3D printed tommy gun

▷ 1928 thompson machine gun 3d models 【 STLFinder 】

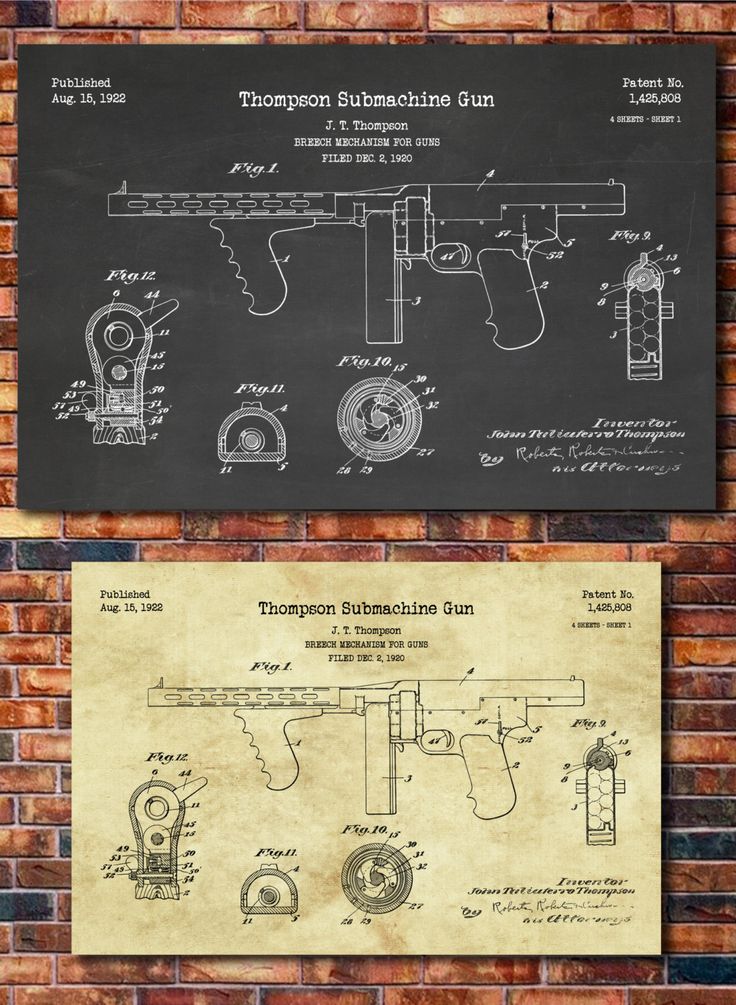

Thompson 1928 Sub-Machine Gun - Functional Assembly

myminifactory

Here is a functional printable assembly of the iconic Thompson sub-machine gun. I have modelled it from technical drawings and then modified part dimensions and certain assembly tolerances so that is printable. The stock, barrel and receiver all...

Thompson 1928 Sub-Machine Gun - Functional Assembly

cults3d

Here is a functional printable assembly of the iconic Thompson sub-machine gun. I have modelled it from machine drawings and then modified part dimensions and certain assembly tolerances so that is printable. The stock, barrel and receiver all break...

Thompson 1928 Tommy Gun

3docean

A Thompson 1928 submachinegun modeled to specs so as to look like the real gun. The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. ...The model comes in 4 formats: -blend, ready to render as seen in the...

Thompson 1928 Submachine gun

3docean

A Thompson 1928 submachinegun modeled to specs so as to look like the real gun. The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. ...The model comes in 4 formats: -blend, ready to render as seen in the. ..

..

Thompson 1928 Submachine gun 3D model

cgtrader

A Thompson 1928 submachinegun modeled to specs so as to look like the real gun. The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. The model comes in 4 formats: -blend, ready to render as seen in the...

Thompson 1928 Tommy Gun 3D model

cgtrader

A Thompson 1928 submachinegun modeled to specs so as to look like the real gun. The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. The model comes in 3 formats: -blend, ready to render as seen in the. ..

..

Thompson 1928 Submachine gun 3D model

cgtrader

A Thompson 1928 submachinegun modeled to specs so as to look like the real gun. The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. The model comes in 4 formats: -blend, ready to render as seen in the...

Thompson Model 1928 Submachine Gun 3D model

cgtrader

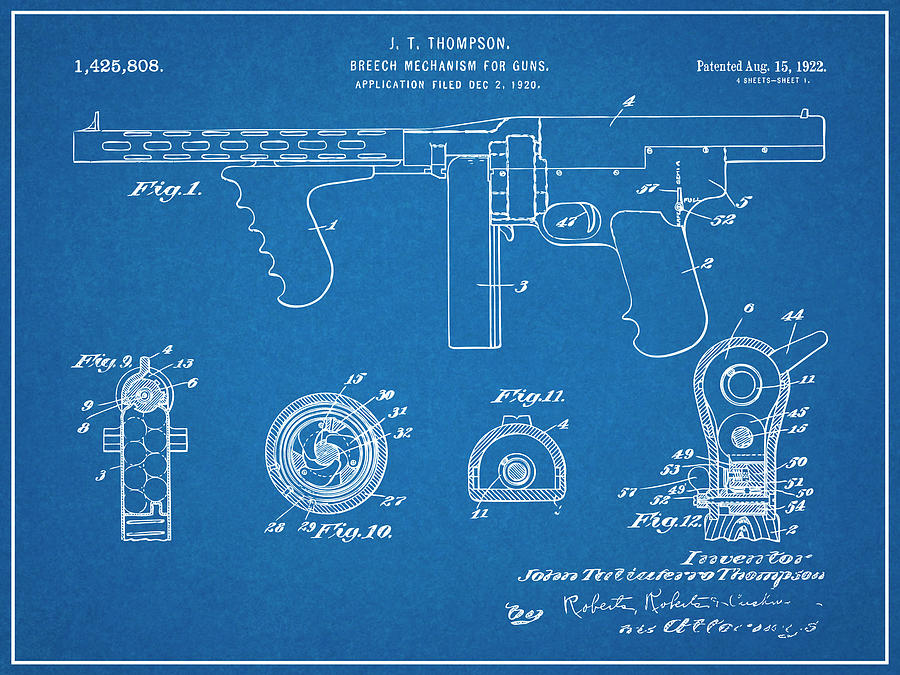

c4d Version R16 Polygones - 33281 Vertices - 31170 - 7 Objects - 8 textures - 4 bumpmaps obj File - lwo file - 3ds file - fbx file Version 2010 The Thompson is an American submachine gun, invented by John T. Thompson in 1919, that became infamous...

Thompson in 1919, that became infamous...

Thompson 1928

grabcad

thompson sub machine gun 1928 Auto Ordnance corporation

Thompson Model 1928 Submachine Gun 3d model

cgstudio

- Phong shading interpolation / Smoothing - 35° - NOTE - In lwo, obj, 3ds and fbx the 2 Bumpmaps (Receiver_Bump, Drum_Bump, Barrel_Bump and Trigger_Bump) must manually load in the Materialcanal. - c4d Version R16 - Polygones - 33281 Vertices -...

Thompson 1928

3docean

A Thompson 1928 submachinegun modeled to specs so as to look like the real gun. The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. ...The model comes in 4 formats: -blend, ready to render as seen in the...

The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. ...The model comes in 4 formats: -blend, ready to render as seen in the...

Thompson 1928

sketchfab

... The Thompson submachine gun was also known informally as the “Tommy Gun”, “Annihilator”, “Chicago Typewriter”, “Chicago Piano”, “Chicago Style”, “Chicago Organ Grinder”, “Trench Broom”, “Trench Sweeper”, “The Chopper”, and simply “The Thompson”.

Thompson 1928

grabcad

My first submachine gun model

Thompson 1928 Tommy Gun Low-poly 3D model

cgtrader

A Thompson 1928 submachinegun modeled to specs so as to look like the real gun. The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. The model comes in 4 formats: -blend, ready to render as seen in the...

The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. The model comes in 4 formats: -blend, ready to render as seen in the...

Thompson 1928 Submachine Gun PBR Low-poly 3D model

cgtrader

Thompson 1928(Tommy Gun) PBR Game-Ready. PBR MetalRough(TEXTURE 4096X4096 ) and (TEXTURE 2048X2048) filexable. Ready for game engines, tested on Unreal Engine and also Marmoset real-time. The models are in real-world scale, and are Intended for...

Thompson gun of 1928 Low-poly 3D model

cgtrader

Low-poly model of a Thompson gun. Made in 3ds max, textured in Substance Painter. There are 3 sets of 2048 textures for 3 parts of the gun. 4096 textures can be provided on require. Maps included: normal, diffuse, metallic, roughness, ambient...

Made in 3ds max, textured in Substance Painter. There are 3 sets of 2048 textures for 3 parts of the gun. 4096 textures can be provided on require. Maps included: normal, diffuse, metallic, roughness, ambient...

Thompson 1928 Gangster

grabcad

Thompson 1928 Gangster

Thompson 1928 Gangster

grabcad

Thompson 1928 Gangster

Custom Thompson Machine Gun

grabcad

Gun model based off a Thompson machine gun

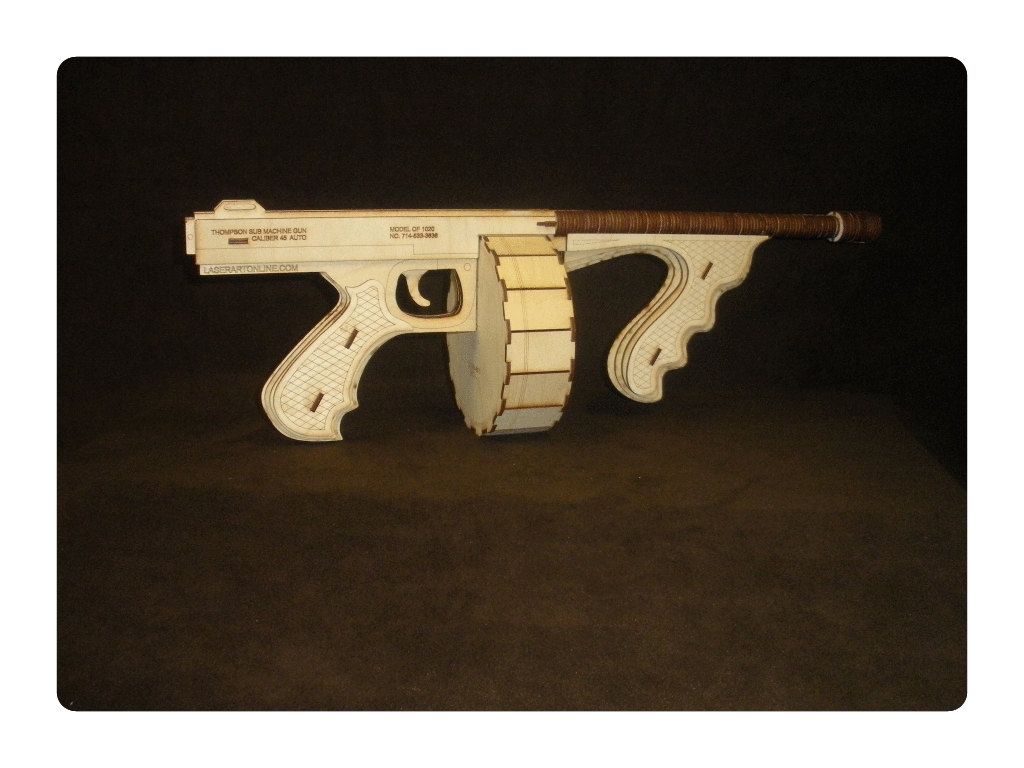

Thompson Sub Machine Gun

myminifactory

Thompson Sub Machine Gun Replica, few moving parts. . ...Enjoy!!

. ...Enjoy!!

Thompson 1928 3D model

cgtrader

A Thompson 1928 submachinegun modeled to specs so as to look like the real gun. The model is built out of quads and is subdivisable. Different parts are separate for ease of handle. The model comes in 4 formats: -blend, ready to render as seen in the...

Thompson 1928 3D model

cgtrader

i made this design based on thompson_1928 using 3ds max and i made materials using keyshot 6

Thompson 1928 bolt adapter

thingiverse

This is an adapter to use a Thompson 1928 bolt in a m1a1. I'm using it in an airsoft aeg to make a dummy replica.

I started with a 1928 bolt by MikeS on GrabCAD. I reworked it using dimensions from a real m1a1 bolt. I moved the charging handle hole...

I'm using it in an airsoft aeg to make a dummy replica.

I started with a 1928 bolt by MikeS on GrabCAD. I reworked it using dimensions from a real m1a1 bolt. I moved the charging handle hole...

Thompson 1928 [LOW POLY]

sketchfab

My 2nd gun model, No textures, enjoy

Thompson 1928 no stock

grabcad

Well, this is only a primitive assembly of the classical sub-machine gun that made history on the hands of criminals and police men in the 30's. There is a lot interference and little errors that will be corrected. The magazine is only for visual...

Thompson 1928 with Guitar Case - Tommy Gun - PBR Low-poly 3D model

cgtrader

Thompson 1928 - Tommy Gun - The Quality you need for your Next Gen Game. Real world scale. PBR textures. The entire model was textured in Substance painter from real references. The pack contain a low model for next game and Textures. All textures...

Real world scale. PBR textures. The entire model was textured in Substance painter from real references. The pack contain a low model for next game and Textures. All textures...

M1928A1 Thompson Sub Machine Gun

grabcad

The Thompson sub machine gun, probably the most iconic and recognizable machine gun ever invented Nicknamed "The Chicago Typewriter" or "The Chopper" Created in Pro/Engineer Wildfire 4 and uploaded in IGS format There are 3 versions, one with the...

Thompson gun

sketchfab

The Thompson submachine gun is an American submachine gun first invented by John T. ...Thompson in 1918 during World War I

Thompson Gun

sketchfab

Army adopted the Thompson submachine gun in 1928. Both the U.S. and British armies used it in World War II, as at various times have other armed forces 3D model of a gun with detachable magazine. 722 verts, 836 tris. Textures are 1024x1024. TGA: 2...

Both the U.S. and British armies used it in World War II, as at various times have other armed forces 3D model of a gun with detachable magazine. 722 verts, 836 tris. Textures are 1024x1024. TGA: 2...

1/18 scale Thompson Machine Gun

thingiverse

GI Joe size Thompson machine gun best with resin printer

The real 3D printed guns

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Is it possible to almost entirely 3D print a functioning firearm? It may be. But only if your name is Beretta and you have been pioneering manufacturing processes in the firearms industry for five centuries. Beretta, the oldest industrial dynasty in the world, recorded its first transaction on October 3, 1526, when master gun-barrel maker Bartolomeo Beretta sold 185 arquebus barrels to the Republic of Venice for 296 ducats.

Fast forward to the 21st century. Beretta Holding has a global presence, spanning 14 different brands and generating yearly revenues of nearly $1 billion, with the US as its largest market. The Beretta factory near Brescia, Italy, produces some of the most precise and trusted firearms for law enforcement, military, and security around the world. Precision is key: Beretta has been forging hunters for 500 years and is a leader in shooting sports. At the last two editions of the Olympic Games, Beretta’s athletes took 10 out of 15 medals in 2016 (as many as the 20th placed nation) and 9 out of 10 in 2020.

Over the past century, starting with Pietro Beretta in 1903, Beretta’s Presidents have invested in modernizing, digitizing and automating their production processes. The latest initiative, under the current President and CEO of Beretta and VP of Beretta Holdings, Franco Gussalli Beretta, is the additive manufacturing laboratory, featuring both metal and polymer additive manufacturing capabilities. We had the unique opportunity to visit this laboratory and learn from Marco Bassoli, Firearm Research & Product Development Director, and Gianmarco Chiari, Process Engineer, how 3D printing is used to make models and functional prototypes, with the sight set on serial production of final parts.

We had the unique opportunity to visit this laboratory and learn from Marco Bassoli, Firearm Research & Product Development Director, and Gianmarco Chiari, Process Engineer, how 3D printing is used to make models and functional prototypes, with the sight set on serial production of final parts.

A truly digital workflow

Attached to the beautiful, centuries-old Villa Beretta, the factory is a state-of-the-art, highly automated facility with capacity of up to 1,000 handguns and several hundred shotguns per day. Because of the scale, the tight tolerances and the high-quality materials involved, manufacturing is carried out via formative and advanced subtractive processes. The Machining Department houses lines of dozens of 5-axis CNC systems that churn out parts day and night, with minimal human operators.

Mr. Bassoli’s team works on digitalizing these workflows, from FEM analysis of models all the way to ERP and PLM implementation. “We apply these tools to all products and workflows, from the very beginning of a new product’s development all the way to production and beyond,” Mr. Bassoli explains, “we are working towards implementing a full digital twin of the value chain, so that we can simulate every aspect of the workflow.”

“We apply these tools to all products and workflows, from the very beginning of a new product’s development all the way to production and beyond,” Mr. Bassoli explains, “we are working towards implementing a full digital twin of the value chain, so that we can simulate every aspect of the workflow.”

Today all these advanced digital capabilities are implemented in digital subtractive workflows – to a degree that only few companies around the world have achieved – however additive manufacturing already plays a part by enabling much faster and more cost-effective development cycles. With such advanced levels of digitalization, it should come as no surprise that Beretta began implementing AM processes for prototyping very early, both through external suppliers and an internal machine.

A look inside the highly automated mass production lines.Functional gun prototypes

“We got our first SLA 3D printer from 3D Systems in 2004,” Bassoli says, “and we used it to start making non-functional models. It was helpful but we what we really needed was the ability to make prototypes that we could test so we used 3D printing to produce silicone molds, to then make the functional prototypes in polyurethane.”

It was helpful but we what we really needed was the ability to make prototypes that we could test so we used 3D printing to produce silicone molds, to then make the functional prototypes in polyurethane.”

The mold to manufacture a Beretta final product can cost several tens of thousands of dollars. Producing such a mold early in the development cycle to test a part is simply not feasible but the company needs functional test parts. “The silicone molds offered us an initial solution but the introduction of SLS technology in 2014 changed everything,” Bassoli says. “Using a glass-fiber-reinforced nylon powder we are now able to produce hundreds of polymer components for prototypes that we can test for form, function and stress resistance. It was a game changer.” It should be highlighted that parts made through this technology are not parts that can withstand the direct force of the shot, such as the gun barrel.

As Bassoli explained, reinforced nylon is an ideal material for many gun and rifle final parts, even for parts produced by traditional means (i. e. injection molding). It is sufficiently strong and at the same time sufficiently elastic to withstand the stresses generated by the forces due to a projectile’s explosion. It’s even better than other high-performance plastics such as PEEK, which are commonly used for metal replacement but are too stiff to be used in firearms.

e. injection molding). It is sufficiently strong and at the same time sufficiently elastic to withstand the stresses generated by the forces due to a projectile’s explosion. It’s even better than other high-performance plastics such as PEEK, which are commonly used for metal replacement but are too stiff to be used in firearms.

In the additive lair

The additive manufacturing laboratory at Beretta today houses the large SLS system with a post-processing station for functional models and a material jetting system for rapid production of visual models. It also has a large, single laser metal PBF 3D printer. It is located inside the larger section dedicated to R&D and small series production. These are getting increasingly larger and can reach a few thousand pieces. In some cases, they are used for bridge manufacturing and are mostly produced using subtractive processes.

But AM is also increasingly playing a role in providing functional parts as delivery times get shorter and shorter. “We usually get requests to deliver parts or products yesterday,” Bassoli jokes. “With AM we can now at least deliver them on the same day.” To further prove this point, Gianmarco Chiari showed us a largely 3D printed automatic submachine gun that was delivered to the Italian Carabinieri, in over 30 units that were in use for testing purposes, while awaiting delivery of the final stock.

“We usually get requests to deliver parts or products yesterday,” Bassoli jokes. “With AM we can now at least deliver them on the same day.” To further prove this point, Gianmarco Chiari showed us a largely 3D printed automatic submachine gun that was delivered to the Italian Carabinieri, in over 30 units that were in use for testing purposes, while awaiting delivery of the final stock.

The importance of rapid functional prototyping at a company like Beretta should not be underestimated as firearms production revolves around dozens of different product models that are optimized for ergonomics, portability, weight, and comfort and can be highly customized. These include sporting and hunting rifles and shotguns all the way to fully automatic, assault weapons for the armed forces and police of many countries around the world. Beretta offers these products along with accessories and clothing. Rifle customization and luxury collector items are also significant businesses where AM could play a part. Serial production of gun and rifle parts using AM is still far away for both metal and polymers, although some applications could start being envisioned.

Rifle customization and luxury collector items are also significant businesses where AM could play a part. Serial production of gun and rifle parts using AM is still far away for both metal and polymers, although some applications could start being envisioned.

Setting sights on production

“Costs are just prohibitive at this time to think that we could use AM for larger productions,” says Bassoli, “Productivity is too low,” he adds, referring to metal parts and components. “In addition, every material needs to be validated for every single new part and the process can take a long time.” To date Beretta has validated different kinds of metals alloys for use with AM. More materials are on the way, but they cannot compare to some of the alloys used for the gun barrels: their quality is a distinguishing element of all Beretta products. The process and materials have been fine-tuned for centuries.

Many of the smaller metal components require extremely tight tolerances which means that not only they have to withstand forces and ensure the utmost levels of reliability and repeatability, but also, they must be finished subtractively when they come out of the 3D printer. “Designing the parts for additive manufacturing can reduce the amount of finishing required but not eliminate it completely and that contributes to drive up costs,” Bassoli explains.

“Designing the parts for additive manufacturing can reduce the amount of finishing required but not eliminate it completely and that contributes to drive up costs,” Bassoli explains.

To implement metal AM into production – which is still the final objective – it became necessary for Bassoli and his team to implement some serious lateral thinking. “When we decided to bring the metal 3D printer in-house in 2018, we leveraged a regional fund and worked to re-imagine a rifle through the new geometric possibilities offered by additive manufacturing, reviewing completely the classical design mindset,” Bassoli says. The first result was a highly customized rifle with a generatively designed stock 3D and a customized handle, all 3D printed in metal.

“It was an exercise to understand the capabilities of this technology and it has helped our team understand many aspects of using metal AM, Bassoli says. “We understood is that costs are currently still too high for serial production. While it could make sense to use AM to make certain collector and unique items, it remains to be seen how many requests we would receive for the items featuring the unique geometries that AM can create.”

“We understood is that costs are currently still too high for serial production. While it could make sense to use AM to make certain collector and unique items, it remains to be seen how many requests we would receive for the items featuring the unique geometries that AM can create.”

Bassoli and his team are at the same time very optimistic about future the possibilities of AM and they are convinced that adoption will continue to grow. “We realize that it is necessary to begin working with, and understanding, the technology now. If you wait until it’s widely adopted it will be too late,” he recognizes: “it’s a matter of identifying the applications where it makes sense to use it.”

A silent transition

This brings us to one of the highlights of our visit: Beretta already has identified the first key application for direct metal additive production: silencers. This is where AM’s capability to build highly complex geometries as single parts can provide significant added value. Silencers are used to reduce the noise and blast of the firearm. They are usually made of multiple “ring-like” parts that are screwed and then bonded or welded together. Each one of these parts provides a layer that reduces and contains the noise and gases released by firing.

Silencers are used to reduce the noise and blast of the firearm. They are usually made of multiple “ring-like” parts that are screwed and then bonded or welded together. Each one of these parts provides a layer that reduces and contains the noise and gases released by firing.

“With additive manufacturing, we can make these as single parts, with a complex internal structure that does not require supports if it’s properly designed,” Bassoli explains. This makes them extremely effective in dispersing the gases that accumulate and can be detrimental to both the operator and the weapon itself. But even more importantly, from a manufacturing point of view, is that this is an additive manufacturing application that has already been validated both technically and commercially. “We are able to assess the exact productivity of our metal 3D printer for this product – Bassoli says – and that means we can define both the price and our ability to deliver these to our customers.” The product is already available on the market (where allowed by local laws) and can be ordered. Beretta is already envisioning a distributed manufacturing network where these are produced on location by Beretta partners.

Beretta is already envisioning a distributed manufacturing network where these are produced on location by Beretta partners.

That’s the beauty of digital, additive manufacturing. Once an application and its workflow has been shown to be profitable and sustainable, making more of them comes down to adding more 3D printers. Seeing by the number of CNC machines already working full time at Beretta, that should not be difficult.

3D printed model of a Kalashnikov assault rifle

3D modeling

Nearly seven decades after its introduction, the Kalashnikov assault rifle remains the most recognizable weapon in the world. High reliability and exceptionally low production costs have made this weapon the most popular assault rifle in human history. Everyone loves this weapon - professional military, security forces, terrorists and lovers of "shooters". The popularity of the assault rifle is such that it has even become a state symbol - for example, the characteristic silhouette of the "Kalash" is present on the flag of Mozambique.

nine0003

nine0003 A user named EasyUsed created a full-size replica of the first large-scale version of the famous 7.62x39mm assault rifle, better known in amateur circles as the AK-47. The replica was modeled using the Blender editor. The Flashforge Creator program was used for preparation and slicing, and the finished digital model was printed on a MakerBot Replicator 1 3D printer. A 3 mm rod was used as a consumable. The model consists of nine parts, which took the designer about 35 hours to print. nine0003

The finished ABS replica weighs approximately 450 grams. The parts of the model were glued together with ABS/Acetone and the outer surfaces were treated with a clean thinner. “Whenever possible, I prefer to use pure acetone with a brush. It’s somehow easier to work with a pure solvent, and you don’t have to worry about adjusting the color of the solution,” the designer explains.

Due to the relatively large size of the parts, some curl and delamination issues were encountered during printing, but these were all corrected by post-treatment with solvent and clamps. nine0003

nine0003

"This replica has a static design, but I'm thinking about refining the design to add a moveable trigger, detachable horn and moveable breech," says the author. “In the next version, parts of the model will most likely be broken down into smaller components to keep deformation to a minimum. In addition, this will allow processing finished parts in a home-made "acetone bath", for which the current components are somewhat large.

Unfortunately, EasilyUsed has decided not to make the 3D model available to the public for the time being, which may be due to their reluctance to put their associates in potentially dangerous situations. After all, the non-profit organization Defense Distributed got into a lot of trouble after publishing the receiver model for the M-16. If you are itching to print your own Kalashnikov assault rifle, then we recommend trying a more innocuous option. For example, like this. nine0003

Follow author

Follow

Don't want

1

Automaton・Cults

Best 3D Printable ModelsThanatar-Kalix (laser cannon).

18 €

cute Santa Claus multipurpose holder

free

Skiing Santa Claus

€1.52 nine0046 -fifty% 0.76 €

Dancing Santa Claus Automatic machines

Free

Ironwrought Brigade III - Steam Warmonger Pack

4.41 €

Autognome

3.40 €

Dozar

3.40 €

nine0004 Ironwrought Brigade III - Steam Patrol Hero "Senshi"2.83 €

Ironwrought Brigade III - Hero of the steam patrol "Spark"

1,60 €

Ironwrought Brigade III - Steam Sentinel Pack

4. 91 €

91 €

British automatic

9.41 €

Winding mechanism (compact and powerful)

Free

Mechanical Dragon

2 €

Sorcerer's Automatic

3.81 €

WIND-UP TIN AUTOMATIC TOY

Free

Cleric of Bartholomew

Free

SPACE PYRAMID OF THE SOULLESS AUTOMATIC

6.29 €

Necromancer reaper

6.29 €

ostrich machine

5.95 €

Diorama "Pokemon Starter

2.33 €

ROBOT M4

1. 32 €

32 €

Fish machine

2.31 €

nine0004 Soulless automata3.15 €

Butterfly machine

Free

Running robot

0.95 €

Cloud, Forward Alchemist

4.70 €

Feres, Bartholomew-artist

4.70 €

Ballista design

€4.70

Perital pump (nema17)

Free

Pencil holder Nier Automata

2.16 €

Cellular automaton house generator

Free

Robot M1

1. 38 €

38 €

Walking Waddling Duck Toy Print in Place

1.55 €

Darth 3.0

Free

A 3D Printed Simple Mechanical Frog.

Free

Netherforge Miner King (28mm/Heroic scale)

Free

Ben and Jerry at the Gym

Free

nine0004 Avengers - End of Loki1.66 €

MotoPig | Lensor Radii

0.93 €

Darth 2: a 3D Printed Animated Darth Vader Helmet.

Free

A 3D Printed Animated Valentine Heart for My Valentine!

Free

A 3D Printed Snake Automaton.