3D printer welder

Researchers Develop a Low-Cost Metal 3D Printer Using MIG Welding - 3DPrint.com

Metal 3D printing, although it has gone down in cost, is still quite expensive. This limits access to the technology for small and medium-sized businesses, meaning that many applications go untried. In a paper entitled “Design and Development of a Low-Cost 3D Metal Printer,” a group of researchers discuss how they created a low-cost metal 3D printer that utilizes metal inert gas (MIG) welding and an open source microcontroller to fabricate parts.

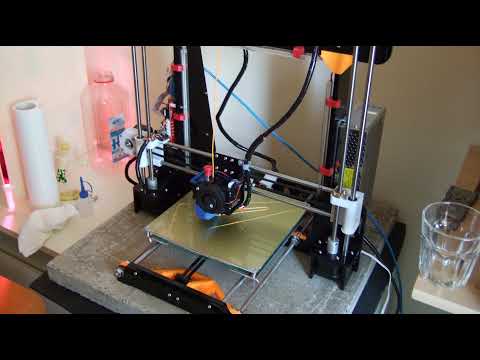

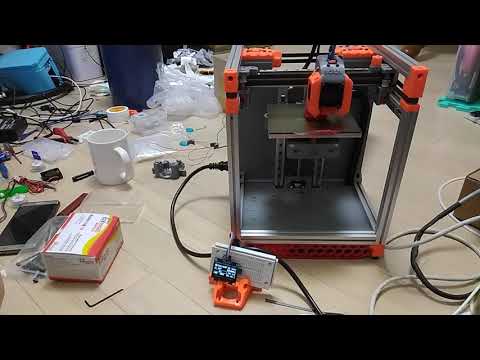

The researchers took the design of their 3D printer from a Prusa i3 system and used several off-the-shelf components to build it.

“The components consist in developing 3D metal printer machine are; a pair of bearing holder and motor bracket, motor casing, shaft holder, ball screw, coupling, limit switch, linear bearing, stepper motor, polyurethane cylinder, polytetrafluorethylane (PTFE) plastic cylinder and various fastener,” they explain.

![]()

A MIG welding machine was used to supply the material and the energy to melt the material. The movement of the printer and the translation of command from the printer’s server to the host computer was controlled by firmware provided with an Arduino microcontroller. The cost of the entire system was about RM 3496, which translates to roughly $840, much more affordable than a typical metal 3D printer.

“In order to ensure the metal print is connected during operations, the MIG welding was set to switch on and off automatically,” the researchers continue. “The shielding gas was set to flow before the printing process starts. The welding torch was placed under the fixture design perpendicular to the bed to build the surface. The distance between the bed surface and nozzle was adjusted to about 6 mm by leveling the height of the welding torch.”

The MIG welding machine begins building a part layer by layer, from bottom to top. In order to test the system, the researchers performed two experiments in which a cylinder and a rectangle were 3D printed.

“The aim for the first experiment is to find the suitable voltage during 3D printing that produce relatively good bead geometry of 3D printed part,” the researchers state. “At first, the welding was deposited along the custom cylinder design. The parameter used for welding voltage varied from 18.5 V to 22.5 V. The first experiment was done with a constant speed of 50 mm/s and current of 100 A. The final dimensions were taken and compared with the actual CAD data. The second experiment was designed so that capability of the newly developed machine to 3D print a rectangular shape can be analyzed. The aim of the second experiment is to find the suitable value of speed in producing good structure.”

Five samples were 3D printed for the first experiment and their average values were recorded. They found that porosity occurred when voltage was either to high or too low, and that higher voltages reduce the size of the specimen due to the excessive flow of the molten metal. A voltage setting of 20.5V produced a good quality part, but it was not dimensionally accurate. In the second experiment, the researchers attempted to find the best printing speed. A too-slow speed resulted in a rough surface and poor fusion. They found that the speed should not be any higher than 20mm/s, however, so that the liquid had time to solidify. Post-processing was required in all cases to get better surface finish. As you can see the results are far from perfect but at this price point many would be able to try to improve such systems. Given more time and investment this could very well be a viable alternative to some metal parts.

A voltage setting of 20.5V produced a good quality part, but it was not dimensionally accurate. In the second experiment, the researchers attempted to find the best printing speed. A too-slow speed resulted in a rough surface and poor fusion. They found that the speed should not be any higher than 20mm/s, however, so that the liquid had time to solidify. Post-processing was required in all cases to get better surface finish. As you can see the results are far from perfect but at this price point many would be able to try to improve such systems. Given more time and investment this could very well be a viable alternative to some metal parts.

Output of printing process (a) speed at 20 mm/s, (b) speed at 40 mm/s, (c) speed at 60 mm/s, and (d) speed at 80 mm/s

“Nevertheless, the study demonstrated that simple design specimens were successfully fabricated using the MIG welding and 3D printing process,” the researchers conclude. “The microstructure shows that the layer perfectly coincides with each printer layer and the top region of manufactured layer has the lowest hardness compared to the initial layer.

However, further research needs to be done in the future to improve the product’s quality and to study the mechanical behavior of the parts produced by this technique.”

Authors of the paper include N.A. Rosli, M.R. Alkahari, F.R. Ramli, S. Maidin, M.N. Sudin, S. Subramoniam and T. Furumoto.

Discuss this and other 3D printing topics at 3DPrintBoard.com or share your thoughts below.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: low-cost 3d printers • metal 3d printer • mig welding • Prusa i3 • welding

Please enable JavaScript to view the comments powered by Disqus.

Students Combine Prusa i3 Printer with a MIG Welder to Create an Affordable Metal 3D Printer - 3DPrint.com

The technology behind 3D printing is still at an early stage, but progressing rapidly. One area where researchers and engineers are focusing their attention now is affordable metal 3D printing. Currently if you wish to fabricate an object out of metal you need to have access to a machine costing close to, if not more than, $1 million. Just like with plastic 3D printing, however, such machines are certain to drop in price as their capabilities expand. There is more than just money keeping these printers out of people’s homes and garages, however. Safety is also a major concern, as high temperatures, powerful lasers, and potential fumes all present dangers to users and their environments.

Currently if you wish to fabricate an object out of metal you need to have access to a machine costing close to, if not more than, $1 million. Just like with plastic 3D printing, however, such machines are certain to drop in price as their capabilities expand. There is more than just money keeping these printers out of people’s homes and garages, however. Safety is also a major concern, as high temperatures, powerful lasers, and potential fumes all present dangers to users and their environments.

With that said, a group of students at Delft University of Technology are in the process of creating what they hope to be an open source metal 3D printer, available to a wide audience, and capable of printing with decent resolutions. The printer — which basically takes an MIG (metal/inert-gas) welder and attaches it to a Prusa i3 — is already capable of printing decent sized test objects.

For those of you unfamiliar with welding, an MIG welder uses a continuous feed of wire which is melted as it acts as both a filler metal and an electrode. A shielding gas flows around the melted wire, protecting it from any sort of local contamination.

A shielding gas flows around the melted wire, protecting it from any sort of local contamination.

The project, which has been inspired by research and development conducted at Michigan Technological University, already seems to be off to quite a start. Basically the MIG welder is tethered to the machine where the extruder and hotend usually are located. Using the Prusa i3’s Cartesian method of printing, the welder slowly but surely melts the metal wire as it places the material down layer by layer. The wire is fed to the welder at a rate of 4 meters/minute. The travel rate of the torch according to the team’s initial settings was 300mm/minute. A typical thermoplastic-based FDM/FFF printer, in contrast, can print anywhere from 3,000 to 18,000 mm/minutes, so this is considerably slower.

A 3D printed test object

Using this method, the team has been able to 3D print a wall-like structure, which is surprisingly solid, as well as uniform, which you can see from the images and video they have provided. Other circular shapes were also made.

Other circular shapes were also made.

There is still a tremendous amount of work to be done on this project; however, this certainly could act as a springboard toward affordable metal 3D printing. Let’s hear your thoughts on this project in the MIG Welder/3D Printer forum thread on 3DPB.com. Check out the video of the machine in action below. For further details and to follow along as the team progresses further on this project, check out their blog.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d metal printer • cheap metal 3d printer • delft university • metal 3d print • michigan technological university • open source 3d printer • tu delft • welder printer

Please enable JavaScript to view the comments powered by Disqus.

With fire and wave: all about metal 3D printing

Everyone knows this: 3D printing today is one of the pillars of world technological progress. It's just a pity that news about revolutionary developments in this area rarely comes from Russia.

It's just a pity that news about revolutionary developments in this area rarely comes from Russia.

The more pleasing are the exceptions. Scientists from the Bryansk State Technical University (BSTU), with the support of the Advanced Research Foundation, have created an installation (the Taimen project), which has become a truly new word in metallurgy and metalworking. nine0003

Among the great variety of additive technologies that exist in the world, two are clearly in the lead - printing with molten plastic and laser sintering of metal powder. In the first case, a low-melting plastic thread is fed to the print head, the tip of the thread heats up and instantly turns into a drop of liquid melt, which is applied to the desired point of the formed product and soon solidifies. It would be nice to print with metal as well, but metal is not plastic or wax. How to create such a temperature in the print head that it instantly turns steel into a liquid? I had to first invent laser sintering for metal printing. nine0003

nine0003

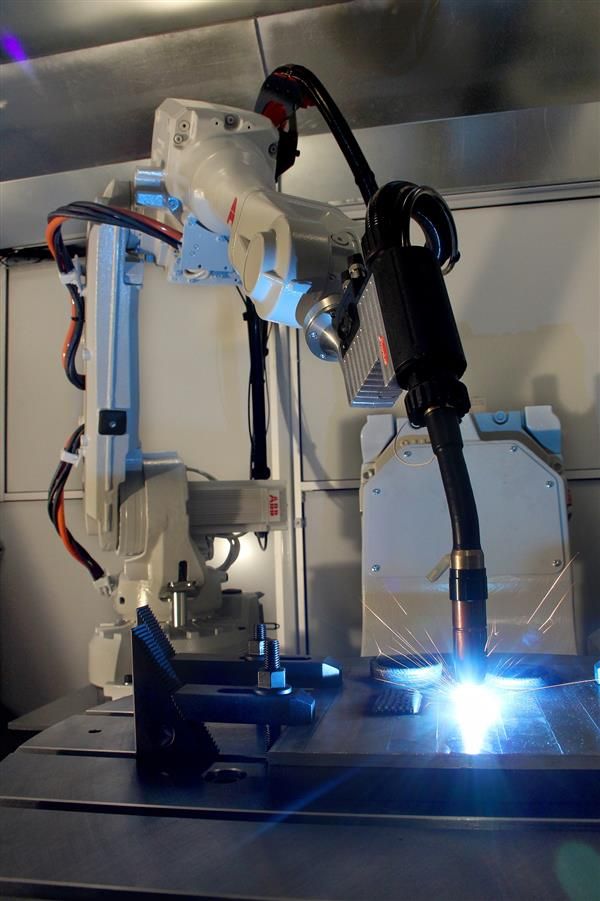

Welding prints

And then the answer was found. Within the walls of BSTU, for a couple of decades, the technology of 3D printing with metal using ... electric arc welding has been developed and improved. Here, almost everything is like in a plastic printer: instead of powder, there is a metal thread fed to the printing point, or simply wire (welders call it filler material). An electric arc discharge melts the filler material and places a drop of metal in a precisely defined place. “Arc welding is only the basis of our method,” says Andrey Kirichek, project manager, professor and vice-rector of BSTU. - In fact, we have to solve a very atypical task for welding work - to give a shape to a printed product, to build up walls. It is impossible to do it manually: we need automation and programmatic control of the process, which we did. On the other hand, there is an opportunity to use the experience gained in the field of welding. Devices and equipment for welding are mass-produced and inexpensive. ” nine0003

” nine0003

Impact on dendrites

3D metal printing technology using electric arc welding has serious prospects. Bryansk developers have competitors from Germany, the USA and Norway, and all these companies are experiencing rapid growth. Being at the forefront is already worth a lot, but Russia has managed to advance the farthest. The fact is that in addition to the additive module, which is actually engaged in growing the product, the domestic installation includes a hardening module. In the standard case, the part printed on the printer will have the crystalline structure of a conventional cast product. But if the build-up layers are periodically compacted with shock pulses, turning large dendrites into colonies of microstructures, then the strength of the part will seriously increase. In the case of austenitic steels, for example, the yield strength of the material increases by 2–2.5 times, and the tensile strength by 1.5 times. This makes it possible to use cheaper alloys. The hardening module is a generator of mechanical impulses, through which a deformation wave acts on the metal - this has a positive effect on the crystal structure, mechanical and operational properties of the hardened metal. nine0003

The hardening module is a generator of mechanical impulses, through which a deformation wave acts on the metal - this has a positive effect on the crystal structure, mechanical and operational properties of the hardened metal. nine0003

Work on the use of strain hardening in additive technologies at BSTU began about five years ago, and at the same time the FPI became interested in this problem, with the support of which a special laboratory was created at the university. Today, there is not a single company in the world that would produce equipment that combines the processes of growing a product by welding and wave strain hardening.

The third module of the installation in question is the milling module, which provides, if necessary, machining of the part. “It must be admitted that, compared to laser sintering, our product formation technology is somewhat rougher,” Andrey Kirichek explains, “but even the most advanced “powder” printers give an error of at least 0.1 mm, and for precision mechanics (for example, in gas turbine) is too much. Therefore, machining, which ensures high accuracy of forms, is still indispensable. The advantage of our installation is the ability to alternate the operation of the modules as required. For example, to grow only a part of the product in order to process its internal surfaces that are hard to reach in the final form. nine0003

Therefore, machining, which ensures high accuracy of forms, is still indispensable. The advantage of our installation is the ability to alternate the operation of the modules as required. For example, to grow only a part of the product in order to process its internal surfaces that are hard to reach in the final form. nine0003

And cheaper, and our

Due to the greater accuracy, laser sintering technology is better suited for medium-sized complex-shaped parts with internal cavities, thin ribs, etc. But there are many large-sized products that also need to be grown. In this case, considerations of economy or scalability come to the fore. And here the new technology has a lot of advantages. Laser sintering is a very expensive technology, and the powder itself is especially expensive. Companies that produce sintering equipment configure it exclusively for powders of their own production. The range of powders even from well-known companies is small. In Russia, they are not produced on an industrial scale, and this greatly limits the capabilities of the technology. Plus, the welding method has a productivity about 6 times higher. And most importantly, it is not economically feasible to produce any large part by sintering, but it is quite possible and profitable to create an installation for printing and hardening metal beams of complex shape. nine0003

Plus, the welding method has a productivity about 6 times higher. And most importantly, it is not economically feasible to produce any large part by sintering, but it is quite possible and profitable to create an installation for printing and hardening metal beams of complex shape. nine0003

Like a hammer, only better

It is interesting to compare the technology of wave work hardening with traditional forging, because the goals and methods of these processes are generally similar. “Indeed, deformation and hardening occur here and there,” says Andrey Kirichek, “but in our case, energy enters the deformation zone in the form of a wave. A wave is a stream of impulses that have duration, amplitude, and shape. When forging, the pulses are short and rare; many processes that can change the structure of the metal simply do not have time to go through. We work with prolonged (10 times longer) pulses with a frequency of 8 to 40 Hz, the impact on the material is long-term, the efficiency of the impact energy on the elastic-plastic deformation of the hardened material is 5-10 times higher compared to a conventional impact and reaches 65% . With a simple impact, this figure is only 5-12%. nine0003

With a simple impact, this figure is only 5-12%. nine0003

The part is created using three modules - additive, hardening and milling. The peculiarity of the process is that the work of the modules alternates depending on the need. For example, machining of a surface can be done even before the complete growth of the part.

The wave passes through all sections of the metal, is repeatedly reflected from areas with different acoustic hardness and from the surface on which the part lies. Due to this, wave states are actually formed in the product. At the intersection nodes of direct and reflected waves, more intense hardening occurs, and at intervals, less intense. This distribution has a good effect on operational properties. In fact, the technology makes it possible to provide a greater depth of hardening, to strengthen all layers at the same time. Perhaps today this is the only way that allows you to achieve such a result. nine0003

Prospects

The range of application of new technologies is potentially huge - from the manufacture of parts for rocket and space and aviation equipment to the automotive industry and the production of special equipment. In June 2019, US-based additive synthesis firm Relativity Space signed an agreement with NASA to convert its Mississippi factory into the world's first automated Relativity Space Terran 1 rocket factory. The factory plans to use a new version of the Stargate printer, which is smaller than the original can be placed on a moving platform to print building-high rocket parts. nine0003

In June 2019, US-based additive synthesis firm Relativity Space signed an agreement with NASA to convert its Mississippi factory into the world's first automated Relativity Space Terran 1 rocket factory. The factory plans to use a new version of the Stargate printer, which is smaller than the original can be placed on a moving platform to print building-high rocket parts. nine0003

In Russia, experiments have already been carried out on the use of wave hardening to impart armor properties to initially non-armor materials, which cost 5-10 times cheaper. It was also possible to increase the bullet resistance of conventional armor by 15-30%.

A lot of power metal parts that are part of machines and structures in a complex stress state could be produced using welded 3D printing with subsequent sealing. “The prospects are huge,” Andrey Kirichek explains, “but there are also many obstacles to the spread of technology. I remember the history of laser cutting systems. When they first appeared, enterprises reacted to the new technology with caution, even with skepticism. The equipment is expensive, there are no trained personnel, the amount of work, the production of which would pay off the complex, is not guaranteed. At first, it was necessary to create regional laser centers where companies placed single orders. 10 years have passed, and manufacturers have realized the advantage of technology, a market has formed; now almost every enterprise has one or more machines for laser cutting and metal cutting. Apparently, we will have to follow a similar path. In addition, the manufacture of critical parts, for example, for aviation, the defense complex, requires certification, and this process is costly and slow. But there are no other options." nine0003

The equipment is expensive, there are no trained personnel, the amount of work, the production of which would pay off the complex, is not guaranteed. At first, it was necessary to create regional laser centers where companies placed single orders. 10 years have passed, and manufacturers have realized the advantage of technology, a market has formed; now almost every enterprise has one or more machines for laser cutting and metal cutting. Apparently, we will have to follow a similar path. In addition, the manufacture of critical parts, for example, for aviation, the defense complex, requires certification, and this process is costly and slow. But there are no other options." nine0003

Source

Tags:

Bryansk State Technical University (BSTU), 3D metal printing, 3D metal printing technology using ... arc welding, laser sintering

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

how additive technologies are quietly changing production, science and life

Today, 3D technologies have quietly penetrated into all spheres of our lives. Rough plastic figures with ribbed edges are a thing of the past. With the help of additive technologies (layer-by-layer creation of something), tablets, metal parts and even meat are being created today. And scientific discoveries in this direction are made regularly. Technologies and areas of application are expanding almost daily. Cars, houses and even bridges are already being printed.

Obsolete information

On the net you can find articles whose authors claim that 3D printers are not capable of working with metal ... But in Amsterdam, the world's first steel bridge has already been printed.

In St. Petersburg, 3D printing technologies for metal products are being developed by a group of scientists from the Peter the Great Polytechnic University. In pursuit of increasing typing speed, they made a scientific discovery.

In pursuit of increasing typing speed, they made a scientific discovery.

How are metal products printed?

Plastic 3D printing, which is already familiar to us, works like this: the printer melts the starting material and uses a dispenser to apply a liquid substance to the product. It freezes. And so on, layer by layer. To pull off such a trick with metal, you need to figure out how to melt it and apply it. Do not destroy the printer. Any welder knows the solution. nine0003

Welding 2.0

Work in the Laboratory of Light Materials and Structures

Oleg Panchenko is in charge of the Laboratory of Light Materials and Structures at the St. Petersburg Polytech. Here, surfacing technologies are being developed. Since the 40s of the last century, they have been used for the manufacture of finished parts. If a hollow metal part was needed, then it was created in the only possible way - by hand. A highly skilled welder built up the walls of the product layer by layer. Long and very difficult. The larger the detail and the more complex the shape, the less chance of success. Even the best worker cannot move with the same speed and accuracy. nine0003

Long and very difficult. The larger the detail and the more complex the shape, the less chance of success. Even the best worker cannot move with the same speed and accuracy. nine0003

Accidental discovery

The team wanted to achieve the highest possible metal printing speed. Physicists were involved in the process. They proposed a solution that scientists had never thought of before. The object of attention was the electric arc that melts the steel wire in the welding machine. Scientists have studied how long burning lasts, the direction of prominences and plasma emissions, how current and voltage affect the rate of metal melting. And as a result, they found a way to redistribute energy for their tasks. Achieved concentration of maximum energy at the desired point. Due to this know-how, the modern welding machine has become twice as powerful. nine0003

Smiths of happiness of the new age

To find out the second one, you will first have to travel back in time three thousand years ago. Then mankind mastered the hardening of metal. Ancient blacksmiths noticed that if an iron object is heated and then cooled sharply, for example, in water, it will become harder. The secret of the processing of swords and daggers was discovered in Asia in the temple record dating back to the 9th century BC.

Then mankind mastered the hardening of metal. Ancient blacksmiths noticed that if an iron object is heated and then cooled sharply, for example, in water, it will become harder. The secret of the processing of swords and daggers was discovered in Asia in the temple record dating back to the 9th century BC.

“Heat until it glows like the rising sun in the desert, then cool it to the color of royal purple, immersing it in the body of a muscular slave. The strength of a slave, turning into a dagger, gives the metal hardness. nine0003

Over time, the methods became more humane, the blacksmiths realized that the properties of the product are affected by the speed of cooling, and not by the liquid, and certainly, to the relief of young strong slaves, not by their strength and health.

The experience of centuries and an industrial robot

Here, the welders from the Polytech loaded metal with some physical properties into the printer, and as a result they got a little different.

“We found superplasticity in an aluminum alloy. We got the same strength, but with the same strength, the elongation of the material before failure was three times greater. This happened because we got into such an interval of the cooling rate of the material, which no one had ever fallen into before. A material that has greater plasticity is more resistant to destruction; like plasticine, it will stretch for a long time before breaking. And it is more reliable if it has minor defects. Simply put, if you make a bumper for a car out of such aluminum, then in an accident it will be able to absorb three times more energy than a regular one. This means that the likelihood that passengers will survive will greatly increase,” says Oleg Panchenko. nine0003

According to the scientist, they can now program a 3D printer so that it prints a product from one source material with areas that have different mechanical properties.

Life in 3D

3D for yourself printer

Today we have already learned how to print food. The scientific process is described as follows. Extrusion printing is used to create food. It sounds complicated, but in fact, any of us can become a 3D printer ourselves. nine0003

The scientific process is described as follows. Extrusion printing is used to create food. It sounds complicated, but in fact, any of us can become a 3D printer ourselves. nine0003

How to become a 3D printer? Instructions:

- Arming with pastry syringe

- Fill it with a thick dough

- Squeeze a layer of dough onto a baking sheet

- Bake cookies

- Add another layer of dough

- Bake two-layer cookies

- READY! You are a 3D printer!

All components on the face. The syringe is an extruder, the hands are a manipulator, the brain is a computer that programs movements. The printer does the same, but more accurately and faster. Today, no matter how loud the phrase “printing food” sounds, the possibilities of the method are very limited. This is more of a semi-finished product than a watermelon rolling out of a printer. But, for example, bakeries are already using 3D technology. They allow you to significantly speed up the process of creating products with a complex design and reduce the number of defects. Robots don't make mistakes. nine0003

Robots don't make mistakes. nine0003

Printing people

It's still far away, but parts of our bodies have been printing for a long time and very successfully. In medicine, additive technologies are now used to create prostheses. In Russia, they were the first to be mastered at the Research Institute of Traumatology and Orthopedics named after R.R. Harmful.

“The main advantage of using 3D printing for the production of endoprostheses is that it can be used to produce unique products that exactly match the shape of the patient’s bone tissue defect, as well as having a special coating of implant-to-bone contact surfaces specified by doctors, which ensures osseointegration , that is, the connection of a bone and a metal structure. Precisely made implant and high-quality osseointegration mean a multiple reduction in the risks of complications and repeated prosthetics,” says Mikhail Zhmailo, Head of the Applied Research and Development Department at Peter the Great St.

Petersburg Polytechnic University. nine0003

And the plastic heart will beat

Doctors turned to biomechanics with a seemingly strange request. And can they print the exact layout of a child's heart with all the physiological details. Scientists have created a program that can analyze computed tomography images and design a layout of an organ in a few minutes.

Printed polymer heart

Of course, such a heart will not beat. But doctors before a complex operation can practice on it. Cut, sew, reprint and try again

Where is the limit?

Are we far from being able to print a living human organ that would replace a donor one. The last major breakthrough in bioprinting was, by the standards of the fast-growing 3D industry, a very long time ago - seven years ago. Scientists were able to reproduce on the printer the thyroid gland ... of a mouse.

“Of course, there is a perspective, but we must understand that this is a very difficult task.

A solution will be found, there are prerequisites and groundwork for this, but printing a human organ is still not the same as printing a bracket, a vase or a hamburger patty,” Mikhail Zhmailo believes. nine0003

The printed world won

3D printing in any form is still a complex and expensive process. And today, additive technologies cannot yet replace the usual means of production. But those studies that are taking place right now allow us to speed up, simplify and reduce the cost of the process.

At Peter the Great St. Petersburg Polytechnic Institute, scientists proudly display a fan blade. These drive air through the mines of a concrete plant. nine0003

Oleg Panchenko demonstrates a printed part. This is not a demonstration model, but a real order. The company needed parts of complex shape. The steel mill took an order of 100 pieces. The complex production process dragged on for months. The printer turned out to be cheaper and faster.