Longer sla 3d printer

LONGER Orange 10 Resin 3D Printer - LONGER 3D – LONGER

$99.99

$119.99

【SLA 3D Printer】Entry-level UV...

US - $99.99 USDEU - $99.99 USDOther Region - $99.99 USD

US

EU

Other Region

Tags: LCD , Orange 10 , Resin

| MODEL | Orange 10 |

|---|---|

| Printing Technology | LCD Stereolithography |

| Printed Size | 98*55*140mm (3. |

| LCD Resolution | 854*480, 115µm |

| Z Axis Resolution | 10µm |

| Printing Speed | up to 30mm/h |

| Lighting Sources | UV Matrix 405nm LED |

| Slicing Software | Longerware / Chitubox /Lychee |

| Connection | TF Card |

| Touch Screen | 2.8 Inch Color Touch Screen |

| Power Supply | Input: AC100-240V, 50/60Hz, 1.6A; Output: DC12V 5A |

| Printer Size | 170*170*360mm |

| Package Size | 220*220*550mm |

| Net Weight | 6. 5KGS 5KGS |

| Gross Weight | 7KGS |

| Printing Material | 405nm UV Resin, Standard Resin, Castable Resin, Dental Resin, etc |

Upgraded UV-LED Module, provide special optical path design, uniform distribution of energy, both contribute to enhance prototype precision, you can get a better printing result.

Resin Flow Back DesignThe Orange 10 is with declined built plate which will facilitates the resin flow back to the resin vat. And this design could prevent the resin is dripping out from the plate for recycle use.

Full Touch Color ScreenOrange 10 is equipped with 2.8-inch colorful touch screen, Easy to use the full-color touch screen, easy to select file printing and preview the printing status real-time.

The printing size is 3.86 x 2.17x 5.5 inch,which is designed accordding to the market survey, can meets the needs of more than 90% customers, especially suitable for teaching, amateurs, designer and artists etc.

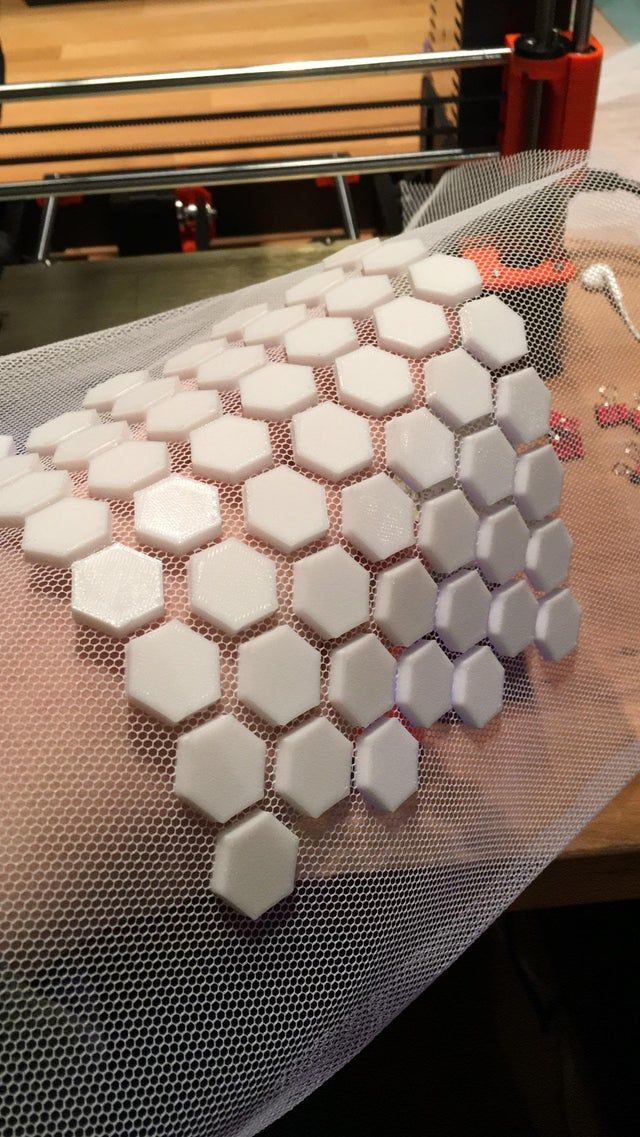

Smart Support and Fast SlicingAutomatically detect suspended parts with one button and add cross-linked grid support, which is more stable, to increase the success rate of complex models printing. And Orange 10 is also compatible with Chitubox.

High Temperature WarningOrange 10 is equipped with temperature detective, when the UV LED temperature is abnormal, it will be auto pause, and resume print after back to normal, provide a safe printing environment and save materials.

LONGER - 3D Printers & Laser Engravers [Christmas Sale] – LONGER

LONGER - 3D Printers & Laser Engravers [Christmas Sale] – LONGER | Best 3D Printers & Laser EngraversBEST 3D PRINTERS

-66%

Orange 4K Resin 3D Printer [Christmas Sale]

$235. 99

99

$699.00

-17%

Orange 10 Resin 3D Printer [Christmas Sale]

$99.99

$119.99

-44%

Orange 30 Resin 3D Printer [Christmas Sale]

$149.99

$269.00

-10%

LK4 PRO FDM 3D Printer

$179.99

$199.99

-21%

Sold Out

LK1 FDM 3D Printer

$219.99

$279.00

-13%

Sold Out

LK4 FDM 3D Printer

$199.00

$229.00

BEST SELLING ACCESSORIES

-20%

Laser Rotary Roller

$79.99

$99.99

Longer 3D Printer Constant Temperature Enclosure

$109. 99

99

PEI Sheet, 3D Printer Heated Bed PEI Sticker, Pre-applied PEI Flex Magnetic Base for LK1/LK4/LK5 Pro FDM 3D Printer

$35.99

Sold Out

Air Assist Kits

$89.99

Honeycomb Working Table 11.8*7.8*0.86inch

$39.99

New Dual Blower Kit

$34.99

LATEST BLOGS & UPDATES

Longer Drawing Machine

by: LONGER 3D

Read more

Longer Fanducts for FDM 3D printers

by: LONGER 3D

Read more

Diode Laser Engraver (450 nm) vs CO2 Laser Engraver (1024 nm)

by: LONGER 3D

Read more

Step-Down Converters & Voltage Regulators

by: LONGER 3D

Read more

Air Assist Kit installation for Longer Ray5 10W

by: LONGER 3D

Read more

Item’s positioning on the printing bed

by: LONGER 3D

Read more

MKSLaser - Longer Ray5 Smartphone App

by: LONGER 3D

Read more

Printing Jerk calibration

by: LONGER 3D

Read more

Installing Octoprint on Laptop/Tablet for Longer 3D FDM printers

by: LONGER 3D

Read more

Longer Ray5 Laser Engraving, Carving and Cutting Applications

by: LONGER 3D

Read more

Longer Ray5 An Introduction to the Laser Engraving Technique

by: LONGER 3D

Read more

Longer Ray5 Laser Engraver – Technical Backgroud

by: LONGER 3D

Read more

Longer LK4 Pro & LK5 Pro – Upgrades by @Ciubecca

by: LONGER 3D

Read more

First Layer Calibration

by: LONGER 3D

Read more

Printing Flow Calibration

by: LONGER 3D

Read more

Bridging Printing

by: LONGER 3D

Read more

Printing Supports

by: LONGER 3D

Read more

Nozzle Size Comparing

by: LONGER 3D

Read more

Tolerance Test for Joints

by: LONGER 3D

Read more

Blobs in 3D Printing

by: LONGER 3D

Read more

Cyclonic Separator

by: LONGER 3D

Read more

Transform a 2D image into a 3D model

by: LONGER 3D

Read more

Transform a 3D model into a 2D image

by: LONGER 3D

Read more

How to upgrade LONGER LK4 PRO into a mini-LK5 PRO

by: LONGER 3D

Read more

How printing temperature calibration on FDM printers

by: LONGER 3D

Read more

FDM printer bridging printing tutorial

by: LONGER 3D

Read more

Welcome to my personal presentation

What our Clients say

our news

SIGN UP FOR LATEST NEWS

Which 3D printer to choose for home and hobby use

A few years ago, 3D printers were bulky industrial machines, but now 3D printing is becoming more accessible for home use. When buying their first printer, many are disappointed. This may be due to the unsatisfactory quality of the resulting models or the complex setup and maintenance of the 3D printer.

When buying their first printer, many are disappointed. This may be due to the unsatisfactory quality of the resulting models or the complex setup and maintenance of the 3D printer.

In the reviews that are found on the Internet, printers are often shown after a lot of upgrades or a long selection of settings for printing. This is not at all the result that a beginner who first got acquainted with 3D printing will get. nine0003

In order not to be disappointed, before buying, you need to understand which model is suitable for your tasks. First of all, it is worth deciding what the printer will be used for. What is the main property that finished products should have? What is more important, the physical properties of the model or the ideal surface and detail? Not only the model depends on this, but also the technology by which the 3D printer will work.

Which technology to choose? FDM or LCD?

If you need to make a small detailed figurine with a perfectly smooth surface, you should pay attention to models that work on LCD technology (LCD works on a principle similar to DLP - Digital Light Processing or “digital light processing”). nine0003

nine0003

LCD prints using a photopolymer resin that cures under UV light. This makes it possible to produce without deformation, even small and thin products that cannot be manufactured using FDM technology.

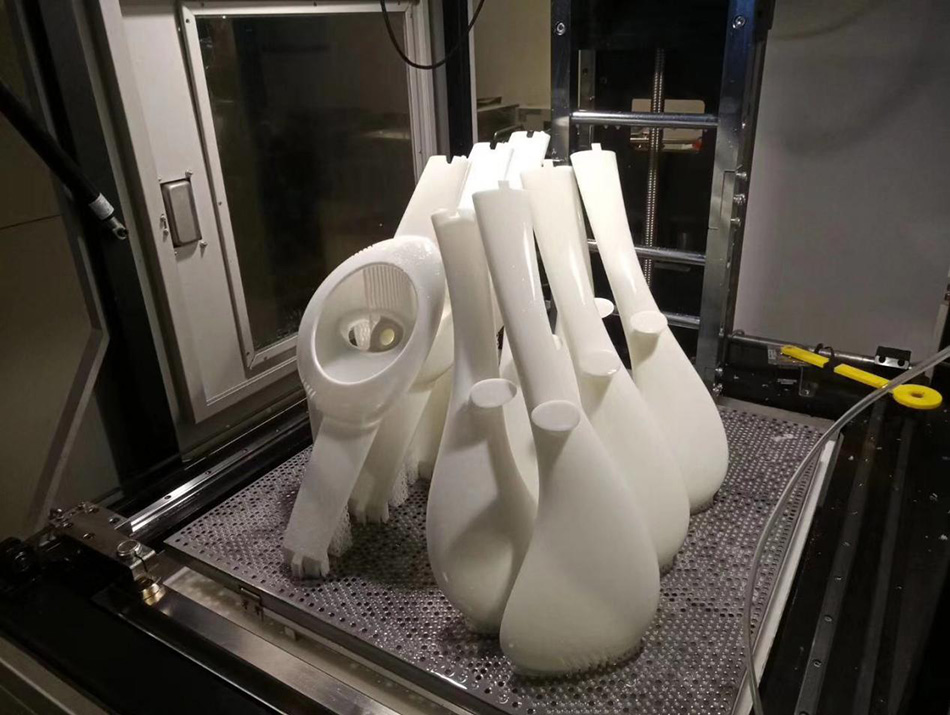

Resin model

Now on sale there are many photopolymer resins with different properties. A few years ago the choice was not great. Basically, finished products were not strong enough for use in functional models. Now engineering resins have begun to appear on sale. Products from them are not inferior in strength to models made using FDM technology from ABS or even nylon. nine0022If it is necessary to produce large products with different properties, or the tasks will be very diverse, then the choice is with FDM technology. But it is important to understand that finished products will not have a perfectly smooth surface. Of course, you can polish the model, but this is additional time and labor costs.

FDM technology builds a model using molten plastic filament, which is fed from the print head.

The print head (extruder) “grows” the model layer by layer on the printing table. nine0003

FDM Models

FDM technology became widespread much earlier than DLP. Thanks to this, a wide variety of 3D printers and consumables for them has appeared. You can find many decorative plastics that mimic various materials, or engineering plastics for making functional models or mock-ups.

Choosing an LCD printer

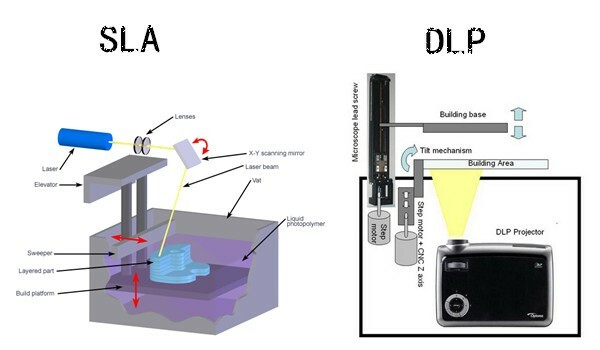

Photopolymer printers work on one of 3 technologies - DLP, LCD or SLA. nine0003

As home printers, devices based on LCD technology are usually used due to their availability and low price.

Printer design

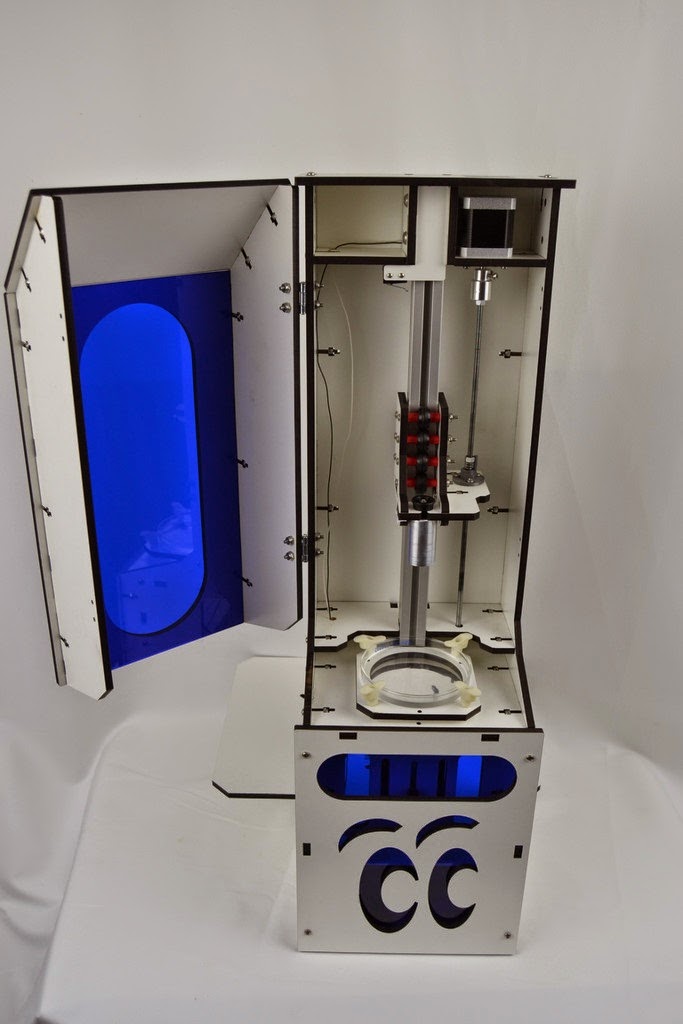

SLA technology appeared the very first among photopolymer printers. With the help of a point-focused beam, the desired areas of the resin are gradually illuminated. This is repeated layer by layer.

How SLA 9 works0018

Since the surface of the model is perfectly smooth, SLA has become used in the jewelry and dental industries.

Pros:

Cons:

DLP technology appeared later than SLA, but it is very similar to it. The main difference is that the light source is not a focused beam, but a projector. This made it possible to illuminate the entire layer at once, which significantly accelerated the production of models. The quality of the surface was slightly inferior to SLA, but modern DLP printers, in terms of the quality of models, are almost as good as SLA technology. nine0003

How DLP works

Pros:

Faster production of models due to the illumination of the entire layer

Consumables are slightly cheaper than SLA

High surface quality (although may be inferior to SLA)

Cons:

LCD technology is the youngest of all. The DLP principle is taken as a basis, but an LCD display is used as a matrix or illumination pattern.

LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

How the LCD printer works

Pros:

small cost

Cheap parts

Cons:

Low accuracy compared to SLA and DLP (for jewelers and dentists, the quality of LSD prints may not be enough, although more and more accurate models appear with the development of technology) nine0003

Possible stray light

The quality of models may decrease at the edges of the printable area (this can be corrected programmatically)

Resins that are used as a consumable for photopolymer printing can smell strongly and unpleasantly during operation. Try to use the printer in a well-ventilated area, or choose a printer with a sealed cabinet and filter.

nine0003

When choosing an LCD printer, pay special attention to the rigidity and positioning accuracy of the platform along the Z axis. If there are poor quality guides along the Z axis or even a slight play, then the surface quality of the finished model may turn out to be sloppy or the model will turn out to be unevenly striped.

Rating of the best LCD 3D printers for home

Anycubic Photon Mono

This is an LCD printer with a matrix that allows you to increase the speed and accuracy of printing. Anycubic Photon Mono will be a good helper for hobbyists and modellers. nine0003

Anycubic Photon Mono SE

Anycubic Photon Mono SE has an unusual parallel light source. This minimizes distortion at the edges of the printable area. You can effectively use the entire working area of the machine and produce many small models at a time.

Phrozen Sonic Mini 4K

Model with high resolution LCD display and large print area.

The monochrome display transmits UV rays better and allows you to print much faster than similar devices with a conventional display. The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task. nine0003

Wanhao GR1

Wanhao GR1 has high precision and large print area (140x78x200mm). The manufacturer tried to reduce distortion at the edges of the display, this allows you to make the most of the entire work area. High precision and large print area make Wanhao GR1 not only for hobby use, but also for production.

Anycubic Photon Zero

Small and very budgetary LCD device. Its resolution and small working area (total 97x54x150 mm) is enough for printing small miniatures, figurines or small engineering models. Anycubic Photon Zero is a good choice for beginners who want to get into photopolymer printing without spending a lot of money.

Choosing an FDM printer

If you plan to produce large and diverse functional models or experiment, a 3D printer that prints using FDM technology is an excellent choice.

First, decide on the size of the printable area and the properties that the finished model should have. After all, some materials require a closed chamber or good airflow to work. nine0019

Some printer models can be “upgraded” in the future. For example, if necessary, buy spare parts for a closed case, put a nozzle of a different diameter, or change the thermal barrier to an all-metal one. But not all manufacturers provide for the possibility of such upgrades.

Printer design

Despite the same principle of operation, there are several different mechanics, which have their pros and cons. nine0003

Kinematics “Prusa” (Prusa)

Perhaps the most popular kinematics among home FDM devices. Mainly due to its simplicity and low cost. The main feature is the table that moves along the Y axis, while the extruder moves along the rest of the axes. Because of this, such kinematics was nicknamed “dragstol”.

Prusa kinematics

nine0056 Pros:

Cons:

Slow print speeds.

A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds.

Some models have design flaws (for example, insufficient frame rigidity), they can be fixed, but for this you have to be a little inventor. Or find a ready-made solution on the Internet. nine0003

This category also includes 3D printers with console kinematics. The same prusa, only halved. Because of this, the frame is less rigid, but the printer itself is more compact.

Kinematics Ultimaker

The extruder moves along the X-Y axes, and the table only along the Z axis. All motors are trying to be fixed on the body to lighten the weight of moving mechanisms, thanks to which it is possible to achieve high print quality at high speeds. nine0003

Ultimaker kinematic diagram

Pros:

Cons:

H-BOT or Core-XY

These are 2 similar but more complex kinematics - the table moves only along the Z axis, and the extruder along the X-Y.

But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

Example Core-XY kinematics

Pros:

High print quality

High print speeds without loss of quality.

Can be easily closed completely

Cons:

nine0056 MakerBot Kinematics

Similar to Ultimaker kinematics, but one of the motors is located on the Y or X axis carriage.

Pros:

Cons:

Delta

Deltas do not have the usual XYZ axes. There are 3 columns in the deltas, along which the carriages move, and the position of the extruder in space is calculated using a complex formula. The table is usually statically fixed to the body. nine0003

Delta printer example

Pros:

Cons:

Nuances of choosing an FDM 3D printer

In addition to kinematics, when choosing a printer, it is important to consider some design features.

One or two extruders?

Two extruders can be used for dual color printing, but most commonly the second extruder is used for solvent support printing. If you need to print complex parts with internal cavities, then you should choose a dual extruder printer. nine0003

Closed or open printer?

Printing of functional models and parts uses plastic, which usually requires a closed chamber. If you plan to print functional prototypes or various models, you should look at printers with a closed chamber.

Bowden or direct?

There are 2 types of material supply to the print head of the printer - bowden and direct. nine0003

In a bowden, the feed mechanism motor is located on the printer body. This allows you to reduce the weight of the extruder and print at higher speeds without losing quality. But because of the long tube, printing with very soft plastics can be problematic.

Bowden feed pattern

In direct feeding, the motor and feed mechanism are located on the extruder. This increases the weight of the print head, but allows you to print with any kind of plastics. nine0003

Direct feeding scheme

Heated table or not?

The heating of the table improves the adhesion of the first layer of the model. And engineering plastics cannot be printed without a heated table.

Many manufacturers add useful additional features. They do not affect the quality of the print, but save time and nerves. The most useful additional functions are the filament presence sensor and remembering the print location after a power outage. nine0003

Filament sensor.

It will automatically pause printing if the plastic runs out. When there is a little plastic left on the spool, this feature will allow you not to stand over the guard printer until the old spool runs out in order to have time to push in a new bar “on the go”.

Power outage protection.

Remembering where to print when the power goes out can save you a lot of nerves when printing large models. You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage. nine0003

There are also many extras. features that make using the printer more comfortable. For example, automatic calibration, touch screen, Wi-Fi and others.

Rating of the best FDM 3D printers for home

Anycubic Mega Zero 2.0

Inexpensive model with Pryusha kinematics. Good for getting started with 3D printing without a big investment. Despite the low cost, Anycubic Mega Zero 2.0 has a heated table and a resume function after a power outage. Thanks to direct feed, printing with soft materials should not be difficult.

nine0003

Creality3D Ender 3 Pro

A very popular device due to its low price. But despite this, the Ender 3 Pro has a heated table and a decent print area. Can be sold assembled or as a DIY kit.

Flash Forge Finder

Small home appliance intended for children or educational institutions. The Finder doesn't have a heated table, but it does have a calibration assistant, a Wi-Fi module, and other additional features that make getting to know it a lot easier. All moving and heated elements are hidden as much as possible in the case so that the child cannot get burned. nine0003

Wanhao Duplicator 6 Plus

Wanhao Duplicator 6 Plus was based on Ultimaker kinematics, but instead of bowden feed, they made direct. Because of this, it will not be possible to print super fast, without quality loss, but there will be no problems with printing with soft types of plastics. There are 2 trim levels - with a closed case and without.

Flashforge Dreamer

The Dreamer is a closed body dual extruder printer with MakerBot kinematics. Thanks to this, he can cope with printing models of any complexity. Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials. nine0003

FlyingBear Ghost 5

Most commonly sold as a kit (assembly kit). Assembly usually does not cause any great difficulties, even for people far from electronics or mechanics. Flying Bear is equipped with a filament sensor, a function to resume printing after a power outage and Wi-Fi connectivity.

The Flying Bear makes a great first printer for the novice user who is ready to build their own printer. nine0003

Totals

In order for the printer not to become a useless toy, you should clearly understand what it is for.

For a fan of miniatures or detailed figurines, a photopolymer printer is a good choice.

A small work area is more than offset by the detail that cannot be obtained using other technologies.

For an engineer or a fan of experiments, an FDM machine with a closed chamber and two extruders is well suited. This will allow you not to limit yourself in the choice of plastics and comfortably experiment with any materials. nine0003

For a beginner who has not yet decided whether he needs 3D printing, you can opt for inexpensive machines with squishy kinematics. Due to their great popularity, you can find a lot of upgrades and reviews on them. In the future, it will be possible to modify the printer for specific tasks or change it to a more suitable model.

For a child, safety is paramount. As the first children's printer, models without a heated bed are suitable, in which the main emphasis is on printing with safe PLA plastic. Or models in which all moving and heating mechanisms are hidden in the case. nine0003

A 3D printer is a handy tool, and whether it brings joy or frustration depends on the user.

3D Printing DLP LCD SLA Photopolymer - Guide to Stereolithography

Stereolithography (SLA) is an additive technology, usually related to 3D printing, which allows, with the help of a light source, layer by layer, through selective exposure to As a result of photopolymerization, transform liquid materials into solid objects. SLA is widely used to create models, prototypes, templates and finished parts in a number of industries - in industrial production, in dentistry, in jewelry, in modeling, in education. nine0003

In this comprehensive resource, you will learn about the different SLA systems, the different materials and their characteristics, and how SLA compares to other technologies available on the market.

A Brief History

The SLA process was first demonstrated in the early 1970s when Japanese researcher Dr. Hideo Kodama invented the modern layer-by-layer approach to stereolithography by using ultraviolet light to cure photosensitive polymers.

The term "stereolithography" itself was coined by Charles (Chuck) W. Hull, who patented the technology in 1986 and for its commercial promotion founded the company 3D Systems. Hull described the technique as creating three-dimensional objects by sequentially printing thin layers from bottom to top with a material that is cured with ultraviolet light. The definition was later extended to include any material capable of curing and changing its physical properties.

Today, 3D printing and additive manufacturing refers to many different processes that differ in layer methods, materials and hardware. nine0003

The patent began to expire towards the end of the 2000s, at which time desktop 3D printers appeared on the scene and expanded access to the technology, offering to start with the introduction of fusing deposition (FDM) to desktop platforms. Although this low-cost, extrusion-based technology has contributed to the widespread adoption of 3D printing, the quality of the resulting parts has limited its use, as repeatable and high-precision results have proven to be critical in professional applications.

nine0003

Prototypes of the Form 1, the first desktop SLA 3D printer

The SLA soon followed FDM's path to the desktop, with the technology appropriately modified by Formlabs in 2011. There was hope that high-resolution printing, previously only possible on industrial systems, would come in a much smaller form factor and at a more affordable price, allowing for a wide range of materials. These capabilities have made 3D printing accessible to a range of applications, including engineering, consumer goods design and manufacturing, dentistry, and jewelry. nine0003

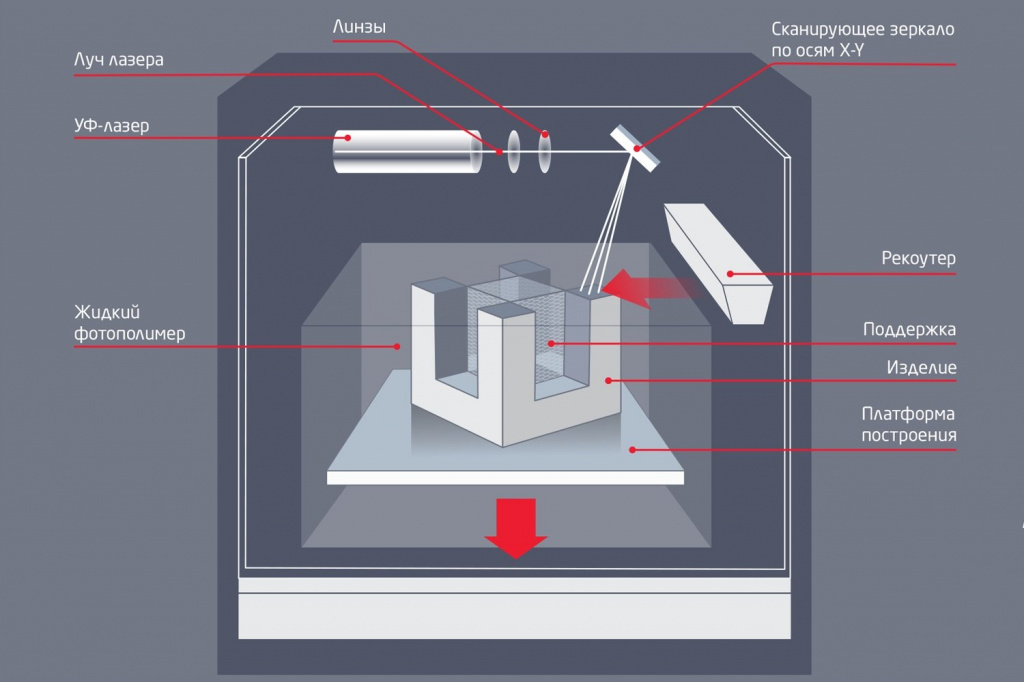

SLA systems

SLA technology belongs to the family of additive bath photopolymerization technologies. Accordingly, SLA printers are built around this principle: a light source (an ultraviolet laser or a projector) is used to turn a liquid polymer into a hardened plastic. The main physical difference between the devices is in the configuration of the main components, such as the light source, work platform, and resin container.

How stereolithography works

Right-Side Up SLA Process

Right-Side Up SLA process units are built around a large liquid photopolymer tank and work platform. The ultraviolet laser is focused on the polymer surface, passing along the profile of the 3D model. Then the platform is lowered a distance equal to the thickness of one layer, and the spatula with photopolymer passes over the bath to replenish it with material. Layers are built one on top of the other until the part is complete. nine0003

This approach is used mainly in large industrial systems and was the standard for stereolithography until the advent of desktop solutions. Its advantages lie in the ability to create very large 3D objects, low stress on the part during the printing process, high detail and clarity.

Due to the large plant size, maintenance requirements and volume of material, normal SLA systems require a large initial investment and are expensive to operate.

The entire print area must be filled with resin, often 10-100 liters or more, resulting in a lot of maintenance, filtering and material replacement. Such machines are very sensitive to their position in space, any misalignment can cause the paddle with the polymer to overturn the part, i.e. to a fatal print failure. nine0003

Inverted (Upside-Down) SLA process

As the name suggests, the inverted stereolithography process is the reverse process. This method uses a tank with a transparent bottom and a non-adhesive (to which it does not stick) surface, which acts as a substrate for the curable liquid polymer, allowing free separation from the newly created layer. The platform is immersed in the polymer tank so that there is a space to the bottom equal to the thickness of the layer or the last completed layer. nine0003

Through a system of mirrors, an ultraviolet laser beam is directed by two mirror galvanometers to a point with the desired coordinates, focusing from below, through the bottom of the bath, onto the curable photopolymer layer.

As a result of the vertical movement of the platform and the horizontal movement of the tank, the cured layer is separated from the bottom of the tank, and the platform rises, leaving a new layer of resin underneath. The process is repeated until the print is complete. In more advanced systems, the tank is heated to provide temperature control, and a paddle is run along the tank under the new layer to circulate the polymer and remove any semi-cured residue. nine0003

The advantage of this inverted approach is that the size of the created object can exceed the volume of the tank, since the apparatus only needs to have enough material to permanently cover the bottom of the bath. This typically facilitates maintenance, cleaning, material replacement, and significantly reduces machine size and cost, and allows SLA technology to be ported to desktop systems.

Inverted SLA systems have their own set of limitations. Due to the cohesive forces acting on the object as it separates from the tank surface, the working volume is limited and more and more support structures are needed to keep the part above the work platform.

Adhesion forces also limit the use of more ductile materials, with a Shore hardness of less than 70 A, as the support structures also become ductile. nine0003

About support structures

Both normal and inverted SLA systems in most cases, depending on the design, require the use of support structures.

In normal systems, these structures hold the parts in position, ensuring that the material is correctly placed on them, as well as resisting lateral pressure when the polymer blade moves. In inverted SLAs, supports are used to attach overhanging elements to the platform, preventing layers from separating under the influence of gravity and adhesion. nine0003

In both SLA systems, support structures are used to attach parts to the work platform.

Most programs create their own support structures during the preparation of 3D models, but manual adjustment may be required. After the printing process is completed, these supports must be removed and the object subjected to finishing.

Comparison of SLA systems

Desktop SLA Inverted

Industrial SLA Normal

Price

From $3500

$60,000 – $1,000,000+

Displacement

Up to 145 x 145 x 175 mm

Up to 1500 × 750 × 550 mm

Pros

Affordable

Easy to use

Cheap to maintain

Take up little space

Easy to change materialLarge displacement

High performanceCons

Medium displacement

Expensive in materials

Expensive equipment

Expensive maintenance

Operator requiredComparison between Formlabs desktop SLA printers and 3D Systems industrial SLA systems.

Materials

SLA 3D printers are tools, but it is materials that allow stereolithography to create a wide range of functional parts for various industries. In this section, we will look at the photopolymerization process and its raw materials, polymers, both in terms of their unique properties and in terms of various combinations for specific applications. nine0003

Polymerization process

Plastics are made up of long carbon chains. The shorter the chain, the less durable the plastic and the more fluid. A polymer is, in this case, a resin consisting of one or more (up to several thousand) short carbon chains. It has all the components of the final plastic, but is not yet completely polymerized. When such a resin is exposed to ultraviolet light, its carbon chains interlock, forming a longer and therefore stronger structure. After enough chains have reacted, a solid part is obtained. nine0003

Steps of the polymerization process

Let's take a closer look at the process.

The chains of monomers and oligomers in a polymer have active molecular groups at their ends. When UV radiation falls on the polymer, the photoinitiator molecule breaks into two parts, and the bond connecting them forms two very reactive radicals. These molecules donate reactive radicals to the active groups of monomer and oligomer chains, which in turn react with other active groups to form longer chains. As the chains lengthen and cross-links occur, the plastic begins to harden. The entire process of transition from liquid to highly polymerized solid state takes place in milliseconds. nine0003

Characteristics of polymers and plastics

Different polymers consist of different main and side groups - different combinations of long and short monomers, oligomers, photoinitiators and additives. This provides unique opportunities to create various formulas with a wide range of optical, mechanical and thermal properties - from clear transparent to colored plastics, from flexible to rigid, from viscous to heat resistant.

Photopolymer resin formulation

Component

Role

Monomers and oligomers

Polymer backbone, carbon chains that later form a solid.

Photoinitiator

Molecules that react when exposed to ultraviolet light to initiate a reaction. nine0003

Additives

Visual and functional additions such as pigments and inks.

Isotropy and anisotropy

Due to the layered nature of 3D printing technologies, in some cases the properties of the object created in this way differ depending on the direction to a certain extent - this is called anisotropy. For example, a 3D printed object may have different tensile strength or stiffness in the X, Y, and Z directions.

During SLA 3D printing, polymer components form covalent bonds. This provides high lateral strength, but the polymerization reaction is not brought to completion. The printing process is modulated in such a way that the layer is maintained in a semi-reacted state, which he calls "green". The green state differs from the fully cured state in one important way: there are still polymerizable groups on the surface that form covalent bonds with the subsequent layer. nine0003

When this subsequent layer cures, the groups of the previous layer are involved in the polymerization reaction, forming not only lateral covalent bonds, but also bonds with the previous layer. This means that at the molecular level, in terms of chemical bonds, there is no or almost no difference along the spatial axes. Any continuous object printed using SLA technology is isotropic.

With SLA printing, there is no difference along the spatial axes in terms of chemical bonds. Any continuous object printed using SLA technology is a continuous polymer network.

nine0003

Isotropy has both mechanical and optical advantages. Isotropic parts are ideal for prototyping as they reflect some of the properties of traditional injection molded thermoplastics and do not suffer from delamination and porosity. The formation of chemical bonds and the absence of visible layers within the object allow optically clear parts to be printed.

Post-curing

When the stereolithography process is completed, the printed part remains on the build platform in the aforementioned "green" state. Although it already has the final shape and appearance, the polymerization reaction is not completed, so that the mechanical and thermal properties are not yet fully formed. nine0003

UV SLA prints. UV curing completes the polymerization and stabilizes the mechanical properties. Photo: formlabs.com

Additional UV curing completes polymerization and stabilizes mechanical properties. This allows the part to achieve the highest possible strength and become more stable, which is especially important in the case of functional plastics for engineering, dentistry and jewelry.

For example, successful burnout in a printed mold requires post-cure, and flexible parts also become stronger after post-cure. nine0003

Thermoset and thermoplastics

Photopolymer resins are thermoset plastics - as opposed to thermoplastics. Sounds similar, but features and applications can vary significantly. The main physical difference is that thermoplastics can be repeatedly melted to a liquid state and cooled back to a solid in different geometries, while thermoset plastics remain permanently in a solid state after post-cure. nine0003

The polymers in thermoset plastics cross-link with each other during the post-cure process, forming virtually irreversible chemical bonds. In the case of the most common thermoset plastics, post-curing is carried out by appropriate irradiation, often under high pressure; in stereolithography, this process is excited by light with the participation of a photoinitiator. The thermoplastic granules soften and liquefy under the influence of temperature, and the process is completely reversible, since chemical bonds are not formed.

nine0003

SLA Materials by Application

Stereolithography materials are typically created for specific applications or industries. Due to the nature of the techniques and processes used, proprietary materials are usually of limited use in specific SLA systems. Below, we'll introduce Formlabs' selection of desktop SLA printer media.

Standard

Interchangeable camera made entirely of Standard polymers, including optically clear lenses. Photo: formlabs.com

Standard resins provide high resolution, fine detail and a smooth surface right out of the printer. While post-cure is recommended, it is not always required, making these resins ideal for rapid prototyping, product development, and general modeling.

Engineering

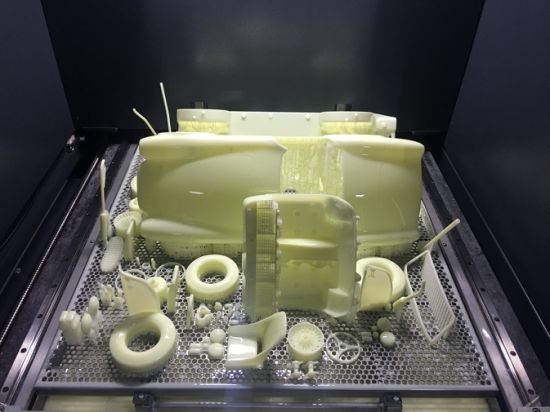

Objects printed with Engineering resins, including thermoforming and injection moulds, shoe insoles and consumer goods. Photo: formlabs.com

Engineering Polymers simulates a variety of molded plastics, helping planners and designers with concepts, prototypes, test pieces, and finished products.

With characteristics such as strength, wear resistance, flexibility or heat resistance, these plastics are used to create prefabricated and solid functional objects, touch surfaces, consumer goods.

Dental

Dental resin model, biocompatible dental implant printed on Form 2. Photo: formlabs.com

Dental materials allow dental laboratories and clinics to create a variety of personalized dental products on site. Such products are modeled according to the results of computed tomographic scanning of the patient's oral cavity. Specific applications include orthodontics, diagnostics, teaching models, as well as biocompatible items such as surgical instruments and drill guides.

Jewelry

Castable resin jewelry and finished ring. Photo: formlabs.com

SLA is ideal for prototyping and molding fine detail jewelry. Conventional modeling resins are recommended for prototyping to create low cost fittings and test pieces to match customer requirements before the part is cast.

Castable resins are designed directly for mold making, enabling jewelers and foundries to move from digital design to 3D printing straight away.

Experimental

Soap dish printed with Ceramic resin and finished for a particularly aesthetic look. Photo: formlabs.com

Different formulas of polymers with additives and composites open up new possibilities for creating experimental materials. The Ceramic polymer allows, after further processing, to obtain aesthetically looking objects that are indistinguishable from traditional ceramic. After firing, the printouts turn into pure ceramic, ready for glazing.

Benefits of a Desktop SLA Printer

To help you decide if the SLA process is right for you, we compare stereolithography with traditional manufacturing methods and other additive technologies.

High resolution and smooth surface

SLA technology immediately produces parts with a finished smooth surface.

It is ideal for applications that require a perfect finish and reduces production time as parts can be easily refinished, polished and painted if desired. nine0003

The usual way to determine the resolution of a 3D printer is to look at the layer height (vertical thickness). On the Form 2 printer, it can be set from 25 to 100 microns, taking into account speed and quality. For comparison: FDM and SLS printers have a characteristic layer thickness of 100 to 300 microns. But 100 micron parts printed on an FDM or SLS printer look different from SLA parts printed at the same resolution. SLA prints have a smoother surface immediately out of the printer due to the fact that the walls of the outer perimeter are smoother due to the interaction of each printed layer with the previous ones, which smooths out the ladder effect. Layers can often be seen in FDM printouts, while SLS has a grainy structure from the sintered powder. nine0003

Rooks printed at 100µ layer thickness on benchtop and industrial FDM, benchtop SLA (Form 2), industrial SLA and industrial SLS.

Photo: formlabs.com

The minimum possible detail is also less in the case of SLA: 140 microns from the laser spot for Form 2, 350 microns for industrial SLS printers, 250-800 microns from the nozzle of FDM machines.

Learn more about 3D printing resolution

Accuracy and repeatability

SLA printers can create precise, repeatable parts. This is especially important for functional applications such as design assemblies, jewelry molds, or scanned dental products. nine0003

The combination of the heated plastic tank and the enclosed space in which the print is made provides nearly identical conditions at every point. Greater accuracy is also due to the lower printing temperature compared to thermoplastic technologies that melt the raw material. Because SLA uses light rather than heat, the printing process occurs at nearly room temperature, and printed objects are free from thermal expansion and contraction artifacts. nine0003

In general, SLA print accuracy is between 50 and 200 microns, depending on size, resin, model geometry, and generated supports.

In recent tests on the Form 2, 95% of printouts had size deviations of 240 microns or less.

Design Freedom

SLA offers the greatest design freedom of any 3D printing technology. Depending on the geometry of the part, concave and convex elements can be made with an accuracy of 300 microns or better. This is especially important for complex applications such as sculptures with small elements and fine jewelry. nine0003

In the case of stereolithography, there is no need to adapt the model for 3D printing. Prototypes can be designed with production in mind. This ensures a seamless transition from prototype to traditional technologies such as machining or casting.

SLA printouts are easy to clean and finish. The internal ducts in the plastic are easily flushed out, allowing the creation of microchannels or cavities not possible with any other 3D printing process.

Micro channels for flow and mixing of liquids, printed with Standard Clear plastic.

Photo: formlabs.com

Rapid prototyping with rapid iterations

Stereolithography helps engineers and designers quickly improve the look and feel of a project. Mechanisms and designs can be checked and modified without problems within a few days, which greatly helps to speed up development and avoid expensive tooling.

Successive iterations of Sutrue, an automated surgical instrument prototyped on Formlabs SLA printers. Photo: formlabs.com

Desktop SLAs are highly scalable, dramatically increasing performance and reducing user wait times. Teams working in different locations can work independently on the same project, sharing physical objects through digital channels and printing them on the same printers. nine0003

Functional parts for a wide range of applications

SLA plastics offer a wide range of features that are suitable for applications from engineering to dentistry and jewelry. Materials can be heat-resistant, biocompatible, optically pure, and meet the parameters of engineering plastics.

The chemical bonds formed between the layers of the SLA object allow the creation of completely dense, water and air tight parts that are isotropic, that is, have equal strength in all directions. nine0003

Pricing and Benefits

Accurate prototypes, fast iterations, and early detection of bugs all lead to a better end result and reduce risk when moving from prototyping to production. In industry, SLA technology reduces the need for expensive machining by making small batches and customized products available. This also applies to the construction of bridges, and the manufacture of jewelry or dental products.

Industrial SLA printers start at $80,000 and require trained personnel and a mandatory service contract. SLA desktop printers offer the quality and functionality of industrial systems while being easy to use, in a small footprint. They cost from $3500. nine0003

Compared to outsourced ordering or traditional machining, home 3D printing reduces costs by 50-90% considering materials, tanks, accessories, maintenance, labor and wear.

In the case of desktop SLAs, the characteristic time for obtaining a result is hours, not days or weeks, as when ordering the same project on the side.

Technology Comparison

There are three common plastic 3D printing technologies today. In layer-by-layer deposition (FDM), thermoplastic filaments are laid out on a work surface, in stereolithography (SLA), a liquid photopolymer resin hardens under the influence of a light source, in selective laser sintering (SLS), a powdered material is sintered by a laser. nine0003

Each technology has its own advantages and disadvantages, so each is recommended for different applications.

FDM

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Pros

nine0533Fast

Cheap systems and materialsGreat price

High precision

Smooth surface

For many functional applicationsRobust functional parts

Design freedom

No support structures requiredCons

Low accuracy

Fine detail

Design restrictionsLimited modeling space

Long-term UV sensitivityExpensive equipment

Rough surface

Material restrictionsApplications

nine0532 Cheap Rapid Prototyping

Functional Prototyping

Dental Solutions

Jewelry Prototyping and Molding

ModelingFunctional prototyping

Short-term, intermediate, custom manufacturingPrice

nine0532 Mid-range desktop printers from $2000, industrial systems from $20,000.

Professional desktop printers from $2000, large scale industrial systems from $80,000.

Industrial printers - from $100,000.

Printing process

Now that we know the theory behind stereolithography, let's look at the printing process on a desktop SLA printer.

Project

Use a regular CAD program to design your model and export the result in a 3D printable format. Photo: formlabs.com

As with any other 3D printing process, SLA starts with 3D modeling, the mathematical representation of a 3D surface. This can be done with a CAD program or based on 3D scan data. The model is then exported to a .STL or .OBJ file that is understood by the program that prepares the data for the 3D printer.

Preparation

Prepare your model in SLA 3D printer software. Photo: formlabs.com

Each SLA printer comes with a program for setting print parameters and cutting the digital model into layers for printing.

In the settings, you can change the orientation of the object, support structures, layer thickness and material. When setup is complete, the software sends instructions to the printer wirelessly or via cable.

Printing

Stereolithographic printing process. Photo: formlabs.com

After a quick confirmation of the correct settings, the printing process begins, and the printer can be left to itself until the job is completed. In printers with a cartridge system, material is added automatically, in other cases and with large volumes, this may require intervention. nine0003

Cleaning

Clean printout with isopropyl alcohol (IPA) to remove uncured plastic. Photo: formlabs.com

When the printing process is complete, the build platform can be removed from the printer. The printout should be cleaned with isopropyl alcohol (IPA) to remove uncured plastic from the surface.

Hardening

Post-harden part to improve material quality.

Learn more