How much does a 3d printer cost uk

The Best Cheap 3D Printers for 2023

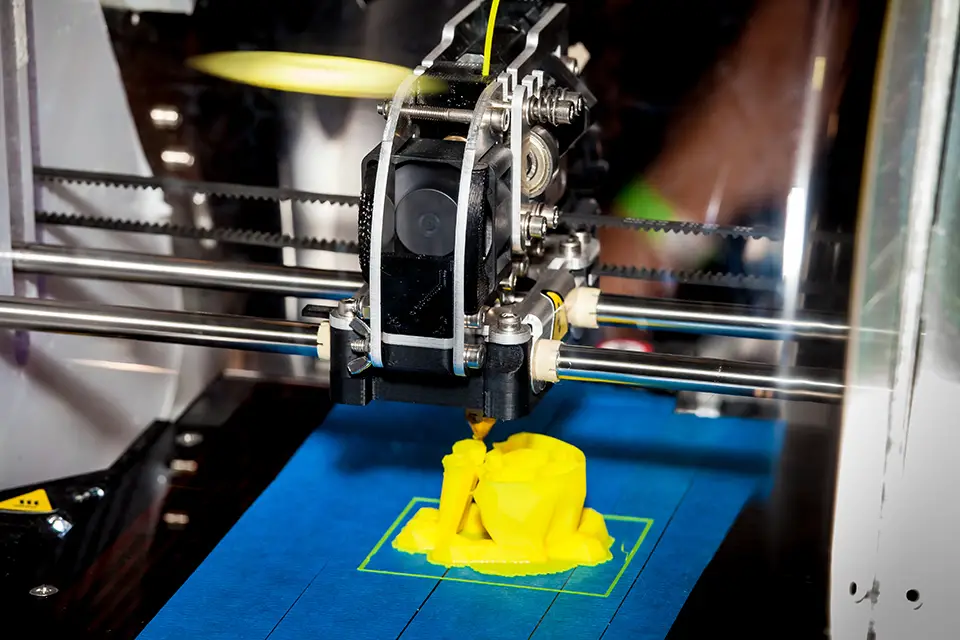

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

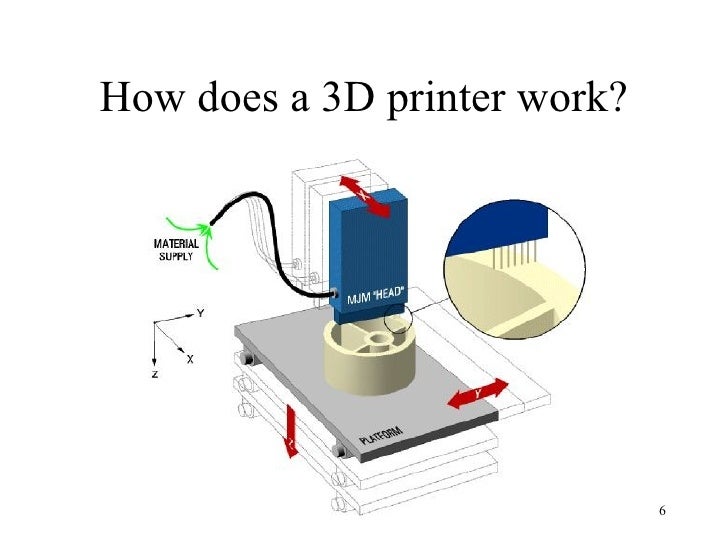

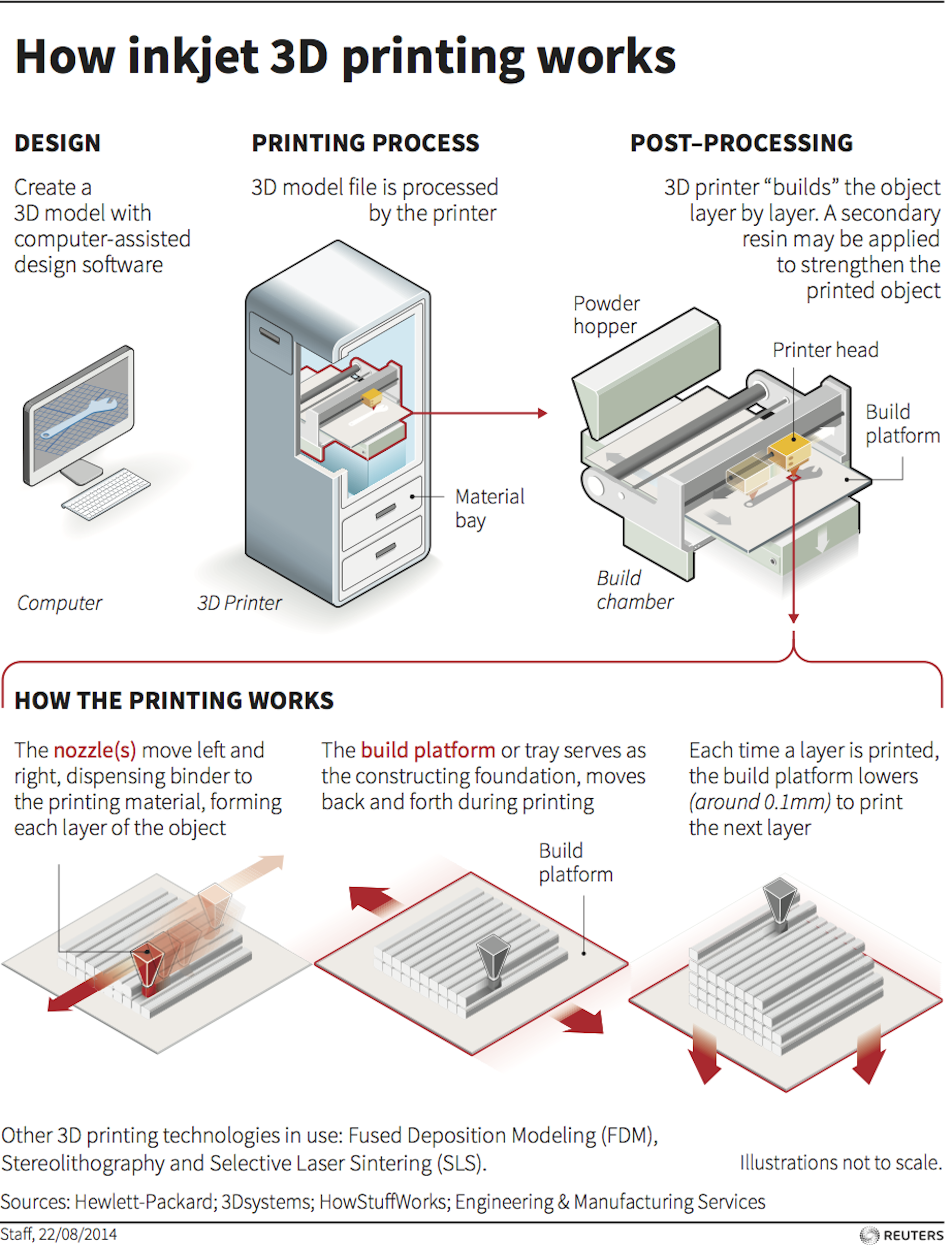

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura.

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura.

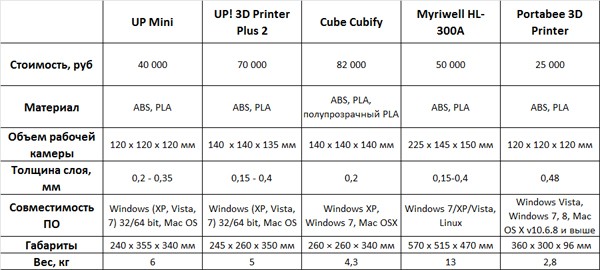

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

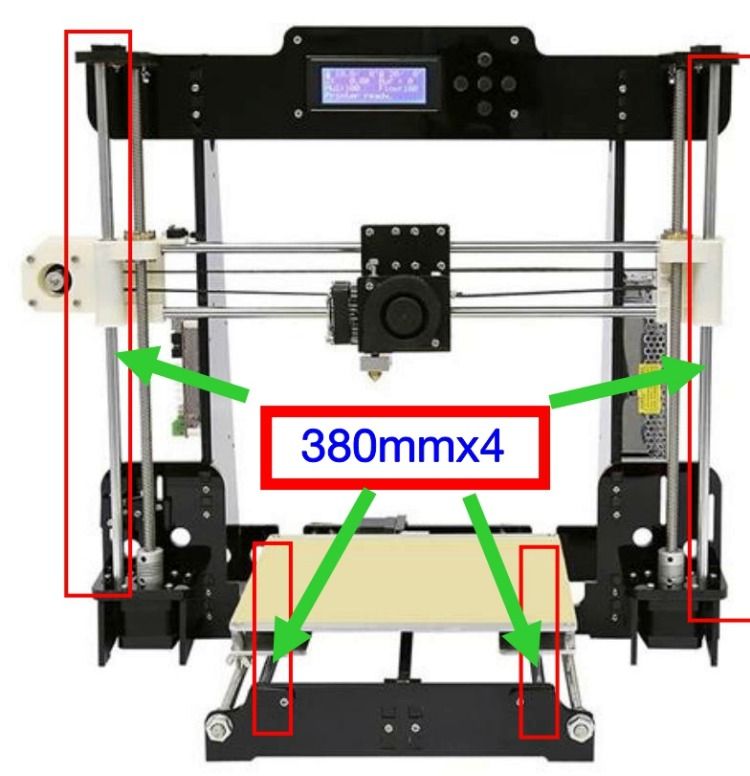

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together. ) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

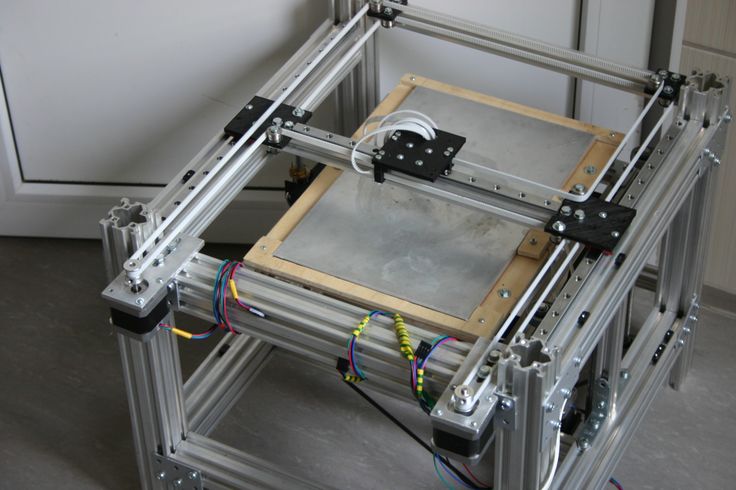

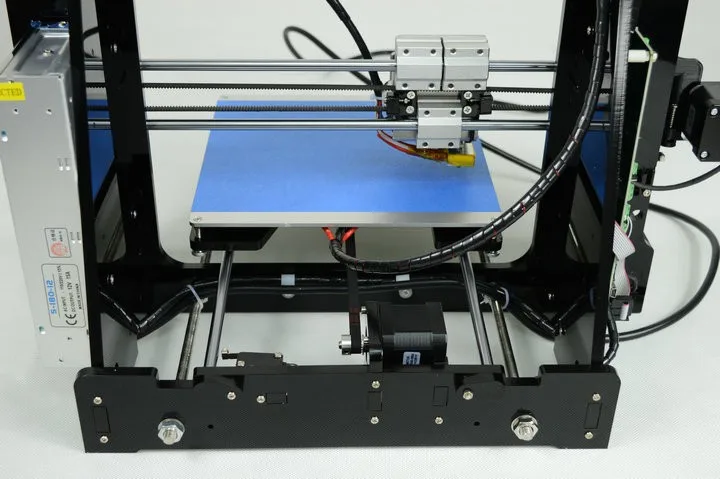

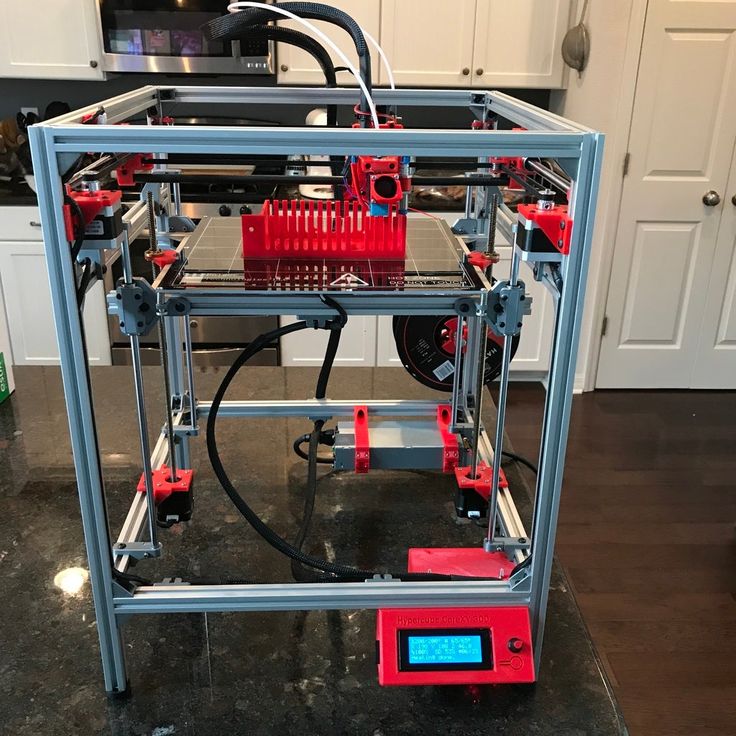

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

Should I Get an Open-Frame or Closed-Frame 3D Printer?

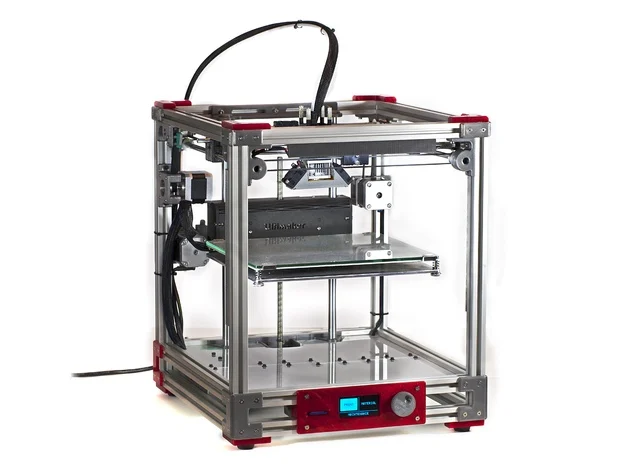

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

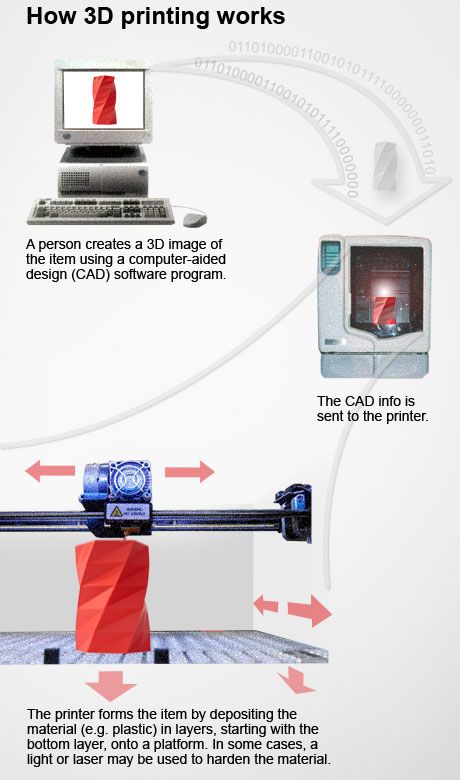

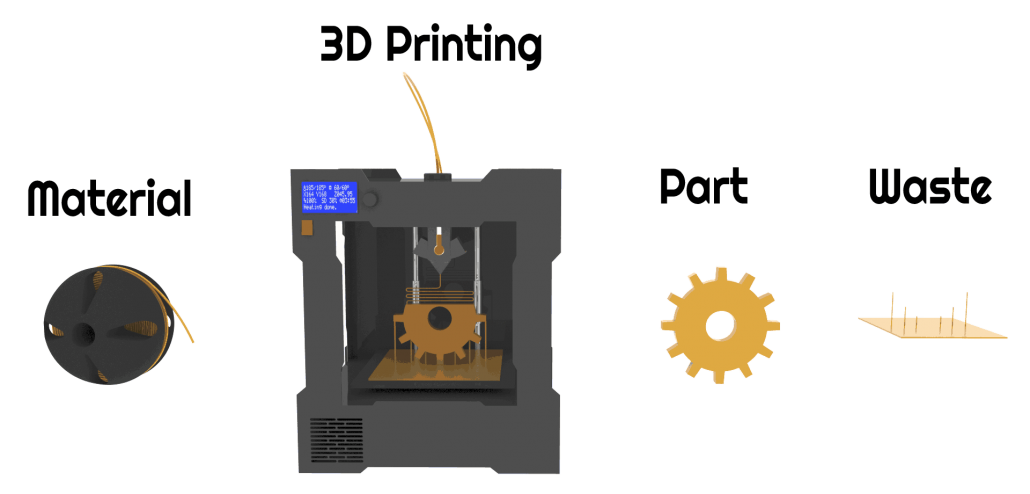

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

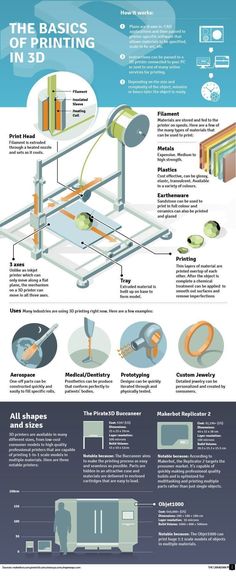

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

Dremel DigiLab 3D45 3D Printer Review - Review 2018

Dremel DigiLab 3D45 3D Printer Review - Review 2018 - PCMag UKWant the best Tech discounts and exclusive codes? - Get VoucherCodes email alerts today

We review products independently, but we may earn affiliate commissions from buying links on this page. Terms of use.

Terms of use.

The Dremel DigiLab 3D45 is featured-packed, prints accurately, and comes loaded with powerful software, making it one of the best 3D printers we've tested.

4.5 Excellent

-

Pros

- Very good print quality.

- Easy to use.

- User-friendly yet powerful software.

- Prints via USB, Ethernet, and Wi-Fi, and from a USB thumb drive.

- Safe design.

- Relatively quiet.

-

Cons

- Limited filament colors compared with competitors.Touch screen is not particularly responsive.

In evaluating a 3D printer, we look at a number of factors, among them ease of setup and use, print quality and consistency, build volume, software, filament, connectivity, and price. Although no printer excels at all of them, the Dremel DigiLab 3D45 3D Printer ($1,799) comes as close as we've seen. It's made primarily for product developers, engineers, and other professionals, and should also be useful in higher education. Although it's priced considerably higher than consumer 3D printers, its ease of setup and use, and its ability to output quality prints with consistency, mean that it could also be a good fit for a tech-savvy hobbyist with some cash to invest. It easily earns our Editors' Choice as a midrange 3D printer.

Although no printer excels at all of them, the Dremel DigiLab 3D45 3D Printer ($1,799) comes as close as we've seen. It's made primarily for product developers, engineers, and other professionals, and should also be useful in higher education. Although it's priced considerably higher than consumer 3D printers, its ease of setup and use, and its ability to output quality prints with consistency, mean that it could also be a good fit for a tech-savvy hobbyist with some cash to invest. It easily earns our Editors' Choice as a midrange 3D printer.

From Tool Manufacturing to 3D Printing

Most 3D printer manufacturers are startups, founded by enthusiasts, and are solely or primarily focused on 3D printing. Dremel, the venerable (86-year-old) Illinois-based toolmaker, is a notable exception. The company primarily makes rotary power tools such as screwdrivers, drills, and sanders. Dremel has a stellar reputation as a tool manufacturer, with its products earning numerous editorial awards from Popular Mechanics and specialized tool and building publications and sites.

Although 3D printers such as the 3D45 ($1,895.81 at Amazon) are far outside Dremel's traditional product line, power tools and 3D printers have one very basic thing in common: They're both used to make things. And Dremel clearly put the same care in designing and crafting the 3D45 as it does in making its tools.

The 3D45 is a fairly large printer, measuring 15.9 by 20.2 by 16 inches (HWD)—making it best suited for a table or a workbench—and it weighs a hefty 47 pounds. It's a closed-frame printer, with a clear plastic door in front that opens outward, and a clear lid on top that swings upward to open. This permits easy access to the print bed when needed, and safety when a print job is in progress.

At 6.7 by 10 by 6 inches, the 3D45's build volume is similar to the Makerbot Replicator+ (5.9 by 9.9 by 7.8 inches) and wider than the LulzBot Mini ( at Amazon) (6 by 6 by 6.2 inches), another Editors' Choice. The printer has a 5-inch touch screen for use in loading filament, printing from a USB thumb drive—the slot for which is just to the right of the display—and other tasks. The touch screen could be more responsive; sometimes I had to press it two or three times before it would accept my command. On the right side of the printer are the on-off switch, a USB port for connecting to a computer via a cable, and an Ethernet port.

The touch screen could be more responsive; sometimes I had to press it two or three times before it would accept my command. On the right side of the printer are the on-off switch, a USB port for connecting to a computer via a cable, and an Ethernet port.

Filament and Setup

Until recently, Dremel had a very limited color range for its filament, but with the launch of the 3D45, the company introduced 11 color choices for its polylactic acid (PLA) filament (white, black, red, blue, pink, orange, gold, silver, green, purple, and translucent white). It's still far fewer than MakerBot, which has twice as many PLA color choices plus 10 colors of ABS (acrylonitrile butadiene styrene) filament. In addition to PLA, Dremel sells Eco-ABS, which is a modified PLA filament with added strength, flexibility, and durability (according to Dremel), and nylon filaments. The PLA lists for $29.95 for a 0.5-kilogram (about 1.1-pound) spool, though it can be found online for less than $25. Eco-ABS and nylon filaments both list at $34. 95 per 0.5-kilogram spool.

95 per 0.5-kilogram spool.

These prices are in line with filament spools sold by major manufacturers for their own printers—MakerBot sells PLA for $48 per 0.9-kilogram spool, for instance. You can also use third-party filaments with the 3D45, with a couple caveats. First, the printer won't be able to automatically identify the filament type, as it can with Dremel's "smart" RFID-equipped spools, so you will have to enter the temperature settings—different types of plastic have different melting points and optimal temperatures—manually with the touch screen. Second, unless the spool you want to use happens to fit the 3D45's built-in spool chamber, you will have to feed the filament from outside the printer and improvise a spool holder that will both support the spool and let it spin freely. You could even 3D print one.

Loading filament is easy enough. When replacing a spool, you will want to first snip the filament close to the extruder and remove the old spool. Once you have seated the new spool in its holder and snaked the loose end of the filament through the guide tube, press the Change Filament button on the touch panel. The extruder will heat up, melting and extruding any filament left from the old spool. Then, insert the loose end of the new filament in the top of the extruder. When all the old filament has been extruded and the new filament color starts to extrude, press Done.

Once you have seated the new spool in its holder and snaked the loose end of the filament through the guide tube, press the Change Filament button on the touch panel. The extruder will heat up, melting and extruding any filament left from the old spool. Then, insert the loose end of the new filament in the top of the extruder. When all the old filament has been extruded and the new filament color starts to extrude, press Done.

Keeping Connected

The 3D45 offers enough connection choices to keep most any user happy. You can print from a computer over a USB, Ethernet, or Wi-Fi connection, as well as from a USB thumb drive. Although Dremel doesn't have a printing app per se, every Dremel printer can connect via the web to the Dremel Print Cloud, from which you can slice files (prepare the layers for printing), launch print jobs, and monitor prints in progress from the 3D45's onboard 720p camera.

Useful Software

Included with the printer is the DigiLab 3D Slicer software, which uses the open-source Cura platform that we have seen in many other 3D printers. It is easy for beginners to use, and powerful and versatile enough for advanced users. With the software installed, you can open, manipulate, and slice a file; launch a print job; or save a file in printable format—the 3D45 can print either G-code or Dremel's own .3gdrem format. Resolution ranges from 300 microns to 50 microns; the low-resolution setting is 300 microns, standard resolution is 200 microns, high resolution is 100 microns, and Ultra resolution is 50 microns. In addition to the DigiLab 3D Slicer, you can send files to Dremel's cloud-based slicer in the Dremel Print Cloud.

It is easy for beginners to use, and powerful and versatile enough for advanced users. With the software installed, you can open, manipulate, and slice a file; launch a print job; or save a file in printable format—the 3D45 can print either G-code or Dremel's own .3gdrem format. Resolution ranges from 300 microns to 50 microns; the low-resolution setting is 300 microns, standard resolution is 200 microns, high resolution is 100 microns, and Ultra resolution is 50 microns. In addition to the DigiLab 3D Slicer, you can send files to Dremel's cloud-based slicer in the Dremel Print Cloud.

Stellar Print Quality and Performance

I printed about 10 test objects with the 3D45, three in high resolution and the rest in standard. Print quality was good to excellent throughout, with no significant difference between standard and high resolution. Even better, there were no misprints, and none of the printed objects showed any serious flaws. It did very well in printing our geometric test object, which includes raised text and various shapes on a steeply inclined surface.

Safety and Noise

As a closed-frame 3D printer, the 3D45 is inherently safer than an exposed open-frame printer. The front door and lid are generally closed during printing, so you don't have to worry about an onlooker getting burned by accidentally touching the hot extruder. And even if you do get your hands inside the frameduring printing, the metal extruder nozzle, which gets very hot during printing, extends only a short distance below the extruder assembly and would be hard to reach. With the door and lid closed, the 3D45 is very quiet; when it was printing, I often couldn't hear it at all from about 30 feet away.

A Great 3D Printer for Makers

The Dremel DigiLab 3D45 3D Printer is a great choice for engineers, product designers, or educators. It's very easy to set up and use, and printed with above-average quality with no misprints in our testing. The 3D45 is more expensive than the LulzBot Mini, the Editors' Choice in its sub-$2,000 price class, but it has a larger build area, better print quality, and a closed frame, and it succeeds the Mini as our current Editors' Choice. While it doesn't have the MakerBot Replicator+'s ($2,325.99 at Dell) wide range of filament choices and some convenience features like the Smart Extruder, it costs $700 less and adds a closed frame. Dremel made its name in designing high-quality power tools, and now it does an excellent job in crafting 3D printers as well.

While it doesn't have the MakerBot Replicator+'s ($2,325.99 at Dell) wide range of filament choices and some convenience features like the Smart Extruder, it costs $700 less and adds a closed frame. Dremel made its name in designing high-quality power tools, and now it does an excellent job in crafting 3D printers as well.

Best 3D Printer Picks

- The Best 3D Printers for 2020

- 3D Printer Filaments Explained

- More 3D Printer Reviews

- More from Dremel

Further Reading

- New 3D Printing Method Takes Seconds

- Ford Creates 3D-Printed Locking Wheel Nuts Using Driver's Voice

- 3D Printing Helps Recreate Voice of 3,000-Year-Old Mummy

- These Huge 3D Printers Want to Save the Earth (and Maybe Mars)

- With 3Doodler App and Pen, Your Phone and Tablet Are the Canvas

The 3D45 is a fairly large printer, measuring 15.9 by 20.2 by 16 inches (HWD)\u2014making it best suited for a table or a workbench\u2014and it weighs a hefty 47 pounds. It's a closed-frame printer, with a clear plastic door in front that opens outward, and a clear lid on top that swings upward to open. This permits easy access to the print bed when needed, and safety when a print job is in progress.

It's a closed-frame printer, with a clear plastic door in front that opens outward, and a clear lid on top that swings upward to open. This permits easy access to the print bed when needed, and safety when a print job is in progress.

At 6.7 by 10 by 6 inches, the 3D45's build volume is similar to the Makerbot Replicator+ (5.9 by 9.9 by 7.8 inches) and wider than the LulzBot Mini ( at Amazon) (6 by 6 by 6.2 inches), another Editors' Choice. The printer has a 5-inch touch screen for use in loading filament, printing from a USB thumb drive\u2014the slot for which is just to the right of the display\u2014and other tasks. The touch screen could be more responsive; sometimes I had to press it two or three times before it would accept my command. On the right side of the printer are the on-off switch, a USB port for connecting to a computer via a cable, and an Ethernet port.

\nFilament and Setup

\nUntil recently, Dremel had a very limited color range for its filament, but with the launch of the 3D45, the company introduced 11 color choices for its polylactic acid (PLA) filament (white, black, red, blue, pink, orange, gold, silver, green, purple, and translucent white). It's still far fewer than MakerBot, which has twice as many PLA color choices plus 10 colors of ABS (acrylonitrile butadiene styrene) filament. In addition to PLA, Dremel sells Eco-ABS, which is a modified PLA filament with added strength, flexibility, and durability (according to Dremel), and nylon filaments. The PLA lists for $29.95 for a 0.5-kilogram (about 1.1-pound) spool, though it can be found online for less than $25. Eco-ABS and nylon filaments both list at $34.95 per 0.5-kilogram spool.

It's still far fewer than MakerBot, which has twice as many PLA color choices plus 10 colors of ABS (acrylonitrile butadiene styrene) filament. In addition to PLA, Dremel sells Eco-ABS, which is a modified PLA filament with added strength, flexibility, and durability (according to Dremel), and nylon filaments. The PLA lists for $29.95 for a 0.5-kilogram (about 1.1-pound) spool, though it can be found online for less than $25. Eco-ABS and nylon filaments both list at $34.95 per 0.5-kilogram spool.

These prices are in line with filament spools sold by major manufacturers for their own printers\u2014MakerBot sells PLA for $48 per 0.9-kilogram spool, for instance. You can also use third-party filaments with the 3D45, with a couple caveats. First, the printer won't be able to automatically identify the filament type, as it can with Dremel's \"smart\" RFID-equipped spools, so you will have to enter the temperature settings\u2014different types of plastic have different melting points and optimal temperatures\u2014manually with the touch screen. Second, unless the spool you want to use happens to fit the 3D45's built-in spool chamber, you will have to feed the filament from outside the printer and improvise a spool holder that will both support the spool and let it spin freely. You could even 3D print one.

Second, unless the spool you want to use happens to fit the 3D45's built-in spool chamber, you will have to feed the filament from outside the printer and improvise a spool holder that will both support the spool and let it spin freely. You could even 3D print one.

Loading filament is easy enough. When replacing a spool, you will want to first snip the filament close to the extruder and remove the old spool. Once you have seated the new spool in its holder and snaked the loose end of the filament through the guide tube, press the Change Filament button on the touch panel. The extruder will heat up, melting and extruding any filament left from the old spool. Then, insert the loose end of the new filament in the top of the extruder. When all the old filament has been extruded and the new filament color starts to extrude, press Done.

\nKeeping Connected

\nThe 3D45 offers enough connection choices to keep most any user happy. You can print from a computer over a USB, Ethernet, or Wi-Fi connection, as well as from a USB thumb drive. Although Dremel doesn't have a printing app per se, every Dremel printer can connect via the web to the Dremel Print Cloud, from which you can slice files (prepare the layers for printing), launch print jobs, and monitor prints in progress from the 3D45's onboard 720p camera.

Although Dremel doesn't have a printing app per se, every Dremel printer can connect via the web to the Dremel Print Cloud, from which you can slice files (prepare the layers for printing), launch print jobs, and monitor prints in progress from the 3D45's onboard 720p camera.

Useful Software

\nIncluded with the printer is the DigiLab 3D Slicer software, which uses the open-source Cura platform that we have seen in many other 3D printers. It is easy for beginners to use, and powerful and versatile enough for advanced users. With the software installed, you can open, manipulate, and slice a file; launch a print job; or save a file in printable format\u2014the 3D45 can print either G-code or Dremel's own .3gdrem format. Resolution ranges from 300 microns to 50 microns; the low-resolution setting is 300 microns, standard resolution is 200 microns, high resolution is 100 microns, and Ultra resolution is 50 microns. In addition to the DigiLab 3D Slicer, you can send files to Dremel's cloud-based slicer in the Dremel Print Cloud.

Stellar Print Quality and Performance

\nI printed about 10 test objects with the 3D45, three in high resolution and the rest in standard. Print quality was good to excellent throughout, with no significant difference between standard and high resolution. Even better, there were no misprints, and none of the printed objects showed any serious flaws. It did very well in printing our geometric test object, which includes raised text and various shapes on a steeply inclined surface.

\n\nSafety and Noise

\nAs a closed-frame 3D printer, the 3D45 is inherently safer than an exposed open-frame printer. The front door and lid are generally closed during printing, so you don't have to worry about an onlooker getting burned by accidentally touching the hot extruder. And even if you do get your hands inside the frameduring printing, the metal extruder nozzle, which gets very hot during printing, extends only a short distance below the extruder assembly and would be hard to reach. With the door and lid closed, the 3D45 is very quiet; when it was printing, I often couldn't hear it at all from about 30 feet away.

With the door and lid closed, the 3D45 is very quiet; when it was printing, I often couldn't hear it at all from about 30 feet away.

A Great 3D Printer for Makers

\nThe Dremel DigiLab 3D45 3D Printer is a great choice for engineers, product designers, or educators. It's very easy to set up and use, and printed with above-average quality with no misprints in our testing. The 3D45 is more expensive than the LulzBot Mini, the Editors' Choice in its sub-$2,000 price class, but it has a larger build area, better print quality, and a closed frame, and it succeeds the Mini as our current Editors' Choice. While it doesn't have the MakerBot Replicator+'s ($2,325.99 at Dell) wide range of filament choices and some convenience features like the Smart Extruder, it costs $700 less and adds a closed frame. Dremel made its name in designing high-quality power tools, and now it does an excellent job in crafting 3D printers as well.

\n\nBest 3D Printer Picks

\n- \n

- The Best 3D Printers for 2020 \n

- 3D Printer Filaments Explained \n

- \nMore 3D Printer Reviews\n \n

- \nMore from Dremel\n \n

Further Reading

\n- \n

- New 3D Printing Method Takes Seconds \n

- Ford Creates 3D-Printed Locking Wheel Nuts Using Driver's Voice \n

- 3D Printing Helps Recreate Voice of 3,000-Year-Old Mummy \n

- These Huge 3D Printers Want to Save the Earth (and Maybe Mars) \n

- With 3Doodler App and Pen, Your Phone and Tablet Are the Canvas \n

The best 3D printers on the Ukrainian market

Ultimaker S5

217 400

UAH.

Flagship of the Ultimaker brand. One of the best semi-professional 3D printers in the world.

High quality reliable 3D printer. Great for business.

Detailed information about the 3D printer

Gigant

Large and robust rail-mounted 3D printer. Huge print area: 40*40*40cm. The 3D printer can be equipped with two extruders. The body is made of steel, and the kinematics are built on the basis of professional machine components, which guarantees high accuracy and long service life of the device. nine0005

Semi-closed housing. Russified firmware. Industrial reliability. Thread 1.75 mm. Cura software support.

Detailed information about the 3D printer

Prime X production

from 29 500

UAH.All-in-one reliable 3D printer for the home or small office. With a small budget, you get full functionality, a large print area and a 12-month warranty from the manufacturer (Ukraine)

Huge build area. Reliable electronics. Rail guides. Russified touch screen.

Reliable electronics. Rail guides. Russified touch screen.

Detailed information about the 3D printer

Flashforge Guider II

55000

High-quality 3D printer from the expensive Chinese segment.

Precision mechanics. Closed construction. Platform auto-calibration sensor. Modern design

3D printer details

MakerPi K5 Plus with auto-calibration

27000

UAH.K5 Plus is a new line from the famous Chinese brand MakerPi. Good print quality and ease of use make this printer a convenient option for both home and business. The kinematics of the K5 3D printer is a copy of Makerbot, which results in very fast printing without loss of surface quality.

Nice blue body. Proven design. Excellent blowing of the print area. High precision mechanics. nine0016

Detailed information about 3D printer

MakerPi 2030X with color mixing extruder

40 000

UAH.

New copy of Ultimaker from Chinese manufacturer MakerPi with mixing extruder. A rugged steel body paired with Ultimaker's high-precision kinematics deliver superior print quality and impressive speed.

Innovative extruder allows you to print with 2 colors/2 materials, as well as mix 2 colors, creating incredibly beautiful gradient 3D printing. nine0005

Robust steel housing. Large color display. Copy of Ultimaker.

3D printer details

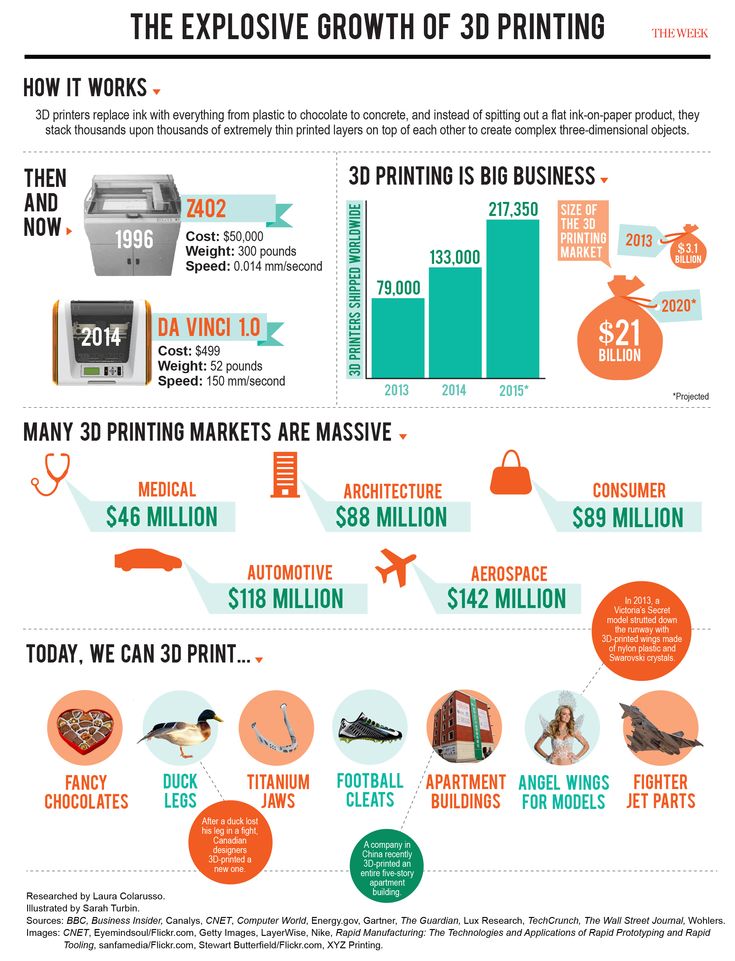

The 3D printer market is in a phase of rapid growth these days. Once a week, a new manufacturer shakes the kickstarter, promising its investors mountains of gold and the best 3D printer in the world.

It is very difficult to get confused in such a variety of 3D printers. Even in our store there are already several dozen. We have already published various reviews and comparisons of 3D printers more than once. If you want to conduct a detailed overview of the market, then you should check out our full set of articles on modern 3D printers and 3D printing. nine0005

nine0005

Well, for those who don't want to spend time looking for and choosing the perfect 3D printer, we decided to create this page.

You won't find much technical information on this page, but here you will find the most important. — 6 best 3D printers on the Ukrainian market. As technology develops, we will update the page so that you can always take advantage of the most up-to-date information.

How much does a 3D printed house cost?

3DPrintStory News How much does a 3D printed house cost?

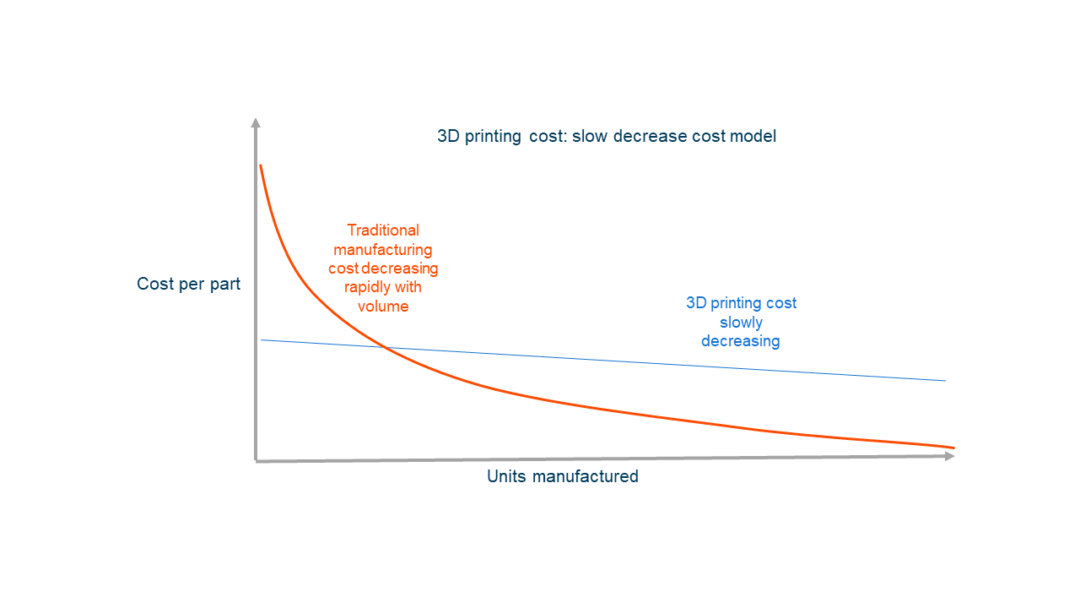

Every new innovation comes to market with a price. For example, large concrete 3D printers had a fairly high price when they first launched. But as with most technology, prices are falling as new, better, and more affordable products are developed. New innovative concrete mixtures also contribute to lower prices. nine0005

New innovative concrete mixtures also contribute to lower prices. nine0005

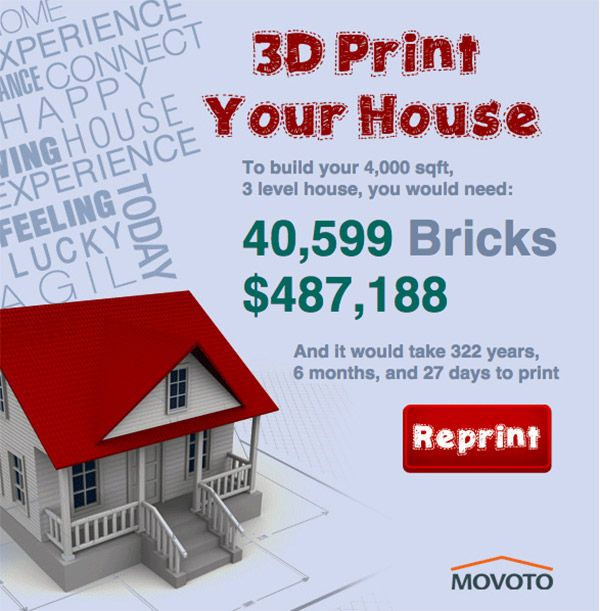

Since there are a number of 3D printed building projects around the world, it is impossible to give an exact price for a 3D printed house. Instead, we'll take a look at some of the most recent and promising projects and their prices.

However, in general, jumping ahead a bit, you will see that a 3D printed house can cost as little as $10,000, sometimes less. Let's take a look!

Example 1 Apis Cor house

One rather promising project from Russia. Apis Cor is a Russian company that specializes in the development of a mobile 3D construction printer capable of printing entire buildings on the spot.

Apis Cor built a 410 square foot home to showcase the potential and capabilities of its mobile 3D construction printer. The 3D-printed house cost the company about $10,150 - an incredibly low amount for building a house. nine0005

Here is a more detailed list of costs, according to the company's website:

- Foundation: $277

- Walls: $1624

- Floor and roof: $2434

- Wiring: $242

- Windows and doors: 3 Windows and doors: 3

- Exterior: $831

- Interior (including stretch ceiling): $1,178.

The company even decorated the house both inside and out. The outside of the house is painted, but inside there is a refrigerator, a large-screen TV, a sofa and other furniture. True, furniture is clearly not included in the price. Apis Cor just wanted to showcase what a finished home could look like. nine0005

Example 2. Is ICON a home for less than $4,000?

Look at the picture above. This house was 3D printed by Texas-based ICON.

ICON specializes in low cost building solutions, so their main project is a 3D printed house.

In partnership with the non-profit organization New Story, ICON plans to build an entire block of these affordable 3D printed houses in El Salvador. The goal is to provide housing for people who, unfortunately, do not yet have adequate housing conditions. nine0005

A prototype 3D printed house cost about $10,000, but the company says it can bring that down to $4,000, which is amazing and impressive news. The approximate assembly time for such a house from ICON is approximately 24 hours.

Example 3 Winsum - 10 houses in one day

Winsun from Shanghai became famous in 2014 by reaching the 3D printing milestone of 10 houses in just one day!

Winsun used large concrete 3D printers, 10 meters wide and 6.6 meters high. The company said that each 3D printed house costs $4,800, which is surprisingly low for 2014! nine0005

Although Winsun's 3D houses are not so exquisite, they have generated a lot of public interest. This project has definitely contributed to the increase in the number of houses made with 3D printers and the development of 3D printers themselves for their production.

Winsun is also known for producing one of the most advanced 3D printed buildings to date, which we will discuss in the next section...

Example 4 Office Building in Dubai in the world, printed on a 3D printer. What it is? Beautiful and futuristic office building in Dubai. nine0005

The entire 3D printing process took Winsun only 17 days. Up to this point, we have mentioned fairly cheap 3D printed houses, but this building was clearly more expensive - around $140,000.