Lpd 3d printer

FDM – Fused Deposition Modeling (or FFF, PJP, LPD) – Additive Blog

These types of 3D printers come under many different names. Fused Deposition Modeling (FDM) was the first technology of its kind and it was commercialized and trademarked by Stratasys around 1991. FFF (fused filament fabrication) is a term that emerged from the RepRap community. It refers to an open source version of technology which is very similar to FDM.

Different companies have developed their FFF printers marketing them under different acronyms. For example, 3D Systems – PJP (Plastic Jet Printing) or Zortrax – LPD (Layer Plastic Deposition) and so on.

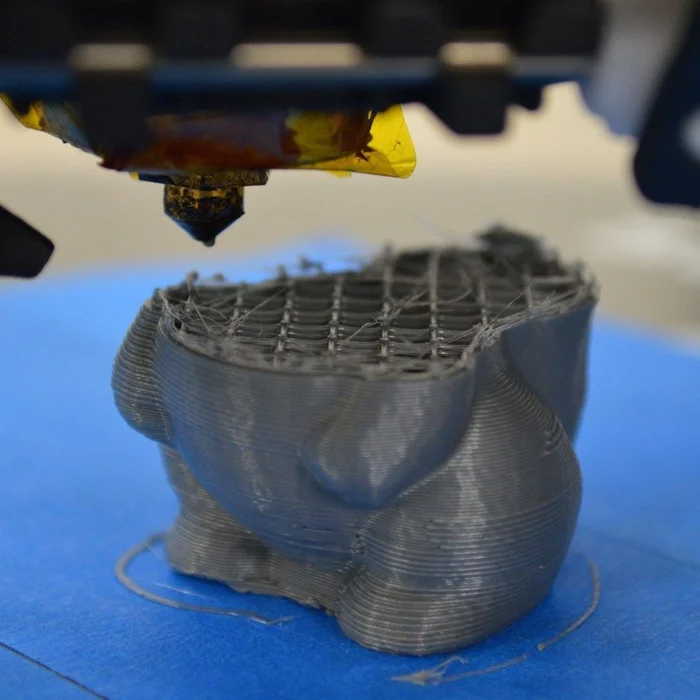

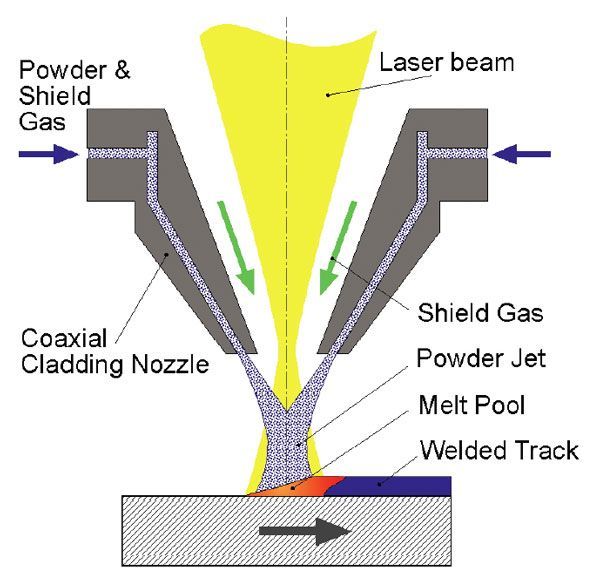

How it works:Every FDM/FFF 3D printer is supplied with a filament – a wire usually made of plastic – which is melted using a print head and extruded onto a build platform underneath. The movement of the print head against the build platform is automated using electronic motors. The print head extrudes the melted filament to “draw” the model one layer at a time. Each time a single layer has been printed, the height of the print head in relation to the build platform increases by an increment. Because the extruded material is hot, all layers are strongly connected together with the first layer sticking to the build platform.

Support structures

Support structures might be required when printing more complex objects. Instances where these supports are used include parts of a model where:

A) Overhang is located

B) Big gaps need to be bridged

C) The part is “floating” in the air

If the 3D printer is a single extruder type, the supports are printed from the same material as the rest of the model. They must be removed manually with small pliers or by hand after the printing is finished. Dual extruder 3D printers use one kind of material for printing the model and a different material for the supports. The support material is usually water soluble, making the removal much easier. The supports will completely dissolve after a few hours of being placed in hot water.

The support material is usually water soluble, making the removal much easier. The supports will completely dissolve after a few hours of being placed in hot water.

Infill

A cool feature of FDM/FFF printers is that you can choose the internal structure of the 3D printed model. You can print models completely filled with material resulting in increased strength. On the other hand, you can print models with internal structure to make them lightweight. You do not have to make the internal structure a part of your 3D design. This can be done automatically in a slicer (software for print job preparation that comes with the 3D printer). You usually enter the infill parameter in %, for example, you want 25% of the interior filled. You then choose the type of pattern, e.g., a honeycomb. There are other settings available which have an effect on the properties of the printed part – for further information see a design guide for FDM/FFF 3D printing.

Applications

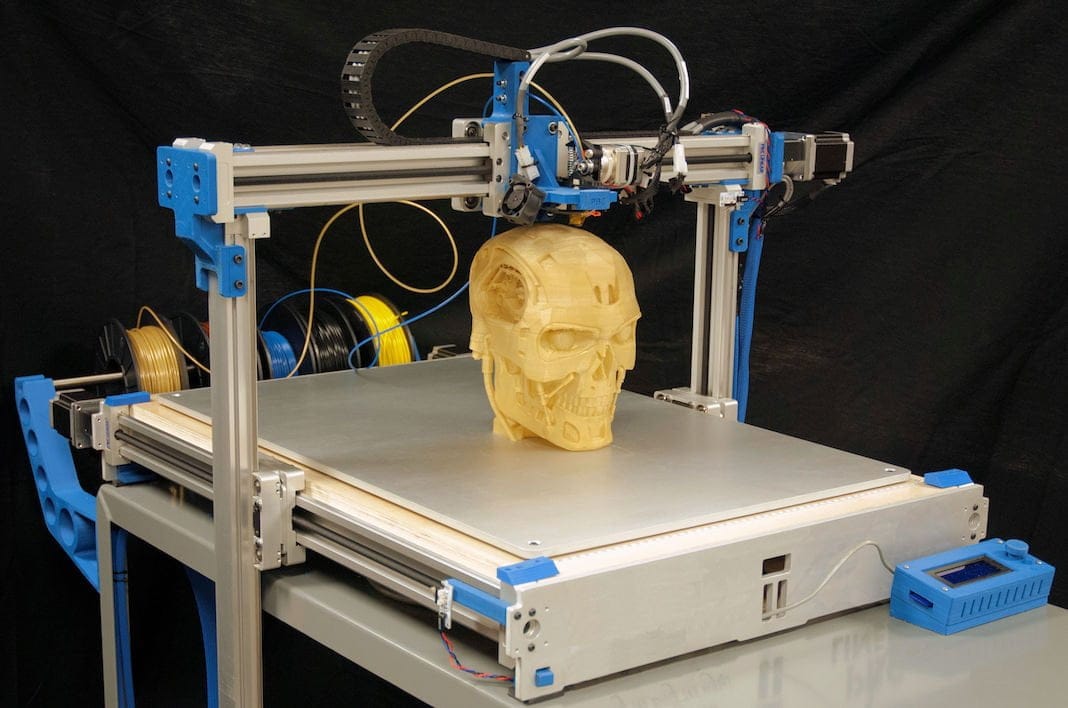

On a high-end level, the most frequent use is rapid prototyping. Mainly (but not limited to) plastic parts that are intended to be produced by injection molding later on. The technology is also suitable for the production of a small series of functional, durable parts, from a wide range of materials. Starting with custom cable clips and ending with aircraft components. The biggest player in this field is Stratasys, with their production series 3D Fortus printers. These machines are expensive, but have a high accuracy of printed parts (understand: no wrapping during print, holes and other dimensions printed exactly as in 3D model, no delamination). Also, the materials come with tested properties and detailed data sheets.

On a desktop level, imagination is your only limit (well…or what your printer is capable of producing).

The list could look like this:

Cheap prototyping of your designs

Gadgets of all sorts (holders, toys, tools – just look at thingiverse. com)

com)

Drone parts

Cosplay, simple jewelry

Sculptures of your favorite hero

Parts of a 3D printer (rep-rap 3D printers)

Manufacturers: Stratasys, Ultimaker, Zortrax, Prusa Research, MakerBot, Printbot, LulzBot, 3ntr, FlashForge …

Layer Plastic Deposition (LPD) - Shree Rapid Technologies

Material Innovations Expands Production Applications.

Layer Plastic Deposition (LPD).

The LPD Plus technology designed for BIG industrial-grade results. With dual-extrusion technology, the model and water-soluble support structures are built simultaneously. Printing movable and intricate designs is possible, as all support structures will dissolve in water.

Zortrax M300 Dual.

Properties

Smart and efficient large-volume 3D printing

Highlights

Large workspace: Its large workspace measuring 265x265x300 mm is sufficient to print big models in one go.

Dual-extrusion system: The LPD Plus technology works with two nozzles and a double hot-end.

Blackout response system: The M300 Dual can detect a power outage and resume the printing from the same spot when the power is back on.

Capacitive sensor: The CDS allows automatic calibration of the printer regardless of the type of build-platform installed.

Advanced filament control: The M300 Dual automatically pauses the print when the filament's jammed, run out, or when the nozzle got clogged.

External materials support: Third-party filaments available on spools are fully supported in both single and dual extrusion modes.

Zortrax M300 Plus.

Properties

Designed to reliable operation in multiple long printing cycles typical for a machine of that size.

Highlights

Large workspace: Large workspace, measuring 300 x 300 x 300 mm, is enough to print big models in one go.

Wide filaments compatibility: The printer is designed to support wide range of dedicated and third-party filaments.

Built-in camera: 3D printing process can be remotely monitored through a built-in camera.

Material end detection: The printer will automatically switch into pause mode when it runs out of filament.

Advanced extruder and nozzle: An extruder with a nozzle geometry designed to support 3D printing with flex and nylon-type materials.

Zortrax M200 Plus.

Properties

Designed for reliable, continuous operation over long periods of time.

Highlights

Material end detection: 3D printing is paused when the material runs out..

Advanced cooling system: Cooling system guarantees the highest efficiency..

Built-in camera: 3D printing process can be monitored remotely..

Wide range of filaments: Wide range of dedicated and third-party filaments is supported.

Materials offered for LPD.

- Filaments.

-

BASF Ultrafuse® PP GF30.

BASF Ultrafuse® PP GF30 is a polypropylene-based composite filament reinforced with a 30% addition of glass fiber. It is characterized by extremely high stiffness and resistance to heat, UV light, and chemicals. PP GF30 is lightweight and provides high dimensional accuracy to printed parts.

BASF Ultrafuse® PAHT CF15.

BASF Ultrafuse PAHT CF15 is an industrial-grade filament consisting of a polyamide base and a 15% addition of micro-carbon fibers. The filament shows high stiffness, high dimensional stability, and chemical resistance. It withstands the temperatures reaching up to 145 °C.

Z-SUPPORT ATP.

Z-SUPPORT ATP is a soluble support filament designed with high thermal stability in mind. Unlike materials based on PVA or BVOH, it does not dissolve in water but in a mild alkaline called Z-SUPPORT ATP Activator

Z-SUPPORT Premium.

Z-SUPPORT Premium is a water-soluble support filament made of butenediol vinyl alcohol co-polymer (BVOH). It's compatible with Z-GLASS, Z-PETG, Z-PLA, Z-PLA Pro, Z-ULTRAT and Z-ULTRAT Plus as it can work in a relatively wide range of printing temperatures. Z-SUPPORT Premium has a very fast dissolution rate and leaves no remnants on the model.

Z-NYLON.

Z-NYLON is a versatile and strong 3D printing filament resistant to high temperatures and various chemicals. It can be post-processed with tools meant for machining metals. Z-NYLON is hard to break and easy to paint as it can be colored with commonly used, acid-based clothing dyes.

Z-FLEX.

Z-FLEX is a thermoplastic polyester elastomer that can be 3D printed at a relatively fast rate of 45mm/s. The filament has great interlayer adhesion and dimensional tolerance falling below +/- 0,02 mm. Z-FLEX is elastic, can bend without breaking, and is resistant to various chemicals including gasoline, ethyl alcohol, butane, and carbon monoxide

Z-PLA Pro.

Z-PLA Pro is a biodegradable 3D printing material with an addition of chalk offering even and matt gypsum-like surface that makes the details more visible. Reduced shrinkage allows to 3D print large models with almost no warping

Z-PETG.

Z-PETG is made of popular PET thermoplasticics enhanced with addition of Glycol to eliminate the brittleness. This industrial-grade material can withstand both UV rays and time.

It also exhibits high resistance to oils and greasy substances

It also exhibits high resistance to oils and greasy substances

Z-ULTRAT Plus.

Z-ULTRAT Plus is a durable ABS-based filament working with the water-soluble support. Use it with Z-SUPPORT Premium to 3D print high-quality end-use parts as well as complex mechanisms. Z-ULTRAT 3D printing material is reinforced for better layer adhesion and higher impact resistance.

Z-PLA.

Z-PLA filament is perfect for precise 3D printing of structurally complex objects, like architectural mock-ups and conceptual models. This biodegradable 3D printing material is derived from environment-friendly sources. Z-PLA offers your models with high-quality details and exceptionally smooth surface.

Z-ULTRAT.

Z-ULTRAT is an exceptionally durable and time-lasting filament. Available in a wide range of colors, Z-ULTRAT is well-suited for all kinds of high-quality applications: functional prototyping, casings, end-use parts, tools and art.

The 3D printing material’s surface can be easily post-processed with acetone and mechanical treatment

The 3D printing material’s surface can be easily post-processed with acetone and mechanical treatment

Z-HIPS.

Z-HIPS 3D printing material is best used for parts and models requiring smooth surface which can be effortlessly post-processed. Its hardness makes it perfect for mechanical prototyping and performance testing. Quality of models 3D printed with Z-HIPS is close to mass-produced objects.

Z-GLASS.

With Z-GLASS transparent filament you can 3D print light-transmitting models and parts ready for final production or precise prototyping. The material is durable, resistant to scratching and remains unaffected by light and chemicals. Z-GLASS is resistant to shrinking.

Z-ASA Pro.

Z-ASA Pro 3D printing filament is designed to withstand adverse environments. The material is highly resistant to the changing weather conditions and UV light, which makes it ideal for outdoor applications, like specialized tools or prototypes tested outside.

Low shrinkage and warping of Z-ASA Pro allow you to accurately 3D print large models

Low shrinkage and warping of Z-ASA Pro allow you to accurately 3D print large models

Z-ABS.

Z-ABS 3D printing material is a universal solution for economical prototyping and manufacturing. Matt surface of this basic plastic filament enables easy post-processing, both mechanical and chemical. Z-ABS is an excellent choice for beginning users, as well as professional looking for low-cost drafting and testing

Z-ABS 2.

Z-ABS 2 is a durable printing filament, perfect for manufacturing prototypes and end-use parts. Compared to Z-ABS, Z-ABS 2 has higher tensile strength and comes in a wider range of colors. It offers semi-mat finish and high surface quality

Z-PCABS.

Z-PCABS is a durable blend of Polycarbonate and ABS characterized by impact, UV light and temperature resistance.

This strong 3D printing filament can also withstand exposure to salts, acids and alkalis and doesn’t change its properties over the course of time

This strong 3D printing filament can also withstand exposure to salts, acids and alkalis and doesn’t change its properties over the course of time

Z-SEMIFLEX.

Z-SEMIFLEX 3D printing material is semi-elastic, resistant to greases and high temperatures. Objects 3D printed with this rubber-like filament can be squeezed and teared without any risk of damaging them. Use Z-SEMIFLEX for tooling and testing in adverse industrial environments or for medical assessment processes.

Z-ESD.

Z-ESD filament grants your models electrostatic discharge protection, making it a reliable choice for electronic industry. Reduced shrinkage and warping allow you to 3D print precise end-use parts and tools. Moreover, Z-ESD material is protected against harmful effects of salts, acids and alkalis

Alone you can go fast, Together you can go far

- African proverb

Let’s create future, together.

How to choose your first 3D printer - advice from Zortrax

3D printing saves money, reduces lead times and provides creative freedom. But when a person finally gets the idea and goes to buy his first 3D machine, he immediately encounters a mass of different manufacturers, technologies and devices at all possible prices. How to choose a 3D printer? Our partner, Zortrax, has published an interesting article to help you navigate the world of 3D hardware. The Polish brand offers five of the most important items to consider when choosing a new 3D device.

What to print

Since there is no such thing as a 3D printer that is good at everything, it is important to choose the right 3D printing technology.

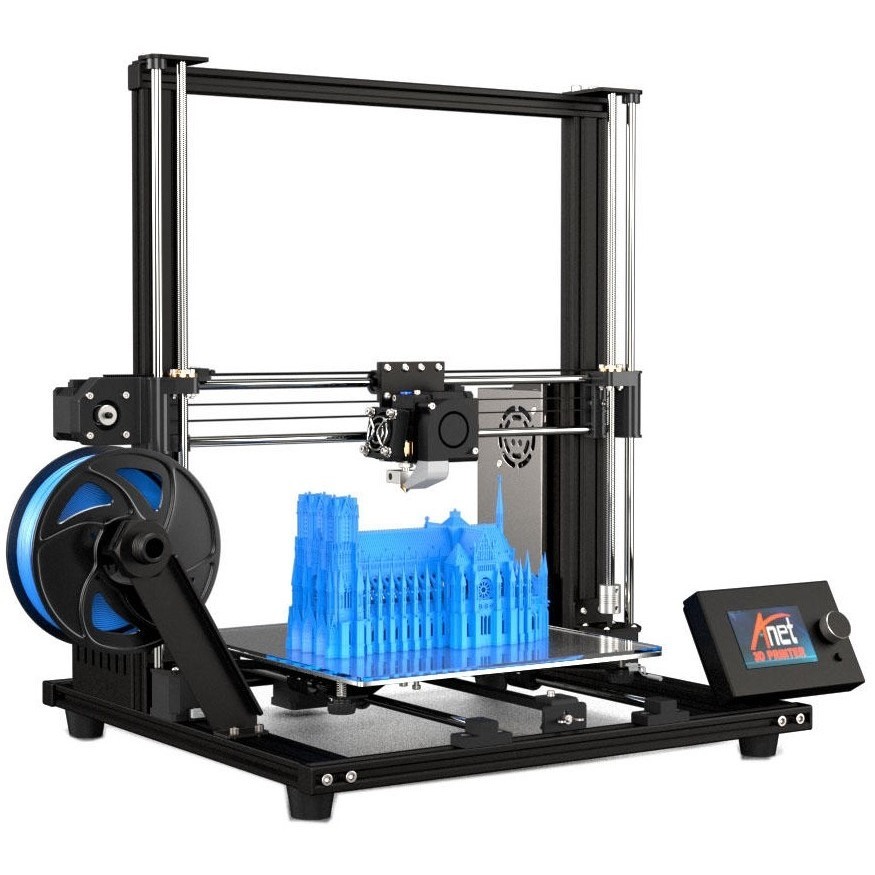

This may seem pretty obvious, but pinpointing needs works wonders in narrowing down your search. If you need to print relatively simple things that do not have to withstand extreme loads or are in really difficult conditions, an extrusion-based 3D printer is your best bet. Standard LPD technology is designed for medium sized models with relatively simple geometry.

Standard LPD technology is designed for medium sized models with relatively simple geometry.

If you need to produce very small but precise parts, an LCD printer with an LCD matrix is better. The working space is usually smaller than LPD machines, and the process is a little more difficult to handle, but the accuracy is much higher. With the help of UV LCD technology, all elements will be recreated with an accuracy of 50 micrometers, which is barely visible to the naked human eye. 3D printers like the Zortrax Inkspire can print very small but incredibly detailed models.

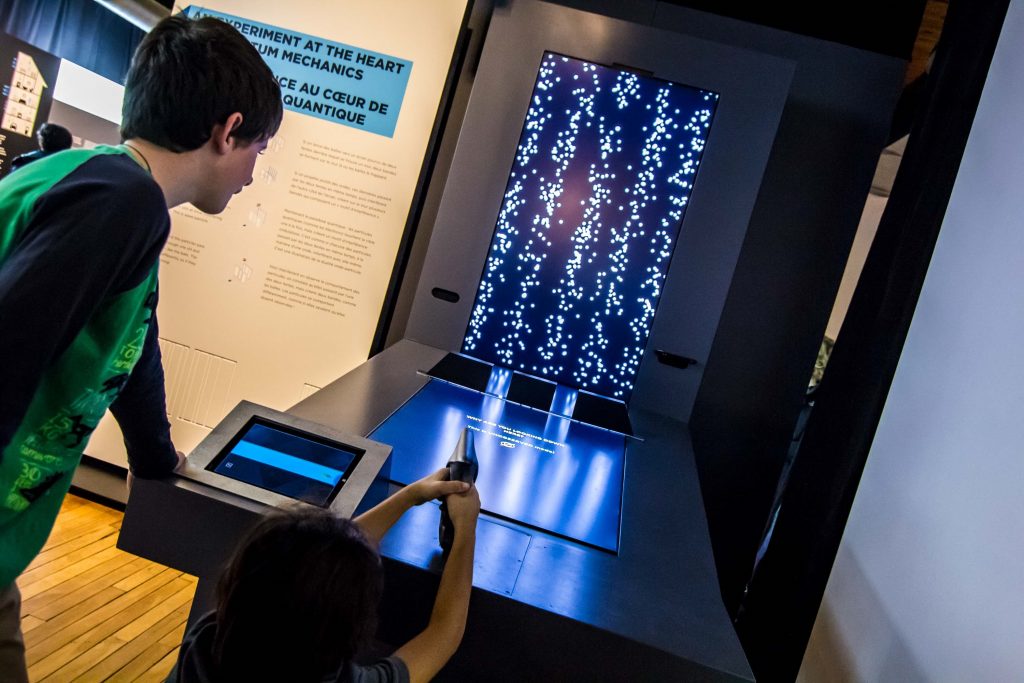

Photo: Zortrax

Key Findings:

- If you need a budget workhorse, you should buy an LPD or LPD Plus 3D printer;

- When extreme precision is required and a roomy working chamber is not needed, a device with a UV display should be taken.

Reliability of Zortrax 3D printers

Once the customer has determined which 3D printing technology suits him best, it's time to choose the right 3D machine.

It is best to buy equipment made with a well-established manufacturer. Warranty claims from market leaders like Zortrax are slightly lower than what is considered the industry standard for laptops or smartphones. So getting one of their products is a pretty safe deal.

Photo: Zortrax

Zortrax's 3D hardware is robust enough that NASA can use it to prototype the tools that astronauts work with during space missions.

Of course, there are many brands that seem to offer the same printers for less money, but the very first breakdown and the resulting delays will likely set back a lot more than the savings made by choosing the lower price.

Zortrax customer service and support

3D equipment, like everything else, sometimes breaks down. And when this happens, it's good if the specialist talks to the buyer on the phone in a language he understands and quickly solves the problem. Therefore, when thinking about which 3D printer to choose, you need to look for brands that have official partners and service centers in different countries.

Photo: Zortrax

Quality customer service is becoming a key factor in choosing a 3D printer for business application-oriented organizations. Zortrax is a leader in the 3D industry with partners in 150 countries. The company's specialists will advise the buyer on any issue, and if necessary, accept a warranty claim. This entire huge network is designed to keep downtime to an absolute minimum when something goes wrong. Visiting a local dealer is much less of a hassle than shipping a car overseas, and the repair process takes less time.

The complete Zortrax 3D printing ecosystem

A 3D printer is just one part of the 3D printing process. On his own, he cannot do anything. The equipment needs slicing software that converts .stl files exported from CAD or 3D modeling programs into accurate machine code in order to properly fabricate the object. Consumables and sometimes post-processing devices are also needed to achieve the intended results. It is best when all these things function well in the complex.

It is best when all these things function well in the complex.

Photo: Zortrax

Having software, hardware and materials from the same manufacturer ensures they work together seamlessly. Therefore, you need to look for brands that offer a complete printing ecosystem along with software, raw materials and post-processing devices. Thus, the user will receive a ready-made kit, which is designed from scratch to function effectively, complementing one another.

Of course, one can use third-party materials and manually enter all the settings into random open source software, hoping that the printer will somehow cope with all this. But with a serious attitude to the matter, you should prefer proven solutions.

Consumables Zortrax

3D printers build objects by adding melted plastics or curing polymer resins. This means that there are parts in the machines that are consumable by design, such as nozzles, that need to be replaced after a certain period. It is good when such components are easily available from local dealers or through Internet sites.

It is good when such components are easily available from local dealers or through Internet sites.

Photo: Zortrax

3D printers are great for printing spare parts for various devices, but sometimes they need the parts themselves. Choosing a brand that always has a variety of elements in abundance will save a lot of time. Well-known global brands such as Zortrax will not leave the buyer of their equipment in a difficult situation, because the necessary parts are no longer produced. Serious manufacturers support their products for a very long time. Therefore, Zortrax machines, if properly maintained, will perform well for many years.

Top Affordable Home Printers with Affordable Consumables

- home

- News AT

- World

- Top Affordable Home Printers with Affordable Consumables

A home printer saves time and helps to realize creative ideas or set up a small production. When choosing a modification, one should be guided by the materials used, the dimensions of the models produced, the need to work in color, and some other specific characteristics. Manufacturers offer a long list of various functions, additional systems and software that expand the capabilities of the equipment.

When choosing a modification, one should be guided by the materials used, the dimensions of the models produced, the need to work in color, and some other specific characteristics. Manufacturers offer a long list of various functions, additional systems and software that expand the capabilities of the equipment.

Top Inexpensive Home Printers

3DSystems

Provider of modern, affordable, task-oriented solutions. When deciding which printer to buy for your home, you should study the brand's equipment, which is safe for the user and easy to use.

The CubeX3D 3D printer is an inkjet printer using plastic filaments. The combination of resources with different properties makes it possible to "grow" products with the required technological and mechanical characteristics. The machine supports up to 3 extruders, and the roomy working chamber is suitable for building large models.

makes affordable printers for the home with low cost consumables, complete with innovative technical tools and control systems.

The Zortrax M300 Dual 3D printer is industrial quality in a compact package. The device works with high performance, produces models from ABS and PLA filaments. The equipment, equipped with upgraded sensors, allows you to control the printing cycle. The spacious desktop is designed for building large models. The emergency shutdown system starts operation after the power supply is restored. The advanced filament control option stops printing if the filament runs out or the nozzle is clogged.

12 months

Zortrax Inkspire 3D printer is a machine that works with photopolymers using UV LCD technology. The liquid crystal display is responsible for uniform irradiation of the working surface. The machine works with the highest precision, compatible with third-party materials. To obtain a certain quality of finished samples, it is recommended to use a special cleaning station Ultrasonic Cleaner. Ultrasonic washing will thoroughly remove raw material residues from complex structures or objects with deep grooves or holes.

The Zortrax M200 Plus 3D printer is an equipment for large-scale production or prototyping. The device guarantees the highest dimensional accuracy. The control system, complete with Z-SUITE 3D slicing cutting software, operates via wireless networks. The building process is controlled through the built-in camera.

Features Zortrax M200 Plus

The Zortrax Inventure 3D printer is an intelligent printer that combines precision and industrial quality. The notification system helps to control the use of materials and the operation of the device, and the HEPA filter is responsible for the safety of work. Additional structures that support the model during printing are removed with the help of a special fluid that provides a smooth surface. The machine produces three-dimensional products with precise dimensions and stable repeatability.

simplifies access to 3D technology with innovative 3D printing tools. The company's equipment regularly ranks first in the ratings of printers for the home.

FORMLABS FORM 3 3D Printer is a scalable item manufacturing and prototyping machine that expands as production grows. The patented optical light transmission unit, containing a special system of mirrors and lenses, guarantees precision and professional print quality. The applied LFS-technology offers improved detailing of elements. The device monitors performance, and special sensors optimize build parameters, inform the operator about the progress of work.

The Formlabs Form 3L 3D Printer is a high capacity machine for large scale production. Large-format equipment is enclosed in a compact case that can be easily placed in the office. In one build cycle, you can create one large part or several small samples.

The equipment guarantees repeatable accuracy, high detail of manufactured objects. A printer equipped with automated dosing of material, and a well-thought-out interface is understandable even for a beginner. Built-in PreForm software offers optimal model orientation and the option to manually adjust parameters.

CreatBot

belongs to China's first 3D machine manufacturing company. The brand's products are distinguished by interesting patented methods and knots. The technique is often mentioned in the tops of home printers.

CreatBot D600 Series 3D Printer - Steel-encased hardware ensures efficient production and stable printing. A feature of the model is a patented nozzle with a heating temperature of up to 400 ° C, working with various filaments. The layer thickness can be varied. A closed workspace reduces the impact of external factors. In the event of a power outage, the technician fixes the current parameters and, after the supply of electricity, continues to work from the previous position.

.jpg)