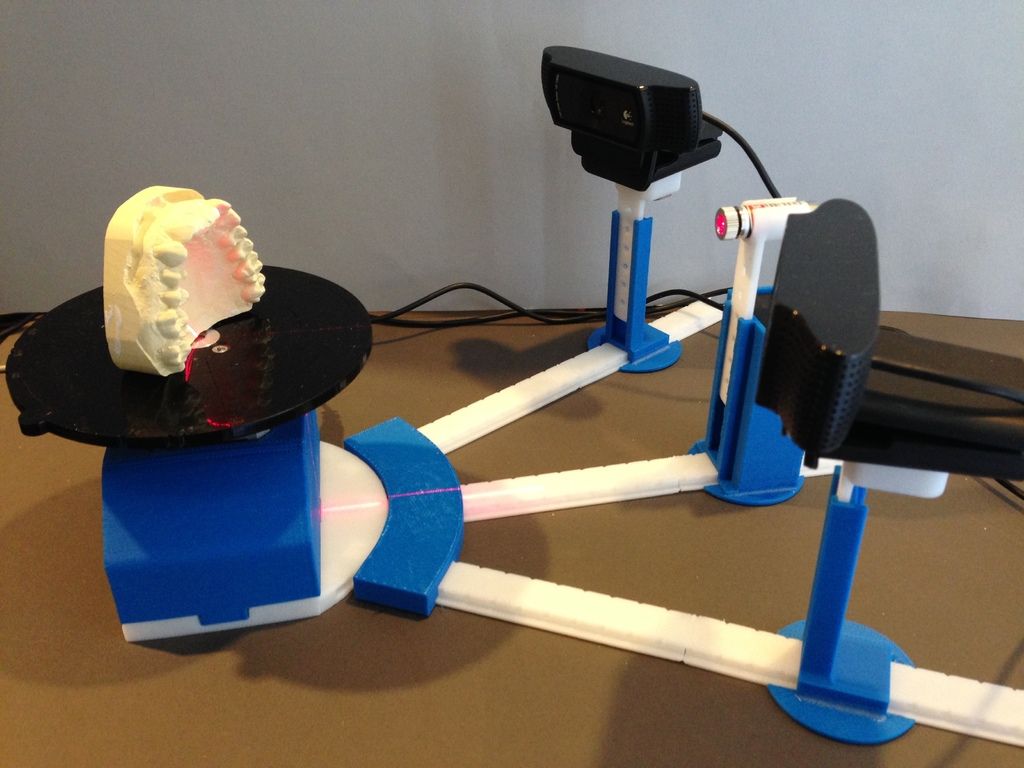

For those looking for an effective SLA 3D printer, and who do not want to pay full price, the Moai kit could be the perfect printer for you. It is so accurate that it can mechanically print up to an astonishing 5-micron layer height, according to Peopoly, though you’ll likely never reach this accuracy because you won’t need to, nor would most resins or models accommodate this.

Featuring a 70-micron laser spot size, once you’ve built this homemade 3D printer you’ll be ready to create resin molds for 3D printed jewelry, dental models, engineering pieces, as well as prototypes for rapid prototyping or fun characters if you use the Moai as a 3D printer for miniatures.

The Peopoly Moai is open to use third-party resins, for those who want to save money on lower-cost resins and are fine with the slight quality drop-off. The printer itself however does not come with any resin, so you’ll need to purchase that with the kit. It is only to be expected that the Moai will take some time to assemble, as resin 3D printers are more complex than their FDM 3D printer counterparts, but most makers will be able to build their own 3D printer within 4 hours.

It is only to be expected that the Moai will take some time to assemble, as resin 3D printers are more complex than their FDM 3D printer counterparts, but most makers will be able to build their own 3D printer within 4 hours.

Best DIY Resin Printer

Creality Ender 3 3D Printer sale

Home Collections Ender 3 DIY 3D Printers Kit | 8.66x8.66x9.84inch | Resume Printing Function$ USD

$ USD

35 Reviews Pricing Not Include Tax

Ship From

United StatesCanadaCzech RepublicAustraliaUnited KingdomChina

Model-1

Ender-3 NEOEnder-3

Ship to

It is expected to arrive within and will cost $ USD to ship

This item can't be shipped to this Country/Region

Bundles

Quantity

28 Available

Add To Cart Buy It Now

Continue To Shopping View Cart

People who bought this item also bought

Official Creality Ender 3 3D Printer Fully Open Source with Resume Printing

- Easy and Quick Assembly: It comes with several assembled parts, you only need about 2 hours to assemble 20 nuts well.

- Advanced Extruder Technology: Upgraded extruder greatly reduces plugging risk and bad extrusion; V-Shape with POM wheels makes it move noiseless, smoothly, and durable.

- Safety Protected Power Supply: Only needs 5 minutes for the hotbed to reach 110℃.

- It is a great project for middle school and high school-aged students. The perfect gift to spark a lifelong love for science and engineering, and provide a deeper understanding of machinery and robotics.

Creality Ender 3:Complete beginner's guide to 3D printing - Assembly, tour, slicing, levelling and first prints

CR Touch Install Guide - From 3D Printscape

Why Most People Choose Ender 3 3D Printer

From 2018 till now, the Ender-3 model has remained in the "Best Selling". Although we are launching new Ender-3V2, Ender-3S1. So why do many choose Ender 3?

Although we are launching new Ender-3V2, Ender-3S1. So why do many choose Ender 3?

1. In terms of price: the price is lower than 200, stable printing quality and 220*220 printing size, supports different filament materials

2. In terms of performance: support resume printing, 5mins rapid heating, reliable power supply

3. Upgrade convenience: ender 3 direct drive, cr touch auto leveling kit, touch screen , tempered glass bed and more. There's do much you can do with it

4. Who chose him: News for 3d printing, 3d printing enthusiast; for DIY makers, for education... Customer

Ender 3' S FAQ:

Filament did not stick on the hotbed?

For newcomers, this is the most common problem. Do not worry, you can solve it easily. Generally,the distance between the nozzle and platform is too far or near. So rotary the knob under the platform to adjust the distance between the nozzle and platform again,at a piece of A4 paper distance or less).

Creality Ender 3 Bed Leveling – All You Need to Know

Any structure needs a strong foundation. The same is true for 3D-printed objects. Leveling the bed on your Creality Ender 3 will ensure that that all-important first layer is solid...

How to level Creality Creality Ender 3?

Move the nozzle so that it’s positioned over the left corner of the bed. A half-inch or so from both sides is a good location.

Slide the paper between the nozzle and the bed. If it doesn’t fit, drop the corner until it does.

Once the paper is able to slide under the nozzle, very slowly raise the corner with the adjuster. Remember: Clockwise moves the bed up. As you do this, gently slide the paper back and forth. The moment you feel even the slightest resistance to your moving the paper, stop turning the knob. That corner is (almost) ready to go.

Do the same for the other three corners of the build plate. Always advance the hot end to a new corner slowly. This will prevent damage to the build plate in case the nozzle starts to drag. If this occurs, simply lower the next corner (before starting the leveling process) to make some room.

If this occurs, simply lower the next corner (before starting the leveling process) to make some room.

After you’ve adjusted each corner once, go back and check the four corners again. You may have to do further adjustments to get all four correct.

Article: Creality Ender 3 Bed Leveling – All You Need to Know.

Download

Download

Download

Download

Download

Download

Download

Download

Download

Customer Reviews

Based on 35 reviews

77%

(27)

17%

(6)

Write A Review

Ask A Question

Reviews (35) Questions (5)$ USD

$ USD

ADD TO CART BUY IT NOW

Write a review

Ask a Question

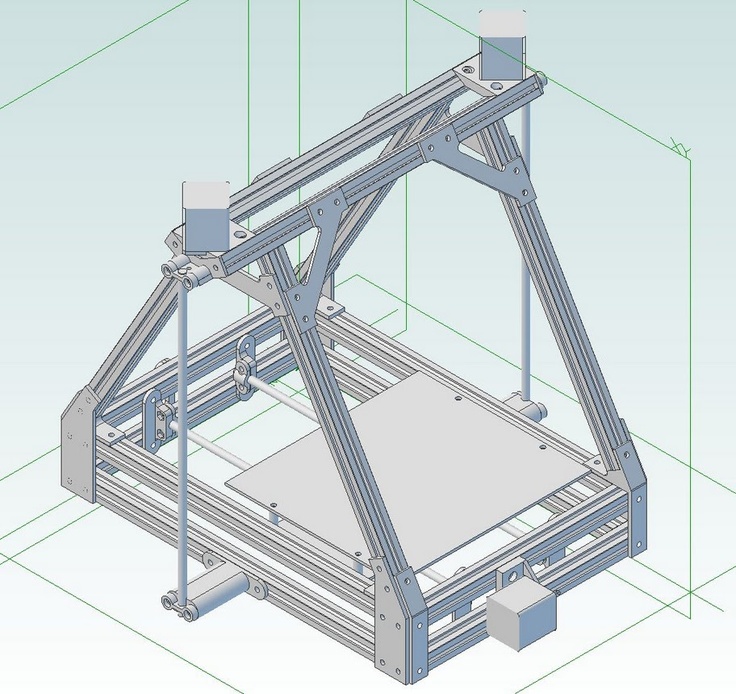

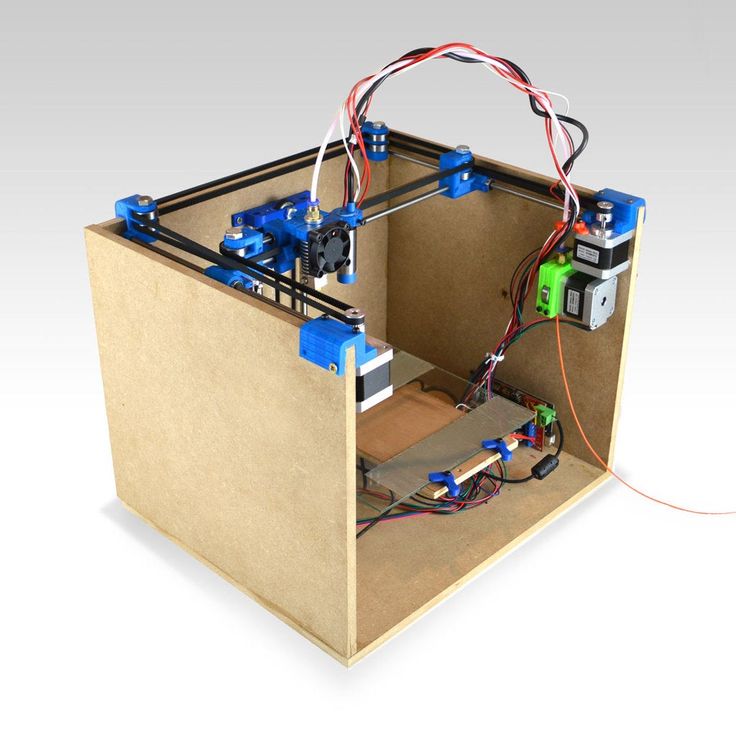

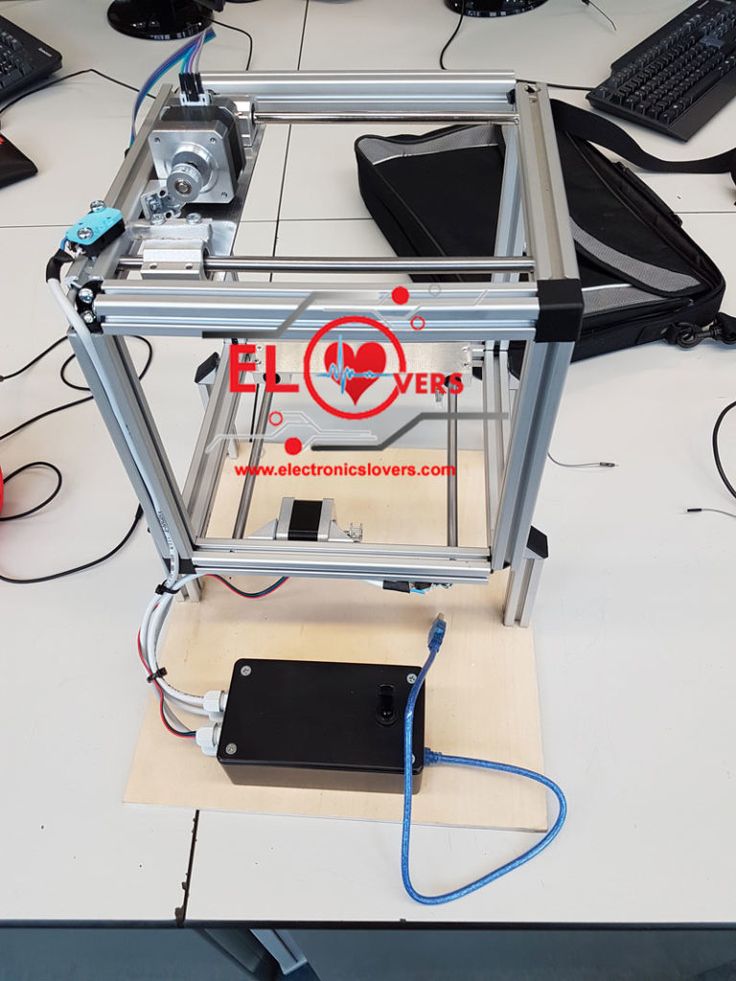

DIY 3D Printer Core XY 310*310 mm

Hi Everyone.

As you know, there are unfortunately no perfect printers in China.

Prush-like drygosts are cheap, but slow at the same time.

Core XY - more interesting, but low-quality components are also used.

Therefore, I decided to assemble my own printer and immediately say is not for sale.

I just wanted to prove to myself that even a humanist is able to develop and assemble a good enough apparatus. nine0003

And he started his journey with the purchase of quality components:

In the Autodesk Inventor program, he developed his version of the printer completely from scratch.

And then he used the services of a company for cutting machine profiles.

With the help of corners 2040, I fastened the profiles together and, by the way, very reliably and evenly

Next I decided to assemble the table on profiles and corners, but in the end I will abandon this idea in favor of the finished version. nine0003

I installed the sfu1204 ballscrew and the table itself on 12mm linear shafts with flange bearings, while the motor uses two 48x, which will eventually be synchronized with each other.

I abandoned the idea with profiles on the table in favor of the usual corners 2040, they turned out to be more convenient for installing the table and at the same time quite rigid due to the rib

This decision fully justified itself.

The motors along the z axis were mounted on aluminum plates 40mm wide and 8mm thick, and the shafts were fixed with shf clamps

The design turned out to be very successful and RELIABLE.

Moving on to the installation of Kinematics

From aluminum strips 40mm wide and 8mm thick, I cut out holders for motors of the XY axes, as well as holders for carriages and pulleys.

As a result, I had to drill, saw, cut, plan, grind and all this on the BALCONY of the apartment, which is not very good, so in the future I will leave this process in favor of the finished version

After all the manipulations and assembly, I measured the weight of the portal without the hot end, which was 650 grams, which is not much.

Then proceeded to installation on the frame

On the same corners of 2040, installed Mosquito hotend with airflow

Now it remains to connect the electronics, since I have two motors along the z axis, I decided to connect them Consistently:

I decided to test 8 liter bottle of water

Test passed without any problems

To control printers, I used an SKR1.3 motherboard with TMC2208 drivers and a TFT V2.0 screen, and this system will be powered by two Minvil 15 amp-24v power supplies.

One PSU is used for motherboard, hot end, fans and lighting.

And the second power supply through the mosfet supplies voltage to the heating table 310 * 310 for 24 volts0003

Initially I installed a Bowden system with a BMG feeder, but then I will replace it with a direct

I launched a test bench boat and I liked everything

I tested it with a Battle, with a speed of 120 mm / s, jerky 20, acceleration of 3000 mm / s2

3

I added a little more

I was satisfied with the print quality at different speeds, but at the maximum the airflow with the PLA could not cope anymore

EVEN COMPARED WITH THE ENDER))

On this it would be possible to complete the project, but as it turned out. Many viewers do not have the ability to saw and drill on their balcony, and this assembly option is completely unsuitable for the majority. nine0003

Many viewers do not have the ability to saw and drill on their balcony, and this assembly option is completely unsuitable for the majority. nine0003

I decided to meet my viewers and subscribers of my YouTube channel ChuchaTV and designed Samosbor ALL INCLUSIVE, which does not require the use of improvised materials and special tools.

In other words, a full-fledged Kit Kit, like from China, but with high-quality components.

I prepared a package with a file for laser cutting, bending, painting and engraving and found companies that did all these operations for me. nine0003

Mounting axle carriages and motors made of 4mm steel with subsequent painting

Table and x-axis carriage made of the same metal but 2mm thick Body sheathed with 1 mm sheet with subsequent flexible, painting and engraving

9002 All holes and the cutouts fit just perfect during assembly, I did not regret the money spent on laser cutting.

The table frame turned out to be ideal both in geometry and in strength and rigidity

Direct weight with MGN carriage 12 amounted to 350 grams

Having figured out the mechanics, I decided to install all the panels and corresponding elements

on the sides of two fans of 80mm, since more in size in size. won't get in. On the one hand there is blowing in, and on the other hand blowing out, for ventilation of the block with electronics

won't get in. On the one hand there is blowing in, and on the other hand blowing out, for ventilation of the block with electronics

I put two filament holders inside

From 5mm acrylic, I cut out the door and the lid exactly to size, and on the self-assembly I printed the curtains and the handle itself a small test of print quality and the result was satisfied

The printer turned out to be very nice)) and practical

Project cost $800, although I bought most of the parts on sale days in China.

I am very pleased with the build quality and operation of the printer, but most importantly, I was able to do it without outside help, despite criticism and negativity addressed to me.

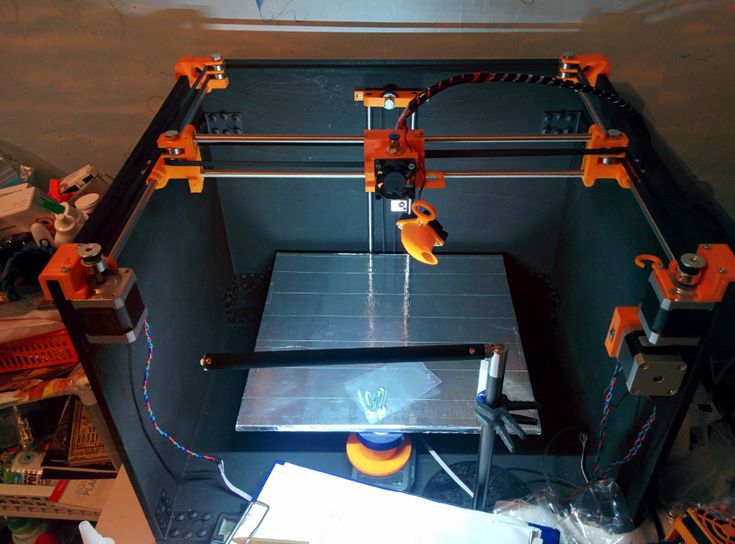

Homemade 3D printer

Skip to content

Admin Electronics

You can buy a ready-made 3D printer with free shipping in this Chinese store. Radio components, arduino at this link. nine0003

Radio components, arduino at this link. nine0003

Contents

- Is it possible to make a 3D printer with your own hands?

- How to build a 3D printer from scratch | 3D printing from scratch

- 3D printer from plywood

- 3D printer design

- Electronics

- Table for 3D printer

Is it possible to make a 3D printer with your own hands?

How to build a 3D printer from scratch | 3D printing from scratch

3dprintingfromscratch.com

If you are reading this article, it means that you have probably decided to join the community of 3D printing enthusiasts and learn more about 3D printers, or perhaps you already have some experience in this and are ready to try to create your own. 3D printer. printer from scratch. nine0003

Items for inventors Store link.

In this article you will find a general idea of how you can create 3D printers, as well as links to really useful resources where you can find more detailed information with a step-by-step description.

There are now a large number of 3d printers on the Internet, already assembled and ready to print immediately after unpacking them from the box, of course, you also need buy filament for 3d printer . Keep in mind that not all 3D printers can use the same types of filament, so please read the instructions before purchasing.

DIY electronics in Chinese store.

But for some people who like to do something new with their hands, it might be more interesting to build their own 3d printer from scratch . Based on our research, the 3D printing community is filled with many enthusiasts, so-called do-it-yourselfers, who are passionate about building 3D printers literally from scratch. nine0003

You can find many examples of how to build a 3d printer on the RepRap website, but we also want to cover some of the more important steps to give you a general idea of what to expect if you do decide to make your own printer.

The first step is to find and buy a 3D printer kit. Kits usually contain most of the parts needed to assemble a printer and can be divided into two main types:

Scratch Built 9 3D Printer0228 - This kit is for those who prefer to build things from scratch or in other words go the DIY RepRap route. In addition to some significant advantages, this approach also has its drawbacks. In theory, this could save you some money, and since you're building it from scratch, you'll know all the nuts and bolts in it by the time you can use it and successfully print your first object. The main disadvantage of this method is time. It literally takes a long time to sort through all those hundreds of bolts, wires, belts and more. In the end you still have to choose and buy or build a controller board, but it depends on your skill level. nine0003 3D printer - This type of kit is good if you want to save money and at the same time not deal with all the problems described in the first type of kit. The next step is to define the design of your 3D printer. In my humble opinion, most DIY 3D printers don't have very exciting and futuristic designs compared to MakerBot and other brands. But it's also a matter of taste, for some people the design is not very important. Once you've purchased your 3D printing kit and selected a design, you can start building the most fun and time-consuming part - building your own 3D printer. Get ready for sleepless nights and lots of fun. Perhaps you will come up with something new and present your results to the RepRap community. nine0003 When the 3d printer hardware is ready, you also need to add the software component. Finally, you can 3d print your first object! If you don't have anything to print, you can find a wide variety of items on dedicated marketplaces like Shapeways, Thingiverse, and more. Before printing, make sure the object you want to 3d print is the correct size and fits on the printer frame. nine0003 First, see how this printer works Now in detail how the device was assembled Recently, the author of the Yar channel promised to show in detail the design of his 3d printer and tell where you can get components for it. Today it will not be possible to make a video on how to build a 3d printer from start to finish, because the printer is already ready. But maybe in the near future a video will appear on the channel on how to make a 3d printer from wood from scratch. Basically, the printer is made of wood, for its construction a single board was used, which the author had. He doesn't have a circular, so the board isn't loosened narrower, it's so big and heavy. In order to assemble the frame, I sawed the board into several parts, glued it here, twisted it with self-tapping screws here, and this made up the frame design of this printer. The board is thick, so stiffness with a margin. Homemade 3D printer The carriages are also driven by motors from scanners, with native gearboxes, with native belts. For some reason, other printers have two motors. But the master decided that there was no difficulty in using the belt. It’s not even clear why they make two motors. nine0283 In order to align the axis, I used paper pads. That is, a lot of small paper sheets that I put under the fulcrum of the guides in order to bring them in parallel with each other. They are, as already shown, right here, right here, right here. Homemade electronics. It is definitely better to buy it, because in the end I got a lot of crap. But that's not the point. The bottom line is that the electronics are made by Arduino Uno Chinese. Here, with a margin, are field-effect transistors. Here are two even with a radiator. Because before it was already at 200 watts. And, of course, four drivers are worth it. Arduino can be bought at this link. nine0003 There is currently no extruder on the 3D printer, or rather, its cold end. There is only the nozzle itself with a heating block. All this is because he started reworking it for a lighter motor. Initially, this motor was here, everything worked perfectly. To be able to fly them faster, you need to reduce weight. Plus, I freed this motor for one of the axles, and bought another one for it. All this is done in order to make the printer a little faster in the future. In the previous video you could see another table, it is quite large and made only of glass. But this is a big problem, because the glass cracks from strong uneven heating. So I had to give up this table. The second table is much smaller, because there was just such a large piece of metal. Already made under replaceable glass. It can be attached here with clothespins. By the way, it also cracked, it was originally in size. nine0003 Standard 5 watt resistances are screwed to this sheet of steel. One of the serious shortcomings of this 3D printer is the lack of ends. That is, the axes do not know where the beginning is, and you have to set them manually.  Many manufacturers sell such kits with "easy to assemble" instructions. I doubt it will be as easy as putting together an IKEA chair, so you still have to have a mechanical tilt and be able to understand the basic geometry. Some of these kits do not contain all the parts, and you may need to buy something extra. nine0003

Many manufacturers sell such kits with "easy to assemble" instructions. I doubt it will be as easy as putting together an IKEA chair, so you still have to have a mechanical tilt and be able to understand the basic geometry. Some of these kits do not contain all the parts, and you may need to buy something extra. nine0003  It mainly performs the following functions: allows you to view and modify 3D graphics objects, as well as convert 3D images into instructions that a 3D printer can understand.

It mainly performs the following functions: allows you to view and modify 3D graphics objects, as well as convert 3D images into instructions that a 3D printer can understand. Plywood 3D printer

Because it will be redone. nine0003

Construction of the 3D printer

Parts from old scanners are used for axes. More precisely, for two axes of three 3d printers. That is, there are two guides for the Z axis. And for the X axis, two guides. nine0283 The Y axis hangs on an aluminum profile, quite thick too. And homemade carriages from ordinary ball bearings. This is what was in the garage just.

In fact, this part should have been used on the Z axis, this will be taken into account when reworking.  Here, however, I had to use a gearbox from one scanner, and a motor from another, so that the movement of this axis coincided in steps with the Y axis.

Here, however, I had to use a gearbox from one scanner, and a motor from another, so that the movement of this axis coincided in steps with the Y axis.

The motor from the scanner is also on the Z axis. It was unipolar, that is, five wires sticking out of it, now four wires are sticking out of it. To do this, I had to cut the jumper there. With a converted gearbox that has the ability to turn just such an M5 stud. And there are two of these pins: one on the right side, the other on the left. They are tied together with a belt.

These pads are also used for rough adjustment of the table.

Electronics

Speaking of speeds. Scanner motors for 12 V allow you to reliably have a speed of about 25 millimeters per second. At higher speeds, they may begin to lose steps. nine0003

Table for 3D printer

Made from scanner glass with steel tie wire underneath. And on the other hand, it is to some extent insulated with glass tape.

It is held on the carriage with the help of these trimming bolts 3 pcs., with nuts screwed on them. They sit on the thread lock, spinning quite tight. Due to this, they can be adjusted in relation to the axes of the printer.

This is one of the few parts printed on this printer. This is the Z axis bearing support. Why did the craftsman print it, because the one that was made of wood was quite skewed. Due to which, on the parts that were printed on this printer, a noticeable unevenness of the layers appeared. That is, with layers 0.1 mm or 0.2 mm thick, they looked like they were about 0.7 thick. And the bonding strength between the layers was low. nine0003

This is the Z axis bearing support. Why did the craftsman print it, because the one that was made of wood was quite skewed. Due to which, on the parts that were printed on this printer, a noticeable unevenness of the layers appeared. That is, with layers 0.1 mm or 0.2 mm thick, they looked like they were about 0.7 thick. And the bonding strength between the layers was low. nine0003

If this does not cause any problems with the X, Y axis, and the author of the model probably did not even make endings on them. For the reason that you can manually set the center of the printer to any place, and thus print several parts in succession from one G-code. But setting the Z-axis manually is very inconvenient. This takes about 5 minutes each time before each print. nine0283 Another disadvantage that is common to many printers is that it is open.

Learn more