Giant 3d printer builds house

Watch this giant 3D printer build a house

Skip to main content

Watch this giant 3D printer build a house

SearchSearchRuby Lott-Lavigna

Business

ItalDron

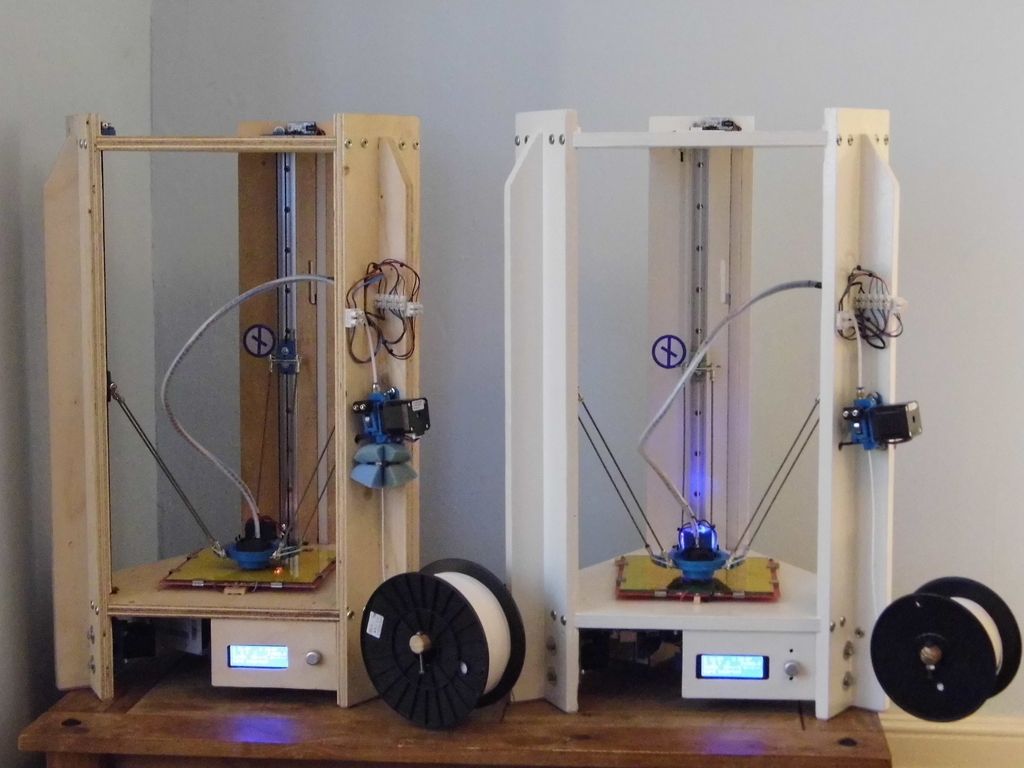

This 3D printer is big enough to build houses. Created by Italian engineering company WASP, the project has aspirations to solve the global housing crisis by building houses using sustainable materials.

The UN estimates that by 2030 approximately three billion people will require housing and 3D printers are being mooted as one potential solution.

The 40 foot tall, 20 foot wide printer is able to build structures using products like clay or dirt in order to maximise its use in areas with limited infrastructure or resources.

The structure -- consisting of a metal frame that suspends a nozzle -- uses very little energy to gradually build up layers of clay, eventually forming a basic house structure. WASP, which stands for World’s Advance Saving Project, is testing out the working prototype on September 26-27 will be documenting the progress on its website.

Building houses from 3D printers isn't unprecedented. In January 2015 a Chinese company built ten houses on the outskirts of Suzhou, a city in eastern China. A Dutch company is also using 3D printers to build a bridge made out of printed steel, but where the bridge will be built is yet yet to be decided.

TopicsCitiesDesignTechnology

More from WIRED UKscience

Pop-Up Farming Pods to Help Colonizers Grow Crops on Mars

Interstellar Lab’s inflatable BioPod is designed to help plants survive inhospitable conditions on Earth and allow explorers to settle on the Red Planet.

By Amit Katwala

science

Electronic Second Skins Are the Wearables of the Future

Flexible e-skins could be used to measure wearers’ blood pressure, temperature, and oxygen levels in real time, assisting with diagnoses and health care.

By Sabrina Weiss

science

The Undersea Art Gallery That Ensnares Illegal Trawlers

Trailing weighted nets across the seabed wrecks fish stocks and kills carbon-capturing seagrasses—but one fisherman’s sculpture project has turned the tide.

By Tristan Kennedy

science

No, Qatar’s World Cup Can’t Be Classed as Carbon-Neutral

Despite efforts to reduce emissions, the 2022 FIFA tournament is highly carbon-intensive. And its road to net-zero relies on questionable carbon credits.

By William Ralston

business

A Row Erupts Over Texas’ Bold Bitcoin Battery Plan

Bitcoin miners say they can help stabilize a shaky power grid and prevent blackouts. Experts say it will make the problem worse.

By Joel Khalili

science

Vertical Farming Needs to Grow More Than Salad

Indoor agriculture promises to massively reduce the water and land needed to support crops. But at the moment, it only works for a tiny percentage of foods.

By Matt Reynolds

7 of the Most Beautiful 3D Printed Houses and Cabins

From hemp fibers to rice waste, companies around the world are coming up with innovative ways to utilize unusual materials.

3D printing is having a big effect on many industries around the world, and the construction industry is no exception.

Here are seven interesting examples of proposed and in-development 3D printed housing projects from around the world. Perhaps you might want to get one printed for yourself in the not-too-distant future?

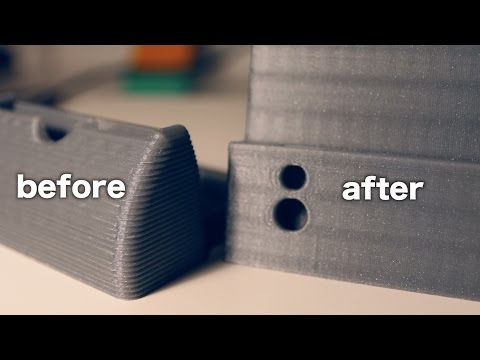

What is a 3D-printed house?The answer is, quite literally, in the name. 3D-printed houses are created using very large 3D printers that, unlike smaller hobbyist or other types of industrial units, are able to extrude concrete, plastic, or other building materials through nozzles, in order to gradually build up a 3D object the size of a house.

3D-printed houses are created using very large 3D printers that, unlike smaller hobbyist or other types of industrial units, are able to extrude concrete, plastic, or other building materials through nozzles, in order to gradually build up a 3D object the size of a house.

These printers, specifically their nozzles, are able to move in multiple planes and are specifically designed to be very robust and hardy, as they generally need to operate outdoors on variable terrain.

To date, there are various research institutions and private enterprises working on the technique, and it is believed by some that the future of the construction industry may eventually come to rely on the descendants of current giant 3D printers.

Can you print a house, and how much does it cost?

3D printed houses are still something of a novelty and are largely still in development, but you can 3D print a house for a lot less money than having one built using more traditional construction methods. For some of the projects that are currently in development, costs are somewhere in the order of $10,000, although this is for a relatively small structure.

For some of the projects that are currently in development, costs are somewhere in the order of $10,000, although this is for a relatively small structure.

According to a report from The Verge on ICON's operation techniques "the 3D-printed house would be made of cement and take up to one day to be printed by large, 3D printing robots. Best of all, the homes would cost just $10,000. And ICON hopes that eventually, it can bring the cost of homes down to $4,000."

AMIE 3D-printed house. Source: Oak Ridge National Laboratory/FlickrBut it should be noted this is for a very small, 2-bed house. Larger constructions would likely cost more.

There are also some 3D homes that have been built up for less than half that.

How long do 3D printed houses last?

Since the vast majority of 3D printed houses are made from concrete, they should last a decent amount of time. With proper maintenance and continuous habitation, there is no reason they shouldn't last as long as more traditional concrete constructions.

Estimates vary, but most agree that they should at least last about 50 to 60 years.

Many 3D printed houses do have timber elements included which may be susceptible to decay over time if they are not treated or maintained properly.

Most Popular

Source: post-apocalyptic research/FlickrSome other 3D printed buildings have been specifically designed to be biodegradable, and are only intended as used for temporary accommodation, for use in disaster relief operations and other short term housing needs.

Is it possible to take up residence in a 3D printed house? Well, most 3D printed houses created to date sway towards proof of concept builds, but there are some projects around the world that are working on techniques to produce 3D houses fit for habitation.

What are some examples of 3D printed houses?

So, without further ado, here are 7 interesting examples. This list is far from exhaustive and is in no particular order.

1. These tiny 3D houses in Mexico are pretty cute

Source: New StoryIn Mexico, a giant 3D printer is being used to create an entirely new neighborhood. Each house takes around 24 hours to complete and can house a small family.

The 32.8 feet (10 mt) long printer quickly churns out the shell of every 498 ft2 (152 m2) area; the roof, windows, and interiors are fitted later. A non-profit called New Story is behind the endeavor.

They have teamed up with ICON to make use of their enormous Vulcan II printer to create the houses.

The idea is to allow low-income residents in rural areas to move out of their shacks into these new, two-bed houses. It is thought that developments like this could one day help solve the housing crisis in many areas around the world.

2. This 3D printed house can operate off-grid

Source: activehouseCalled the PassivDom House, this house was designed to be as sustainable and energy-efficient as possible. It runs entirely on solar power and can even generate its water from the moisture in the air with an optional add-on.

It runs entirely on solar power and can even generate its water from the moisture in the air with an optional add-on.

It is created using a large 3D printer in a factory in Nevada and could be a game-changer for small housing in the future.

The shower in the bathroom can also clean and recycle water. All around, the house is designed to use as few resources as possible. Initially, the company wasn't aiming at creating an off-grid house, but as they developed upon their ideas, the team realized that it's a feasible option.

3. This Italian 3D-printed house is tiny but full of potential

Source: 3dwaspAn Italian 3D-printing company called WASP is building tiny houses to showcase the abilities of their revolutionary Crane WASP printer. This modular 3D printer can create homes in a variety of formats and sizes very rapidly indeed.

These new 3D printed houses, called Gaia, are 322 sq ft (30 sq mt) dwellings with a 3D printed outer shell and internal timber beams supporting each unit's timber roof. The above example was printed in situ in Massa Lombardo, which is a town in the Italian region of Emilia-Romagna in October of 2018.

The above example was printed in situ in Massa Lombardo, which is a town in the Italian region of Emilia-Romagna in October of 2018.

The material for the house contains mud from the surrounding area and waste byproducts from rice production, such as straw and husks. Apparently, the house is also biodegradable!

4. These 3D printed houses look like something from an alien world

Source: Houben/Van Mierlo ArchitectsDeveloped through the collaboration of the Eindhoven University of Technology and Houben/Van Mierlo Architects, these 3D printed houses look like something you'd find on an alien world. They hope to produce a few units in the near future to be rented out at a reasonable price.

The Dutch university is set to construct around 5 of the buildings over the next five years and each one is almost completely made of concrete.

"The project is the world's first commercial housing project based on 3D-concrete printing," said the university. "The houses will all be occupied, they will meet all modern comfort requirements, and they will be purchased and let out by a real estate company. "

"

5. This 3D printed house is also a work of art

Source: WATGBack in 2016, a team of architects in Chicago proposed an amazing design for a 3D printed house made of printed plastic, carbon-fiber panels, and glazed walls. The team won first prize in the Freeform Home Design Challenge and for a good reason.

The design for the 3D printed dwelling is incredibly bold and, compared to other examples above, makes the most of the technology. Called Curve Appeal, the building is actually a thing of beauty.

The plan was to 3D print the building in Chattanooga in Tennessee. It is planned to be completed in 2020.

6. This Amsterdam-based company created micro 3D printed homes

Source: DUSDUS Architects are planning to build tiny 3D printed micro-homes in Amsterdam. Each tiny 26.2 ft2 (8 m2) cabin comes with its own internal bathtub and is very cozy indeed.

Each 3D cabin is built using bio-plastic and the project is intended to demonstrate how additive manufacturing can offer solutions for temporary housing solutions in disaster areas, among other applications. When the cabin is no longer needed, it can be destroyed and almost all the materials can be reused.

When the cabin is no longer needed, it can be destroyed and almost all the materials can be reused.

"The building is research into compact and sustainable dwelling solutions in urban environments," said the team behind the cabins.

7. These 3D printed houses are made out of hemp

Source: MirrecoThere are plans to build a set of hemp-based 3D printed houses in Australia in the not too distant future. Designed by the biotech company Mirreco, they hope to harness the "explosive potential of industrial hemp."

The company believes it should be possible to 3D print the floors, walls, and even roofs of buildings using carbon-neutral hempcrete panels. The company recently unveiled its plans that were developed in collaboration with Arcforms, an architectural company based in Perth.

“The floors, walls, and roof will all be made using hemp biomass, and the windows will incorporate cutting-edge technology that allows light to pass through the glass where it is converted into electricity,” Mirreco stated.

And that's your lot for today.

For You

science

A recent study highlighted the crucial role dams could play in securing long-term food security. IE discovers more in an exclusive interview with one of the researchers.

Sade Agard | 11/21/2022

scienceDoes being a veggie make you depressed? – The Blueprint

Alice Cooke| 10/23/2022

healthA breakthrough study reveals that food allergies can be reversed in mice

Deena Theresa| 8/21/2022

More Stories

culture

Japanese man travels 4,000 miles to spell ‘marry me’ on Google Earth

Loukia Papadopoulos| 12/7/2022

science

Olkaria VI, Kenya: Inside the world's largest single-turbine geothermal plant

Sade Agard| 11/4/2022

transportation

Goodbye Boeing 747: the last one has now been built

Christopher McFadden| 12/7/2022

A house can be built with a 3D printer in just 24 hours

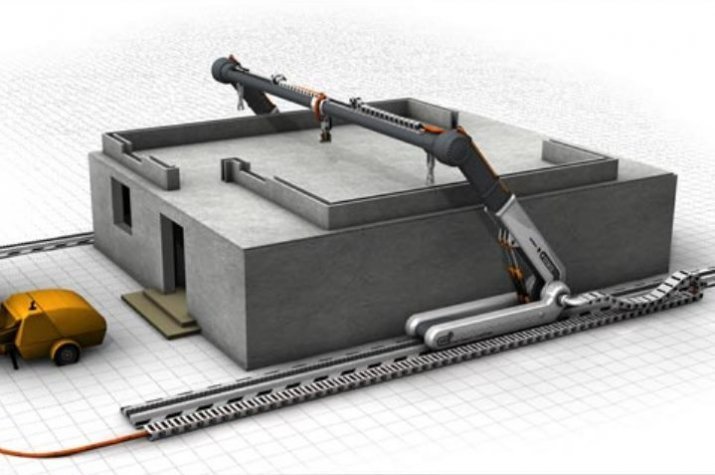

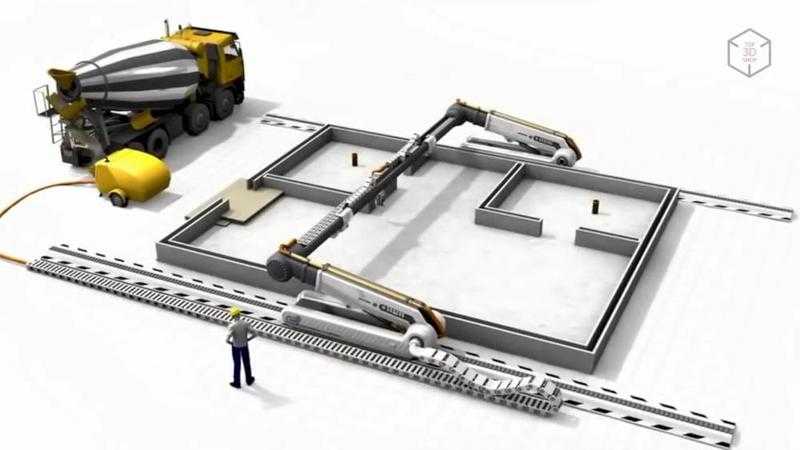

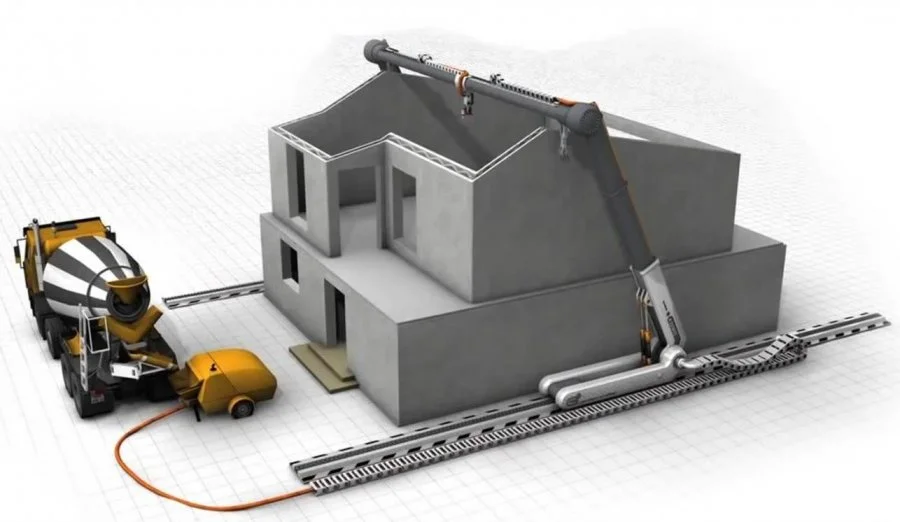

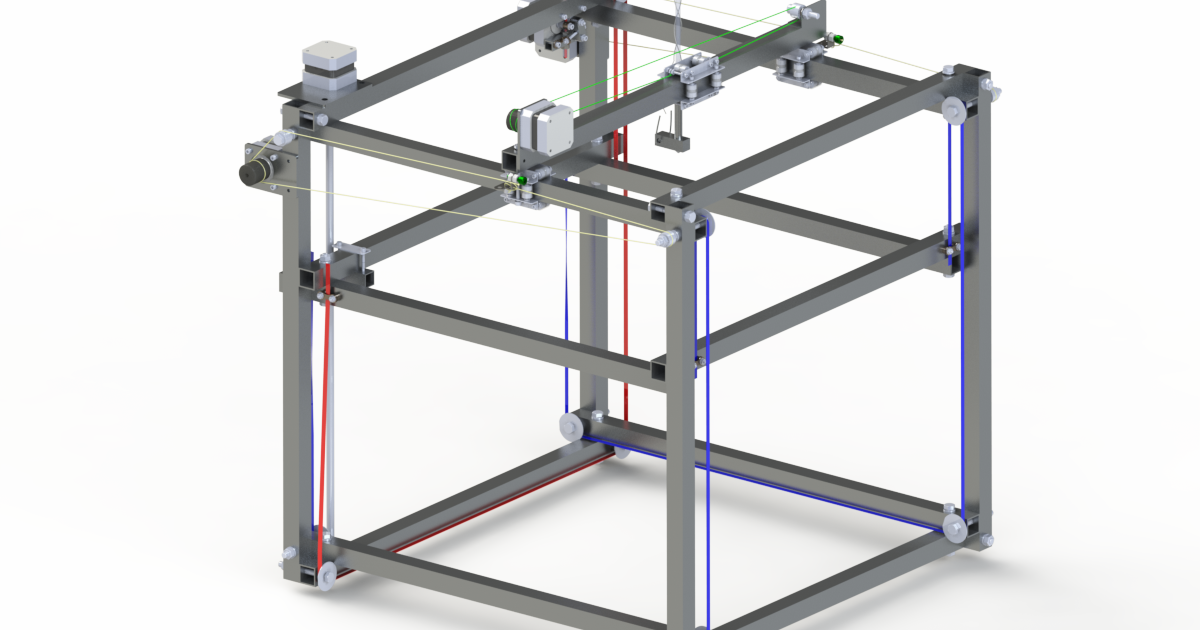

Professor Beroch Khoshnevis has designed a huge robot that can replace construction workers. This robot sprays the concrete mixture and shapes the structure of the house according to the computer model. The technology, called Contour Crafting ("contour manufacturing"), can become a revolution in the field of construction.

This robot sprays the concrete mixture and shapes the structure of the house according to the computer model. The technology, called Contour Crafting ("contour manufacturing"), can become a revolution in the field of construction.

Contour Crafting in the future will reduce the cost of building houses and make housing more affordable for many people. This technology can be used in areas prone to natural disasters to create temporary shelters. For example, during Typhoon Haiyan in the Philippines, almost 600,000 people lost their roof over their heads. Contour Crafting could quickly provide housing for all those affected. In addition, there are currently about 1 billion people across the planet living in uninhabitable homes. Professor Khoshnevis' technology could handle this problem as well.

Contour Crafting is explained by Brad Lemley, co-author of Discover Magazine: this place. A gantry crane with an overhead nozzle and a boom for supplying components moves along rails. The nozzle sprays cement in layers to create hollow walls and then fills them with additional cement. The only thing left for people to do is to put in windows and doors.”

The nozzle sprays cement in layers to create hollow walls and then fills them with additional cement. The only thing left for people to do is to put in windows and doors.”

“This is a CAD/CAM 3D modeling technology. The design of buildings is developed by a computer, which builds these buildings,” says Khoshnevis. Contour Crafting will allow entire neighborhoods to be built at a low cost, in less time, with greater safety and greater architectural decision making. Contour Crafting also makes it possible to create structures that are more robust than traditional construction. During the tests, the following data was obtained: the strength of the wall made using the Contour Crafting technology was 10,000 lb/in² versus 3,000 lb/in² for a conventional wall.

This technology can be used not only for the construction of residential buildings, but also for the construction of high-rise office buildings. According to Khoshnevis, the crane can be equipped with multiple nozzles and can even be made to climb outside walls.

Many people think that all Contour Crafting buildings will look the same. However, the design can be diversified by changing the program. According to Khoshnevis, such houses can be even more extravagant than ordinary buildings. You can add interesting architectural details (for example, make the walls curved) without incurring additional costs.

There are fears that Contour Crafting will put many construction workers out of work. The sector employs almost 110 million people worldwide, according to the International Labor Organization. The construction sector plays an important role in reducing unemployment and labor surpluses in rural areas. In 1900, 62% of Americans were farmers, today their proportion has dropped to 1.5% due to advances in technology. The same thing can happen to the construction industry. “Construction is a dangerous job, more dangerous than working in mines or in agriculture. Every year, 10,000 people die during construction. Due to its characteristics, this sector is prone to corruption. In addition, construction is an expensive process that sucks a lot of money out of the budget,” says Khoshnevis.

In addition, construction is an expensive process that sucks a lot of money out of the budget,” says Khoshnevis.

In 2006, the National Inventors Hall of Fame and History Channel's Modern Marvels program recognized Contour Crafting as one of the 25 Greatest Inventions. Currently, this technology is still in the testing phase.

In Japan, robots are already being used in construction. So, the Sekisui House company uses them for the manufacture of building structures.

Julia Kozhevnikova, Tranio.Ru

Receive latest articles by mail

We will send a compilation of materials no more than once a week

Subscribe

I agree with Tranio's personal data processing rules and privacy policy

Done!

Giant 3D printer builds a house in 24 hours

?Previous Entry | Next Entry

3D printer builds a house

According to scientists, soon the construction of houses will be fully automated. Professor Berok Khoshnevis of the University of Southern California has developed a 3D printer that can build a detached house of 250 square meters. during the day.

Professor Berok Khoshnevis of the University of Southern California has developed a 3D printer that can build a detached house of 250 square meters. during the day.

Khoshnevis' invention is, in fact, a giant robot with a nozzle mounted on a frame, through which the concrete mixture passes and is applied layer by layer according to a plan pre-designed by a computer. “In fact, this is an analogue of a 3D printer for construction,” explains the professor.

The work of the scientist is based on the Contour Crafting technology: all that is required of the workers is to install rails along the contour of the future house and install a 3D printer structure on it. The computer will do the rest: the robot will move along the rails, laying down the concrete mixture until the house is completed. The share of the builders will be the installation of windows and doors in the prepared openings.

Contour Crafting will significantly reduce the cost of building a house, Khoshnevis promises, the system can also be used to repair buildings damaged by earthquakes and other natural disasters.

_RlfzhrZzWj.jpg?auto=compress&w=900&h=675&fit=min&fm=jpg)