3D printed reactor

How to Make an Impossible Nuclear Reactor (3D Printer Sold Separately)

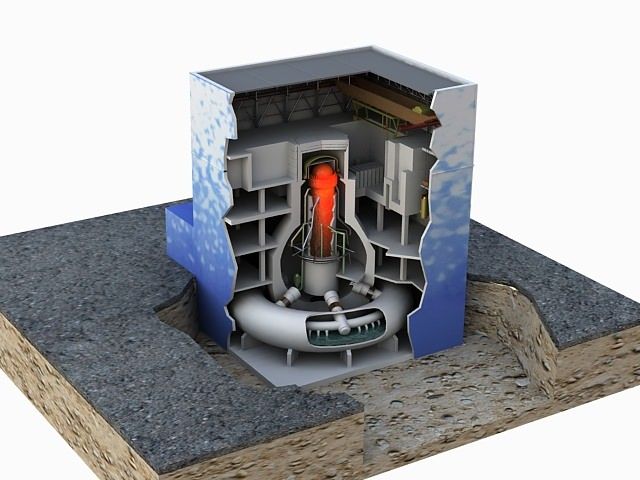

Jutting out from the coast of China’s Fujian province, Changbiao Island may seem small and unremarkable. It is anything but. This is where the China National Nuclear Corp. is building two fast-neutron nuclear breeder reactors, the first of which is slated to connect to the grid in 2023, the second in 2026. So China could start producing weapons-grade plutonium there very soon.

They are called breeder reactors because they produce more nuclear fuel than they consume. According to Chinese authorities, the ones on Changbiao are civilian power reactors, designed to generate 600 megawatts of electricity each, which amounts to a little more than 1 percent of the total capacity of China’s nuclear power sector. But each reactor could also yield up to 200 kilograms of weapons-grade plutonium each year, enough for about 50 nuclear warheads—which is making nuclear-arms-control experts in Western countries nervous.

“China is in the middle of a big buildup of its nuclear-weapon arsenal,” says Frank von Hippel, a physicist and nuclear-policy expert at Princeton University. “My belief is that one of the purposes of these reactors is to produce weapons-grade plutonium for that buildup.”

Fast breeder reactors date back more than half a century, when the global nuclear community thought there wouldn’t be enough uranium fuel available for the nuclear-power industry. Natural uranium is composed of only 0.7 percent uranium 235 (U-235), which can support the fission reactions needed for generating power. The rest is U-238, which cannot sustain a chain reaction. But when bombarded with neutrons, U-238 is readily transformed into an isotope that can: plutonium-239.

Breeder reactors use plutonium as the fissile fuel in the core, which is surrounded by a blanket rich in U-238. Fast neutrons—that is, ones with 1 megaelectron-volt or more of kinetic energy—split the plutonium atoms, releasing secondary neutrons that are captured by the U-238 and convert some of that U-238 into plutonium. Liquid sodium is used as a coolant because it does not slow down neutrons as much as water does. Weapons-grade plutonium can be separated chemically from the blanket.

Liquid sodium is used as a coolant because it does not slow down neutrons as much as water does. Weapons-grade plutonium can be separated chemically from the blanket.

While many countries explored the possibility of using fast breeder reactors early on, only one of the breeder reactors built in France, Germany, the United Kingdom, or the United States survived into the 21st century before it, too, was shut down. Japan also developed a fast breeder power reactor, one that proved to be a costly mistake, prompting a decision in 2016 to decommission it.

Not so in China, India, and Russia. India has had a breeder-reactor prototype under construction for about two decades, von Hippel says. Starting even earlier, Russia has built two fast breeder reactors, which are still operating today . But Russia has decided not to build another one until the 2030s, because they are more expensive than conventional water-cooled reactors.

Each reactor could also yield up to 200 kilograms of weapons-grade plutonium each year, enough for about 50 nuclear warheads.

The new breeder reactors in China, meanwhile, are demonstration projects, the second step in a three-step program to develop fast breeder reactors to reduce the country’s dependence on coal. The first step was a 20-MW experimental fast breeder reactor near Beijing, which was begun in 2000 but took many years to complete and connect to the grid. The country will soon decide whether to continue to the third step of building a commercial 1,000-MW breeder reactor. The China National Nuclear Corp. did not respond to inquiries from Spectrum about its plans.

On its own, building a fast breeder reactor is not necessarily a signal that a country intends to produce nuclear weapons, says Jake Hecla, a graduate student in nuclear engineering at the University of California, Berkeley. But the reactors slated for Changbiao are viewed with suspicion in the West, particularly after the recent discovery that China is constructing missile-silo fields in three locations.

China already has between 3 and 5 tonnes of plutonium for warheads, Hecla says. And they are building 250 additional silos. “So they likely need more plutonium,” he says. “One way of doing this would be to create civilian infrastructure that is dual use, and this fast breeder program is perfect for that. If China flipped on old plutonium-processing reactors, the international response would be strong and negative. This provides a way to get around that.”

An added concern is that China stopped voluntarily disclosing its civilian plutonium stockpiles to the International Atomic Energy Agency in 2018. Other nations with plutonium stockpiles, such as Japan, France, and the United States, “work with the international community to disclose their plutonium stockpiles, providing reassurance that the material is not being misused,” says Hecla.

These concerns are valid in light of the expansion of China’s nuclear arsenal and the modernization of its nuclear weapons, says Hui Zhang, an expert on China’s nuclear policies at Harvard University. But, he points out, there are more straightforward ways to produce weapons-grade plutonium.

But, he points out, there are more straightforward ways to produce weapons-grade plutonium.

“Direct plutonium production could make much more fuel each year,” says Zhang. “Because China is already a nuclear state, if they really wanted to build up [their] nuclear-weapon arsenal, it would’ve been better to dedicate a plutonium fast breeder reactor for that purpose, not to build a reactor for civilian purposes.”

But no matter how they intend to do it, if Chinese weapons builders are trying to catch up to the United States, which has nearly 88 tonnes of plutonium, they still have a long road ahead.

This article appears in the January 2023 print issue as “China’s New Breeder Reactors May Produce More Than Just Watts .”

3D-printed nuclear reactor promises faster, more economical path to nuclear energy

News

Topics: Nuclear Science and Technology Clean Energy

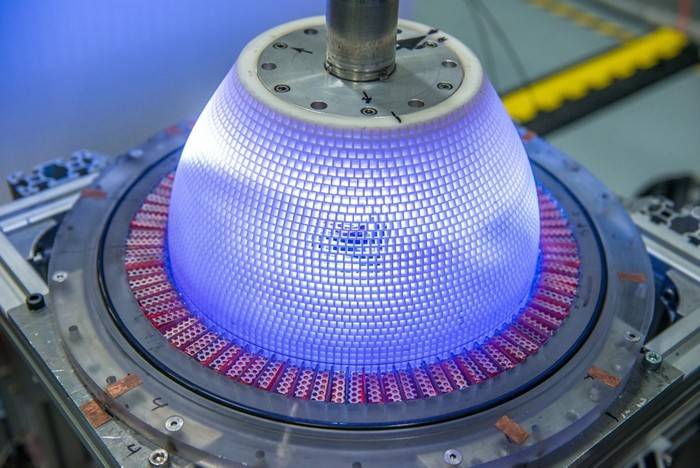

The Transformational Challenge Reactor Demonstration Program uses thermal imaging to actively monitor the direct deposition of stainless steel to 3D print a component. Credit: Oak Ridge National Laboratory, U.S. Dept. of Energy

Credit: Oak Ridge National Laboratory, U.S. Dept. of Energy

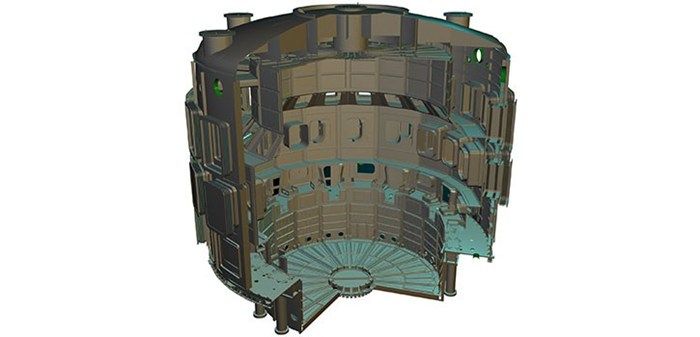

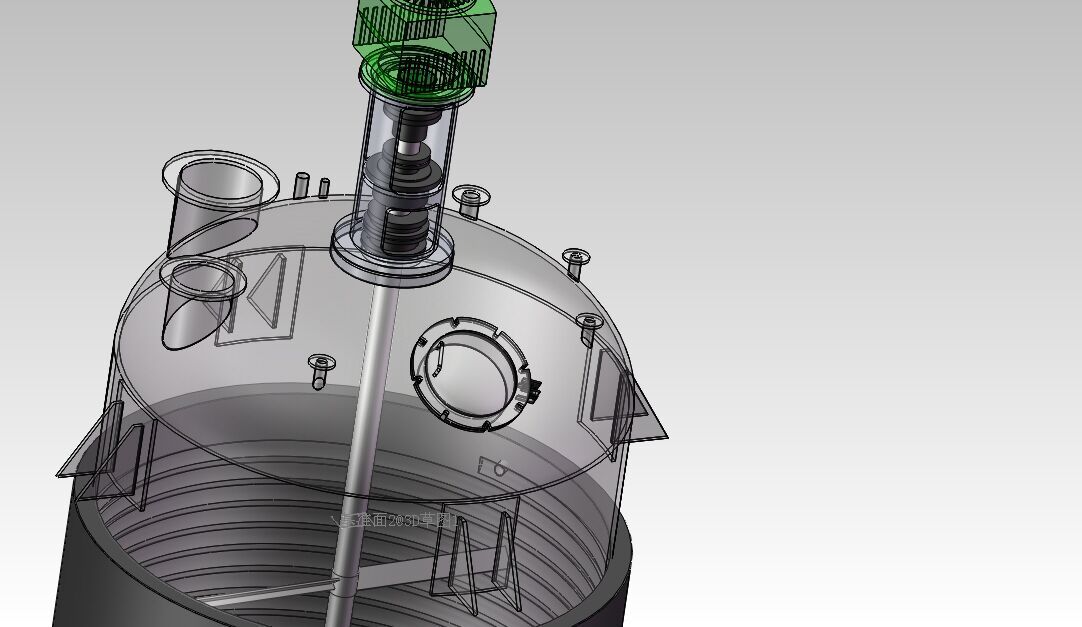

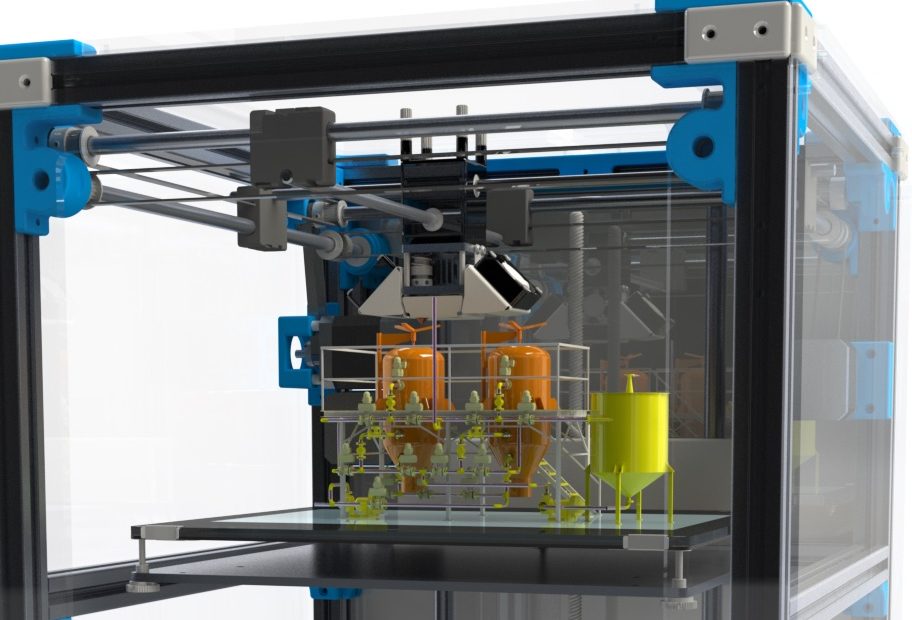

OAK RIDGE, Tenn., May 11, 2020 — Researchers at the Department of Energy’s Oak Ridge National Laboratory are refining their design of a 3D-printed nuclear reactor core, scaling up the additive manufacturing process necessary to build it, and developing methods to confirm the consistency and reliability of its printed components.

The Transformational Challenge Reactor Demonstration Program’s unprecedented approach to nuclear energy leverages advances from ORNL in manufacturing, materials, nuclear science, nuclear engineering, high-performance computing, data analytics and related fields.

The lab aims to turn on the first-of-its-kind reactor by 2023. The program has maintained its aggressive timeline during the COVID-19 pandemic, using remote work to continue design and analysis efforts. [TCR video]

“The nuclear industry is still constrained in thinking about the way we design, build and deploy nuclear energy technology,” ORNL Director Thomas Zacharia said. “DOE launched this program to seek a new approach to rapidly and economically develop transformational energy solutions that deliver reliable, clean energy.”

“DOE launched this program to seek a new approach to rapidly and economically develop transformational energy solutions that deliver reliable, clean energy.”

Reactor development and deployment have traditionally relied on materials, fuels and technology pioneered in the 1950s and ’60s, and high costs and decades-long construction times have limited the United States to building only one new nuclear power plant in the last 20 years.

TCR will introduce new, advanced materials and use integrated sensors and controls, providing a highly optimized, efficient system that reduces cost, relying on scientific advances with potential to shape a new path in reactor design, manufacturing, licensing and operation.

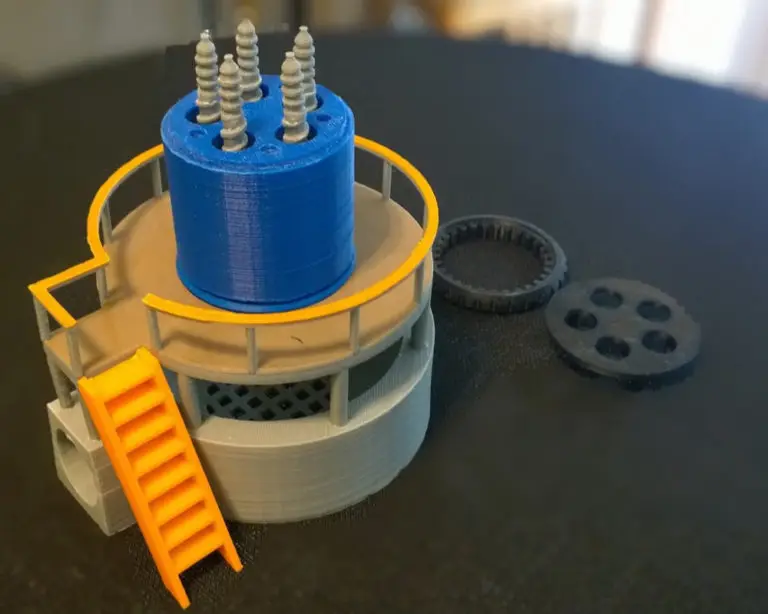

The TCR program has completed several foundational experiments including selection of a core design, and a three-month “sprint” that demonstrated the agility of the additive manufacturing technology to quickly produce a prototype reactor core.

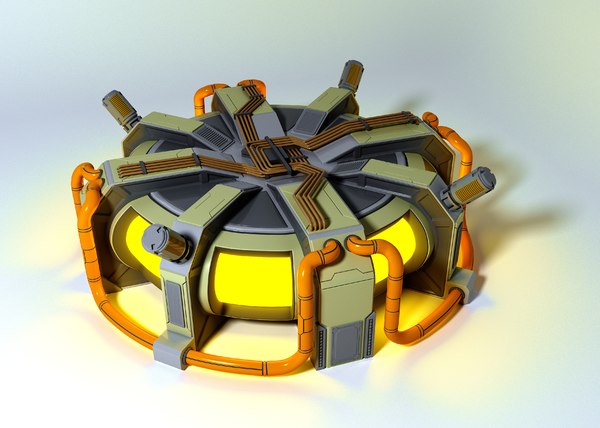

ORNL scientists have selected and optimized a design for printing over a three month period, demonstrating the ability to rapidly produce a prototype reactor core. Credit: Brittany Cramer/Oak Ridge National Laboratory, U.S. Dept. of Energy

Credit: Brittany Cramer/Oak Ridge National Laboratory, U.S. Dept. of Energy

Researchers will now focus on refining the selected design and the processes that will ensure an optimal and reliable energy system. Monitoring technologies continually assess the manufacturing process, providing live data streams that enable real-time qualification of the printed material and performance analysis through artificial intelligence. The team also conducts extensive post-build testing to assess component performance and establish links between the behavior of each unique part and its live manufacturing data.

“We have been aggressively developing the capability to make this program a reality over the last several months, and our effort has proven that this technology is ready to demonstrate a 3D-printed nuclear reactor core,” said Kurt Terrani, the TCR technical director. “The current situation for nuclear is dire. This is a foundational effort that can open the floodgates to rapid innovation for the nuclear community. ”

”

As part of deploying a 3D-printed nuclear reactor, the program will also create a digital platform that will help in handing off the technology to industry for rapid adoption of additively manufactured nuclear energy technology.

“The entire TCR concept is made possible because of the significant advances in additive manufacturing process technology,” Terrani said. “By using 3D printing, we can use technology and materials that the nuclear community has been unable to capitalize on in the last several decades. This includes sensors for near autonomous control and a library of data and a new and accelerated approach to qualification that will benefit the entire nuclear community.”

Through the TCR program, ORNL is seeking a solution to a troubling trend. Although nuclear power plants provide nearly 20 percent of U.S. electricity, more than half of U.S. reactors will be retired within 20 years, based on current license expiration dates.

“The TCR program will provide a new model for accelerated deployment of advanced nuclear energy systems,” Zacharia said. “If cost and construction times are not addressed in the very near future, the United States will eventually lose its single largest source of emissions-free power.”

“If cost and construction times are not addressed in the very near future, the United States will eventually lose its single largest source of emissions-free power.”

ORNL is partnering with Argonne and Idaho national laboratories and engaging with industry to enable rapid adoption for commercial use.

The Transformational Challenge Reactor builds on ORNL’s 77-year history of international leadership in nuclear science and technology development. The lab began as home to the world’s first continuously operating reactor, and its scientists and engineers pioneered technology and expertise in the first decades of the Atomic Age.

Today, the lab operates the High Flux Isotope Reactor, a DOE Office of Science user facility that provides a world-leading source of neutrons for a variety of research and produces isotopes for medicine, industry, and space exploration. TCR will be the 14th reactor built and operated by ORNL.

“Since its inception as the home of the X-10 Graphite Reactor, ORNL has been at the forefront of nuclear science and engineering,” Zacharia said. “Today, our expertise and unparalleled scientific tools create an opportunity to chart a new course in the nuclear field.”

“Today, our expertise and unparalleled scientific tools create an opportunity to chart a new course in the nuclear field.”

TCR is supported by DOE’s Office of Nuclear Energy.

UT-Battelle manages ORNL for DOE’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. The Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit https://energy.gov/science.

Media Contact

3-D Printing/Advanced Manufacturing

Advanced Reactors

Nuclear Energy

Transformational Challenge Reactor

US scientists develop 3D printed nuclear reactor

News

the core of a nuclear reactor, while working out methods for quality control and reliability of 3D printed components.

Scientists are looking for a solution to a growing problem: currently, about twenty percent of the country's electricity needs are covered by nuclear power, but over the next twenty years, more than half of the nuclear generating capacity is scheduled to close due to the end of its operating life.

Engineers traditionally rely on materials, fuels, and technologies developed in the 1950s and 1960s to design, build, and commission nuclear reactors. High costs and long periods of decades seriously limit the ability of the United States to increase nuclear generating capacity: over the past twenty years, the country has taken up the construction of only one new nuclear power plant.

“The nuclear industry is still conservative in its approach to the design, construction and operation of nuclear power technologies. The Department of Energy launched this program with the goal of finding new approaches to quickly and cost-effectively create transformative clean and reliable energy solutions,” says ORNL Director Thomas Zachariah.

The Transformational Challenge Reactor (TCR) demonstration program is still experimental in nature and aims to introduce ORNL developments in manufacturing technologies, materials science, nuclear physics and engineering, high-performance computing, data analysis and related areas. Work is proceeding at a high pace despite the pandemic, which forced scientists to work remotely.

Work is proceeding at a high pace despite the pandemic, which forced scientists to work remotely.

To date, a number of fundamental experiments have been carried out under the TCR program - from the selection of a suitable core design to a three-month track on the additive production of reactor prototypes. The next step will be the optimization of the selected design in the direction of increasing efficiency and reliability. 3D printing and processing are under constant supervision, and the resulting data is used to qualify products and analyze the effectiveness of workflows using artificial intelligence in real time. Prototype products are also subjected to extensive performance testing, and the test results are used to optimize manufacturing methods.

“The TCR program was made possible by significant advances in additive manufacturing technologies. Thanks to 3D printing, we can apply technologies and materials that have remained inaccessible to the nuclear industry for several decades. This includes sensors for almost fully automated control, extensive data archives, and new, faster approaches to qualification that the entire nuclear industry will benefit from,” says Kurt Terrani, TCR project technical director.

This includes sensors for almost fully automated control, extensive data archives, and new, faster approaches to qualification that the entire nuclear industry will benefit from,” says Kurt Terrani, TCR project technical director.

Part of the program to develop a 3D printed reactor will be the creation of a digital platform for the transfer of technologies to nuclear industry enterprises in order to quickly implement developments in the use of additive manufacturing technologies. The researchers expect to start testing the first reactor of its kind by early 2023.

3D printing technologies are already of limited use in the American nuclear industry: Westinghouse Electric recently reported on the installation of a 3D printed component in the reactor of the first unit of the Byron nuclear power plant in Illinois.

energy nuclear ORNL reactor

Subscribe to the author

Subscribe

Don't want

4

3D printing of nuclear reactors for entertainment and enrichment

In recent decades, additive technologies, also known as 3D printing, have become increasingly common in manufacturing. First of all, they are well suited for prototyping new products - there is little time between development and testing. However, they are increasingly used in the production of everything from small batches of goods to bespoke cases, and even rocket engine components.

First of all, they are well suited for prototyping new products - there is little time between development and testing. However, they are increasingly used in the production of everything from small batches of goods to bespoke cases, and even rocket engine components.

The obvious advantage of additive technologies is that they use non-specific equipment and common materials as resources, they do not need expensive molds, as in the case of injection molding, and they do not require long and waste-producing processing on milling and similar machines . All production comes down to feeding a 3D model and one or more input materials into the printing device - and this device turns the 3D model into a physical object with very little waste.

The nuclear industry has not overlooked these benefits. As a result, various components are made on 3D printers - from those that keep existing reactors running to tools that help process spent fuel and even entire nuclear reactors.

This is no ordinary Fused Fused Modeling

Any user of a 3D printer working with PLA, ABS or UV-sensitive SLA resin can attest that the cost of producing items this way is hard to beat. The process of manufacturing everything from a broken gear in an engine to a special case for a new printed circuit board will be faster and cheaper than traditional ones - if we are talking about making a small number of copies.

The process of manufacturing everything from a broken gear in an engine to a special case for a new printed circuit board will be faster and cheaper than traditional ones - if we are talking about making a small number of copies.

Relativity Space prints the Aeon Engine

It is because of this that the aerospace industry, from NASA to start-ups in this field, is warm to the use of additive technologies for prototyping and production itself. Rocket engines and their myriad components, including turbopumps and valves, are ideal for 3D printing. Each engine prototype is different, and only a few hundred are produced each year - as is the case with the Merlin 1D engine from the SpaceX Falcon 9 rocket.. Startups such as Relativity Space are envisioning the use of additive technologies to completely transform the space industry.

Naturally, here we are not talking about a printer costing up to $ 2000, which manufactures parts from PLA or ABS plastic using FDM technology (layer-by-layer modeling). And not even about fashionable SLA printers (laser stereolithography), costing a car. To print aluminum, or even titanium parts, you need an SLM (selective laser melting) printer, also known as a direct metal laser melting printer. This is another step up from SLS (selective laser sintering) printers, which bind materials together (nylon, metal, ceramic or glass) but do not melt them.

And not even about fashionable SLA printers (laser stereolithography), costing a car. To print aluminum, or even titanium parts, you need an SLM (selective laser melting) printer, also known as a direct metal laser melting printer. This is another step up from SLS (selective laser sintering) printers, which bind materials together (nylon, metal, ceramic or glass) but do not melt them.

SLM is similar to SLA, only the principle of printing is reversed. Fresh metal powder is added on top of the printed part, the laser melts it and adds a new layer. Everything happens in a sealed container filled with an inert gas to prevent oxidation. You can guess that SLM machines cost about as much as a whole house.

For comparison, on the All3DP website there is such a plate, which lists the cost of manufacturing a standard Benchy boat model when printing from various metals.

| Metal plastic (former aluminum - PLA with aluminum) | $22. 44 44 |

| Stainless steel, galvanized, brushed | $84.75 |

| Bronze, solid, ground | $299.91 |

| Silver, solid, polished | $713.47 |

| Gold - plated, polished | $87.75 |

| Gold solid 18K | $12 540 |

| Platinum, solid, polished | $27 314 |

Nuclear Reactor

The next natural step for additive technologies will be to move from the thermal hell of a rocket engine to the calmer—though perhaps more radioactive—environment of a nuclear reactor. It is advantageous to manufacture nuclear reactors in large quantities, then economies of scale work. However, over the past decades in the United States, for example, this market has practically disappeared, although it used to be quite extensive.

However, over the past decades in the United States, for example, this market has practically disappeared, although it used to be quite extensive.

When the former giants of the nuclear industry wanted to get back in the game - the US with the AP1000 reactor and France with the EPR reactor - it turned out that exactly the same nuclear power plants were built in China (which has a strong nuclear industry). 4 AP1000 reactors and 2 EPR reactors were connected to the grid many years before the countries that developed them plan to build and connect them. Ironically, the US-made cooling pumps in the AP1000 are prone to constant failure.

The problem with any significant infrastructure project is having the right knowledge and supply chains. When a country regularly builds and maintains nuclear power plants, it retains both the supply chains and the skills required to operate them. When a country stops building new nuclear power plants for several decades, supply chains disappear and knowledge is lost. Of course, you can rebuild the entire production and attract people, but it makes sense to consider more efficient approaches to the production of such equipment.

Of course, you can rebuild the entire production and attract people, but it makes sense to consider more efficient approaches to the production of such equipment.

In an attempt by the US to catch up with countries such as Canada, Russia [which has the world's largest number of nuclear power plants under construction] and South Korea, the US Department of Energy has tasked Oak Ridge National Laboratory with the task of spearheading the Transformational Challenge Reactor (TCR) program. The program is to "demonstrate a revolutionary approach to the deployment of new nuclear energy systems." Essentially, the goal of the project is to 3D print as many microreactors as possible to demonstrate the possibilities offered by additive technologies.

Working on details

Together with Argonne National Laboratory (ANL) and Idaho National Laboratory (INL), ORNL is working on many of the details associated with this radical change in the manufacturing process, taking into account the increased requirements for materials used in a nuclear reactor. Questions arise about thermal distortion and fatigue of materials compared to conventionally fabricated components. Some of the results of these studies are described in a new paper that gives an idea of the amount of work that has gone into investigating the viability of this approach.

Questions arise about thermal distortion and fatigue of materials compared to conventionally fabricated components. Some of the results of these studies are described in a new paper that gives an idea of the amount of work that has gone into investigating the viability of this approach.

ANL has already published discoveries made in the SLM printing process using high-speed X-ray imaging, which allows us to see the process in detail. One of the main problems they found related to forced airflow, which sucks colder material into the molten mass. As a result, these pieces of cold material lead to defects in the finished product.

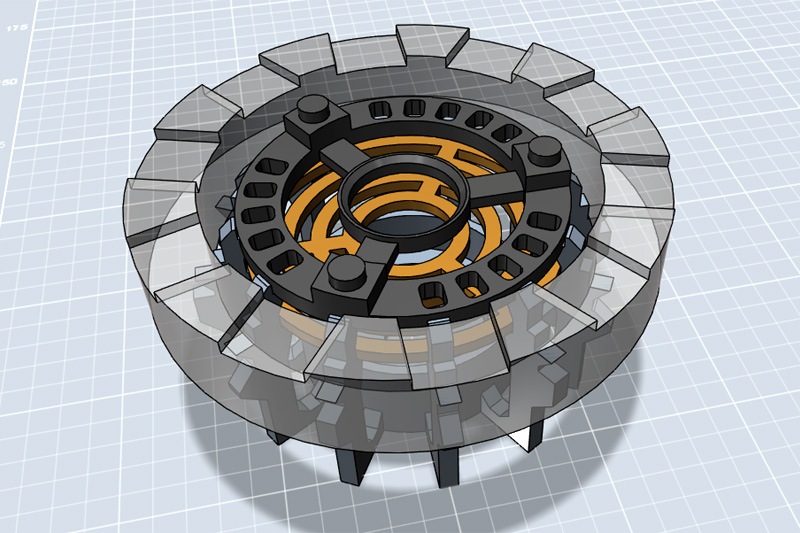

The TCR project fact sheet describes that the microreactor will need to use TRISO (uranium nitride) fuel particles, a yttrium hydride neutron moderator, and a 3D printed silicon carbide and stainless steel core. The reactor will be cooled with helium, which is quite unique since most modern reactors use water, heavy water, or sodium for cooling.

Since the TCR program is quite young (first published in 2019), it is difficult to assess its progress or understand what can be expected from it. To do this, we can evaluate what has already been achieved in the process of integrating additive technologies into the nuclear industry.

To do this, we can evaluate what has already been achieved in the process of integrating additive technologies into the nuclear industry.

Integration of additive technologies in the nuclear industry

So far, relatively simple components are printed on a 3D printer for nuclear reactors. In 2017, Siemens replaced a 108mm impeller in a fire pump at the nuclear power plant in Krsko, Slovenia, with a 3D printed copy. The manufacturer of the original pump has already closed, because the pump was installed somewhere around 1980 year.

Westinghouse is also working in this direction, and recently installed a 3D-printed coupling on the first module of the Byron nuclear power plant. This device holds the fuel rods while they are lowered into the reactor. One of the main motives for its installation is the desire to understand how the environment of a nuclear reactor will affect materials printed on a 3D printer, and whether there will be a difference with components made in the usual way.

To sum up

It is clear that 3D printing has a promising future in manufacturing. In the case of the nuclear industry, it not only offers a good way to produce replacement parts for reactors over 60 years old, more than half of whose suppliers have already closed or changed production. Along with a host of other new manufacturing technologies, it also offers exciting new opportunities for the production of next generation nuclear reactors, whether fusion or fission reactors.

It has many obvious advantages - to accelerate the prototyping of new reactors and concepts, to ensure the operation of reactors in remote settlements and future colonies on the Moon and Mars without having to rely on a complex supply chain. Last but not least is the issue of cost - the production of a reactor by this method should be much cheaper, and, possibly, it will allow the production and assembly of reactors directly on the ground.

All this is obviously not very interesting to people who do not have access to SLM printers - but who knows, maybe in ten years we will all be printing our own rocket engines and fusion reactor components at home.