Dws 3d printers

DWS Systems | Additive manufacturing

DWS Systems | Additive manufacturing|

XFAB 2500HD |

XFAB 3500HD |

028J Plus |

029JL2 |

029X |

029XC |

XPRO S |

XPRO SL |

XPRO Q |

|

XFAB 2500PD |

XFAB 3500PD |

029JL2 |

029X |

029XC |

XPRO S |

XPRO Q |

DFAB |

LFAB |

|

XFAB 2500SD |

XFAB 3500SD |

029JL2 |

029X |

029XC |

XPRO S |

XPRO SL |

XPRO Q |

JEWELLERY & FASHION

DENTAL LAB & CLINIC

MANUFACTURING & DESIGN

MANUFACTURING & DESIGN

JEWELLERY & FASHION

DENTAL LAB & CLINIC

Proseguendo la navigazione, accetti l'utilizzo dei cookies di questo sito. Per maggiori informazioni consulta l'informativa..

CHIUDI

DWS Introduces New XCELL, XFAB's and XPRO S Systems » 3D Printing Media Network

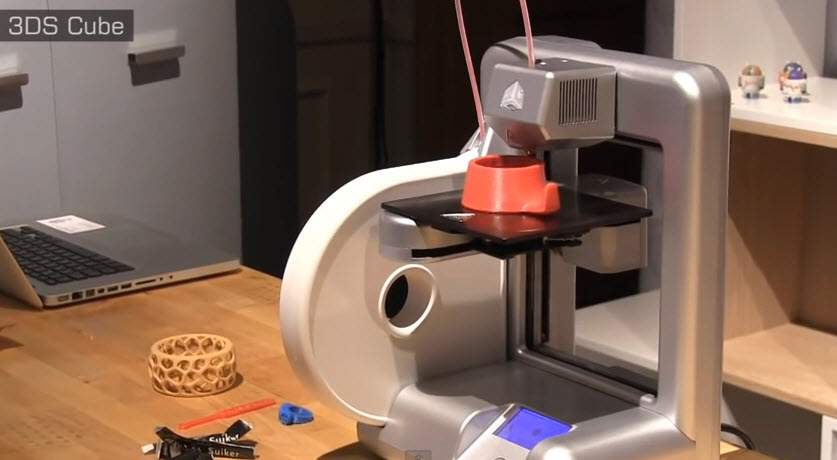

The impressive new XCELL system from DWSStay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

DWS, a trusted Stereolithography pioneer and leader that is making additive manufacturing 4.0 real for everyone, today announced several bold steps that are designed to extend its additive manufacturing leadership and presence globally. The company is bringing to FormNext four new advanced SL printers including the first ever fully automated high-speed all-in-one Stereolithography manufacturing cell. The company also revealed details of its ground-breaking partnership with one most dynamic additive manufacturing leaders, XYZ printing that is designed to accelerate the adoption of professional desktop 3D printers. Finally, DWS shared that in move to decisively expand its geographical coverage, it teamed up with XponentialWorks and opened a new facility and showroom in California to immediately expand its reseller network and provide local sales and marketing coverage throughout North America.

“This is a very exciting and defining moment for our company, “said Maurizio Costabeber, General Manager of DWS. “For over two decades we have been pioneering and disrupting segments of the additive manufacturing industry with our innovative Stereolithography systems and materials to the benefit of our customers” continued Costabeber. “Today we are taking bold steps to make additive manufacturing 4.0 real and affordable through our ground-breaking new products and our significantly expanding global presence,” concluded Maurizio.

Enter XCELL

At formnext DWS unveiled the XCELL 3D, the first ever fully automated high-speed integrated all-in- one Stereolithography manufacturing cell that delivers seamless push-button solution from file to part fast. The revolutionary XCELL takes DWS legendary print quality to a new level using a new printing process that delivers both outstanding speed, precision and post processing integration within a single manufacturing cell.

The XCELL automated 3D printer can deliver direct casting molds, and ready to use parts using DWS tailored polymers at standard manufacturing tolerances as well as at the most demanding dental and jewelry resolution. The integrated All-In-One solution delivers greater print speed and eliminates the labor associated with washing and curing manual labor altogether. Simply load a file and click the print button and the printer will autonomously print, wash, cure and deliver a ready to use part at a fraction of the time it takes using other printers. For greater ease-of-use, DWS also integrated its revolutionary XPOD cartridge, a clean and simple systems that speeds up the entire process and facilitated fully autonomous printing.

The company announced a significant expansion of its industrial strength family of professional and dental 3D printers, materials and software bringing four new printers and two new materials to FormNext. DWS is committed to digitizing the entire design and manufacturing process focusing its expertise on dental and medical, jewelry and luxury goods, automotive and aerospace with price points and performance attributes that cover the entire professional user base from SME’s and dental lab to large Industrial companies.

The expanded product portfolio firmly consolidates DWS leadership in high-productivity additive solutions, with favorable ratio of speed to building envelope and scalab

XFAB Expansion

DWS, today announced that it is decisively expanding its professional-grade desktop offering with two new models. In a direct response to its customer’s request, DWS is leveraging its successful professional-grade XFAB desktop 3D printer to introduce three new models; the XFAB 2000; and the XFA B2500 and XFAB 3500.

The new XFAB 2000 leverages DWS innovative XFAB desktop platform and is equipped with the latest professional grade printers, include proprietary integrated material and vat management and our new generation of BluEdge laser. It is the ideal 3D printer to achieve ready to use smooth surfaces.

The new XFAB 2500 is perfect for design prototyping, digital dental modelling, and artisanal jewelry making, as well as education. It packs the legendary DWS industrial-grade resolution and boasts cylindrical print area of 180 mm in diameter and is compatible with 12 DWS performance materials that are tailored for specific applications. The XFAB 2500 is available in the following models:

The XFAB 2500 is available in the following models:

- · XFAB 2500SD comes with the added flexibility of DWS Professional version of Nauta software that includes manual settings for customized parameters of tailored materials and a wider range of functional materials. It is the ideal perfect multipurpose printer for professional applications.

- · XFAB 2500HD is our jewelry workhorse. In combination with our industry recognized jewelry materials, this printer delivers outstanding results for high volume jewelry production application. It comes equipped with unique beam delivery systems that has been tailored for jewelry manufacturing including demanding filigree designs.

- · XFAB 2500PD is our dental-Lab professional printer. It combines large print volume with the highest resolution delivering a remarkable productivity. It come with the most comprehensive range of proven dental materials that are tailored for the broadest range of dental application.

The new 3500 series represent a completely brand-new benchmark in professional-grade desktop printing.

- · XFAB 3500SD is an advanced version in XFAB family. This printer sports combined higher resolution and larger print envelope. It delivers exceptional design and manufacturing prototypes and functional parts as well precious metal casting for jewelry and models for rubber molding.

- · XFAB 3500HD is our advanced jewelry manufacturing system. In combination with our industry recognized jewelry materials, this printer delivers production quality and throughput for high volume jewelry production application. It comes equipped with DWS advanced beam delivery systems that has been tailored for jewelry manufacturing.

- · XFAB 3500PD is our Advanced Dental-Lab manufacturing printer. It combines large volume with the highest resolution delivering a remarkable productivity. It come with the most comprehensive range of proven dental materials that are tailored for the broadest range of dental application.

Going Large

Finally the company also released (with immediate availability) a new industrial-grade large-format 3D printer, the XPRO S. This new system is one of the most powerful and affordable large- format 3D printer on the market today. Priced starting at $100,000, the XPRO S delivers the most cost-effective precision parts using the best of DWS purpose made materials at convincing scale. XPRO S shares DWS’ large-format industrial-grade platform its top of the line O30S quad-laser system and boasts a print platform of 300 x 300 x 300 mm. The XPRO S is a game changing 3D printer developed to provide the highest levels of productivity and quality in the industrial sector. It was developed specifically for large companies that require a large printing area to quickly produce high-quality, high-resolution precision models: realistic models, concept models, functional prototypes, and prototypes of consumer products. This 3D printing system is notable for its silent operation, and for the resolution and precision of the objects produced for every application. This is also due in part to the vast range of materials that DWS has developed specifically for the industrial sector: ABS- like, polypropylene-like, rubber-like, and transparent materials; nano-ceramic resins; materials for investment casting models and silicone molding masters; and many more.

This new system is one of the most powerful and affordable large- format 3D printer on the market today. Priced starting at $100,000, the XPRO S delivers the most cost-effective precision parts using the best of DWS purpose made materials at convincing scale. XPRO S shares DWS’ large-format industrial-grade platform its top of the line O30S quad-laser system and boasts a print platform of 300 x 300 x 300 mm. The XPRO S is a game changing 3D printer developed to provide the highest levels of productivity and quality in the industrial sector. It was developed specifically for large companies that require a large printing area to quickly produce high-quality, high-resolution precision models: realistic models, concept models, functional prototypes, and prototypes of consumer products. This 3D printing system is notable for its silent operation, and for the resolution and precision of the objects produced for every application. This is also due in part to the vast range of materials that DWS has developed specifically for the industrial sector: ABS- like, polypropylene-like, rubber-like, and transparent materials; nano-ceramic resins; materials for investment casting models and silicone molding masters; and many more. With low running costs and zero planned maintenance cost, the printer has been designed to operate 24 hours a day, ensuring maximum reliability. We invite interested customers to apply for its early access program and qualified resellers and end-users alike to visit us at FormNext November 14-17 and see our entire portfolio in action including the XFAB 1000. Both companies expect to achieve full commercial status during the second half of 2018.

With low running costs and zero planned maintenance cost, the printer has been designed to operate 24 hours a day, ensuring maximum reliability. We invite interested customers to apply for its early access program and qualified resellers and end-users alike to visit us at FormNext November 14-17 and see our entire portfolio in action including the XFAB 1000. Both companies expect to achieve full commercial status during the second half of 2018.

To increase its reach, DWS entered into a strategic agreement with XYZprinting, the leading global provider of desktop and professional 3D printing products, that is designed to accelerate the adoption of affordable professional grade 3D printers globally. As part of this agreement XYZprinting will manufacture and sell under its own brand certain DWS SL printers leveraging its global channel reach and unparalleled manufacturing capabilities and DWS will market under its own brand certain XYZprinting DLP printers expanding its reach into the fast-growing sub $5,000 professional category. This strategic partnership will expand global market reach to affordable professional grade SL desktop 3D printers where both companies expect unlimited growth potential. This partnership brings together the capabilities of DWS, a respected pioneer and innovator of precision Stereolithography systems and materials with XYZprinting, the clear desktop 3D printer sales leader and one of the world top contract manufacturing companies with more than four decades of delivering affordable high-quality systems at convincing unit scale of millions of products from calculators to computers, set-top boxes and smart connected devices in the millions monthly. We invite qualified resellers and end-users alike to visit us at FormNext November 14-17 and see our entire portfolio in action including the XFAB 1000. Both companies expect to achieve full commercial status during the second half of 2018.

This strategic partnership will expand global market reach to affordable professional grade SL desktop 3D printers where both companies expect unlimited growth potential. This partnership brings together the capabilities of DWS, a respected pioneer and innovator of precision Stereolithography systems and materials with XYZprinting, the clear desktop 3D printer sales leader and one of the world top contract manufacturing companies with more than four decades of delivering affordable high-quality systems at convincing unit scale of millions of products from calculators to computers, set-top boxes and smart connected devices in the millions monthly. We invite qualified resellers and end-users alike to visit us at FormNext November 14-17 and see our entire portfolio in action including the XFAB 1000. Both companies expect to achieve full commercial status during the second half of 2018.

For North America the company teamed up with XponentialWorks, an expert in additive manufacturing advisory and opened the doors to a new facility and showroom in Ventura California. With this move, DWS plans to leverage the deep expertise, strong presence and access of XponentialWorks and immediately expand its reseller network. As part of this expansion, DWS invested in a state of the art show room and training facility in Ventura California and is ready to provide local sales and marketing coverage throughout North America. Armed with the most comprehensive portfolio of professional-grade Stereolithography systems and materials, DWS expects to attract some of the most qualified professional resellers in the U.S. that are likely to find the DWS portfolio very compelling both in terms of overall system performance and total cost of ownership.

With this move, DWS plans to leverage the deep expertise, strong presence and access of XponentialWorks and immediately expand its reseller network. As part of this expansion, DWS invested in a state of the art show room and training facility in Ventura California and is ready to provide local sales and marketing coverage throughout North America. Armed with the most comprehensive portfolio of professional-grade Stereolithography systems and materials, DWS expects to attract some of the most qualified professional resellers in the U.S. that are likely to find the DWS portfolio very compelling both in terms of overall system performance and total cost of ownership.

Related Articles

3D printing engine (5 best models for 3D printing)

3DPrintStory 3D printing process How to 3D Print an Engine (Top 5 Models for 3D Printing)

3D printing at home has come a long way. To date, there are a huge number of 3D printers in various price ranges, there are plenty to choose from. And as there are more and more happy owners of 3D printers, the community is growing, there is a huge number of 3D models that people share. But the static figures downloaded from Thingiverse are gradually getting bored and I want new challenges and experiments. Well, you've come to the right place. How about printing a running electric motor?

To date, there are a huge number of 3D printers in various price ranges, there are plenty to choose from. And as there are more and more happy owners of 3D printers, the community is growing, there is a huge number of 3D models that people share. But the static figures downloaded from Thingiverse are gradually getting bored and I want new challenges and experiments. Well, you've come to the right place. How about printing a running electric motor?

If you're interested, then wellcome to the rest of the article, because here we have collected for you the best options for engine designs that you can print on your 3D printer.

Brushless motor

This motor, designed and manufactured by Christophe Laimar, has impressive power. The 3D printed motor uses a 3D printed rotor and stator and delivers 600W of power with an efficiency of 80%. The complexity of 3D printing rightly allows it to be used as a demonstration of technical prowess as well as knowledge of 3D printing.

Where to find : You can download the part files from the developer's website for a fairly small $10 license fee. Also included is an approved list of 3D printing hardware and engine components.

How to make : Christophe provides very detailed information on how to print and assemble this impressive brushless motor project. You can find the full instructions for 3D printing and assembling this model on Instructables.

In the video below you can see how this engine works.

Simple DC Motor

This motor is amazing in its simplicity: it was designed for training purposes by user Thingiverse for MakerEd Challenge 2.0.

Where to find : Thingiverse has all the parts you need to 3D print this DC motor. In addition, there are detailed instructions for assembling the model, as well as materials with examples of its use.

How to make : Follow instructions on Thingiverse where the author recommends printing at a high resolution of 0.1mm. In addition, it provides a complete list of required parts for a complete build so that even before starting this project, you can be fully prepared and armed with everything you need.

A short video demonstrating the operation of this 3D printed motor is shown below.

Mendocino small solar motor

As stated by the creator, "The Mendocino engine is a solar-powered electric motor with magnetic levitation." Watching a video of his work will definitely make you wonder how interesting this design really is. The assembled model is practically a work of art, with a stylish floating design.

Where to find : This unusual engine model can be found on Thingiverse.

How to make : The author used a 0. 5 mm nozzle with a layer height of 0.2 mm for the stator components. Detailed instructions are also provided on the Thingiverse page.

5 mm nozzle with a layer height of 0.2 mm for the stator components. Detailed instructions are also provided on the Thingiverse page.

Tesla Turbine

The model was originally designed and manufactured by the Portuguese manufacturer and engineer Integza. This 3D printed engine is based on a Tesla turbine. It is propelled by the use of high-pressure air, acting in a vortex through thin, 3D printed plates. The original design used a few 3D printed components, but the current second iteration is almost entirely 3D printed.0005

Where to find : The author has posted 3D printing files and instructions on her Thingiverse page.

How to make : unfortunately the author does not offer any technical documentation. But the author has a video where he reveals some background of this project, and also describes the build process.

Spring Motor

Designed and printed by Greg Zumwalt, this powerful 3D printed spring motor demonstrates the unique properties of PLA plastic. And it's especially impressive that Greg has created many other models based on the lessons learned in this project.

Where to find : Greg Zumwalt posted all his part files on MyMiniFactory.

How to make : Greg has posted instructions on MyMiniFactory that explains in detail how to print and assemble each of the parts. The most important tip is to print with 100% coverage. In addition, he recommends using light machine oil for lubrication.

Here are just a few options to make your 3D printed projects even more colorful and impressive. As you can see, 3D printing is about more than just static miniatures. Implement at least a couple of the above projects, and your knowledge in the field of 3D printing (and not only) will expand significantly. Well, if the above electric motor designs are too easy for you, then why not create your own?

stepper motor choice, which is better

With the advent of 3D printers, people's lives have become much easier. Devices are successfully used in many areas - dentistry, industry, jewelry and medicine. Now a 3D printer is not a luxury item, but a design that is quite affordable. But still there are those who decide to independently manufacture printing presses. Next, let's talk about how to choose a stepper motor for a future 3D printer and what features should be taken into account.

Motor on a 3D printer

In the design of a 3D printer, the main function for the movement of the extruder along the axes is performed by stepper motors. They have low weight and high torque.

A stepper motor is a motor without a commutator, whose rotation is not smooth, but discrete (in steps). By setting the speed and duration of the pulses, you can make the device rotate in a certain direction.

In this case, it is possible to adjust the direction of rotation and the number of revolutions of the rotor.

If we talk about the design of such devices, then there are three main types:

- Motors with variable magnetic resistance - have several poles on the stator and a rotor made of soft material, and 3 windings independent of each other. This type is practically not used.

- Permanent Reluctance Motors - Includes stator and magnetized rotor. Such motors have 24 to 48 steps per revolution.

- Devices combining variable and constant magnetic resistance (hybrids) - combination of the best properties of an AC and a constant rotating motor. The number of steps is from 100 to 400.

The hybrid engine is the most common design, which, in turn, is divided into unipolar and bipolar types.

Which stepper motors to choose for a 3D printer: the best options

When buying a rotator for a 3D printer, you should pay attention to the following parameters:

- rotating structure size;

- holding torque - 2.

5-4 kg/cm;

5-4 kg/cm; - rated current - optimal version for 1.7 A;

- Shaft - Diameter must match the design of the printer.

The most common motors that are installed on the design of the printing device are bipolar with four leads. Such structures in the event of a breakdown are easy to find and replace.

NEMA marked rotary motors are installed in 3D printers.

NEMA is a National Electrical Manufacturers Association that standardizes rotating devices in terms of flange size and fit. This standard allows different manufacturers to produce engines according to certain parameters, depending on the marking.

Most popular models in the NEMA series:

- NEMA 17 with 42*42mm flange;

- NEMA 23 with 57*57mm flange;

- NEMA 34 size 86*86mm.

Stepper motor drivers for 3D printer

To control motors in 3D devices, drivers installed in the board slot have been developed.

There are several types of drivers:

- Constant voltage - such drivers are inefficient and are used in a product with low speeds.

- Two-Level - These controllers support step and half step modes. They reduce engine heat and are efficient in operation.

- PWM drivers are the most popular on the market. They are highly intelligent and have many additional features.

Also, when choosing a driver, you should pay attention to the following parameters:

- current strength;

- supply voltage;

- presence of optoisolated inputs;

- availability of resonance suppression mechanisms;

- availability of protocols necessary for engine operation;

- surge protection;

- micro stepping;

- driver quality.

It is quite possible to assemble a high-quality 3D printer if you follow the recommendations and carefully study the design devices. It is quite possible that such a printing press will cost its owner less.