3D printer layer height vs nozzle diameter

3D Printing Layer Height vs. Nozzle Size

- Author

- Recent Posts

Martin

Martin has a M.Sc. in physics and has gained many years of experience in industry as a lab manager and quality assurance manager. He has now tested dozens of 3D printers and is happy to share the collected experience with each new article.

Latest posts by Martin (see all)

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

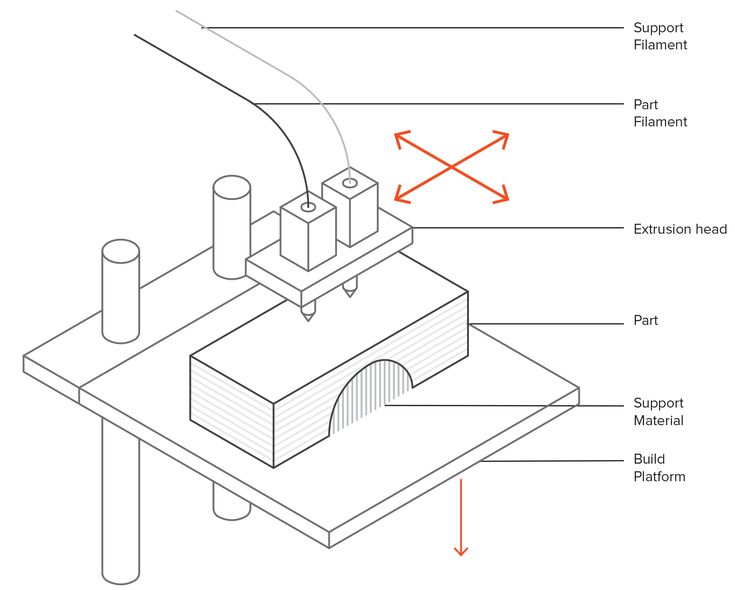

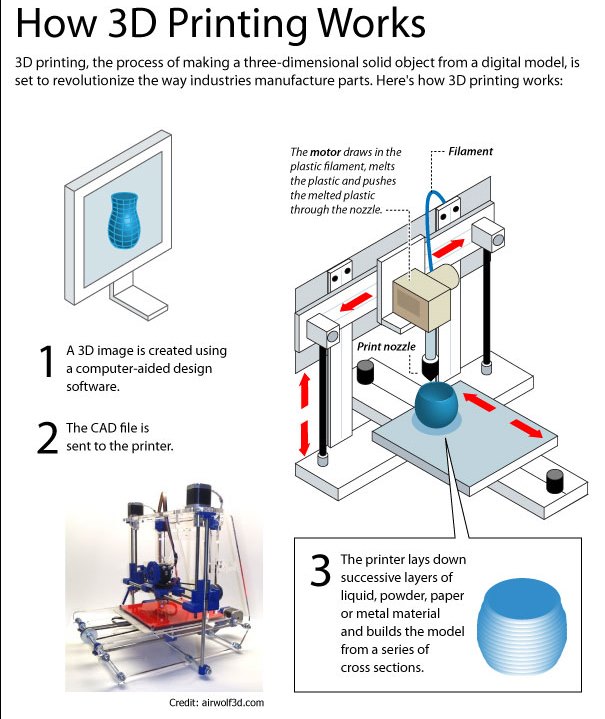

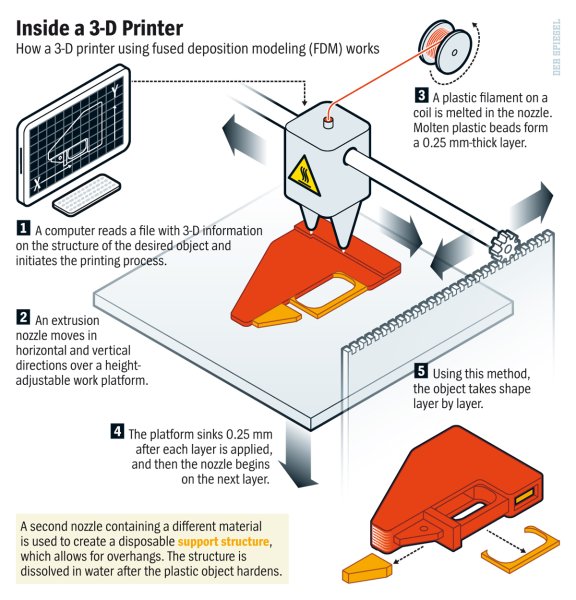

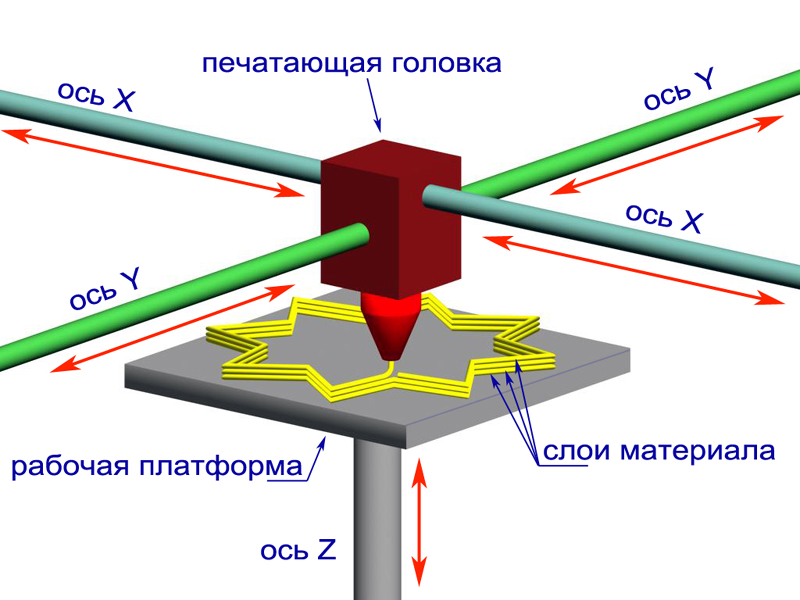

What influence do the layer height and the nozzle diameter have on the end result in a 3D print? In a 3D printer, individual layers are applied on top of each other using a filament. The layer height refers to the height of each individual layer.

For most printers, the adjustable layer height is between 0.1 and 0.4 mm. At the same time, however, the layer height also depends on the nozzle diameter. This is because the nozzle diameter results in a maximum and a minimum achievable layer height.

But how do the layer height and nozzle diameter affect print quality?

Thicker layers offer higher printing speeds with lower resolution. With thinner layers, higher resolution can be achieved with increased printing time. The maximum layer height is about 75% of the diameter of the nozzle and the minimum layer height about 25%.

That was the short version. You can find out exactly how that works in this article.

Table of Contents:

- 1 Layer Height

- 2 Nozzle

- 3 Relationship Between Layer Height and Nozzle Diameter

- 4 Practical Test & Comparison

- 5 Related Questions

- 6 Conclusion

Layer Height

In 3D printing, the object is built up layer by layer. For commercially available 3D printers, the layer height is approximately between 0.1 and 0.4 mm. Of course, there are also 3D printers available that can also create a layer height below 50 μm (= 0.05 mm).

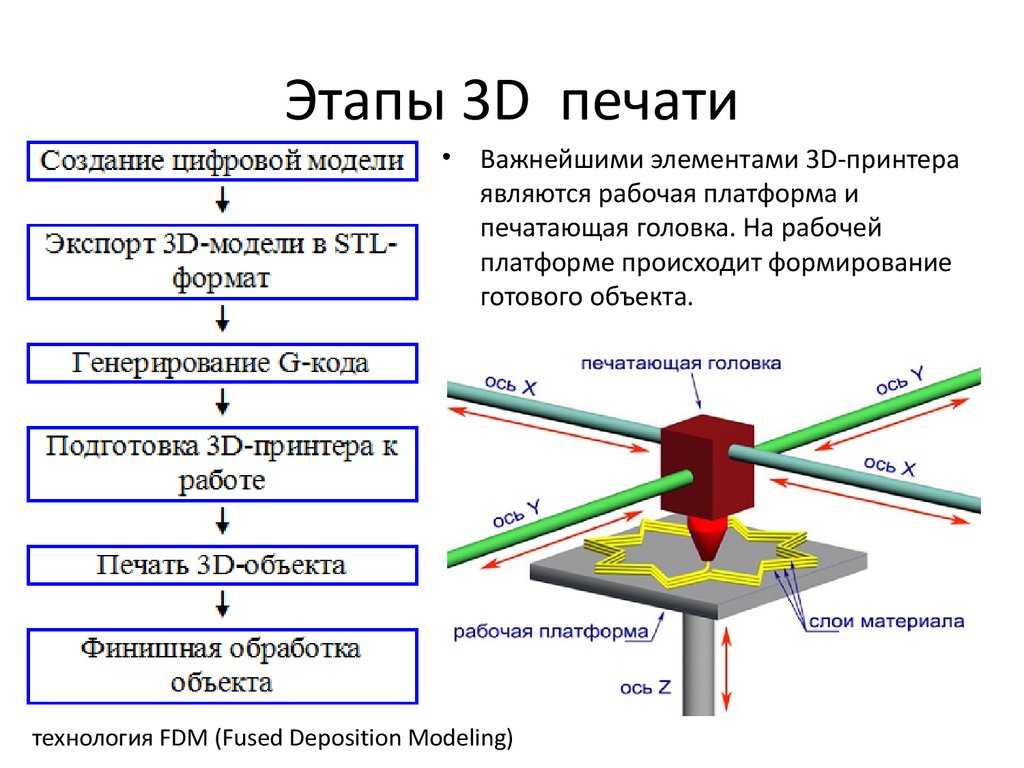

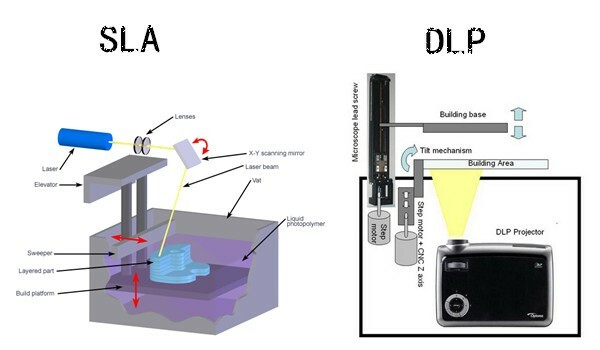

With some printing processes, the layer height has hardly any effect on the result. But especially with the SLA and FDM processes, the choice of layer thickness is a very important factor.

But especially with the SLA and FDM processes, the choice of layer thickness is a very important factor.

The effect of layer height on the printing process

The selected layer height has a direct effect on the print result. Choosing the right layer height is quite comparable to deciding on the resolution of a TV screen. A lower layer thickness leads to a higher resolution of the object and to smoother surfaces. The layer thickness (= Z-resolution) can be set on every 3D printer and is sometimes also dependent on the 3D printing process.

On the other hand, the layer height has significant effects on the printing process. If, for example, the layer height is halved from 300 μm to 150 μm, then printing takes twice as much time and the costs also increase enormously. With a lower layer thickness, more layers are applied on top of each other, this circumstance leads to a higher error rate.

When lower layer thicknesses make little sense

A lower slice height leads to a higher Z-resolution, nevertheless, it is not always useful. The key question when deciding on the slice height is – is appearance more important or functionality?

The key question when deciding on the slice height is – is appearance more important or functionality?

If the object has only horizontal surfaces and no or hardly any curves, then the effects of a lower layer height are hardly noticeable. If the angle between two layers is 90°, then a reduced layer height makes no sense. If the target object is, for example, a cube with an edge length of 60 mm, then reducing the layer height from 150 μm to 60 μm has no effect.

With a lower layer height, not only the printing time and the costs increase. In the end, a greater layer height often leads to improved mechanical properties. If, for example, the part is to be post-processed (sanded or painted), then a reduced layer height is more of a disadvantage.

The advantages of a lower layer height

The result of a lower layer height is a higher Z-resolution and thus a smoother surface. If you are dealing with delicate, detailed objects, then you should tend to use a lower layer height.

The effect is most effective when the object has curves, angles, or holes. Imagine there is a hole printed along the horizontal axis.

The hole would have to be cut in several superimposed layers, resulting in stair-like edges on the surface. With a significant proportion of curves, the lower layer height leads to higher accuracy and detail.

Nozzle

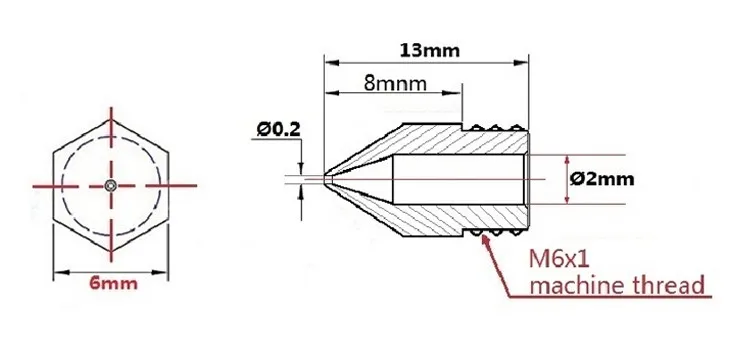

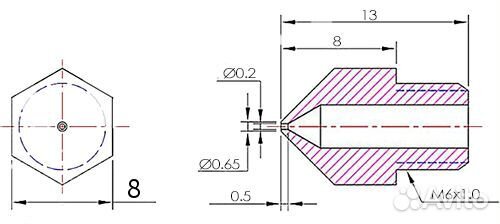

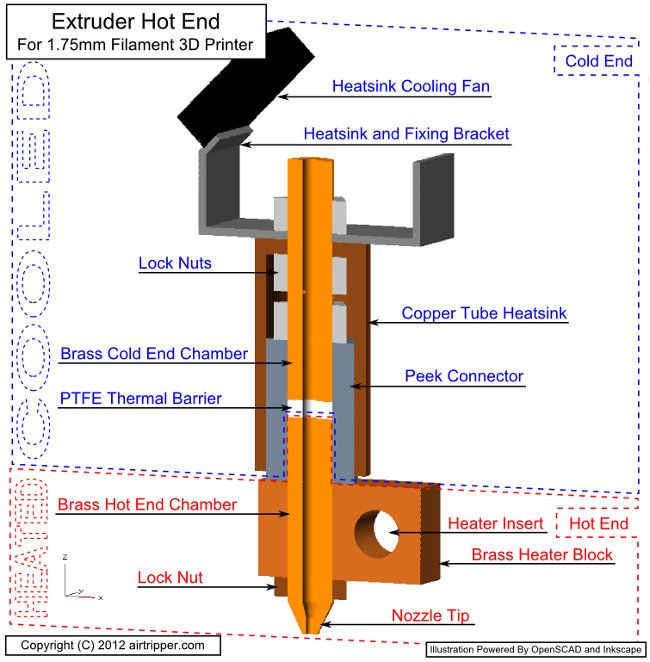

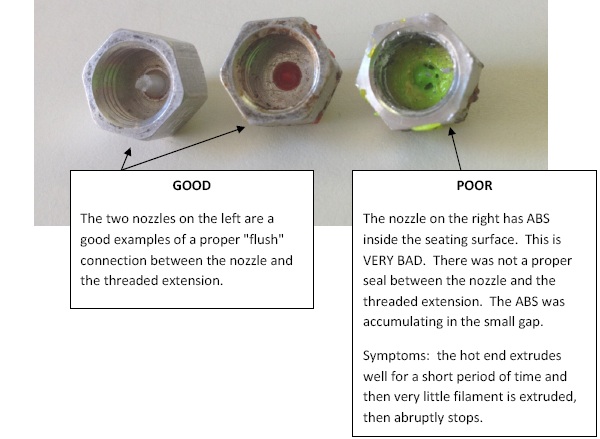

The nozzle is one of the most important components of a 3D printer. The nozzles have a tapered shape and are made of various materials.

They have a thread at the bottom end with which they can be screwed to the hot end of the 3D printer. The length of the thread and also the diameter can differ for the individual nozzles. You should therefore check in advance whether the respective nozzle is compatible with your 3D printer and for which filaments it is suitable.

Nozzle diameter

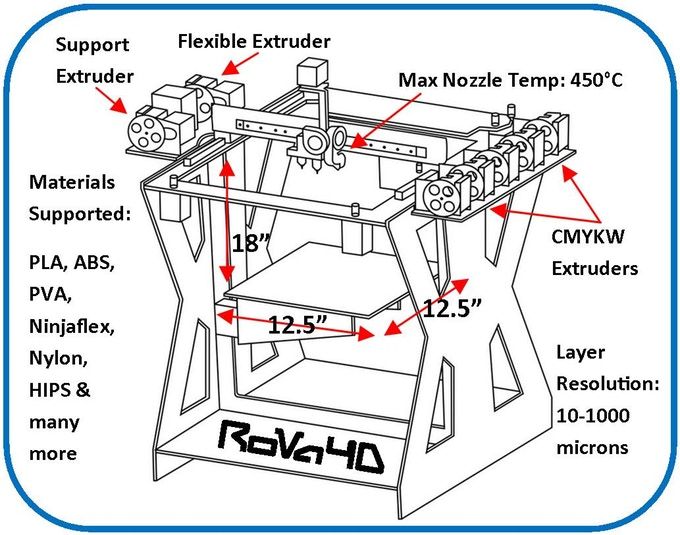

The borehole diameter (nozzle diameter) for most nozzles is between 0.1 and 2 mm. The standard are nozzles with a diameter of 0. 4 mm. It is worth buying a set of different nozzles. The nozzle diameter has a significant influence on the printing result.

4 mm. It is worth buying a set of different nozzles. The nozzle diameter has a significant influence on the printing result.

Nozzles with a large diameter are suitable for an increased layer height, nozzles with a small diameter are ideal for a low layer height and thus for a higher resolution.

Nozzle materials

The nozzles for 3D printers are often made of brass, copper or (stainless) steel*. Optionally, a coating is also available. Depending on the intended use and requirements, nozzles made of other materials or alloys are also available. Some nozzles are made of ruby at the tip, for example.

The ideal material depends on the filament and your own requirements. For example, for a very hard filament, stainless steel nozzles are more suitable than brass, even if the thermal conductivity is somewhat worse.

Relationship Between Layer Height and Nozzle Diameter

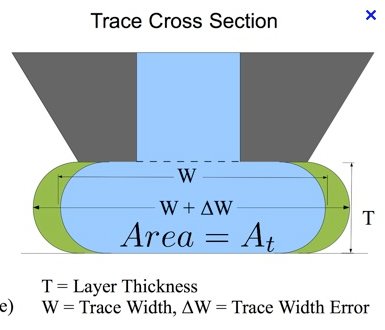

The nozzle diameter in the 3D printer has a direct influence on the recommended layer thickness and thus also on the printing speed. Depending on the nozzle diameter, there is a recommended maximum and minimum layer height.

Depending on the nozzle diameter, there is a recommended maximum and minimum layer height.

The maximum layer height is calculated according to formula 1, the minimum layer height according to formula 2:

- maximum layer height = 0.75 * nozzle diameter

- minimum layer height = 0.25 * nozzle diameter

Of course, these are rules of thumb, but they are helpful for orientation. If the nozzle diameter is 500 μm, then the maximum layer height is 375 μm and the minimum layer height is 125 μm. For example, many experts print with only half the nozzle diameter. With a nozzle diameter of 0.2 mm (= 200 μm), they print with a selected layer height of 100 μm. The given nozzle diameter limits the maximum amount of material that can be extruded.

A very small nozzle diameter also implies some low printing speed for the following reasons:

- the diameter limits the amount of material to be extruded

- more pressure is needed to press a large amount of filament through a small nozzle

- at an increased speed, more material must be transported in the same time period

With an increased nozzle diameter, it is therefore possible to print faster. With a larger nozzle, however, you have to choose a larger layer height, which leads to a coarser resolution.

With a larger nozzle, however, you have to choose a larger layer height, which leads to a coarser resolution.

Practical Test & Comparison

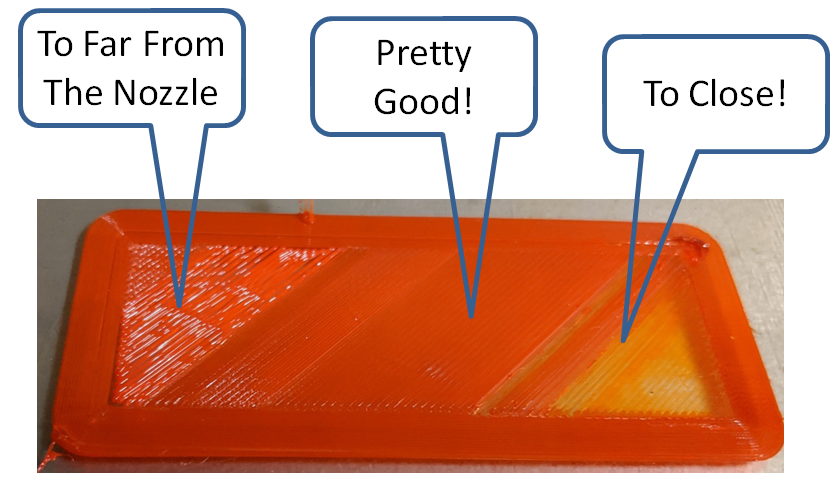

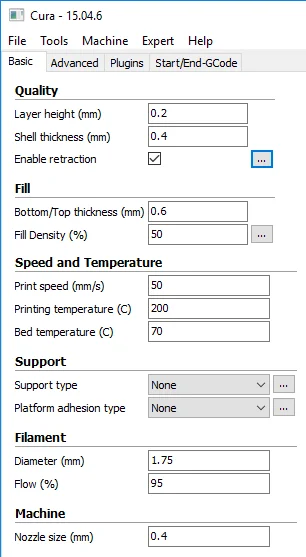

To put these formulas to the test, I equipped my Anycubic Mega S with different nozzles. I set the layer height to 25%, 50% and 75% of the nozzle diameter respectively.

| Layer Height | Nozzle Diameter | Print Time |

|---|---|---|

| 0.7 mm | 1.0 mm | 0:06 |

| 0.5 mm | 1.0 mm | 0:08 |

| 0.25 mm | 1.0 mm | 0:15 |

| 0.6 mm | 0.8 mm | 0:07 |

| 0.4 mm | 0.8 mm | 0:10 |

0. 2 mm 2 mm | 0.8 mm | 0:19 |

| 0.45 mm | 0.6 mm | 0:13 |

| 0.3 mm | 0.6 mm | 0:18 |

| 0.15 mm | 0.6 mm | 0:37 |

| 0.3 mm | 0.4 mm | 0:24 |

| 0.2 mm | 0.4 mm | 0:38 |

| 0.1 mm | 0.4 mm | 1:03 |

| 0.225 mm | 0.3 mm | 0:46 |

| 0.15 mm | 0.3 mm | 1:07 |

| 0.075 mm | 0.3 mm | 2:15 |

0. 15 mm 15 mm | 0.2 mm | 1:26 |

| 0.1 mm | 0.2 mm | 2:08 |

| 0.05 mm | 0.2 mm | 4:18 |

What is directly noticeable in the pure data is the big difference between the printing times.

Especially with the smaller diameters, this difference becomes greater and greater. With the 0.2 mm nozzle and at 25%, i.e. 0.05 mm layer height, this is already over four hours for the selected object!

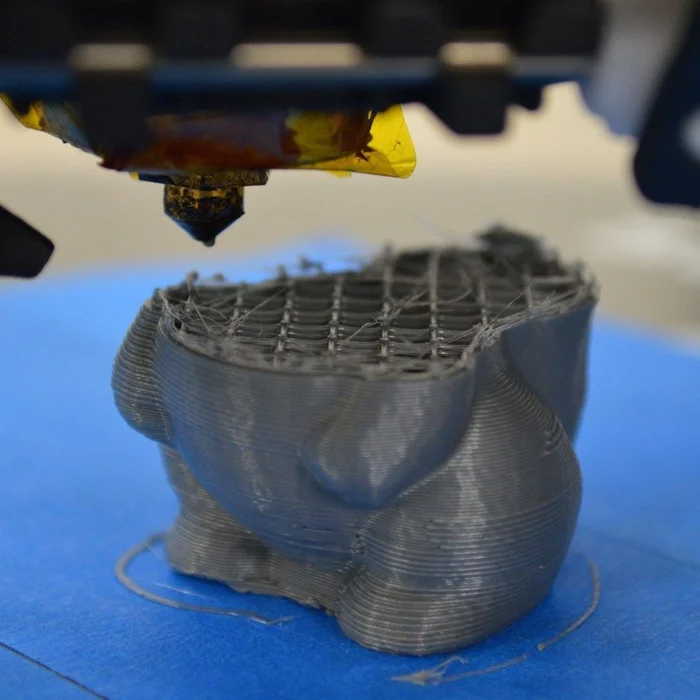

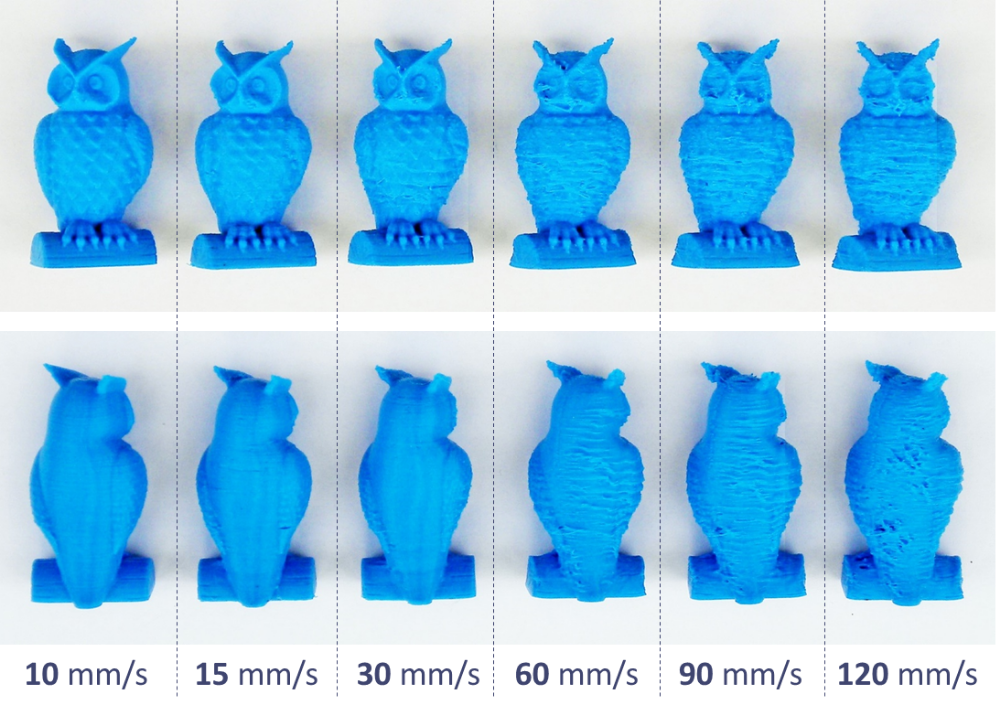

Here you can see how the settings and the different nozzle diameters affected the surface:

From the tests, I have learned that for most objects it makes no difference to the eye if you use a layer height of 0. 1 mm or less.

1 mm or less.

You can really only see the difference between 0.1 mm and 0.05 mm if you look very closely.

Besides, it’s always a question of whether it’s worth the time.

The printing time doubles very quickly. Likewise, the printing time doubles quickly if you want to print the same layer height with a smaller nozzle (e.g. 0.15 mm layer height with a 0.6 mm nozzle takes 37 minutes and 0.15 mm with a 0.3 mm nozzle takes 1 hour and 7 minutes).

This is, of course, because you have to print the same volume. With a smaller extrusion width, the printhead has to travel more distance and print more infill walls to get the same printed volume.

Related Questions

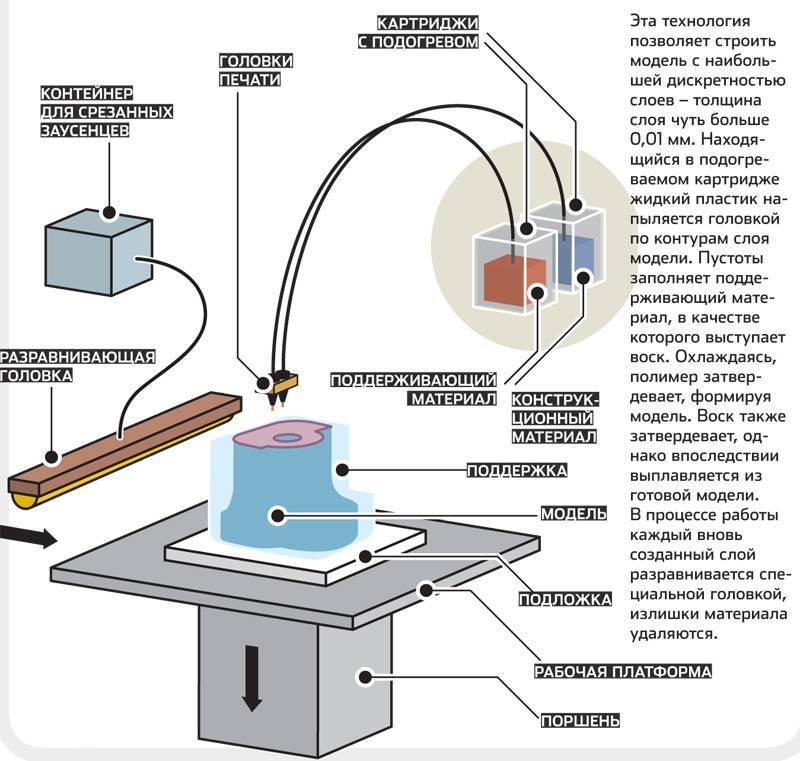

Which layer heights are typical for the different printing processes?

- FDM 0.05 to 0.4 mm (standard 0.1 mm)

- SLA/DLP 0.025 mm to 0.1 mm (standard 0.05 mm)

- SLS 0.08 mm to 0.12 mm (standard 0.1 mm)

- Material jetting 0.016 to 0.03 mm (standard 0.016)

- Binder Jetting 0.

1 mm

1 mm - DMLS 0.03 mm to 0.05 mm

What materials are most nozzles made of and why?

Most 3D printer nozzles are made of brass. Brass has proven itself especially due to its good thermal conductivity. These nozzles are very easy to manufacture and are inexpensive. Brass nozzles are not suitable for filaments with a strong abrasive effect.

What are brass nozzles coated with?

A coating protects the brass nozzle from excessive abrasion. Chrome or nickel can be used as a coating.

What are stainless steel nozzles suitable for?

Stainless steel nozzles are much more robust than those made of brass or copper. A disadvantage is the poorer thermal conductivity, so you have to set a higher pressure temperature.

How much does a nozzle actually cost?

The price, of course, depends on the material. The cheapest are nozzles made of nickel without coating, these are sometimes available for less than 10 bucks. The price for stainless steel nozzles ranges from $15 to $25. Noticeably more expensive are nozzles with ruby, these can also cost $90 or more.

Noticeably more expensive are nozzles with ruby, these can also cost $90 or more.

Which nozzle diameter is suitable for what? What is the standard diameter?

Most 3D printers are equipped with 0.4 mm nozzles. Nozzles with a diameter of < 0.4 mm are suitable for objects with intricate details. Nozzles with a diameter of 0.6 to 1 mm are perfect for less precise and fast 3D prints.

What else should be considered for the nozzle diameter?

With a higher nozzle diameter and a higher printing speed, more filament must be melted. Note that the extruder and the heating cartridge have a power limit.

Conclusion

Both the layer height and the nozzle diameter have a decisive influence on the printing time, the costs and the printing result. The given nozzle diameter results in a minimum and a maximum layer height each (see formulas 1 and 2).

Basically, the higher the nozzle diameter, the greater the maximum possible layer height. A greater layer height often also leads to fewer print defects and improved material properties. If the part is to be reworked, then a greater layer height is optimal.

If the part is to be reworked, then a greater layer height is optimal.

In 3D printing, the object is built up layer by layer, with the layer height defining the height or thickness of each individual layer. A low layer height leads to a higher Z-resolution and to a significantly increased printing time. The maximum printing speed is also limited by the nozzle diameter. A higher nozzle diameter enables faster printing.

Nozzles with a small diameter of < 0.4 mm are suitable for printing fine, delicate objects with many details. The ideal material for the nozzles depends on the filament, but nickel is often a very good choice. With numerous curves, a better result is achieved this way due to the flatter surface. One disadvantage is that it increases the time needed for printing. If you halve the layer height, then the 3D printer will take twice the time.

So, when choosing nozzle diameter, the following factors are crucial:

- Does the object have many curved surfaces, holes or fine details? Then small nozzles and a low layer height are ideal.

For non-curved objects with horizontal surfaces and 90° angles (cubes, cuboids), you should choose a high layer height.

For non-curved objects with horizontal surfaces and 90° angles (cubes, cuboids), you should choose a high layer height. - Is it a matter of visual appearance or functionality? If the object has to be reworked, then a greater layer height is clearly more practical. After all, printing is also a question of cost. If it’s mainly about functionality, then you should go for a greater layer height.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.

Everything about nozzles with a different diameter

The default nozzle diameter for most of today’s printers is 0.4 mm, and the nozzles used in Original Prusa i3 MK3S+ and the MINI printers are no exception. Changing the nozzle takes just a few minutes and it can bring a number of benefits. According to our survey, only approximately 20 % of users tried replacing their printer’s nozzle at some point, which is quite a low number. Let’s look at how changing the nozzle can improve your experience.

Changing the nozzle takes just a few minutes and it can bring a number of benefits. According to our survey, only approximately 20 % of users tried replacing their printer’s nozzle at some point, which is quite a low number. Let’s look at how changing the nozzle can improve your experience.

A smaller nozzle is great for detailed (but slower) prints, while larger nozzles print faster, but the quality suffers – or does it? In reality, it’s a bit more complicated. In our article, we will demonstrate the benefits of smaller and larger nozzles in real situations. But first, we need to clarify something users often get wrong – the correlation between layer height and nozzle diameter.

Layer height vs nozzle diameter

Layer height should not exceed 80 % of the nozzle diameter. If you are using the standard 0.4mm nozzle, the maximal layer height is about 0.32 mm. However, with a 0.6mm nozzle, it’s possible to achieve up to a 0.48 mm layer height.

If you are using the standard 0.4mm nozzle, the maximal layer height is about 0.32 mm. However, with a 0.6mm nozzle, it’s possible to achieve up to a 0.48 mm layer height.

Apart from these limitations, the two parameters are independent of each other. Tweaking their settings separately will bring completely different results. The nozzle diameter affects the overall level of detail almost exclusively in the horizontal plane (parallel to the print surface). What does this mean? With a smaller nozzle, you will be able to print a more detailed text – assuming it’s placed on the top side of the printed object. Contrary to that, the layer height affects the level of detail on vertical and slanted sides of an object. You have a much greater chance of seeing individual layers on organic-looking objects. The lower you set the layer height, the better the overall result. On the other hand, it makes little sense to print rectangular-shaped objects with very low layer height. There will be little to no difference in the end result, plus the printing time will be unnecessarily long.

There will be little to no difference in the end result, plus the printing time will be unnecessarily long.

Print up to 4 times faster!

3D printing is not exactly a fast process. Even a print that is just a few inches tall can take several hours to complete. So it’s quite puzzling how overlooked large-diameter nozzle printing is, despite the fact that it can lead to a dramatic improvement of the printing speed.

STL download link – Chibi Grim by Tanya Wiesner

A larger-diameter nozzle lays down wider perimeters, which means that it uses fewer perimeters than a smaller-diameter nozzle to print a wall of the same thickness. A nozzle with a larger diameter also allows for printing with increased layer height. Combining these two effects leads to a noticeably shorter print time. There’s a catch, though: if you keep the same layer height to print something with just one perimeter, like a vase, you won’t notice any improvement in speed. Because the nozzle has to go through exactly the same sequence of moves, independent of diameter. Yes, the vase will have a slightly thicker wall, but the print time will be almost the same.

Because the nozzle has to go through exactly the same sequence of moves, independent of diameter. Yes, the vase will have a slightly thicker wall, but the print time will be almost the same.

Effect on mechanical properties

Another advantage of using larger nozzles is the increased toughness of printed objects. An impact resistance test revealed that the objects printed with the 0.6mm nozzle absorbed up to 25.6 % energy more than those printed with a 0.4mm nozzle. And objects printed with a 0.25mm version absorbed 3.6 % less energy than those printed with a 0.4mm nozzle. This test was performed on ten different samples. We then removed the minimum and maximum values, which is why you can see values of 8 samples. To learn more about the Charpy impact strength test, please visit this link.

Supports

Supports are usually printed as a one perimeter wide polyline. If you go to slicer settings, you may often notice that the supports are deliberately underextruded, so they are easier to remove. And, of course, using a different printer nozzle directly affects the width of support walls. You can turn this into an advantage. By simply using a smaller nozzle supports will be thinner and easier to remove. Using larger nozzles has an opposite effect leading to wider and sturdier supports, which can be a bit difficult to remove.

And, of course, using a different printer nozzle directly affects the width of support walls. You can turn this into an advantage. By simply using a smaller nozzle supports will be thinner and easier to remove. Using larger nozzles has an opposite effect leading to wider and sturdier supports, which can be a bit difficult to remove.

How to replace the extruder nozzle?

Ready-made settings for 0.25mm, 0.6mm, and 0.8mm nozzles

If you want to try 0.25mm, 0.6mm, or 0.8mm nozzle and own an Original Prusa printer, you don’t need to create brand new slicer profiles. We’ve done that for you! Open the Configuration Wizard in PrusaSlicer and tick the nozzle diameter checkbox under your printer corresponding to your nozzle size. Then simply select it as the active printer profile.

Then simply select it as the active printer profile.

0.25mm nozzle

Pros

Better looking printed texts

Better resolution in XY axes – perfect for jewelry, logos…

Extremely easy-to-remove supports

Cons

Significantly longer print times

Higher risk of nozzle getting clogged

Not compatible with some filaments (filaments containing larger particles)

Examples of practical use (0.25 mm)

Printing texts

As already mentioned, the nozzle diameter has a noticeable effect on the printing resolution of the plane parallel to the print surface. This means that a 0.25mm nozzle is suitable for printing detailed text. Let’s compare it to the default 0.4mm nozzle. Despite the fact that ‘Detect thin walls’ is enabled, parts of the letters can be lost during slicing. This won’t happen with a 0.25mm nozzle, so you can use it to print an unusual business card to woo the crowds 🙂 It’s worth mentioning that changing the layer height won’t affect the text legibility.

Slic3r preview shows that the object’s details are too small for the selected nozzle

Left: Business card printed with a 0.4mm nozzle. Right: Same model, printed with a 0.25mm nozzle.

Printing jewelry

This is another great use of a smaller nozzle. The difference between a 0.4mm and a 0.25mm nozzle is not so dramatic, because even a 0.4mm nozzle can print small objects reasonably well. Improvements will be visible especially when printing thin lines.

Printing miniatures

Surprisingly, printing miniatures using a small-diameter nozzle leads to a fairly minor improvement in print quality. You’ll notice the biggest improvement while printing supports for these objects. Supports printed with a 0.25mm nozzle are easy to remove and they leave nearly invisible marks on the object.

STL download link

On the other hand, if you don’t need supports, the difference between a 0.4mm and a 0.25mm nozzle is close to zero. Honestly, if we had switched the labels above those two chests, could you tell?

Honestly, if we had switched the labels above those two chests, could you tell?

STL download link

0.60mm nozzleA 0.60mm nozzle is suitable for any print that doesn’t rely on tiny details. Headphone stands, various holders, racks or flower pots… can all be printed in half the usual time. We have been mostly using a 0.4mm nozzle during the past few months, so frankly it was a pleasant re-discovery of how nifty the 0.6mm nozzle is.

Pros

Print times up to twice as fast

Almost the same print quality as a 0.4mm nozzle

More durable prints

Low risk of a clogged nozzle

Cons

Worse resolution of tiny details and texts

Supports are more difficult to remove

Examples of practical use (0.6 mm)

Flower pots and vases

Flower pots usually don’t feature any intricate details, so the difference between a 0.4mm and a 0.6mm print is nearly impossible to tell. In the example below, we’re using the same layer height. With an increased layer height, the 0.6mm would finish the print even faster. And thanks to the shape of the flower pot, the difference wouldn’t be too noticeable.

In the example below, we’re using the same layer height. With an increased layer height, the 0.6mm would finish the print even faster. And thanks to the shape of the flower pot, the difference wouldn’t be too noticeable.

STL download link

Buddy the Dog

Buddy is quite a detailed model. However, the 0.6mm nozzle has no trouble with that whatsoever at this scale.

Voroni lamp

Thanks to the shape of this lamp (large flat surfaces), almost no quality has been sacrificed. A 0.6mm nozzle requires one perimeter less to achieve the same thickness of the wall as a 0.4mm nozzle (3 perimeters with 0.4 mm vs 2 perimeters with 0.6 mm). This saved a huge amount of time with the reduction of the print time by nearly 9 hours!

STL download link

1mm nozzleOne millimeter?! 0.04 inches? Yep, correct. Forget everything you think you know about 3D printing. Even prints that take dozens of hours to finish can be done in only a few hours using a 1mm nozzle. You can achieve up to 5 times faster printing speeds compared to a 0.4mm nozzle. Of course, there is a price to pay. With a 1mm nozzle, you will usually print at a layer height of 0.5 mm, but it’s possible to go even higher. Sure, the printed object’s layers will be highly visible, but sometimes that doesn’t hurt. In some cases, it can even give the model an interesting aesthetic, which could be quite challenging to achieve using other methods. We will, of course, demonstrate that on several examples below.

You can achieve up to 5 times faster printing speeds compared to a 0.4mm nozzle. Of course, there is a price to pay. With a 1mm nozzle, you will usually print at a layer height of 0.5 mm, but it’s possible to go even higher. Sure, the printed object’s layers will be highly visible, but sometimes that doesn’t hurt. In some cases, it can even give the model an interesting aesthetic, which could be quite challenging to achieve using other methods. We will, of course, demonstrate that on several examples below.

Pros

Extremely fast printing

Very sturdy prints

Unusual look with highly visible layers

Nearly zero risk of a clogged nozzle

Cons

Lack of detail

Visible layers

Supports very difficult to remove

Filament seems to disappear from the spool

Examples of practical use (1 mm)

Dinosaur – a toy for children

A surprising advantage of using a 1mm nozzle is its ability to print rounded edges naturally – without any extra settings. This is great for printing toys for children because the risk of cutting one’s finger on a sharp edge is minimized. Plus, the toy was printed five times faster compared to the default 0.4mm nozzle.

This is great for printing toys for children because the risk of cutting one’s finger on a sharp edge is minimized. Plus, the toy was printed five times faster compared to the default 0.4mm nozzle.

STL download link

Pencil holder

STL download link

Transparent prints without infill

Models printed using a transparent filament (e.g. PETG) without an infill and with a very high layer height have the ability to refract light in an interesting way. Especially, if you can print them with only one or two perimeters. Achieving a similar look would be otherwise quite challenging.

Conclusion

If we could recommend buying only one nozzle as an alternative to the 0.4mm nozzle, our vote goes to the 0.6mm option. It offers noticeably shorter printing times, but it’s still possible to print reasonably detailed models. If you usually print tiny models with texts, jewelry or logos, you should also consider the 0. 25mm nozzle. The 1mm version has a limited use, but it’s still pretty fun to use. Even the original E3D nozzles, which can be purchased through our e-shop or directly from E3D, are just around 7 EUR per unit. This small investment can have a surprisingly large impact on how you print.

25mm nozzle. The 1mm version has a limited use, but it’s still pretty fun to use. Even the original E3D nozzles, which can be purchased through our e-shop or directly from E3D, are just around 7 EUR per unit. This small investment can have a surprisingly large impact on how you print.

Nozzles for 3D printer. Part two. Diameter

Today we will talk about nozzle diameter. At the moment, nozzle diameters are very different. Their diameter starts from 0.1 mm to 1.2 mm (there are more, but they are rarer). As a result, we have a difference between the smallest and largest diameters by more than 10 times. The question arises - for what? Why do companies create nozzles of different diameters? We will try to answer these questions today in this article.

The most important factors that affect the nozzle diameter are the layer height and the width of the printed line. From these two most important settings in 3D printing, a lot of side factors follow, such as print speed, the strength of the printed model, and so on. On the one hand, we did not change the print speed. On the same model, it was conditional 60 mm / s, but by installing a nozzle with a diameter twice as large, we can also significantly reduce print time. But first things first.

On the one hand, we did not change the print speed. On the same model, it was conditional 60 mm / s, but by installing a nozzle with a diameter twice as large, we can also significantly reduce print time. But first things first.

Let's start with the main question, why are there so many sizes?

We all use our 3D printers for different purposes and no single nozzle can meet all the needs of all users. Someone prints the smallest and most detailed objects, someone prints models of huge sizes, for all these types there are different nozzle diameters.

Most printers come standard with a 0.4mm diameter nozzle which is considered standard and is suitable for most common applications. This is also due to the fact that most printers have a print volume of 200 * 200 * 200 mm. With a given amount of print space with a 0.4 mm nozzle, even at maximum resolution, printing will not take too long. But there are exceptions, such as Picaso Designer printers come with a 0.3 mm nozzle, because. printer and is positioned as a tool for printing objects with maximum quality and detail.

printer and is positioned as a tool for printing objects with maximum quality and detail.

As we already wrote, the nozzle diameter affects the layer height (layer height), how to calculate it? The formula is simple Layer Height = Nozzle Diameter/2~4. That is, with a nozzle diameter of 0.4 mm, the minimum layer height will be 0.1 mm, and the maximum 0.2 mm. With these values, your models will be of the highest quality. There is time and I want more detail, put a smaller layer; you need to print urgently, and the appearance is unimportant, we set the maximum layer height that your nozzle allows.

The nozzle diameter also affects the line width, this allows you to print parts much faster, as well as make the model stronger. Typically, the nozzle can extrude a line wider than 2 times the diameter of the nozzle. What does it mean? This means that you can print parts several times faster without changing the nozzle, as well as increase the strength of the part. One of the interesting options is to increase the line width on the inner contour of the wall and infill, while maintaining the standard value of the line width of the outer contour. In this case, reducing the line width to less than the nozzle diameter is not recommended. In this case, the formation of unprinted parts begins.

In this case, reducing the line width to less than the nozzle diameter is not recommended. In this case, the formation of unprinted parts begins.

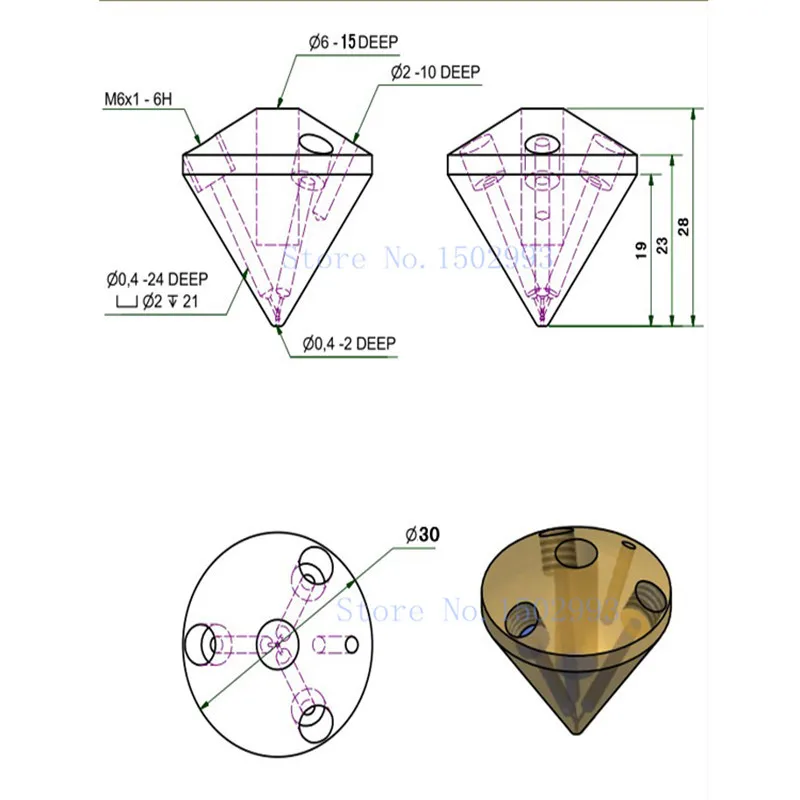

The influence of the line width on the strength of the part was tested by CNC Kitchen on his channel, he posted a video with tests. The parts to be tested look like this:

The test was carried out on four types of hooks. With printing lines of 100% of the nozzle width of 0.4 mm (that is, the line width is also 0.4 mm), 100% in 4 perimeters, 3 perimeters at 133%, and also 2 perimeters at 200%.

The test showed that the maximum strength was achieved exactly on the part printed with two perimeters of 200% of the line width. Increasing the line width greatly increases interlayer adhesion, which adds strength to the model. It's scary to imagine what will happen to a part printed with nylon with an increased line width.

What will happen if we install a nozzle with a diameter less than the standard 0.4 mm. Line width can be reduced down to 0. 1mm and layer height down to 0.05mm, which is incredible for FDM printers. In this case, the printing of each cubic centimeter will take forever.

1mm and layer height down to 0.05mm, which is incredible for FDM printers. In this case, the printing of each cubic centimeter will take forever.

What about the effect of the installed nozzle on the system and printing. When setting a nozzle with a diameter larger or smaller than the standard one, it is necessary to evaluate the possibility of its installation. After all, if you plan to install a nozzle of a larger diameter, then you need a more powerful blowing and cooling system for the extruder. If your system is not ready for this, for normal printing you will have to reduce the print speed, and you may get unpleasant print artifacts such as underextrusion or streaks from insufficient cooling.

Setting a nozzle with a smaller diameter can increase the load on the extruder. In this case, it is best to use a geared extruder. Also, nozzles with a diameter of less than 0.4 mm are very often clogged, they are almost impossible to print with composite materials such as Wood, Carbon.

That's all we wanted to say about nozzles with different diameters. On our website, nozzles are presented in sizes from 0.2 mm to 1 mm, they can be found in the Accessories tab.

And as always, we hope that this article was useful for you, the next article will be about nozzles from different materials.

How to choose the nozzle size for a 3D printer? Pros and cons

3DPrintStory 3D printing process How to choose nozzle size for 3D printer? Pros and cons

When choosing your 3D printer, the nozzle size of your 3D printer may have been the last thing on your mind. This is a detail that is often overlooked. But depending on what you need to print, the wrong nozzle diameter can get in the way.

In this article, we'll take a look at the different 3D printer nozzle sizes and why you should consider this assembly, what materials it's made from, understand the relationship between nozzle size and layer height, and how to measure the actual nozzle diameter.

How does nozzle size affect 3D printing?

Nozzle diameter affects the extrusion width of the 3D printer line. This affects some elements of your model. If you are 3D printing for business (make a lot of orders), you need to make sure your extruder is feeding the right amount of material. If too much material is fed, then more filament is used than is actually required for successful 3D printing. Well, a smaller number can simply lead to marriage.

Or maybe you're printing different models, some of them very detailed and intricate, and some more practical (like a replacement doorknob) that just needs to be printed quickly and with maximum durability.

In any case, you will need the correct setting to save time, material and ensure the normal quality of the 3D model.

There is no easy answer to what is the best nozzle size for a 3D printer. You need to weigh what you want to achieve and what elements of the 3D model are most important to you.

Depending on your 3D printer, the nozzle can be quite easily replaced (most of them are mounted on screws), and buying a package with different sizes will cost you a lot.

Most common 3D printer nozzle options

The most common standard nozzle size is the 0.4mm (or 0.35mm) nozzle used by most modern 3D printer manufacturers. The reason for this is that it is a rather large and yet versatile nozzle size. This means that you can print with exceptional detail in no time.

With the 0.4 mm 3D printing nozzle you can print up to a layer thickness of only 0.1 mm or up to 0.3 mm. The lower the layer height, the better the detail (on the Z axis) and the larger the layer height, the faster your 3D print will be, but with worse detail quality.

A common misconception is that if someone doesn't get good enough 3D print quality on their printer with a 0. 4mm nozzle, they immediately think they need a smaller 3D print nozzle.

4mm nozzle, they immediately think they need a smaller 3D print nozzle.

Another common smaller size is 0.25 mm. Some 3D printers offer 0.2mm, 0.15mm, and Mass Portal is even experimenting with 0.1mm 3D printer nozzles. And the experiments are really interesting. Thanks to this miniature nozzle, they were able to print the clock mechanism with excellent detail.

How is nozzle diameter related to 3D printer resolution?

Theoretically, smaller 3D printer nozzles allow for greater precision. But for many 3D printers, especially cheaper or older models, a smaller extruder nozzle won't necessarily make a difference if your printer doesn't support the higher resolution you need. It's like putting low-profile, high-performance tires on an old classic car - it doesn't make it go faster, and it doesn't necessarily make it better cornering.

This is also similar to how the specifications of a 3D printer on paper (eg claimed resolution) do not always result in the best print quality of the finished product. Just like Ultimaker and Zortrax have very similar resolutions on paper, but in many actual tests Zortrax produces better models than Ultimaker 2.

Just like Ultimaker and Zortrax have very similar resolutions on paper, but in many actual tests Zortrax produces better models than Ultimaker 2.

smaller nozzles as resolution across the board is getting better every day.

Let's look at the pros and cons of 3D printing with smaller nozzles. Some are less obvious than others. Next, we'll look at the larger, underpriced nozzles available. I hope after reading this article you will be able to answer the question: "What nozzle size should I print?".

You probably already guessed that the smaller the size of the nozzle in the extruder, the more detailed model you can get as a result of 3D printing. The thin nozzle is great for complex figures, or if you need to print very thin walls for aircraft skins, or high transparency models, etc.

The photo below shows the printed skin of a model aircraft that was made with a standard 0.4mm nozzle. If the same skin is printed with a nozzle with a diameter of 0.2 mm, then the weight (and strength) would be halved.

It is worth noting that a 3D printer with a 0.2 mm nozzle feeds half as much material as a 0.4 mm nozzle. And this actually leads to an increase in print time by the same two times. It should be noted that strength and detail are reciprocals of time. So to get high-quality 3D models using a thin nozzle and high resolution, you will have to be patient (2 times more than when printing with a standard 0.4 extruder :)). In some cases this is justified, in others it is a waste of time...

As a general rule, the smaller the nozzle size, the higher the chance of problems with the 3D printer. Especially if you are using cheap materials - they can work well with low models and thicker nozzles, but if you need detailed models that are printed using a thin nozzle, then you should also be puzzled by buying quality filaments for 3D printing.

Other factors are less obvious when 3D printing with a thin diameter nozzle - for example, protrusions can be a problem. This is because each layer has a smaller width for the next layer. Crossing bridges can also be difficult.

Crossing bridges can also be difficult.

But there is good news too! Where overhangs form, the caliper material will be much easier to remove if printed with a thin nozzle. Due to the increased accuracy, your slicer can use a minimum amount of material between your model and supports, so they will break off more easily and have fewer damaged pads that need to be sanded.

And finally, the most annoying thing about a thin nozzle is the ease with which it clogs. If you downsize to 0.2mm or even 0.1mm, you'll need a small particle to clog the hotend. You need to be very careful about the cleanliness of your 3D printing material and regularly clean the nozzle of your 3D printer. Otherwise, you will not end up with additional unnecessary problems.

It is also worth taking the time to understand the relationship between nozzle size and layer thickness. In short, the first parameter determines the horizontal detail (along the x and y axes), and the second adjusts the resolution along the vertical or z axis.

How to measure the nozzle size of a 3D printer?

Although the actual nozzle diameter should be engraved on the side of the nozzle, it is not always possible to read this value if it is already installed in the extruder or if you have been printing with it for some time. After all, there is the concept of wear and you may not be sure that the nozzle is the same size as before.

To determine what size your nozzle really is, very slowly extrude some material into the air (high speed may change shape or size) at the lowest setting you can feed material at (approximately 1 mm/s). Once cool, use a micrometer if you have one. They are generally more accurate than digital calipers. Keep in mind that the filament will probably expand after being extruded. Poor quality material or an extruder that is too hot (especially if you extrude at 1mm/s) will cause the material to expand more, resulting in inaccurate readings.

It is also useful to know the size to which your material expands after extrusion if you are working on getting a really nice and accurate model. So feel free to experiment with higher speeds that are a bit more like your actual 3D printing.

So feel free to experiment with higher speeds that are a bit more like your actual 3D printing.

What is the relationship between 3D print layer height and nozzle diameter?

In simple terms, this is the thickness of each line of extruded material that makes up each layer of your model. The thinner the layer height (or layer thickness), the finer the print detail in the Z-axis (the vertical dimension of your model), but the more layers will be required. Increases print time.

These characteristics are related, but not completely. For example, you can print using a thinner, thicker nozzle if vertical resolution is less important to you. Or you can use a thicker nozzle with a very small layer height. Although in this case, do not get too carried away. To maintain adequate pressure, your layer height should be at least 20% less than your nozzle width - and in most cases, for best 3D printing results, it should be around 50%.

How to determine the correct distance from the nozzle to the desktop of a 3D printer?

With the correct setting of the distance between the table and the nozzle, the base of the finished model should have an almost perfectly smooth, glassy surface. Many people assume that you need to use a stylus to properly set the distance between the nozzle and the 3D printer bed, but in fact, even that can be too thick. So it's worth thinking in the direction of the already proven table calibration with a piece of paper. You should use thin paper. For example, check paper is a great choice. Place the receipt paper under the nozzle and gradually lower the nozzle down until the receipt paper resists a little when you try to push it out. 3D printing at this height will give the bottom of the model a great look, and in the case of tall models, the print will definitely not go astray.

Many people assume that you need to use a stylus to properly set the distance between the nozzle and the 3D printer bed, but in fact, even that can be too thick. So it's worth thinking in the direction of the already proven table calibration with a piece of paper. You should use thin paper. For example, check paper is a great choice. Place the receipt paper under the nozzle and gradually lower the nozzle down until the receipt paper resists a little when you try to push it out. 3D printing at this height will give the bottom of the model a great look, and in the case of tall models, the print will definitely not go astray.

What is the maximum 3D print layer height compared to the nozzle size?

You don't necessarily need a layer height calculator on your 3D printer, but typically the maximum layer height is 50% of the nozzle width. In some cases, you can go higher (perhaps 75%), but in this case, you must be aware that you can sacrifice reliability.

It's best to experiment with the parameters of your model if you understand the relationship between the 3D printer's nozzle size and the layer height you'll be using to print. So for a 0.4mm nozzle, you will need to print with a layer height of 0.2mm, or up to 0.3mm. Your minimum should be around 0.1mm. If less, then in fact you just increase the waiting time without much benefit (on the same 0.4 mm nozzle).

So for a 0.4mm nozzle, you will need to print with a layer height of 0.2mm, or up to 0.3mm. Your minimum should be around 0.1mm. If less, then in fact you just increase the waiting time without much benefit (on the same 0.4 mm nozzle).

In most cases, it is worth printing thinner layers with smaller nozzle diameters and generally thicker layers with thicker nozzles. Just note that if you are printing with a thicker nozzle diameter and very thin layer height, you will need to lower the extrusion settings in your slicer to prevent overfeeding.

It's also worth noting that regardless of size, you should always make sure you always have a clean nozzle. One of the easiest ways to do this is to use a high quality cleaning floss. You only need to use a few grams of it each time you brush, but this will prevent carbon buildup over time.

So why should I use a 0.8mm nozzle or thicker?

Similar nozzle sizes were more common on older 3D printers but are making a comeback. It's all about using what you need and nothing more. For a large number of models, the 0.4mm headroom that your 3D printer probably comes with may be overkill in terms of detail.

It's all about using what you need and nothing more. For a large number of models, the 0.4mm headroom that your 3D printer probably comes with may be overkill in terms of detail.

If you're looking for strength and speed, but detail is less important, a 0.8mm or even 1.0mm nozzle is worth it. And don't forget that models printed with a 0.8mm nozzle can be very detailed, as a lot depends on your 3D printer as well.

The only slight disadvantage may be that you use more material, but with thicker part walls you can probably compensate with less infill.

There is no single optimal nozzle size for all models, you just need to take all factors into account and decide which nozzle size is best for you.

What nozzle size should I use for composite materials?

It is worth noting that composite materials (any particulate filament such as wood filler, copper filler, carbon fiber nylon or glass reinforced nylon) will cause extrusion problems when using a thinner nozzle.

.jpg)