Polisher 3d printer

Polymaker Polysher - 3D Print Finishing Machine

- Home

- Store

- 3D Printer Filament

- Polymaker Filament

- Polymaker Polysher and PolySmooth PVB Filament

The Polysher by Polymaker is a desktop-sized solution that can streamline your 3D print post-processing efforts by removing layer lines using alcohol vaporization. Employing Polymaker’s Layer-Free technology, the Polysher creates a fine mist of isopropyl alcohol around your 3D print, which smooths the model and virtually removes visible layer lines. This leaves your 3D prints with a smooth finish every time.

Compatible only with Polymaker’s PolySmooth Filament

*Isopropyl alcohol not included

20% off - use code BESTDEALS during checkout - offer ends12/31/2022

Remove from wishlist Add to wishlist loading. ..

Product No. M-MK8-EQZZ

| List Price: | $299.00 |

|---|---|

| Price: | $299.00 |

| Price: | $... |

| Order Now: | Ships calculating... Free U.S. Shipping |

EASY PRINT, EASY POLISH

The Polymaker Polysher, along with PolySmooth 3D printing filament, brings you a simple experience that creates a low barrier for entry into the world of post-processing 3D prints. Place a model 3D printed with Polymaker’s PolySmooth PVB-based filament inside the Polysher, set the timer, and watch as mist fills the chamber and your 3D print is smoothed! The Polysher will fill with vaporized isopropyl alcohol and completely cover the part. The polishing process usually takes a half hour to an hour, depending on the size of the 3D print you are smoothing. The Polymaker Polysher automatically rotates your part to ensure an even polish, and the textured surface for your 3D print is raised to make ensure the vapor gets underneath your 3D print as well.

Need PolySmooth filament? Buy yours today!

TECHNICAL SPECIFICATIONS

- Compatible Materials: Polymaker PolySmooth ONLY - the isopropyl alcohol has no effect on PLA.

- Polishing Liquid: Isopropyl Alcohol, 70% or higher (90% or higher recommended)

- Polishing Time: 20-40 minutes depending on 3D print size, alcohol concentration, and ambient temperature

- Product Dimensions: 230 x 270 x 370mm

- Maximum Part Size: 150mm diameter x 180mm tall

- Operating Temperature: 15 – 32 °C

- Storage Temperature: 0 – 38 °C

- The Polysher is constructed from ABS, and so attempting to use acetone with the Polysher to smooth ABS parts will destroy the machine - you have been warned.

Leia would have left him in if he looked this good!

The left part is fresh off the printer, the right is after 25 minutes in the Polysher with 90% Isopropyl Alcohol

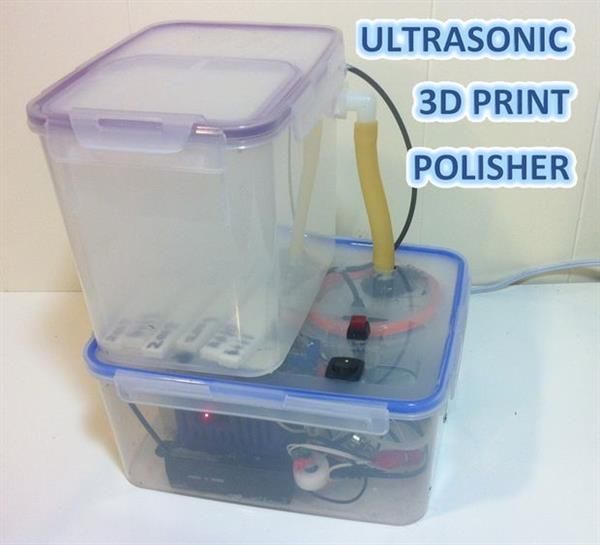

TOPPOSH Nebulizer3D print polisher - Geeky Gadgets

By Julian Horsey

3D printers who wish to polish their PLA and ABS 3D printing models to a glossy finish may be interested in a new 3D print polisher called TOPPOSH. Featuring a 10 minutes quick polishing cycle, uniform heating and compatibility with both ABS and PLA printing filaments the Nebulizer 3D print polisher is capable of polishing both simple and complex structures as well as carrying out boat processing.

Featuring a 10 minutes quick polishing cycle, uniform heating and compatibility with both ABS and PLA printing filaments the Nebulizer 3D print polisher is capable of polishing both simple and complex structures as well as carrying out boat processing.

Backer early bird pledges are now available for the interesting project from roughly $159 or £118 (depending on current exchange rates).

“To ensure an improved post-processing experience for 3D printing enthusiasts, TOPPOSH developed a special solvent to achieve quick and effective PLA polishing. This solvent is a blend of acetone, alkanes, and various stabilizers and can soften both PLA and ABS without deforming the models. By using heat as a catalyst, the layer lines will melt and quickly merge into a perfectly smooth surface. Models polished with TOPPOSH eliminate layer lines while preserving all of the model’s intricate details. TOPPOSH will not damage any print details and leaves your designs looking smooth and shiny. ”

”

Assuming that the TOPPOSH funding campaign successfully raises its required pledge goal and production progresses smoothly, worldwide shipping is expected to take place sometime around December 2022. To learn more about the TOPPOSH 3D print polisher project play the promotional video below.

“With TOPPOSH, polishing 3D prints is more efficient than ever before. A longer polishing time is recommended for larger models, but generally not more than 20 minutes to avoid over polishing. Although solvent steam provides more uniform polishing results than soaking, the vapor created by heating alone tends to cause uneven results. Therefore, we added a nebulizer to the lid to spray the solvent mist from above. “

“The design of the model tray is also a great help when using TOPPOSH with some complex designs. By using the tray, direct contact can be avoided with the solvent or the surface of the model, further protecting the model. For further versatility there are brackets on either side of the tray, allowing the model to be suspended with fishing line or wire for a better finish from top to bottom. ”

”

For a complete list of all available pledge options, stretch goals, extra media and detailed specs for the 3D print polisher, jump over to the official TOPPOSH crowd funding campaign page by checking out the link below.

Source : Kickstarter

Filed Under: Hardware

Latest Geeky Gadgets Deals

Disclosure: Some of our articles include affiliate links. If you buy something through one of these links, Geeky Gadgets may earn an affiliate commission. Learn more.

STL file polisher・3D printer design download・Cults

Coaster

0,58 €

weed

0.62 €

Covid

0.58 €

Weed bowl and cup

0.82 €

weed

0. 58 €

58 €

weed box

0.78 €

MMU Light

1.29 €

Ducati keychain

0.58 €

Best 3D Printer Files in Jewelry Category

Hyena Skull Pendant with Loop

Free

Deer Ring

32.93 €

Deactivated

Golden Ring

14.11 €

Facets Ring - Part 2

4.75 €

US map keychain (separate states)

Free

nine0003 Keychain with cannabis symbol1.25 €

Ring - Face profile

Free

Bestsellers in Jewelry category

Crown of Viserys Targaryen - an accessory corresponding to the series

9,40 €

HORSE

1,50 €

nine0003 What a stupid keychain 2. 05 €

05 €

Power Ranger Communicator

4,70 €

polymer clay cutter 5 size

1.85 €

Llavero pikachu

0.82 €

Graduate Flork

1.64 €

CHRISTMAS 2023

1 €

lord of the rings

1 €

Music box "Anastasia" and jewelry for 3D printing

3 €

CHRISTMAS/WINTER SNOWFLAKES ROLLER PIN stl file

1,63 €

Off-White x Nike Air Jordan 1 Charm

2.15 €

nine0003 Key ring with Guy Fawkes mask1.22 €

Hanger rack with hoops

3 €

heart-shaped web earrings

0. 55 €

55 €

keychains - Star Wars

2.28 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

How 3D printing will change the jewelry industry « Treasures of St.

Petersburg Jewelry Exhibition

Petersburg Jewelry Exhibition

Three-dimensional printing is one of the revolutionary inventions that have become quite widespread in recent years. It can fundamentally change the traditional jewelry industry, and today we will talk about what changes await us in the next five years. nine0006

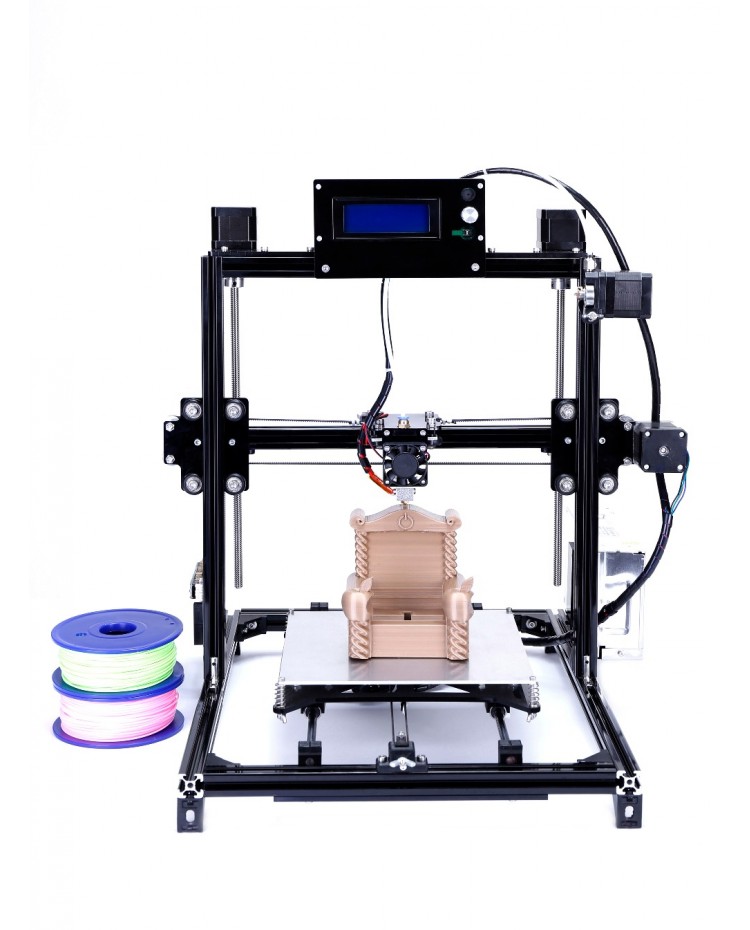

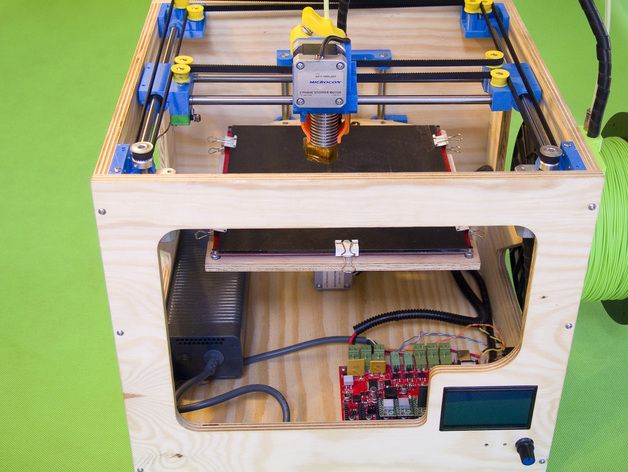

In 1983, American engineer Charles Hull discovered a new printing method that allowed the creation of three-dimensional objects. 3D printers work on the principle of layer-by-layer “growing” of a solid model and form an exact copy of a digital 3D prototype. Unlike a two-dimensional printer that outputs two-dimensional information to a sheet of paper, its three-dimensional counterpart is already capable of outputting information in three dimensions at once, that is, creating three-dimensional physical objects.

3D printing has exploded in the past few years, driven by the mass production of 3D printers at more affordable prices, the development of digital technologies and the expansion of the list of materials used in printing. They say that the third industrial revolution is just around the corner. nine0006

They say that the third industrial revolution is just around the corner. nine0006

Jewelry belongs to the category of products that can be created using 3D printers today. Amazon.com, the number one U.S. online supermarket, already has a section for 3D merchandise, where "printed" jewelry has a whole "shelf" in its own category called "jewellery for those who keep up with fashion."

This is a great opportunity for independent designers looking to tap into a large consumer market. Printing your own designer jewelry is already becoming a fashion trend in the West. nine0006

The list of materials for the production of jewelry using 3D printing is also constantly expanding. For example, New York-based Shapeways, a 3D printing hub for designers and developers, added platinum, 18k gold, 14k rose gold, and 14k white gold to its range of metals that can be used for 3D printing. Today, this company offers the widest selection of materials for 3D printing of jewelry. nine0006

US President Barack Obama, in his 2013 State of the Union address, said that 3D printing has great potential to revolutionize the manufacturing method by which almost everything is made.

What does all this mean for the traditional jewelry industry?

From the point of view of the end user, this is simplicity, convenience and high speed of receiving your order. For example, you have lost one of your earrings and want to order a replacement for the lost one. Using 3D printing, you can simply purchase a file with a three-dimensional model of your earrings (CAD file) and print the missing pair at home on your own 3D printer or contact one of the printing centers. True, if there are stones in the earrings, you will need the help of a jeweler who will install them in the product. nine0006

From a jewelry retailer's point of view, there are also many advantages. First, there is no need to spend money on inventory and its maintenance. It will exist in virtual form, as a catalog of designs and accompanying samples. It will be enough for the seller to stock up on raw materials, materials and computer files to make an order.

High print-to-order speeds mean that the need for stockpiles of finished goods is reduced, so manufacturers can cut costs for warehouse space, storage, and warehousing personnel. nine0006

nine0006

3D printing will allow manufacturers to significantly reduce the cost of production, in particular by reducing labor costs. In other words, instead of jewelry masters, the main work will be done by ... industrial printers. In small-scale and piece production, this can reduce the cost by 2-3 times.

“With our platform, the cost and labor savings are phenomenal. There is no longer a jeweler with a blowtorch on our bench. We enable consumers to create jewelry in real time,” Forbes quotes Eddie Bakhash, CEO of New York-based jewelry company American Pearl. nine0006

American Pearl is one of the pioneers of 3D printing in the jewelry world. The company offers the service of recreating a piece of jewelry from its photograph. First, a 3D computer model of the product is prepared. Then a three-dimensional printer based on it forms an exact copy. The polisher and stone setter complete the process by presenting a sparkling duplicate of the piece to the client. Ideal for restoring lost family values, for example. American Pearl has a patented computer-aided design (CAD) system and a Solidscape T-76 3D printer. nine0006

American Pearl has a patented computer-aided design (CAD) system and a Solidscape T-76 3D printer. nine0006

3D printing has the potential to bring production back to countries that today mostly import goods. The main problem of competitiveness, in particular, of American jewelry manufacturers is the high cost of labor in the United States. They cannot compete with cheap foreign production (read: China, Thailand and India) in the cost of production.

3D printing solves this issue simply - the printer does not need to pay a salary, only the purchase price and materials. nine0006

In addition, there will be localization of production, it will be concentrated closer to the consumer. Hence, the reduction of costs for cargo transportation and all other logistics of finished products. It is likely that the role of large mass production centers will also gradually decline.

Manufacturers, both small and large, will find it much easier to turn ideas into working models and marketable products. The flexibility of 3D printing-based manufacturing will allow production of test batches without the high cost of a new production process. nine0006

The flexibility of 3D printing-based manufacturing will allow production of test batches without the high cost of a new production process. nine0006

Of course, the spread of 3D printing will raise many new questions. What will happen to the jewelry profession? After all, 3D printers will be able to perform many jewelry functions faster and cheaper than a person, while avoiding the mistakes inherent in people.

How will brands protect intellectual property? Xeroxing jewelry from Tiffany, Cartier and other luxury brands from a technological point of view is not difficult based on photographs and promotional products. The answers are yet to be found. nine0006

3D printing opens up new possibilities for the jewelry industry. By incorporating it into the process, manufacturers will be able to reduce production costs, increase production efficiency and flexibility, and offer customers a million options for making jewelry truly personal and unique. In the next 5 years, we will see the rise of new names and designers successfully putting 3D printing to the service of their creative talent.