Make magazine 3d printer review

Make Magazine: Review on Professional 3D Printer

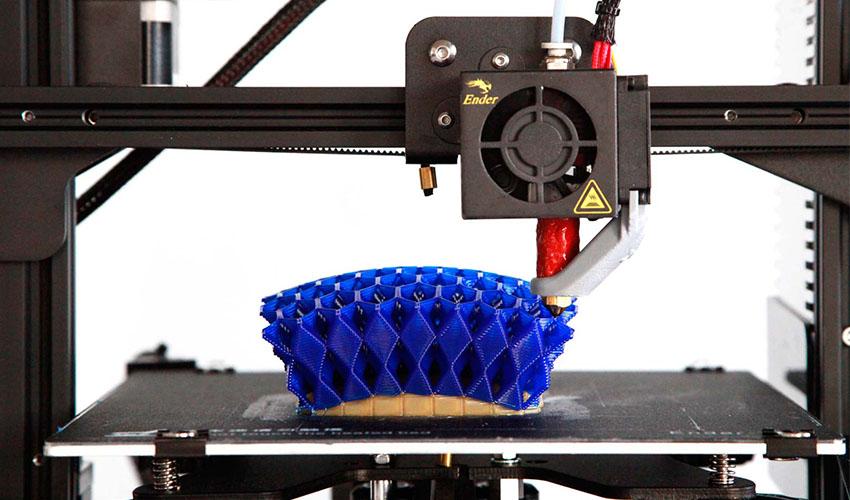

Bolt 3D printer reviewThe Bolt is an advancement in the technology of 3D printing that uses multiple materials in parallel. Manufacturer Leapfrog has developed its own method to take away the unused nozzle when printing with multiple materials.

Admittedly, a 3D printer of 6000 Euro’s exceeds the typical test range of the Make-redaction. That is why few FabLabs will invest in such an expensive machine – let alone private users. The fact that we did try the Leapfrog Bolt has two reasons. On one hand, they developed their very own technique for the machine in order to fix the issue of printing with two materials in parallel. On the other hand, we repeatedly test the Creatr HR and monitor the company and its developments.

The Leapfrog Bolt has a completely enclosed casing. This way, the heat from the heated print bed and the extruders gets outside. An activated carbon filter protects against poisonous fumes, which may arise for instance when printing with ABS.

One thing was clear in the test. You cannot operate larger machines than these because they simply do not fit in the test room they have.

Despite its large interior space, the maximum object size for work pieces at the Bolt is smaller than it may seem at first glance: the height is limited to 20.5 cm; The red bust takes full advantage of this height. The filament leads also need a good piece of height.

The best demo object is this bolt – the right one from red PLA, left of flexible material. You can print both of thse in sync mode, in one go: each of the print heads prints one piece on one half of the bed.

These two replicas of an object from the British Museum have been printed in mirror mode…

… and it is sufficient to prepare a single print file and then select the appropriate mode on the display on the printer. Instead of a mirrored copy, the change to the sync mode for a non-mirrored character would have been possible with a single touch.

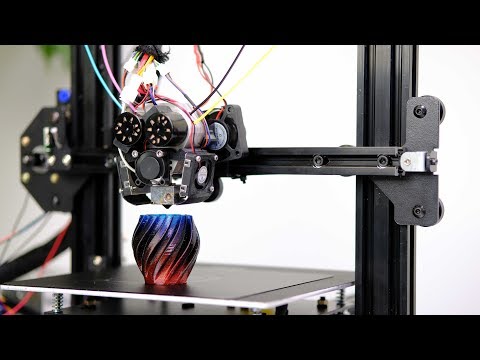

The two print heads can, of course, work alternating on an object. In this mobile robot, the red parts are made from Leapfrog PLA while the orange colors are printed from the filament of Avistron. The video shows how the head changes between the two materials.

The two heads sit on common axes, but separate belts drive them. The Y and Z positions of both are therefore identical for both, in the X direction they are independent.

The Leapfrog Bolt is fully network-capable with WLAN access, thanks to a Raspberry 3 under the hood. It automatically obtains firmware updates through the network. Using a built-in camera, you can keep track of the progress of long prints and stop the machine from afar in the event of an incident.

HeavyIn order to be able to test the machine at all, the c’t editors kindly let us into their printer test lab, but also there we nearly exceeded the size of the test booths: the Bolt measures 72. 3 cm × 83.1 cm × 80.1 on the outside; the device weighs more than 60 kilos and could only be lifted on the table with combined forces. You can comfortably access the machine via large touch screen. Inside is a Raspberry Pi 3, which also brings WLAN. An update during the test period came automatically via LAN connection to the device. It updates by itself and there is no need for you to connect anything to the computer. You can handle all maintenance procedures as well as material changes by only using your finger tips. There is a possibility to translate the interface to another language (German for example) after the automatic update.

3 cm × 83.1 cm × 80.1 on the outside; the device weighs more than 60 kilos and could only be lifted on the table with combined forces. You can comfortably access the machine via large touch screen. Inside is a Raspberry Pi 3, which also brings WLAN. An update during the test period came automatically via LAN connection to the device. It updates by itself and there is no need for you to connect anything to the computer. You can handle all maintenance procedures as well as material changes by only using your finger tips. There is a possibility to translate the interface to another language (German for example) after the automatic update.

The big problem with conventional dual-head printers that combine two extruders in one unit is that the inactive nozzle often scratches directly over the freshly melted material layer from the other nozzle and damages it. If you have a lot of bad luck, the painstakingly created object is detached from the platform and the print fails – unfortunately, this is common in many older double head printers. We have also experienced this with the Bolt’s predecessor, the Creatr HS.

We have also experienced this with the Bolt’s predecessor, the Creatr HS.

We have recently tested one way around this problem on the Ultimaker 3: this unit drives the unused nozzle a bit higher than the one currently active, which worked well in practice. Leapfrog, on the other hand, has come up with a different idea: the two extruders are located in structurally separate print heads, which only move on a common X-axis. Your Y position is always the same, but the unused print head can be moved to the side and is completely out of the way.

Mirror, Sync or Dual ExtrusionWith the two print heads decoupled in one dimension, the Bolt has three basically different operating modes:

- Sync: The two heads move parallel and print two identical copies of the work piece on each half of the construction platform. You can request to make the prints out of different materials.

- Mirror: Like Sync, except that one of the objects is mirrored.

This mode can be useful when printing symmetrically designed housings in multiple parts.

This mode can be useful when printing symmetrically designed housings in multiple parts. - Dual Extrusion: Combining two materials in a single work piece. In each layer of the 3D model, the first head prints its part of the work piece, then a change takes place, and the other prints its part. This way many combinations are possible; for example, two-colored parts or components consisting of multiple materials with different properties such as rigid and flexible parts.

For the Sync and Mirror modes, by the way, it is enough to place the work piece on the right side of the construction platform during the print preparation in the software. Therefore you can simply select one of the two copy modes directly on the touch display on the printer.

The video shows that in dual extrusion the change between the heads takes place in a few moments, resulting in only a minimal delay. The freshly activated nozzle is wiped off and the start printing immediately on the work piece; intermittent printing of an auxiliary structure as with the Ultimaker 3 is not needed. With this setup, the Bolt succeeded in producing clean prints made of several materials. Just like with the Ultimaker 3 in this respect, Leapfrog’s approach to dual-extrusion printing works well.

With this setup, the Bolt succeeded in producing clean prints made of several materials. Just like with the Ultimaker 3 in this respect, Leapfrog’s approach to dual-extrusion printing works well.

Short overview

| Machine | Bolt |

| Manufacturer / reseller | Leapfrog / a.o. 3Dmensionals |

| Build volume | 30 cm × 32 cm × 20,5 cm (bei Dual Extrusion) |

| Print Bed | Heated glass plate |

| Software | Simplify3D or Creatr (both free) |

| Filament width | 1,75 mm |

| Print through… | USB-Stick, WLAN, LAN |

| Price | ca. 6000 € (incl VAT) |

The Bolt is a powerful device with industrial mechanics and proved to be easy to use in the test. The dual extrusion mode works well, thanks to the enclosed installation space, the heat output of the extruders (up to 360 degrees Celsius) and the construction platform (up to 90 degrees Celsius), the machine is suitable for a wide range of materials. Among other things, it should also be possible to print a work piece made of ordinary plastic and to support its overhangs with the water-soluble material PVA, which is washed away afterwards – for reasons of time we have not tried this ourselves.

Among other things, it should also be possible to print a work piece made of ordinary plastic and to support its overhangs with the water-soluble material PVA, which is washed away afterwards – for reasons of time we have not tried this ourselves.

If, on the other hand, you need larger quantities of objects printed from a material, the sync mode will be appreciated because the parallel printing of two work pieces will halve the time per copy – with printing times of often a few hours, this is no small advantage. This all has its price, of course, and the Bolt is four-digit in the middle range. Nevertheless you get a lot of 3D printer per euro with this machine. (Pek)

This was a translation of the original German version of MAKE’s Bolt review which can be found here.World's Leading 3D Printing Magazine

News

How To 3D Print Replacement Car Parts

If you’re looking to create your own car parts, you can do so with ease. Here is a guide on how to 3D print replacement car parts very cheap. (Read more)

Here is a guide on how to 3D print replacement car parts very cheap. (Read more)

Latest

Reviews

uPrint SE 3D Printer Review

So is the uPrint SE 3D printer worth the money today or are you better off with something entirely else? Read the full review here and find out!

Reviews

Fortus 400MC 3D Printer Review

Is the Fortus 400MC 3D printer worth the money or are you better off with another 3D printer? Read the complete review here and find out!

Reviews

PowerSpec 3D Pro Review

Here’s a detailed and comprehensive review of the PowerSpec 3D Pro 3D printer. See if it is something for you!

Reviews

Objet30 Pro 3D Printer Review

The Objet30 Pro 3D printer is without a doubt of the highest-quality printers out there. Read our full review of it here and discover why you should get it!

Read our full review of it here and discover why you should get it!

Reviews

Solidoodle 4 Review

We reviewed the popular Solidoodle 4 3D printer. See our complete review here to find out if the Solidoodle 4 is worth it for you!

Reviews

PowerSpec Ultra 3D Printer Review

We reviewed the somewhat popular PowerSpec Ultra 3D printer and here’s everything that we found out. Spoiler alert: we didn’t like it!

Reviews

FlashForge Creator X Review

We tested the popular FlashForge Creator X 3D printer and here’s everything that we discovered about it. Find out if this 3D printer is something for you!

Reviews

Fortus 250MC Review

We had the pleasure of buying and testing the Fortus 250MC 3D printer. Read our complete review of this 3D printer here to see why it is so GOOD.

Reviews

Solidoodle 3 3D Printer Review

Read our full review of the Solidoodle 3 3D printer to see why it is so bad and can’t be recommended to anyone. Save your money now!

Reviews

Projet 1200 3D Printer Review

We tested and reviewed the Projet 1200 3D printer to see if it is worth the money. Heres everything that we found out about this incredible 3D printing device!

Reviews

CEL Robox 3D Printer Review

We tested the CEL Robox 3D printer and were not impressed. Read our full review here to find out exactly why this 3D printer is not worth your money.

Reviews

Form 1+ 3D Printer Review

Is the Form 1+ 3D printer worth it? We tested it and here’s everything that we found out! Read the full review here.

Reviews

FlashForge Finder 3D Printer Review

We tested the popular FlashForge Finder 3D printer to see if it was worth buying. Here’s what we found out during our review!

Reviews

Cetus 3D Printer Review

Here’s everything you need to know about the Cetus 3D printer and whether or not it is the right 3D printer for you!

Reviews

Flashforge Dreamer Review

We tested the Flashforge Dreamer 3D printer and discovered how awesome it is. Learn what we found out in this comprehensive review here!

Reviews

Leapfrog Creatr 3D Printer Review

Is the Leapfrog Creatr 3D printer worth it today? Read our review of it here and find out if it’s the right 3D printer for you!

Reviews

Rapide Lite 200 Review

Here’s a review of the Rapide Lite 200 3D printer. Is this 3D printer worth it for you? Read here and find out today!

Reviews

MakerBot Replicator Z18 Review

We reviewed the popular MakerBot Replicator Z18 3D printer to see if it was worth the money. It’s pleasing to say that it was! Read our full review here.

Reviews

Mojo 3D Printer Review

Here’s a full and comprehensive review of the Mojo 3D printer, which is a pretty popular product and with good reason! Here’s our full review of it here!

Reviews

QIDI Tech 1 3D Printer Review

We tested and reviewed the QIDI Tech 1 3D printer. Read our article here and discover why it is so GOOD compared to other 3D Printers.

Reviews

CubePro 3D Printer Review

Is the CubePro 3D Printer worth your money right now? We tested it and here’s everything you need to know about this 3D printer!

Reviews

RigidBot 3D Printer Review

We tested and reviewed the RigidBot 3D printer. If you’re considering this 3D printer, then check out our review of it here and see if it is worth it!

Reviews

Raise3D N2 Review

Is the Raise3D N2 3D printer worth the money or is it obsolete? With the 3D printing industry moving forward at lightspeed, here’s an updated review of this 3D printer!

Reviews

Printrbot Play Review

So is the Printrbot Play 3D Printer worth your money? Is it better than the competitors? Here are some reasons why you should or shouldn’t buy this 3D printer!

Reviews

MOD-t 3D Printer Review

Should you buy the MOD-t 3D printer? Read our complete review of this 3D printer here and see if it is something for you!

Reviews

Ultimaker 2 Extended Review

We reviewed and tested the Ultimaker 2 Extended 3D printer, which is considered to be a state-of-the-art 3D printer. Should you buy it? Find out.

Reviews

Ultimaker 2+ Review

Read this review to discover why the Ultimaker 2+ is such a good 3D printer. You’ll learn all the good and bad things about it here.

Reviews

Cube 3D Printer Review

Do you consider buying the Cube 3D printer? Don’t! At least not before you read our revealing review of it right here.

Reviews

TronXY X5S 3D Printer Review

Considering buying the TronXY X5S 3D printer? Do yourself a favor and DON’T! Read our review of it here first and see if it’s something for you.

Reviews

BCN3D Sigma Review

We tested and reviewed the BCN3D Sigma 3D printer. Learn more about this 3D printer and learn if it is something for you!

Reviews

Airwolf HD 3D Printer Review

Is the Airwolf HD 3D Printer worth it? Should you buy it? Read our review of this 3D printer here to discover if this is something for you!

Scientific journal "Videoscience" - 3D printing: a review of the latest news

Koktsinskaya E.M.

Scientific journal "Videoscience"

Abstract. 3D printing is of great interest and is considered revolutionary, as it makes it possible to produce products of given dimensions with high precision at a low cost of manufacturing them. This article provides an overview of the latest news from the 3D printing industry.

Keywords: 3D, 3D printing, 3D printer, metal

All news provided by our partner - the World of Modern Materials portal (website: http://worldofmaterials.ru).

3D printing technology has developed rapidly in recent years and now covers a wide range of materials. At the same time, the cost of 3D printers themselves has decreased so much that it has made their use even at the household level possible. Materials such as metals, plastics, ceramics, food and even human tissue are beginning to be printed using this technology. 3D metal products are used in the aerospace industry, motor transport and energy, biomedicine, and robotics.

Researchers at the Massachusetts Institute of Technology have recently discovered a new possibility in 3D printing: the ability to print optically transparent glass objects. Printed using the developed high-temperature technology, glass objects are durable and completely transparent to light. Objects can be pre-modeled in a design computer program, similar to other currently existing 3D printers [1].

A large number of works are devoted to the use of 3D printers to improve the properties of metals. Researchers at the University of Missouri Science and Technology are developing a way to use 3D printing technology to create new metals that are stronger and lighter than existing ones. These metallic materials are created by using a laser to melt metal powder, which is then deposited layer by layer to form a 3D printed object. As a result of this technology, structural amorphous metals are obtained [2].

Another team of researchers proposes a way to improve the quality of the structure and thus the properties of 3D printed metal parts. The level of control they have achieved on the manufactured product is absolutely unique. The researchers worked with the technology of electron beam melting, in which an electron beam sequentially welds together layers of metal powder, forming a 3D object. It was found that by controlling the heating parameters during the printing process, it is possible to monitor the curing process throughout the volume of the entire product. As a result, it turns out that the orientation of metal grains and the microstructure of the material can be very accurately controlled. Since the microstructure of a metal plays a decisive role in its physical and mechanical properties, by improving it, one can thereby improve the properties of a 3D product [3].

A team of interdisciplinary researchers in Los Angeles is working on a unique 3D printing solution. Their solution is aimed at combating greenhouse gases that are emitted during the production of concrete and electricity in power plants. The researchers plan to create a closed process that includes the capture of carbon on the pipes of power plants and its use in the creation of a new building material - carbon dioxide concrete CO 2 NCRETE (English "concrete" - concrete) - using 3D printing technologies [4].

3D printing of tablets is allowed in the USA. And earlier, the production of medical devices - including prosthetics - using 3D printing technology was approved [5].

In Dubai, they are going to build a fully functional building using 3D printing. Such an office will be printed layer by layer. The 3D printer required for this will be a 6 m high device. The area of the office will be about 186 m 2 . All internal details, furniture and structural components will be built using 3D printing technology based on a mixture of fiber reinforced plastic, special reinforced concrete and glass fiber reinforced gypsum [6].

But some things, until very recently, still remained inaccessible to 3D printing, such as hair and fur. Printing such objects required several hours for the initial calculations and simulations, and only after that they could be printed on a printer. Instead of using standard computer design programs, a team at MIT has developed a new "Cilllia" program that allows users to determine the angle, thickness, density and height of thousands of hairs in just a few minutes. Using this program, the researchers modeled arrays of hair-like structures with a resolution of 50 microns (on the order of the thickness of a human hair). After that, they were printed on flat and curved surfaces using a conventional 3D printer, obtaining objects from coarse bristles to fine fur [7].

Sources :

1. Printing transparent glass in 3-D // MIT News. 2015. URL: http://news.mit.edu/2015/3-d-printing-transparent-glass-0914 (Accessed 06/19/2016).

2.Researchers develop new metal materials through 3D printing // 3D printer and 3D printing news. 2015. URL: http://www.3ders.org/articles/20151019-researchers-develop-new-materials-through-3d-printing.html (Accessed 06/19/2016).

3. New high-precision metal 3D printer // World of modern materials. 2014. URL: http://worldofmaterials.ru/164-novyj-vysokotochnyj-3d-printer-metallov (accessed 19.06.2016).

4. UCLA researchers turn carbon dioxide into sustainable concrete // UCLA Newsroom. 2016. URL: http://newsroom.ucla.edu/releases/ucla-researchers-turn-carbon-dioxide-into-sustainable-concrete (Accessed 06/19/2016).

5. First 3D-printed pill approved by US authorities // BBC News. 2015. URL: http://www.bbc.com/news/technology-33772692 (Accessed 06/19/2016).

6. Dubai to build the first fully functional 3D building in the world // Gulf News. 2015. URL: http://gulfnews.com/news/uae/government/dubai-to-build-first-fully-functional-3d-building-in-the-world-1.1543227 (accessed 19.06.2016).

7. Need hair? Press "print" // MIT News. 2016. URL: http://news.mit.edu/2016/3-d-print-hair-0617 (Accessed 06/19/2016).

Abstract. 3D-printing is considered a revolutionary technology because it gives an opportunity to produce the product with specified dimensions and with high accuracy at a low cost of manufacture. This article is an overview of the latest news of the 3D printing industry.

Key words: 3D, 3D printing, 3D printer, metal.

Overview of 3D printer manufacturers

3D printing appeared in the late 1980s, but 2020 became a breakthrough year for the technology. The pandemic disrupted supply chains, and it was 3D printing that made it possible to quickly obtain the necessary items and spare parts, ranging from consumables for hospitals and clinics to parts for medical, industrial and other equipment.

The prospects and pace of development of the sector in recent years have significantly increased its investment attractiveness, however, there are certain risks that should not be discounted.

Vadim Kizimov

private investor

Author profile

Buy

Buy

Buy

Buy

Service in partnership with Tinkoff Investment Quotes are updated every 15 minutes

Technology Brief

3D printing is the process of converting a model developed on a computer into a real three-dimensional object. Printing occurs due to the successive layering of thin layers of material. These are mainly thermoplastics of various types, but ceramic, biocompatible and other composite mixtures can also be used. That is why this technology is called additive.

3D printing technologies differ depending on the materials and equipment used, but the general scheme of the process is always the same:

- A virtual model of the object is created on the computer, and in order to make a model, you do not need to have 3D modeling skills. A special scanner photographs a real object from different angles, creating a digital copy of it.

- The program makes slicing - splits the model into many thin horizontal layers.

- The template is loaded onto the 3D printer, the device reads the diagram and prints it layer by layer in volumetric form.

Application

Using a 3D printer, you can copy any object or create your own. The possibilities for additive printing are almost limitless. Now the technology has already found application in various industries:

- health care: the creation of orthopedic orthoses, dentistry, transplantology, the manufacture of prostheses;

- industrial production: parts of machine tools and equipment;

- space, aviation and automotive industries;

- robotics;

- construction: models of buildings or individual structural elements;

- food production: figured chocolate, jellies and other desserts;

- household items: from smartphone cases and collectible figurines to shoes and interior items;

- jewelry.

At the moment, additive technologies are most in demand in medicine — 3D printing makes it possible to create consumables, prostheses, orthoses, mouth guards, and even absolutely accurate models of human organs — and in industrial production when creating parts and equipment elements.

But the scope of 3D printing is constantly expanding, opening up new opportunities for both large companies and small start-ups.

Industry Prospects

At the moment, 3D printing does not yet allow you to get fast and large-scale results, but the technology has proven itself in areas that require precision and uniqueness.

The increased availability of equipment and the absence of the need for long training of personnel to work with 3D printers also played a role. Over the past six years, the number of global and specific industries that use 3D printing technology has increased, and this market is truly limitless:

- large companies or organizations may refuse to purchase the necessary consumables or parts, producing them on their own in the volumes they need;

- the role of additive printing in medicine has already been mentioned above, and there are also broad development prospects here;

- 3D solutions lower the barrier to entry for new players.

Now, to launch your own production, there is no need to rent a room and purchase sophisticated equipment. For example, niches for creating custom car tuning parts, collectible figurines for computer game fans or unique gifts have just begun to open and have already begun to gain popularity.

At the end of 2021, the additive printing market was worth $15 billion, based on 3D printing costs and the production of printers and components. In the coming years, the expert agency Business Insights predicts an annual growth of the segment by more than 24%. At this pace, by the beginning of 2029, the size of the 3D printing market will grow at least five and a half times.

Technology deficiencies and company risks

Despite the promise of 3D technology development, 3D printing is not yet a profitable industry. There are a number of difficulties that do not allow you to fully rely on additive technologies.

Still high cost of equipment. Cheap 3D printers allow you to print small objects. To create parts of large dimensions, it is necessary to purchase expensive equipment, which may turn out to be unprofitable.

Poor performance. This disadvantage should be considered in conjunction with the previous one: now the speed and cost of 3D printers do not allow them to be used in mass production, making a tangible profit.

Insufficient strength of manufactured parts. The layered structure is more brittle in the direction of the layers than the monolith and cannot withstand heavy loads.

Lack of stability. The use of additive technologies on an industrial scale requires equipment and materials that can provide higher production reliability. At the moment, 3D printing is most often used for prototyping, quality control, or for the production of single parts.

The need for post-processing , which increases the cost and time of production of each unit.

Unpredictability. Additive manufacturing is constantly evolving, new materials and printer models are emerging, and there is always a risk that equipment that has been heavily invested in will suddenly become obsolete.

3D printing companies on the St. Petersburg Stock Exchange

There are quite a few companies associated with 3D printing on the St. Petersburg Stock Exchange, and it is not their main activity. This industry is so young that at the moment it does not even have a benchmark significant index.

But the global trend of increasing demand for additive technologies in various areas of life can open up new prospects for industry pioneers.

Proto Labs (NYSE: PRLB). Capitalization - 2.56 billion Proto Labs was founded in 1999 in Minnesota, and by 2022 it already has more than ten branches in seven countries of the world. The company specializes in the creation of prototypes and finished parts for individual orders. In this niche, Proto Labs is one of the largest and fastest manufacturers: it takes only a few days to create a part of any complexity.

Since 2014, Proto Labs has been using additive technology for manufacturing parts. In total, the company operates in four areas:

- Injection molding, revenue growth +4% year-on-year.

- CNC machining, +41%.

- 3D printing, +17%.

- Sheet metal production, +24%.

While 3D printing still made up only 14.8% of the company's revenue as of the end of 2021, the technology's growing popularity trends could bring more tangible profits in the future.

Source: Tinkoff Investments Source: Tinkoff Investments3D Systems Corp (NYSE: DDD). Capitalization - 1.88 billion. The company was founded in 1986, headquarters - in Rock Hill, South Carolina.

3D Systems manufactures and sells equipment, software and materials for additive manufacturing. Most often, the company's products are used in the aerospace, automotive, semiconductor and healthcare industries.

In 2021, 3D Systems announced two separate acquisitions. The company has agreed to acquire Titan Additive LLC, a developer and manufacturer of large-format industrial 3D printers, and Kumovis, a German provider of additive manufacturing solutions for personalized medical applications.

After the announcement of the results for the fourth quarter of 2021, the company's quotes increased by 15%. This positive reaction was driven by double-digit revenue growth of 13.1% yoy, excluding sales of part of the business. In addition, 3D Systems reduced its net loss by almost three times, and the revenue forecast for 2022 was increased by 10%.

Source: Tinkoff Investments Source: Tinkoff Investments Align Technology (NYSE: ALGN). Capitalization - 32.4 billion American company Align Technology is a manufacturer of medical equipment for dentistry and orthodontics. The patented Invisalign bite treatment system is based on the use of transparent removable orthodontic caps, which are printed on a 3D printer individually for each client.

The company is headquartered in Silicon Valley and has a rapidly growing branch network covering Russia, Mexico, Costa Rica, the Netherlands, Australia and Japan.

Digital orthodontics is rapidly evolving, and Align Technology is not going to give up just yet. The percentage structure of revenue for 2021 is distributed as follows: 80% - sales of Invisalign products, 20% - sales of intraoral scanners and other dental equipment.

Source: Tinkoff Investments Source: Tinkoff InvestmentsHP Inc. (NYSE: HPQ). Capitalization - 39.7 billion. The company does not specialize in the production of 3D printers, but is still one of the leaders in the additive printing market.

In 2014, HP developed Multi Jet Fusion 3D powder printing technology to lower the price and speed of industrial 3D printers, and two years later, the first HP Multi Jet Fusion models went on sale.

In 2017, Hewlett Packard introduced the world's first 3D lab for testing various types of additive printing raw materials. And in 2018, it announced Metal Jet technology for 3D printing of industrial quality metal products.

HP Metal Jet Printer delivers 50 times the performance and significantly lower cost of finished parts than other technologies.

On April 7, 2022, investors were shocked by the news that Warren Buffett had bought $4.2 billion worth of shares in the company. Immediately after the announcement of the deal, HP shares grew by 14.75%.

Compare companies by multiples, growth rates, and R&D spending.

Source: Tinkoff Investments Source: Tinkoff InvestmentsCompany multiples

| Capitalization, billion dollars | P/E | Forecast P/E | P/S | Debt to equity | |

|---|---|---|---|---|---|

| PRLB | 2.56 | 38.00 | 28.00 | 2.81 | 0.01 |

| ALGN | 32.40 | 41.00 | 32.00 | 8.18 | 0.04 |

| DDD | 1. | 5.30 | 5.00 | 2.88 | 0.60 |

| HPQ | 39.70 | 6.80 | 8.70 | 0.69 | −3.58 |

Capitalization, billion dollars

PRLB

2.56

ALGN

32.4 DDD 9008 0002 HPQ 39,7,000 Algn 32 HPQ 8.7 PRLB 2.81 Algn 8,18 DDD 2.88 HPQ 0.69 9000 9000 DEBT TO equity PRLB 0.01 Algn 0.04 DD 0.6 HPQ −3.58 2019 458 (+2.69%) 2020 434 (−5.24%) 2021 488 (+12.44%) 2019 2406 (+22 %) 2020 2471 (+3%) 2021 3952 (+60%) 2019 636 (−8%) 2020 557 (−12%) 2021 615 (+10.4%) 2019 58 760 (+1.3%) 2020 56 630 (−3.62%) 2021 63 000 (+11.25%) 2019 63 2020 50 2021 35 2019 442 2020 1775 2021 772 2019 −69 2020 −149 2021 322 2019 3152 2020 2884 2021 6503 2019 7.2 2020 8.5 2019 6.5 20200003 7.1 2021 6.3 2019 13.1 2020 13.3 2021 11,2,2 2019 9000 2020 9,0003 2.6 Summarizing the data, several conclusions can be drawn: Modern 3D printers can significantly reduce time and costs when solving geometry control and reverse engineering problems in the automotive, aviation, mechanical engineering, shipbuilding, jewelry and medicine industries. Revenue growth rate, million dollars

2019 2020 2021 PRLB 458 (+2.69%) 434 (−5.24%) 488 (+12.44%) ALGN 2406 (+22%) 2471 (+3%) 3952 (+60%) DDD 636 (−8%) 557 (−12%) 615 (+10. 4%)

HPQ 58,760 (+1.3%) 56,630 (−3.62%) 63,000 (+11.25%) BECTION PRICES, million dollars

2019 2020 2021 PRLB 63 50 35 ALGN 442 1775 772 DDD −69 −149 322 HPQ 3152 2884 6503 R&D costs, as a percentage of revenue

2019 2020 2021 PRLB 7. 2%

8.5% 9.0% ALGN 6.5% 7.1% 6.3% DDD 13.1% 13.3% 11.2% HPQ 2.6% 2.6% 3.0%

Bottom line

Learn more