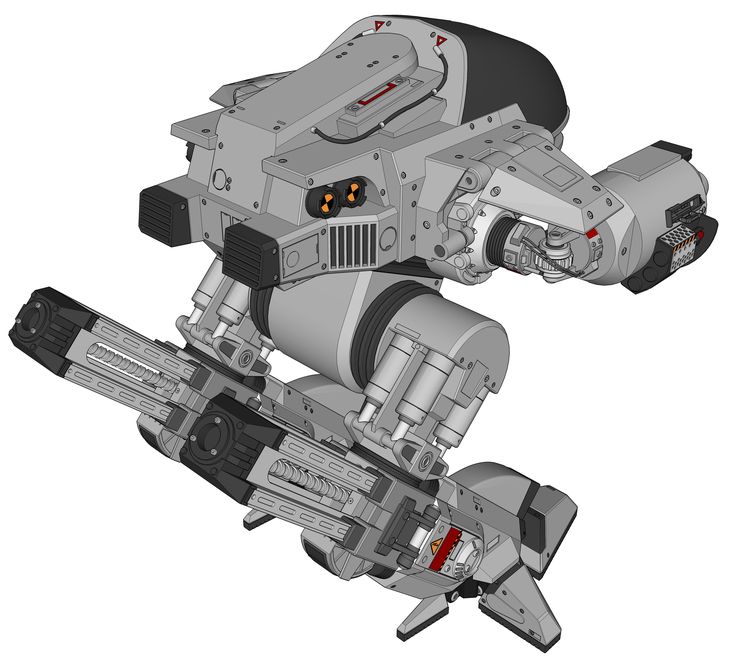

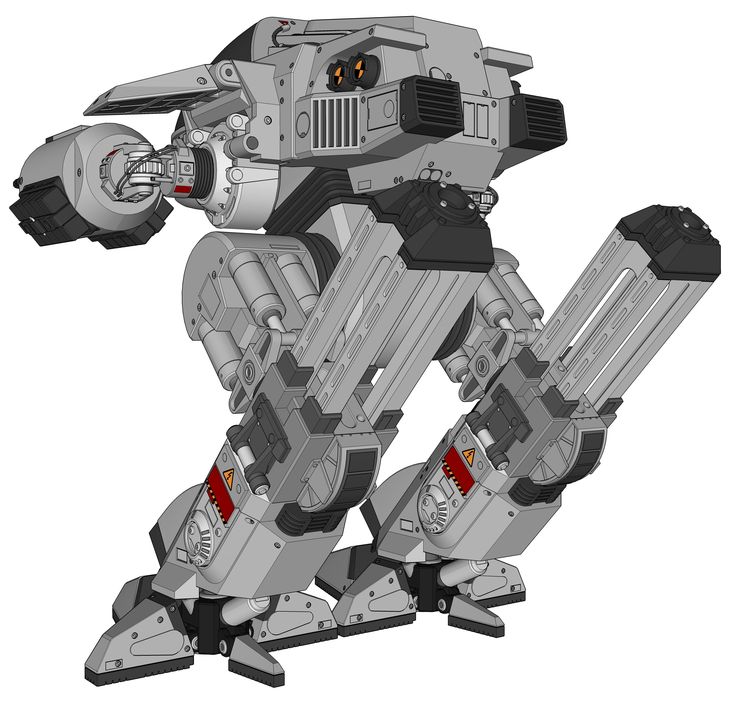

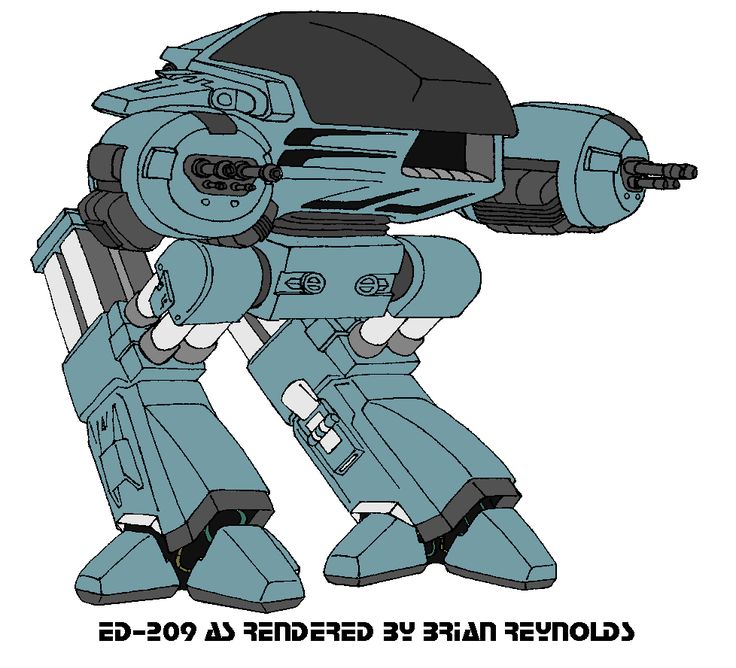

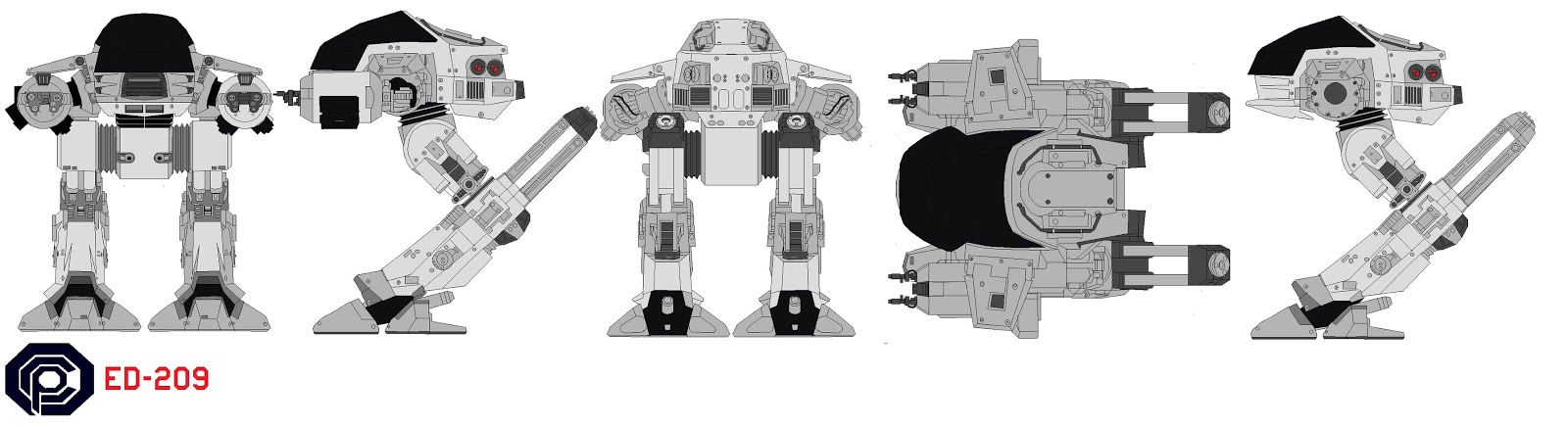

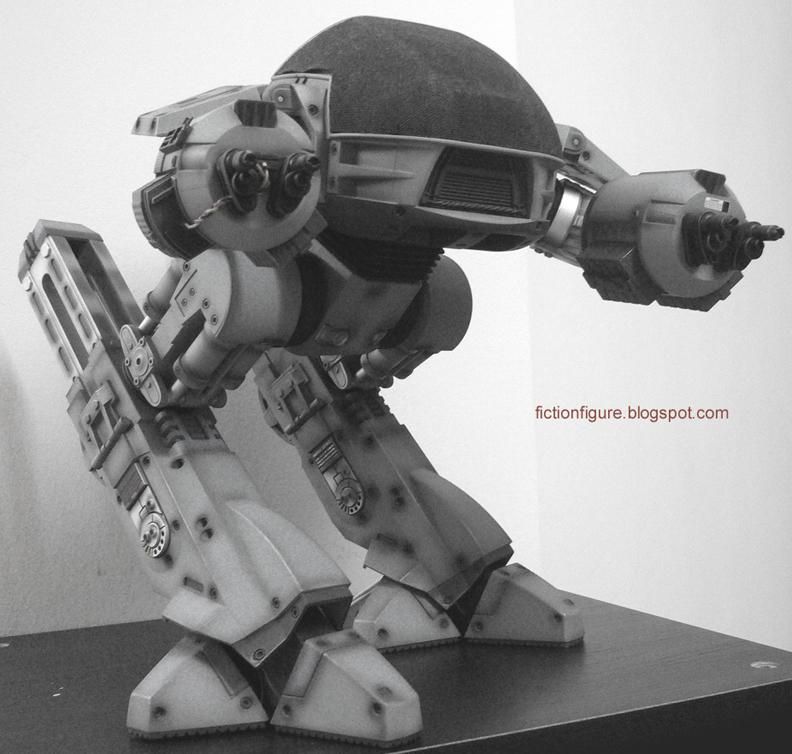

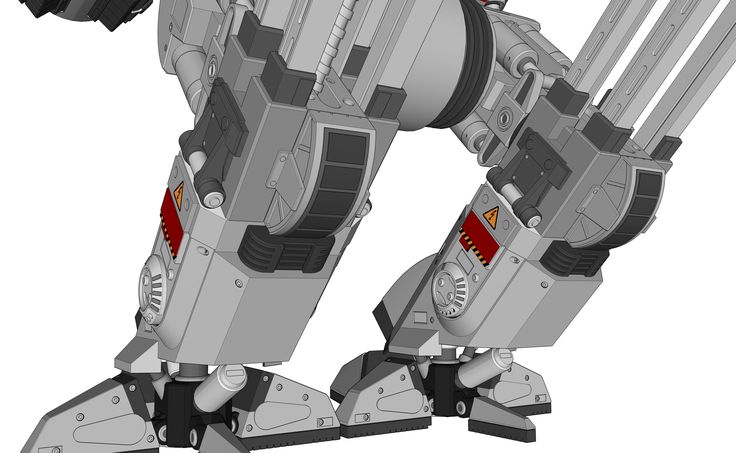

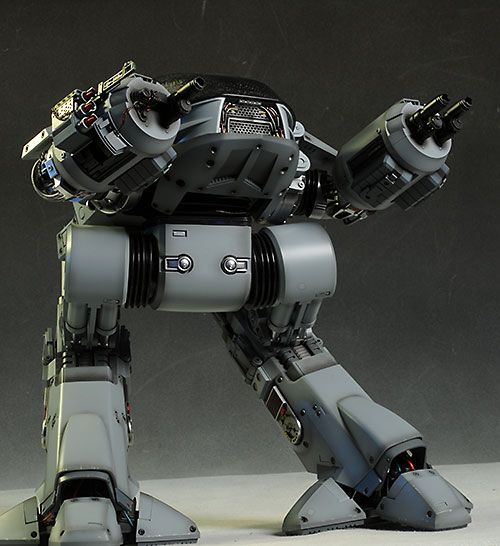

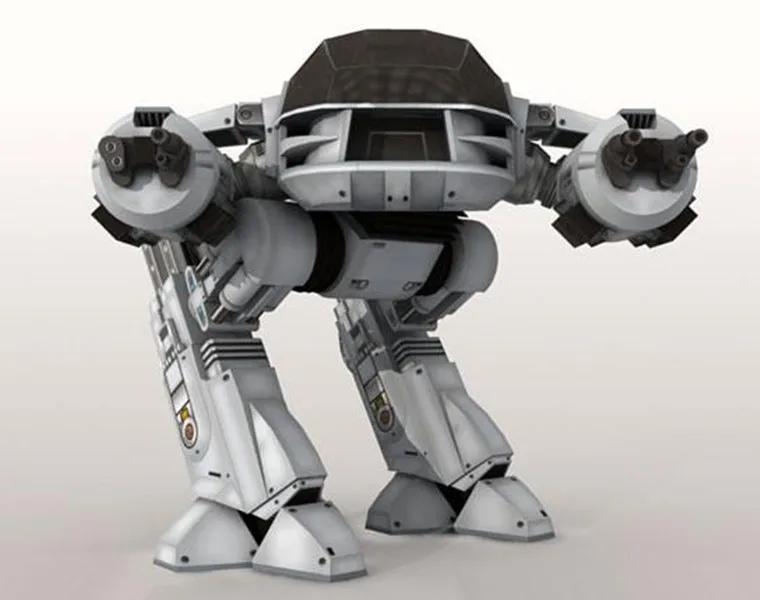

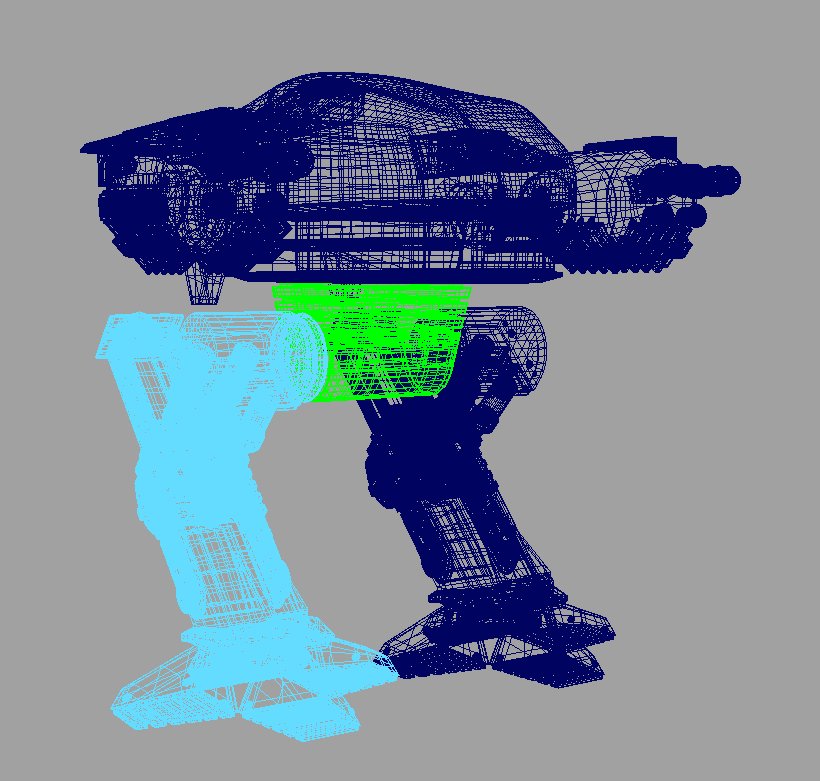

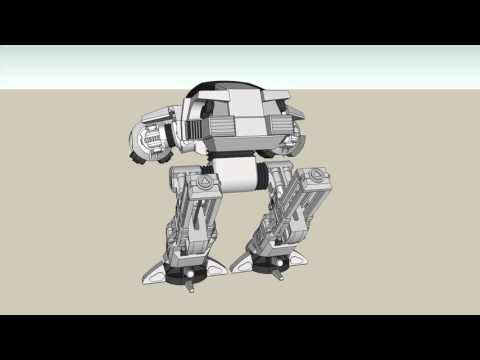

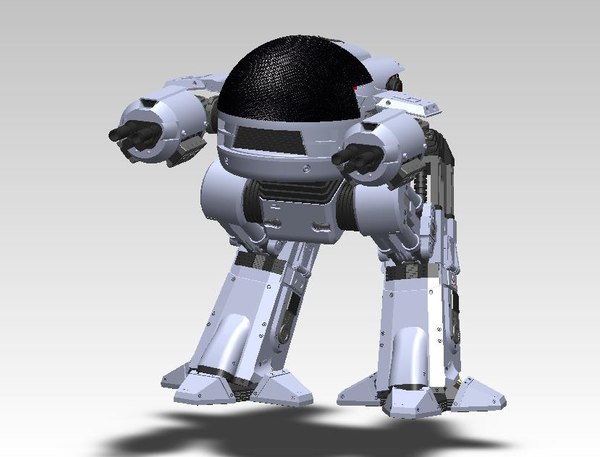

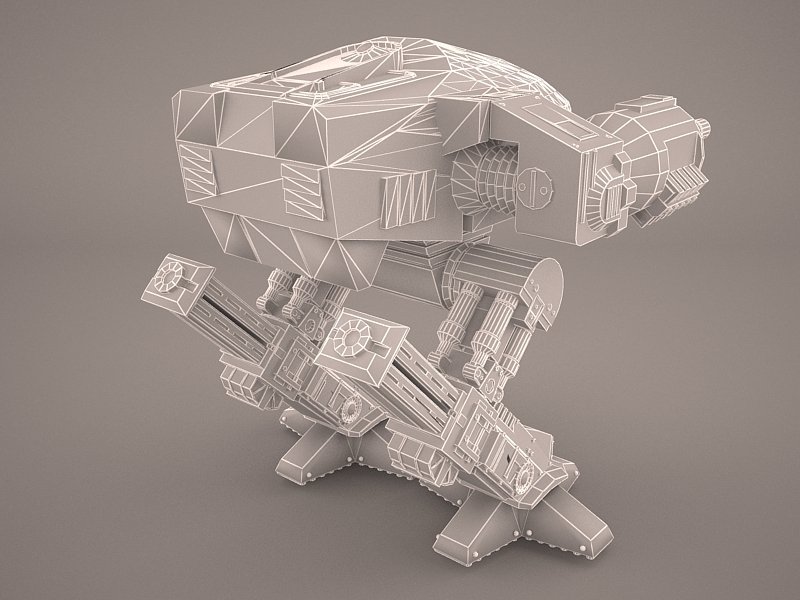

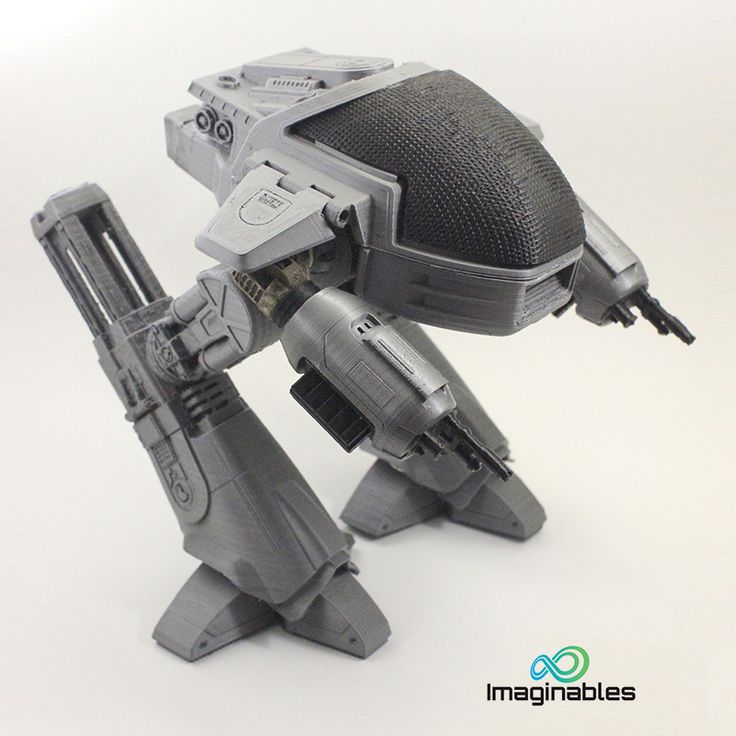

Ed 209 3d print

STL file ED-209 - Robocop 1987・3D printable design to download・Cults

Korban Dallas - 5th Element Taxi Studio Scale

€28.82

Star Trek Mk2 Phaser - Star Trek Continues

€24.02

5th Element Police Car

€28.82

Fallout ED-E Model Kit

€24.02

Fortnite Star Trek Phaser

€9.61

Jeep JK 2007 - 2010 Phone Holder

€4.80

Among Us - Dead or Alive Pegged Version

Free

Among Us - Dead or Alive

Free

Best 3D printer files of the Game category

Robot HORIKAWA style

Free

DEVILMAN / AMON / DEBIRUMAN / デビルマン

€12. 80

Carterpillar (articulated)

Free

le FabShop Wolverine Claws

Free

Helicopter child

Free

Crusader Castle Gate

Free

Redemp-Tau-r Thicc Boi of Immense Heresy

€10.14

Best sellers of the category Game

Articulated Snowman

€2.87

RC 1/10 Dodge Challenger

€7.50

Octopus 2.0

€3.83

Chopper Motorcycle Print-In-Place

€1

Heavy Imperial Fire Support Weapons [Presupported]

€5

SM Healer Conversion Kit

€6

Dirt Bike

€1. 40

40

Lazy Cat

€3.83

Warriors of Iron Heads and MK 3 Shoulder pads

€4.28 -15% €3.64

Alteyr Emberwatch

€9.61

Voidwalker Exosuits Truescale

€14.83

Beaky Boyz Builder: PF_MK-Six

€12.01 -15% €10.20

Catafrac Heavy Armoured Warriors - Limbs Pack

€1.85

Catafrac Heavy Armoured Warriors - Ninth Season Weapons Pack

€3.10

Exolothreftes Truescale

€5

WARFORGED VOIDWALKER EXOSUITS UPGRADE KIT

€9. 61

61

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

ED-209 stl. Files for 3d Printing

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

-

Loading

Click to zoom

Star Seller

Star Sellers have an outstanding track record for providing a great customer experience—they consistently earned 5-star reviews, shipped orders on time, and replied quickly to any messages they received.

| 2,270 sales |

5 out of 5 stars€40.44

Loading

VAT Included

Star Seller. This seller consistently earned 5-star reviews, shipped on time, and replied quickly to any messages they received.

Listed on Sep 18, 2022

75 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies. Tell us more about how this item violates our policies.

Tell us more about how this item violates our policies.

Prospects for the development of 3D printing in construction

Authors : Lokhmutov Nikita Dmitrievich, Kulichkov Denis Vasilievich, Ermolaeva Veronika Viktorovna

Category : Information technology

Posted by in young scientist #23 (209) June 2018

Publication date : 11.06.2018 2018-06-11

Article viewed: 1391 time

Download electronic version

Download Part 3 (pdf)

References:

Lokhmutov, N. D. Prospects for the development of 3D printing in construction / N. D. Lokhmutov, D. V. Kulichkov, V. V. Ermolaeva. - Text: direct // Young scientist. - 2018. - No. 23 (209). — S. 177-179. — URL: https://moluch.ru/archive/209/51318/ (date of access: 11/29/2022).

D. Prospects for the development of 3D printing in construction / N. D. Lokhmutov, D. V. Kulichkov, V. V. Ermolaeva. - Text: direct // Young scientist. - 2018. - No. 23 (209). — S. 177-179. — URL: https://moluch.ru/archive/209/51318/ (date of access: 11/29/2022).

This article is devoted to the prospects for the development of 3D printing in Russia as a manufacturing element of the construction industry. The level of development of construction 3D printing in Russia and foreign countries is shown. Examples of the use of construction 3D printers in Russia and other countries are considered.

Keywords: 3D printing, construction 3D printer.

Development 3 D - print

3D printing is done in several ways, using different materials, but each of the methods uses the technology of creating a layered solid object. 3D printing was invented by American researcher Chuck Hull. In 1986, he showed people his invention, to which he gave the name "installation for stereolithography." But over the years, Scott Crump invented the technology that powers all low-consumption 3D printers today. The technology was called FDM (Fusible Material Decomposition Modeling). In 2008, all 3D printers continued to use only ABS plastic as the main material. But Objet Geometries Ltd introduced a multi-material printer that same year. Today, the number of materials used in 3D printing has already exceeded 100, with biomaterials and concrete being the most interesting among new materials.

3D printing was invented by American researcher Chuck Hull. In 1986, he showed people his invention, to which he gave the name "installation for stereolithography." But over the years, Scott Crump invented the technology that powers all low-consumption 3D printers today. The technology was called FDM (Fusible Material Decomposition Modeling). In 2008, all 3D printers continued to use only ABS plastic as the main material. But Objet Geometries Ltd introduced a multi-material printer that same year. Today, the number of materials used in 3D printing has already exceeded 100, with biomaterials and concrete being the most interesting among new materials.

3 D - printing in construction

In 2014, active construction of buildings began using a 3D printer, concrete was used as the main material. In the same year, the Chinese company WinSun planned to build ten 3D printed houses, and they planned to build them in a day, subsequently they built another five-story house and a mansion. At the university with a technical direction, which is located in Eindhoven, in early 2015, work began on the creation of a 3D printer for making houses. During this time, the team made a small number of projects using a 3d printer, for example, bridges, small pavilions and, most importantly, began designing residential buildings. The buildings built in Eindhoven will have an unusual shape that can only be made with 3D printing. The partners of the university are working hard to make a design of high quality and reliability, which brings innovation to the usual design of houses in the Netherlands. The first tenants will be able to move into their new 3D-printed one-story houses in early 2019year, in the future it is planned to build multi-storey buildings. The details of the first houses will be made on the university's own 3D printer, the next goal of the engineers is to gradually transfer production to the construction site. The final house will be 3D printed directly on the construction site.

At the university with a technical direction, which is located in Eindhoven, in early 2015, work began on the creation of a 3D printer for making houses. During this time, the team made a small number of projects using a 3d printer, for example, bridges, small pavilions and, most importantly, began designing residential buildings. The buildings built in Eindhoven will have an unusual shape that can only be made with 3D printing. The partners of the university are working hard to make a design of high quality and reliability, which brings innovation to the usual design of houses in the Netherlands. The first tenants will be able to move into their new 3D-printed one-story houses in early 2019year, in the future it is planned to build multi-storey buildings. The details of the first houses will be made on the university's own 3D printer, the next goal of the engineers is to gradually transfer production to the construction site. The final house will be 3D printed directly on the construction site. Also in other countries, the use of this technology in construction has begun. As an example, New York City architects are using 3D printing to restore the look of historic buildings. The motivation for the EDG project was the desire to restore the facade design of a historic house on Fifth Avenue in New York City that was due to be demolished. The architects say that the classical ornaments on the facades are too difficult or even impossible to reproduce at the present time - which is why teams around the world do not often turn to the restoration of the remaining historical examples. A new technique using 3D printing makes it possible to create and embed elements of a facade ornament at a very low cost. EDG hopes that the development can be applied to other cities and countries around the world. The technology brings back the feeling of “handmade” production and also democratizes the design process, making it accessible to all industries.

Also in other countries, the use of this technology in construction has begun. As an example, New York City architects are using 3D printing to restore the look of historic buildings. The motivation for the EDG project was the desire to restore the facade design of a historic house on Fifth Avenue in New York City that was due to be demolished. The architects say that the classical ornaments on the facades are too difficult or even impossible to reproduce at the present time - which is why teams around the world do not often turn to the restoration of the remaining historical examples. A new technique using 3D printing makes it possible to create and embed elements of a facade ornament at a very low cost. EDG hopes that the development can be applied to other cities and countries around the world. The technology brings back the feeling of “handmade” production and also democratizes the design process, making it accessible to all industries.

Development 3 D - print in Russia

In Russia in 2015, within the framework of the Machine Tool Building exhibition (Crocus-Expo), CJSC SPETSAVIA presented Russian developments and industrial samples of construction 3D printers. Less than two years later, in February 2017, a completely 3D-printed house was created in Stupino near Moscow. It was erected right on the construction site. And quite quickly, construction technology using 3D printing reached the regions. At the end of May 2018, Yaroslavl engineers made a diagnosis of the first construction 3D printer in Bulgaria. AMT-SPETSAVIA specialists demonstrated how to handle the equipment to the personnel of the purchasing company. In addition to managing the printer, the training program included the formation of G-codes, the selection of recipes from local materials and the preparation of mixtures for printing, routine maintenance of equipment, and test printing.

Less than two years later, in February 2017, a completely 3D-printed house was created in Stupino near Moscow. It was erected right on the construction site. And quite quickly, construction technology using 3D printing reached the regions. At the end of May 2018, Yaroslavl engineers made a diagnosis of the first construction 3D printer in Bulgaria. AMT-SPETSAVIA specialists demonstrated how to handle the equipment to the personnel of the purchasing company. In addition to managing the printer, the training program included the formation of G-codes, the selection of recipes from local materials and the preparation of mixtures for printing, routine maintenance of equipment, and test printing.

As a result, a local construction company received an AMT S-6044 Long construction printer with a working field of 8x8 meters. The printer can print with standard cement based formulations M 300-500. The print speed is about 10 square meters. m / h in terms of a single-chamber wall.

Rice. one.

one.

Also, AMT-SPETSAVIA 3D printers are already operating in Denmark, Kazakhstan, Moldova, and Uzbekistan. To date, the most famous project of the company is the 3D printing of a residential building in the Yaroslavl region.

3 D - printing on large objects

In the European organization for nuclear research CERN, 3D printing technologies are being introduced into the development of new materials and parts - since 2014, elements of the Large Hadron Collider have been produced using SLA technology using a 3D printer of their own design. Now CERN experts are exploring ways to 3D print metal, engineers are especially interested in magnetic superconductors and parts for working with radio frequencies.

Simufact Additive will partner with CERN to develop selective laser melting (SLM) 3D printing technologies. The Simufact team will provide CERN researchers with computer simulations to predict the results of 3D printing, enabling more efficient and cost-effective use of expensive parts. The Simufact Additive Platform is a digital tool integrated with the Materialize Magics software and has been on the market for over a year. The simulation is used by more than 60 customers, including the German manufacturer of precision components Toolcraft.

The Simufact Additive Platform is a digital tool integrated with the Materialize Magics software and has been on the market for over a year. The simulation is used by more than 60 customers, including the German manufacturer of precision components Toolcraft.

The value of Simufact simulations for engineers at CERN is obvious - predicting the results of 3D printing allows you to get perfect parts from expensive materials the first time. In addition to 3D printing, the Simufact Additive platform calculates the results of heat treatment, removal of support materials and the print platform, as well as other methods of processing metal parts.

Conclusion

3D printing has a wide range of applications in our lives. 3D printing can, if not solve, then help solve many global problems. The development of a building project of any complexity and its construction will take several times less time, and this technology will also allow in the future to build structures on other planets, in particular on Mars. For Russia, the technology of erecting buildings using a 3D printer is quite relevant. From February 1, 2017, all Russian citizens can apply for a “Far Eastern hectare”. With the help of 3D printing technology, it is possible to build a whole village in the Far East in a week. This technology, of course, has its drawbacks, including the high cost of equipment, but if we rationalize this industry a little, our future undoubtedly belongs to it. This article highlights only a part of the possibilities of 3D printing, it plays an equally important role in medicine and many other areas.

For Russia, the technology of erecting buildings using a 3D printer is quite relevant. From February 1, 2017, all Russian citizens can apply for a “Far Eastern hectare”. With the help of 3D printing technology, it is possible to build a whole village in the Far East in a week. This technology, of course, has its drawbacks, including the high cost of equipment, but if we rationalize this industry a little, our future undoubtedly belongs to it. This article highlights only a part of the possibilities of 3D printing, it plays an equally important role in medicine and many other areas.

Literature:

- http://www.3dpulse.ru

- https://en.wikipedia.org

Basic terms (automatically generated) : CERN, Russia, EDG, ABS, FDM, SLA, SLM, New York, main material, Eindhoven.

Keywords

3D printing, construction 3D printer3D printing, construction 3D printer

Similar articles

3D printer is the technology of the future | Journal article.

..

.. Core technologies ( SLA , SLS, DLP, EBM, HPM). Printing on 3D printers can be done in different ways, in

1) SLA - technology - laser stereolithography. Fusion Printing Technology ( FDM ) was designed by S. Scott...

Problems and prospects of creating the World Financial Center

...New - York .

Basic terms (automatically generated): Russia , global financial center , Moscow, GFCI, financial market, government RF , creation, Russian Federation, international financial center , Central Bank.

Analysis of the change in the metaphorical image

of Russia ...The material of research are articles about the relationship between Russia and the world since July 2015 in English and American newspapers

the image of V. V. president of Russia — main threat in...

V. president of Russia — main threat in...

On- and off-trade channels as

main communication channels...Glenny M. Dark Market : cyberthieves, cybercops, and you, New York , NY: Alfred A. Knopf, 2011.

Basic terms (automatically generated tobacco products, healthy lifestyle): , Russia , tobacco consumption, cigarette, human health, harm of smoking.

Desktop 3D Printer | Article in the journal "Young scientist"

1) SLA - technology - laser stereolithography.

Basic terms (automatically generated): FDM , original material , ABS , SLS, PLA, PET, PCL, HDPE, DMLS, laser radiation.

The heyday of social advertising on the example of the United States | Article in the collection.

..

.. The main economic role of advertising in such an environment is to create artificial needs, to expand the market through

In an institutional strip ad in the New - York Times, the Chamber of Commerce appealed to Americans to "Save America!".

Evaluation of the economic efficiency of the implementation of cloud...

In the banking sector Russia , only in the last five years began to show interest in the cloud ABS .

- cost of development and implementation of the project; - involvement of external consultants; - initial purchases main SW

The role of northern-eastern trade route in the relationships of the...

Basic terms (automatically generated): XVII-XVIII, Russia , Moscow state, Russian geography, XII-XVII, XVI-XVIII, XVI centuries

XVII - XVIII centuries. and " Russia and Mongolia". Undoubtedly, the most valuable materials and conclusions are contained in the works of the well-known ...

and " Russia and Mongolia". Undoubtedly, the most valuable materials and conclusions are contained in the works of the well-known ...

Analysis of the system of production and consumption of clothing in fashion...

The Internet, as the main means of obtaining information from a modern person personifies

For example, New - the York SOLS company, which is one of the first to use three-dimensional

The current state of the baking industry Russia.

Similar articles

3D printer is the technology of the future | Journal article...

Basic technologies ( SLA , SLS, DLP, EBM, HPM). Printing on 3D printers can be done in different ways, in

1) SLA - technology - laser stereolithography. Fused deposition printing technology ( FDM ) was developed by S. Scott...

Scott...

Problems and prospects of creating the World Financial Center

...New - York .

Basic terms (automatically generated): Russia , global financial center , Moscow, GFCI, financial market, government RF , creation, Russian Federation, international financial center , Central Bank.

Analysis of the change in the metaphorical image

of Russia ...The material of research are articles on relationships Russia and the world since July 2015 in English and American newspapers

the image of V.V. Putin as President RF is still the most striking and controversial; president of Russia — main threat in. ..

..

On- and off-trade channels as

main communication channels ...Glenny M. Dark Market : cyberthieves, cybercops, and you, New York , NY: Alfred A. Knopf, 2011.

Basic terms (automatically generated): tobacco products, healthy lifestyle, Russia , tobacco consumption, cigarette, human health, harm of smoking.

Desktop 3D Printer | Article in the journal "Young scientist"

1) SLA - technology - laser stereolithography.

Basic terms (automatically generated): FDM , original material , ABS , SLS, PLA, PET, PCL, HDPE, DMLS, laser light.

The heyday of social advertising on the example of the United States | Article in the collection.

..

.. The main economic role of advertising in such an environment is to create artificial needs, to expand the market through

In a strip institutional advertisement in the New - York Times, the Chamber of Commerce appealed to Americans with the appeal: “Save, America! ".

Evaluation of the economic efficiency of the implementation of cloud...

In the banking sector Russia , only in the last five years began to show interest in the cloud ABS .

- cost of development and implementation of the project; - involvement of external consultants; - initial purchases main software

The role of northern-eastern trade route in the relationships of the...

Basic terms (automatically generated): XVII-XVIII, Russia , Moscow state, Russian geography, XII-XVII, XVI-XVIII, XVI centuries

XVII-XVIII centuries. and " Russia and Mongolia". Undoubtedly, the most valuable materials and conclusions are contained in the works of the well-known...

and " Russia and Mongolia". Undoubtedly, the most valuable materials and conclusions are contained in the works of the well-known...

Analysis of the system of production and consumption of clothing in fashion...

Internet as basic means of obtaining information from a modern person personifies

For example, New - York company SOLS, which is one of the first to use three-dimensional

The current state of the baking industry Russia .

A little about 3D printing | PC World

What should you pay attention to when choosing a 3D printer? Tips for newbies.

The first 3D printers appeared quite a long time ago, back in the 80s of the XX century. Over the past time, printing technology has stepped far forward, and now there are many models on the market that implement various types of printing. The most popular and affordable 3D printers are based on FDM (Fused Deposition Modeling) technology.

The most popular and affordable 3D printers are based on FDM (Fused Deposition Modeling) technology.

Their principle of operation is simple: a plastic thread, called a filament, enters the heater, where it is melted, and then ejected through a tiny hole in the printing nozzle. The moving head of the printer can be compared to a very precise glue gun, but the molten plastic flows out of the nozzle of the 3D printer (extruder) in a much thinner stream. By successive passage of the head, the printer is able to build very thin layers of plastic, each subsequent of which is superimposed on the previous one.

If there is nothing at the bottom—for example, when you print an arch or a roof surface—the printer creates a special support that can be removed when the print is complete. Some models build relief by cooling with air flow. You can create anything, it depends on your imagination and the physical dimensions of the printer.

If you decide to purchase such a device, you should pay attention to a few points.

First, accuracy and speed. Accuracy is usually understood as the height of the layer when printing - the smaller it is, the higher the accuracy. Currently, the most accurate 3D printer is capable of printing with a layer height of 50 microns. Speed refers to the rate at which the model grows, measured in square centimeters per hour. When printing, you should pay attention to the fact that the higher the accuracy, the lower the speed, and vice versa. For example, printers with an accuracy of 150 microns are suitable for the home.

Secondly, you should take into account the declared accuracy of printing and the conformity of the materials and components from which the 3D printer is made. Sometimes manufacturers claim very high print accuracy (for example, 50 microns is less than the pixel size of the iPhone), and the printer body is assembled from plywood, which does not provide a rigid structure and similar accuracy.

Most printers are compatible with one type of filament, usually ABS (acrylonitrile butadiene styrene) or PLA (polylactic acid, which is basically polyester). ABS and PLA are the most common now. Some printers can print with both types, others only with one of them. But, in addition to them, other threads with different properties can be used: solubility in water; glow in the dark; great flexibility; structure and smell of wood; increased strength, etc.

ABS and PLA are the most common now. Some printers can print with both types, others only with one of them. But, in addition to them, other threads with different properties can be used: solubility in water; glow in the dark; great flexibility; structure and smell of wood; increased strength, etc.

It is likely that you will not need most of the plastics, but you can hardly know this in advance. And therefore, if you like to experiment or still don’t really know what type of model and what you plan to print from, choose a 3D printer with the maximum number of supported types of plastic filaments.

Many manufacturers supply 3D printers in a box with individual elements, which are assembled by the user. If the DIY approach doesn't suit you, choose a pre-assembled model.

In the early days of 3D printing, assembling a printer was a very complex process, involving pins on a printed circuit board (and often searching for missing components). To date, this procedure has been greatly simplified. Kits like the Ultimaker contain few parts, do not require soldering, drilling and cutting, and all components are connected to each other with standard screws or bolts.

To date, this procedure has been greatly simplified. Kits like the Ultimaker contain few parts, do not require soldering, drilling and cutting, and all components are connected to each other with standard screws or bolts.

Another option is to purchase all the necessary components in the nearest store. If you have enough experience and patience, you can build a RepRap (Replicating Rapid Prototyper) printer. RepRap printers usually consist of widely used elements and components that can be printed on the 3D printer itself. The use of printed components eliminates the need for custom manufacturing, but you must have access to other 3D printers during the assembly process

And the last thing you should pay attention to is the printing software. It tells the printer how to move when printing an object. It also allows you to control the speed of ejection of the plastic thread from the extruder, the heating temperature of the filament, the speed of formation of layers and their thickness.

For some 3D printers, the required software is not included in the package. If not, you should go to the manufacturer's website and look for relevant links or recommendations.

For those who are new to 3D printing, we decided to clarify a few topical issues. To do this, we talked with Mikhail Loktev, a design engineer at Foto-Business.

– What is 3D printing for?

– Simply put, the printer takes any three-dimensional model and implements it in plastic or some other material and simplifies the work of creating an object. This is actually where it all began - fast and easy prototyping. You are an engineer who has designed a new door handle or gear. Before launching it into a series and spending a large investment, it is reasonable to check it. What was done before - they took plasticine, a file, an expensive CNC machine, which made this model from wood, metal. But the machine can cut far from everything, and it will take a lot of time to set it up to make some kind of detail. The printer also allows, roughly speaking, to do the same thing in 20 minutes to 20 hours, only practically without any human participation. There is a model, just press a few buttons and the process has started. Some of the first who were our customers were filmmakers, they constantly need to make some items for films and to be inexpensive. For example, a pistol or a blaster - printed, painted as needed and ready. Printers are also bought by state corporations that need to make some kind of model, because there are secret things, military developments, dual-use. But they do not want prototyping to be carried out on the side and extra people were admitted to them. Buy and place a machine in KB - is not affordable for everyone, but the printer solves this problem and allows you to get rid of information leakage. This is true for commercial structures as well.

But the machine can cut far from everything, and it will take a lot of time to set it up to make some kind of detail. The printer also allows, roughly speaking, to do the same thing in 20 minutes to 20 hours, only practically without any human participation. There is a model, just press a few buttons and the process has started. Some of the first who were our customers were filmmakers, they constantly need to make some items for films and to be inexpensive. For example, a pistol or a blaster - printed, painted as needed and ready. Printers are also bought by state corporations that need to make some kind of model, because there are secret things, military developments, dual-use. But they do not want prototyping to be carried out on the side and extra people were admitted to them. Buy and place a machine in KB - is not affordable for everyone, but the printer solves this problem and allows you to get rid of information leakage. This is true for commercial structures as well.

Plastic is an exceptionally plastic material. We can make very low volume parts without significant mold and casting costs. Again, personalized products, souvenirs. Now many businesses are founded by students, for example, they print custom phone cases with silhouettes of something, a logo or the name of the customer. It's cheap enough.

The printer allows you to simplify existing technological processes, improve any detail, refine it. For example, a customer came from the food industry, they are constantly changing something in the form of bakery products. Before launching them into a series, you need to see how it will look. They print both the form and the sample itself.

– Is food grade plastic used in printing and is it possible to print kitchen utensils?

- Let's just say that PLA plastic - organic material is theoretically absolutely safe in terms of chemical composition, but I would not expose it to high temperatures when cooking. In general, a great variety of plastics are now appearing - luminous, with the smell of wood, flexible, conductive, etc. It is possible that soon they will also be used to create dishes, the potential for chemistry is huge and there is room to move. The main thing is that there are tasks, it pushes manufacturers.

In general, a great variety of plastics are now appearing - luminous, with the smell of wood, flexible, conductive, etc. It is possible that soon they will also be used to create dishes, the potential for chemistry is huge and there is room to move. The main thing is that there are tasks, it pushes manufacturers.

– Is it difficult to master printing on a printer without knowing 3D modeling programs?

– Nothing really complicated. Depending on perseverance - from several hours to several days, but this time is necessary to master the printer itself - after all, such a printer is now like a fashionable gadget. Knowledge of modeling programs is not required, although it will not hurt. The Internet is full of model files optimized for printing. For example, there are no cases for the iPhone. Download, print. If you want something of your own, there are, in addition to complex programs, many simple visual editors.

– What is the cost of consumables?

- The cost of printing using good quality plastic is about 1.5-1.7 rubles per gram. The cost of the finished model depends on the filling. It is worth considering that the printer allows you to print both thin-walled and fully filled models, everything can be adjusted.

Plastic comes in 1kg spools and is easy to buy.

– Do I really need to take care of the ventilation of the room, can I, for example, put the printer at home?

– The situation is this: PLA plastic can be printed without problems at home. With ABS plastic, everything is more complicated, there are noticeably more emissions from it, you should take care of a separate, well-ventilated room. However, it is noticeably stronger.

However, it is noticeably stronger.

– What is the average life of a 3D printer?

– For some American models, the service life is about two to three months with daily constant use. Domestic models, for example PrintBox 3D One, are noticeably better - the resource of the mechanism is enough for several years of operation, with Chinese ones it is more and more difficult - the quality is unstable.

– How do you feel about self-assembly printers?

- Self-assembly printer - is, in my opinion, a blende. The person who is able to assemble such a device will do it without buying a kit. 95% of those who decide to save money in this way will simply not collect it or will suffer with it for a very long time.

Learn more