Local 3d printing companies

San Antonio 3D Printing Service

High quality and large scale 3D printing service in San Antonio, Texas. Get high quality 3D printed parts in no time.

No signup required.

Contact us

3D printing projects we did for our clients in San Antonio, Texas

3D printing materials that we offer

Looking for a material that isn't listed here? Shoot us an email at [email protected]

ABS

ABS plastic is a strong and durable material. They're ideal for prototyping mechanical parts. For prototypes that require high-precision, consider CNC machining ABS or printing in other materials. For production parts, we suggest using injection molding instead.

Nylon PA12

Nylons is a strong and durable material that is also flexible. Ideal for live hinges and functional parts.

Standard Resin

Perfect for complex 3d models that require high details and smooth finishing.

SOMOS Resin

SOMOS resin is the industrial version of standard resin.

It's perfect for almost any 3d that require smooth finishing and high details. We recommend this material for any projects such as high-detailed models, architecture, art sculptures and engineering prototypes.

SOMOS Waterclear 10122 Resin

Somos® WaterClear Ultra 10122 is a clear resin that produces colorless, functional and accurate parts that simulate an acrylic appearance. Parts produced from Somos® WaterClear Ultra 10122 exhibit excellent water and temperature resistance.

What makes PrintAWorld different from the other San Antonio 3D printing companies

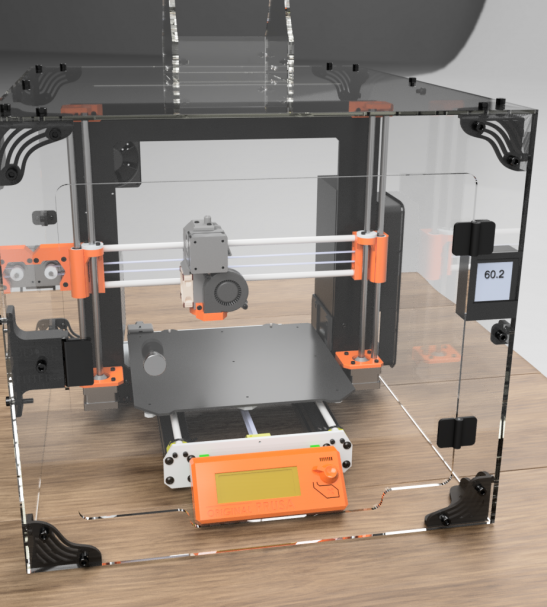

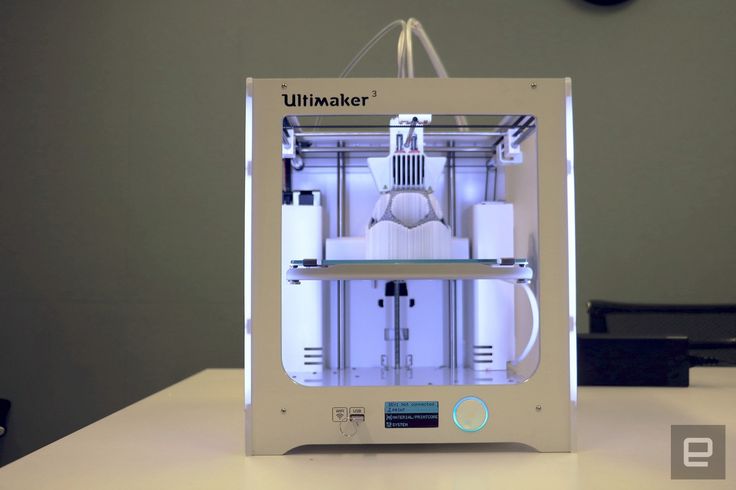

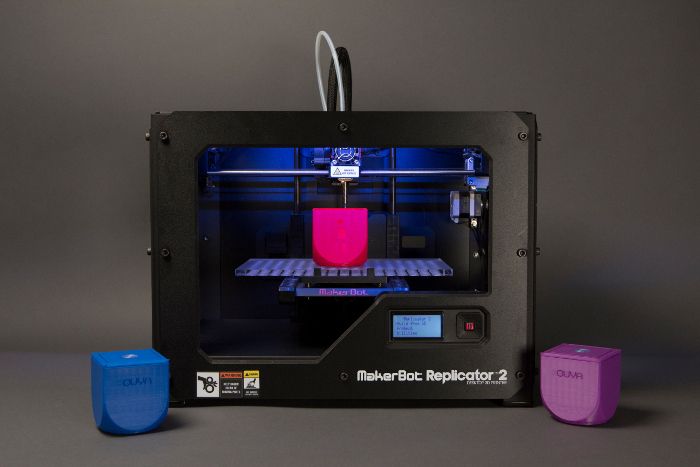

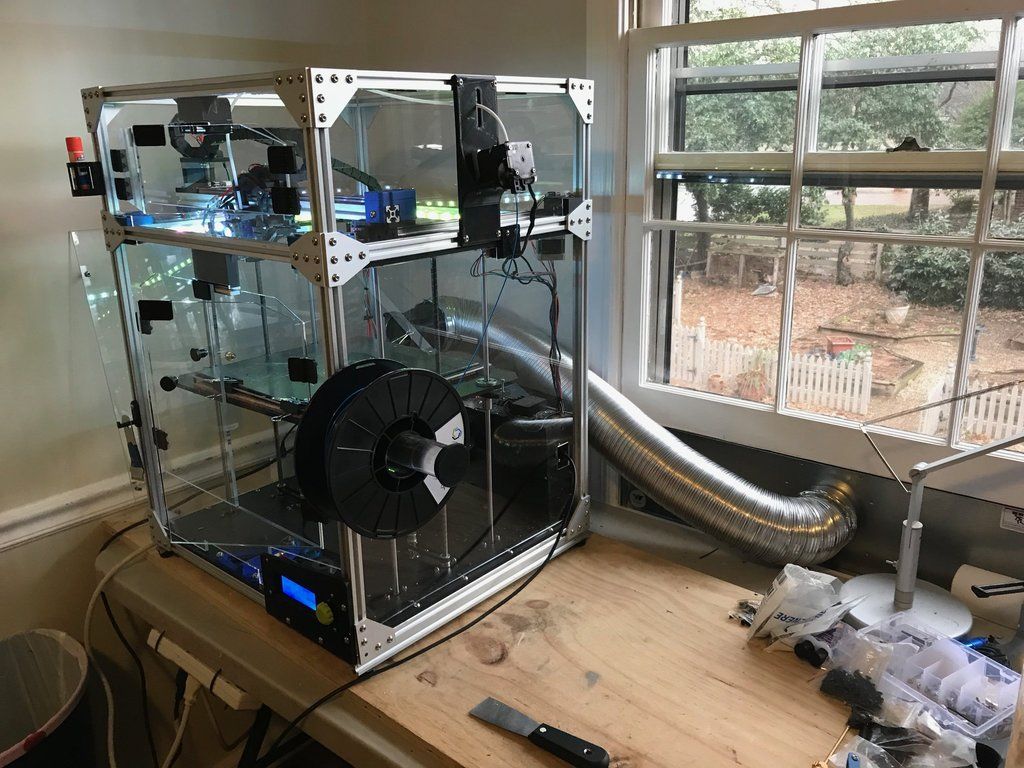

Get access to industrial 3D printers

High resolution and large scale 3d printers are expensive. At PrintAWorld, you'll get the benefits of industrial 3d printing without the cost that comes with it.

Get expert help

We'll help you every step of the way from fixing your file to figuring out the best way to get your project done within budget and time.

Fast turnaround

On a tight deadline? Need it over the weekend? We can help you get your 3d printing project done in no time.

How our 3D printing service in San Antonio works

0

1

.

Send us a few information

The material you need, quantities and a short description of your project. If you're unsure, don't sweat it. We will guide you to the perfect solution!

0

2

.

Upload a 3D File

Send us your.stl or .obj files. Don't have a file ready? We also provide a professional 3D modeling service.

0

3

.

Receive a quote

You'll get an email and a call from us immediately so we can talk about the best and most cost effective way to approach your project.

No minimum order quantities!

No minimum order quantities!0

4

.

Pay and print

Once the quote is approved we will start 3D printing your idea. We'll keep you updated and we'll make sure the result is exactly what you want or even more. No minimum orders.

0

5

.

Shipping or pickup

We offer nationwide delivery or you can pick it up from one of our local studios near you.

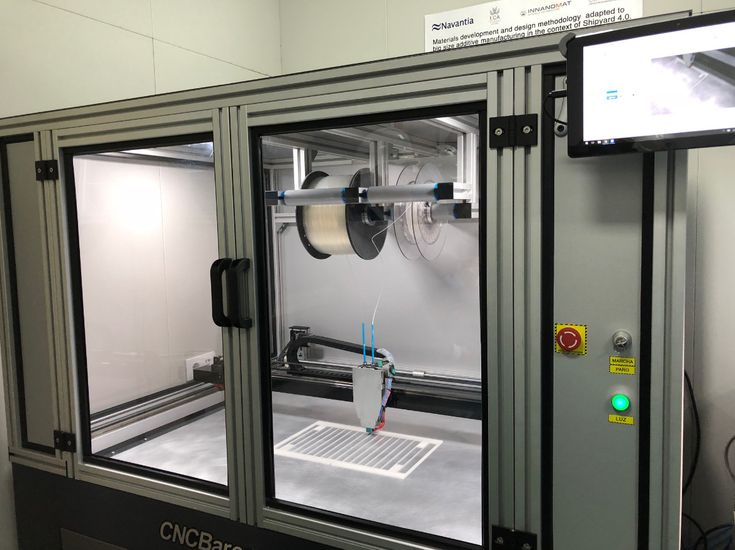

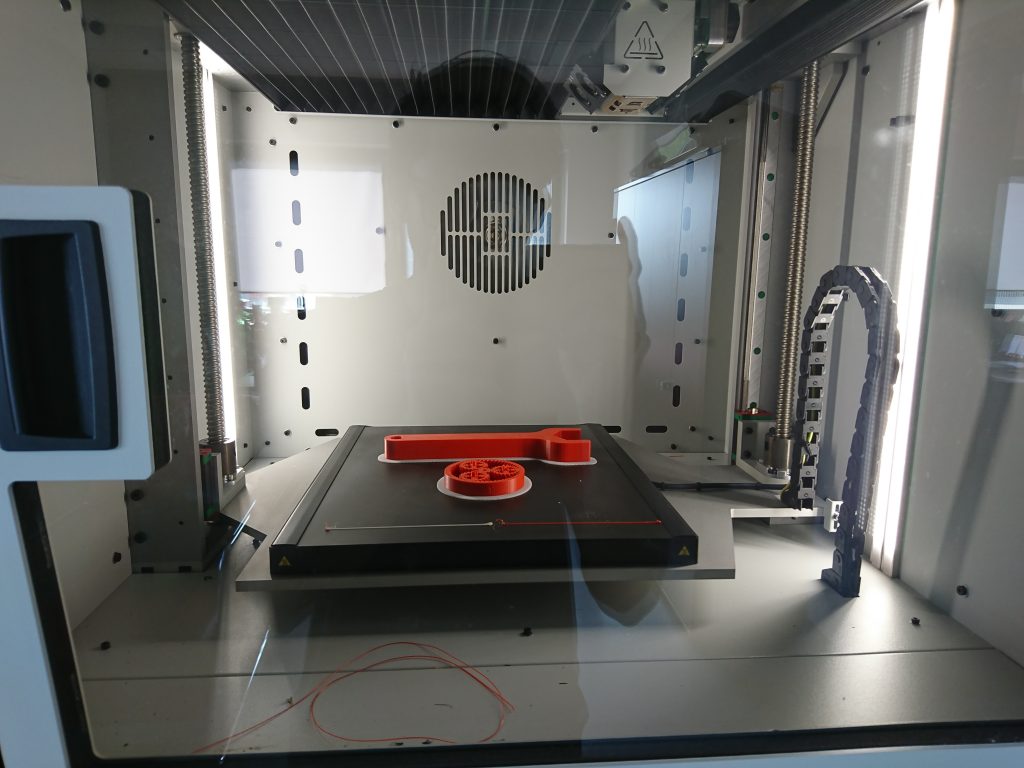

3D printing technologies that we use

These 3D printing technologies are what powers our 3D printing process

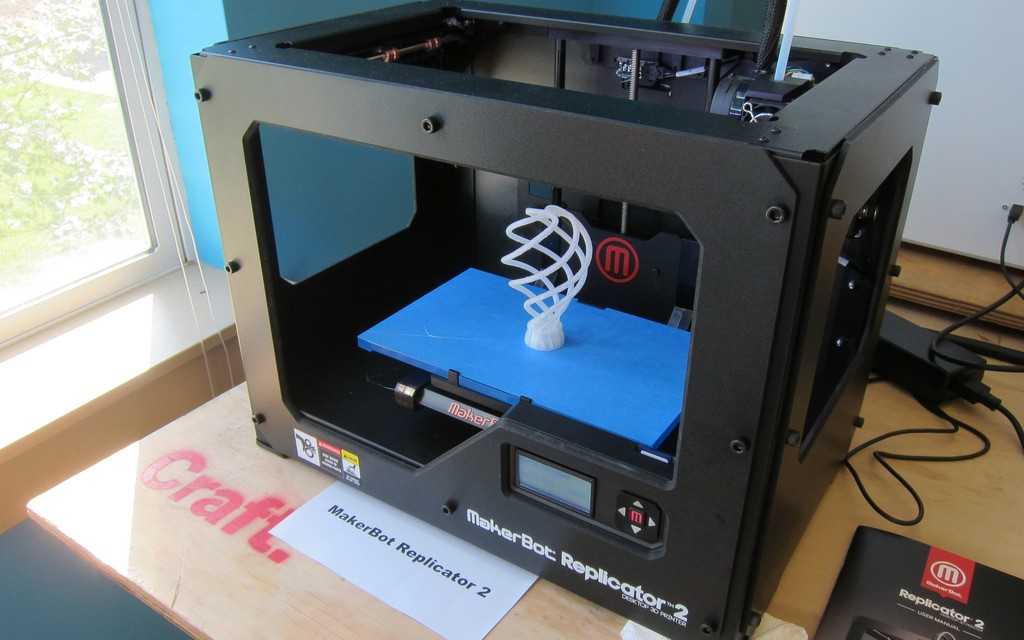

Fused Deposition Modeling (FDM)

We use Fused Deposition Modeling (FDM) for low-cost and simple 3d printed parts. We don't use this process as much because we find the quality lacking and the amount of post processing work involved negates the money you save from low material cost. This is good for prototyping but for manufacturing end products, they might not be cost effective as there are better printing methods. If you want to produce low-cost end use parts at a large volume, injection molding might be a better solution.

This is good for prototyping but for manufacturing end products, they might not be cost effective as there are better printing methods. If you want to produce low-cost end use parts at a large volume, injection molding might be a better solution.

Selective Laser Sintering (SLS)

Selective laser sintering is another great additive manufacturing technology for rapid prototyping. SLS allows us to 3d print objects in different materials such as nylon and metal at large volume without the need for supports. SLS greatly reduces the time spent for post-processing.

Stereolithography (SLA)

Stereolithography allows us to 3d print accurate and high resolution prototypes . We us this process to create functional prototypes that are highly detailed. We recommend SLA for almost any 3d printing projects because we believe it produces the highest quality prints.

Multi-Jet Fusion (MJF)

Multi Jet Fusion is what helps us 3d print end-use production in 24 hours.

F.A.Q

Do you offer delivery?

Yes, we can ship anywhere in San Antonio, Texas and surrounding states.

3D Printing | 3D Print Services

Find a 3D Printing Location

Print Functional Prototypes

You can use 3D printing for prototypes or one-of-a-kind items. Let The UPS Store® bring your ideas to life. We can even use your 3D CAD file.

Construct Manufacturing Jigs and Fixtures

We understand when you do your own manufacturing, jigs and fixtures are critical for insuring high-quality and efficiency during assembly and testing. Our 3D printer can create complex parts so you are not dependent on a CNC machine.

Create Custom Accessories

Want to design your own smartphone case or money clip? Most items that are smaller than a breadbox and can be made out of single color of plastic are perfect for 3D printing.

Build Architectural Models

You can work in just about any 3D architectural design program and then export to common 3D CAD file types. The finished product is ready to show off or you can sand and paint your building to give it just the right look.

The finished product is ready to show off or you can sand and paint your building to give it just the right look.

3D Printing Services Expanded Across Nation

The UPS Store continues to expand 3D printing services nationwide to meet the growing demands of its small business customers. 3D printing now available at approximately 20 The UPS Store locations. Use the interactive map below to find a participating location near you, or check out the full list of all The UPS Store locations offering 3D printing services.

3D CAD and 3D Scanning Services

The UPS Store 3D print locations can now also offer you 3D CAD and 3D scanning services through HoneyPoint3D. Getting a custom 3D print has never been easier - you dream it, HoneyPoint3D designs it, The UPS Store prints it. Enjoy the HoneyPoint3D benefits of an easy quoting process, affordable and quality engineering, online viewing of your 3D files, and efficient turn-around times. Get your 3D CAD or scan quote today!

Netfabb® at The UPS Store®

Participating The UPS Store 3D print locations are utilizing Netfabb software for 3D print file preparation and customization. Services available at these locations include:

Services available at these locations include:

- File fixing

- Text labeling

- Logo labeling

- Cutting

Contact or visit these Netfabb locations to learn more about their advanced 3D offerings.

3D Printing Frequently Asked Questions

Here a few questions we frequently hear about 3D Printing.

Please feel free to contact your local The UPS Store for any other questions you may have

-

What is 3D printing?

-

3D Printing is a manufacturing process that uses a digital file to create three-dimensional objects one layer at a time. We run a system that uses ABS plastic and soluble supports to create realistic prototypes and marketing models.

-

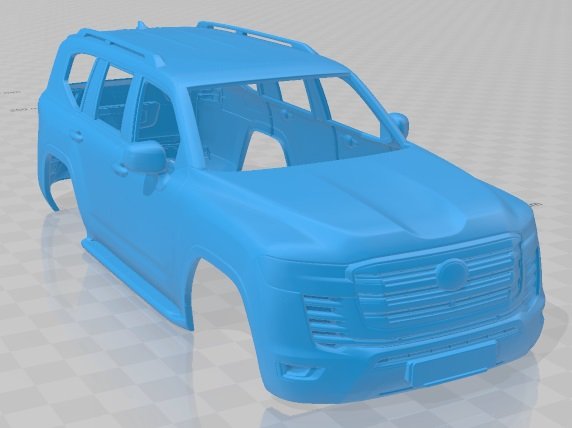

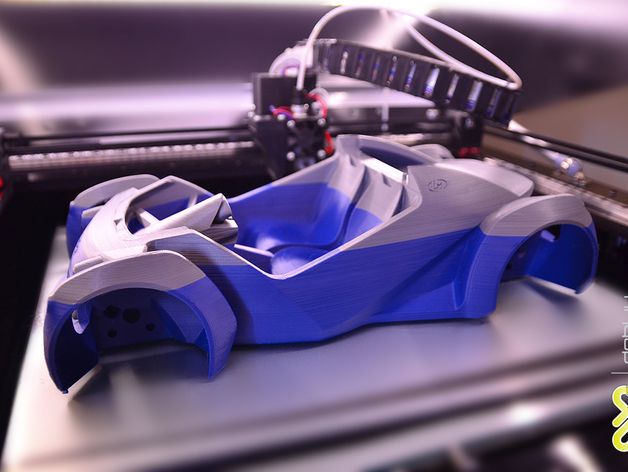

What kinds of things can I 3D print?

-

Small business owners and aspiring entrepreneurs will have the opportunity to print prototypes as part of the new product development process. With this printer, The UPS Store locations will be equipped to produce items like engineering parts, functional prototypes, acting props, architectural models, fixtures for cameras, lights and cables.

-

How long does it take to print?

-

The time it takes to print an object will depend on the complexity of the design. A simple object may take 4-5 hours, while a complex object may take 24 hours.

-

Which UPS Store locations are offering 3D printing?

-

The UPS Store is in the process of rolling out nearly 100 3D printing locations across the country. Visit /print/3d-printing/locations for more information.

Top 10 3D printing companies listed on the stock exchange

So, we present to your attention the ranking of 3D printing companies in terms of annual turnover.

Stratasys: $750 million

Industry leader Stratasys grew 54% over the past year with sales exceeding $750 million. This is partly driven by demand for the new Object500 Connex3 model, as well as the traditionally popular PolyJet and industrial FDM 3D printers. Another growth driver was the acquisition of other companies such as Solid Concepts and Harvest Technologies (now part of Stratasys Direct Manufacturing). At the same time, the American-Israeli company (which includes, among other things, MakerBot Industries and SolidScape) recorded a net loss of $119 in its financial statements.million. This figure is more than four times higher than last year, which is also due to active acquisitions and investments. The forecast for 2015 is positive, it is expected that the revenue will be $940 million. If Stratasys manages to beat expectations by 6%, it could become the first pure 3D printing company to reach $1 billion in revenue.

At the same time, the American-Israeli company (which includes, among other things, MakerBot Industries and SolidScape) recorded a net loss of $119 in its financial statements.million. This figure is more than four times higher than last year, which is also due to active acquisitions and investments. The forecast for 2015 is positive, it is expected that the revenue will be $940 million. If Stratasys manages to beat expectations by 6%, it could become the first pure 3D printing company to reach $1 billion in revenue.

3D Systems: $650 million

Although 3D Systems' revenue rose 27% to a record high, the company still lost the top spot to Stratasys last year. The head of the company, Avi Reichental, said he was not entirely satisfied with how the company realized the potential of its technology portfolio. 3D Systems has some of the most advanced 3D printing technology in the industry, but hasn't shown enough willingness to go mainstream. However, according to 3D Systems financial statements, the company turned out to be in positive territory with a net profit of $1. 6 million at the end of the year. Although the forecast for 2015 is generally positive, it is likely that 3D Systems will again be behind Stratasys, with revenues of $850-900 million.

6 million at the end of the year. Although the forecast for 2015 is generally positive, it is likely that 3D Systems will again be behind Stratasys, with revenues of $850-900 million.

Materialize: $81 million

Materialize is one of Europe's leading 3D printing service providers and a developer of innovative 3D printing software. In 2014, the company's revenue amounted to $81 million, which is 18.4% more than last year. The company's net profit reached $1.8 million, half of what it was in 2013, but still significant. Materialize's core business is the development and sale of 3D printing software (22% of sales) and medical 3D printing services (37%). The industrial segment, including the i.materialise 3D printing service, generated 40% of the company's total revenue. Materialize is expected to grow by 20% next year and reach €100 million in annual turnover.

ExOne: $43.9 million

Last year, ExOne grew by 10% with revenues of approximately $43. 9 million. The main contribution to this result was made by the fourth quarter, during which sales increased by 50%. This state of affairs resulted in a gross profit of $10 million, but ExOne's operating costs were $21 million. This was mainly due to investments in the expansion of the company (new production facilities in Russia and Italy), as well as research and development (more than $8 million). In addition, ExOne announced the creation of a new large-scale 3D printer, Exerial.

9 million. The main contribution to this result was made by the fourth quarter, during which sales increased by 50%. This state of affairs resulted in a gross profit of $10 million, but ExOne's operating costs were $21 million. This was mainly due to investments in the expansion of the company (new production facilities in Russia and Italy), as well as research and development (more than $8 million). In addition, ExOne announced the creation of a new large-scale 3D printer, Exerial.

Arcam: $39 million

Arcam, a Swedish manufacturer of electron beam melting (EBM) systems, recorded revenues of approximately $39 million. Thus, sales grew by 70% in a year, and profits exceeded $6 million. However, it is likely that in the financial markets such results were considered too good to be true. Compared to a record high at the end of 2013, Arcam shares are down more than 70% and are now trading for around $17.

SLM Solutions: $36 million

Germany's SLM Solutions posted similar results to Arcam, with record earnings of approximately $36 million and 56% growth in 2014. At the same time, the company's shares fell from a record high of €21 to €18. However, SLM Solutions boasts a more stable stock price than most other members of the 3D printing industry. At the moment, for the past period of 2015, SLM Solutions reports an increase in the number of orders twice year-on-year.

At the same time, the company's shares fell from a record high of €21 to €18. However, SLM Solutions boasts a more stable stock price than most other members of the 3D printing industry. At the moment, for the past period of 2015, SLM Solutions reports an increase in the number of orders twice year-on-year.

Alphaform: $30 million

German company Alphaform offers rapid prototyping services. Alphaform made its first steps in the consumer market as part of the Artshapes project to apply 3D printing to the arts. The company reported record revenue of $30 million in 2014, up 11.6%. While Alphaform lost more than $3 million in the same period, this is a significant improvement from $6.5 million in 2013.

voxeljet: $17-18 million

Analysts have criticized the German company voxeljet for not selling enough devices while offering special deals to customers to increase orders. However, it should be taken into account that voxeljet manufactures large industrial equipment, the print volume of which reaches 8 cubic meters - in other words, the company occupies a very specific niche. Estimated revenue for 2014 (updated data will be available at the end of March) is $17-18 million. In addition, according to voxeljet forecasts, the company expects to grow by almost 50% this year.

Estimated revenue for 2014 (updated data will be available at the end of March) is $17-18 million. In addition, according to voxeljet forecasts, the company expects to grow by almost 50% this year.

Organovo: $0

Organovo is the only listed biomaterials 3D printing company. However, most of Organovo's activities are still research and the first commercial product, exVive3D human liver tissue, was released just recently. The company has created its own bioprinter and uses it to 3D print organic tissues, which it then sells to major pharmaceutical companies for research purposes. The company's annual operating costs are approximately $20 million. At the same time, Organovo is confident that its products can bring more than $100 million in profit in the foreseeable future.

Renishaw: data not available

Rounding out the top ten was British company Renishaw, which recorded $520 million in revenue and $100 million in marginally lower profits. As of now, Renishaw has yet to disclose earnings for its 3D printing business, limiting itself to commenting that "demand has been solid." The stability of demand can be judged by the fact that, having entered the market with the AM250 device operating on SLM technology, in 2014 the company has already introduced a new EVO system.

As of now, Renishaw has yet to disclose earnings for its 3D printing business, limiting itself to commenting that "demand has been solid." The stability of demand can be judged by the fact that, having entered the market with the AM250 device operating on SLM technology, in 2014 the company has already introduced a new EVO system.

Tags: Stratasys, 3D Systems, Materialize, ExOne, Arcam, SLM Solutions, Alphaform, voxeljet, Organovo, Renishaw

REC Wiki » Who makes money on 3D printing and how Okay, but before diving head first into the business, it would be nice to understand exactly how 3D printing is changing the face of the industries around us in order to find its niche. Let's watch.

The market is growing

From Bugatti to Adidas, 3D printing is making its way into one industry after another, influencing not only design processes but also manufacturing processes. Even the pandemic did not stop the development of the additive market. The situation turned out to be twofold: on the one hand, many manufacturers of 3D printers and consumables suffered losses due to reduced demand, but already bounced back in 2021, as more and more enterprises began to resort to localized additive manufacturing of components due to problems with global logistics . It's time to join the trend and row money with a shovel. A shovel, by the way, can also be printed.

It's time to join the trend and row money with a shovel. A shovel, by the way, can also be printed.

The main applications of 3D printing technologies are prototyping and additive manufacturing. As a prototyping tool, 3D printing helps speed up the development and refinement of products, and as an additive manufacturing tool, it allows you to make final products. Prototyping with 3D printing greatly accelerates the work of designers, providing low-cost, functional prototypes for enterprises of all sizes. In manufacturing, 3D printing is used for mass customization, on-demand production, and even distributed production.

3D printing is everywhere you look

As the subtitle suggests, there is no hiding from 3D printing, it is already everywhere. On the other hand, adoption rates vary from industry to industry. 65% of the use of additive technologies is in engineers working on the creation of new industrial and consumer products.

Example: Three-quarters of American and German automotive companies, including BMW, Ford, Volkswagen, Audi, Porsche, Mercedez-Benz and General Motors, are already actively using 3D printing technology in the mass production of tooling, parts and spare parts. But the matter is not limited to cars alone: medicine, the service industry, architects, artists, and so on and so forth have picked up an additive fever. And what do they do, you ask? Now let's show.

But the matter is not limited to cars alone: medicine, the service industry, architects, artists, and so on and so forth have picked up an additive fever. And what do they do, you ask? Now let's show.

Construction

3D printing is a new word in construction. "Office of the Future" is a demonstration project in Dubai carried out by the Chinese company WinSun in 2016. Six meters high, thirty-six long, twelve meters wide, plus 50% savings on labor. For everything about everything, including decoration and landscaping - seventeen days. The emirs have big plans: the same Saudi Arabia intends to build one and a half million houses to solve the housing crisis, actively attracting developers of construction 3D printers. It is understandable, because the salaries of local builders are high, and the economy should be economical.

The Dubai 3D printing office was just one of the first wake-up calls, and now, six years later, construction 3D printing is being mainstreamed by companies such as ICON, Apis Cor, COBOD, AMT-Spetsavia. The illustration above shows a series of low-income homes built by Texas-based ICON in their native Austin. The houses are small, only thirty-seven square meters each, but are equipped with a bedroom, a living room, a fully equipped kitchen and a bathroom.

The illustration above shows a series of low-income homes built by Texas-based ICON in their native Austin. The houses are small, only thirty-seven square meters each, but are equipped with a bedroom, a living room, a fully equipped kitchen and a bathroom.

And this is one of the projects of the Russian company 3D4art: a pavilion with a 3D printed concrete cat was erected on a private plot in Yaroslavl and serves as a summer kitchen. 3D4art uses 3D printers developed by the local company AMT-Spetsavia, which is also engaged in construction, in parallel with the production of additive technology. Now AMT-Spetsavia is busy building a whole 3D-printed village, in total it is planned to build twelve houses according to individual projects.

“From a hardware point of view, a construction 3D printer is not much different from conventional 3D printing with molten plastic. These are the same CNC machines, only construction 3D printers are larger. However, they allow realizing any architect's fantasy: the printer doesn't care what to print - a simple rectangular building or a house with curved facades, turrets and columns. And to automate the process as much as possible, thanks to which the time for construction is reduced by one and a half times compared to the traditional one,” said Alexander Maslov, General Director of AMT-Spetsavia.

And to automate the process as much as possible, thanks to which the time for construction is reduced by one and a half times compared to the traditional one,” said Alexander Maslov, General Director of AMT-Spetsavia.

Tissue engineering and organs

No one has yet learned how to print working livers, but the process is underway. For example, Prellis Biologics is working on methods for 3D printing of functional organs, including hearts, livers, kidneys and lungs, and the Russian company 3D Bioprinting Solutions has already conducted several bioprinting experiments in space.

Even if the technology is not yet ready for 3D printing of organs for transplantation, it is already useful, allowing the growth of living tissue samples for toxicological research in the development of new pharmaceuticals, as well as research in the treatment of various dangerous diseases, such as cancer.

Cars and motorcycles

Finding and buying a four-wheeled classic is not that difficult, if you have money. It is more difficult to bring the often rusty collection of no longer produced parts up to standard. Mercedes has found a simple solution by offering owners of older cars, including the legendary 300 SL coupe, 3D printed parts. Ride for health.

It is more difficult to bring the often rusty collection of no longer produced parts up to standard. Mercedes has found a simple solution by offering owners of older cars, including the legendary 300 SL coupe, 3D printed parts. Ride for health.

The Russian studio Box3D went in a slightly different direction, customizing cars and motorcycles. In some cases, the company immediately prints parts on 3D printers using durable composites, such as REC X-Line filaments, in others, it prints master models from PETG, from which matrices are removed, and carbon or fiberglass parts are made from matrices. The illustration above is one example. This is a custom motorcycle Giotto 31 based on Harley-Davidson V-Rod. All plastic parts are printed in PETG with fiberglass reinforcement.

And this is a very extreme example from the USA - the Czinger C21 hypercar with a structure made of carbon fiber and 3D-printed titanium parts made using selective laser metal powder fusion (SLM) technology. The machine is equipped with a hybrid power plant based on a turbocharged V-engine with a capacity of 925 hp. With. with the main drive to the rear wheels and auxiliary to the front. From zero to one hundred kilometers per hour Czinger C21 accelerates in just 1.9 seconds. Last year, the prototype set a new lap record at Laguna Seca and improved the previous best time set by the McLaren Senna by a full two seconds. The company plans to produce just eighty of these cars, costing about $1.7 million each.

The machine is equipped with a hybrid power plant based on a turbocharged V-engine with a capacity of 925 hp. With. with the main drive to the rear wheels and auxiliary to the front. From zero to one hundred kilometers per hour Czinger C21 accelerates in just 1.9 seconds. Last year, the prototype set a new lap record at Laguna Seca and improved the previous best time set by the McLaren Senna by a full two seconds. The company plans to produce just eighty of these cars, costing about $1.7 million each.

Shoes and fashion in general

Sooner or later the day will come when you will put on freshly printed underpants in the morning. Think this is a joke? Maybe. However, the same Adidas brand is already actively pursuing the idea of mass distributed additive manufacturing of shoes. Each has its own size, its own shape, its own color, and even at the place of residence. The company has already released several sneaker models with comfortable and resilient 3D printed soles made on Carbon's high-speed photopolymer 3D printers.

Bicycles

This is the Arc Bicycle, a 3D printed bicycle designed by Delft University of Technology students and manufactured by MX3D. And the uncle on a bicycle is the Minister of Economy of the Kingdom of the Netherlands Henk Kamp, who tested the novelty at the Innovation Expo in Amsterdam. It's a well-known fact: the Dutch love 3D printers and bicycles. Especially when 3D printers are printing bicycles, for the perfect synergy. The frame of this two-wheeled vehicle was printed by an industrial multi-axis robotic arm that fuses metal wire.

And this e-bike has a carbon fiber composite frame, but also 3D printed. Such bikes are produced under the Kimoa brand, founded by the famous racing driver Fernando Alonso. The production is carried out by the Californian company Arevo, which has developed a special 3D printer: an additive system prints a combination of thermoplastics and continuous reinforcing fibers.

Instead of a thermal block, a laser emitter is responsible for melting the polymer, and immediately after application, the melt and the reinforcing thread are pressed by a roller, increasing the isotropy. Thanks to the multi-axis positioning system, the reinforcing threads can be overlapped, and the high power-to-weight ratio of the system makes it possible to work even with refractory structural thermoplastics such as polyetheretherketone (PEEK).

Thanks to the multi-axis positioning system, the reinforcing threads can be overlapped, and the high power-to-weight ratio of the system makes it possible to work even with refractory structural thermoplastics such as polyetheretherketone (PEEK).

Food

Who wants a delicious cake? Only cakes are not simple, but made according to intricate 3D printed forms. These sweets were invented by a former Ukrainian architect, and now a confectioner Dinara Kasko. The unusual shape of the cake was obtained using a silicone mold made from a 3D printed master model. With 3D modeling in Grasshopper 3D, Dinara was helped by a friend, Ukrainian artist Andrey Pavlov, who is engaged in general and architectural design.

Fashion

Let's get back to our clothes. Dutch designer Anouk Wipprecht knows the safest way to ride the subway. This 3D-printed "spider" outfit not only flatters the figure, but can tear apart anyone who will unravel their hands. We have warned you. But there are other options: go to the store in such a dress, elegantly lean on the counter and ask: “How much?” Discount guaranteed.

And now to space

When someone enthusiastically mentions "space technology", they mean 3D printing. Seriously. We have already mentioned 3D Bioprinting Solutions, but NASA has long appreciated the possibilities of 3D printing, operating the second FDM 3D printer on board the ISS and even funding the development of 3D printers for printing in outer space. The Russian "space" polymer 3D printer (pictured above) is due to leave for the ISS on June 3, 2022.

SpaceX's rockets and spacecraft are powered by 3D printed engines, and California-based startup Relativity Space is already gearing up to launch the first 3D printed orbital launch vehicle.

Relativity Space relies on at least two 3D printing technologies: for example, engines are manufactured using selective laser sintering technology using industrial 3D printers from the German company Electro Optical Systems (EOS GmbH), and fuel tanks are printed by an additive system of our own design - a robotic complex Stargate on hybrid technology of laser-plasma deposition of welding wire. Through the use of robotic manipulators, the system is easily scaled up, allowing you to create large-sized products.

Through the use of robotic manipulators, the system is easily scaled up, allowing you to create large-sized products.

The first flight of an experimental Terran 1 rocket with a payload mock-up is scheduled for June 2022. The company estimates the cost of one launch at twelve million dollars, and the production time for serial samples is only two months.

Architecture

And I'm walking, walking on… a 3D printed bridge. Not so unexpected: 3D printed bridges have been built in Spain, the Netherlands and China. These are all reinforced concrete structures, although there are also plastic ones, but the engineers of the already mentioned Dutch company MXD3 designed an all-metal steel bridge.

The bridge was installed in the center of Amsterdam in the summer of 2021. The opening ceremony turned out to be quite funny: Her Majesty Queen Maxima deigned to press the big green button, thereby graciously giving the red ribbon to be torn to pieces by a robot-manipulator armed with scissors.