3D printer milling

Hybrid 3D printers available on the market

Published on September 3, 2020 by Aysha M.

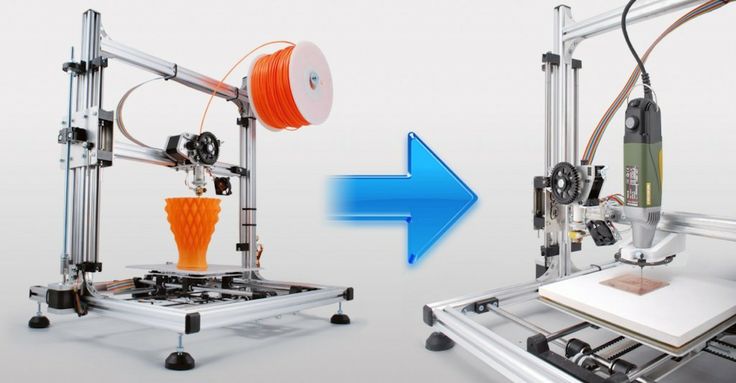

Hybrid machining combines additive and subtractive manufacturing methods in one single solution. The concept was around since 1990’s but it was not commercially popular until recently. Today, more and more manufacturers are developing hybrid 3D printers as the demand for such machines keeps growing. Some manufacturers are offering even more functions than 3D printing and CNC – laser engraving and cutting and paste extrusion are often added to offer a versatile solution for the customer. Therefore, such hybrid printers are also known as “All-in-one printer” or “3-in-1 printer”. We have prepared a list of 14 hybrid 3D printers available on the market, divided into desktop and industrial categories and ranked in alphabetical order.

Desktop hybrid 3D printers

5axismaker

The 5AXISMAKER solution was launched in 2015 by UK-based manufacturer 5AXISWORKS. This machine is available in two versions, the 5xm400 and 5xm600 according to the maximum manufacturing size. Both support any CAD/CAM software (provided a post processor is available) and include a one-year commercial subscription to Autodesk® Fusion 360 TM Ultimate. They include a set of tools including a 5-axis CNC router, touch probe, 3D printer, 3D scanning and measurement, and hot wire cutter, plus the potential to add more items via their adapter. As we have said they have a printing volume of 400mm3 or 600mm3 depending on the version, and are compatible with engineering thermoplastics, such as nylon, PC, etc. You can purchase one of these hybrid multifunction 3D printers for $6,500 on the manufacturer’s website.

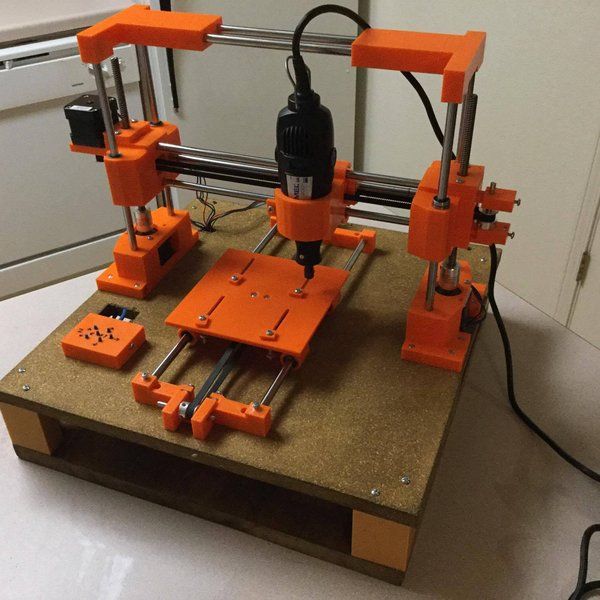

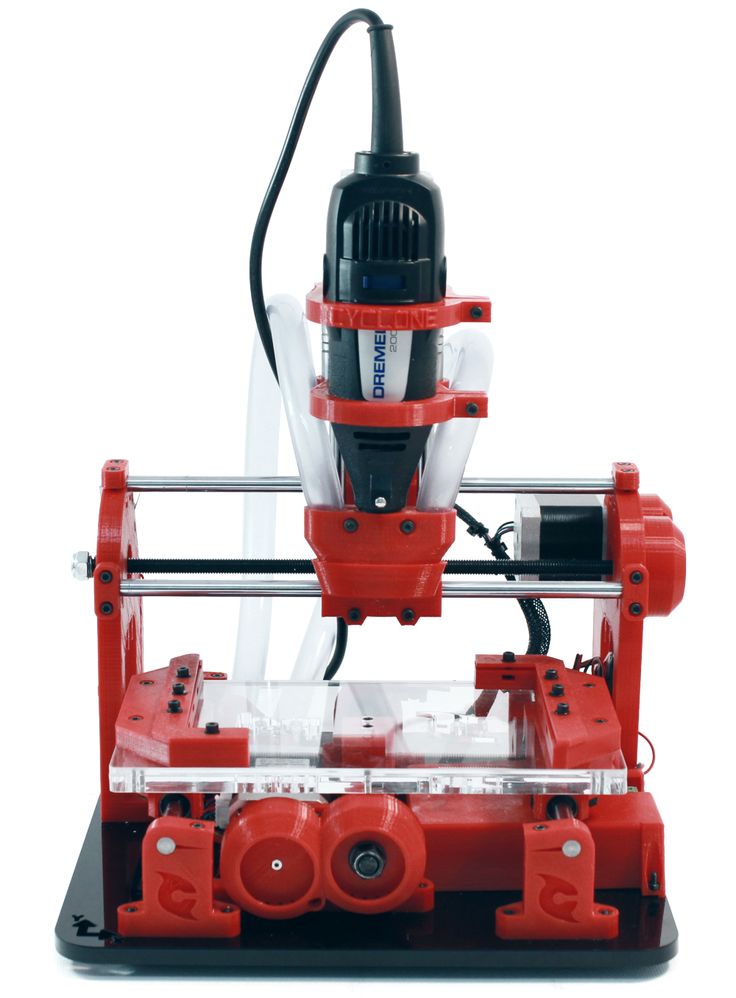

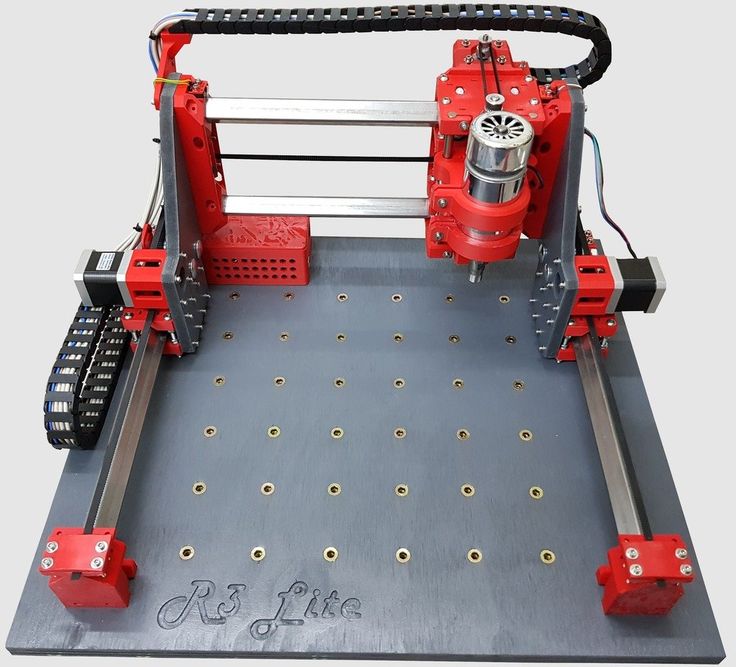

Creality CP-01

Creality 3D, a low-cost 3D printer manufacturer, has unveiled its Creality CP-01, a hybrid printer that can be used as a 3D printer, CNC milling machine, and laser engraving machine. The integrated FDM-based 3D printer prints with ABS, PLA, PVA, TPU and wood components at a maximum print speed of 80 mm/sec. The heating plate can be heated up to 100°C. The maximum volume is 200 x 200 x 200 mm and it must not be exceeded even for components that are milled or engraved. The integrated laser can engrave wood, plastic and paper with a laser power of 500mW. The same materials extended by printed circuit boards can also be milled with a maximum spindle speed of 4,800 rpm. The three individual modules of the hybrid printer (extruder, CNC milling and laser engraving unit) can be easily exchanged as required. By combining three units in one, the CP-01 saves not only space but also costs. However, the CNC milling and laser engraving units are entry-level models, so they do not provide above-average performance. In summary, the CP-01 is a good option for makers and hobbyists, but it is not at an industrial level.

The maximum volume is 200 x 200 x 200 mm and it must not be exceeded even for components that are milled or engraved. The integrated laser can engrave wood, plastic and paper with a laser power of 500mW. The same materials extended by printed circuit boards can also be milled with a maximum spindle speed of 4,800 rpm. The three individual modules of the hybrid printer (extruder, CNC milling and laser engraving unit) can be easily exchanged as required. By combining three units in one, the CP-01 saves not only space but also costs. However, the CNC milling and laser engraving units are entry-level models, so they do not provide above-average performance. In summary, the CP-01 is a good option for makers and hobbyists, but it is not at an industrial level.

da Vinci 1.0 Pro 3-in-1

Taiwanese manufacturer, XYZPrinting, entered the global 3D printing market with easy-to-use FDM desktop 3D printers. Today, the company is known for its da Vinci line of products for their value for money. The da Vinci 1.0 Pro 3 in 1 is a hybrid printer that integrates both a 3D printer based on FDM technology and a 3D scanner. If that’s not enough, a laser engraving unit can be added. The 3D printer prints parts from PLA, ABS, PETG, HIPS and wood PLA at a maximum print speed of 120 mm/sec. Because the da Vinci 1.0 Pro 3 in 1 has an open filament system, the materials do not necessarily have to be purchased from XYZPrinting, but can be purchased from third-party suppliers. The heating plate can be heated up to 90°C and the maximum construction volume is 200 x 200 x 190 mm. The 3D scans can have a maximum size of 15 x 15 cm with an accuracy of 0.25 mm. The optional laser engraving unit has an engraving area of 20 x 20 cm with a laser power of 350 mW. Due to its features, the da Vinci1.0 Pro 3 in 1 is suitable for professionals.

The da Vinci 1.0 Pro 3 in 1 is a hybrid printer that integrates both a 3D printer based on FDM technology and a 3D scanner. If that’s not enough, a laser engraving unit can be added. The 3D printer prints parts from PLA, ABS, PETG, HIPS and wood PLA at a maximum print speed of 120 mm/sec. Because the da Vinci 1.0 Pro 3 in 1 has an open filament system, the materials do not necessarily have to be purchased from XYZPrinting, but can be purchased from third-party suppliers. The heating plate can be heated up to 90°C and the maximum construction volume is 200 x 200 x 190 mm. The 3D scans can have a maximum size of 15 x 15 cm with an accuracy of 0.25 mm. The optional laser engraving unit has an engraving area of 20 x 20 cm with a laser power of 350 mW. Due to its features, the da Vinci1.0 Pro 3 in 1 is suitable for professionals.

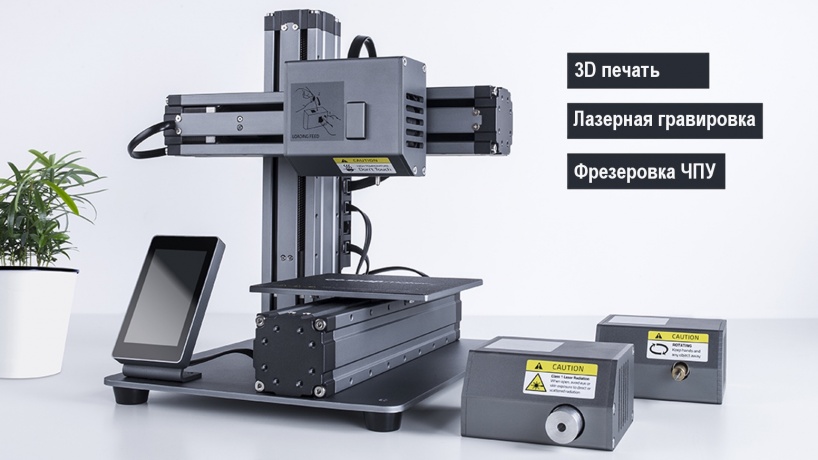

DOBOT MOOZ 2 PLUS

Shenzhen Yuejiang Technology Co. (DOBOT) is a leading global provider of intelligent robotics solutions. DOBOT’s product line includes the MOOZ 2 PLUS. The DOBOT MOOZ 2 PLUS is a hybrid printer that combines 3D printing, CNC milling and laser engraving to print parts made ofPLA, TPU, PETG and flexible materials at a maximum print speed of 80 mm/sec. The heating plate can be heated up to 80°C. The maximum construction volume is 200 x 200 x 190 mm and this volume must not be exceeded even for components that are to be milled or engraved. The integrated laser can engrave wood, bamboo, leather, paper, plastic, fabric and opaque acrylic with a laser power of 1.6 W. The CNC milling machine mills wood, bamboo, acrylic, PCB, carbon fiber boards, plastic, etc. with a maximum spindle speed of 8,000 rpm. The DOBOT MOOZ 2 Plus is a desktop printer that is ideal for makers.

The DOBOT MOOZ 2 PLUS is a hybrid printer that combines 3D printing, CNC milling and laser engraving to print parts made ofPLA, TPU, PETG and flexible materials at a maximum print speed of 80 mm/sec. The heating plate can be heated up to 80°C. The maximum construction volume is 200 x 200 x 190 mm and this volume must not be exceeded even for components that are to be milled or engraved. The integrated laser can engrave wood, bamboo, leather, paper, plastic, fabric and opaque acrylic with a laser power of 1.6 W. The CNC milling machine mills wood, bamboo, acrylic, PCB, carbon fiber boards, plastic, etc. with a maximum spindle speed of 8,000 rpm. The DOBOT MOOZ 2 Plus is a desktop printer that is ideal for makers.

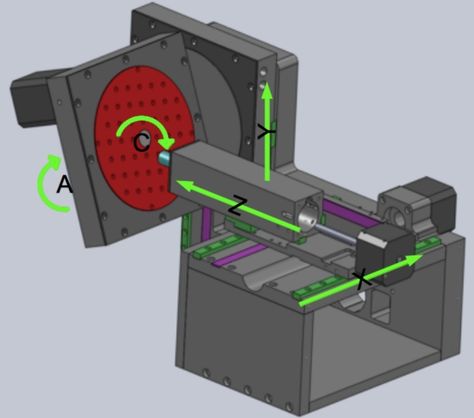

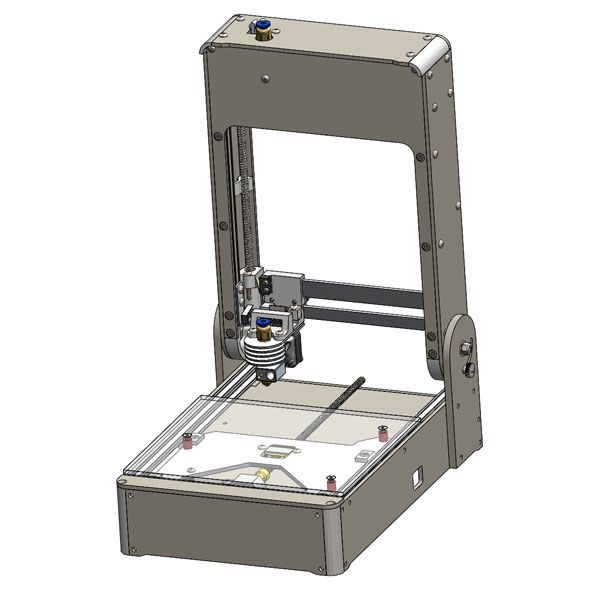

H-Series by Diabase Engineering

The H-Series from Diabase Engineering is a hybrid machine that offers CNC machining and 3D printing in a single interface. The machine has been carefully engineered to solve real problems in the desktop manufacturing toolchain. It is a machine that enables the manufacture of functional products with high accuracy and a professional finish. Depending on the number of axes you decide to go for, whether 3, 4 or 5, the machine offers different build volumes. The build volume on the 3-axis machine is 416mm x 186mm x 210mm. On the 3D printing side, you can print a range of engineering-grade thermoplastics such as ABS, PLA, NYLON, PETG, TPU, water-soluble materials and more. The machine is equipped with an active nozzle cleaning system, a heated filament cabinet, a changeable heated build platform and various subtrative tool heads for milling, engraving and surfacing. As mentioned you can also go for a rotary modular axis for 4th and 5th axis printing and milling.

It is a machine that enables the manufacture of functional products with high accuracy and a professional finish. Depending on the number of axes you decide to go for, whether 3, 4 or 5, the machine offers different build volumes. The build volume on the 3-axis machine is 416mm x 186mm x 210mm. On the 3D printing side, you can print a range of engineering-grade thermoplastics such as ABS, PLA, NYLON, PETG, TPU, water-soluble materials and more. The machine is equipped with an active nozzle cleaning system, a heated filament cabinet, a changeable heated build platform and various subtrative tool heads for milling, engraving and surfacing. As mentioned you can also go for a rotary modular axis for 4th and 5th axis printing and milling.

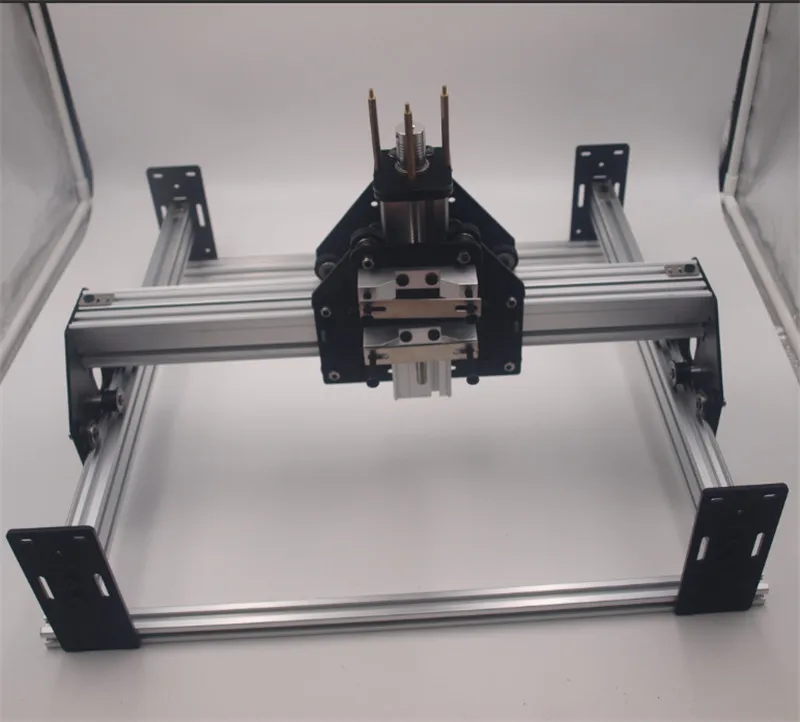

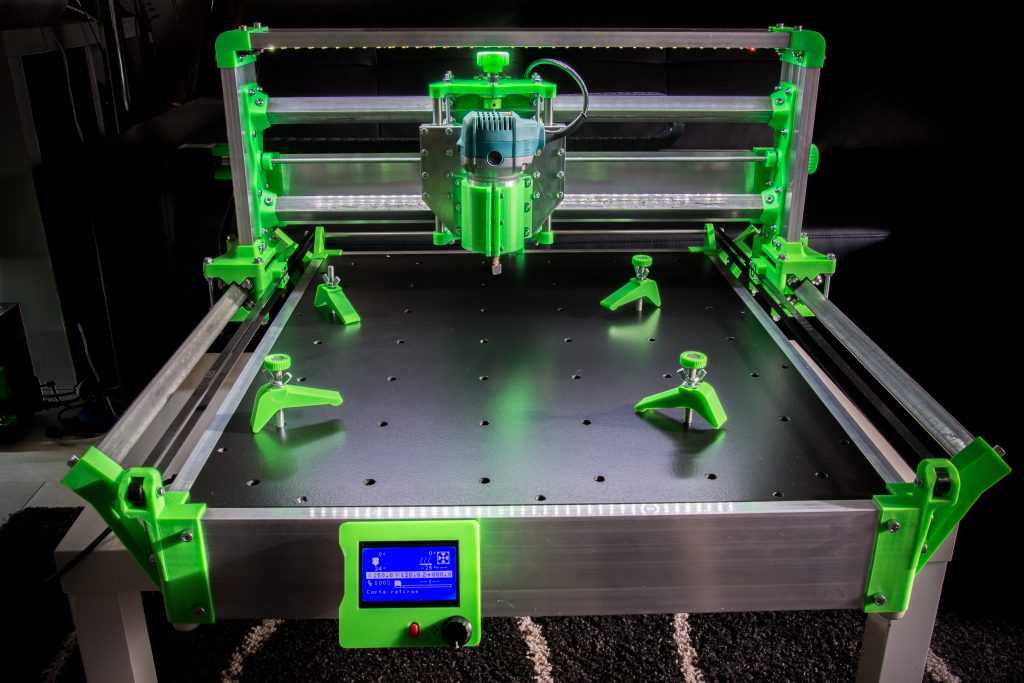

Snapmaker 2.0

Snapmaker 2.0, is a 3-in-1 machine that enables 3D printing, laser engraving and cutting, and CNC carving. It supports several 3D printing materials such PLS, ABS, wood, etc. For CNC carving you would be able to use carbon fiber sheet, PCB, platane wood, and more. You can also perform laser engraving and cutting on a diverse range of materials including plywood, fabric, leather, and acrylic. Snapmaker 2.0 comes with a smart touchscreen that simplifies the workflow of your projects, letting you manage the most-used tasks directly from the touchscreen. This desktop hybrid 3D printer retails for $1,039.

You can also perform laser engraving and cutting on a diverse range of materials including plywood, fabric, leather, and acrylic. Snapmaker 2.0 comes with a smart touchscreen that simplifies the workflow of your projects, letting you manage the most-used tasks directly from the touchscreen. This desktop hybrid 3D printer retails for $1,039.

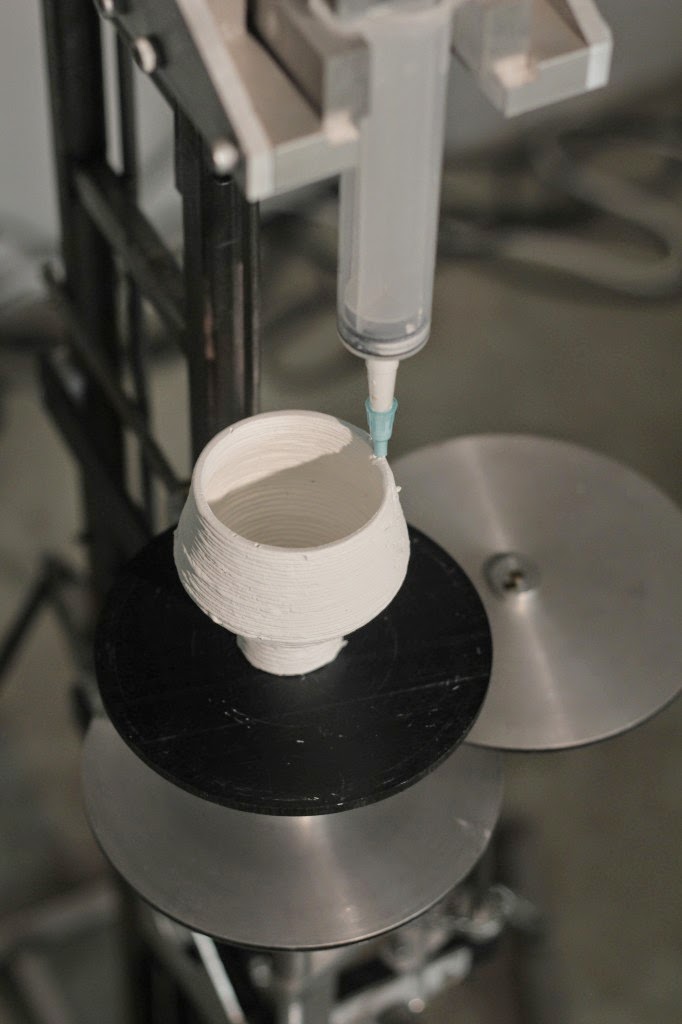

ZMorph VX

ZMorph VX is considered by many to be one of the best desktop hybrid 3D printers currently available on the market. This versatile solution supports single and dual extrusion, CNC milling, laser engraving and cutting, and paste extrusion. ZMorph VX works with virtually all 3D printing materials on the market, so the users can take advantage of 3D printing with advanced materials like nylon, HIPS, PC/ ABS, and more. Silent X and Y steppers reduce noise by 50%. The paste extrusion function works with chocolate, dough, cream cheese, frosting, and more. To ensure a smooth workflow process for the users, the Polish company also released a designated software Voxeliser 2.

Industrial hybrid 3D printers

Aconity

MIDIThe 3D printer AconityMIDI was launched by the German manufacturer Aconity3D in 2018 with the intention of providing a flexible production system to users. AconityMIDI is equipped with an optional second camera that allows for parallel setup times while the main system is still in production. It has a maximum production volume of Ø 170 mm x H 200 mm and a layer thickness of up to 10 μm. In addition, the system integrates process monitoring or high temperature preheating (up to 1200°C). This hybrid 3D printer is also available as a DUAL-Laser system that allows for maximizing productivity. Weighing 1450kg, AconityMIDI can be equipped with the unique vacuum option and Micro-LBM configuration. This is certainly an advanced solution for professionals in the 3D industry.

AMBIT Series 7

The new multitasking system AMBIT Series 7 has been developed by the company Hybrid Manufacturing Technologies with the aim of opening up new opportunities in the production of metal parts. It provides a perfect integration of 7 production technologies in the same tool without precedents. This new multitasking system integrates DED technology heads with a robust performance to deposit metal from 0.5 to 3mm thickness. It also features a column that functions as a universal docking station to monitor and control manufacturing processes to ensure quality parts. Its main novelty is the subsequent verification of manufacturing quality thanks to the eddy current inspection head, which allows the detection of surface and subway cracks. The AMBIT Series 7 solution is undoubtedly an innovative way to integrate additives in conventional manufacturing!

It provides a perfect integration of 7 production technologies in the same tool without precedents. This new multitasking system integrates DED technology heads with a robust performance to deposit metal from 0.5 to 3mm thickness. It also features a column that functions as a universal docking station to monitor and control manufacturing processes to ensure quality parts. Its main novelty is the subsequent verification of manufacturing quality thanks to the eddy current inspection head, which allows the detection of surface and subway cracks. The AMBIT Series 7 solution is undoubtedly an innovative way to integrate additives in conventional manufacturing!

INTEGREX i-400 AM by MAZAK

Manufactured by the Japanese company MAZAK, the INTEGREX i-400 AM is a hybrid multi-tasking machine that provides additive manufacturing technology and high-precision finish machining operations for large format manufacturing. The AM technology is based on Directed Energy Deposition (DED) process. The nozzle deposits the molten metal layer by layer to build the part. DED is interesting for repair applications of worn or damaged components such as aerospace turbine blades. In terms of its Multi-Tasking capabilities, the INTEGREX i-400 AM provides full 5-axis machining to process prismatic parts from solid billets or castings, round parts, highly contoured parts and AM manufactured parts.

The nozzle deposits the molten metal layer by layer to build the part. DED is interesting for repair applications of worn or damaged components such as aerospace turbine blades. In terms of its Multi-Tasking capabilities, the INTEGREX i-400 AM provides full 5-axis machining to process prismatic parts from solid billets or castings, round parts, highly contoured parts and AM manufactured parts.

Kraken hybrid 3D printer

The KRAKEN project is a European project that was launched to bring an all-in-one hybrid manufacturing machine to the market at an affordable price. Therefore, the KRAKEN system provides 3D printing technologies, robotics and subtractive technologies. It has been developed for the production of end-use parts and large customized functional parts, measuring up to 20 meters long with 0.1mm precision. The creators claim that the system is 40% faster than competing methods thanks to high deposition rates during the AM process and a seamless switch to milling and finishing operations (with an interchangeable manufacturing head). KRAKEN is also said to be 25% more productive and take up to 90% less floor space. On the 3D printing side, it integrates multiple technologies too: wire arc AM, resin 3D printing, and a thermal spray process to allow metal 3D printing on top of a polymer part. This is a very complete solution to say the least!

KRAKEN is also said to be 25% more productive and take up to 90% less floor space. On the 3D printing side, it integrates multiple technologies too: wire arc AM, resin 3D printing, and a thermal spray process to allow metal 3D printing on top of a polymer part. This is a very complete solution to say the least!

LASERTEC 65 3D Hybrid by DMG Mori

The German-Japanese manufacturer DMG Mori, the result of the merger between the German company DMG and the Japanese company Mori Seiki, offers industrial manufacturing solutions for all industries. Its product range includes hybrid manufacturing machines that can both print and machine parts. Among them is the LASERTEC 65 3D Hybrid, a machine with a spray nozzle that offers additive metal fabrication and milling capabilities. It can create parts up to a maximum size of 735 x 650 x 560 mm and is based on the DED process. Equipped with 5 axes, it can change its laser head to mill the designed part. The LASERTEC 65 3D Hybrid integrates Siemens software solutions to maximize your design and control your manufacturing process.

LENS 860 hybrid 3D printer by Optomec

The LENS 860 has been designed by Optomec to provide industrial companies with large metal parts: it combines a DED process and a milling spindle for finishing work. Its maximum printing volume is 860 x 600 x 610 mm and its laser reaches a maximum power of 3kW. Four versions are now available, with or without milling, and with or without controlled atmosphere. Depending on the configuration you choose, you will be able to print non-reactive metals such as steel or flap, or metals such as titanium.

LUMEX Avance -25 by Matsuura

Released in 2002, LUMEX Avance-25 is a hybrid 3D printer developed by a Japanese manufacturer Matsuura. It combines metal 3D printing technology with conventional milling, CNC. This hybrid solution uses a 400 W Yb fiber laser and can store up to 20 tools, as well as 3D print parts at a speed of 7 cubic cm per hour, for a maximum part weight of 90 kg. An interesting advantage of this machine is its APR System (Automatic Powder Recovery System), which means that powder supply, collection and reuse can be fully automated without the need for the operator to directly touch the powder. Excess powder that remains after sintering is automatically sieved and reused for subsequent sintering.

Excess powder that remains after sintering is automatically sieved and reused for subsequent sintering.

Did this list of hybrid 3D printers help you? Let us know what you think of these hybrid 3D printers. Leave a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

All-in-one 3D printer 2022 - Laser engraving, CNC milling & more

All-in-one 3D printers are 3D printers with additional functionalities like CNC milling or laser engraving and cutting. There are very few options available on the market today- find out which ones in this guide. If you make a purchase through one of our affiliate links, we may earn a small commission to support our content and site.

Last update March 19, 2020

In our Fall update, we removed discontinued products (XYZprinting, FLUX, …), added new brands (Hyrel 3D, Diabase) and models (Snapmaker 2. 0), and did some minor adjustments here and there. We also added the E3D ASMBL Tool Changer as s special mention.

0), and did some minor adjustments here and there. We also added the E3D ASMBL Tool Changer as s special mention.

Table of contents

What’s an all-in-one 3D printer?

Top all-in-one 3D printers in 2022

CNC milling

Paste extrusion (syringe extruder)

Laser cutting and laser engraving

Other functionalities

VX

System 30M

Snapmaker 2.0 A150

Snapmaker Original

Stepcraft-2/840 (Kit)

Optimus C1

5AXISMAKER CNC machine

H-Series

Special mention: ASMBL Tool Changer

AIO Robotics Zeus 3D printer and scanner combo

ATOM Atom 2.5 EX 3D Printer Kit

FABtotum Core PRO

FLUX Delta

MAG iCreatum

MakerArm, the ultimate 4-in-1 3D printer for fablabs?

XYZprinting Da Vinci 1.0 Pro 3-in-1

What’s an all-in-one 3D printer?

Like a modern Swiss Army knife, all-in-one 3D printers (a.k.a. AIO 3D printers, multifunctional 3D printers, or multitool 3D printers) boast features such as laser engraving and cutting, vinyl cutting, drawing, and more.

AIO 3D printers can be multi-purpose fabrication tools for makers, professionals, businesses, and hobbyists alike. However, there aren’t that many desktop options available today. We decided to take a closer look at the multitool 3D printer market and list the best all-in-one 3D printers currently available.

We only included multifunctional 3D printers that cost less than $9,000, excluding industrial all-in-one 3D printers that require advanced knowledge (and budget).

Top all-in-one 3D printers in 2022

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Snapmaker | Snapmaker Original | 125 × 125 × 125 mm4.92 × 4.92 × 4.92 in | – | $ 799812 €709 £119,096 ¥ | Contact |

| Snapmaker | Snapmaker 2. 0 A150 0 A150 | 160 × 160 × 90 mm6.3 × 6.3 × 3.54 in | – | $ 1,1991 219 €1,064 £178,718 ¥ | Contact |

| Stepcraft | Stepcraft-2/840 (Kit) | 600 × 840 × 140 mm23.62 × 33.07 × 5.51 in | – | $ 1,6991 479 €1,507 £253,246 ¥ | Contact |

| Febtop Tech | Optimus C1 | 280 × 280 × 280 mm11.02 × 11.02 × 11.02 in | – | $ 2,4992 540 €2,217 £372,491 ¥ | Quote |

| ZMorph | VX | 250 × 235 × 165 mm9.84 × 9.25 × 6.5 in | – | $ 2,7992 845 €2,483 £417,208 ¥ | Quote |

| Diabase | H-Series | 400 × 180 × 180 mm15.75 × 7.09 × 7.09 in | – | $ 8,5008 500 €7,540 £1,266,976 ¥ | Quote |

| 5AXISWORKS | 5AXISMAKER CNC machine | 400 × 400 × 400 mm15.75 × 15.75 × 15.75 in | United Kingdom | upon request | Quote |

| Hyrel 3D | System 30M | 225 × 200 × 200 mm8. 86 × 7.87 × 7.87 in 86 × 7.87 × 7.87 in | United States | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Product | Brand | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|

| Snapmaker Original | Snapmaker | – | $ 799812 €709 £119,096 ¥ | Contact manufacturer |

| Snapmaker 2.0 A150 | Snapmaker | – | $ 1,1991 219 €1,064 £178,718 ¥ | Contact manufacturer |

| Stepcraft-2/840 (Kit) | Stepcraft | – | $ 1,6991 479 €1,507 £253,246 ¥ | Contact manufacturer |

| Optimus C1 | Febtop Tech | – | $ 2,4992 540 €2,217 £372,491 ¥ | Get a quote |

| VX | ZMorph | – | $ 2,7992 845 €2,483 £417,208 ¥ | Get a quote |

| H-Series | Diabase | – | $ 8,5008 500 €7,540 £1,266,976 ¥ | Get a quote |

| 5AXISMAKER CNC machine | 5AXISWORKS | United Kingdom | upon request | Get a quote |

| System 30M | Hyrel 3D | United States | upon request | Get a quote |

All-in-one 3D printer functionalities

A range of functionalities can be included in all-in-one 3D printers: CNC milling, laser cutting and engraving, paste extrusion, and more.

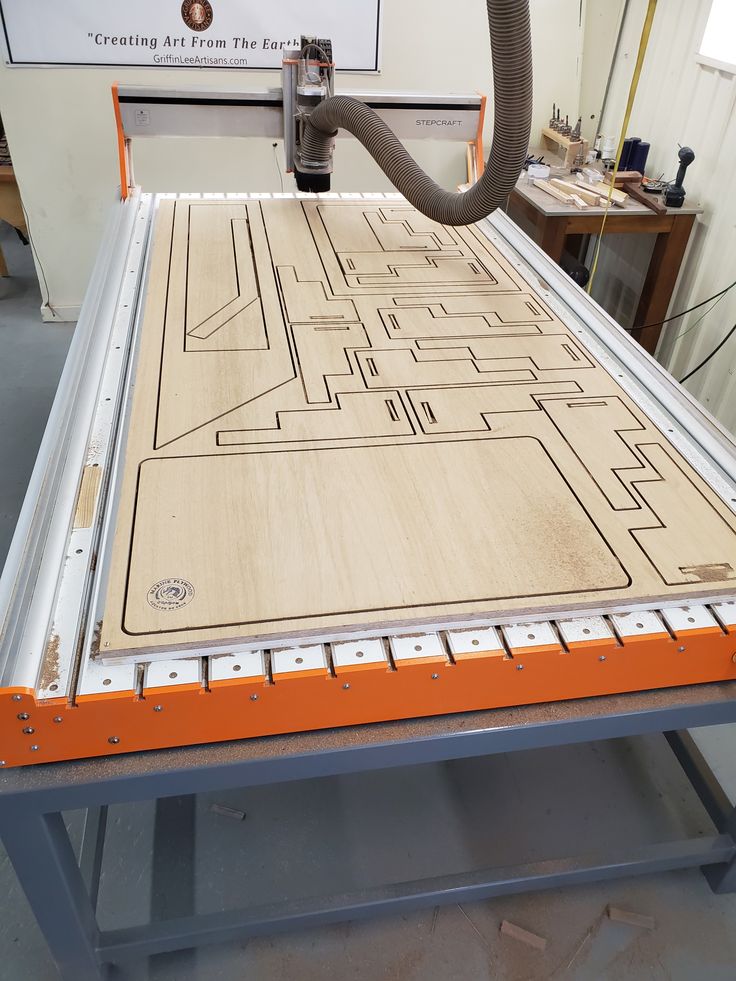

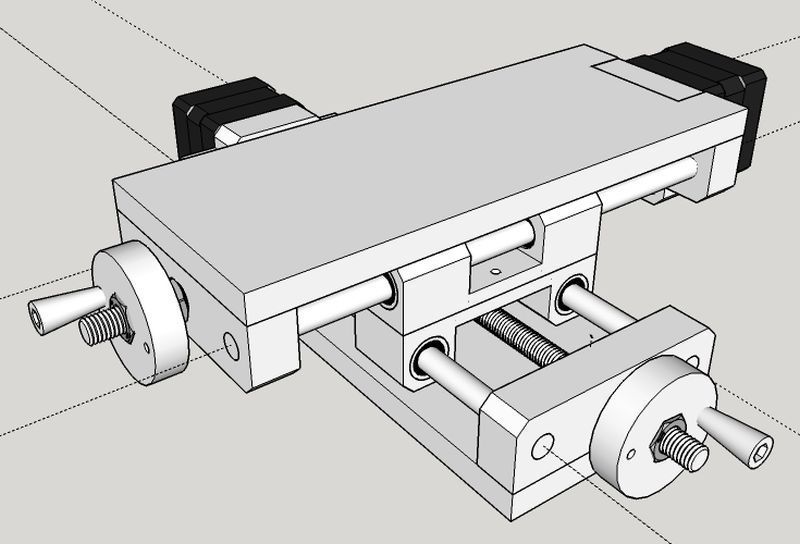

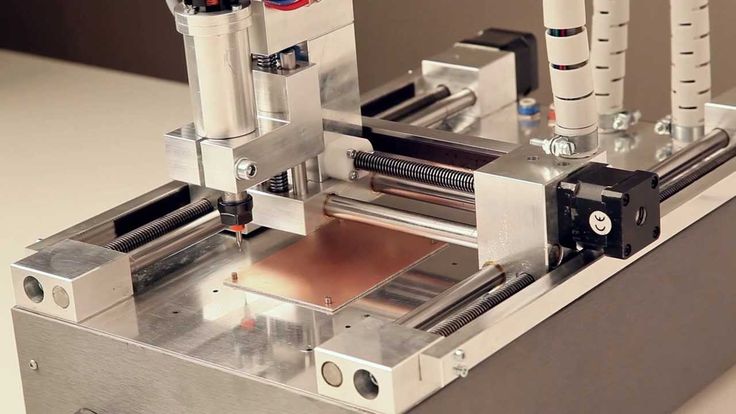

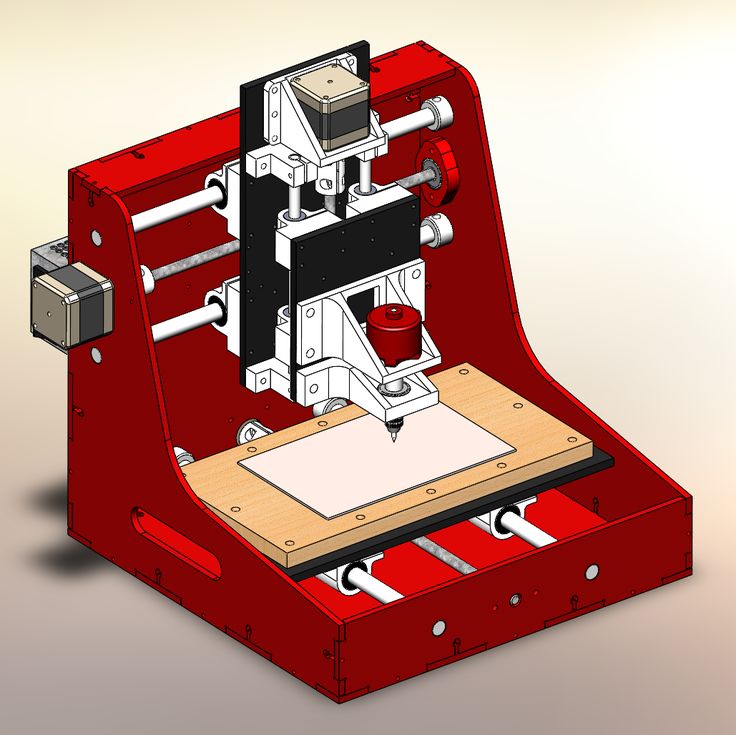

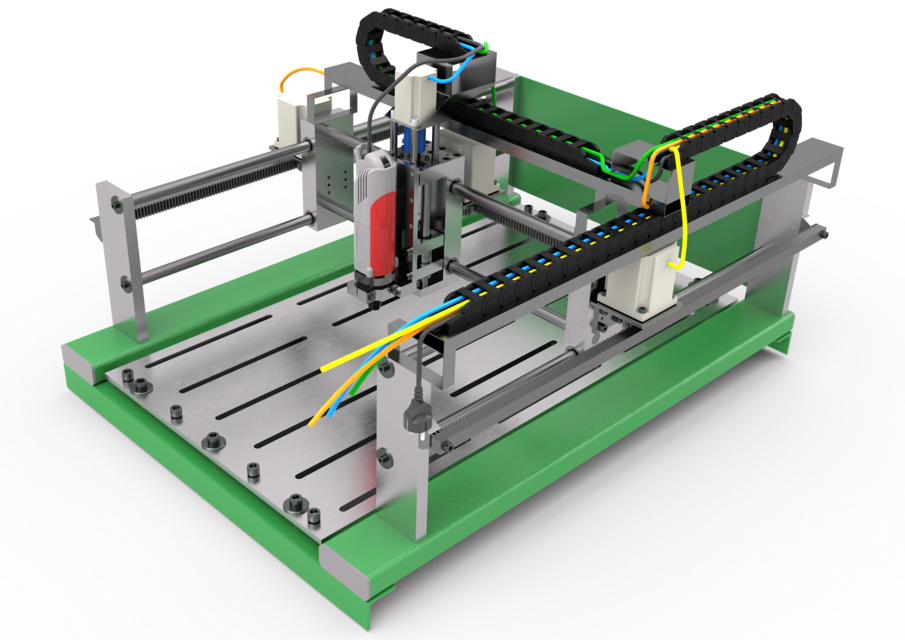

CNC milling

Computer numerical control (CNC) milling is the removal of material through a specific process that uses rotary cutters, performed by computer-controlled machines that are also known as machining centers or stations. CNC milling, a process similar to drilling and/or cutting, is considered subtractive manufacturing in contrast to 3D printing which is an additive method.

Paste extrusion (syringe extruder)

Paste extrusion is the process of simply pushing any paste-type filament such as PVC foil, EVA foam, machining wax, and even chocolate (food 3D printing!) through a special tube and nozzle. Paste extruders are also known as syringe extruders.

Laser cutting and laser engraving

Laser cutting is quite simple; a computer-controlled machine directs the laser beam onto the material and moves according to the desired shape. Engraving works the same way, but with less laser power. Compatible materials – for non-industrial desktop machines – include different kinds of plastics as well as soft metals and wood. Check out our guide to laser engravers and cutters for further information.

Compatible materials – for non-industrial desktop machines – include different kinds of plastics as well as soft metals and wood. Check out our guide to laser engravers and cutters for further information.

Other functionalities

Some of the all-in-one 3D printers included in this article feature other functionalities besides the ones mentioned above. Some of these functionalities include:

- Drawing: a writing instrument such as a pen or marker can be attached to a 3D printer’s tool head in order to create automated (or CNC) drawings.

- Hot-wire cutting: the 3D printer is equipped with a wire made of stainless steel, ideal for cutting foam and similar materials.

- Vinyl cutting: a technique where a drag knife, also known as a “craft cutter”, is used to cut out shapes or letters from thin, adhesive plastic (ie. for stickers) through adjustable-depth cutting.

Multifunctional 3D printers overview

The ZMorph VX is a powerful all-in-one desktop 3D printer made by ZMorph, a manufacturer based in Poland. Thanks to its interchangeable tool heads, the ZMorph VX enables users to rapidly switch between functionalities: CNC milling, laser engraving/cutting, 3D scanning, and paste extrusion.

The VX comes with Voxelizer software (Voxelizer 2). This software allows users to slice models for 3D printing but also to access the printer’s CNC mill and laser engraving/cutting capacities.

ZMorph’s multitool 3D printer VX is ideal for professionals and enthusiasts in the woodworking business since its CNC mill is capable of cutting several materials such as plywood, beech, oak, maple, walnut, pine, chestnut, machining wax, PCB, plexiglass and PVC foam.

Main functionalities: CNC milling, laser cutting/engraving, paste extrusion

Contact manufacturer Get a quote Add to comparison

The System 30M by American manufacturer Hyrel 3D is an ultra modular 3D printer. It’s compatible with Hyrel’s wide range of nozzles and extruders, thus making it eligible to print high-temperature materials, standard or engineering plastics, clays, hydrogels, and more.

This printer features a sturdy, all-metal chassis with an enclosed build to protect jobs from room drafts or temperature changes. It comes with a table PC and boasts an onboard camera and lighting for remote monitoring.

Main functionalities: CNC milling, laser cutting/engraving, paste extrusion

Contact manufacturer Get a quote Add to comparison

The Snapmaker 2.0 is Snapmaker’s second-generation multifunctional 3D printer. This time, it comes in three different versions – A150, A250, and A350 – each offering varying build volumes.

Through an intuitive and easy user interface, the included software handles all of the machine’s multiple facets: 3D printing, CNC milling, and laser engraving/cutting. Users can control the Snapmaker 2.0 via its removable touchscreen (it looks like a smartphone).

Users can control the Snapmaker 2.0 via its removable touchscreen (it looks like a smartphone).

An optional enclosure is available.

Main functionalities: CNC milling, laser cutting/engraving

Contact manufacturer Add to comparison

The Snapmaker 3D printer is an affordable all-in-one 3D printer that started as a Kickstarter project and managed to gather the considerable amount of $2,227,182 from 5,050 backers.

The Snapmaker Original features a heated bed capable of reaching up to 80°C, and a CNC milling work area of 90 x 90 x 50 mm.

Main functionalities: CNC milling, laser cutting/engraving

Contact manufacturer Add to comparison

The Stepcraft-2/840 is a professional AIO 3D printer made by the German manufacturer Stepcraft. In addition to its many functionalities, the Stepcraft-2/D.840 can be equipped with a hot wire cutter, a drag knife and a mini engraving point for faster but less detailed engraving than with the laser.

The original Stepcraft-2 was introduced as a Kickstarter project in 2015 and managed to gather over $500,000 by 211 backers.

Main functionalities: 3D scanning, CNC milling, laser engraving

Contact manufacturer Add to comparison

The Optimus C1 is a three-in-one delta 3D printer made by the Swedish manufacturer Febtop Tech. The original Optimus 3-in-1 3D printer was an Indiegogo project that managed to gather over $360,000, well over its $50,000 goal.

This version, the C1, offers a large 3D printing build volume of 300 x 300 x 300 mm. Its closed frame boasts an air filter and a color touchscreen for an enhanced user experience.

Main functionalities: CNC milling, laser cutting/engraving

Contact manufacturer Get a quote Add to comparison

The 5AXISMAKER is a professional 3D printer CNC mill combo made by 5AXISWORKS, a manufacturer based in the United Kingdom. This 2-in-1 3D printer is also available in a bigger version with a 3D printing build size of 600 x 600 x 600 mm.

Besides CNC milling, the company is working on providing a 3D scanning touch probe extension.

Main functionalities: CNC milling

Contact manufacturer Get a quote Add to comparison

This multifunctional 3D printer offers a wide build volume of 400 x 180 x 180 mm. It can be equipped with up to 5 print heads at a time or 4 spindles, or any combination of the two. The built-in cleaning station helps keep each nozzle clean between switches.

It can be equipped with up to 5 print heads at a time or 4 spindles, or any combination of the two. The built-in cleaning station helps keep each nozzle clean between switches.

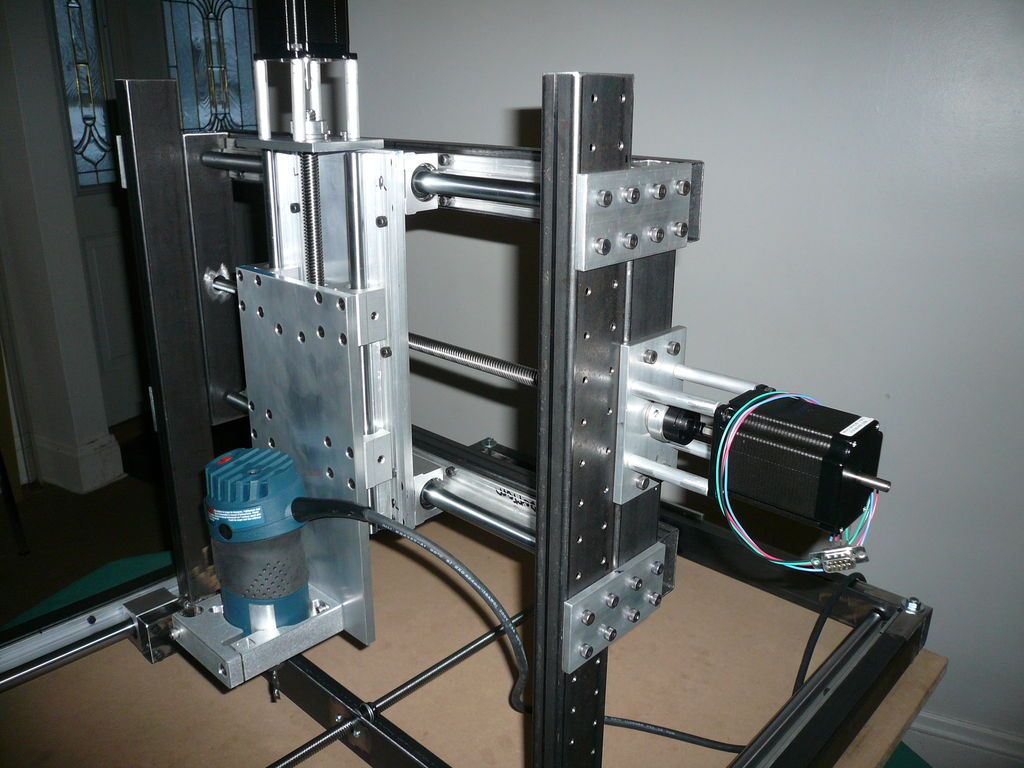

Diabase refers to their H-Series machine as a “Hybrid manufacturing” system for professionals. You first 3D print your part and then use the spindle head to add CNC-level precision (sharper edges, finer details, …).

Main functionalities: CNC milling

Contact manufacturer Get a quote Add to comparison

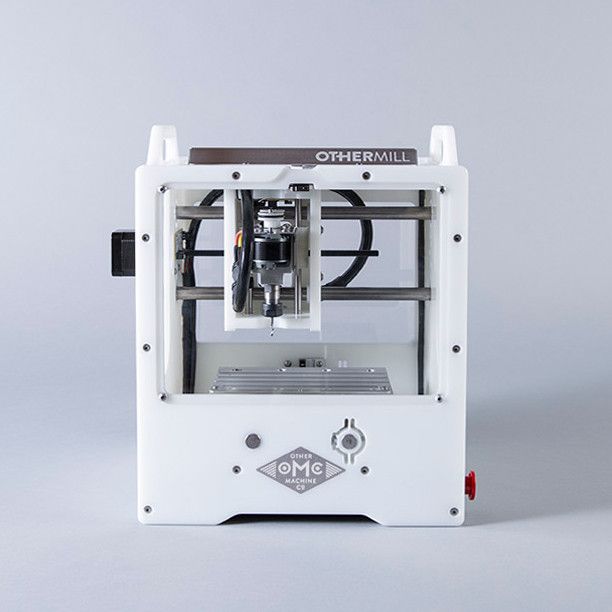

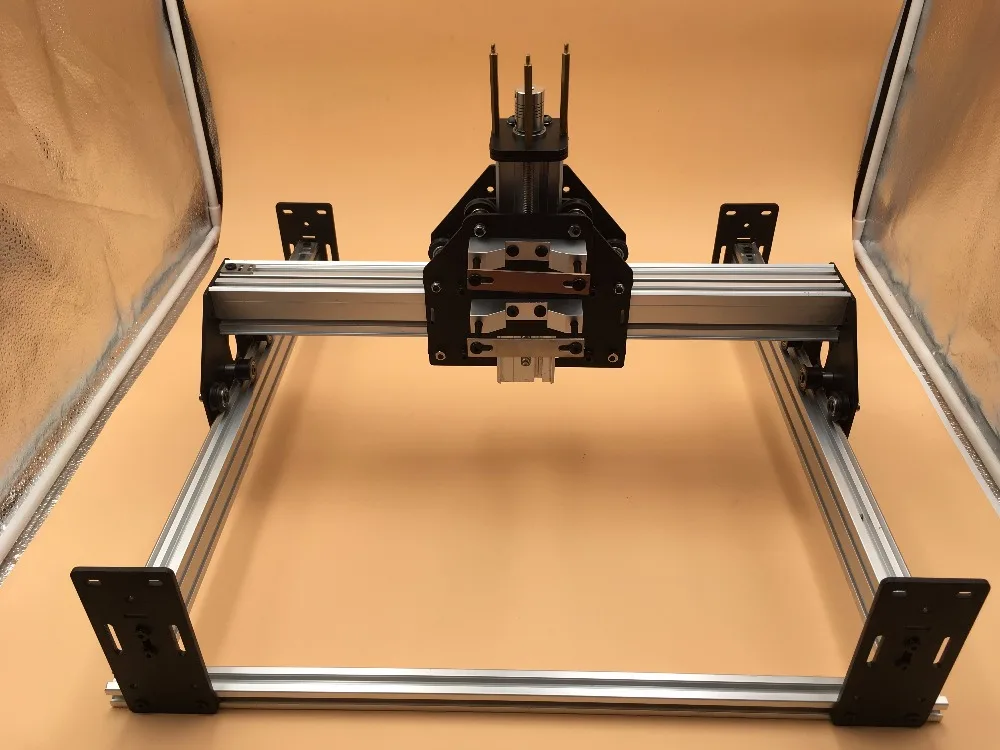

E3D is a leading extruder and nozzle manufacturer from the United States. They recently launched their ASMBL (Additive and Subtractive Manufacturing by Layer) system, enabling users to use both 3D printing and CNC milling in the same run.

Similarly to Diabase, the goal is to achieve better part tolerance, higher accuracy and obtain sharper edges by combining both technologies (hybrid manufacturing).

Discontinued multitool 3D printers

Various all-in-one 3D printer manufacturers have closed down or stopped manufacturing their products. Other were Kickstarter projects that didn’t make it on the market. We listed them here (below) for those that may be wondering why a certain printer or brand isn’t on our main list.

Other were Kickstarter projects that didn’t make it on the market. We listed them here (below) for those that may be wondering why a certain printer or brand isn’t on our main list.

AIO Robotics Zeus 3D printer and scanner combo

Zeus, a 3D printer and 3D scanner combo made by the US manufacturer AIO Robotics, was one of the most popular AIO 3D printers on the market. However, AIO Robotics no longer manufactures any 3D printers.

ATOM Atom 2.5 EX 3D Printer Kit

The Atom 2.5 EX was a professional delta 3D printer with a laser engraver. ATOM had announced an Atom 3 in 2018, but it isn’t possible to purchase 3D printers on their website anymore.

FABtotum Core PRO

The FABtotum Core PRO was capable of CNC milling, laser cutting cardboard and paper, and laser engraving. This 3D printer is no longer available, as the brand is in liquidation.

FLUX Delta

FLUX was an interesting multifunctional option from Taiwan, but they stopped manufacturing printers and now sell sunglasses!

MAG iCreatum

This multifunctional 3D printer was supposed to feature 3D printing, ink plotting, and other functionalities for only $300. Kickstarter suspended its campaign in 2017 as the project violated its rules.

Kickstarter suspended its campaign in 2017 as the project violated its rules.

MakerArm, the ultimate 4-in-1 3D printer for fablabs?

The MakerArm started as a Kickstarter project and managed to gather over $430,000 from 340 backers in November 2015. After unexpected rises in component costs, the MakerArm team decided to refund their backers.

XYZprinting Da Vinci 1.0 Pro 3-in-1

Although it’s still displayed on XYZprinting’s website, this 2-in-1 3D printer and scanner has been out of stock for quite some time.

Using a 3D printer as a router

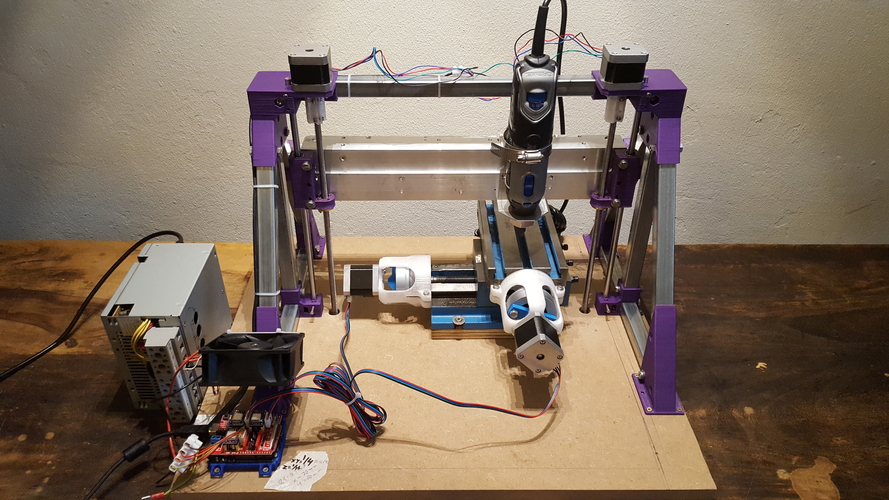

They gave me a separate 3D printer for my desktop. But with the condition - to master the work with a replaceable set for engraving and milling. Yes, not just like that - but 3D milling. In general, it turned out, but you need to improve your skills. And it is desirable to get a couple of tips from the manufacturer (SkyOne, we need you).

Until recently, I used a working printer in those moments when it was not used for work processes. Several toys for the child and little things for myself were printed. But here is a happy day - they gave me a separate copy.

A separate word about the printer itself - we use SkyOne 3D printers of the first model, with a removable table and head. They come with a separate engraving and milling kit. It was such a copy with a replacement kit that I got.

Started learning, inspired by a post by crazysova, who has already tried 3D milling on his printer. I also saw an example of such milling from a printer manufacturer on 3dtoday.

First of all, I downloaded the recommended Blender program (or rather, BlenderCAM - with the milling addon).

No installation required. Starts up and works. In the process of work, I realized that a separate issue is to find a model suitable for milling. Therefore, the best way out is to learn how to create models yourself. For this purpose, I downloaded a 'clean' version separately from the Blender website, for studying and immersing myself in the world of 3D modeling.

Therefore, the best way out is to learn how to create models yourself. For this purpose, I downloaded a 'clean' version separately from the Blender website, for studying and immersing myself in the world of 3D modeling.

BlenderCAM Blender A whole evening was spent figuring out the BlenderCAM settings and getting a G-code usable for milling.

The finished code is loaded into the Repetier-Host program. To turn on the spindle in the Repetier-Host, you need to turn on the extruder. The temperature of the extruder is responsible for the speed of rotation of the spindle - set to maximum.

Next several attempts

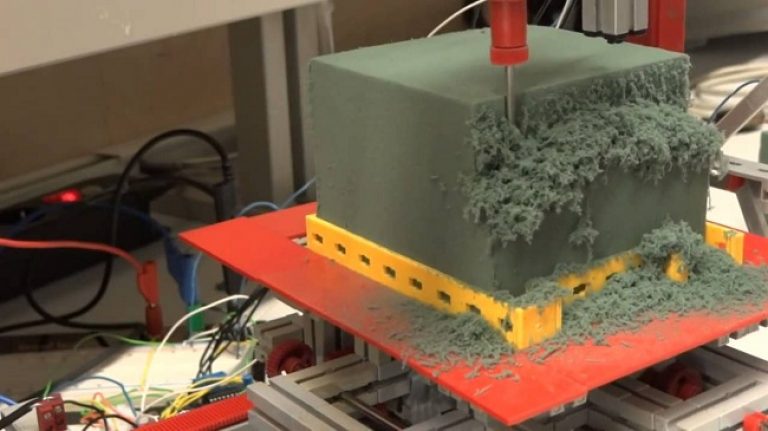

milling. Based on a ready-made free model from the milling site. In BlenderCAM, the model is scaled down and adjusted to fit on the workpiece.

The first attempt started more than well - everything went well until I decided to increase the feed rate. I started with 30%. Gradually increased to 300%. The model was half ready when the cutter broke (cylindrical 1 mm - from the kit, the depth of the model is up to 6 mm).

I started with 30%. Gradually increased to 300%. The model was half ready when the cutter broke (cylindrical 1 mm - from the kit, the depth of the model is up to 6 mm).

I changed the cutter to 3 mm (bought separately) - it mills beautifully, you can set high speeds, but the contour itself turns out to be rough.

Changed the cutter to 2 mm, installed a new workpiece. Here is the result of the work:

The result is a bit crooked, because the process had to be stopped and resumed several times.

Here are the comments and problems that I encountered:

1. The fasteners that come with the kit for fixing the workpiece make it possible to fix the part up to 6 mm high. By replacing two screws, this limitation can be extended to 10 mm. My last blank (wooden board) 22 mm high did not want to be attached in any way. For this reason, the standard mounts have been slightly modified (short screws have been replaced with long ones).

2. When working on the edge of the table, long screws start to catch on the arms of the SCARA mechanism.

For this reason, I had to pause the Repetier-Host several times and bite off the upper part of the screw (it's good that strong male colleagues are nearby).

The last (on the photo) milling has a depth of 6.4 mm - when the cutter is completely deepened, the mounting lamb in the extreme position almost rests on the shoulder.

In the photo above, the shoulder is above the lamb, then it is lowered. A couple of times they scratched the shoulder with a screw, but nothing broke :)

Hence the conclusion: other fasteners are needed or the workpiece/pattern should be positioned differently.

3. The manufacturer's instructions describe the preparation and milling/engraving process on the SkyOne. There is an important point there - zeroing the Z coordinate (G92 Z0). I forgot to reset this coordinate twice. Once I broke the cutter (dia. 1.5 mm), the second time I went through the workpiece and scratched the table. Not scary, of course, but a little annoying.

Once I broke the cutter (dia. 1.5 mm), the second time I went through the workpiece and scratched the table. Not scary, of course, but a little annoying.

I would like to somehow add a button to the Repetier-Host immediately after printing starts: 'Did you forget to reset Z?'. And only after that start

milling.

4. If something went wrong during the work, I want to stop everything as soon as possible.

There are three possibilities for this:

a) press pause in the Repetier-Host

b) press 'Kill print' in the Repetier-Host

c) press the off button on the printer body

But in the first two cases, work continues until the end of the current code execution. And if that code is moving along the Z axis - it won't stop until it reaches the end. In my trial attempts - until the cutter passes through the workpiece and rests against the aluminum table, or until the mounting lamb or screw rests against the SCARA shoulder. In both cases, there is a high probability of spoiling something.

In both cases, there is a high probability of spoiling something.

If the printer is turned off with the button, the SCARA arms immediately drive the head to the origin, i.e. if at this moment the cutter is immersed in the workpiece, something breaks. In my case, cutters with a diameter of 1 mm and 1.5 mm are broken.

5. Sawdust!!! There are many and they are small. Hello allergy sufferers!

In the case when the workpiece is small, the protective screen from the kit saves a little.

But for desktop performance, more radical methods are needed.

Also, I think sawdust can get inside the printer. Hope it doesn't spoil quickly. While the lower furrows for moving along Z after setting the zero coordinate I seal it with tape.

6. The last remark concerns the preparation of the G-code in the blender.

Blender and Repetier-Host have different starting coordinates. In the SkyOne printer and in the Repetier-Host program, the origin is at the center of the table, and in Blender it is at the edge. Because of this, it is inconvenient to 'guess' the location of the model when preparing the g-code. Empirically, in a blender, she indicated that the workpiece allegedly hangs from the edge of the table. And only in this case it was possible to generate code that will actually center the picture. Taking into account that for complex models the path in the blender is generated for a rather long time (several minutes), it was not at all immediately possible to adjust the code so that the milling was in the center.

Because of this, it is inconvenient to 'guess' the location of the model when preparing the g-code. Empirically, in a blender, she indicated that the workpiece allegedly hangs from the edge of the table. And only in this case it was possible to generate code that will actually center the picture. Taking into account that for complex models the path in the blender is generated for a rather long time (several minutes), it was not at all immediately possible to adjust the code so that the milling was in the center.

But here, probably, you need to study software. I would be grateful if someone could tell me where to set up something to change the origin of coordinates in blender.

In general, everything. I would be grateful for advice and comments on the above points. The printer itself is a sweetie: I got it turned on and everything works right away. I did not even expect that everything is so simple. I will continue to study blender and learn how to create models myself.

Milling and 3D printing: comparison and benefits

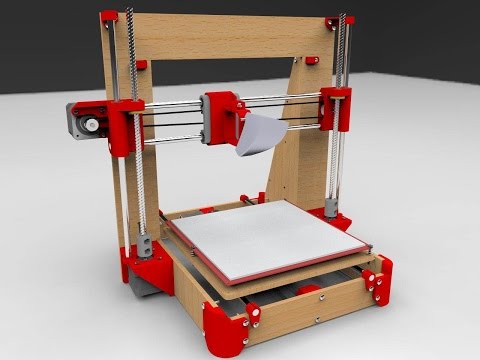

3D printing is the latest technology designed to solve problems that conventional milling cannot handle. Compared with milling, three-sided printing has such advantages as:

- Economical consumption of raw materials. When milling, up to 90% of materials become waste. 3D printing allows you to dose raw materials and use only the amount you need to make a certain form;

- Maximum precision. During milling, the master is limited in his actions: the diameter of the cutter, the selected angle. Not every shape can be obtained during milling. The wizard cannot perform some actions because some elements cannot be directly accessed. 3D printing is much easier, a fashion designer can print any shape, the design of which is limited by the artist's imagination;

- Speed. During milling, one mold can be produced at the same time, with the help of 3D printing, it is possible to simultaneously produce several objects.

Comparison of milling machine and 3D printer in jewelry production

During their development, jewelry workshops sooner or later think about automating the process. One popular way is to buy a jewelry mold making machine. The business owner is faced with a question regarding the choice of equipment.

CNC machines are used for milling. Using the machine, wax models are created. There are different types of milling machines: some work with wax, others can work with metal. When processing metal, a large amount of waste appears, which is not beneficial in the manufacture of jewelry.

Start up a milling machine in jewelry production inexpensively. The material and the purchase of equipment for production will cost the business owner inexpensively. However, the milling machine can cast one piece at a time. Some models cannot process details as deep as the sketch requires. In this case, the operator has to remove excess wax manually.

Jewelery requires clean lines and a perfectly smooth surface. The best way to cope with the task is a 3D printer. The smallest details are obtained with maximum accuracy, large objects require refinement of the lines by the jeweler. Some models have a large platform and work slower, while others, on the contrary, have a small print area and work many times faster.

Mastering a CNC machine is easier than learning the basics of computer modeling and 3D printing. Equipment manufacturers offer courses to make working with equipment easy and convenient. The final result of part manufacturing depends on training and technical support.

Milling and 3D printing technology

The function of 3D printing and milling is to make a finished product from a material. Milling machines have been in operation since the 1950s. Working on CNC machines is the opposite of 3D printing. In the second case, a computer is used for control, in the first case, a tool for drilling the base.