Light based 3d printing

Guide to Resin 3D Printers

There are many 3D printing processes on the market. Getting familiar with the nuances of each helps to clarify what you can expect from final prints to ultimately decide which technology is suitable for your particular application.

Stereolithography (SLA) and digital light processing (DLP) 3D printing are the two most common processes for resin 3D printing. Resin printers are popular for producing high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish.

While these technologies were once complex and cost-prohibitive, today’s small-format desktop SLA and DLP resin 3D printers produce industrial-quality parts at an affordable price point and with unmatched versatility thanks to a wide range of materials.

Both processes work by selectively exposing liquid resin to a light source—SLA a laser, DLP a projector—to form very thin solid layers of plastic that stack up to create a solid object. While very similar in principle, the two technologies can produce significantly varying outputs.

In this in-depth guide, we walk through the details of the two resin 3D printing processes and explore how they compare in terms of resolution, accuracy, build volume, speed, workflow, and more.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

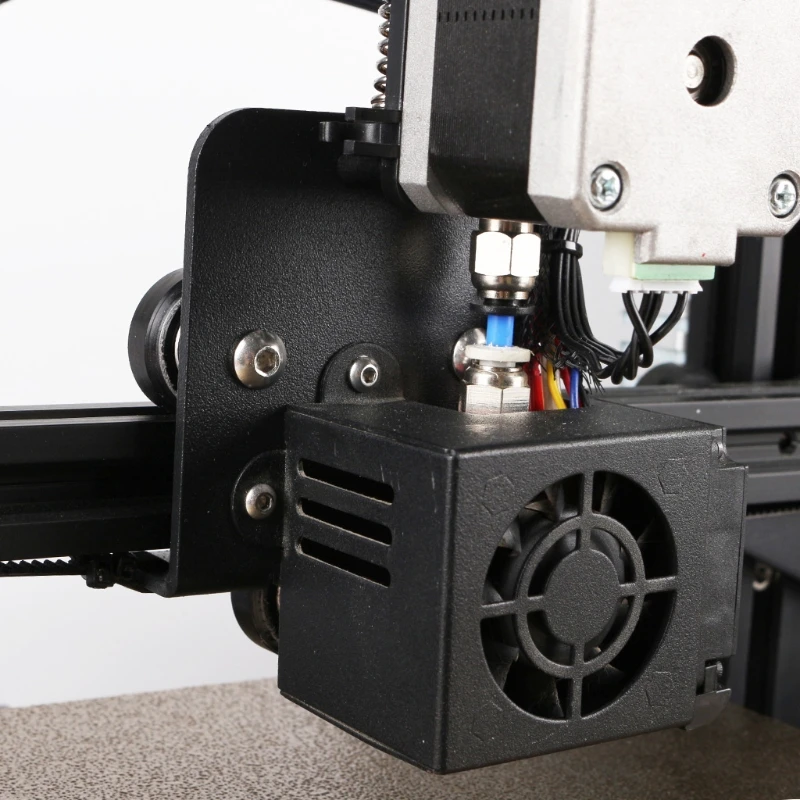

Desktop SLA 3D printers contain a resin tank with a transparent base and non-stick surface, which serves as a substrate for the liquid resin to cure against, allowing for the gentle detachment of newly-formed layers.

The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or the last completed layer, and the bottom of the tank. A laser points at two mirror galvanometers, which direct the light to the correct coordinates on a series of mirrors, focusing the light upward through the bottom of the tank and curing a layer of resin.

The cured layer then gets separated from the bottom of the tank and the build platform moves up to let fresh resin flow beneath. The process repeats until the print is complete.

Low Force Stereolithography (LFS) technology, used by the Form 3+ and Form 3L, is the next phase in SLA 3D printing.

In LFS 3D printers, the optics are enclosed in a Light Processing Unit (LPU). Within the LPU, a galvanometer positions the high-density laser beam in the Y direction, passes it through a spatial filter, and directs it to a fold mirror and parabolic mirror to consistently deliver the beam perpendicular to the build plane and ensure accurate, repeatable prints.

As the LPU moves in the X direction, the printed part is gently peeled away from the flexible bottom of the tank, which drastically reduces the forces exerted on parts during the print process.

LFS 3D printing drastically reduces the forces exerted on parts during the print process, using a flexible tank and linear illumination to deliver incredible surface quality and print accuracy.

This advanced form of stereolithography delivers vastly improved surface quality and print accuracy. Lower print forces also allow for light-touch support structures that tear away with ease, and the process opens up a wide range of possibilities for future development of advanced, production-ready materials.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

Just like their SLA counterparts, desktop DLP 3D printers are built around a resin tank with transparent bottom and a build platform that descends into a resin tank to create parts upside down, layer by layer.

The difference is the light source. DLP 3D printers use a digital projector screen to flash an image of a layer across the entire platform, curing all points simultaneously.

The light is reflected on a Digital Micromirror Device (DMD), a dynamic mask consisting of microscopic-size mirrors laid out in a matrix on a semiconductor chip. Rapidly toggling these tiny mirrors between lens(es) that direct the light towards the bottom of the tank or a heat sink defines the coordinates where the liquid resin cures within the given layer.

Because the projector is a digital screen, the image of each layer is composed of square pixels, resulting in a three-dimensional layer formed from small rectangular cubes called voxels.

Resolution shows up more often than any other value in 3D printer spec sheets, but it’s also a common ground for confusion. The basic units of the SLA and DLP processes are different shapes, making it difficult to compare the different machines by numerical specifications alone.

In 3D printing, there are three dimensions to consider: the two planar 2D dimensions (X and Y) and the third vertical Z dimension that makes 3D printing.

Z resolution is defined by the layer thicknesses a 3D printer can produce. Resin 3D printers like SLA and DLP offer some of the finest Z resolutions—thinnest layers—of all 3D printing processes and users can normally choose from a range of layer height options between 25-300 microns, allowing designers to strike a balance between detail and speed.

In DLP 3D printing, XY resolution is defined by the pixel size, the smallest feature the projector can reproduce within a single layer. This depends on the resolution of the projector, the most common being full HD (1080p), and its distance from the optical window. As a result, most desktop DLP 3D printers have a fixed XY resolution, generally between 35 to 100 microns.

For SLA 3D printers, XY resolution is a combination of the laser’s spot size and the increments by which the laser beam can be controlled. For example, the Form 3 LFS 3D printer features a laser with an 85 micron spot size, but because of the constant line scanning process, the laser can move in smaller increments and the printer can consistently deliver parts with 25 micron XY resolution.

However, resolution in itself is often just a vanity metric. It offers some indication, but it doesn’t necessarily correlate directly with accuracy, precision, and print quality.

Learn more about resolution in 3D printing in our in-depth guide.

Because 3D printing is an additive process, each layer introduces an opportunity for inaccuracy, and the process by which layers are formed affects the level of precision, defined as the repeatability of the accuracy of each layer. Accuracy and precision depend on many different factors: 3D printing process, materials, software settings, post-processing, and more.

In general, both SLA and DLP resin 3D printers are among the most accurate and precise 3D printing processes. Differences in accuracy and precision are often better explained by the differences between machines by various manufacturers than differences between the technologies themselves.

For example, entry-level SLA or DLP printers might use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers will try to get the best performance possible out of these parts. Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Accuracy and precision are crucial for parts like dental splints (left) and surgical guides (right).

Calibration is also crucial. With DLP projectors, manufacturers need to deal with the non-uniform light distribution on the build plane and optical distortion of the lenses—meaning that pixels in the middle are not the same size or shape as pixels on the edges. SLA 3D printers use the same light source for every part of the print, which means it’s uniform by definition, but they still require extensive calibration to account for distortions.

Even a 3D printer with the highest quality components and degree of calibration can produce widely varying results depending on the material. Different resins require optimized material settings to perform as intended, which might not be available for off-the-shelf materials or resins that are not thoroughly tested with a specific 3D printer model.

The takeaway? Accuracy and precision are almost impossible to understand from the technical specifications alone. Ultimately, the best way to evaluate a 3D printer is to inspect real parts or ask the manufacturer to create a test print of one of your own designs.

With DLP 3D printers, there’s a direct trade-off between resolution and build volume. The resolution depends on the projector, which defines the number of pixels/voxels available. If one moves the projector closer to the optical window, the pixels get smaller, which increases the resolution, but limits the available build area.

Some manufacturers stack multiple projectors next to each other or use a high-definition 4K projector to increase the build volume, but this leads to substantially higher costs that often price these machines out of the desktop market.

As a result, DLP 3D printers are generally optimized for specific use cases. Some have a smaller build volume and offer high resolution to produce small, detailed pieces like jewelry, while others can produce bigger parts but at a lower resolution.

The stereolithography process is inherently more scalable, since an SLA 3D printer’s build volume is completely independent of the resolution of the print. A single print can be any size and any resolution at any location within the build area. This makes it possible to 3D print large parts at high resolution or a large batch of detailed small parts to increase throughput with the same machine.

The other main barrier to increasing build volume in both SLA and DLP 3D printers is the peel force. When printing larger parts, the forces exerted on the parts increase exponentially as a cured layer separates from the tank.

In LFS 3D printing, the flexible film at the base of the resin tank gently peels away as the build platform pulls the part up, significantly reducing the stress on the part. This unique feature has made it possible to substantially increase the build volume for the first accessible large format SLA 3D printer, the Form 3L.

The Form 3L is the first affordable large format SLA 3D printer with a build volume of 30 cm x 33. 5 cm x 20 cm.

5 cm x 20 cm.

Webinar

Want to learn more about the Form 3L and Form 3BL ecosystem, and the new large format post-processing machines?

In this demo, Kyle and Chris will expain how to navigate the Form 3L end-to-end workflow, including post-processing.

Watch Now

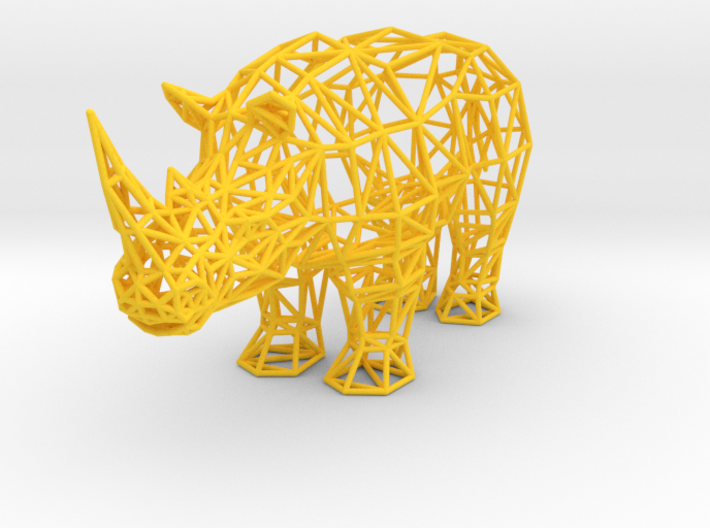

SLA and DLP resin 3D printers both known for creating parts with the smoothest surface finish of all 3D printing processes. When we describe the differences, in most cases these are only visible on tiny parts or highly detailed models.

Because objects are made of layers in 3D printing, 3D prints often have visible, horizontal layer lines. However, because DLP renders images using rectangular voxels, there is also an effect of vertical voxel lines.

DLP 3D printers render images using rectangular voxels, which causes an effect of vertical voxel lines. In this image, see the vertical voxel lines as they appear naturally on the left, and then outlined to more easily identify on the right.

Because the unit is rectangular, voxels also have an effect on curved edges. Think of building a round shape out of LEGO bricks—the edges will appear stepped on both the Z axis and the X-Y plane.

The rectangular shape of voxels makes curved edges appear stepped. Removing the appearance of voxel and layer lines requires post-processing, such as sanding.

In LFS 3D printing, layer lines are close to invisible. As a result, surface roughness is reduced, which ultimately leads to smooth surfaces, and for clear materials, more translucent parts.

When thinking about speed in 3D printing, it’s important to consider not just raw print speed, but also throughput.

Raw print speed for SLA and DLP resin 3D printers is comparable in general. As the projector exposes each entire layer all at once, print speed in DLP 3D printing is uniform and depends only on the height of the build, whereas, SLA 3D printers draw out each part with a laser. As a rule of thumb, this results in SLA 3D printers being comparable or faster when printing small or medium-size single parts, while DLP 3D printers are faster to print large, fully dense prints, or builds with multiple parts that fill up much of the platform.

But once again, it’s worth considering the trade-off between resolution and build volume for DLP printers. A small DLP 3D printer can print a small part or a (small) batch of smaller parts fast, at high resolution, but the build volume limits the part size and the throughput. A different machine with a larger build volume can print larger parts or a batch of smaller parts faster, but at a lower resolution than SLA.

SLA 3D printers can produce all of these options in one machine and offer the user the freedom to decide whether she wants to optimize for resolution, speed, or throughput.

SLA 3D printers offer a larger build volume, allowing users to batch parts and print overnight to increase throughput.

Speed can also depend on the material choice. Printing four times faster than Formlabs standard materials, Draft Resin fast-printing resin that is ideal for initial prototypes, rapid iterations, as well as dental and orthodontic models. From fast print initiation speeds to minimal support removal, wash, and cure times, Draft Resin has an optimized workflow to truly maximize efficiency.

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Just like with accuracy and precision, the workflow and available materials differ more from machine to machine than technology to technology.

Most SLA and DLP 3D printers are “plug and play,” with easily swappable build platforms and resin tanks. Some more advanced models also come with a cartridge system to automatically refill the tank with liquid resin, which requires less attention and facilitates printing overnight.

Some printers come with proprietary software to prepare 3D models for printing, such as PreForm for Formlabs SLA 3D printers, while other manufacturers offer off-the-shelf solutions. Features differ by software tool, for example, PreForm offers one-click print setup, powerful manual controls to optimize support density and size, adaptive layer thickness, or functions to save material and time. Luckily, the software can be easy to download and test before purchasing a 3D printer.

Resin 3D printers offer a variety of materials for a wide range of applications.

One of the most significant benefits of resin 3D printing is the variety of materials that make it possible to create parts for diverse applications. Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

However, the range of supported material options depend on the 3D printer model, so we recommend inquiring with the manufacturer before purchase.

Parts printed with both SLA and DLP technologies require post-processing after printing. First, the parts need to be washed in a solvent to remove excess resin. Some functional materials like engineering or biocompatible parts also require post-curing. For SLA 3D printers, Formlabs offers solutions to automate these steps, saving time and effort.

At last, 3D printed parts printed on supports require these structures to be removed, a manual process that is similar for both SLA and DLP 3D printers. LFS 3D printing simplifies this step by offering light-touch support structures that use very small touchpoints to enable easy removal with minimal support marks left behind.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

After sorting out the differences in technology and outcomes, we hope it’s much easier to select a resin 3D printer that best matches your workflow and output needs.

To explore the next generation of SLA 3D printing, learn more about the Form 3 and Form 3L LFS 3D printers.

Curious to see the quality firsthand? Order a sample part shipped to your office.

Request a Free Sample Part

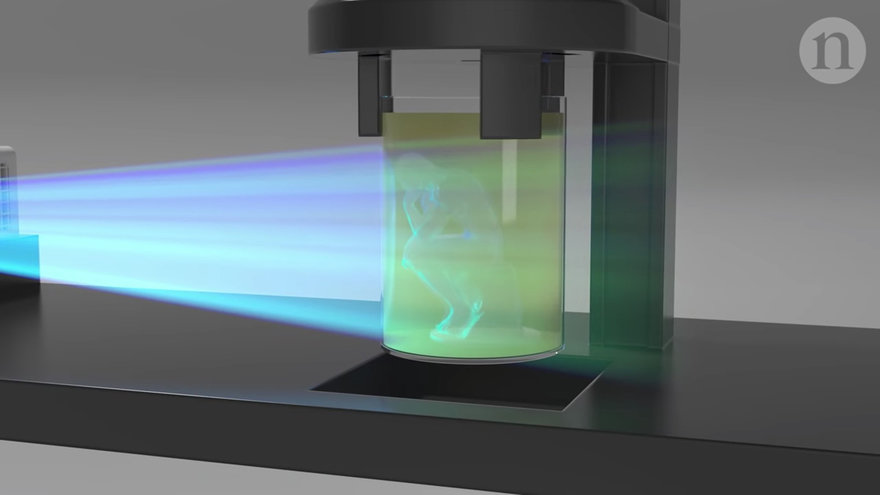

3D Printing with Rays of Light

Most 3D printers build up 3D objects layer by layer. This creates a “stair-step” effect along the edges. It also limits the printer’s ability to build flexible objects because bendable materials often deform during printing; and stiff supports are required to print objects of certain shapes such as arches and overhangs.

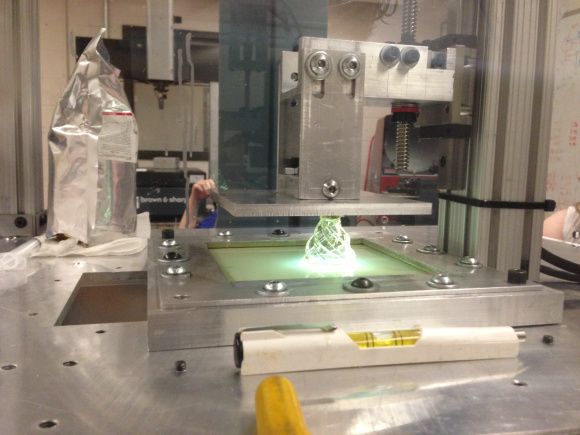

A new printer developed at UC Berkeley relies on a viscous liquid that transforms into a solid when exposed to a certain amount of light. That light is precisely projected as a carefully crafted pattern into a transparent rotating cylinder of the liquid that solidifies into the printed object “all at once.”

The 3D printer works by shining changing patterns of light through a rotating vial of liquid. A computer algorithm calculates the exact patterns of light needed to shape a specific object. (Courtesy: Hayden Taylor)

“Basically, it’s an off-the-shelf video projector I brought from home, and you plug it into a laptop and use it to project a series of computed images, while a motor turns a cylinder that has a 3D printing resin in it,” explains Hayden Taylor, a mechanical engineering professor. “Obviously there are a lot of subtleties to it, including how you formulate the resin and how you compute the light patterns that will be projected, but the barriers to creating a simple version of this tool are not that high. ”

”

Taylor and his used the printer to create a series of objects, from a tiny model of Rodin’s “The Thinker” statue to a customized jawbone model. Currently, they can make objects up to 4 in. in diameter.

The researchers formulated a thick, syrupy liquid that hardens into a solid when exposed to a certain threshold of light. (Courtesy: Stephen McNally)

Besides patterning the light, which requires complex calculations to get the exact shapes and intensities right, the other major challenge was formulating a resin that stays liquid when exposed to a little bit of light but forms a solid when exposed to a lot of light.

“Even liquid you don’t want cured gets exposed to some light, so there needs to be a threshold of light exposure for this transition from liquid to solid,” Taylor says.

UC Berkeley researchers used a new light-based 3D printing technique to add a handle onto a screwdriver shaft. (Courtesy: Stephen McNally)

The resin consists of liquid polymers mixed with photosensitive molecules and dissolved oxygen. Light activates the photosensitive compound which depletes the oxygen. Only in regions where oxygen has been depleted will polymers form the “cross-links” that turn the resin into a solid. Unused resin can be recycled by heating it in an oxygenated atmosphere.

Light activates the photosensitive compound which depletes the oxygen. Only in regions where oxygen has been depleted will polymers form the “cross-links” that turn the resin into a solid. Unused resin can be recycled by heating it in an oxygenated atmosphere.

The technique generates almost no material waste and uncured material is 100% reusable—another advantage of support-free 3D printing.

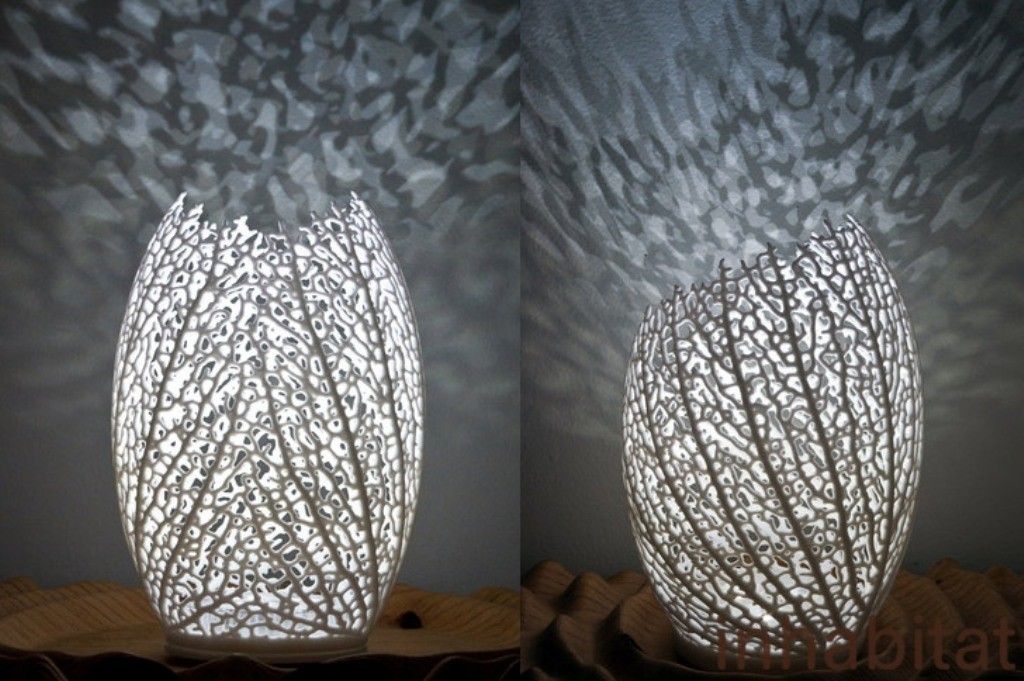

The new printing method can create objects that are smoother, more flexible, and more complex than what is possible with traditional 3D printers. It can also encase objects with new materials. For example, it can add a handle to a metal screwdriver shaft, something current printers struggle to do.

The objects also don’t have to be transparent. Researchers printed objects that appear to be opaque using a dye that transmits light at the curing wavelength but absorbs most other wavelengths.

Do-it-yourself lightsaber or choosing transparent plastic for 3D printing Bringing what we see on the big screen to life in a believable way requires a lot of trickery, and with limited resources and budgets, creative skills are sharpened to the limit.

PapaTony's Shield&Hammer team offers their own solution to the task of making a lightsaber.

One of the rare materials is transparent tubes. They can be obtained in advertising workshops, where light structures are made. We conducted an on-duty call to all those involved in such a case within a radius of 500 kilometers around Krasnoyarsk. All that they could offer us was the certainty that some factory would put the required pipe into the production plan and it might be delivered in 3-4 months. Plus prepayment. Obviously not our choice.

Decided to do everything by hand. nine0003

In general, we did not make a Jedi sword, but the design is similar. So, to create a luminous blade, you need a strong transparent plastic.

For tests, we took materials already known to us and decided to master new ones:

- Natural PLA is a material widely known to everyone working with 3d printing. Differs in ease of the press, high rigidity.

- Natural Watson (SBS) is a very popular thin-walled plastic. The ease of post-processing to give the product evenness and transparency has made this plastic the best choice for creating vases/bottles/dishes/lamps, etc. They are easy to print with moderate softness. nine0018

- Natural PETG is a material that has recently gained popularity. It has excellent interlaminar adhesion. Practical experience with him is not enough, we will catch up.

- Transparent ABS is a very mysterious material. Natural ABS is ivory white with a slight warm yellowish tint. Apparently, transparency is achieved by adding some substance. According to the manufacturer, printing and processing is no different from conventional ABS.

A printer with a print height of 1 meter was also not found, and there was not enough time to assemble my own. Therefore, a test for bonding strength was added to the test for the strength of the structure itself.

Therefore, a test for bonding strength was added to the test for the strength of the structure itself.

Printing was done with the following settings:

- The print and bed temperatures for each material were selected closer to the upper limit of the manufacturer's recommendations - this way there is a higher probability of obtaining a stronger adhesion of the layers

- Nozzle 1.2 mm, layer 0.6 mm, extrusion width 2.4 mm. Print mode - spiral vase. nine0018

- Airflow is switched on from 3 layers even for ABS - there is a risk that a thick layer of plastic will not have time to cool and the structure will float.

- Print speed 15 mm/sec — you should not rush when printing such objects, the lower the speed, the better the sufficiently thick plastic layer cools down.

- Model - a simple cylinder with a diameter of 30 mm and a height of 200 mm (print height of the vast majority of popular printers).

PETG looks the most transparent in appearance due to the excellent adhesion of the layers. Next comes Watson. ABS and PLA are tied for third place. nine0003

Next comes Watson. ABS and PLA are tied for third place. nine0003

Since the print height of the printer is not enough for a more or less decent sword, it remains only to glue:

- PLA - with dichloromethane.

- Watson - solvent or xylene (let's try both options).

- PETG - no solvents were found, so we will use cyanoacrylate (aka superglue).

- ABS - acetone.

When printing with a spiral vase, the tubes are smooth on one side, with a step on the other:

It is not necessary to cut the step - it is great for joining the two upper parts of the tube:

Cyanoacrylate hards due to moisture in the air, to accelerate the process, the moisturizer was included:

Ready for tube tests:

To begin with, all gluings were tested for static load. A package with dumbbells weighing 2 kg was suspended from the center of each rod.

PLA turned out to be the most rigid, 60 cm of the tube practically did not bend:

ABS confidently holds 2 position on the deflection

Petg slightly lags behind ABS

, Watson behaves softer than all

To evaluate the strength in the dynamics, we decided to break the trumpets of Sinai-a training sword sword for kendo.

All specimens withstood at least one well placed impact. The fragments were collected for study.

PLA parted along the seam in the first place of gluing, broke near the seam in the second:

Watson is split and broken:

PETG is half split at the joint, half cracked:

ABS is split at the bond. At the point of impact, a change in the transparency of the plastic is visible:

Subtotal: all plastics held up with dignity. To be honest, I expected that everyone would break with one blow.

Based on the test results, we chose transparent ABS in our project - in case of breakage, it is easily and quickly glued with acetone / dichloromethane and perfectly processed (were sanded so that the light from the LEDs was more uniform). nine0003

nine0003

The resulting sword is:

A little about lighting. The problem with LED strips, and LEDs in general, is pointiness. Without tricky tricks it is impossible to create the effect of a uniform glow in any type of plastic:

However, if you add a frosted tube to the center, the lighting is evened out

. nine0003

Transparent ABS was a pleasant discovery for me - it retained the qualities of conventional ABS (easy to process, high strength, solvents available, high temperature resistance, great printing experience with this material) and at the same time expanded the boundaries of the material.

Thank you for your attention, and may the Force be with you.

Light 3D printing creates a microneedle vaccine patch.

Home / News / Light 3D printing creates a microneedle vaccine patch. nine0003

Publication date: 10/06/2021

US researchers used a fast light 3D printing process to create an intradermal microneedle vaccination patch. Testing in mice showed that the patch resulted in stronger immune responses compared to traditional vaccination methods.

Testing in mice showed that the patch resulted in stronger immune responses compared to traditional vaccination methods.

New articles

Laser absorption tomography for the measurement of ammonia in diesel exhaust gases (continued) nine0004 This article presents the results of a study of the ammonia content in the exhaust gases of diesel engines using laser absorption tomography Laser absorption tomography for the measurement of ammonia in diesel exhaust gases (beginning of the article)This article presents an experimental setup for studying the distribution of ammonia concentration in the presence of a selective catalytic reduction system

Hyperspectral mid-infrared sensor based on a MEMS Fabry-Perot interferometer for remote sensingThis article describes a new hyperspectral sensor based on a MEMS Fabry-Perot interferometer and a custom-made mid-infrared (IR) supercontinuum laser

nine0164 Thermal optical nonlinearity in photonic crystal fibers filled with nematic liquid crystals doped with gold nanoparticles (continued)This article presents the results of a study of thermal optical nonlinearity in photonic crystal fibers

Thermal optical nonlinearity in photonic crystal fibers filled with nematic liquid crystals doped with gold nanoparticles (beginning) nine0004 This article is a description of a recently identified class of nonlinear processes observed in 5CB liquid crystals doped with gold nanoparticles Estimation of Total Nitrogen in Rice Field Soils Using Visible and Near Infrared SpectroscopyThis article discusses the use of visible and near infrared spectroscopy as an alternative method for rapidly measuring total soil nitrogen

Do you have a special request?

Do you have a special request?

Quite often, our customers know better than we do what equipment they need.