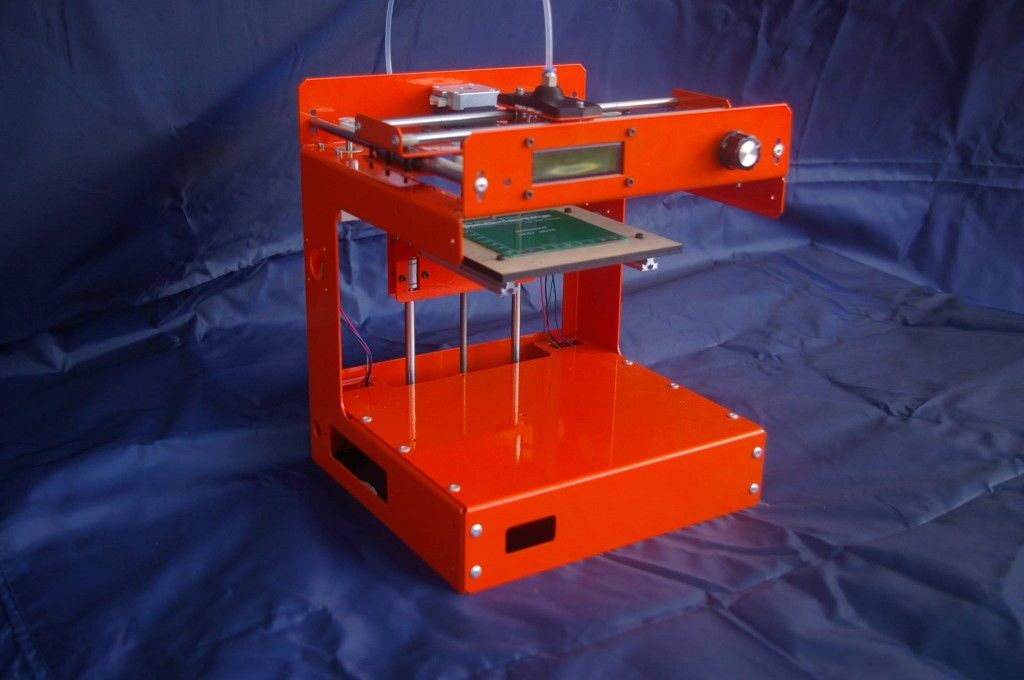

Low cost 3d printing service

11 Best Cheap and Fast 3D Printing Services Online (Dec. 2022)

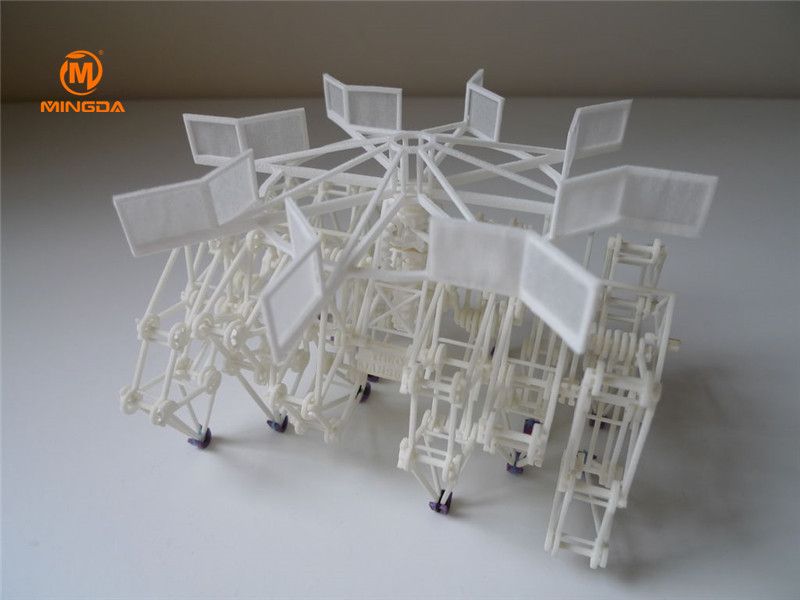

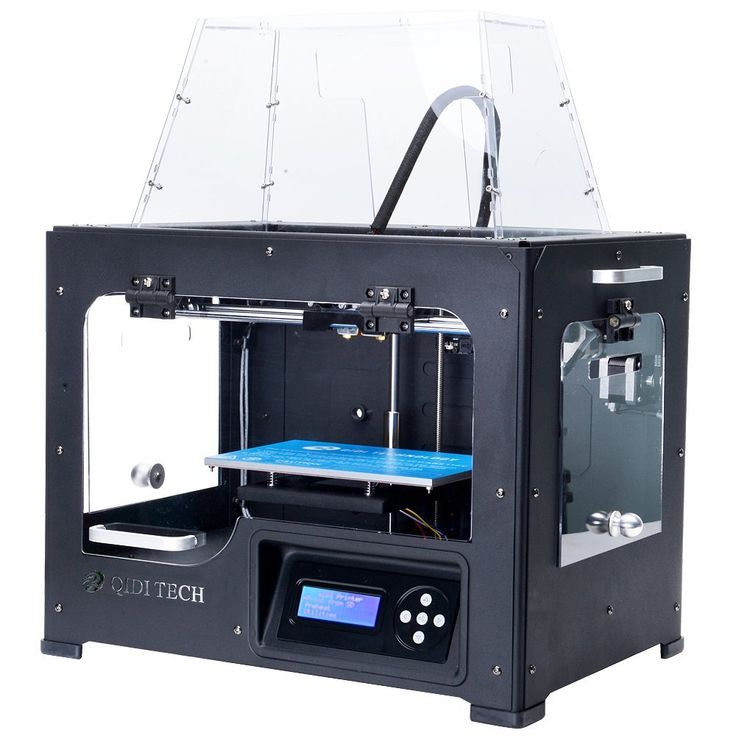

3D printing services allow you to bring to reality the 3D designs that you have in mind. You can avail of different types of 3D printing services such as rapid prototyping, laser cutting, 3D designs, and more.

If you want to 3D print an object but you don’t have a 3D printer or you’re too busy to look for the nearest shop near you, don’t worry. There are many online 3D printing services that can help you do the job.

Contents

- 1 Top Cheap 3D Printing Services

- 2 What Do 3D Printing Businesses Offer?

- 3 Who Needs This Service?

- 3.1 You’re a Business Person

- 3.2 You Want Lesser Investment Risk

- 3.3 You’re Not Technology Savvy

- 3.4 You Want to Customize Something

- 3.5 You Want to Try New Stuff, Materials, Designs

- 3.6 You Want to Save Money on 3D Printing

- 4 How much do these services cost?

- 5 Best Online Services for 3D Printing

- 6 3D Hubs

- 7 3D Printing Ally

- 8 i.

Materialise

- 9 MakeXYZ

- 10 Ponoko

- 11 Proto Labs

- 12 Sculpteo

- 13 SD3D

- 14 Shapeways

- 15 Voodoo

- 16 Xometry

- 17 Conclusion

Top Cheap 3D Printing Services

The answer is on the tip of your fingertips. To help you find one, check out our comprehensive list below.

Before I give you the list of the 3D printing companies that offer the best services online, I’ll give you an overview of what this industry has to offer.

What Do 3D Printing Businesses Offer?

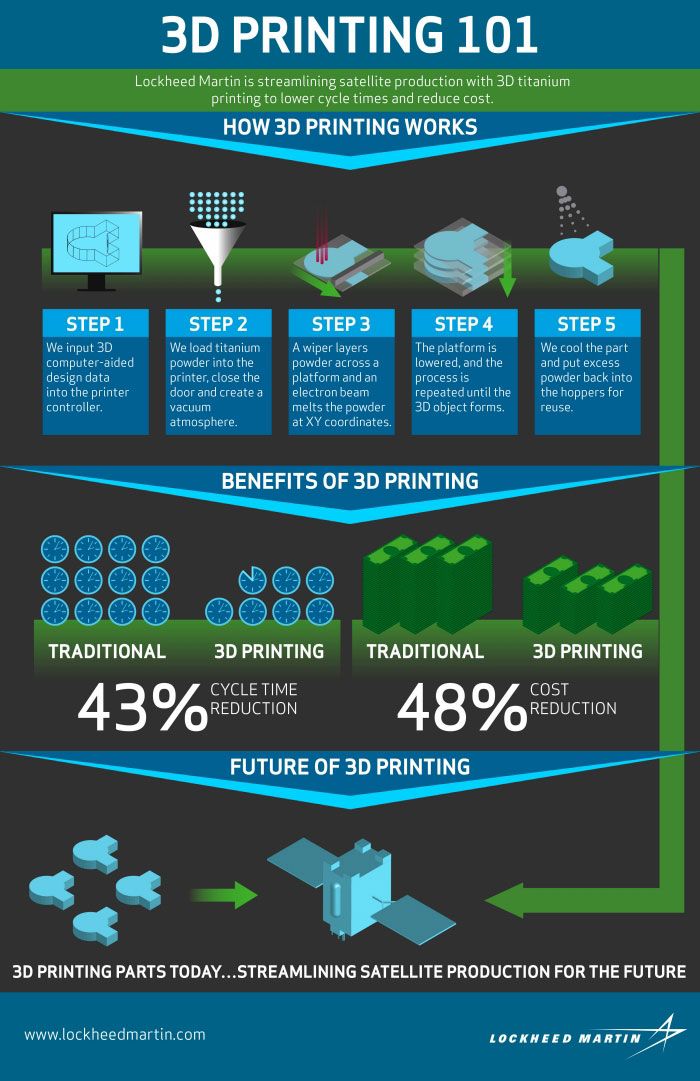

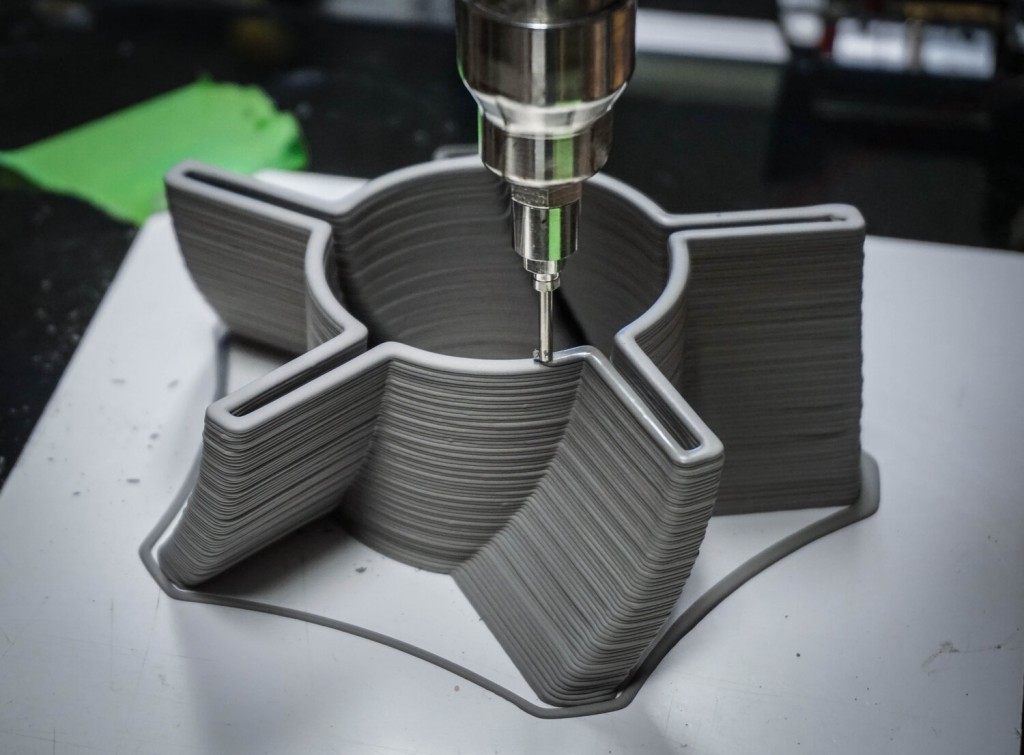

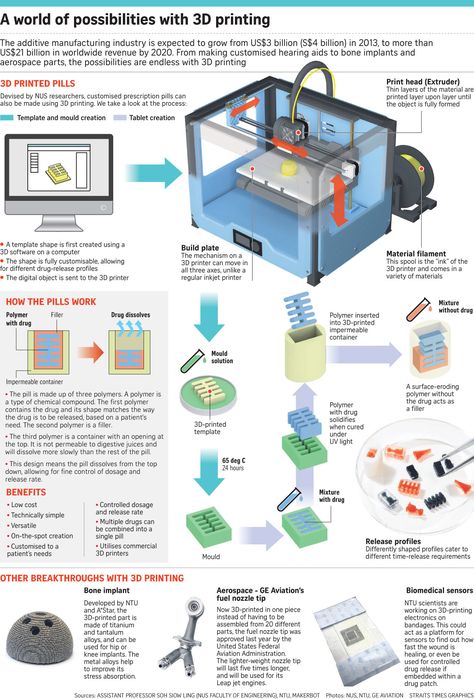

3D printing companies offer 3D printing jobs like 3D design and printing. This is very useful for prototyping or bringing to life your ideas in reality. This technology is practical and is also applicable to aerospace, medicine, and education.

For this reason, 3D printing manufacturers and companies have become in demand. In fact, they are experiencing rapid growth and this is expected to continue in the coming years. Even individuals who own a 3D printing machine and are knowledgeable of the craft offer this to those who need it.

Even individuals who own a 3D printing machine and are knowledgeable of the craft offer this to those who need it.

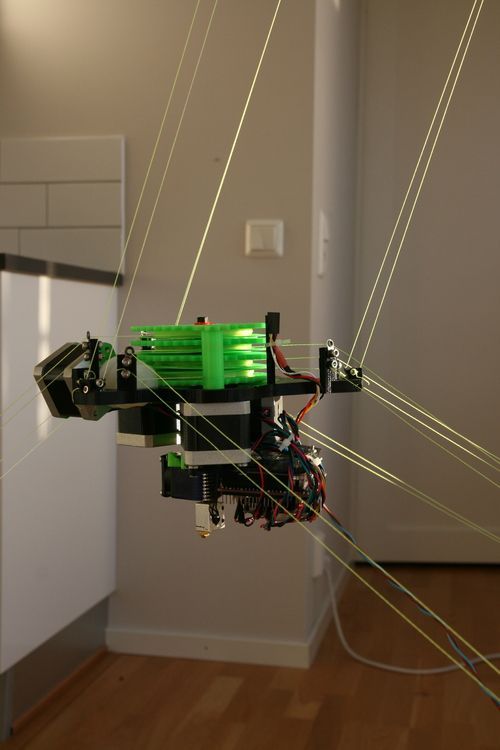

3D printing technologies are very accessible. In fact, there are a lot of 3D printing online shops and you can easily find them when you browse and check the internet.

Who Needs This Service?

3D printing applies to almost any area of your life. So getting your own machine will be very helpful. However, if you are not willing to invest in one, then a 3D printing service is perfect for you.

Here are more reasons why you should get a 3D printing service.

You’re a Business Person

If you are in business and you need a working prototype for a client presentation, using a 3D printer will make the process easy and fast by delivering 3D printed parts and functional prototypes.

Some of the individuals who use this type of service include Architects, Engineers, Real Estate Brokers, Interior Designers, and Business owners. They prefer this approach because it reduces cost, time and labor.

You Want Lesser Investment Risk

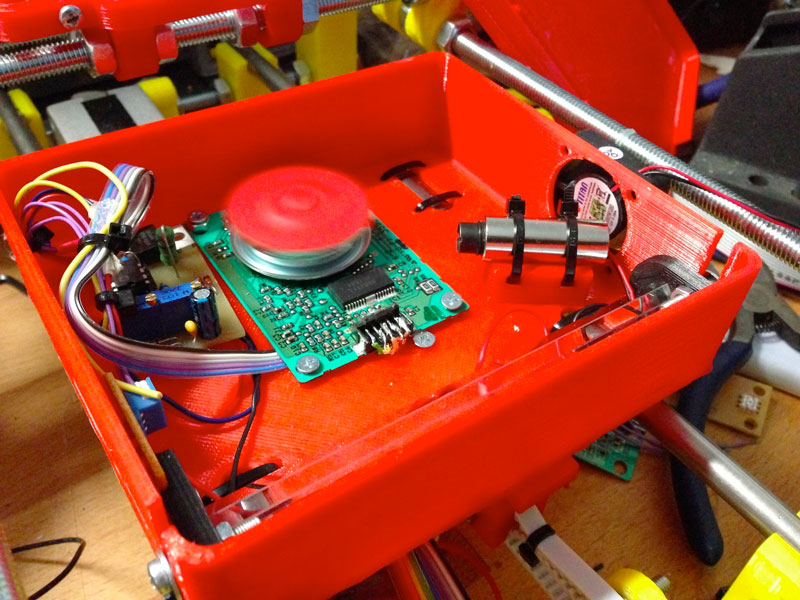

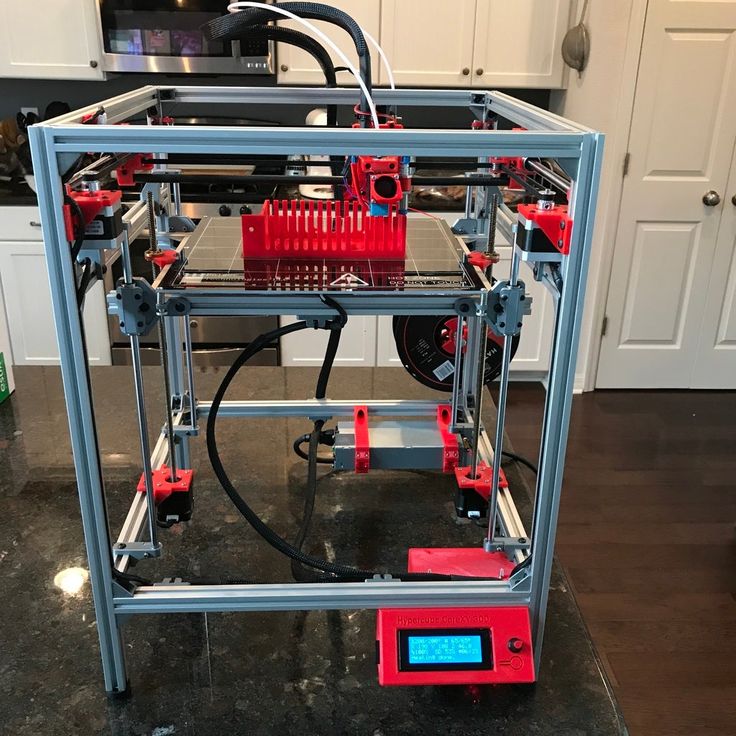

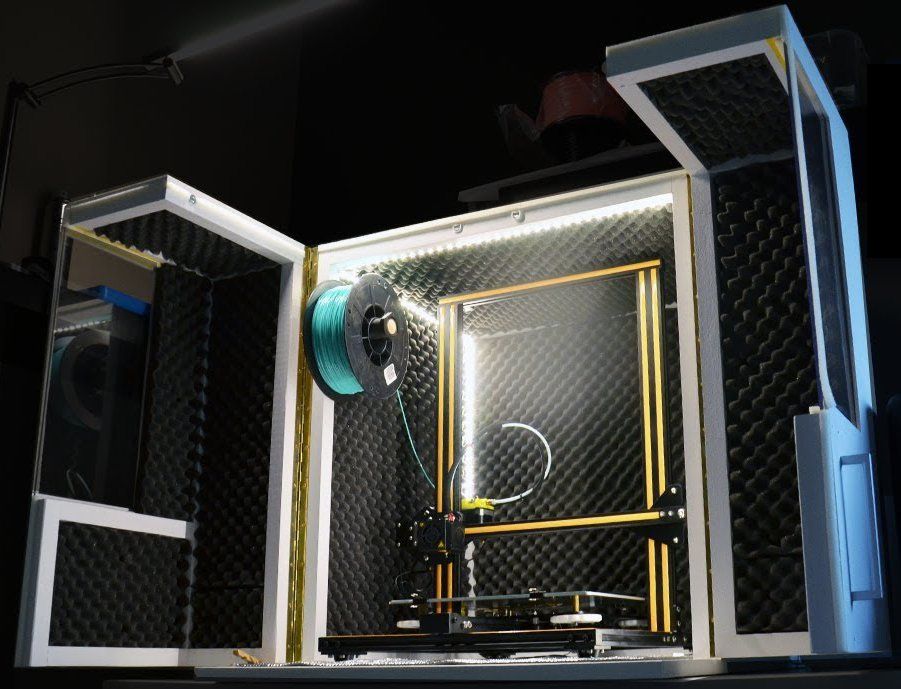

3D printers can be cheap or expensive depending on the brand and model. However, buying one and maintaining it isn’t that easy and practical especially if you do not use it often. These types of machines are not a plug-and-play thing, there are tons of things that you have to consider when you want to get one.

Sometimes it might involve training yourself or staff, setting up software, maintenance, purchasing materials (filaments, print heads, etc.) and disruption operations. This type of service makes 3D printing affordable and accessible to anyone who needs it.

You’re Not Technology Savvy

Owning a high quality 3D printer can help you save if you have a business or you have to do three-dimensional printing often for some reason. Yes, owning one will be practical if you know how to use it and make money from it. However, if you don’t and if you rarely need it, then the best option for you is to get a 3D printing company’s service.

Yes, owning one will be practical if you know how to use it and make money from it. However, if you don’t and if you rarely need it, then the best option for you is to get a 3D printing company’s service.

You Want to Customize Something

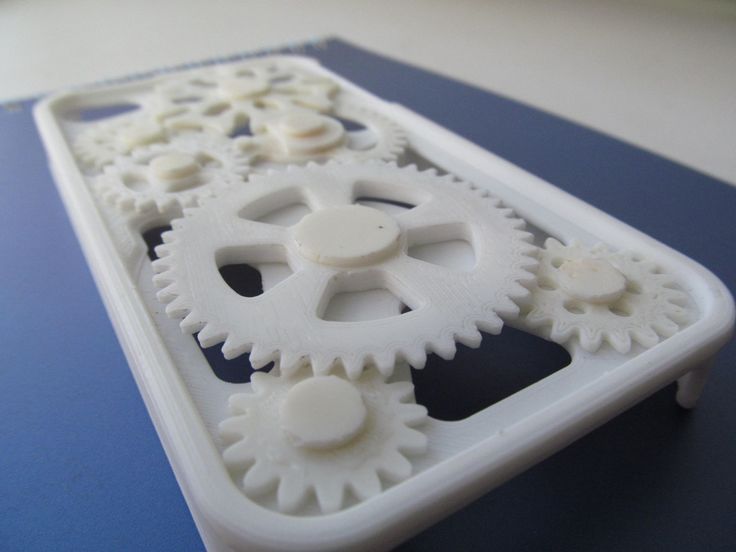

Customized items are very popular nowadays. In most cases, even gifts like mugs or key chains are now customized by adding the recipient’s name or photo. Custom 3D printing is a real thing.

With this, you can almost realize anything you have in mind be it a stand for iPad, a bottle opener, a pencil container, a cup, an accessory holder or even a shoe.

The benefit of customizing shoes is that it caters to the actual shape and size of your feet, which delivers great comfort. For athletes, this could help them maximize their performance.

You Want to Try New Stuff, Materials, Designs

Companies that 3D print objects from models are not only for those who are completely inexperienced because even experts seek this type of service from time to time to try or learn new stuff, materials and design.

According to Stratasys Directs, a number of 3D printer owners come to them to try new materials that they don’t have or to customize their tools, jigs, and fixture.

You Want to Save Money on 3D Printing

At some point, you might think that owning a machine will help you save more, but this also depends on how frequently you need it and how much the maintenance cost is.

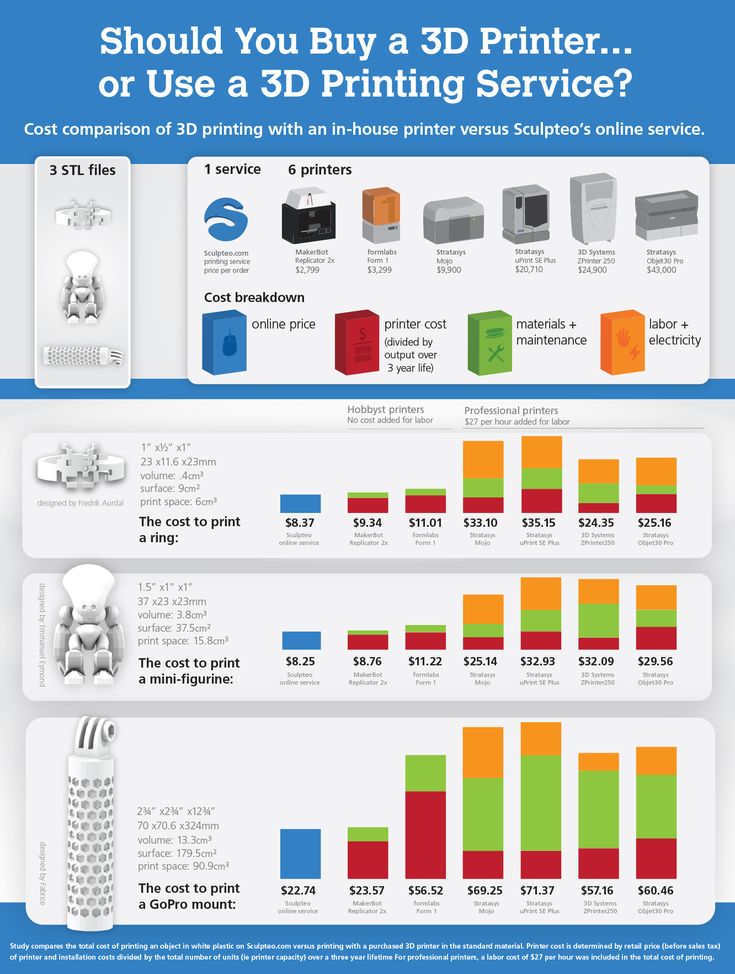

For instance, according to Sculpteo.com, it is more affordable to avail of this service from a 3D printing business than buying Makerbot Replicator 2x and Formlabs Form 1 for one or a few 3D prints.

Sculpteo.com calculates its 3D printing price by considering the printer cost (divided by output over 3-year life) materials, maintenance, labor, and electricity.

So, for example, a ring measuring 23 x 11.6 x 23mm will cost $8.37 from Sculpteo, $9.34 from Makerbot Replicator 2x, $11.01 from Formlabs Form 1 and $33.10 from Stratasys Mojo.

How much do these services cost?

Online 3D printing service cost depends on several factors. For Shapeways, service cost includes the materials used, machine space and labor.

For Shapeways, service cost includes the materials used, machine space and labor.

On the other hand, Sculpteo’s pricing considers these three factors: investment cost of the printer, materials and maintenance, and labor and electricity. It can also use this formula: retail price of printer and installation cost over a 3-year timeframe.

A small item is cheaper compared to bigger items because it uses less material and reduced labor. However, the complexity of the design and the number of parts have nothing to do with the price.

Source: SculpteoIf you are looking for this type of service it is important that you check the price well because the cost can differ up to 100%. You can use 3D Printing Price Check. The site allows you to upload an STL file in mm or in units and will give you an estimate.

You can only find a cheap service after making a few rounds of comparison. The price should not be a great concern though as this technology is deemed low-cost and fast. In addition, more and more companies are starting to offer this service. With tighter competition, the price will surely go down.

In addition, more and more companies are starting to offer this service. With tighter competition, the price will surely go down.

Best Online Services for 3D Printing

We know that there are tons of 3D printing businesses out there, so choosing the best one might be challenging. So, to spare you from the hassle of research and to help you save time, we create this comprehensive list of 3D printing stores that offer commercial 3D services.

This is a network of thousands of 3D printers all over the world. You can upload your 3D design in .stl or .obj format, choose a material for your application and select a 3D printing service from various 3D printers.

To help you decide it will show you the price, speed, and quality produced by different individuals or businesses who offer the service. The average work around time is 2 days (48 hours) but 50% of the orders are delivered within 24 hours.

3D Hubs also offers a number of materials to choose from including fiber-reinforced nylon that is as strong as aluminum but as cheap as plastic. Rigid opaque plastic for realistic and functional prototypes with impressive details and high accuracy. Meanwhile, transparent plastics work well for see-through parts and prototypes, full-color sandstone, simulated ABS and Industrial metals to name a few.

Rigid opaque plastic for realistic and functional prototypes with impressive details and high accuracy. Meanwhile, transparent plastics work well for see-through parts and prototypes, full-color sandstone, simulated ABS and Industrial metals to name a few.

Pros

- A network of thousands of 3D printers around the globe

- Upload your 3D design, choose your material, and select a 3D printing service

- Shows you the price, speed, and quality produced

Visit the site here

Go to top

3D Printing Ally's online 3D printing service caters to any industry and 3D print any product in any size. It offers custom parts and has a fast turnaround time of 24 hours.

They also offer an instant 3D printing quote by uploading your .stl file. If you have a CAD design but can't decide the material that you should use for it, the site has a model uploader feature for this.

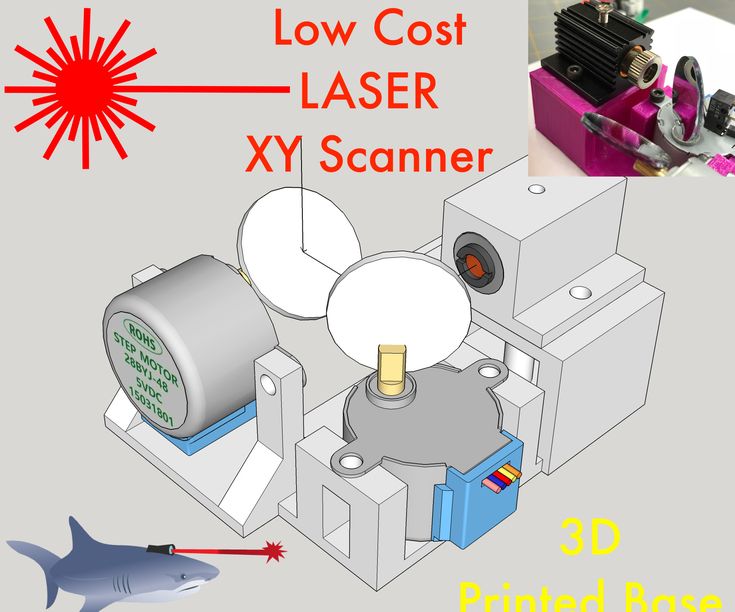

This site uses different technology including Selective Laser Sintering (SLS), Fused deposition modeling (FDM), Stereolithography (SLA), MultiJet Printing (MJP) and ColorJet Printing (CJP).

It also offers a number of materials like DuraForm PA, ABS-M30, Polycarbonate, Ultem 9085, VisiJet SL Clear, VisiJet Crystal and Ceramic to deliver any 3D printed object you have in mind.

Pros

- 3D print any product in any size

- Offer instant quote by uploading your file

- Uses different technology and materials

Visit the site here

Go to top

This site is more than an online 3D printing service as it helps you discover the unimaginable. With its 20 different materials and over 100 possible color combinations, you can turn all your ideas into 3D printed reality. They also offer polishing, dyeing, gold plating and more.

The site also includes 3D printing tutorials to help you design, print, scan and get yourself familiar with 3D printing materials. For those who do not have the inclination to learn 3D designing, the site has a "Hire a 3D Designer" section.

The process with i. Materialise is fast, easy and affordable. You can order in seconds with instant pricing and automatic file checking.

Materialise is fast, easy and affordable. You can order in seconds with instant pricing and automatic file checking.

Pros

- 20 different materials with 100 color combinations

- Also offer polishing, dyeing, gold plating

- Instant pricing and automatic file checking

Visit the site here

Go to top

MakeXYZ is a US company that offers a full menu of 3 printing services including different technologies like FDM, SLA, SLS, and Polyjet. The site is very versatile because it also accepts different types of files and materials.

The process is very easy because you can have a MakeXYZ print manager to handle everything. If you have a 3D file, you can also upload it and the print manager will handle the logistics. If you just want to connect to a 3D printer directly, that is possible too.

The site includes a "Find 3D Printers" list that includes the printer's name, location and his/her 3D print capabilities..jpg) One advantage of this is that working with a 3D printer may speed up the process and you might get the print soon, like on the same day.

One advantage of this is that working with a 3D printer may speed up the process and you might get the print soon, like on the same day.

Pros

- Offers different technology like FDM, SLA, SLS, Polyjet

- Work with materials like ABS, PLA, Nylon, Wood, Paper, sandstone, ceramic, resin, etc

- Can provide a print manager to handle the complete process

Visit the site here

Go to top

Source: Skilled UpThis site is a 3D printing marketplace because it connects the customers to manufacturers. Ponoko doesn't do the manufacturing itself but uses a network of manufacturers all over the world who perform the additive manufacturing process using their own machines.

Ponoko has a standard turnaround period of 1 week but it is also possible to ship the 3D printed parts on the same day. It has 180,000 designers, 550,000 custom products, over 99 beautiful materials and big-time customers like Oracle, Google, Cisco, Disney and Autodesk to name a few. Most importantly, they offer one of the cheapest services.

Most importantly, they offer one of the cheapest services.

Pros

- 3D printing marketplace and network that connects customers to manufacturers

- The process easy, fast and low-cost

- Offers over 99 types of materials

Visit the site here

Go to top

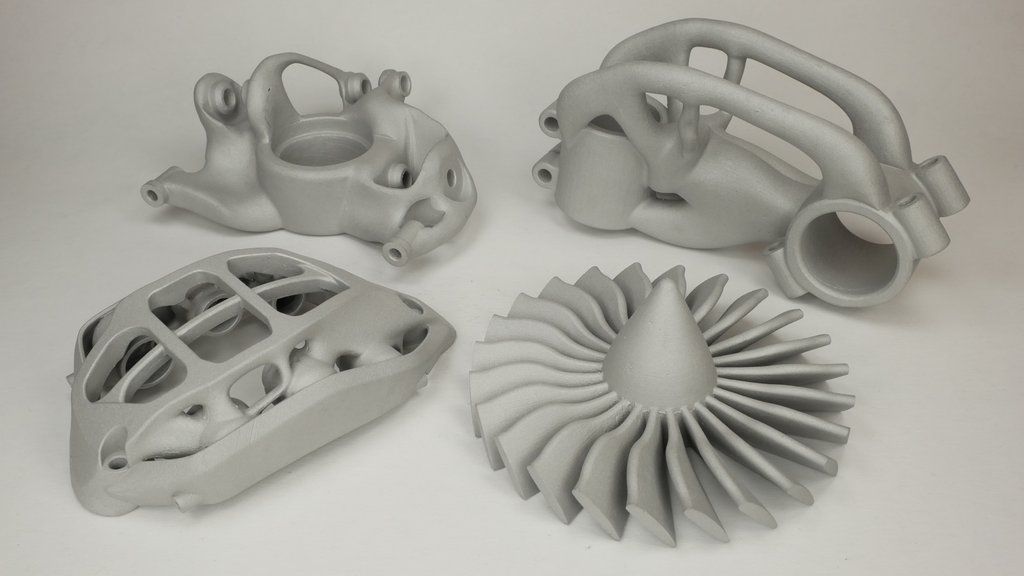

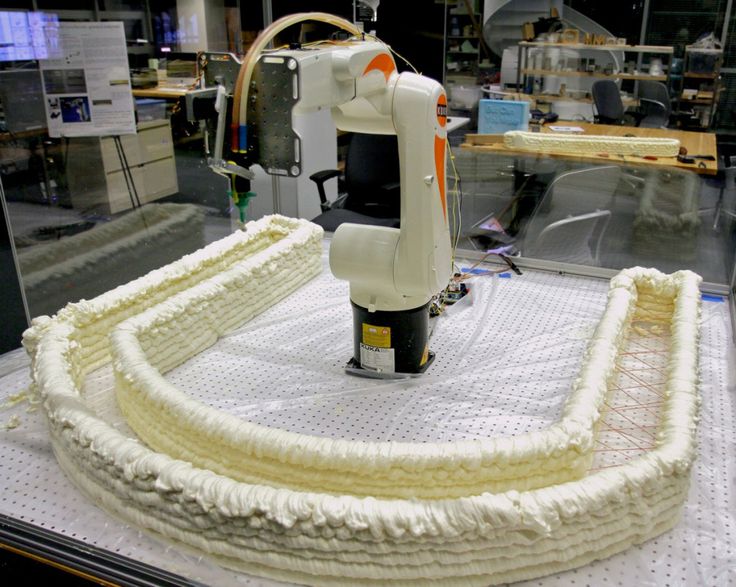

This 3D printing service uses Industrial 3D printing, an additive manufacturing process that works best for rapid prototyping, complex designs, multipart assemblies, and functional end-use parts. Proto Labs is one of the companies with the fastest turnaround time.

They can ship or deliver custom prototypes and low-volume production parts in as fast as one day. It has global facilities in Europe and Japan. The company is now the world's fastest on-demand manufacturer of custom and functional prototypes and low-volume production parts with manufacturing facilities in seven countries.

Pros

- Fast product development

- 3D printing service uses industrial 3D printing

- Uses materials like ABS, aluminum, Polypropylene, nylon, stainless steel, cobalt chrome

- With global facilities in Europe and Japan

You can visit the site here

Go to top

This 3D printing service aims to connect you to 3D designers to give you access to thousands of ideas from designers and businesses. You can browse their collection and customize your 3D model for printing. If you need training resources to learn 3D printing or expand your expertise, the site includes ebooks, webinars, and tutorials.

You can browse their collection and customize your 3D model for printing. If you need training resources to learn 3D printing or expand your expertise, the site includes ebooks, webinars, and tutorials.

Sculpteo uses different technologies to cater to different materials. These are the technologies they use for each material you wish to utilize on your application.

- Plastic/Alumide

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

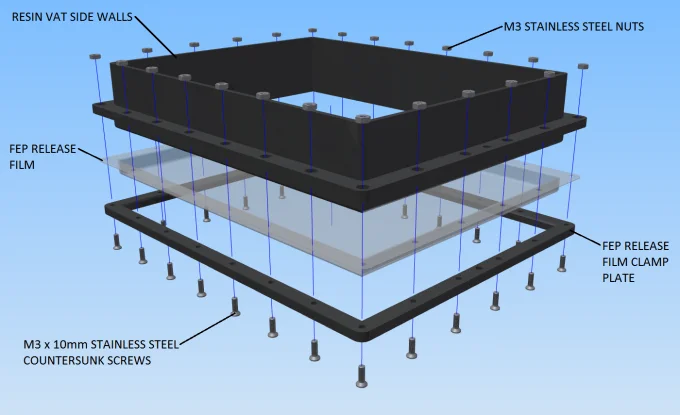

- Resin/Wax

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- MultiJet Printers

- Metal

- DLP

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

- Multicolor

- Binder Jetting

- Selective Deposition Lamination

- Triple-jetting technology(PolyJet)

Here’s a table of the technology, process, materials used by Sculpteo including the advantage and disadvantages of using it in delivering the 3D printed objects you desire.

Just like other 3D printing services, Sculpteo is very easy to use. Just upload your file, the website allows over 25 formats for your convenience. They will repair it if there are issues and give you an instant online quote. Then, set up the quantities, optimize your object using their 3D tools and place your order.

Their normal turnaround time is 24 to 72 hours. The company is asking for an extra 2 days for dyed plastic. As for silver material, the average delivery time is 21 days.

Pros

- Just upload your file, allows over 25 formats

- They repair if there are issues

- Set up the quantities, optimize your object, and just place order

Visit the site here

Go to top

SD3D aims to be the one-stop-shop for 3D printing services in San Diego, CA by bringing you a group of aspiring entrepreneurs from different fields of background including engineering, design, business, and economics.

The company has an automated system that offers one of the most affordable prototyping and manufacturing solutions in the 3D printing market. They also use a Cloud-based network to monitor print status and print objects in batches.

They also use a Cloud-based network to monitor print status and print objects in batches.

SD3D offers a huge variety of materials. Their standard turnaround time is 3 to 7 days but they also offer an expedition service with a $40 fee depending on the size and quantity of your project.

Due to the extensive options that the company offers, you can surely find a service that is within your budget be it for pure rapid prototyping, high-resolution 3D prints with an added finish or large volumes.

Pros

- Uses cloud network to monitor print status

- Materials include PLA, ABS, T-Glase, PET+, Bridge Nylon

- Services include pure rapid prototyping, high-resolution 3D prints with a finish, large volumes and more

Visit the site here

Go to top

Shapeways is one of the leading 3D printing services in the world. It is a marketplace where users can design and upload their own files. As these designers easily sell their work, Shapeways process the manufacturing, distribution, customer service, and payment.

The company offers over 50 materials to 3D print your project including plastics, porcelain, aluminum, porcelain, silver, and sandstone to name a few. Standard turnaround time with Shapeways depends on the material ordered and the shipping option.

However, they offer a rush production that delivers within 2 business days. The website has a Customer Service team to help customers deal with late orders, returned items or issues after delivery.

Pros

- The leading 3D printing services in the world

- Offers over 50 materials to 3D print your project

- Marketplace where users design and upload their own files

Visit the site here

Go to top

Voodoo Manufacturing offers small-batch manufacturing with high-volume 3D printing. It offers to bridge the gap between prototype and mass productions, which makes it one of the best 3D printing services in the US.

It offers to bridge the gap between prototype and mass productions, which makes it one of the best 3D printing services in the US.

The process with Voodoo is very easy. First, you will start with your own 3D model or have their professional designers create one for you. You can make one anywhere from 1 to 10,000 parts in as fast as 24 hours.

The company offers direct print, volume printing, print API, and 3D design. They have worked with Autodesk, Syfy, Intel, Universal and Microsoft to name a few, so you can guarantee the quality of their output as they have worked with these prominent companies.

Pros

- 3D prints high-volume for mass productions

- Start with your own 3D model or have professional designers create

- Offers direct print, volume printing, print API

- Offers small-batch manufacturing with high-volume 3D printing

Visit the site here

Go to top

XometryXometry offers high-quality 3D printing services including prototypes and production parts. The best part that I love about it, is that it offers free shipping on all US orders with no minimum orders. You can order any type of 3D project because they have over 60 metal and plastic materials in different colors. They have materials for all applications.

The best part that I love about it, is that it offers free shipping on all US orders with no minimum orders. You can order any type of 3D project because they have over 60 metal and plastic materials in different colors. They have materials for all applications.

Xometry is making waves and is becoming more and more popular because it is versatile. It 3D prints anything you have in mind. It offers millions of possible combinations of materials, finishes, tolerances, markings, and certifications for orders. They are also easy to use. You can get the parts delivered right to your door without the hassle of sourcing, project management, logistics, and shipping.

They also deliver custom parts to your specifications. Most importantly, they guarantee quality because they back every part they ship with the Xometry Quality Guarantee. You can get an instant quote for any 3D printing service you desire to get from them by just uploading the 3D model. If you have a lot of 3D models, no worries, Xometry allows you to drag and drop unlimited numbers of 3D models.

Pros

- Easy to use

- No minimum order

- Guarantee quality

- Offers instant quote to any project

- Endless options with over 60 materials

- Free shipping on all U.S. orders

Visit the site here

Go to top

ConclusionGetting online 3D printing services or a professional 3D printing service is the most convenient solution if you want to get a prototype or a certain 3D project done fast without spending too much. If you own industrial 3D printers, this is also a good chance for you to offer a printing service online.

If you need to learn more about 3D printing technology or additive manufacturing, feel free to check our homepage.

Best cheap 3D printing service – Real use case example

In this definitive guide, we will be taking a look at the most economical way to get custom 3D printing projects done from start to finish. We will start with the idea, then design and finally to getting that custom design 3D printed. For this we will be looking at online 3D printing services for the design phase as well as the 3D printing phase.

For this we will be looking at online 3D printing services for the design phase as well as the 3D printing phase.

Disclosure: This post contain affiliate links, we may earn advertising commissions for sharing products we know and love.

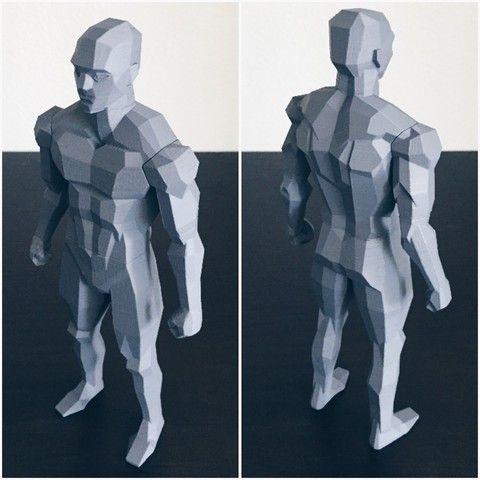

The idea is to design and 3D print a character model. The plan is to hire a designer to design a 3D model based on the character model of a charming llama with sunglasses, budget $30.00 to $90.00. To test both ends of the price points we’ll also hire a different designer to model a low poly Shiba Inu. We’ll set the budget to $30.00 to $90.00, and try to keep the total under $55.00.

These models once 3D printed would serve as a custom decorative piece for a room in the house. The models would possibly be added as a video game characters or even sold as props.

There are quite a few online 3D printing service providers that can help us achieve the end result of producing this custom print at a relatively low cost. 3D printing services on the Fiverr platform are arguably the most economically priced 3D printing, 3D modeling and design services.

Until recently, the 3D printing services offered on the platform flew cleanly under the radar. What makes Fiverr unique in our case is that it offers the most flexibility, in that we can communicate our ideas directly with a product designer or CAD 3D modeler in order to produce the exact design we’re after.

The value per dollar offered by freelancer on the platform easily exceeds other competing 3D printing services, as well as other freelance marketplaces. Though it must be noted that the $5 service cost often cited with this platform serve as a base price, whereas detailed custom work generally run upwards of $30.

Thanks to the immediacy of online platforms, it is tempting to jump straight in and get started with a custom 3D printing project. While that may seem like the right thing to do, if you have precise details for the 3D print, then this approach is unfortunately, not recommended.

Some key preparations that one should always do before hiring design services are given below:

- It is best to have a budget in mind beforehand.

The budget for our project was set to $30-$90 per model. To do this, simply “shop around” for 3D modeling design and 3D printing services to gauge the “standard” rates and try to set your budget below that. No point in going through all the trouble of buying services online if it would cost you more, instead of less.

The budget for our project was set to $30-$90 per model. To do this, simply “shop around” for 3D modeling design and 3D printing services to gauge the “standard” rates and try to set your budget below that. No point in going through all the trouble of buying services online if it would cost you more, instead of less. - The designer would most likely want a better idea to get started on the 3D model than just a verbal description. While there are 3D print designers with exceptional sketching and perspective drawing skills, it is best to discuss the conceptualization and design requirements ahead of time. Else it would be more time/cost effective to find a sketch and perspective artist to draw out your idea in 2D, whether on paper or digital form, before finding a 3D artist for the 3D modeling and printing.

- It is also important to consider the scale and physical size of your proposed custom 3D print. Try to account for that in both the budget as well as in the initial sketch-ups or modeling.

We’ll continue with the Fiverr approach since it is the service we tend to use. We’ll also include below other alternative should a more industrial grade service be required.

Like other freelance marketplaces, browsing services on the site does not require one to create an account. Looking up services by the various sellers couldn’t be simpler: simply type “3D printing design” in the search box and presto! Fiverr will give a list of matching 3D printing services, such as 3D modeling and 3D printing for you to examine and choose from.

Remember to consider the following few pointers when browsing all the sellers to get to the right one for you:

- First and foremost, filter the given search based on your decided budget. To do this, you can click on the “Budget” button and put in a maximum and minimum (optional) amount in the two boxes and let the revised search list load.

- Some sellers may pop up in your search results simply based on their lowest priced package.

This may or may not cover your needs, so you still need to peruse further in and filter out sellers based on other criteria such as “Service Options” and other details.

This may or may not cover your needs, so you still need to peruse further in and filter out sellers based on other criteria such as “Service Options” and other details. - New sellers would most likely charge you less for their services, so it is a smart option to not exclude them.

- If you plan on selecting a seller who can design as well as 3D print the custom item, then be sure to consider an option that will best account forshipping.

Never move the deal off the platform. Even if the seller requests so (some will). Remember that the platform is there to guarantee delivery and satisfaction. Also, you are still working with a real person. So, finding the right person and setting the right expectation from the start is key.

Once you have shortlisted potential service providers, contact them via private message and ask them to quote their best price to you if they can do the described job.

You would first need an account if you decide buy a service on the platform.

As a buyer, you don’t need to do anything more than just sign in and start communicating with sellers. This would give you at least a chance to somewhat haggle the price if the seller is open to negotiate.

We chose a level 2 seller who had completed several projects similar to what we were after.

Don’t simply place an order without communicating first, as this may end up with the service provider not being on the same page as you in achieving your vision.

Make sure to agree to the terms before placing an order, including delivery time, 3D model file format, revisions allowed and any other criteria in addition to the price.

After communicating our plans with the designer and submitting the photo shown above, along with another photo of a cartoon llama with sunglasses as a reference, he sent an offer for the price of $80.00, with details on delivery times, revisions and the number of renders.

We did not try to haggle the price down since that was everything included in the seller’s package for $80. We certainly could have found a better deal, but maybe the skill level would have dropped a bit. Instead, we kindly asked to increase the number of renders up from 4 to 5, accepted the offer and proceeded to wait for the 5-day delivery time.

We certainly could have found a better deal, but maybe the skill level would have dropped a bit. Instead, we kindly asked to increase the number of renders up from 4 to 5, accepted the offer and proceeded to wait for the 5-day delivery time.

As for the Shiba Inu model, we messaged several designers on the platform and settled on the price of $50.00, with 10-day delivery. We tried to negotiate the price down to $30, however that would require longer wait time. So, we opted for the faster option.

If all the terms have been discussed and agreed upon, you can simply ask the seller to send an offer. Another alternate route for finding the right seller is to post a job request. To do this, once you are logged in, click on the light blue “post a request” button and give an in-depth write-up with regards to what your ideal service package would be.

Select a reasonable budget and an acceptable delivery timeline. And be sure to attach the sketch/drawing of your desired custom 3D print.

Select the category as, “graphics and design, industrial and product design”.

Once posted, the request will show up for eligible sellers and the interested sellers will send you a custom proposal. Simply begin a conversation with the most promising sellers and work out a mutually beneficial arrangement and place an order or accept their custom offer.

Payment occurs at the buyer’s end when one confirms and places an order. These funds stay in an escrow system till the buyer accepts the seller’s delivery.

The platform charges $2 service charges on orders under $40, and 5% service charges on orders exceeding $40. This cost is borne by the buyer and paid directly to Fiverr.

The $80 order came up to a total of $84 and the second order came up $52.75. Both orders together totaled up to $136.76, $44.00 less than the max budget.

Two days into the wait, the designer for the llama gave update on the progress with the following photo.

Shortly after, we get the typical email from the platform informing us on the delivery. Here are the results for the first project, the llama.

Here are the results for the first project, the llama.

Once the seller makes a delivery, the buyer has 3 days to either accept, reject the delivery or request a revision. Upon expiration of the 3-day period, the order would automatically be marked as delivered and the funds would be released to the seller.

One thing to note about ordering 3D printing services on platforms such as Fiverr is that the service providers often try to undercut the time necessary to generate the best work. While some sellers are able to over deliver on both quality of work and turnaround times, others tend to fall behind. From our experience, about 5 percent of projects require a revision or extension. So, it is a good idea to plan for additional time on top of the seller’s quoted delivery date.

For our project the seller initially delivered this model.

It was quite clear that he had rushed the process. He himself admitted it, citing personal reason as the cause.

The revised version turned out quite nice. With the exception of the eyes.

With the exception of the eyes.

Those eyes look like they belong on a human more than they do on a llama. But that’s no big deal, since they will be post processed with paint after being 3D printed anyways. We’ll choose a closed eye design for the post processed print. Maybe a low poly model would have been a better design choice after all. Nevertheless, this goes in as a successful project.

The second project was delivered on the 10th day as agreed. This one did not require a revision. Here are the results for the Shiba Inu model.

If the seller is late on delivery, then the option to cancel the order also opens up. In which case the original amount paid is refunded to the buyer.

And lastly, once the delivery is made, both the buyer and the seller are asked to review their respective experience.

3D print and 3D modeling services on Fiverr start at $5, with physical 3D printing services starting from $10. Combo services tend to start over $30 for simple prints.

While these prices are enticing, based upon the complexity of your custom 3D print, the quoted price may go up so high that it would be worthwhile to check out other websites and 3D printing design services as well.

While there are numerous avenues available as alternate routes for hiring a 3D print designer, some of the available online platforms are listed below that also focus on economical services and are at the very least as easy to use as Fiverr for getting a custom part designed and printed.

Like Fiverr, Etsy is famous in its niche for its diverse product listings, as well as its customer friendliness. Etsy has loads of custom 3D printing listings available on its platform, from design services, to cheap 3D printing services to more professional 3D printing services as well.

Etsy is a good place to shop for a 3D print designer for your custom part if you are focused first and foremost on a budget conscious purchase.

Shapeways is well known for its 3D printing on-demand services. Through its partnership with Zverse, Shapeways also supports a 3D print design workflow.

Through its partnership with Zverse, Shapeways also supports a 3D print design workflow.

You’re given the option of receiving a custom quote for the idea that needs to be converted to a custom 3D print. You can also attach a drawing for better clarity. For more complicated parts, this should certainly be an option to consider.

Cadcrowd is a specialized freelance marketplace focused on 3D modeling, CAD and other modeling services. Unlike most other freelance marketplaces, Cadcrowd is quite protective of its freelancers in that you can only apply for a quote through Cadcrowd to get a free estimate.

The website has a large listing of serious professionals. Despite its user-unfriendliness at a glance, it should be considered for projects that need that extra bit of care.

If you own your own 3D printer, you can use the STL files from the designer to print the model.

Provided you did not opt for a bundled service, the next stop to bring your custom 3D print into the physical world, is of course, a 3D printing service.

Plastic prints would certainly be cheaper and easier, whereas metal 3D prints cost more in terms of both time (for desired finishing) as well as money.

The most affordable option for 3D printing the model is by far Fiverr. The next most economical option is Ponoko. If metal is the required material, it would be best to choose a well-reputed industrial grade online 3D print service to ensure the cost is worth the quality.

Craft Cloud, is an online 3D printing price comparison service. So instead of searching through 10 different 3D print on-demand online services for quotations, one may simply upload their STL or 3D print file to Craft Cloud, and the service would then list the best available prices.

The website has very positive reviews overall and claims to achieve 50% savings when compared to other 3D printing services.

It also provides a very diverse selection of materials including plastics and metals, as well as worldwide shipping.

This marketplace is operated by Dassault Systèmes. Unlike Craft Cloud that compares prices for you, this website is much more of a marketplace where you can find a 3D manufacturer for hire.

Unlike Craft Cloud that compares prices for you, this website is much more of a marketplace where you can find a 3D manufacturer for hire.

The website provides instant quotes, a 3D parts catalog and numerous other manufacturing and machining services on-demand.

3D Hubs is the community alternative to the swathe of professional 3D printing on-demand services available. 3D Hubs has definitely grown from its community roots and now stands head and shoulders with all its professional peers.

3D Hubs is a popular destination for on-demand 3D printing. It also supports instant quotes as well as a broad selection of materials. A notable feature of 3D Hubs is that it also quotes turn-around times in addition to monetary quotations, which may or may not be a crucial factor to you, but are good to know nevertheless.

Shapeways is arguably one of the most popular online 3D printing services today, with its suite of professional 3D printers covering nearly all types of materials which includes plastics, resins and metals. It is hard to go wrong with Shapeways for your custom 3D part.

It is hard to go wrong with Shapeways for your custom 3D part.

It may not be the cheapest, but it is well-known for its quality.

While it is impossible to cover every 3D printing on-demand service available, we believe the above four platforms provide a good base to work with when hunting for the best value for money, and highest bang for one’s 3D printing buck.

3D printing as a technology promises to make ideas into reality. 3D printing services open this promise up to the masses. So whenever that spark comes to you next, that you must convert to a physical 3D print, we hope that this guide serves as a trusty tool to ensure you get to do so at the most affordable of costs.

Tags: 3D design service3D modeling3D printing serviceCustomcustom 3D designCustom 3D printings

List of 3d printing services / Sudo Null IT News

AndreyPanov

3D printers

Good afternoon everyone!

On Habré, you can relatively often see articles on 3d printers, comparing their prices and ordering opportunities with us.

And what about the finished 3D models?

What if I don’t want to buy a printer yet, but it would be interesting to “feel” the printed model. And it is advisable to choose from a catalog of ready-made models, and not draw it yourself.

Are there many resources where they can be downloaded, bought or printed from the catalog?

Answering these questions, I decided to make a small list of resources with the ability to select ready-made models and order printing.

Foreign services:

- www.thingiverse.com is probably the most well-known one in existence. The service was created for the free exchange of models under the GNU General Public License. The service has been operating since 2008. Owned by MakerBot Industries, USA.

- www.shapeways.com - custom printing. The service has been operating since 2011. Production (printing) is located in the Netherlands and the USA. You can add your own, you can even create your own store.

Due to the extensive fleet of 3d printers, they provide a large selection of materials, including ceramics and steel. They deliver to Russia.

Due to the extensive fleet of 3d printers, they provide a large selection of materials, including ceramics and steel. They deliver to Russia. - i.materialise.com/gallery - Print models from the catalog. The company has been operating since 1990 and is located in Belgium.

- It is also possible to evaluate your model and choose a material

- www.sculpteo.com/en/gallery/today - print 3d models and sell your own. There are quite complex and expensive models.

- www.kraftwurx.com - a platform for creating 3d models and selling them.

- www.turbosquid.com — database of 3d models for game designers, architects, etc. Many models were not created for the purpose of 3d printing, you can find something.

Russian services:

- 3dmarket.org is a service that allows you to download and upload models, as well as select an artist for printing.

If the list is not complete, please add in the comments, I will update the post.

UPD:

from foreign ones, the service https://www.ponoko.com was added, they are engaged not only in 3d printing, but also in laser cutting.

From Russian:

- 3dprintus.ru is a start-up, manufacturing various products according to individual sketches.

- can-touch.ru - there is a catalog with ready-made models. Large selection of materials.

- Gets a unique metal surface and look

- Ideal for jewelry, figurines, housewares, replicas

- Durability

- Objects are not flexible (structure dependent)

- Objects do not dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C

- Extremely low shrinkage on cooling

- No table heating required

- Printing complexity is high, requires fine tuning of nozzle temperature, feed rate, post-processing

- ColorFabb's 750 gram Bronzefill spool is $56.36

- ColorFabb 750g Copperfill Coil $56.36

- Protopasta's Polishable Stainless Steel PLA Composite is $56 for 56 grams of

- Rustable Magnetic Iron PLA Composite from Protopasta is $34.99 for 500 grams of

- aluminum

- steel

- brass

- copper

- bronze

- sterling silver

- gold

- platinum

- titanium

- Metal plastic: $22.44 (former alumide, PLA with aluminium)

- Stainless steel: $83.75 (plated, polished)

- Bronze: $299.91 (solid, polished)

- Silver: $713.47 (solid, mirror polished)

- Gold: $87.75 (gold plated, polished)

- Gold: $12,540 (solid, 18K gold)

- Platinum: $27,314 (solid, polished)

- The most common case is surgical and dental implants, which are considered the best option for patients today. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines.

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Metal 3D Printing - A Fundamental Guide

There is no hotter trend in 3D printing today than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials.

Metal 3D printing has grown in popularity over the past few years. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils.

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. In fact, some of the printed parts are just as good (if not better) than those made with traditional methods.

In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

So, what do we need to know about metal 3D printing?

Metal 3D printing at home

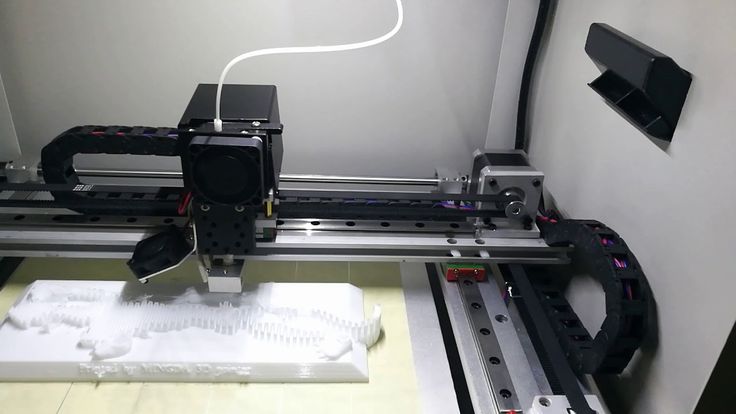

If you want to make objects that look like metal at home, metalized PLA filaments are your best bet. (Photo: colorFabb) ? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

(Photo: colorFabb) ? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object.

Materials for metal 3D printing at home

Even though you can't print actual metal objects at home, you can turn to plastic filament that has metal powders added to it. ColorFabb, ProtoPasta and TreeD Filaments all offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain pliable enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Metal 3D Printing Filament Spools, in this case from SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze (Ancient Bronze) from Formfutura

Here are the key points about metal printing at home

Preparing Your Home Printer for Metal 3D Printing

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if you are an entry-level printer. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

You will also need to take care of the final finishing of the surface (cleaning, sanding, oiling, waxing or priming) so that the printed metal object shines as it should.

How much does metal filament for 3D printing cost?

And what about metal filament for 3D printing? - you ask. Here are a few examples:

Industrial metal 3D printing

But what if you want a better result or even full metal 3D printing? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

Lowering Metal 3D Printing Costs

In case you are not going to open a metal 3D printing business, but still need a professionally 3D printed metal part, it is better to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing.

They currently work with the following metal materials in 3D printing:

If you are a jeweler, you can also order wax models for casting in precious metals.

If we talk about wax models, then in most cases they (with subsequent melting) are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services.

The reason big companies love 3D printing so much is that it can be used to build fully automated lines that produce "topologically optimized" parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone.

Please note that metal 3D printing requires special CAD programs for modeling. It is worth paying attention to the recommendations of Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of Benchy test model prices for metal 3D printing:

As you might expect, solid metal 3D printing prices are quite high.

Metal 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at Avio Aero (Photo: GE)

There are several industries already using 3D printers to make everyday objects - you may not even know that these objects are printed.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed.

Metal 3D printing.

Technologies

Most metal 3D printing processes start with an “atomized” powder

You can talk a lot about “metal” 3D printers, but their main problems remain the same as any other 3D – printers: software and hardware limitations, material optimization and multimateriality. We won't talk too much about the software, we'll just say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that as a result of the 3D metal printing process, you can get any shape you want.

In general, printed metal parts can be as strong as parts made by traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

3D printed metal can have different resolutions. At the highest resolution, layer thickness is 0.0008 - 0.0012" and X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045".

However, let's look at what metal 3D printing technologies are. formed layer)

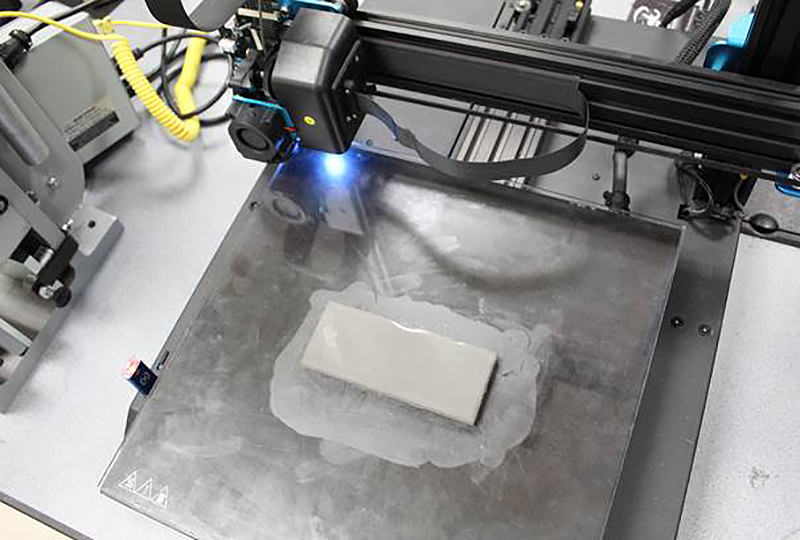

The metal 3D printing process used by most relevant large companies today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object.

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Metal 3D printing No. 2:

binder Jetting (spraying the binder)

under 3DP-technology EXONE Metal objects are printed due : ExOne)

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

Another option, which is similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains

This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

Metal 3D printing process #3: 9Metal Deposition This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding. Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm.

Normally the whole process takes place in a closed chamber, but the MX3D project used conventional 3D printing techniques to build a full-size bridge. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

Metal 3D printing. Metals

3D Printing Metal #1: Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing and is definitely one of the most versatile, strong and lightweight. Titanium is used both in the melting process in a preformed layer and in the process of spraying a binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

3D printing metal #2: Stainless steel

Stainless steel is one of the cheapest 3D printing metals. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

3D Printing Metal #3: Inconel

Inconel is a superalloy manufactured by Special Metals Corporation, its registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

3D Printing Metal #4: Aluminum

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used.

3D Printing Metal #5: Cobalt Chrome

gap). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

3D printing metal #5. Copper and bronze

With few exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

3D printing metal #6. Iron

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

3D printing metal #7. Gold, Silver and Other Precious Metals

Most preformed layer companies can 3D print precious metals such as gold, silver and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

Metal 3D printing. Printers

Do not hesitate - the purchase of a metal 3D printer will not pass without a trace on your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

Metal 3D Printer #1:

Sciaky EBAM 300 - metal filament printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military.

Sciaky's largest production printer is the EBAM 300. It prints objects in a volume of 5791 x 1219 x 1219 mm.

The company claims the EBAM 300 is also one of the fastest industrial 3D printers on the market. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m. The metal powder 3D printer is the Concept Laser XLine 1000. It has a modeling volume of 630 x 400 x 500 mm and is the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new machine, the Xline 2000.

This machine uses two lasers and has a working volume of 800 x 400 x 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metallic 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs.

Metal 3D Printing Service #1: Shapeways

The world's most popular 3D printing service, Shapeways offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

3D printing metals: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i.materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them to fabrication in a wide range of materials . Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project.

Extensive technical documentation will help identify design flaws and select the right material for the project.

3D printing metals: alumide (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialize is a company that works with industrial customers to prototype 3D printed products. For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their website.

3D printing metals: alumide (plastic with aluminum powder), brass, bronze, copper, gold, silver, steel, titanium.

Metal 3D Printing Service #4: 3D Hubs

Through 3D Hubs, you can search for individuals and companies that offer 3D printing services in your area, upload STL files (which are immediately evaluated for defects ) and contact service providers directly to get the job done.

_RlfzhrZzWj.jpg?auto=compress&w=900&h=675&fit=min&fm=jpg)