3D printing fashion brands

3D Printed Fashion: The Top Designs

Published on August 4, 2022 by Alexandrea P.

Fashion brings together several industries, whether it is clothing, cosmetics, or luxury. All sorts of products are being created to embellish and affirm a style, a look, a way of being. In the world of fashion, it is necessary to know how to stand out and how to present ever more original and innovative designs. For that reason, many brands and designers are now turning to 3D technologies, which is understandable, given the number of new options the technologies present to express creative freedom while allowing mass customization and a reduction of environmental impact. The textile industry, as you’ve probably already heard, is known to have a negative impact on our planet. 3D printing, however, presents an opportunity to mitigate these effects, by using only the material that is necessary and by producing on demand. What applications of 3D printing are available today in the fashion industry? From haute couture dresses to handbags, we’ll take a look at a few initiatives, listed in alphabetical order.

NFT Collection by Danit Peleg

Danit Peleg is the first designer in the world to have created a collection entirely using desktop 3D printers. The structure of his designs is inspired by mixing traditional textile properties with new technologies, which is how this lace-like texture was created. According to the designer, 3D printing allows digital fashion to become physical, which reduces the limits of creativity. The garments are printed layer by layer with a flexible filament using a desktop 3D printer to create a three-dimensional structure that fits the body shape. Danit Peleg believes that in the near future, we will have more wearable materials made by additive manufacturing to choose from.

Iris van Herpen

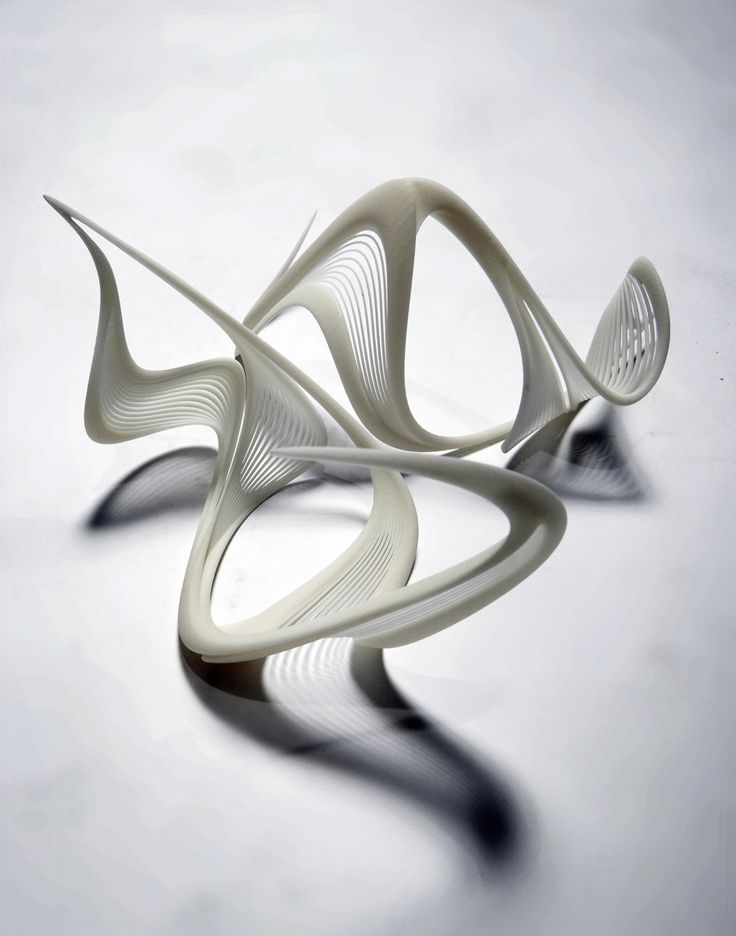

Dutch designer Iris van Herpen was one of the first to use 3D printing in the fashion industry. She already managed to impress everyone at this year’s Met Gala with her extraordinary 3D printed creations which were worn by Teyana Taylor, Winnie Harlow, and Fredrik Robertsson. At this year’s Fashion Week in Paris, she also unveiled a 3D-printed haute couture dress that was developed in a collaboration between the designer and Belgian ice cream brand Magnum. The dress was made entirely from a vegan organic material based on cocoa bean shells. Iris van Herpen’s work is an intersection of fashion, design, technology, and science. In her designs, she brings together nature, fashion, and technology by using unconventional materials and technologies and combining them with traditional sewing techniques.

At this year’s Fashion Week in Paris, she also unveiled a 3D-printed haute couture dress that was developed in a collaboration between the designer and Belgian ice cream brand Magnum. The dress was made entirely from a vegan organic material based on cocoa bean shells. Iris van Herpen’s work is an intersection of fashion, design, technology, and science. In her designs, she brings together nature, fashion, and technology by using unconventional materials and technologies and combining them with traditional sewing techniques.

Galerie Dior

Additive manufacturing also found its way into the field of haute couture, as the example of the reproduced fashion pieces at Galerie Dior in Paris shows. On display at the Boutique Dior located in the world-famous Avenue Montaigne, interested visitors can find several hundreds of 3D-printed replicas of former Dior garments, handbags, or even shoes. The manufacturing process took place thanks to the collaboration between the ALIGHIERI agency and LA FERME 3D ©. Together, they invested over 100,000 hours of printing and 10,000 hours of post-processing in the reproduction of the fashion elements. The printing was done by more than 30 3D printers, which were put to work for a total of six months, day and night, to complete the iconic Dior project. The material used for the production is entirely bio-based.

Together, they invested over 100,000 hours of printing and 10,000 hours of post-processing in the reproduction of the fashion elements. The printing was done by more than 30 3D printers, which were put to work for a total of six months, day and night, to complete the iconic Dior project. The material used for the production is entirely bio-based.

Kornit Digital and Its 3D Printed Knitwear

The high amount of society’s consumption of fast fashion was the turning point for Ronen Samuel, CEO of Kornit Digital, a sustainable fashion brand that uses additive manufacturing to produce knitwear. For its sustainable and waste-reducing fashion, Ronen uses direct-to-yarn printing, which is printing directly onto all types of textiles. In this case, the company uses MAX technology, which applies ink layer by layer. The result is a garment that looks like it was knitted traditionally. Ronen Samuel’s designs have already been presented at the Tel Aviv Fashion Show.

A 3D Printed Skeletal Mask for High Fashion

A great example of how 3D printing can be used to create a unique piece that can even give an outfit the missing touch which ultimately completes it is this skeletal mask created by designer Kevin Freitas Conlin. The exotic-looking accessory, that was worn by drag queen Aquaria on the tenth season of the popular show Ru Paul’s Drag Race, helped her win in the show’s final. The bone-like structure of the mask, which was customized to Aquaria’s face, was reportedly 3D-printed in laser-sintered nylon by American AM company Shapeways. This was the first time that 3D printing technologies were used on the show, and it inspired designers in later seasons of Ru Paul’s Drag Race to experiment with it as well and create other unique pieces, such as the fashionable exoskeleton worn by contestant A’whora during season 12.

The exotic-looking accessory, that was worn by drag queen Aquaria on the tenth season of the popular show Ru Paul’s Drag Race, helped her win in the show’s final. The bone-like structure of the mask, which was customized to Aquaria’s face, was reportedly 3D-printed in laser-sintered nylon by American AM company Shapeways. This was the first time that 3D printing technologies were used on the show, and it inspired designers in later seasons of Ru Paul’s Drag Race to experiment with it as well and create other unique pieces, such as the fashionable exoskeleton worn by contestant A’whora during season 12.

Julia Daviy’s 3D Printed Skirt

Julia Daviy started creating 3D printed fashion back in 2017 and has since released a variety of amazing 3D printed clothing collections. With a special focus on sustainability, the California-based fashion designer, who has quickly become a pioneer of sustainable 3D-printed fashion, designed and produced many examples of fashion, jewelry, and home décor. One interesting example of her work is The Organic Skirt. This particular piece is the central element of a 3D-printed collection that was released in 2019. In the project titled the After Forever Collection, all items of clothing were 3D-printed by using large-format 3D printers. The Organic Skirt was the first digital 3D-printed piece of clothing available on the U.S. market and is digitally customizable in over 1,000 variants.

One interesting example of her work is The Organic Skirt. This particular piece is the central element of a 3D-printed collection that was released in 2019. In the project titled the After Forever Collection, all items of clothing were 3D-printed by using large-format 3D printers. The Organic Skirt was the first digital 3D-printed piece of clothing available on the U.S. market and is digitally customizable in over 1,000 variants.

VIP TIE

VIP TIE is an Italian company that is famous for 3D printing ties. The goal of the company is to offer fashionable accessories that are as personalized as possible in order to satisfy the needs and desires of the customers. VIP TIE combines both luxury and innovative high-tech design. The creation process of just one tie can include an intricate mix of several complementary procedures and materials: craftsmanship, embroidery, 3D printing, exotic leather, mother-of-pearl, carbon fiber, silver, gold, and silver plated solid. Apart from highly customizable products, another advantage of VIP TIE is that more than 80% of the materials used are 100% environmentally friendly.

Patronace

Patronace is a sports brand created by award-winning designer Bastian Müller. The Munich-based brand offers 3D printed activewear for those who lead a fast-paced lifestyle. The clothes are made for everyday urban mobility, no matter if you commute by skateboard, scooter, or e-bike. For the production of the clothes, the brand uses a lightweight and flexible textile printing technology called GRDXKN, which transforms substrates into smart textiles. This unique material, with which Patronace manufactures these garments includes integrated protection and insulation, and has a special kind of grip thanks to the textile layer that controls moisture, is breathable, water repellent, abrasion resistant, and shock absorbing. The fashion created by the company with its intelligent textile allows you to feel both, safe and stylish at the same time.

3D Printed Leather Which Could Revolutionize the Fashion Industry

When it comes to materials in fashion, one that will never go out of style is leather. For jackets, boots and everything in-between, leather is a cornerstone in the industry. However, ethical use of the material can be difficult. Real leather is often touted as far superior to its alternatives, but many still would prefer leather to be animal free. Thankfully, researchers from Tufts University might have a solution. Using silk cocoons from the silkworm Bobmyx mori and 3D printing on a custom-built pneumatic extrusion 3D printer, the researchers were able to produce an environmentally friendly, animal-free leather alternative that not only resembles real leather but also has the same mechanical properties. Though as of now they have only made a wallet out of the material, the find could have a major impact on the fashion industry at large in the near future.

For jackets, boots and everything in-between, leather is a cornerstone in the industry. However, ethical use of the material can be difficult. Real leather is often touted as far superior to its alternatives, but many still would prefer leather to be animal free. Thankfully, researchers from Tufts University might have a solution. Using silk cocoons from the silkworm Bobmyx mori and 3D printing on a custom-built pneumatic extrusion 3D printer, the researchers were able to produce an environmentally friendly, animal-free leather alternative that not only resembles real leather but also has the same mechanical properties. Though as of now they have only made a wallet out of the material, the find could have a major impact on the fashion industry at large in the near future.

Stratasys and The SSYS 2Y22 Reflection Collection

Recently, well-known manufacturer Stratasys introduced its new commitment to the 3D printed fashion world with the launch of its J850 TechStyle 3D printer. Following that, the American-Israeli company has continued to demonstrate the capabilities of additive manufacturing in this field. During Milan Design Fashion Week, it unveiled its SSYS 2Y22 Reflection collection, consisting of high-end accessories and apparel, which were all 3D printed. This was possible thanks to the collaboration with 7 other groups of designers that, together with the technology of its J850 TechStyle solution, allowed the development of an innovative line of products that aim to reflect the social impact observed in recent years. In the video below you can see the use of 3D printing to create these fashion garments, specifically from the hand of Ganit Goldstein, one of the designers who participated in the SSYS 2Y22 Reflection:

Following that, the American-Israeli company has continued to demonstrate the capabilities of additive manufacturing in this field. During Milan Design Fashion Week, it unveiled its SSYS 2Y22 Reflection collection, consisting of high-end accessories and apparel, which were all 3D printed. This was possible thanks to the collaboration with 7 other groups of designers that, together with the technology of its J850 TechStyle solution, allowed the development of an innovative line of products that aim to reflect the social impact observed in recent years. In the video below you can see the use of 3D printing to create these fashion garments, specifically from the hand of Ganit Goldstein, one of the designers who participated in the SSYS 2Y22 Reflection:

What do you think of this 3D printed fashion? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Must Know 3D Printed Clothing Designers in 2021

With companies like Voxel8, 3D printing technologies are penetrating the fashion industry, particularly in haute couture. Additive manufacturing offers innovative new techniques for 3D printed clothing that not only give designers a cutting edge tool for expressing their creativity but also allows them to connect with a fashion-forward audience.

If you are a fashion tech designer looking to get inspired, here are the top 3D printed clothing designers who are famous in the industry.

The mother of high-tech couture — Iris Van HerpenSource / Iris Van Herpen

With her Spring 2021 Couture, Iris Van Herpen continue to impress us with her new dialogue between fashion, nature and technology. This collection, she partnered with Parley, Adida’s recycled shoes manufacturing partner, and used upcycled marine debris to inject her designs with a unique yet sustainable spin.

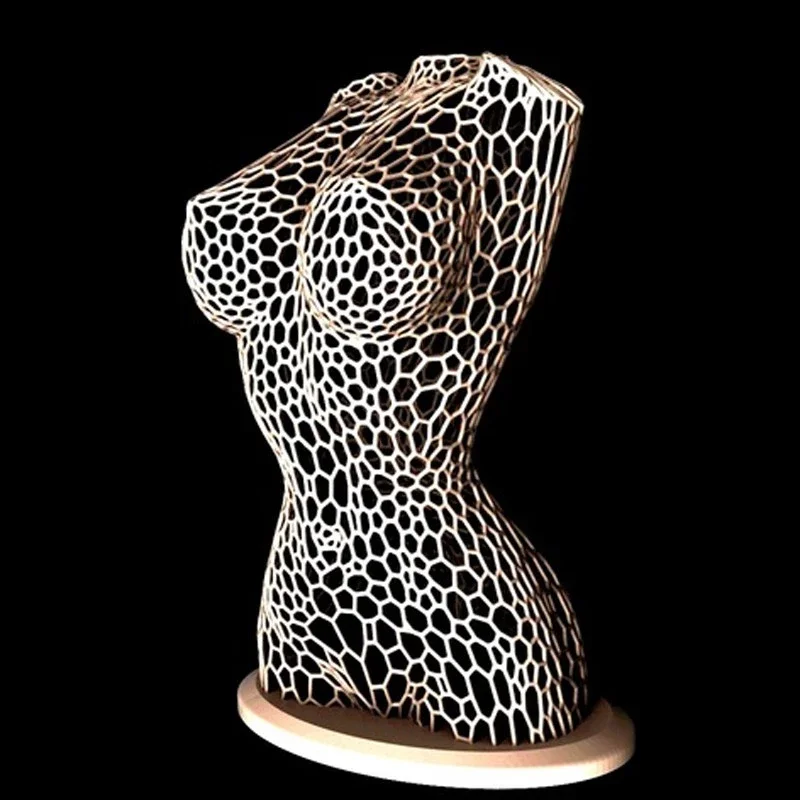

Iris Van Herpen is known for her crazy structural wearables infused with technologies. She has worked with MIT Media Lab professor Neri Oxman in 2013 to create armours that acts like second skin. “The ability to vary softness and elasticity inspired us to design a “second skin” for the body acting as armor-in-motion; in this way we were able to design not only the garment’s form but also its motion,” explains Oxman. “The incredible possibilities afforded by these new technologies allowed us to reinterpret the tradition of couture as “tech-couture” where delicate hand-made embroidery and needlework is replaced by code….”

She has worked with MIT Media Lab professor Neri Oxman in 2013 to create armours that acts like second skin. “The ability to vary softness and elasticity inspired us to design a “second skin” for the body acting as armor-in-motion; in this way we were able to design not only the garment’s form but also its motion,” explains Oxman. “The incredible possibilities afforded by these new technologies allowed us to reinterpret the tradition of couture as “tech-couture” where delicate hand-made embroidery and needlework is replaced by code….”

Practice covid 19 precautions with The Proximity Dress Source / Anouk Wipprecht

Designed by Anouk Wipprecht, a Dutch fashion designer, the Proximity Dress combines elements of tech and fashion to create sensors that can detect movement near the wearer’s body. If someone gets too close to the wearer, the dress expands forming a barrier between the wearer and the external stimuli. The dress was designed using Stratasys PolyJet technology and the SLS process.

Opt for sustainable fashion with a zero-waste 3D printed clothingSource / Julia Daviy

This 3D printed dress is designed by fashion tech designer Julia Daviy. She sees 3D printing as a viable solution to move away from conventional fashion production to an environmentally-friendly design and development. Designed using recyclable filaments, the skirt produces less than 1% waste, which makes it highly sustainable in a time where sustainability is much needed.

Print your own 3D dress with Danit Peleg designs Source / Danit Peleg

Danit Peleg loves to create 3D printed garments to make this fashion tech trend accessible to everyone. Peleg wants to make sure that anyone can shop for her digital fashion designs, experience how the designs look through augmented reality, download the design file on NFTs, and print their own dress on any 3D printer.

Sustainable 3D printed collection by Zerera Studio Source / Zerera Studio

Using biodegradable filaments and garments, the ZRE collection design studio creates sustainable 3D printed fashion that offers both stylish and eco-friendly choices for fashion enthusiasts. The studio is experimenting with other technologies including a body scanner and a laser cutting machine to create unique fashion articles that do more than just save the planet.

The studio is experimenting with other technologies including a body scanner and a laser cutting machine to create unique fashion articles that do more than just save the planet.

Get inspired by Julia Koerner’s collectionSource / Black Panther

If you have seen Black Panther then you are familiar with this fashion tech designer on our list. Julia Koerner created stunning costumes for the film in collaboration with Ruth E Carter harnessing the power of 3D printing to produce fine garment structures.

Accessory: 3D handbags with XYZ BAGSource / XYZ Bag

Next on our list is a CAD modeled handbag collection that is customized based on the user’s preferences. Based in Italy, the company allows its customers to choose a design from 3 different product options and place the order.

The company then uses CAD technology to print the handbag. Originally, the company’s handbags were offered in a standard black color, but customers can also choose a different color which will then be hand-painted to give a seamless design. According to the company’s CEO Annalisa Nicola, the 3D designs allow for greater freedom in terms of creativity.

According to the company’s CEO Annalisa Nicola, the 3D designs allow for greater freedom in terms of creativity.

If you’re looking for the latest emerging designers that we have our eyes on, click here.

How photopolymer 3D printing can be useful in the fashion industry

We are witnessing what many call the third industrial revolution: 3D printing or additive manufacturing could move us away from the era of mass production and lead to a new reality of customized custom manufacturing. A good example is fashion. In the recent past, "fashion houses" were more like multidisciplinary research institutes. To create a collection of clothes, in addition to an expert sense of style, you need knowledge in anatomy, advanced sewing machines, appropriate fabrics and accessories, accessories, shoes, people (cutters, seamstresses, models, and many others). Through trial and error, an art object is created, rarely successful, but always laborious. 3D printing is a toolless manufacturing method that allows physical objects to be produced from a 3D model, usually in layers. The term is also used generically as a synonym for rapid prototyping. The scope of technology is endless - from tools and toys to robots and mechanical parts. There is no limit to what a 3D printer can create. nine0003

The term is also used generically as a synonym for rapid prototyping. The scope of technology is endless - from tools and toys to robots and mechanical parts. There is no limit to what a 3D printer can create. nine0003

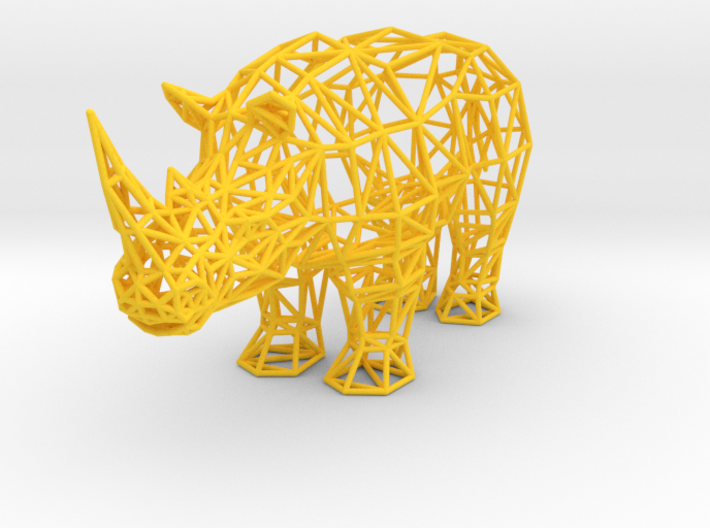

Fashionable, futuristic design requires innovative production technologies, and this is where 3D printing comes to the rescue. A wide variety of fashion accessories including bracelets, rings, brooches, necklaces and pendants can now be easily 3D printed. Let's take a closer look at how this technology can be used in the fashion world.

Individual design

One of the unique aspects of 3D printing is the ability for designers to create custom shapes and sizes that would be impossible to produce with traditional methods. nine0003

Photopolymer 3D printing allows designers to produce products in small batches. Fashion designers can now create bold, one-of-a-kind pieces. In addition to time, technology can significantly reduce costs.

Accessories

The range of fashion accessories depends more on the imagination of the creator than on the capabilities of your wallet. All this can be easily printed using a conventional photopolymer 3D printer. Need a flower ring? No problems! 3D printing can do this and more. What else can be produced in this way? nine0003

Brooches

Brooches are intricate pieces of jewelry that will highlight your personality. Business women especially like to use them to decorate and complement their business suits. For example, Madeleine Albright, the first female US Secretary of State, over the years of her career has created a new diplomatic language, full of metaphors and hidden meanings. Through jewelry, she expressed her mood, intentions or the situation at the negotiations, and political scientists and journalists vied with each other to interpret the images on the left lapel of her jacket. 3D printing can be used to produce a custom brooch that can complement the look, and perhaps say something to the "initiates". nine0025

nine0025

Rings

3D printing can be used to prototype a ring before making it into the final form in precious metals and stones. This will allow the designer to easily and quickly make adjustments, ensuring the ring fits perfectly and matches the client's expectations and end result. Important factors are saving time, money and certainly a significant reduction in the likelihood of errors in the final product.

If earlier only professional 3D printers costing from 50 thousand dollars were suitable for the purposes of the jewelry industry, now, with the introduction of inexpensive mono LCD displays with 4K resolution, such printing is available to any jewelers and designers. The budget for such a purchase fell below $500. nine0003

Bracelets

Similarly, intricately designed bracelets can be created using photopolymer or wax 3D printers. It can be an exclusive version, one of a kind, which, if necessary, can be mass-produced. Technology allows you to think more broadly and not be afraid to experiment with expensive precious metals and stones. After all, modern consumables allow you to create prototypes with a high level of reliability. nine0003

Technology allows you to think more broadly and not be afraid to experiment with expensive precious metals and stones. After all, modern consumables allow you to create prototypes with a high level of reliability. nine0003

Clothing and footwear

Shoes, dresses and other fashion items can also be printed using 3D printers. This allows you to create ready-made items for wear, as well as improve the design of the model before launching into mass production. Shoes with geometrically complex 3D designs often find their way into the fashion mainstream. And for more mundane purposes, there are sneaker soles. For example, Adidas makes them from a mixture of polymer resin with the addition of polyurethane and prints in a lattice structure that promotes proper load distribution. According to Adidas, Futurecraft 4D shoes are characterized by incredible comfort, as well as unique ergonomics and wear resistance. nine0025

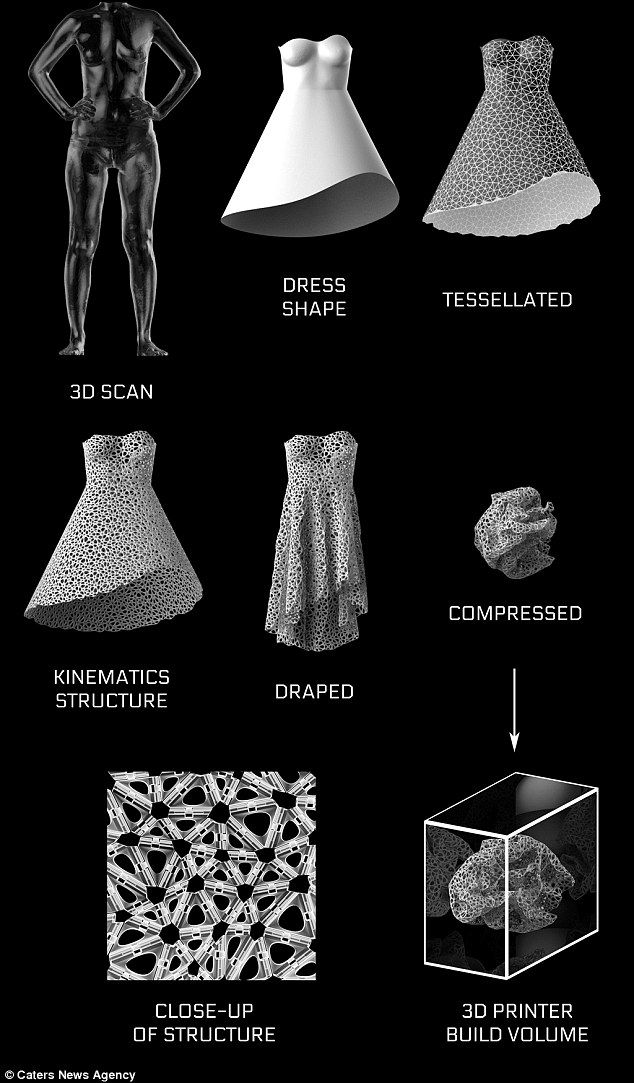

Simultaneously with shoes, there are numerous experiments on the use of 3D printing to create designer outfits and especially dresses.

One of the first 3D printed dresses was presented by American model and singer Dita Von Teese in March 2013 in New York. Couturier Michael Schmidt and Francis Bitonti teamed up with 3D printing service Shapeways to print it using additive manufacturing technology. It consisted of 17 nylon pieces that were painted black and encrusted with 13,000 Swarovski stones. nine0003

In 2019, a whole series of such models was already presented at the famous charity Met Gala in New York. The photo shows American celebrities in outfits with 3D printed elements. Especially everyone was struck by the dress in the form of a rose petal

(center) in which British model Jourdan Dunn appeared at the ceremony.

It, like the entire collection, was created by fashion designer Zac Posen in collaboration with GE engineers and 3D printers and made a splash on the red carpet of the event. nine0003

It is too early to talk about the widespread introduction of 3D printing in the fashion industry, but it is already clear that this process will continue. Creating jewelry to order is not a trend of the future, but of the present, a prerequisite for meeting the needs of the customer.

Creating jewelry to order is not a trend of the future, but of the present, a prerequisite for meeting the needs of the customer.

Source: https://www.if24.ru/3d-pechat-v-industrii-mody-novoe-izmerenie/

How additive technologies are changing the world of fashion / Sudo Null IT News

Additive technologies are actively storming the world of high fashion: 3D-printed clothes, shoes and accessories are increasingly appearing on the catwalks. If earlier these were rare collections, today almost every eminent designer is trying to introduce at least a small 3D printed part into their products. nine0003

How long ago did 3D-fashion appear? Will things created on a 3D printer become a trend for everyday looks? Which designers are experimenting with 3D printing in Russia?

The answers to these questions are later in the article.

A brief history of the development of the 3D-fashion direction

The 3D-fashion direction loudly declared itself in 2011. It was then that designers succeeded in creating original 3D printed shoes, and at the Paris Haute Couture Week, Iris van Herpen presented a collection of spring-summer dresses printed on a 3D printer. It was a success. Everyone is talking about a new technology that will revolutionize the fashion world. nine0003

It was then that designers succeeded in creating original 3D printed shoes, and at the Paris Haute Couture Week, Iris van Herpen presented a collection of spring-summer dresses printed on a 3D printer. It was a success. Everyone is talking about a new technology that will revolutionize the fashion world. nine0003

But there was no major upheaval. At that time, 3D printing was an expensive technology, so only a few could experiment. And they experimented. And how! In 2013, in addition to collections with 3D printed models, two interesting projects were implemented. Americans Michael Schmidt and Francis Bitonti printed a dress for burlesque diva Dita Von Teese. And Chinese designer Xie Wei Lunom created a shocking outfit for Lady Gaga. The dresses were revealing and uncomfortable, but spectacular. Wow effect achieved. nine0003

Famous shoe brands have also noticed the new technology. In 2013, NIKE used 3D printing to create the Vapor Laser Talon Cleat, a unique model with virtually weightless soles. Later, the brand created the Zoom Superfly Flyknit, in which Allison Felix won the gold medal at the Rio de Janeiro Olympics. The company refused to mass-produce shoes with 3D printed soles. Adidas took the lead.

Later, the brand created the Zoom Superfly Flyknit, in which Allison Felix won the gold medal at the Rio de Janeiro Olympics. The company refused to mass-produce shoes with 3D printed soles. Adidas took the lead.

As additive technologies became more accessible, not only well-known designers, but also small studios began to use them. In 2014, the Massachusetts company Nervous System created flexible jewelry using a 3D printer. They consisted of thousands of original fragments connected by hinges. Later, in 2016, the studio wowed the fashion community with a scarlet kinematic scale dress. It sat perfectly on the figure and effectively reacted to the movements of the model. nine0003

What now?

Few people believed that 3D printing would leave the podium and go to the masses. However, it happened. We will describe only a few 3D fashion projects implemented over the past six months.

Renowned New York designer Alexis Walsh creates unique handmade clothing with 3D printed elements. She is one of the few who has been specifically trained in 3D fashion design. Collaborated with Proenza Schouler and Lululemon Athletica Lab NYC. Her unique collections caused a sensation in New York, Paris, London, Berlin. Everything goes to the fact that soon such clothes will become a trend. nine0003

She is one of the few who has been specifically trained in 3D fashion design. Collaborated with Proenza Schouler and Lululemon Athletica Lab NYC. Her unique collections caused a sensation in New York, Paris, London, Berlin. Everything goes to the fact that soon such clothes will become a trend. nine0003

By the way, soon the designer will visit Moscow and hold a fashion show of his creations.

Also available online is a fully 3D printed bomber jacket by Tel Aviv-based designer Danit Peleg. It can be ordered remotely by adjusting the dimensions in a virtual fitting room. The designer plans to expand the list of 3D printed clothing offered.

Well-known clothing manufacturers are interested in the Loom dress, which was printed by a young designer from the USA, Maria Alejandra Mora-Sanchez. It combines textiles and additive technologies, and its main feature is the ability to stretch, adapting to body movements. nine0003

At the beginning of summer, the aRks studio from Palermo presented the Coral 3D printed bikini collection. The swimwear turned out to be rather frank, but they are worthy of attention, as they meet the qualities of ergonomics, environmental friendliness and were created exactly according to the figure of a particular model. The products are quite thin, which ensures maximum comfort, and cotton liners allow you to wear a bikini as underwear.

The swimwear turned out to be rather frank, but they are worthy of attention, as they meet the qualities of ergonomics, environmental friendliness and were created exactly according to the figure of a particular model. The products are quite thin, which ensures maximum comfort, and cotton liners allow you to wear a bikini as underwear.

adidas has launched mass production of 3D printed shoes. So far, the batch is small - the circulation of the Futurecraft 4D model will be just over 100 thousand pairs. It is important that the use of additive technologies has allowed the company to speed up and reduce the cost of creating a 3D printed sole, while it has become more durable and flexible. In the future, adidas wants to launch an online custom shoe ordering service. nine0003

Also showcasing a collection of 3D printed shoes during Portland Fashion Week. The collection was created by local designer Seth Aaron and 3D-printed shoe startup Feetz. Interestingly, the models are printed from 100% recyclable materials. After the show, visitors will be able to scan their feet and order innovative shoes for themselves. It will be made and shipped within a few weeks.

After the show, visitors will be able to scan their feet and order innovative shoes for themselves. It will be made and shipped within a few weeks.

How the 3D fashion industry is developing in Russia

The first to use 3D printing in the Russian fashion industry was designer Snezhana Paderina. In 2014, she implemented a fashion project to create clothes with 3D printed elements. Today, the designer's fashion collections are regularly shown on the catwalks of New York. She has been shown at the Metropolitan Museum of Art at the Fashion in the Age of Technology exhibition, at the IoT Media Mash conference, the Identities Fashion Show, etc. She continues to experiment with 3D printing, creating unique evening and casual outfits. In October, residents of the capital will also have the opportunity to see the work with their own eyes. nine0003

Not so long ago, the domestic startup Try.Fit proposed a revolutionary technology of virtual shoe fitting. The essence of the development is that the user scans his foot and uploads the data to the network, where a special program compares the 3D scan of the foot with the last of a particular pair of shoes. Brands such as NIKE and New Balance are already interested in the technology, as it will help them significantly increase the percentage of online sales. In Russia, the company is already cooperating with adidas and Ekonika.

Brands such as NIKE and New Balance are already interested in the technology, as it will help them significantly increase the percentage of online sales. In Russia, the company is already cooperating with adidas and Ekonika.

In addition, today there are many 3D printing platforms in the country that offer to create customized accessories or any other products on order. Among them is 3DPrintus. One of the company's activities is the production of 3D printed jewelry.

According to 3DPrintus co-founder Konstantin Ivanov, in Russia additive technologies are mainly used at the stage of modeling clothes or shoes, as well as for creating unique accessories, jewelry and small decorative elements. 3D printing also helps designers to find new forms and implement bold ideas faster. We are not talking about mass production yet. nine0003

However, there are also optimists. for example, Alexander Shumsky, head of the National Chamber of Fashion, states: “Now the clothing market in the world is transforming and reaching a new level, and “Russia has a chance to integrate into this process,” Shumsky believes.