Lumex 3d printer

LUMEX Avance-25 | Hybrid Metal 3D Printer LUMEX Series

The World’s First Hybrid Metal 3D Printer (Since2002)

HIGH SPEED

High output fiber laser

Standard500W

Option1kW

The sintering and milling time is shortened by improved powder distribution speed and optimized galvano control / sintering conditions and milling paths. A maximum build speed of 35 cc/h*1*2 can be achieved.

1:The above is the calculation value, not the guaranteed value.

2:Laser output 1 kW

Pre-milling powder suction

By removing metal powder around the built part before the start of milling, a faster cutting feed rate can be used, thereby shortening the milling time.

※Patents relating to “hybrid laser sintering & milling device” used under license from Panasonic Corporation.

LARGE CAPACITY

MAX. WORK SIZE

90kg

- Max.

work size

- W256mm×D256mm×h285mm

- Max. work weight

- 90kg

MAX. WORK SIZE

150kg

- Max. work size

- W256mm×D256mm×h400mm

- Max. work weight

- 150kg(※h400 mm option)

AUTOMATION

Option

APR System(Automatic Powder Recovery System)

Powder supply, collection and reuse can be fully automated without the need for the operator to directly touch the powder. Excess powder that remains after sintering is automatically sieved and reused for subsequent sintering.

SPEC

Hybrid Metal 3D Printer LUMEX Avance-25 | Hybrid Metal 3D Printer LUMEX Avance-60 | |

|---|---|---|

| Laser oscillator | Yb fiber laser | Yb fiber laser |

| Laser Power:W | 500Standard 1000Option | 1000Standard |

Max. Work Size: mm Work Size: mm | W256 × D256 × h285 W256 × D256 × h400 | W600 × D600 × H500 |

| Max. Part Size: kg | 90 150Option | 1300 |

| Spindle Speed:min-1 | 45,000Standard | 45,000Standard |

| Travel(X/Y/Z):mm | 260/260/100 | 610/610/100 |

| Feed Rate(X/Y/Z):m/min | 60/60/30 | 60/60/30 |

| NC System | i-Tech Avance | i-Tech Avance |

Sample Work

MORE

Promotion Video

Hybrid Metal 3D Printing | Matsuura Machinery Corporation

Hybrid Metal 3D Printing

-

Automation and

Unmanned System -

Media Library

-

Sample Work

-

Looking Back on 30 years

Looking Back on 30 years

Looking Back at Matsuura’s 30 Years Technological Innovation in the Heisei Era (1989-2019)

History 06

Hybrid Metal 3D Printing

LUMEX Series

Hybrid Metal 3D Printing

LUMEX series

Hybrid metal 3D printer

(metal laser sintering + high speed milling)

In 2000, Matsuura took part in a regional joint research program in Fukui prefecture to promote the development of laser-based materials manufacturing technology. Through the research carried out during this project, Matsuura developed the world’s first hybrid metal 3D printer in 2002: the M-PHOTON 25Y, which was able to reduce mold making times to one third of the usual cycle by using a laser. The M-PHOTON 25Y was the first innovative hybrid metal 3D printer capable of performing powder sintering and high speed milling on a single machine to create molds with just one process. The second generation LUMEX-25C was developed and released in 2004. This machine was equipped with a high-power CO2 laser (500W) and sintering time was reduced by 40%. In 2006 the 3rd and 4th generations of the LUMEX Avance-25 were developed, equipped with 200WYb and 400WYb fiber lasers respectively. In 2016, the much larger LUMEX Avance-60 was developed with a max part size of 600x600x500mm. Moving forward, Matsuura strives to continue the development of revolutionary new manufacturing processes through the use of hybrid metal 3D printing.

Through the research carried out during this project, Matsuura developed the world’s first hybrid metal 3D printer in 2002: the M-PHOTON 25Y, which was able to reduce mold making times to one third of the usual cycle by using a laser. The M-PHOTON 25Y was the first innovative hybrid metal 3D printer capable of performing powder sintering and high speed milling on a single machine to create molds with just one process. The second generation LUMEX-25C was developed and released in 2004. This machine was equipped with a high-power CO2 laser (500W) and sintering time was reduced by 40%. In 2006 the 3rd and 4th generations of the LUMEX Avance-25 were developed, equipped with 200WYb and 400WYb fiber lasers respectively. In 2016, the much larger LUMEX Avance-60 was developed with a max part size of 600x600x500mm. Moving forward, Matsuura strives to continue the development of revolutionary new manufacturing processes through the use of hybrid metal 3D printing.

History of LUMEX series

2002

M-PHOTON 25Y

World’s first hybrid metal 3D printer.

(Unveiled at JIMTOF 2002)

2004

LUMEX 25C

2nd generation hybrid 3D printer

Equipped with 500W CO2 laser

2006

LUMEX Avance-25

3rd and 4th generation of hybrid 3D printer

Equipped with 400W/500W fiber laser

2016

LUMEX Avance-60

Large hybrid metal 3D printer.

Max. work size 600x600x500mm

Equipped with 1kW fiber laser.

APR system standard.

2017

LUMEX Avance-25

5th generation of hybrid metal 3D printer.

Increased speed, APR system standard

3D printer helps in the manufacture of analytical measuring instruments

Lumex-Marketing LLC specializes in analytical measuring instruments, and is currently working on a completely updated version of the instrument for capillary electrophoresis.

Lumex Group of Companies produces a wide range of analytical instruments for:

- luminescent and photometric analysis;

- atomic absorption spectrometry;

-FTIR spectrometry;

- high performance liquid chromatography;

- capillary electrophoresis;

- Microwave mineralization; dosimetry;

- clinical diagnostics;

- mass spectrometry.

Instruments developed by Lumex are used for the analysis of atmospheric air, drinking and waste water, food products, natural waters and soils, radiation protection, medicine, veterinary, sanitary-epidemiological and technological control. One of the main components of the Capel 205 capillary electrophoresis device is a cassette with protruding quartz capillaries. One of them is immersed in the investigated liquid medium, the other is located above the test tube for draining the spent liquid body. The immersion of the capillary into the sample occurs due to the raising of the test tubes. In the initial state, all test tubes are closed with lids. The device has a node responsible for removing the covers. However, it is extremely important to ensure that the cover is removed before lifting. Otherwise, when lifting the tube, the capillary may bend or break, which will entail the replacement of the cassette.

Mikhail Svintsov, design engineer of the department of separation methods of analysis, notes that for the new device it was decided to develop an optical detection unit for the lid. Open channel optocouplers were used. Moreover, one optocoupler determines the presence of the cover in the closed state, the second monitors the situation in which the cover is open and tilted to the side.

Open channel optocouplers were used. Moreover, one optocoupler determines the presence of the cover in the closed state, the second monitors the situation in which the cover is open and tilted to the side.

The LED and phototransistor must be positioned so that the radiation emitted by the photodiode is reflected from the surface of the cover and hits the surface of the phototransistor. It is not possible to use mirror reflection due to the material of the vial cap. Polyethylene is transparent to IR radiation. For detection, the property of the beam to be reflected from the section of two media is used. The greater the angle of incidence, the greater the signal on the phototransistor. Further, the signal is recorded by the stand for setting up the optical sensor. Typical signal values with the cover present are in the range of 3-4 V. In the absence of the cover, the signal value is in the range of 0.5-0.7 V.

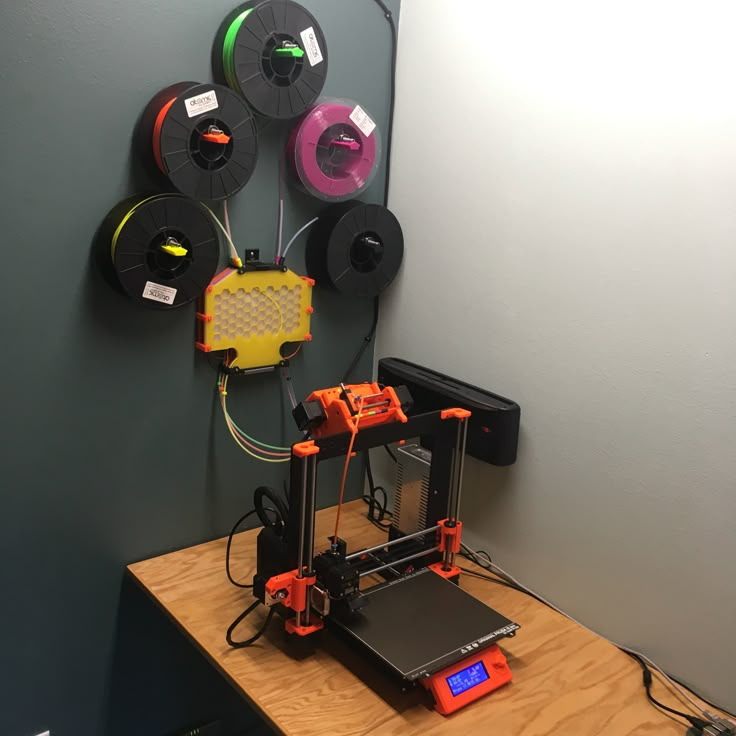

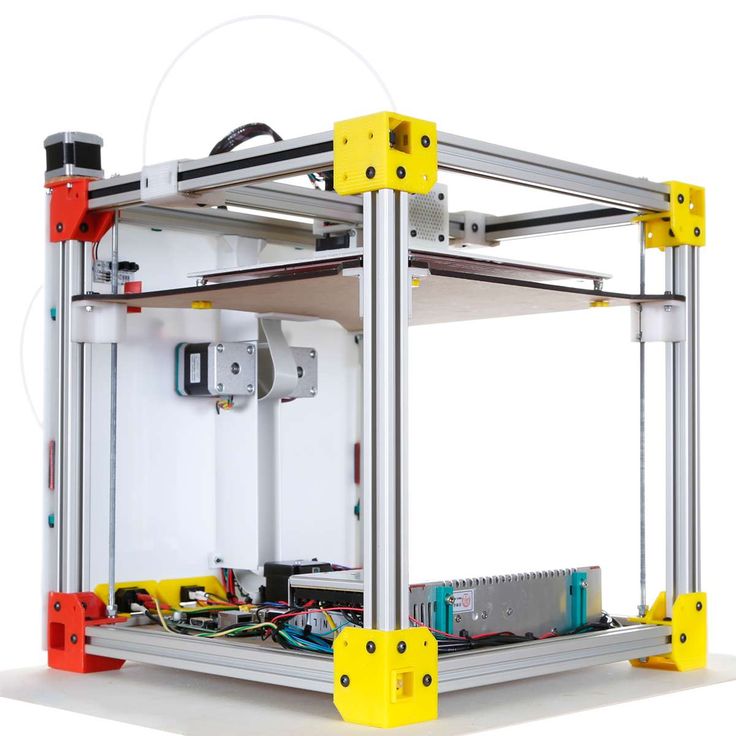

The PICASO 3D Designer PRO 250 3D printer was used to create the optocoupler housing. During development, engineers sought to increase the angle of incidence of the rays to increase the Fresnel reflection *. The distance between the test tube and the detector and the desire to reduce the angle determined the geometry of the structure. The first version of the housing was attached directly to the optical sensor board. Positioning relative to the plate attached to the test tubes was carried out by means of a protruding tooth on the plate.

During development, engineers sought to increase the angle of incidence of the rays to increase the Fresnel reflection *. The distance between the test tube and the detector and the desire to reduce the angle determined the geometry of the structure. The first version of the housing was attached directly to the optical sensor board. Positioning relative to the plate attached to the test tubes was carried out by means of a protruding tooth on the plate.

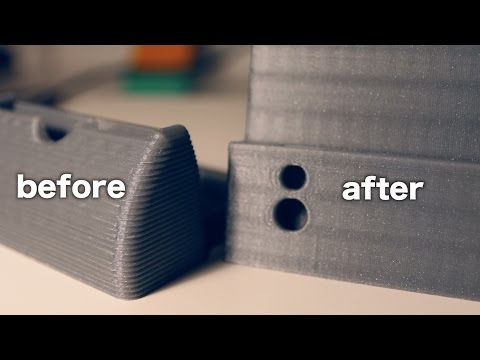

This design did not meet the requirements for positioning accuracy and gave unstable results. The manufacturer decided to redesign it so that the body of the optical system, printed on a 3D printer, is positioned directly on the plate. This was done due to the protruding element in the part. In addition, this design made it possible to bring the optical channels as close as possible to the object under study. When developing a new design, engineers abandoned the use of a second optocoupler that detects a flipped cover. When testing the device, it turned out that the tilted cover leads to jamming of the drum. The hull design has become more complex. The board mounting system has changed. The outputs of the optocoupler were passed through the holes in the clamping bar to the surface of the board, where, after adjustment, they were soldered.

The hull design has become more complex. The board mounting system has changed. The outputs of the optocoupler were passed through the holes in the clamping bar to the surface of the board, where, after adjustment, they were soldered.

The developers had to make a number of changes to the printing process. If the first version was printed only from ABS, then support was required for new parts. It was made of HIPS material, which mechanically separates well from ABS after the parts have cooled. The quality of the parts allows them to be used without modification directly from the 3D printer table. Printing one set of parts for the device took about an hour and a half. The company's engineers have chosen the roughest printing modes for maximum production speed: layer thickness - 0.25mm, fill percentage - 30%, print speed - 60mm/sec. Thus, five sets for an experimental batch were printed during the working day.

According to Mikhail Svintsov, last year a printer with one nozzle appeared in another department of Lumex-Marketing LLC. The company's specialists were able to use it in their developments, and closer to the new year, it was decided to buy a model with 2 nozzles for the department. Printed parts have proven to be cheaper than single-piece production through machining. It turned out that the payback at 50% load in time is 4 months. In a fairly short period of time (1 month), a new design of the optical sensor for the presence of covers was developed and tested.

The company's specialists were able to use it in their developments, and closer to the new year, it was decided to buy a model with 2 nozzles for the department. Printed parts have proven to be cheaper than single-piece production through machining. It turned out that the payback at 50% load in time is 4 months. In a fairly short period of time (1 month), a new design of the optical sensor for the presence of covers was developed and tested.

The company's conclusions are simple: the use of a 3D printer significantly reduces the process of developing new components.

*Fresnel reflection - reflection of light, described by the amplitude and intensity of the refracted and reflected electromagnetic waves when passing through a flat interface between two media with different refractive indices.

materials, equipment and technologies for advertising production

- Product catalog

Product catalog

Go to expanded catalog

PDF catalogs

CONSUMABLES

- Silk-screen materials

- Advertising and decorative lighting

- Chemistry (adhesives, paints, varnishes, special chemicals, cleaners)

- Mounting and packaging materials

- Aluminum and plastic profiles

- Materials and equipment DTF

- Digital printing ink

- POS materials and equipment, Joker, Uno and Tritix systems

- Mobile stands, Flagpoles, Pavement signs, Fencing posts

- Rigid sheet materials

- Colored self-adhesive films

- Materials for printing and lamination

- Reflective materials

- Thermal transfer materials

- Souvenir and premium products

- Clothes and accessories for labeling

- CRAFT materials and equipment

EQUIPMENT AND TOOLS

- Printers for printing and transfer printing

- Thermopresses

- Printers for advertising production

- 3D printers

- Equipment for nesting and cutting

- Milling and engraving equipment and laser engravers

- Fabric printing equipment

- T-shirt printers

- Laminators

- power tool

- Aluminum ladders and ladders

- Equipment for the production of liquid acrylic letters

- Trimmers, abrasives, film tools

- Eyelets and tools for their installation

- Knives, blades, scissors, mats

- Silk-screen equipment

- Spare parts, add.

hardware and software

hardware and software

Sale New Year

- Zenon Academy

- Video

- Articles

- Webinar Schedule

- About Us

- About company

- Our staff

- News

- News

- Stock

- New

- Developments

- Seminars

- Exhibitions

- Congratulations

- Webinars

- Service

- Signage calculation

- Service

- Working conditions

- Shipping

- Payment

- Contacts

You are using an outdated browser

In order to use all the features of the site,

download and install one of the following browsers:

Google Chrome

download the latest version0003

download latest version

Yandex Browser

download latest version

article

Subscribing to the newsletter

A confirmation email has been sent to the email you specified.

Please follow the instructions in the letter.

Sorry, an error has occurred, please try the service later.

To subscribe to the newsletter, please fill in ALL fields of form

Subscription regions

- Moscow - Golyanovo

- Moscow - Losiny Ostrov

- Moscow region - Odintsovo

- Moscow region - Podolsk

- Arkhangelsk

- Barnaul

- Belgorod

- Vladivostok

- Vladimir

- Volgograd

- Voronezh

- Yekaterinburg

- Izhevsk

- Irkutsk

- Kazan

- Kaliningrad

- Krasnodar

- Krasnoyarsk

- Kursk

- Lipetsk

- Nizhny Novgorod

- Novosibirsk

- Omsk

- Orenburg

- Penza

- Permian

- Pyatigorsk

- Rostov-on-Don

- Ryazan

- Samara

- St.

Petersburg

Petersburg - Saransk

- Saratov

- Simferopol

- Smolensk

- Sochi

- Stavropol

- Tambov

- Tolyatti

- Tomsk

- Tula

- Tyumen

- Ulyanovsk

- Ufa

- Khabarovsk

- Cheboksary

- Chelyabinsk

- Yakutsk

- Yaroslavl

I agree for the processing of personal data

Application for goods:

You can submit this product request form, or contact us by phone or by email , informing the manager of the article .