3D print peeling up

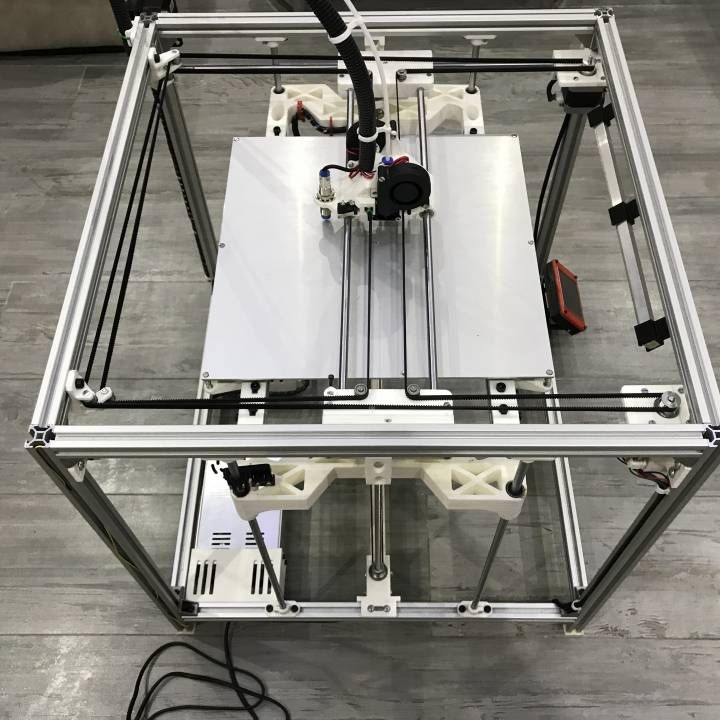

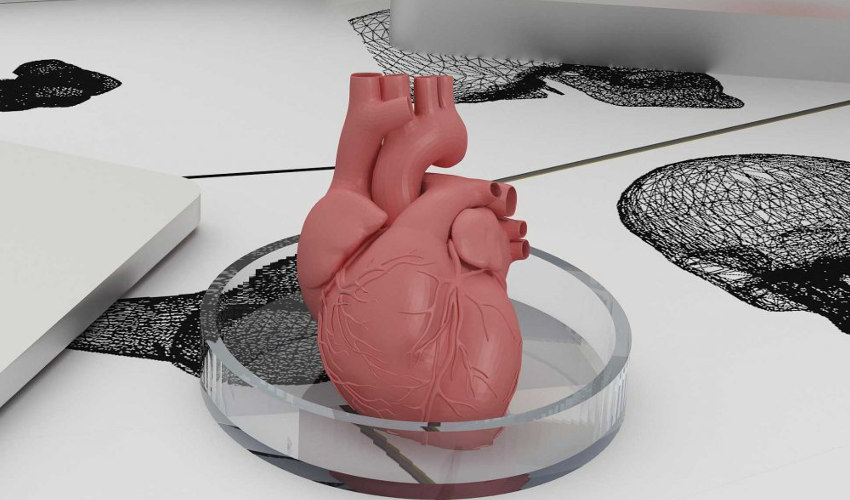

3D Prints Warping or Curling? – Why It Happens and How to Prevent It

In this guide, we’re going to cover what causes warping, and how to remedy it. Including tips for specific materials, and how to make sure it doesn’t happen again!

If you’ve used a 3D printer, then it’s likely that you’ve experienced 3D print warping. Warping is one of the most common problems encountered in 3D printing and it’s one of the most annoying.

But luckily, it is easily preventable – depending on your material and printing conditions, there are different remedies we’ll cover below.

3D printing curling doesn’t always cause a catastrophic failure of the object being printed like some other problems can. However, it does cause the object to deform enough to look unacceptable and unprofessional.

The worst case is your warping 3D printing can pop off the heated bed, causing it to fail completely.

Why Has My 3D Print Warped?

A 3D printer warping problem typically occurs when an object is cooling unevenly after printing.

Cooling, as you know, causes contraction and this contraction causes stress along the object’s lateral surfaces. The quicker the cooling occurs, the greater the stress on the object.

This stress is greatest at corners where two sides meet. There, the pulling stress exerted on both sides causes the corner of the object to deform and pull up and inward. The result is not pleasing to the eye and usually makes the object unusable.

There are really only three ways to prevent 3D printer curling; increasing ambient temperature to reduce cooling time, or seriously improving your bed adhesion. Luckily there are simple ways to do all three, which we’ll cover shortly.

But first, what if it’s too late – and you have a warped print right now? Well, maybe not all is lost just yet…

How To Fix a Warped Print?

While not all warped prints can be fixed, if the print bottom warping is slight – and your print isn’t too thick or large in volume you might just be able to salvage it.

To do this, you’ll need to heat up the print close to its glass transition temperature (where it’ll get just soft enough to mold back down).

You’ll need a large metal surface, like a frying pan, big enough to place the print bed side down (just the way up it came off your print bed).

Get a hairdryer and place the print in the pan. Heat it up on full power, and move the dryer around to evenly heat it.

After a minute or so, you can turn off the dryer and you should be able to hold the print down to bend it back to a flat shape. You’ll need to hold it for a few minutes until it’s cooled a bit.

Repeat this process until it works sufficiently. Don’t bother just putting the print back on a heated bed, or worse heating the pan – because this will just heat the bottom of the print. You’ll need to heat it up evenly all over.

So, let’s take a quick look at some of the ways that can help you prevent print warping:

Heated Bed

Once upon a time, heated print beds were relatively rare. Because of this, printed objects tended to cool very quickly once a job was underway.

Because of this, printed objects tended to cool very quickly once a job was underway.

This caused high levels of lateral stress and ABS curling was commonplace.

Today, most people are printing on a heated print bed. This causes a printed object to cool much more slowly. This reduces the stress caused by contraction which, in turn, helps to reduce warping.

Heated beds are not an all-in-one solution to warping, but when used in conjunction with other preventatives, they do lower the chances that your object will warp.

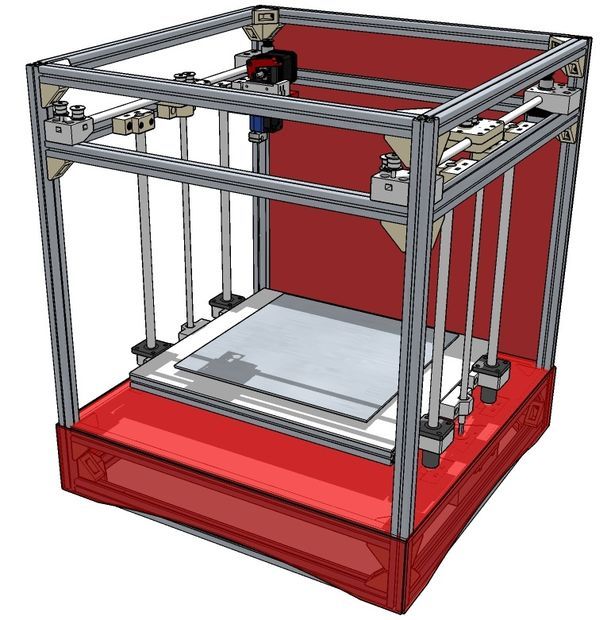

One thing to note with heated beds, is that the heating element isn’t always the full size of the bed – this means the edges might not get hot enough (depending on your printer). The diagram below illustrates the common causes of warping.

So it’s worth taking this into consideration if large prints warp, but smaller central ones don’t. Here you see the print warped, or is curling at the edges.

This is also assuming the heat on your bed is even. Still getting ABS warping on a heated bed? It could be because the heating elements are not even under the glass or metal plate.

Still getting ABS warping on a heated bed? It could be because the heating elements are not even under the glass or metal plate.

Check out this thermal image of a very popular model of 3D printer. Can you guess what it might be?

This is taken from the heated bed on a Prusa MKIIThe target temp for this bed is 50°C, notice the cooler area in the center. Commonly this is where people normally place smaller prints. So you may be getting small prints warping, but larger prints staying flat and printing fine.

It should also explain why you may be getting your PLA curling in some areas of the print but not others, for example.

It’s also worth noting that if your bed is made of particularly thick aluminum or glass – the thermometer may be reading full temp before the actual surface of the bed has had the chance to fully heat up yet.

In this instance, you’re best off waiting a good 10 minutes after your bed is reading the correct temperature before you start to print. This could mean the difference between first layer success and your ABS lifting later in the print.

This could mean the difference between first layer success and your ABS lifting later in the print.

How to Avoid Warping 3D Prints

It’s extremely important to regard how different printing materials are affected. For example, PLA doesn’t require a heated bed. However, when printed on one at around 50°C it can help those first few layers adhere a little more consistently.

But if you’re getting 3D print warping PLA then it’s likely at too high a heated bed temperature (eg. over 60°C) can cause it to warp.

Rule of thumb for PLA warping on a heated bed – you’re likely printing too hot.

Whereas if you’re getting 3D printer ABS warping with the heated bed, a big culprit is likely to be that the heated bed simply isn’t getting hot enough. So usually just turn it up!

Another way to prevent ABS from misbehaving, as it can be a common issue, is to improve the ambient temperature of the printing enclosure to slow down the cooling of the print.

Generally, it’s always best to print ABS in an enclosure, or failing that a warm ambient environment.

With something very sensitive to cooling too fast, like the UV resistant ASA; you’ll definitely want to make sure it’s printed in a warm ambient area with no drafts or it can warp so badly you see cracks in the print. More on this later.

These rough assumptions are based on you using the correct adhesive or surface for your material. This is also really important to prevent 3D printing warping – but don’t worry, more on this below.

So, how to prevent warping

Use a Build Surface that Promotes Adhesion

This is quite likely the most important step that you can take to eliminate warping in your printed objects. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth.

A key aspect when working out how to prevent ABS warping is getting your adhesion for the bed sorted perfectly.

Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. The result is that warping caused by cooling becomes more pronounced.

The solution is to start using build surfaces that enhance adhesion. There are a number of things that you can try in order to achieve this. Painter’s tape and Kapton tape both work well to reduce warping in PLA and ABS respectively.

Hairspray applied directly to the build surface to increase tackiness is used by many in a pinch, but it is messy and has limited durability.

If you’re having persistent issues with your ABS print warping, you may want to use a mixture of ABS slurry or ABS juice on your bed, which should significantly aid adhesion.

What is ABS juice?

ABS juice is a mixture or partially dissolved ABS scraps in acetone, to make a solution that can be painted evenly onto your heated bed.

Pritt stick accomplishes the same effect much more efficiently and with much less mess.

Finally, a substance like PEI (polyetherimide) comes in sheets that are easily attached to your build surface, are affordable and give excellent adhesion to just about any print material (except Nylon). Find out more about build surface adhesion solutions here.

PEI for the most part is one of the best bed surfaces to avoid warping, unless you’re using Nylon based materials that tend to respond best with Tufnol.

Clean Your Build SurfaceNo matter how adhesive your build surface is, dirt and grease will conspire to reduce that adhesion and put you back at square one when it comes to warping.

Make sure that your build surface is as clean as possible before you begin printing.

An ammonia-based product like Windex or Halford’s Glass Cleaner works great to remove grease and fingerprints from the build surface. Isopropyl alcohol and water solution also work well.

When your build surface is clean, your print material has a much greater chance of adhering which will reduce warping.

Your PLA curling at the corners? One interesting way to reduce warping is to design objects that have rounded corners whenever possible.

A rounded corner tends to ameliorate the amount of upward stress that occurs where two or more flat surfaces meet, by distributing that stress over a wider area.

Less stress means less warping and less 3D print curling, which means more successful printing.

Check Your Starting Z CoordinatesSometimes, printing a good first layer is key to achieving a successful result. One way to increase the odds of putting down a decent first layer is by checking your starting Z coordinates before printing.

If the Z-axis is starting too high, extruded print material has a longer distance to travel before contacting the build surface.

The longer the distance that the material has to travel, the cooler the material becomes and the greater the chances are that it will not adhere correctly.

If you’ve tried everything and are still experiencing warping, try lowering the Z-axis height in 0.05mm increments and see if that corrects the problem.

As you do this, keep in mind that you never want your extruder nozzle to come too close to the build surface, as this will cause its own set of problems.

If your print has a low surface area, and is proving hard to stick down it may also be worth printing a brim or skirt around your print to encourage extra adhesion to the bed.

Here’s an example:

Eliminate DraftsThe key to controlling warping is a slow and steady cooling process.

The quicker that cooling occurs, the more likely it is that your object will warp, no matter how many steps you’ve taken to prevent it.

This is why eliminating all drafts while you’re printing is extremely important if you want to reduce the instances of warping.

You should consider printing in a room in your house or place of business that provides the steadiest ambient temperature. Remind others in the area that you have a print job running and ask them to stay out of the room in question for the duration.

Remind others in the area that you have a print job running and ask them to stay out of the room in question for the duration.

Having someone open a door while your printer is running can cause the warping that you’re trying to prevent.

If your home or office is especially drafty, or if your printer must be located in a somewhat high traffic area, you might want to consider enclosing it so that temperature remains stable, or just significantly hotter while you print.

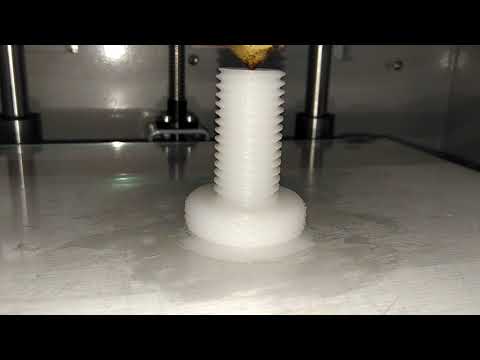

What is Elephant’s Foot?

Related to warping, but a slightly different fault is something we call 3D Print Elephant Foot – it’s when the base of your print widens out, shaping the object like, well – an Elephant’s large foot. It’s got elephants foot AND it’s warped? Oh lets all just go home…

You can see the bottom few layers here have spread out wider than the rest of the print. Here’s how this phenomenon happens and how to solve it:

Essentially your first few layers are being squashed, causing them to ooze out to the side. This is usually caused by a combination of factors:

This is usually caused by a combination of factors:

- Your bed is likely to be much too hot. If the object also warps off the bed, this is almost certainly the main cause. Having a bed that is too hot also allows heavier prints to compress the lower layers, causing them to sag and flow outwards.

- Having your nozzle too close to an overly-hot bed can cause a lesser version of this. In some cases, it may exacerbate the other two factors quite considerably if not corrected.

(Some beds such as FR4 or PEI require a higher temperature to ensure initial bed adhesion with PLA so) there’s nothing wrong with putting down the first layer onto a bed at say 55-60°C, as long as you reduce it to 45°C for all subsequent layers.

Don’t forget, the bed will take time to cool.

To Solve 3D Printing Elephant Foot:

Assuming the elephant’s foot is happening evenly on all base sides of your print, increase the Z-axis offset slightly, to allow more room for those first layers to settle at the correct height. We recommend starting in 0.1mm increments.

We recommend starting in 0.1mm increments.

Too much and you’ll risk there not being enough pressure for the print to have sufficient adhesion to the bed.

If the elephant’s foot is only on one or two sides, you’ll need to re-level your bed.

Finally, if you’re finding that it’s a heavy, large model weighing down those first layers (you’ll notice this effect increases the larger the print gets if this is the case) then you’ll need to reduce temperature of the heated bed.

Too hot and you’ll soften the material too much.

To prevent Elephants foot in a nutshell:

- Level your heated bed

- Adjust z-axis offset/or the nozzle height from the bed

- Correct heated bed temperature

As we said, warping is one of the most common problems that occurs when 3D printing. The good news is that even though it can be caused for a number of reasons, it is relatively simple to prevent.

Related articles:

- 3D printer troubleshooting – 44+ problems fixed

- How to smooth PLA

- How to acetone smooth ABS

- How to fix a clogged extruder nozzle

9 Ways How to Fix 3D Prints Warping/Curling – PLA, ABS, PETG & Nylon – 3D Printerly

Most people who’ve worked with 3D printers are familiar with warping and it’s a problem that plagues many users. You’ll be happy to know there are a series of methods to reduce warping to the point where you can get consistently successful prints without experiencing warping.

You’ll be happy to know there are a series of methods to reduce warping to the point where you can get consistently successful prints without experiencing warping.

This article will show you precisely, how this problem is solved for good.

To fix warping/curling in 3D prints, use an enclosure to control the ambient printing temperature and any rapid cooling that causes shrinkage in your prints. Use a good build plate temperature for your filament, make sure your build plate is clean and use adhesives so the print sticks to the build plate properly.

There’s more detail behind fixing 3D prints that warp so keep on reading for more.

What is Warping/Curling in 3D Prints?

Warping or curling in 3D prints is when the base or bottom of a 3D print starts to curl upwards and lift away from the build plate. It results in 3D prints losing dimensional accuracy and can even ruin the functionality and looks of a 3D model. It occurs due to shrinkage in the material from rapid temperature changes.

What Causes Warping & Lifting in 3D Printing?

The main causes of warping and curling is from temperature changes which causes shrinkage in your thermoplastic filament, along with a lack of adhesion to the build surface.

Below are some specific causes of warping in 3D printing:

- Rapid temperature changes from hot to cold or room temperature too cold

- Bed temperature too low or uneven heating on bed

- Drafts blowing cold air onto model, no enclosure

- Bad adhesion to the build plate

- Cooling settings not optimized

- Build plate not leveled

- Build surface is dirty with grime or dust

Whether your PLA is warping mid-print, warping on a glass bed or heated bed, the causes and fixes will be similar. Many people who have a 3D printer like an Ender 3 or Prusa i3 MKS+ experience warping, so let’s look into how to fix it.

How to Fix Warping in 3D Printing – PLA, ABS, PETG & Nylon

- Use an enclosure to reduce rapid changes in temperature

- Increase or lower your heated bed temperature

- Use adhesives so the model sticks to the build plate

- Ensure cooling is turned off for the first few layers

- Print in a room with a warmer ambient temperature

- Make sure your build plate is properly leveled

- Clean your build surface

- Reduce drafts from windows, doors, and air conditioners

- Use a Brim or Raft

1.

Use an Enclosure to Reduce Rapid Changes in Temperature

Use an Enclosure to Reduce Rapid Changes in TemperatureOne of the best methods to fix warping and prevent it happening to your 3D prints is to use an enclosure. This works because it does two things, keeps a warmer ambient temperature so your print doesn’t cool rapidly, and also reduces drafts from cooling your model.

Since warping usually occurs due to temperature changes, an enclosure is a perfect fix to preventing warping happening to your 3D prints. It should fix a lot of the issues but you may still need to implement some other fixes to get rid of warping once and for all.

I’d recommend getting something like the Comgrow Fireproof & Dustproof Enclosure from Amazon. It has plenty of positive reviews from other 3D printer users mentioning just how effective and useful the enclosure is.

One user mentioned that after they started using this enclosure, they no longer has prints warping on the corners, and adherence to their heated glass bed got a lot better. It also even slightly cuts down on noise pollution, so you don’t disturb others or yourself as much.

It also even slightly cuts down on noise pollution, so you don’t disturb others or yourself as much.

There are other temperature-related defects that 3D prints go through, so having this enclosure helps with many problems at once. Setup is pretty easy and it looks good overall.

3D prints that warp on one side can be quite annoying, so getting an enclosure can help to solve this issue.

2. Increase or Lower Your Heated Bed Temperature

Usually, increasing your bed temperature helps to reduce warping because it stops that rapid change in temperature since the heat emits nicely on the model. Follow your filament recommendation for bed temperature, but try increasing the bed temperature on the higher end.

Even for a filament like PLA, 60°C can work well even though many people recommend 30-50°C, so give different temperatures a try and see how it works for you. There are many types of 3D printers out there, as well as personal printing environments that can affect these things.

Check out my article on How to Get the Perfect Build Plate Adhesion Settings & Improve Bed Adhesion for more info.

One bed temperature for one user might work well, while it doesn’t work too well for another user, so it’s really down to trial and error.

You can also have a bed temperature that’s too high that can lead to warping due to rapid temperature changes, possibly due to having a cool ambient temperature.

If you have tried increasing your bed temperature, you can also try lowering it to see if it has a positive effect on reducing warping.

3. Use Adhesives so the Model Sticks to the Build Plate

Since warping is a movement that shrinks material, especially corners of your 3D prints, sometimes having a good adhesive on the build plate can stop the material from moving away.

Many people have fixed warping or curling in their 3D prints by simply applying a good adhesive and letting it do its magic.

There are plenty of adhesives out there that work for 3D printer beds. The most popular type of adhesive I’ve seen in the 3D printing community has to be glue sticks.

The most popular type of adhesive I’ve seen in the 3D printing community has to be glue sticks.

I’d recommend going with something like FYSETC 3D Printer Glue Sticks from Amazon.

A few coats of glue stick on the bed should give you a lovely foundation for your model to stick to so it doesn’t warp and shrink away from the build plate.

You can also take it to the next level and use a 3D printer specific adhesive like LAYERNEER 3D Printer Adhesive Bed Weld Glue from Amazon.

I wrote an article called Best 3D Printer Bed Adhesives – Sprays, Glue & More.

4. Ensure Cooling is Turned Off for the First Few Layers

Your slicer should have default cooling settings that turn the fans off for the first few layers, but you may want to turn it off for more layers if you are getting warping. I’d usually recommend trying out the other fixes before you do this because cooling contributes to better 3D print quality.

For a material like PLA, they usually recommend your cooling fans being on 100% so you may not want to turn it down for that.

If you are experiencing warping on a material like PETG or Nylon, you want to try adjusting your cooling settings to be lower so the material isn’t cooling too quickly.

You can change the layer height that your 3D printer fans start their regular speed directly in your Cura settings. If you get warping early on, it could be worth delaying where you start the fans.

Check out How to Get the Perfect Print Cooling & Fan Settings for more details.

5. Print in a Room with a Warmer Ambient Temperature

Similar to the fixes above, the main thing is having a better control on your temperature, especially the ambient temperature. If you are printing in a cold garage in the winter, you are a lot more likely to experience warping in your models, compared to printing in a warm office.

Be aware of the general temperature of where your 3D printer is placed so it’s not in an environment that’s too cool.

As mentioned above, an enclosure here can help. Some people have reduced warping by even using a space heater near their 3D printer, or placing the printer close to a radiator.

Some people have reduced warping by even using a space heater near their 3D printer, or placing the printer close to a radiator.

6. Make Sure Your Build Plate is Properly Leveled

Warping usually happens due to pressure from the rapid cooling and shrinking of material, but this can be countered by making sure your build plate is leveled better.

In addition to using adhesives like a glue stick, when your build plate is leveled nicely, it improves the adhesion of material to the build plate.

If your build plate isn’t leveled very well, the foundation and adhesive is going to be weaker than usual, increasing the chances that you experience warping.

Follow the video below by Uncle Jessy to level your build plate nicely.

For more details, check out my article How to Level Your 3D Printer Bed – Nozzle Height Calibration.

7. Clean Your Build Surface

Just like leveling your build plate is important for adhesion which helps to reduce warping, cleaning your build surface is equally as important.

We want to provide strong adhesion to the material extruded from the nozzle, but when the build plate is dirty or grimy, it doesn’t stick so well to the bed surface, especially with glass beds.

If you want to reduce warping in your 3D prints, make sure your build surface is nice and clean.

Many people would do something like clean it with isopropyl alcohol and a cloth, or even do a full clean with dish soap and warm water. You can also get sterile pads to help clean your beds, it’s really up to you what you do.

I wrote an article How to Clean a Glass 3D Printer Bed – Ender 3 & More that goes into more depth.

The video below shows you how to clean a print surface on the Ender 3 using a sock and some 70% Isopropyl Alcohol.

8. Reduce Drafts From Windows, Doors, and Air Conditioners

If you don’t have an enclosure, you definitely want to stop cool air and drafts from blowing on your 3D printed parts. I remember I had a strong draft due to having a window and a door open while 3D printing, and it resulted in really bad warping.

Once I closed the door and stopped the draft from blowing around the room, that warping quickly stopped and I successfully created my 3D model.

Try to identify where any gusts of wind are coming from, even from something like an air conditioner or air purifier, and try to reduce it or the impact on the 3D printer.

9. Use a Brim or Raft

Using a Brim or Raft focuses on the adhesion side of warping. These are simply extra layers of extruded material that provide a foundation around your 3D model.

Here is a Brim around a calibration cube. You can see how the Brim would help reduce warping since the actual model isn’t on the outside, so the Brim would warp first before the warping can reach the actual model.

Here is a Raft around a calibration cube. It looks very similar to the Brim but it is actually placed around and underneath the model, along with being thicker and having more settings to customize.

I usually prefer to use a Raft versus a Brim because it does the job better and you actually have a great foundation to remove your print from, but Brims still work well.

Check out my article about Skirts Vs Brims Vs Rafts – A Quick 3D Printing Guide for more details.

How to Fix a 3D Print That Has Warped – PLA

To fix a 3D print that has warped, try using a method of heat and pressure. Get a large metal surface like a frying pan which your 3D print can fit into the same way it came off the build plate. Take a hair dryer and heat up the 3D model all around evenly for about a minute. Now hold the print down and bend it flat.

Now hold the print down and bend it flat.

The model will need to be held for a few minutes until it cools down, then repeat this process until your print is back to the shape you desire. Remember to heat up the model evenly with the hair dryer each time you do this. It requires you reach the glass transition temperature so it can be molded.

This method from RigidInk has worked well for many users to fix a warped 3D print, so it’s definitely worth a try.

As long as the warping on your model isn’t too bad or your 3D print isn’t too thick, it’s possible to save it.

You can also try this method in the video below with hot water by Make Anything.

How Do You Stop PETG 3D Prints From Warping?

To stop your PETG 3D prints from warping or curling, you should:

- Make sure the active cooling fans are turned off, at least for first layers

- Use a better build surface for adhesion like BuildTak

- Use a good adhesive substance for your build plate – hairspray or glue sticks

- Print slowly on your first layer

- Try decreasing your printing temperature and increasing your bed temperature

- You can also dry your PETG filament to reduce its moisture content

Using a combination of the solutions above should help you with your PETG warping. It can be a fairly stubborn filament to work with, but once you get a good routine going, you’ll start to enjoy plenty of successful PETG prints.

It can be a fairly stubborn filament to work with, but once you get a good routine going, you’ll start to enjoy plenty of successful PETG prints.

There isn’t necessarily a PETG warping temperature, so you can try different bed temperatures to reduce warping.

How to Keep Nylon Filament From Warping

To keep Nylon filament from warping, get yourself a heated enclosure and try using a smaller layer height. Some people have success by slowing down their print speed to around 30-40mm/s. Make sure your heated bed is hot enough for your specific brand of Nylon filament. PEI build surfaces work well for Nylon.

You can also try 3D printing a raft in a different material like PETG, then switching out for your Nylon filament to help reduce warping. PETG is a good material to use since it shares a similar printing temperature with Nylon.

One user mentioned that they overcame warping by printing a really large brim. Nylon sticks quite well to Blue Painter’s Tape according to some users, so that could work well to reduce warping.

Turning off your cooling fans should help to reduce warping in Nylon filament.

How to Fix PLA Warping on PEI

To fix PLA warping on a PEI bed surface, clean your bed surface with rubbing alcohol. For larger 3D prints, you can try turning on the bed for an extra few minutes so the heat has enough time to travel through the bed, especially if you have glass. Lightly sanding the PEI surface with 2,000 grit sandpaper can work.

For people struggling with various 3D printing issues, you might want have wanted more guidance towards getting ideal 3D printing results. I created a course that's available to get called Filament Printing 101: Beginner's Guide to Filament Printing that takes you through some of the best 3D printing practices early on, so you can avoid those beginner mistakes.

Problems, defects, 3D printing errors and solutions

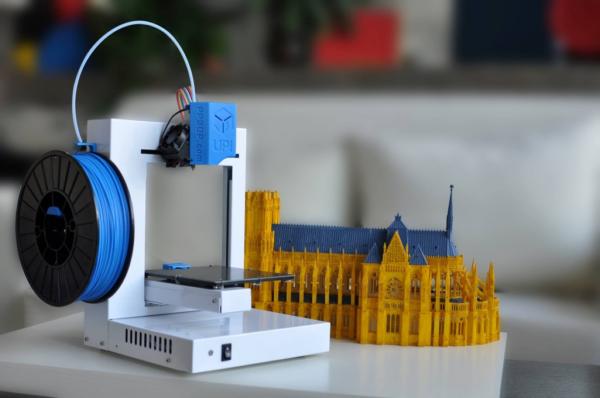

Often during the operation of a 3D printer, problems may arise due to which defects appear on the finished model. Or instead of a neat product, plastic noodles suddenly appear on the table.

Or instead of a neat product, plastic noodles suddenly appear on the table.

In fact, the causes of defects can be conditionally divided into 2 types - these are physical and software.

Physical ones are those that arise due to problems with the mechanics or any other causes that can be eliminated physically. These include problems with printer mechanisms (belt tension, backlash), clogged or deformed nozzle, incorrect table geometry, etc.

Software - these are defects that occur due to incorrect slicer settings or, less often, errors in the printer firmware. For example, incorrectly selected print speed, retract settings, incorrectly selected temperature for plastic, etc.

Very rarely, the problem may lie in the wrong or “flying” printer firmware (although usually the printer simply will not start then), overheating of some boards during printing, etc. These are rather special cases, so we will not consider them.

Model peels off or does not stick to the build plate

This is the most common 3D printing problem. Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Gap between table and nozzle 9 too large0023

This is the most common reason. You just need to set the correct gap between the table and the nozzle.

Modern printers often use an auto-calibration (auto-leveling) table system or an auxiliary table leveling program. To calibrate such printers, use the instructions. If there is no manual, it can be downloaded from the manufacturer's website.

If you have a simple printer without auto-calibration, a self-assembly or KIT kit, use a probe or a piece of paper folded in half to calibrate. The probe should be slightly pressed against the table by the nozzle. Before calibration, the table and extruder must be heated. Align the table surface over each adjustment screw (there may be 3 or 4) in turn, and only then check the center point.

If you're having trouble getting your table surface perfectly level, try raft printing. Raft is a thick substrate in several layers that is printed under the model. It will help smooth out the slight curvature of the table.

A small cheat sheet to determine the correct gap on the first layer

Plastic with poor adhesion

Some types of plastic, due to various reasons, such as large shrinkage, do not adhere well to the surface of the printing platform. In this case, try using stickers or special 3D adhesives to improve adhesion between the table and the first layer of plastic.

In the early days of 3D printing, there were experiments with different homemade 3D adhesive recipes. ABS diluted in acetone, BF glue, sugar syrup and even beer. Some experiments have been successful. Until now, some enthusiasts use some types of hairspray or glue sticks as 3D glue. But still they are inferior in their properties to industrial 3D adhesives.

Some types of high temperature plastics with a high percentage of shrinkage (ABS, Nylon, etc.) may peel off the table during printing. This is due to uneven cooling and “compression” of the model (the lower layers have already cooled down, but the upper ones have not yet). For such plastics, it is imperative to use a 3D printer with a heated table and a closed case.

Plastic temperature too low

The hotter the plastic is when it exits the nozzle, the better it will adhere to the print platform. It is better to print the first 5-10 layers at a higher temperature (+ 5-10 degrees) and turn off the blower fan.

Wrong first layer settings (speed and thickness)

A thicker layer sticks easier, so the standard first layer is 0.3mm thick. With an increase in print speed, the heating block may simply not have time to heat the plastic to the desired temperature and it will stick to the table worse. Before printing, check the speed and thickness settings of the first layer in the slicer.

A lot depends on how the 3D printer prints the first layer. Try to control the printing of the first layer and only then leave the printer to work alone.

Plastic does not choke from nozzle

The printer has already begun to print, but the print table remains empty. Or part of the model did not print.

Clogged nozzle

In 3D printing, a nozzle is a consumable. The nozzles are clogged or worn out (frequency depends on the type of plastic). The simplest thing is to replace the nozzle. But if there was no spare at hand, you can try to clean the old one. To do this, there is a whole set of thin needles. Or you can heat a clogged nozzle above the melting point of the plastic and “burn out” the blockage. But later it is still better to replace the nozzle.

Low temperature nozzle

You need to increase the temperature of the extruder in the slicer settings or check the thermistor and heating block. Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

If the problem occurs after replacing the thermistor - contact the manufacturer or read articles about PID tuning.

Empty extruder

As the extruder heats up, plastic begins to ooze out of the nozzle. Because of this, the extruder may start printing half empty. Because of this, part of the first layer is not printed. You can push the plastic manually by simply pushing the bar into the nozzle. Or solve this problem programmatically - in the slicer, add a contour print around the model (one line).

Some manufacturers and 3D enthusiasts add a line print on the edge of the table at the beginning of each GCode. This is done so that there is plastic in the nozzle by the time the model is printed.

Feed mechanism does not push through plastic

The plastic pushes the feed mechanism to the extruder - a motor with a special pulley put on the shaft. If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

Elephant foot

The first layers of the model are wider and protrude beyond the boundaries of the model. This is due to the fact that the upper layers put pressure on the first ones that have not yet cooled down and flatten them.

High table temperature

Due to the too high temperature of the table, the lower layers remain soft for a long time. Try lowering the table temperature. It is better to reduce gradually (in increments of 5 degrees). You can try to turn on the blower when printing the first layers.

Small gap between nozzle and platen

If, when printing the first layer, the nozzle is too close to the table, then excess plastic will be forced out. After a few coats, this will not be as noticeable, but can lead to the effect of an “elephant's foot”.

Plastic re-extrusion

When too much material is squeezed out of the nozzle, the walls of the model are not smooth, but bumpy, with sagging.

The solution is software - in the settings of the slicer, you need to set the material feed rate (fluidity) to a lower value. The average value is 95-98%.

It is worth checking the diameter of the rod. If its size is greater than 1.75, then the plastic will be squeezed out more than necessary.

Plastic underextrusion

The plastic is squeezed out too little, because of this, gaps may appear between the layer. The finished model will be fragile and fragile.

Wrong thread diameter

Check the filament diameter in the slicer settings. Sometimes, instead of the popular 1.75, the default is 2.85.

Incorrect feed factor settings

Check the fluidity settings in the slicer. The average should be 95-98%.

Clogged nozzle

Something could get into the nozzle and partially block the exit of the plastic. Visually, the plastic will choke from the nozzle, but in a smaller amount than necessary for printing.

Hairiness or cobwebs on finished model

Thin threads of plastic protrude from the outer wall of the model (most often on one side). The defect appears due to the flow of plastic from the nozzle during idle movement.

Insufficient retract

A retract is a slight pull of a plastic filament from an extruder. Due to the retract when the extruder is idle (from layer to layer or from model to model), heated plastic does not drip from the nozzle. For some flowable plastics (eg PETG) the speed and amount of retraction must be increased.

"Hairiness" can be easily removed by grinding or cutting off the threads with a sharp scalpel.

High temperature extruder

The higher the extruder temperature, the more fluid the plastic becomes. It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

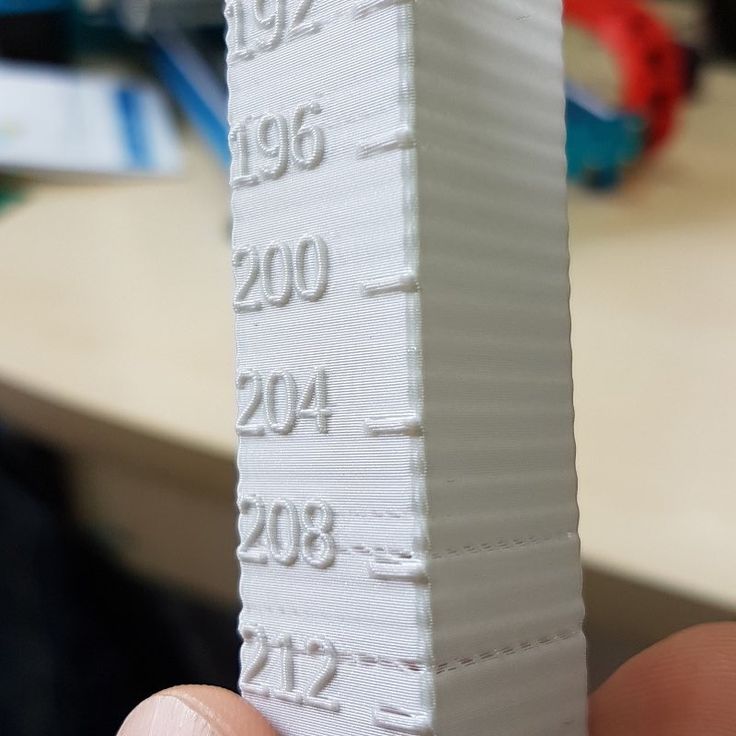

In the selection of the optimal extruder temperature, a test model - a tower - helps a lot. It clearly shows how plastic behaves when printed at different temperatures.

.

Temperature test

Top "perforated" or uneven

The top of the model is bumpy or with holes. The problem may arise if the top of the model is flat. For example, like a cube.

Insufficient airflow

When printing the top plane (cover), the plastic does not have time to cool down and remains too liquid. Because of this, the threads are torn and holes are formed. Increase the fan speed on the last layers.

Few top layers

The top of the print may be too thin and deform as a result. Check slicer settings. The number of upper layers is not recommended to be set less than 6.

Low percentage of filling

If the infill percentage is too low, then the top layer will simply have nothing to rely on. Increase the fill percentage in the slicer settings.

Increase the fill percentage in the slicer settings.

Model deformation

Some parts of the model seem to have melted in some places or on one side. The problem most often occurs when printing with PLA plastic. The defect appears due to the fact that the plastic does not have time to cool and deforms.

Insufficient airflow model

Turn the fans on to maximum. If their power is not enough (in some printers, the fan is located only on one side), you can put a regular desktop fan and direct it to the 3D printer table.

Small model

Small models are difficult to blow well. Try to print small items alongside larger ones, or place several identical models in different corners of the table. So the plastic will have more time to cool.

Layer offset

Layers shift along the x or y axis during printing.

Print head jam

Turn off the printer and try to move the extruder along the x and y axes with your hands. The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

Electronics overheating

Sometimes electronics problems can be to blame for misaligned layers. The most common cause is overheating of the drivers or too low current exposed to them.

Table top is loose

This is most often seen in 3D printers with glass. During printing, the nozzle may hit the model and move the glass slightly. Before printing, check if the glass or other printing surface is well fixed on the heating table.

Skip layers

Small holes are visible on the print, or the shell of the model is not continuous.

Teflon tube deformed

There are 2 types of thermal barriers - all-metal and with a Teflon tube. If overheated, the Teflon tube may deform. Plastic will pass through it, but in a smaller amount.

Low extruder temperature or high print speed

If the extruder is not heated enough, then the plastic will not be liquid enough and simply will not have time to be forced through the nozzle. The higher the print speed, the higher the extruder temperature should be.

Sometimes the outer walls print well, but the infill is “torn”. In this case, slow down the infill print speed in the slicer.

Model bundle

Cracks form on the surface of the printout during or after printing. Cracks can be large or very small. Most often, this problem occurs with plastics with a high percentage of shrinkage - ABS or Nylon.

Sudden temperature difference (if model delaminates during printing)

With a sharp temperature difference (for example, a draft), part of the model cools down faster. This leads to uneven shrinkage and incorrect distribution of internal stress. For plastics with low shrinkage, this is not critical. But if the shrinkage percentage is more than a few percent, the model may burst in layers.

But if the shrinkage percentage is more than a few percent, the model may burst in layers.

For printing with such plastics, it is recommended to use a printer with a closed housing. If this is not possible, try to avoid drafts and sudden temperature changes in the room where the 3D printer prints as much as possible.

Print temperature

Due to too low printing temperatures, the layers may not “stick” well to each other. Raise the print temperature in the slicer settings.

Hardening (if the model cracks after printing)

Sometimes cracks appear on the model a few days after printing. This is due to uneven distribution of internal stress after cooling. You can try to “harden” the finished product.

For hardening, the model is placed, for example, in an oven, and heated to the softening temperature of the plastic. After that, the heating is turned off and the oven is left to cool slowly with the model inside. Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Ringing

In places where the extruder changed direction, ripples are visible. Most often it looks like a shadow around the “sharp” protruding elements of the model.

Mechanical problems

Sometimes the problem occurs due to extruder play. Check if the extruder mount to the rails is loose. Be sure to check the tension of all belts.

High print speed or high accelerations

Moving the extruder too fast can cause vibrations that cause ripples on the wall of the model. The lighter the weight of the extruder, the less noticeable the ripples will be. To get rid of ringing, simply reduce the print speed in the slicer settings.

Slits for thin-walled models (not solid shell)

The thin wall of the model is not solid, but consists of two thin walls with a narrow gap between them. This problem is often faced by fans of printing "cutting" for baking.

This problem is often faced by fans of printing "cutting" for baking.

Left model with wall defect, right without

Wall thickness and nozzle diameter mismatch

If the wall thickness is 1 mm, and the nozzle diameter is 0.4, it turns out that for a solid wall, 2 nozzle passes are few, and 3 are already many. The result will depend on the slicer algorithm, but most often you will get 2 walls with a thin slot in the middle (the slicer cannot change the wall thickness). The solution to the problem may be a slight refinement of the 3D model or the use of a different slicer.

Algorithms for calculating 3D models are constantly being improved and refined, and now this problem is less common.

When modeling, take into account not only the thickness of the nozzle, but also the percentage of “overlapping” of lines on each other. If you have a nozzle with a diameter of 0.4 - make the wall in your model not 0.

8, but 0.7 - 0.75.

Wrong model geometry

When instead of a circle you get an oval, and instead of a square you get a semblance of a rhombus.

The main reason is malfunctions in the mechanics of the printer. Be sure to check:

Belts

Check belt tension in x and y. Belts stretch over time and may need to be tightened or replaced. Each 3D printer has its own way of tightening the belt. If the belts are slightly stretched, you can tighten them with the help of a "spring".

Loose pulleys, etc.

Check if all bolts and nuts are tight. Are there backlashes. Pay special attention to tightening the pulleys located on the motors along the x and y axes.

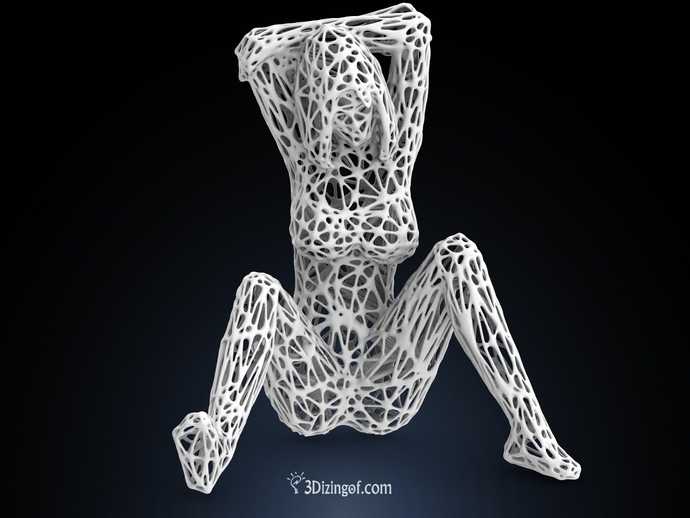

Sagging of some parts of the model

Some parts are not printed, broken, or instead of a neat surface, a swollen plastic snot is obtained.

No support for overhangs

A 3D printer cannot print in the air, so if there are overhanging elements in the model, you need to set supports - supports. The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

When printing with soluble support, you can set the gap between the model and support - 0. This will make the surface smoother. If the support material and the model are the same, you need to add a small gap. Otherwise, it will be difficult to separate the support from the model.

Split model

Sometimes the supports can take more plastic than the model. In this case, to save material and time, it will be more convenient to cut the model. If you have more than one 3D printer, then the model will print several times faster.

When cutting the model, you can leave grooves or mortgages so that the pieces of the model are connected without displacement.

Totals

In this article, we talked about the most popular 3D printing defects and how to solve them. Don't be intimidated by such a long list. Some problems are rare and you are unlikely to encounter them.

Some problems are rare and you are unlikely to encounter them.

There is a list of problems that arise due to the design features of a 3D printer, so try to choose a printer that suits your needs. To do this, you need to understand what products and what material you need.

Problems associated with printing algorithms are quickly eliminated by software developers.

Do not be afraid of possible difficulties and each print will be successful.

Troubleshooting 3D printing・Cults

This article should help you identify various 3D printing problems. Find the image or description in this list that best describes the problem you're experiencing. We offer some tips that should help you solve this problem.

As you know, 3D printing is an empirical process and it is through mistakes that you learn to understand, set up and use your machine. With the help of this list, you should be able to resolve the major bugs. If you are still experiencing issues or have additional tips to add to this list, feel free to contact us and let us know!

#1 Drooling

Symptom

Thin threads are woven into gaps between different parts of a 3D printed part.

Common Name: oozing

Possible Cause

Plastic continues to leak out of the head as it moves due to residual pressure in the heater and fluidity of the molten plastic.

Suggested remedies

Increase filament retraction length in Slic3r, retraction distance in CuraEngine. Retracting the filament will cause the pressure in the print head heater to drop. The effect can be modulated by adjusting the retraction speed directly in the slicer.

Increase print head speed. This allows the melted plastic to spread less time and leave marks between the printed parts.

Reduce the extrusion temperature of your plastic. If it is too high, the plastic becomes more fluid and flows out of the extruder faster.

#2 It is collapsing

Symptom

Collapse or poor quality of the overhanging surface, leaving small bumps.

Common name: overhang

Possible cause

The plastic deposited on the periphery of the protrusion does not solidify fast enough, so the deposited filament moves before it solidifies. The phenomenon is repeated or emphasized from one layer to another.

The phenomenon is repeated or emphasized from one layer to another.

Suggested fixes

Vent the deposited plastic more efficiently, for example by adding a fan to the extruder or directly with a portable fan.

Create print supports under the overhangs.

Reorient the part to avoid overhangs.

#3 Flaky sides or top

Symptoms

Contours not bonded enough.

Flat surfaces are not completely covered.

Possible cause

Not enough material is deposited. Too narrow, the deposited wires do not touch each other enough and therefore do not stick to the adjacent wire.

There is dirt in the nozzle, which prevents the passage of the melt.

The extrusion temperature is too low, the wire dries out too quickly or shrinks and therefore does not stick to the adjacent wire.

Suggested Tools

Calibrating the extruder to obtain material flow according to data received from the slicer.

Unlock the extrusion nozzle.

Increase extrusion temperature.

Increase the blending speed in your slicer.

#4 Not enough material on thin parts

Symptom

The edges of a very thin area are not strong enough, not enough material.

Possible cause

Recycling or reworking is not effective enough.

Incorrect filament solidification.

Slippage of the thread drive during retraction.

Suggested remedies

Reduce the retraction speed and length while printing.

Increase "extra leg length when retracting" when using Slic3r.

Increase the spring pressure on the driven gear.

#5 Blisters

Symptom

Blisters, mismatched geometry, such as small bumps that are seen mostly in areas with a small surface area.

Possible cause

The filament is too hot during extrusion or the filament cooling system is not effective enough.

Suggested media

Place more parts on the plate while printing. In this case, the nozzle will print more objects and therefore allow more time for the part to cool before passing over it again.

Improve the cooling of your 3D printed object by adding cooling systems.

#6 Thin walls delaminate

Symptom

At a thin wall without filler, the threads diverge, they are not glued together on the sides.

Possible Cause

The walls of your 3D print are too thin or they don't fit so small.

Suggested tools

Draw thicker walls to adapt to the thread thickness.

In the slicer settings, set a sludge width that is a sub-multiple of the wall width while remaining consistent with the extrusion diameter and layer height.

Change slicer.

#7 Layer shifts horizontally

Symptom

The layer is shifting in the X or Y axis (or both).

Possible Cause

Print head or plate movement problem.

Suggested fix

Reduce the acceleration on the axis that has the problem.

#8 Layers shift evenly

Symptom

Layers almost always shift along the X and/or Y axis after a certain print height.

Possible Cause

Head or plate offset failure due to overheating of motors going into safe mode.

Suggested fix

Cool engines with cooling systems (fans).

#9 Corners curl up

Symptom

Deformation in Z direction during 3D printing. This figure increases in case of a strong overhang.

Common name: curling

Possible cause

Poor curing, shrinkage effect due to temperature difference of the wire deposited on the previous cooled layer.

Suggested Solutions

Increase slope in the 3D part to reduce overhang.

Further cooling of the deposited plastic using a ventilation system.

Add print supports to affected areas.

#10 Corners fall off

Symptom

The corners of the printed object are peeling off the plate, creating an uneven base.

Common name: warping

Possible cause

Poor fit between workpiece and insert.

Material shrinkage factor too high.

The first layer is not pressed enough against the board.

Suggested Solutions

Change media as PLA is less likely to warp.

Apply adhesive to the printing plate (glue, tape, varnish, etc.).

Correctly adjust the plate height before printing.

Apply a thinner first layer to further crush the deposited wire.

Add a bezel under the first layer.

Heat up the stove.

Clean and degrease the base.

Change the filling strategy. Fill the bottom concentrically instead of linearly, then fill the inside in a honeycomb pattern to avoid any shrinkage effect.

Reduce the internal fill density of your 3D printed object.

#11 Extrusion density too low

Symptom

Incorrect material density.

Possible cause

Material consumption too low

Suggested remedies

Unlock the extrusion nozzle.

Filament blocked upstream of extruder (e.g. spool assembly)

Check thread drive (e.g. knurled screw problem)

Corners #12 not forming correctly

Symptom

The corners are not straight enough, they can even stick out and increase the size of the part.

Possible Cause

Too much material is deposited in the corner because the nozzle slows too much as it passes through the corner.

Suggested remedies

Intentionally soften the corner of the part in the 3D modeling software.

Increase the "jerk" on your 3D printer's axis control.

#13 There are black drops

Symptom

Burnt (blackened) plastic in some areas of the printed object.

Possible Cause

Poor nozzle seal causing burnt PLA or ABS to drip around the nozzle.

Suggested fix

Remove the nozzle and close it again.

#14 Layers poorly welded

Symptom

Part breaks at attachment point between two printed layers.

Possible cause

Too much cooling, the deposited layer does not adhere well to the previous layer, because it was not hot enough during the deposition.

Suggested remedies

Reduce fan speed during printing.

Increase the minimum print speed in the slicer.

#15 Bubbles form on the first layer

Symptom

The first layer comes off the plate locally in the form of bubbles.

Possible Causes

Moisture present in the material which gradually evaporates upon contact with the heating plate.

Insufficient heating plate temperature for the material being used.

Suggested products

Store raw material rolls in a dry place, in closed packaging, with a desiccant bag.

Dry damaged material: place in a rotary oven at 40°C for approximately 3 hours. Be careful not to heat above 45°C or 50°C as this may cause the threads to stick together in the bobbin and even lose their cylindrical shape.

Increase the temperature of the heating plate.

Printing on tape or special adhesive.

#16 Fragile top and bottom

Symptom

Horizontal sides too thin and brittle.

Possible Causes

Insufficient material thickness above and below thin fill print. The laid threads have too few support points and break between the threading ribs.

Suggested products

Place at least 2 or 3 fully filled layers ("Solid layers" option in Slic3r) for the "top" and "bottom" faces.

Increase the fill of your object.

#17 Hole tops collapse

Symptom

Horizontal center hole top wires collapse during construction.

Possible causes

Plumb line too horizontal.

Mismatch between nozzle temperature, wire cooling and speed.

Suggested fixes

Reduce or eliminate this overhang area by modifying the 3D file geometry. An example is in the large hole in the photo, shaped like a drop of water, not a cylinder.

Add print supports below this area if the ledge is too difficult for the 3D printer.

Avoid too much slowdown in this area, even if the layer print time is short.

#18 Color or clarity varies

Symptom

The color or transparency of the material changes in different areas during 3D printing.

Possible causes

Different crystallization of the material due to different cooling rates. This may be due, for example, to the printing time of individual parts of the object or to the power of the fan.

Radiation from the nozzle can affect the thermal cycle of the previous layer and thereby change its appearance.

The applied layer is too hot because the underlying layer has not had time to cool.

Be careful, the physical-mechanical properties of the part may change due to these differences in crystallization!

Suggested fixes

Better control of cooling with slicer settings: change fan power based on plate cooling time or slow print speed in proportion to plate surface.

Reduce extrusion temperature for faster and more uniform phase transition.

#19 Layers are delaminating

Symptom

Some layers are flexing and cracks appear between the different printed layers.

Possible causes

Twisting phenomenon due to the effect mentioned in #9 the above happens between layers.

The wire cools too quickly at the exit of the nozzle, it does not weld properly with the previous layer.

Severe contraction of the material during cooling or phase change.

Some materials extruded at high temperature (ABS, PC...) may present a significant shrinkage phenomenon.

Suggested remedies

Change the extrusion temperature.

Change the media.

Avoid blowing on a deferred wire, reducing fan power, or placing the printer in a draughty room.

Close the assembly area in a controlled cabinet at a temperature close to the glass transition temperature of the material.

#20 Drops appear

Symptom

Drops of material are deposited at various points on the side surface of the 3D printed object.

Possible causes

Excessive extrusion when resuming extrusion after stopping extrusion when moving from one point of the part to another or when changing layers.

Suggested Remedies

Some slicers have a setting that allows, after a pause in printing, to request that more be pushed in before resuming normal printing than was removed by retraction.

#21 Bowden extruder salivation

Symptom

Extruder Bowden is either running too hard or not running enough. First impressions of your extruder are not great, too much extruded material, bridges between different areas in motion where extrusion should stop.

Possible cause

Insufficient thread shrinkage to compensate for gap in Bowden tube. Depending on the diameter of the tube and filament, as well as the length of the body, the motor must draw a certain length of filament through the bends of the tube before the filament is drawn out of the heating head.

Depending on the diameter of the tube and filament, as well as the length of the body, the motor must draw a certain length of filament through the bends of the tube before the filament is drawn out of the heating head.

Suggested fixes

Increase the "pull" distance in the slicer. The detail on the left was printed with 1.5 mm of indentation, which was clearly not enough. When the pull-in distance was increased to 6mm, the center part was printed. Too much shrinkage causes hot material to enter the thermal break, the temperature of the thermal break gradually rises, and the melting thread eventually gets stuck in the thermal break. The engine is no longer able to effectively push it. Reducing the retraction distance to 4 mm results in the part shown on the right.

#22 Streaks or regular patterns on extrusion

Symptom

Repeating patterns appear on the walls of 3D prints.

The pattern may change depending on the direction of movement of the motors.