3D printing fishing lure molds

Lure best STL files for 3D printer・Cults

Lure paint help tool Clamp

€4.47

AM bait fish 12cm hoof form for predator fishing

€5.40

AM bait fish 12cm hoof form for predator fishing

€5.40

AM bait fish 12cm hoof form for predator fishing

€5.40

Oreno

€2 -50% €1

Arrow Tail Dropshot Wrom

Free

fishing lure type carp

€12.79 -30% €8.95

Predator V2 Form

€2. 50

Predator V2

€2

SOFT LURE

€2.50

AM bait fish 9cm hoof form for predator fishing

€5.40

AM bait fish 13cm hoof form for predator fishing

€5.40

AM bait fish 12cm hoof form for predator fishing

€5.40

Squid HD

€1.04

AM bait fish 16cm hoof form for predator fishing

€6.23

AM bait fish 16cm hoof form for predator fishing

€6.23

Spinnerbait Chatterbait Lead / Tin / pewter master mold FISHING LURE

€2

FLOATING TACKLE BOX

€0.62

FLEXI SEA BASS

€0. 83

83

stand for the wobbler

Free

The Bass Klacker

Free

adjustable stand

Free

AM bait fish 16cm hoof form for predator fishing

€6.23

Froggy Dolphin Popper 90mm 12gr

€25

Pencil Popper 110mm 14gr

€25

Realis Jerkbait 120S 14gr

€25

LRF Popper 40mm 3gr

€25

anti-ecrevice

€1.50

stencil

€0.50

Counter mould 5 shad belly striped++.

€4

Fishing lure

€1. 50

50

SOFT MOLD LURE - BLACK MINNOW 10CM (2 sides)

€2 -50% €1

Soft mold lure - Black Minnow 10cm

€1.50 -50% €0.75

squid fishing lure mold

€9.50

Fishing lure mold - SOFT BAIT

€3.50 -50% €1.75

flexi Flat fish

€0.83

Beaver Tail Creature Bait

Free

DUMBELL molds 6 sizes

€2. 50

50

led lamp of a carp

€3

Two peace injection worm mold

€4.74

swimbait 160mm

Free

grub mold-CRAYFISH.crayfish-grub mold

€2.50

Merry christmas pike detailed texture trophy taxidermy for 3d printing

€6.23

common bream / three-part 12cm bait for 3d print

€8.31

Common rudd / three-part 12cm bait for 3d print

€8.31

Perch / two-part 12cm bait for 3d print

€12.47 -20% €9.97

Perch / three-part 12cm bait for 3d print

€12. -20% €9.97 47

47

Rainbow trout / two-part 12cm bait for 3d print

€12.47 -20% €9.97

3d Printed Fishing Lure Molds - Making Silicone Molds

Today we are going to make a couple of swimbait designs that I've created. We're going to make molds out of them with silicone and 3d printed molds. Making a mold master and then pouring silicone over the top of it to create an excellent open-pore mold is one of the best ways to develop lures with your 3D printer. Follow my journey to start!

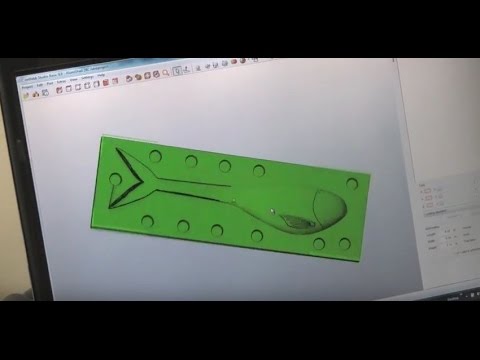

The Design Mold

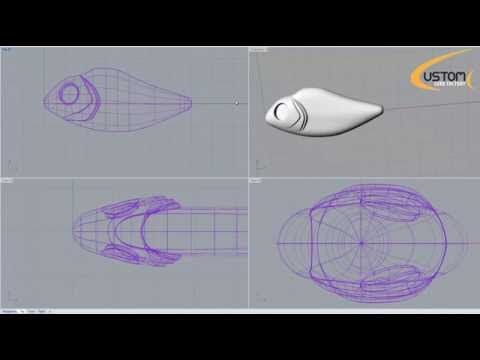

First, let's start with the design. I'm not going to walk you through the whole procedure with fusion 360. I'm going to be doing a whole series of tutorial videos coming soon on lure design and mold design of fusion 360. Be on the lookout and subscribe to my blogs or videos to stay up to date on my latest content.

Be on the lookout and subscribe to my blogs or videos to stay up to date on my latest content.

As you are aware, I gave away all of my fishing lures recently. One of the lures that I was most concerned about replacing is the down south lure burner shad. I crush fish with this lure in the spring and the summertime along the gulf coast. It's a small three and a quarter inch swimbait. I knew right away that I needed to get a replacement because when the fishing turns on in the spring, I will be throwing this design all the time. I came up with two very similar designs. I call the first one little butt swim because its tail looks like a small butt, and the other one, I call burn before fishing shad (or the BBFS).

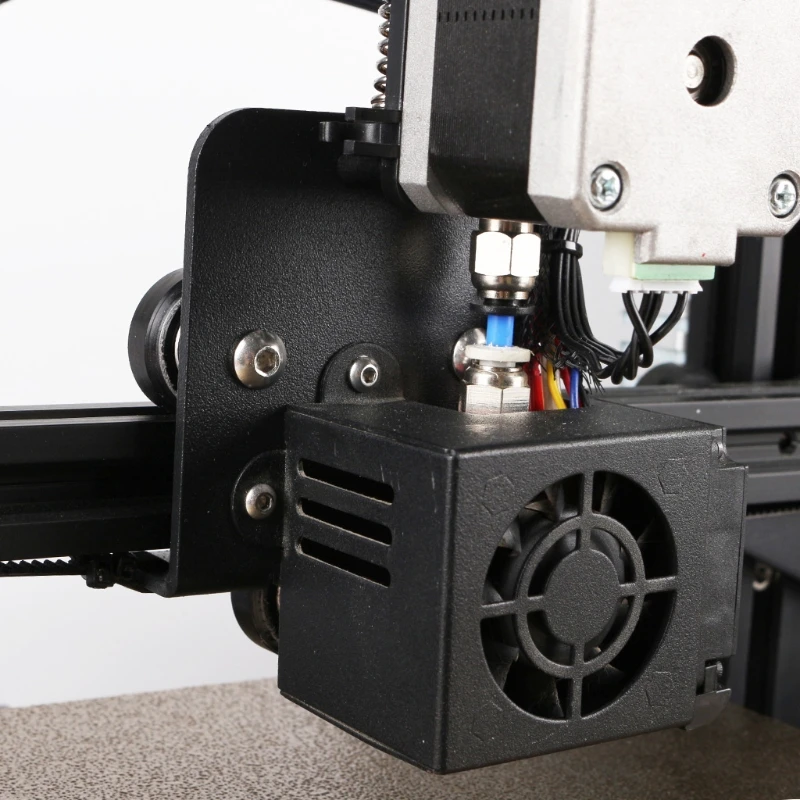

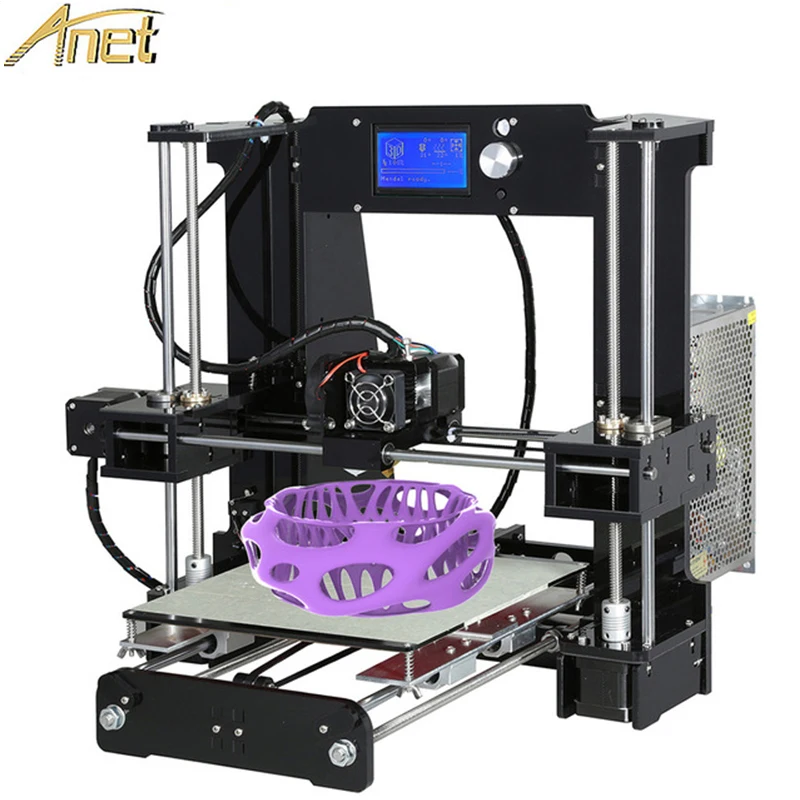

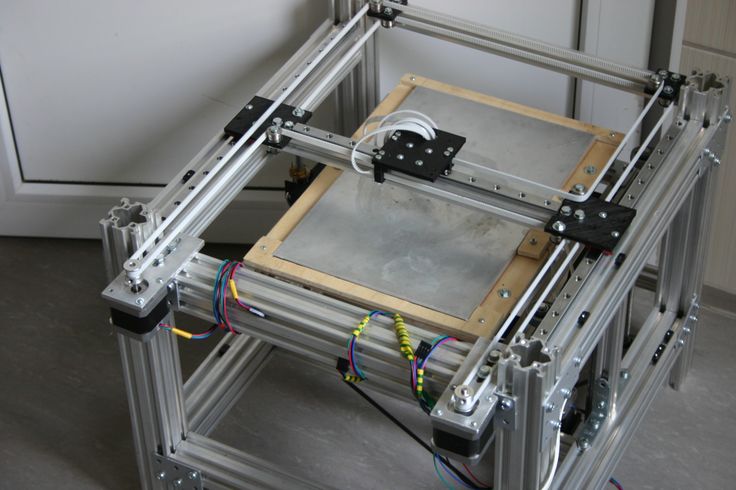

As you can see, here is the burn before fishing shad in Fusion 360. I create a floor and wall around the side. To complete the mold master, I can pour the silicone directly when I want to make the mold. It's just that simple. You can make as many copies of the lure as you wish. This process will make the cavities in your mold, build a floor and build the walls. I'm using my sidewinder X1 for the FDN prints. I recently purchased this FDN printer. and always make sure to review the product I am using. Be on the lookout for an upcoming review soon.

This process will make the cavities in your mold, build a floor and build the walls. I'm using my sidewinder X1 for the FDN prints. I recently purchased this FDN printer. and always make sure to review the product I am using. Be on the lookout for an upcoming review soon.

I like to get a good overview of the printer to see how it's working by using the fine setting to get it as high detail as possible. This product did a pretty great job. I also decided to print out just the floor with the lures on my resin printer. This printer is my LU Saturn. I wanted to see how it compares to the FDM prints. I didn't print out the walls here because it would not be a fair use of my time. If I print them flat, it will create a giant suction cup and not print well. Another option to print this way would be to print virtually. Unfortunately, that process would take 20 plus hours. I printed this on the build plate, and it took roughly two hours. I then went back and printed the wall for the outside on the FDM printer to snap it in place. This process makes it super easy.

This process makes it super easy.

Now that you have one of your bold masters all printed out, the next thing you probably want to do is put a thin coat of paint epoxy. It's best to use Paint epoxy, or in my case, I'm going to use polyacrylic. I'm using this because my friend Adam said he used it with some success, and I already have some laying around in the garage. I ended up doing two separate coats. Afterward, I let it dry a few hours in between. For the best use, follow the directions on the can.

Prepping for the Pour

In my opinion, It came out pretty well. I still have ridges, and I could have probably kept going with some more coats. This stuff is relatively thin, but it didn't matter to have a few little lines on there at the end of the day. You will need to do a few touch-ups. I got a few little holes in there, either from air bubbles or from things floating around in my vat. Patching these up is straightforward. You take some of the resin that you're already using in your 3d printer and dab the holes with it. I also use a little needle and hit it with a UV light source. In this case, I'm using a UV flashlight. It hardens it up just like if it were in the printer and creates a patch.

I also use a little needle and hit it with a UV light source. In this case, I'm using a UV flashlight. It hardens it up just like if it were in the printer and creates a patch.

Next up, we're going to prep the silicone. One thing to keep in mind, if you're going to pour silicone over a resin 3d print, you may want to make sure it is a tin cure silicone as opposed to a platinum cure silicone. Platinum cure silicone does not cure when it comes into contact with the resin from a 3d resin printer. The result will end up being a big gloopy mess. Make sure to use tin cure silicone all the way. Now, we need to estimate how much silicone we'll need. I typically fill up my molds with water, dump them all into a container, and get my silicone volume from this method. it's not an exact science. I always like to think of the difference between water volume and silicone volume, so I can still bump it up. In this case, I got 22 ounces. I decided on pouring 24 ounces of silicone, which ended up being just about perfect. Silicone tends to stick, so I'm looking at ways to avoid this. I always bump it up and go on the high side.

Silicone tends to stick, so I'm looking at ways to avoid this. I always bump it up and go on the high side.

The Pour

We're ready to pour. I'm going to get my UMU 25 out. This silicone is one of my favorites for a couple of reasons. One, it's pretty forgiving on the mix. It mixes at a straightforward one-to-one ratio by volume, and it cures pretty quickly. Typically, it takes 25 minutes of cure time or 75 minutes when it's exposed to air. It's effortless to work with. I pour it from a corner and allow it to fill up. It will roll over well and will help prevent air bubbles from forming. You can also make sure you have a very, very thin stream coming out of the cup you are using that'll break up some of those more giant air bubbles as well. You could put it in a vacuum chamber. Again, this is a quick and dirty mold. For me, it's a prototype. I don't even know if these will work, so I'm not too hung up on air at this point.

After a couple of hours, I go to de-mold them. The top, exposed to the air, is nice and firm, but the underside is still very soft. The mold is airtight, so not a lot of air is penetrating here. You want to be careful when you're de-molding here to make sure you don't add too much stress and get deformation in your molds. I pop it out. For this one, I kind of bent one a little bit too much, and ended up getting a tail a little bit wider than another one. Next, I let them cure again for four hours, as recommended by the package. At this point, it's about nine o'clock at night. I leave them overnight, and I come back the next morning, and they are good to go. Nice and solid, very tight. No issues whatsoever with my molds. I am super stoked!

The top, exposed to the air, is nice and firm, but the underside is still very soft. The mold is airtight, so not a lot of air is penetrating here. You want to be careful when you're de-molding here to make sure you don't add too much stress and get deformation in your molds. I pop it out. For this one, I kind of bent one a little bit too much, and ended up getting a tail a little bit wider than another one. Next, I let them cure again for four hours, as recommended by the package. At this point, it's about nine o'clock at night. I leave them overnight, and I come back the next morning, and they are good to go. Nice and solid, very tight. No issues whatsoever with my molds. I am super stoked!

Idiot Moves

Now it's time to talk about my big idiot moves. I make a lot of big idiot moves, but this one, I decided to try to do a three-color pour immediately out of the bat after never pouring these molds before, and I was trying to replicate the chicken of the sea color. The first thing I do is I pour my chartreuse. I go ahead and pour the whole mold chartreuse. I come back in, and I clip the tails off and de-mold the bodies. So far, it's looking pretty good. Then, I come in with my bottom layer. The DSL looks like this bottom layer is clear plastic with a ton of silver flake in it. I decided to go with what I call disco monk, which is interference violet, a black flake, one drop of black you could use, and white. It would brighten it up a little bit.

The first thing I do is I pour my chartreuse. I go ahead and pour the whole mold chartreuse. I come back in, and I clip the tails off and de-mold the bodies. So far, it's looking pretty good. Then, I come in with my bottom layer. The DSL looks like this bottom layer is clear plastic with a ton of silver flake in it. I decided to go with what I call disco monk, which is interference violet, a black flake, one drop of black you could use, and white. It would brighten it up a little bit.

In this case, I went black, and it darkens it up a little bit, gets a little more purple coming out, disco holographic. Flake all those things together and make my cake on monkey's milk, which I call disco monkey because it has a half flake. It's like disco, bro. I'll get that poured in for the bellies. At this point, I'm not feeling terrific because I'm heating my top color, and it's taking a long time. I have one tiny microwave that takes about three and a half minutes to heat even six ounces of plastic. My topcoat will be some pearlex green mica powder, dark melon dead on plastics color and some red flake, and a little bit of black to darken it up.

My topcoat will be some pearlex green mica powder, dark melon dead on plastics color and some red flake, and a little bit of black to darken it up.

Let's take a look at the results. I think they came out pretty good. You can see a few artifacts from the 3d print. A few lines here and there, but overall, I'm super happy with how the mold came out. Unfortunately, when I went to test these lures, they swim like absolute garbage, especially the little butt lure there. I think its body is way too big. When I go swimming, it just kind of twirls like this. It looks like garbage, so I'm back to the drawing board on that one. The BBFS was okay. I think my body is still a little small. When I put it on the jig head I was using, it blew up big, and the tail doesn't have the great action I'm looking for in a lure.

I think that one is closer to saving than the little butt swim, so I'm going to do a few more revisions of that. The thing I learned during this process is that I shouldn't have printed a six-five six cavity mold when I don't even know the lures are working. I've gone back to the drawing board on the BBFS, and I'm going to print a single cavity mold for my next revision of this pour. If it works, and then I'll expand it out to a six cavity mold. There's no reason to make a six cavity mold of a lure if you don't even know. Stay tuned. I'll continue to revise the BBFS. We'll show you the next version in a video coming out shortly.

I've gone back to the drawing board on the BBFS, and I'm going to print a single cavity mold for my next revision of this pour. If it works, and then I'll expand it out to a six cavity mold. There's no reason to make a six cavity mold of a lure if you don't even know. Stay tuned. I'll continue to revise the BBFS. We'll show you the next version in a video coming out shortly.

Finally, If you want these models as soon as I have them perfected, I'm going to be releasing them to my mailing list. You can click that link below to join my mailing list and get these for free if you found this video and blog at all useful. I'll see you guys again soon!

STL file Fishing lure mold・3D printer design to download・Cults

Project box with clip Flipper zero

4,49 €

Flipper zero universal leather with belt holder

2,69 €

Portal Turret Key Pendant

1. 35 €

35 €

9.16 €

DJI Phantom 1,2,3 wide and tall landing gear

1,79 €

Mold for making fishing lures

3 €

Insect bait mold

3 €

Fishing lure mold

3 €

The best files for 3D printers in the Tools category

Deadbolt Combination Lock

Free

Bird feeder

Free

Mason jar water bong bubbler

3.49 €

USB Foot Switch Controller

Free

10" Raspberry Pi Desktop

Free

Flat Penny Change Holder

Free

Multi-Color Game of Thrones Coaster - House Lannister

Free

20mm Calibration Cube Stand (CHEP cube)

Free

Bestsellers in the Tools category

telephone ring holder

0,90 €

Case for Chill Buddy lighter

0,93 €

Cooling system Minimus Hotend

€2. -10% 2.42€ 70

70

ENDER 3 S1/S1 PRO REEL HOLDER AND DEPORTED REEL

2,13 €

PET-Machine, make your own plastic bottle filament at home!

15 €

Ender 3 S1 pro fan duct 5015 4020

1,30 €

Armadillo - flexible wire conduit

1.68 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1.91 €

Display holder FLSUN v400

€9.99 -50% 4.99 €

SUPERBOX

1,50 €

nine0003 Ratchet holders - magnetic - holders for toolbox organization 2. 68 €

68 €

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, PROBE NO Y OFFSET

€2.28 -20% 1.83 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2.37 €

'ELEGANCE' Bambu lab set and general 3d printers

5 €

Generativ Design Y-Filamentsplitter Bambulab AMS-Extern RS-CONCEPTS

2,50 €

Ender 3 S1 BEST cable guide - vertical

2,50 €

Do you want to support Cults? nine0037

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments of . Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

affiliation: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

3D printed artificial lures

Leave a comment

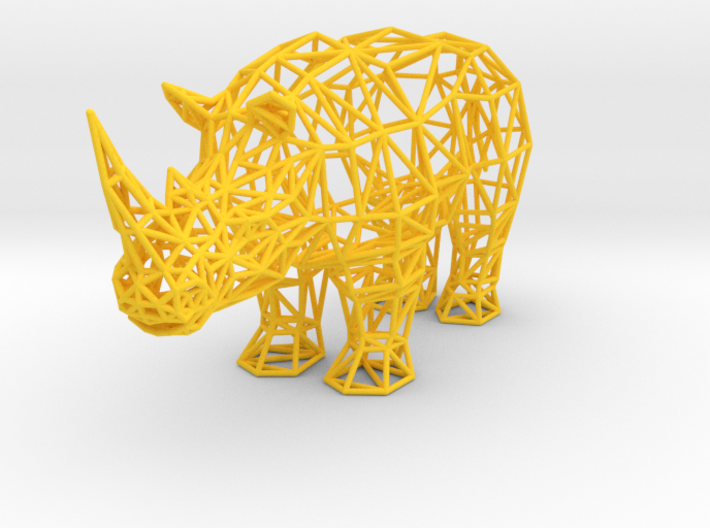

3D printing technology is gradually taking its place in the production of various products. The presence of such a printer allows you to print car parts, household items without leaving your own home. nine0150 The boom in 3D printing has also affected the fishing tackle industry. The greatest interest in this area is the manufacture of soft silicone lures.

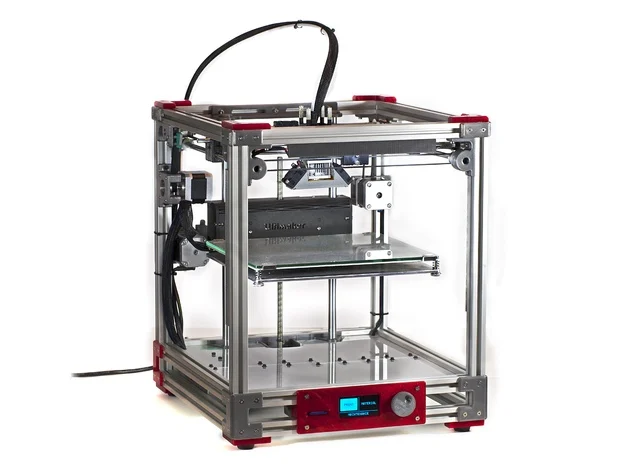

One of the first 3D technologies of to be used by a rapidly growing and promising company from the United States, BioSpawn Lure Company. Using 3D printers, she creates high-precision silicone molds for casting twisters and worms.

Using 3D printers, she creates high-precision silicone molds for casting twisters and worms.

A few years ago, BioSpawn Lure, seeing the promise of 3D printing, approached New York-based 3D printing company Shapeways to collaborate. Last week, employees of the companies revealed to the public the details of their partnership. nine0006

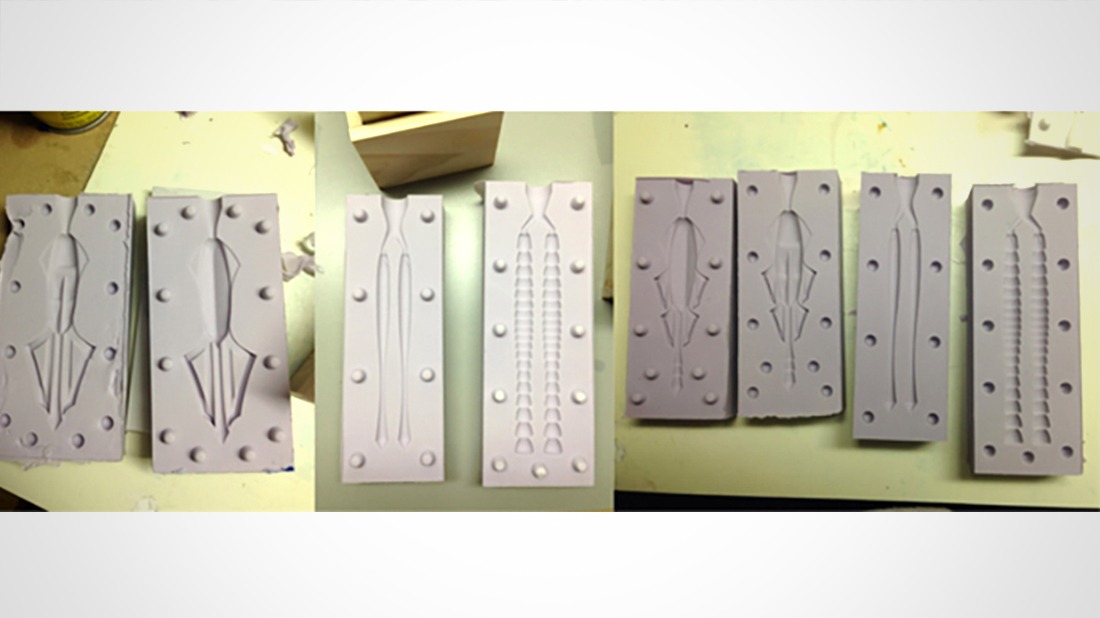

Initially, BioSpawn Lure Company designers developed models of future lures in a special 3D Solidworks editor and sent their work to Shapeways, who made prototypes and sent them back. With their help, molds for casting were made. The resulting models were quite rough and the manufacturing process was labor intensive.

Then the developers came up with a new idea - to print on a 3D printer not prototypes, but forms. This decision significantly accelerated the production process, and the products became much better. nine0006

The lure design process takes a long time, according to BioSpawn Lure employees, and the layout often undergoes many improvements and changes before being put into production.

3D technologies allow to turn any ideas of developers into reality and significantly speed up the production process. Unlike traditional methods, the printer produces extremely accurate forms.

According to BioSpawn Lure , they reviewed many lure material options and settled on soft plastic, which has a number of advantages over other industries.

Are you interested in fishing with "ends" in winter? Read more about this in our article.

And in this article you will learn how to fish with a scarf in the winter.

Silicone production does not require special equipment and high melting temperatures. The mold for the bait can be made at home - just heat the plastic in the microwave and give it the desired structure. nine0006

For , this opened up a wide range of design possibilities at minimal cost. We just had to come up with a design for the bait and make a shape for it.