Wideboy 3d printer

Widebody best STL files for 3D printing・Cults

SPOILER DS2 - DIFFERENT MOUNT OPTIONS 1:24 SCALE MODELS

€4.26

Spoiler DS1 - different mount options 1:24 scale models

€4.26

DODGE CHARGER SRT HELLCAT WIDEBODY 2020 PRINTABLE CAR BODY

€5.67

DODGE CHARGER SRT HELLCAT WIDEBODY 2020 PRINTABLE CAR IN SEPARATE PARTS

€10.21

Dodge Charger SRT Hellcat Widebody 2020 Printable Car

€12.50

Tamiya 1/24 Supra Custom Wide Body Kit

€14 -10% €12.60

Lamborghini Gallardo Liberty Walk kit

€2.35

Ferrari F430 Liberty Walk Body Kit

€47. 05

HGK wide body for Supra a90

€13.10

Audi 5 Liberty Walk - Style Bodykit

€12

AUDI Q8 Prior Design Style Bodykit

€15

BMW M4 Liberty Walk Style Bodykit Printable

€20

Rear Mounted Turbos with rear panels For 350Z Tamiya 1/24 MODELKIT

€7.34

Universal fender flares for 1:24 cale model cars

€4.26

2010 GT500 Widebody kit 2- 13SEPT22-02

€9.43

Nissan S15 widebody

€3

CUSTOM HOOD FOR MUSTANG BOSS 1970 REVELL 1-24TH

€6.40

1/24 R32 Skyline GTR Widebody kit

€11. 46

46

PRO TOURING MCS Low-Pro - Wide Body for 1960 Fleetside

€12.22

Sakura d5 drift chassis 10th rims/ Calipers/ rotors

€1

Custom Widebody C3 Vette

Free

Window Louver for CAMARO 69 Revell 1-25th Modelkit

€4.52

Toyota Supra A90 StreetHunter Wide body Transkit 1\24 - 1\10

€7.28

1/12 scale bmw 2002 group 5 widebody

€10

wide e36 keychain

Free

Wide body STREETHUNTER

€13.10

Bodykit for Mustang BOSS 1970 Revell 1-24th

€11.86

PRO HOOD for Camaro 69 Revell 1-25th

€6. 40

40

Custom HOOD for Camaro 69 Revell 1-25th

€6.45

Bodykit for Camaro 69 Revell 1-25th

€11.76

GOLF 1 BB01 BODYKIT For REVELL 1-24th scale

€11.29

MAZDA MIATA ROLLCAGE For TAMIYA 1/24 MODELKIT

€3.94

T1 R - PANEL BUS - Custom body and chassis

€11.29

Ford Capri wide body display

€4.99

MST Insert Yaris (extreme offset)

€10

1/24 Scale Universal Fender ( 34 mm ) Widebody - Body kit

€1.20

DODGE CHARGER (2006-2010) BODY KIT - 31dec-01

€9.29

TC2000 Wide body kit for model car - custom diecast - RC - Slot

€1. 95

95

BRONCO ACCESSORIES - 01JAN22-01

€9.29

*ON SALE* DODGE CHARGER (2011-2014) BODY KIT - 31dec-01

€6.53

1967 Camaro body kit - 27DEC21 -01

€9.17

CUSTOM M1 MODELKIT FULL KIT

€13.37

F40 Widebody kit - 16dec21 -01

€7.99

10TH SCALE CRAWLER TRAILER

€2

1970 CORVETTE BODY KIT - 28nov-01

€9.29

Universal wheel flares 26nov-WF03

€6.23

Project Tofu 1/24 FULL MODELKIT

€12.35

1969 MUSTANG BODY KIT - 20nov-01

€9.14

Makism3D Wideboy 3D Printers – WesleyTech.

com

comHardware / nob

- by Wes Novack - Leave a Comment

This is a Sponsored post written by me on behalf of Makism for SocialSpark. All opinions are 100% mine.

Makism3D Wideboy 3D Printers

Makism 3D Corp, a company based out of Cambridge in the United Kingdom, is promoting their new Wideboy™ family of 3D printers to the professional and consumer markets. With the Wideboy™ family of 3D printers, Makism3D aims to provide an affordable solution for both organizations and individuals to create high-quality 3D printed prototypes, parts and objects, all with high precision.

So what is 3D printing and what can it do? Good ole Wikipedia tells us that "Additive manufacturing or 3D printing[1] is a process of making a three-dimensional solid object of virtually any shape from a digital model. 3D printing is achieved using an additive process, where successive layers of material are laid down in different shapes. [2] 3D printing is also considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes)."

[2] 3D printing is also considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes)."

In other words, with a 3D printer, you can turn a concept (a computer generated 3D model) into a real world, physical object. Even highly complex objects, such as a working hand gun, can be manufactured using 3D printers. Controversy erupted earlier this year when Cody Wilson and his company Defense Distributed released the CAD diagrams for a 3D printed hand gun. Within days, the US Government forced the company to remove the blueprints from their website, but the cat was out of the bag. The design files spread like wildfire across the internet and were distributed across the globe. This illustrates just how powerful and "game changing" low cost 3D printers will be to our world.

So what makes Makism 3D Printers different than other 3D printers? Let's see what the company has to say about it themselves.

"Our Wideboy™ printers offer a minimalist yet elegant design that fits any office or professional space. They feature high quality British/German engineered components, and unlike competitor 3D printers, they come ready to use directly out-of-the-box.

Dual all-metal extruders and a temperature stabilized build chamber permits the Wideboy family of printers to print with exotic materials such as nylon, polycarbonate and a wide range of support materials. The end result is a safer, more user-friendly 3D printer with a high level of print consistency and operational stability."

So there you have it! The Wideboy™ 3D printers are ready to be used straight out of the box, unlike their competitors. They also support 3D printing with a wider range of build materials, which allows for more flexibility and even more types of product printing.

I would love to have a 3D printer to experiment with. I could fix broken items around the house by printing a replacement part. I could create new toys and games for my boys to play with. If I was missing a tool that I needed for a specific job, I could just print it! Try to imagine the crazy art projects that could stem from 3D printing. The project possibilities are endless!

I could create new toys and games for my boys to play with. If I was missing a tool that I needed for a specific job, I could just print it! Try to imagine the crazy art projects that could stem from 3D printing. The project possibilities are endless!

To learn more about 3D printers, visit the Makism 3D Products page. If you enjoyed this post, please share it on Facebook, Twitter or your preferred social network. Thanks for reading!

About Wes Novack

Wesley Novack is a Technologist working in the software industry, with extensive experience building and managing highly available applications, services, and systems in the public cloud. He has a breadth of experience in online publishing, the consumer electronics industry, and building internet communities. Wes enjoys hanging with his family, skateboarding, hiking, the vegan lifestyle, and a good cup of tea. You can find him on Twitter @WesleyTech.

View all posts by Wes Novack →

$250 room-sized 3D printer / Habr

Why not make a 3D printer out of a garage or an empty room? An open source project from Sweden makes this possible for $250. Who is less?

Who is less?

Article by Glenn McDonald from Seeker.com translated for you by Top 3D Shop .

Swedish inventor Thorbjørn Ludwigsen has spent the last three years developing a new kind of large-format 3D printer that can create large objects. His invention can print furniture right in the room - it's very easy and relatively cheap. Ludwigsen's invention, the "Hangprinter", uses a system of wall, floor, and ceiling-mounted cables and computer-controlled drives on a print head unit. The device uses the room itself as a 3D printer case. nine0011

Hangprinter is not the first large format 3D printing system, but it is unique. First, it's cheap. All hardware and firmware components can be purchased for approximately $250. In addition, it is an open project, which means that any user can improve the system and use third-party updates. Finally, Hangprinter is self-sufficient - most of the components necessary for its creation can be printed by it.

It all adds up to a system that Ludwigsen hopes will open up the potential of 3D printing to more people. The developer believes that 3D printing should not be an expensive perk. In his opinion, Hangprinter is not only a technical, but also a social experiment. nine0011

“In particular, I want 3D printing to avoid the fate of 2D printing, where machines are programmed to self-destruct after a certain number of objects are made. The best chance to do this is not only to use open source, but also to create self-replicating hardware. Hangprinter manufactures most of the necessary elements for itself.”

- he said.

The Hangprinter project is part of a larger initiative in the 3D printing community known as RepRap. All developers try to optimize prototyping processes as much as possible. The idea is to spread 3D printing technology to low- and middle-income people through open design solutions and self-replicating mechanisms. nine0011

“Open technology can empower middle- and low-income families, and I grew up in one of those families,” said Ludwigsen.

The innovator is taking this project very seriously. As a physics student at Umeå University in Sweden, he recently completed his master's thesis on the subject.

In the Hangprinter video, Ludwigsen showed how a 3D printer creates a relatively simple and functional object - a lampshade. nine0011

The Hangmaker has also been involved in more artistic projects - Ludwigsen recently used the system to assemble a five-foot sculpture of the Tower of Babel.

Hangmaker prints the Tower of Babel sculpture. Author: Thorbjorn Ludwigsen.

As the device is optimized, Ludwigsen hopes the Hangprinter will become versatile enough to print furniture, tools and possibly fully functional machines with moving parts. He also hopes to raise money through crowdfunding to continue research and development in this direction.

Although the current version of Hangprinter is fully functional, there are many upgrades ahead of the device, according to its author. In fact, improvements are another reason why the author decided to develop the project as open-source.

In fact, improvements are another reason why the author decided to develop the project as open-source.

“It's a flexible manufacturing technique, so it will be useful in situations I can't foresee. Some of them can be very important/cool/useful. I would not want to interfere with important and useful discoveries.0010 ,

- he said.

Share your opinion in the comments.

Large Format Raise3D RMF500 for 3D Printing with Carbon Fiber Reinforced Materials

Last fall, the well-known Chinese 3D printer manufacturer Raise3D announced a new 3D printer for small-scale production in the industrial sector - RMF500 . The unique feature of the novelty is combination of the ability to print with carbon fiber reinforced material (colloquially carbon fiber), wide format and affordability .

We all know that high technology is becoming more accessible every day, and the RMF500 is a prime example of this. There have been systems on the 3D printing market for several years that print carbon fiber composites of similar quality, but, unfortunately, they are not available to all companies due to the very high cost and supply problems. For example, such professional 3D printers are produced by the American company Stratasys - Fortus 450mc, but they are equipped with less technological features and are much more expensive. nine0011

Let's take a closer look at what the RMF500 is and how it differs from other 3D printers.

The RMF500 is specifically designed for printing complex parts with high durability. It will enable 3D printing companies to expand their product portfolio with carbon fiber and fiberglass end parts. Both materials specially developed by Raise3D, such as PA12 CF, and materials from other manufacturers approved by Raise3D under the Open Filament Program (OFP) will work. Parts made of carbon and fiberglass are more rigid, durable, resistant to heat and shock than parts made of other plastics. For carbon and fiberglass printing, the RMF500 uses silicon carbide nozzles with a hardness of more than 60 HRC. nine0011

PA12 CF filament is the result of a long-term development by Raise3D engineers. This is a carbon fiber reinforced filament with increased stiffness and reduced shrinkage and does not require a thermostatic print chamber. The parts obtained from it are light and extremely durable, sometimes they can even be used instead of metal. In addition, the company has developed glass-filled filament PPA GF specifically for the RMF500 and plans to release PET-CF, ASA-GF, PPSU-GF and PP plastics for medical use. Raise3D promises that all fiber reinforced plastics will be competitively priced. nine0011

This is a carbon fiber reinforced filament with increased stiffness and reduced shrinkage and does not require a thermostatic print chamber. The parts obtained from it are light and extremely durable, sometimes they can even be used instead of metal. In addition, the company has developed glass-filled filament PPA GF specifically for the RMF500 and plans to release PET-CF, ASA-GF, PPSU-GF and PP plastics for medical use. Raise3D promises that all fiber reinforced plastics will be competitively priced. nine0011

The RMF500 has a huge building area 500x500x500 mm. The size of the build area matters in the production of large parts and small-scale production. For comparison, the print area of the Fortus 450mc is 406x355x406mm.

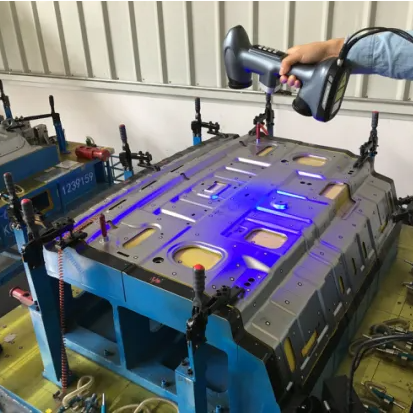

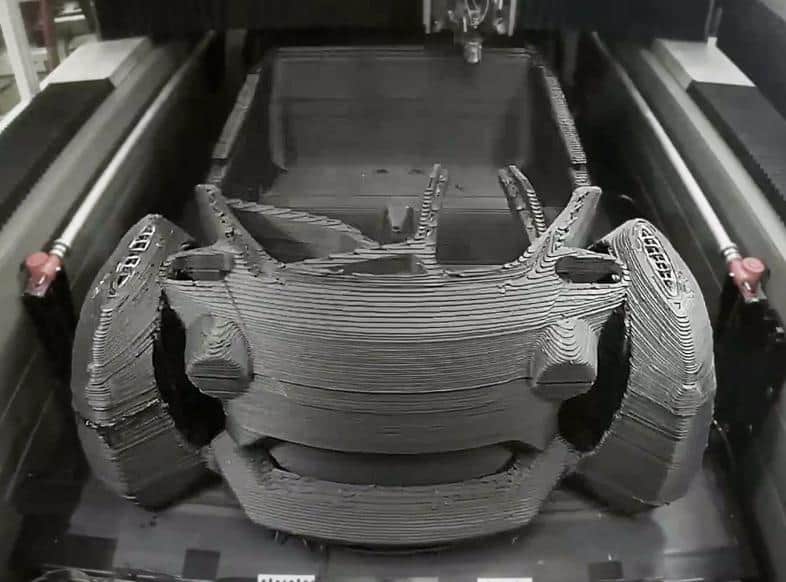

In the photo: printing a large model with carbon fiber in the RMF500 3D printer from Raise3D.

Repeatability and print speed are very important for low volume production. The maximum print speed of the RMF500, according to the manufacturer, can reach 300 mm/s. Positioning accuracy along the XY axis - 1 micron, along the Z axis - 0.09765 microns.

Positioning accuracy along the XY axis - 1 micron, along the Z axis - 0.09765 microns.

Synchronous feedback control with 1 µm accuracy reduces speed fluctuations as motor load changes, further improving accuracy. Stability and repeatability of printing has long been a hallmark of Raise3D printers. The FFF technology on which this 3D printer is based allows the production of parts with a high degree of repeatability, high positioning accuracy and uniform extrusion. The RMF500 can quickly print large batches of identical parts. nine0011

In the photo: production of lots from a large number of parts on the RMF500.

The printer has a printing system with two independent IDEX extruders. It allows you to print with one or two extruders at once. The RMF500 can run two jobs at the same time, further increasing productivity and task speed. The extruders are manufactured using high temperature alloys and industrial ceramic composite materials. These characteristics provide stable and high extrusion speed up to 500 g/h. nine0011

nine0011

The RMF500 has a strong design . The one-piece frame is made of hardened steel. Stainless steel linear guides have a design load of approx. 100 kg. The bearing of the linear guides has minimal backlash and does not require frequent maintenance.

An important detail - Raise3D developed a special support material for printing with reinforced plastic PA12 CF, which can be easily detached.

Pictured: Parts printed on the RMF500 with PA12 CF filament with special proprietary support. nine0010

The RMF500 is equipped with four large compartments for plastic spools. Switching between the main and auxiliary compartments occurs automatically. This feature reduces the amount of time spent threading the filament. The humidity control system keeps the relative humidity in the chamber below 5%, preventing humid air from entering from outside.

What else is there in the RMF500 from nice additional options. The front of the printer has a large 13. 3-inch touch screen. Supports connection, management and printing via Wi-Fi and LAN. There is a reliable auto-calibration system from Raise3D. nine0011

3-inch touch screen. Supports connection, management and printing via Wi-Fi and LAN. There is a reliable auto-calibration system from Raise3D. nine0011

Carbon fiber printed parts are strong enough to be used in the automotive and aerospace industries. Of course, they will not replace functional parts that have a special load, but their scope can be very wide. Raise3D has already presented the results of the first RMF500 printing and its application.

Pictured: Functional parts, accessory tools and fixtures, car décor printed on the RMF500. nine0010

Pictured: Functional parts, accessories and aerospace prototype printed on the RMF500.

In the photo: on the left is a prototype of the hinged window mechanism (details are printed with metal filament and carbon fiber), on the right is a carbon fiber fixture. Carbon parts printed on RMF500, metal parts printed on Metalfuse. Printing with fiber-filled plastics does not require a heated chamber, peak power consumption is less than 3 kW.