3D printing the future science museum

3D Printing - An Explosion Of Creativity!

Suzy Antoniw, Content Developer in the Contemporary Science Team, looks at the creation of a new exhibition on 3D printing.

Suzy Antoniw, Content Developer in the Contemporary Science Team, looks at the creation of a new exhibition on 3D printing.

What can make impossible shapes solidly real and create unique, one-off medical treatments that could change your life? A 3D printer of course!

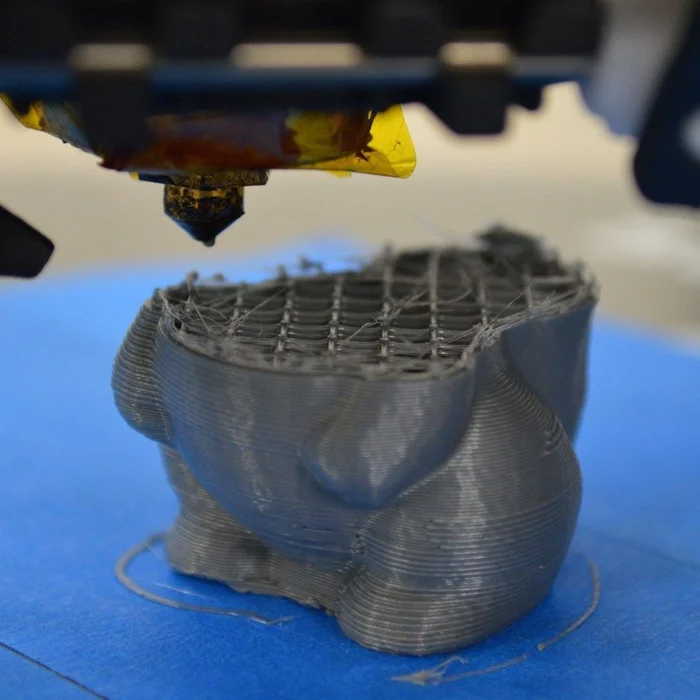

A demonstration of a 3D printer making a miniature figurine at the launch of 3D: Printing the Future. Image credit: Science MuseumAround nine months ago we were given the exciting challenge of creating 3D: Printing the Future, a new Contemporary Science exhibition to show off the real-life capabilities of these hugely hyped machines and highlight the latest 3D printing research.

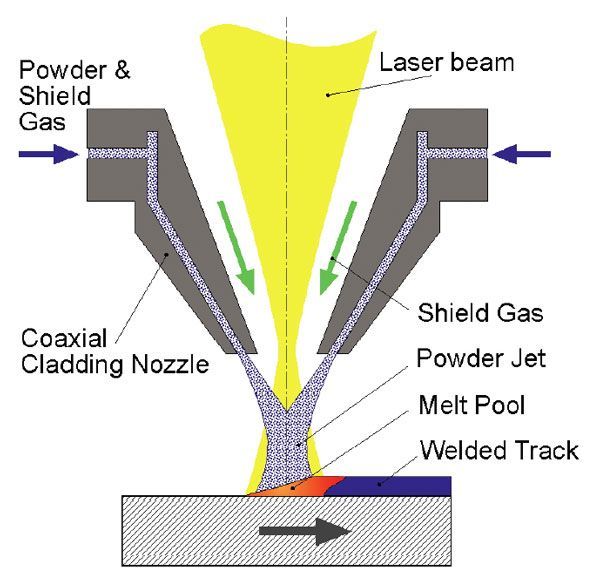

The ‘ghost walking in snow’ effect of a sophisticated laser sintering printer at work – an invisible laser fuses together an object layer by layer out of powdered polymer.But hang on, what exactly is a 3D printer? Even if you’ve read stories about them in the news you probably don’t have one sitting on your desk just yet. So here’s our definition: A 3D printer is a manufacturing machine that turns 3D computer data into a physical object, usually by building it in layers. They come in a variety of types that range from simple consumer models to sophisticated industrial printers.

A prosthetic arm concept made specially for the exhibition by Richard Hague, Director of Research, with students Mary Amos, Matt Cardell-Williams and Scott Wimhurst at the Additive Manufacturing & 3D Printing Research Group, The University of Nottingham. Image credit: Science MuseumAs well as covering the basics, we decided that our exhibition should focus on the incredible things that 3D printers can create – such as replacement body organs and teeth, that could make a difference to the lives of our visitors.

3D printed white bone scaffold inside model of a head, by Queensland University of Technology, Institute of Health and Regenerative Medicine, Australia, 2013. Image credit: Science Museum

Image credit: Science Museum3D printers have been around for decades, so what’s changed? In recent years the patents on simple 3D printing technologies have run out. 3D printers have become available to more people in the form of affordable consumer models, or even as open source plans freely available on the internet.

Hipsterboy 3D printer machine, for display purposes only (several components omitted), by Christopher Paton, United Kingdom, 2013. Image credit: Science MuseumThis new freedom to invent has generated an explosion of creativity. And it’s not just hackers, tinkerers and makers who’ve felt the benefits of this new breath of life for engineering and design, but established industry and academia too. So how do you represent a diverse and dynamic explosion of creativity?

Close up view of the objects on display in the 3D: Printing The Future exhibition. Image credit: Science MuseumIn July we began collecting 3D printed stuff for what has been known as ‘an explosion’, our ‘mass display’, ‘the wave’, ‘the wall’ and (my favourite) a ‘tsunami of objects’. The display contains over 663 objects – the largest number we’ve ever acquired for a Contemporary Science exhibition, thanks to generous loans, donations and the enthusiasm of the maker community.

The display contains over 663 objects – the largest number we’ve ever acquired for a Contemporary Science exhibition, thanks to generous loans, donations and the enthusiasm of the maker community.

Among the amazing ‘wave’ of objects you can see a display of 150 miniature 3D printed people – visitors who volunteered to have themselves scanned in 3D at the Museum over the summer holidays. Look closely at the wall and you may spot actress Jenny Agutter reading her script, model Lily Cole and BBC Radio 4 presenter Evan Davis – with his arm in a sling!

A wall of miniature 3D printed figures in the new exhibition 3D: Printing the Future. Image credit: Science MuseumThe free exhibition is open to the public from 9 October and will run for nine months.

3D: printing the future | Meer

Horse Marionette posed, credit Science Museum Michaella Janse Van Vurren

Replacement body organs, artworks, aeroplane parts and a music box are among over 600 3D printed objects on display in 3D: printing the future – a new free exhibition at the Science Museum.

The exhibition opened to the public on Wednesday 9 October and will run for 9 months.

The increasing availability and decreasing cost of 3D printing technology has led to an explosion of creativity among innovators, from big businesses and the medical industry through to small start-ups, students, hackers and artists. This exhibition will explore the rapidly evolving field of 3D printing and its growing impact on society.

Suzy Antoniw, Exhibition Leader, Science Museum said, “3D printing enables engineers and designers to manufacture things they couldn’t make with traditional methods. Every week we learn about new ways in which people from across society are capitalising on the technology to realise their ideas and enrich people’s lives. Our exhibition aims to shine a light on the latest developments and discuss where the technology may take us in future.”

3D: printing the future will take visitors on a journey through three key sectors in which the technology is driving innovation – industry, medicine and small-scale projects and businesses.

Stories featured in the exhibition will include:

- The new ways in which the medical industry is researching 3D printing to fix our bodies by creating replacement parts, from teeth to ears and even simple organs.

- A glimpse into a medical future where doctors may be able to use 3D printing technology to create tablets that can be tailored to each patient’s needs.

- How engineers are using 3D printing to create lighter and more efficient parts for aeroplanes and space probes – potentially saving airlines costs for fuel and materials.

- Carpenter Richard Van As and prop-maker Ivan Owen collaborated 10,000 miles apart to make a 3D printed mechanical hand, following an accident in which Van As lost four fingers. They made the designs for the “Robohand” freely available to anyone online; it has been downloaded more than 27,000 times from MakerBot’s Thingiverse.com.

- An artwork - Inversive Embodiment by Tobias Klein – a sculptural piece printed in nylon using data from MRI scans of Tobias Klein’s own body and the iconic structure of St.

Paul’s Cathedral.

Paul’s Cathedral.

The exhibition will also feature a number of miniature 3D printed figures created from 3D scans of visitors who took part in workshops at the museum during the summer holidays. These workshops were part of a whole summer of 3D themed activities at the Science Museum between 25 July and 1 September.

3D: printing the future is a free exhibition and will run in the Antenna gallery at the Science Museum for 9 months from 9 October 2013.

The exhibition is supported by Principal Funder EADS, Major Funders Renishaw, the Engineering and Physical Science Research Council (EPRSC) and the Additive Manufacturing & 3D Printing Research Group (3DPRG) based at The University of Nottingham.

Science Museum

Striving to be the best place in the world for people to enjoy science, the Science Museum's world-class collection forms an enduring record of scientific, technological and medical achievements from across the globe.

Museum profile

Location

London, United Kingdom

Founded in

1857

London Science Museum unveils the future of 3D printing

Theme of the day

- home

- Technology

October 10, 2013, 10:51 am Print

Among the advantages of 3D printing, there is less damage to the environment compared to industrial production, lower energy consumption, less financial and human resource consumption.

- You will also be interested >

-

Consequences of missile strikes: internet outages observed in three Ukrainian cities 05.

12 15:42

12 15:42 -

5,000-year-old owl plaques may be ancient children's toys 05.12 14:36

-

Ukrainian specialists created a website to search for places to work with light and the Internet 05.12 11:28

-

Winter is on the doorstep: three ways to defrost the windshield that you should not resort to 04.

12 04:00

12 04:00 -

Ukrainian discovered a giant exoplanet that surprised researchers 02.12 19:05

-

Tesla introduced a new generation of its trucks 02.12 13:38

-

"James Webb" took a picture of the clouds on the largest moon of Saturn 02.

12 13:16

12 13:16 -

Actual now: tips to help you choose a power bank for your laptop 02.12 09:00

-

Scientists recreate the appearance of an ancient woman with a fatal disease 01.12 17:41

-

Magnetic storms in December: dangerous days forecast 01.

12 14:15

12 14:15 -

Amazon will provide Ukraine with $75 million in support 01.12 13:36

-

Musk said that Apple did not intend to remove Twitter from the app store 01.12 13:07

-

Latest news

- U.S. focused on Ukraine returning territories seized after Feb. 24 - Blinken 11:41

- Export to the EU: Ukrainian suppliers have problems due to sanctions 11:35

- The legendary ex-football player of Barcelona got into a fight with a fan at the 2022 World Cup in Qatar 11:31

- Now you need to be patient: Zelensky explained why Ukrainian journalists cannot communicate with the president 11:12

- The leader of Dnipro-1 refused to renew the contract with the club and intends to move to Europe 11:09

All news

Welcome! Registration Password recovery Log in to be able to comment on content Register to be able to comment on materials Enter the email address you registered with and a password will be sent to it

Forgot your password? To come in

The password can contain uppercase and lowercase Latin letters, as well as numbers The entered e-mail contains errors

Register

Name and surname must consist of letters of the Latin alphabet or Cyrillic The entered e-mail contains errors This email already exists The First and last name field has no errors Email field has no errors

Remind password

The e-mail entered contains errors

No account? Register! Already registered? Sign in! Don't have an account? Register!

Beyond the realm of 3D printing: A 3D printed mammoth in a museum.

Application

Subscribe author

Subscribe

Don't want

16

Article applies to printers:

UP Plus 2 UP! miniWe would like to start the 'Beyond the 3D Printing Area' column with the first article, which answers the main user question: 'Is the size of the printable model limited by the printable area of the 3D printer?'

National Taiwan Museum of Science and Technology (NMST) invited Go Hot Technologies (Tiertime and UP Printer's representative in Taiwan) to participate in Printed Collection Journey as an exclusive 3D printing partner. The essence of the proposal was to make a realistic 3D model of a prehistoric mammoth from the Ice Age using Tiertime's flagship 3D printer - UP Plus 2.

As a result, the exhibit received general recognition from visitors and became the highlight of the exhibition. In this way, the museum manages to attract more people to science education by reproducing and showing extinct animal species in three-dimensional format.

In this way, the museum manages to attract more people to science education by reproducing and showing extinct animal species in three-dimensional format.

The Museum's 'Printed Collections Journey' exhibition first took place in early 2014 to showcase the evolution of 3D printing technologies. The museum curator proposed the idea of 3D printing a mammoth as a demonstration of the technology's capabilities and to associate 3D printing with the "Mammoth Exhibition" of that period. “If all exhibitions are based on the history of the past, then we must look to the future,” says the director of Journey Through Printed Collections. Thus, thanks to the cooperation with Go Hot Technologies, the museum was able to get a replica of a prehistoric mammoth, which was made using Tiertime's flagship desktop 3D printer model - UP Plus 2.

But when translating the idea into reality, NMNT employees had to solve a number of technological problems.

Model size

The first problem was the difficulty of printing a mammoth, about 1 x 1 x 1 m in size on the UP Plus 2 printer with a working area of 14 x 14 x 13. 5 cm. To solve it, the entire model had to be divided into 197 parts. “The horizontality, verticality of the walls of products and the accuracy of manufacturing parts are of great importance. Even a small deviation of one part can lead to serious assembly inconsistencies.” says the museum's 3D designer.

5 cm. To solve it, the entire model had to be divided into 197 parts. “The horizontality, verticality of the walls of products and the accuracy of manufacturing parts are of great importance. Even a small deviation of one part can lead to serious assembly inconsistencies.” says the museum's 3D designer.

The choice of HMHT designers for UP Plus 2 was influenced by two things:

- high surface quality, eliminating the need for post-processing of finished parts;

- a small tolerance for axis deviations, which affects the quality of parts joining during final assembly.

Production speed

The second task facing HMNT is to reduce the time of model verification and the time of its printing. It was solved thanks to the convenience and stability of UP Plus 2. “Printing can be done with a single keystroke. The model is formed quickly and verified in the same way, in case of a satisfactory design check. At the same time, modeling errors (if any) can be corrected in the shortest possible time, ”says a museum employee. What's more, UP Plus 2 automatically generates supports, eliminating the hassle of printing overhanging parts. “The UP Plus 2 also has excellent long-term print stability and a very low failure rate. This technical advantage is very important in achieving the goals of increasing efficiency and reducing print times,” added the worker.

At the same time, modeling errors (if any) can be corrected in the shortest possible time, ”says a museum employee. What's more, UP Plus 2 automatically generates supports, eliminating the hassle of printing overhanging parts. “The UP Plus 2 also has excellent long-term print stability and a very low failure rate. This technical advantage is very important in achieving the goals of increasing efficiency and reducing print times,” added the worker.

In addition, UP Plus 2 produces virtually no production waste, which is also in line with the Museum's commitment to environmental protection.

Since the Journey Through Printed Collections exhibition, the reproduction of the prehistoric mammoth has become very popular and famous. “We came to understand that 3D printing can be applied not only in science and technology. Production methods are changing, soon digital technologies will penetrate much deeper into our lives. Things from our imagination can be easily printed, which speeds up the implementation of any concept. Such a concept will lead the consumer market and bring it to a new level. The popularization of science and education must be adjusted to educate the next generation so as to embrace the revolutionary advances in the digital age,” said the museum curator.

Such a concept will lead the consumer market and bring it to a new level. The popularization of science and education must be adjusted to educate the next generation so as to embrace the revolutionary advances in the digital age,” said the museum curator.

Follow author

Follow

Don't want

16

Article comments

More interesting articles

3

Subscribe to the author

Subscribe

Don't want

(Photo: University of Basel, Christian Flierl)

Using additive manufacturing...

Read more

3

Subscribe to the author

Subscribe

Don't want to

Some projects surprise not with the complexity of execution, but, on the contrary, with simplicity.

.jpg)