Dr nim 3d print

▷ dr nim game online 3d models 【 STLFinder 】

Dr NIM game

thingiverse

http://www.cs.miami.edu/home/burt/learning/Csc427.152/491_Dr-Nim-Manual5b15d.pdf It is an exact copy of the classic game but on a smaller scale so that it can be printed from one piece. all parts have 20% fill and two outer layers. except the...

Dr NIM game (large version)

thingiverse

http://www.cs.miami.edu/home/burt/learning/Csc427.152/491_Dr-Nim-Manual5b15d.pdf It is an exact copy of the classic game this time instead of printing in one piece is printed in four so it is bigger and also works better because the balls are...

Dr Nim storage box.

thingiverse

Dr Nim storage box =============== Just a simple box to keep my precious [Dr Nim](https://www.thingiverse.com/make:635348) game safe ! The main board slides into the box and locks thanks to the hinged stand. This way it is secured and the marbles...

Nim marble game

thingiverse

15 marble x 3 column Nim game. Gameplay Players agree on the number of marbles to be used. Players flip to determine who will go first. Player who lost flip places the marbles into the stacks. The...

The Game of Nim

prusaprinters

This is a set of stacking tokens to play the mathematical game of Nim. ... If you know the winning strategy, you will never lose unless the other player also knows the winning strategy.This is a first draft and I intend to create stacking version...

... If you know the winning strategy, you will never lose unless the other player also knows the winning strategy.This is a first draft and I intend to create stacking version...

The Amazing Dr. Nim Scale Model

thingiverse

Nim Manual](http://icarus.cs.uiuc.edu/friendsofdigicomp/Files/Nim_Manual.pdf) There are many good online references for the game. The following video is especially informative and entertaining: And this article speaks to the relevance of a game like...

The Amazing Dr. Nim - Remix

thingiverse

This is a simple remix for 200mm printers. You can print B and C together. ...Then glue A and B before finally attaching C.

...Then glue A and B before finally attaching C.

Laser cut (3 mm) version of "The Amazing Dr. Nim Scale Model "

thingiverse

Nim game as a binary mechanical construction. I sliced the scale version of Dr. Nim and created a lasercut version of it. The board consist of 4 layer of 3 mm mdf glued together. The flipflops are consiting of 3 layers. I lasercut the trigger out...

XTD NIM Cover Plate

thingiverse

This is a NIM cover plate for application. ...Print Settings Printer Brand: LulzBot Printer: TAZ 6 . ..

..

NIM bare faceplate

thingiverse

A bare faceplate for a single- or double- wide NIM bin. ... Reworked from jdc_idlab's original for XTD.

NIM for the JDDX2RS

thingiverse

NIM for the Jesse Dean JDDX2RS It will make it easier to swap faders without opening the turntable, also mount it at 45 degrees.

ROBOCON 22 ONLINE Game Field

grabcad

ROBOCON 22 ONLINE Game Field

The Simpsons Game (2007) - Dr. Zoidberg

Zoidberg

sketchfab

Model of Doctor Zoidberg from The Simpsons Game (2007) by EA.

The Simpsons Game (2007) - Dr. Hibbert

sketchfab

Model of Doctor Julius Hibbert from The Simpsons Game (2007) by EA.

dr

grabcad

dr

Dr.

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=408698 Instructions Using the following options: text_thickness = 3. 5 pencil_width = 14 pencil_sides = 6 text = Dr.Volkmann letterspaces = [0,59,52,50.5,52,50,50,50,50,50,50,50,50,50,50]...

5 pencil_width = 14 pencil_sides = 6 text = Dr.Volkmann letterspaces = [0,59,52,50.5,52,50,50,50,50,50,50,50,50,50,50]...

DR

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=739573 Instructions Using the following options: glyph_coalesce_strategy = bar and glyphs font_with_style = font_weight = 0 bar_length_trim = 0 borderextruder = extruder2 inner_margin_width =...

Pakari "regular" Voya Nui Online Game

thingiverse

This mask is based on the "regular" mask of stone ( the elements were labeled wrong) from the 2006 Bionicle Voya Nui Online Game.

Noble Kakama Voya Nui Online Game (VNOG)

thingiverse

This mask is based on the "noble" mask of earth ( it was labeled with the wrong element in game) from the Bionicle Voya Nui Online game. ...I like to call it the grumpy kakama because it looks like the mask is frowning.

...I like to call it the grumpy kakama because it looks like the mask is frowning.

Noble Hau Voya Nui Online Game

thingiverse

This mask is based on the 'noble mask of fire' from the 2006 bionicle voya nui online game which was based on the great hau. ...Should fit mata and metru heads.

Regular Miru Voya Nui Online Game

thingiverse

This mask is based on the 'regular mask of air' from the voya nui online game which was based on the great miru. ...It uses the miru model as a base and should fit any mask the miru can fit.

Lava Ape Head Voya Nui Online Game

thingiverse

This skakdi mask is based on the terrifying lava apes (unless you had the nui blaster) from the voya nui online game. ...I had to change the design slightly to get it to fit, but it should fit skakdi heads.

...I had to change the design slightly to get it to fit, but it should fit skakdi heads.

Akaku "regular" Voya Nui Online Game

thingiverse

This mask is based on the "Regular Mask of Ice" from the 2006 Bionicle Voya Nui Online Game, which is based on the kanohi akaku. ...It has a stud connection and fits mata and metru heads.

Regular Hau Voya Nui Online Game

thingiverse

This mask is based on the 'regular mask of fire from the 2006 bionicle voya nui online game which was based on the great hau. ...Should fit mata and metru heads.

Great Miru Voya Nui Online Game (VNOG)

thingiverse

A modified version of the Miru Nuva made to look like the great miru from the 2006 bionicle voya nui online game. Should fit mata and metru heads. ...scale stud connection version to 42%.

Should fit mata and metru heads. ...scale stud connection version to 42%.

Great Akaku Voya Nui Online Game (VNOG)

thingiverse

This mask is based on the "Great mask of Ice" from the 2006 bionicle Voya Nui Online Game, which was in turn based on the Akaku Nuva that Kopaka Nuva wore. ...The large version fits the metru and mata heads.

Great Kaukau Voya Nui Online Game

thingiverse

This mask is based on the "great mask of water from the 2006 Bionicle Voya Nui online game. Not much has changed on it from the Kaukau Nuva. ...I only added a few parts and the visor which is meant to connect with lego "bars".

Great Kakama Voya Nui Online Game

thingiverse

This mask is based on the "Great mask of earth" (the element was labeled incorrectly) from the 2006 Bionicle Voya Nui Online Game. ...The top half is from the actual kakama nuva model from 2002, and the bottom half was remodeled to more closely resemble...

Noble Miru Voya Nui Online Game

thingiverse

This mask is based on the 'noble mask of air' from the voya nui online game which was based on the great miru. It uses the miru model as a base and should fit any mask the miru can fit. ...I accidentally made too many 'teeth' on the first model, so now. ..

..

Great Pakari Voya Nui Online Game

thingiverse

This mask design is based on the "Great mask of stone" (the element was labeled wrong) from the 2006 Bionicle Voya Nui Online Game, which was based on the pakari nuva. ...For some reason the Pakaris got gas mask canisters on their chins.

The Amazing Dr. Nim (Fall 2018) — Vintage Computers

The Amazing Dr. Nim

On the left is my 2:3 scale The Amazing Dr. Nim reproduction, and on the right an original I was able to obtain after my reproduction was completed.

Manufactured By: E.S.R., Inc.

Designed By: John Thomas Godfrey

Release Date: 1966

The Amazing Dr. Nim is a marble-powered plastic computer capable of playing the game of Nim. The machine selects its moves through the action of the marbles falling through the levers of the machine.

Nim is a marble-powered plastic computer capable of playing the game of Nim. The machine selects its moves through the action of the marbles falling through the levers of the machine.

The "game board" is a based on the mechanical Digi-Comp II digital computer (also a Godfrey creation). It has memory switches that hold bits of data. The unit is programmed by lobed levers that affect and are affected by marbles that are released from the top of the game. Three of the levers set the start position. The fourth lever is the 'equalizer' option; if set, the player can win if they play perfectly. The last lever is used to indicate who's turn it is, the human or Dr. Nim's.

The Amazing Dr. Nim was the next on my E.S.R. list to make. I did not in fact own an original Dr. Nim when I created this model. The model was developed from pictures obtained online, and from pictures and information graciously provided by Dr. Nim owners. Thank you so much Jaap Scherphuis and Charles E. Leiserson!

I didn’t think that Tinkercad would be a good choice for recreating a Dr. Nim. Because I was still learning about 3D printing in general I was watching a lot of instructional YouTube videos where Fusion 360 seemed to be the tool of choice for modelling parts to print. Seeing as it is free for non-commercial use I decided to give it a try.

Nim. Because I was still learning about 3D printing in general I was watching a lot of instructional YouTube videos where Fusion 360 seemed to be the tool of choice for modelling parts to print. Seeing as it is free for non-commercial use I decided to give it a try.

A Dr. Nim photo that can be loaded into Fusion 360 as a “canvas”. With the ruler in place it is easy to calibrate the image size.

Creating my Dr. Nim reproduction and learning Fusion 360 happened in tandem. I had decided to create a 2/3 scaled model so that it would fit onto the bed of my 3D printer. A key discovery made during this process was the “Canvas” feature of Fusion 360. This allows you to import a photo of an object to be modelled as a background to the sketch area, and to precisely define that object’s size with Fusion 360. With that calibrated image in place, it’s a fairly simple matter to “trace” the features of the object using Fusion 360 sketching tools (lines, curves, etc. ). I have used this feature in virtually all of the subsequent reproductions that I have done.

). I have used this feature in virtually all of the subsequent reproductions that I have done.

As with all of my reproductions, build files and instructions for making a Dr. Nim of your own have been posted to both Instructables and Thingiverse. In one sense Dr. Nim has been one of my most successful reproductions based on the number of people that have used those instruction to make one of their own. This is very gratifying.

Build Instructions

hackaday.io

Boing Boing

"Doctor, can you print out a new heart for me?" / News of the Society of Krasnoyarsk and the Krasnoyarsk Territory / Newslab.Ru

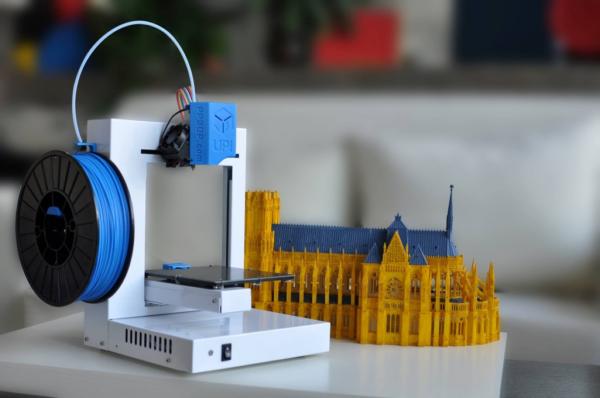

Sometimes it even becomes scary at the thought of the incredible speed with which modern technologies are developing. Even in the foreseeable past, about 15 years ago, it was cool to have an inkjet black-and-white printer at home, now many are seriously asking for portable 3D printers that can recreate, for example, a lost part from a food processor, a basketball or ... fantastic armor for cosplay parties. nine0004

Even in the foreseeable past, about 15 years ago, it was cool to have an inkjet black-and-white printer at home, now many are seriously asking for portable 3D printers that can recreate, for example, a lost part from a food processor, a basketball or ... fantastic armor for cosplay parties. nine0004

But technology is primarily a public good, not a private entertainment. For example, for the medical field, the spread of 3D printing technologies opens up truly limitless possibilities for the treatment of diseases and injuries that previously caused a life-long disability of a person or even led to his death.

More and more people around the world are acquiring “spare parts” and 3D models of their bodies that allow doctors to understand pathology: for example, figure out how best to get to an insidious cancerous tumor that has grown between vital organs, or plan a complex operation on heart muscle. Surprisingly, often the idea to print an organ does not come to doctors, but to patients and their relatives who are trying their best to save the situation: they themselves develop software and come up with materials for a future model, and then go to doctors with a ready-made proposal. Over time, such unique cases become precedents - and give hope to patients with similar diseases around the world. nine0005

Over time, such unique cases become precedents - and give hope to patients with similar diseases around the world. nine0005

Having studied several examples of the use of 3D printing in medicine, I divided them into several groups, depending on the purpose of creating models.

3D printing in surgery planning

If modern medical technologies such as computed tomography or magnetic resonance imaging allow you to see a 3D projection of internal organs on a computer screen, why not print the desired model on a printer? After all, it is one thing to look at a picture, and another to hold in your hands an exact copy of the part of the body that is to be cured. nine0005

During the EuroEcho-Imaging 2014 conference, which took place in Vienna last December, Dutch doctor Peter Feschhoeven demonstrated to the assembled colleagues a 3D model of a human heart printed on a high-tech printer. While under normal conditions, children with congenital defects sometimes require up to 4 operations at different times of their lives to eliminate the defect, a plastic copy of the heart can reduce the number of interventions to 1-2, since doctors have the opportunity to pre-select and plan the necessary surgical appointment. In addition, with the help of a 3D heart, it will be easier for a doctor to explain to patients and parents the essence of the defect and its treatment methods. nine0005

In addition, with the help of a 3D heart, it will be easier for a doctor to explain to patients and parents the essence of the defect and its treatment methods. nine0005

Another example is that the wife of American 3D designer Michael Balzer was diagnosed with meningioma, a brain tumor 3 cm in diameter, which was located behind the woman’s left eye. In accordance with the standard surgical technique, in order to remove the formation, it was necessary to perform a trepanation and actually move the brain inside the skull. This, in turn, threatened with death on the operating table or unpredictable complications after the intervention. Balzer did not want to take such a risk and independently created a 3D model of his wife's skull with a tumor on the inside of the eye socket. Turning to the US neurosurgical community via the Internet, the designer quickly found a doctor who was ready to remove the tumor microinvasively, through a small incision above the patient's left eye. The doctor noticed that by the time of the operation, the tumor was already so large that it touched the optic nerve, and in a few months Balzer's wife could go blind. But now she is healthy and, according to her husband, a small scar on her eyelid is visible only to her. nine0005

But now she is healthy and, according to her husband, a small scar on her eyelid is visible only to her. nine0005

In the same way, 3D printing pioneers create models of the pelvic organs in preparation for complex surgery, and cosmetic surgeons can show the patient in advance what his face with a reshaped nose will look like.

Functional prostheses

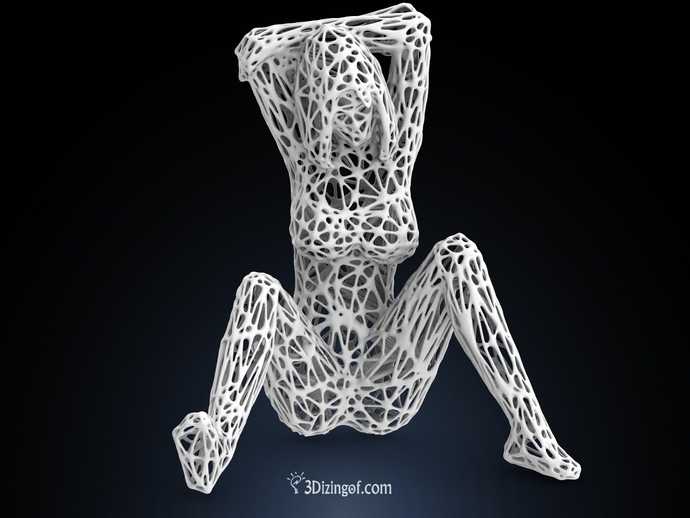

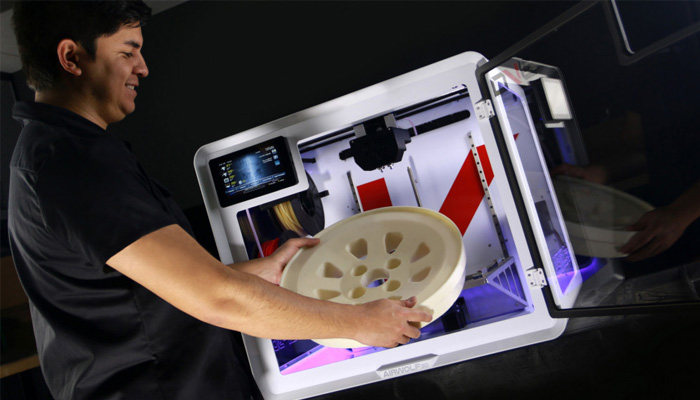

If 3D printing of mock-ups does not require complex material selection, then the creation of functional prostheses can be considered the next step in the evolution of the frenzied 3D medicine printer.

For example, several patients have already returned to normal life after receiving a lower jaw prosthesis (it is often destroyed due to tumor diseases or severe maxillofacial injuries). nine0005

3D printing is also suitable for printing vertebrae: scientists say that such constructions can be implanted even in childhood, because, due to its porous structure, it acquires full-fledged bone tissue with age. A 12-year-old boy in China has already become the lucky owner of such an artificial bone this summer.

A 12-year-old boy in China has already become the lucky owner of such an artificial bone this summer.

The 3D printer can also help with loss of other bones in the body, such as the scapula or calcaneus.

Cosmetic prostheses

Fans of the TV series will surely remember the creepy mask of Dr. Thackery's former lover from the Knickerbocker Hospital, behind which she hid the flaws of a syphilis-stricken face. Nowadays, it has become much easier to hide cosmetic defects after injuries and diseases, which is important for the patient both in terms of aesthetics and in terms of physical comfort.

A 3D-printed prosthesis can be unique, and it can be created even without the participation of doctors. Here is an example from Russia: a girl named Olga, who was fond of extreme sports, lost her calf muscle, which led to a visible asymmetry of her legs. Moscow 3D printing specialists made a kind of cosmetic orthosis for her (and earlier, these same guys developed several finger prostheses for children and adults). nine0005

nine0005

Another example is 3D printed skull bones, which are often damaged in traffic accidents. In these cases, the plates covering the defect have both a protective and cosmetic function. Previously, they were made of titanium, but modern technologies make it possible to replace 75% of damaged bones with a plastic copy, on which, among other things, small details are engraved that stimulate the growth of bone tissue cells around the “patch”.

Printing organs

And, finally, the pinnacle of aspirations is the printing of fully functioning organs. There is no need for donation and the fear of losing a kidney or liver due to an overly careless lifestyle. But here everything is somewhat more complicated: after all, stem cells should act as the "ink" for the device, which must be arranged in the correct sequence so that the future organ functions as a "natural" one. nine0005

But the possibilities of human thought seem to be limitless: experiments on "printing" an artificial liver are being carried out in several laboratories around the world, and Russian scientists from Skolkovo promise to create a thyroid gland suitable for transplantation already this year, and an artificial kidney - in 2018- m.

With organs that do not have a parenchymal structure (a complex organization of cellular tissues), things are somewhat simpler: in May 2013, scientists from the USA published a scientific report on the successful creation of a "bionic" ear, which contains an antenna sensitive to radio waves and living cells . nine0005

In general, I suspect that while I was writing this text, the world has come up with some other medical application for 3D printing. And in about 15 years, this article in the archives of Newslab.ru will cause laughter - similar to what today, for example, a note in a Soviet newspaper about the possibilities of newfangled adding machines can cause. Well, so be it.

The second part of the 3D printing guide for beginners. Timeline of 3D printing

The birth of modern 3D printing. 1980-1990

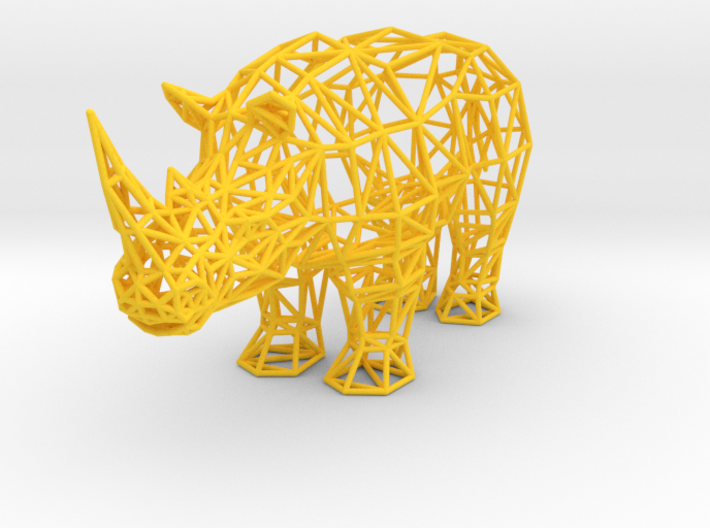

The earliest modern 3D printing technologies first appeared in the late 1980s, at which time they were called Rapid Prototype (RP) technologies - RapydPrototype (RP). This is because processes were originally conceived as a fast and cost-effective way to create prototypes for industrial product development.

This is because processes were originally conceived as a fast and cost-effective way to create prototypes for industrial product development.

Interestingly, the very first patent application for the application of BP technology was filed by Dr. Kodama in Japan on May 1980 years. Unfortunately for Dr. Kodama, the full patent specification was not filed until one year after application, which is particularly unfortunate given that he was a patent lawyer.

Hideo Kodama (Hideo Kodama)

In reality, however, 3D printing started in 1986, when the first stereolithography apparatus (SLA) patent was issued. This patent belonged to Charles (Chuck) Hull, who first invented the SLA machine at 1983 year. Hull continued to collaborate with 3D Systems Corporation, one of the largest and most prolific organizations active in the 3D printing sector today.

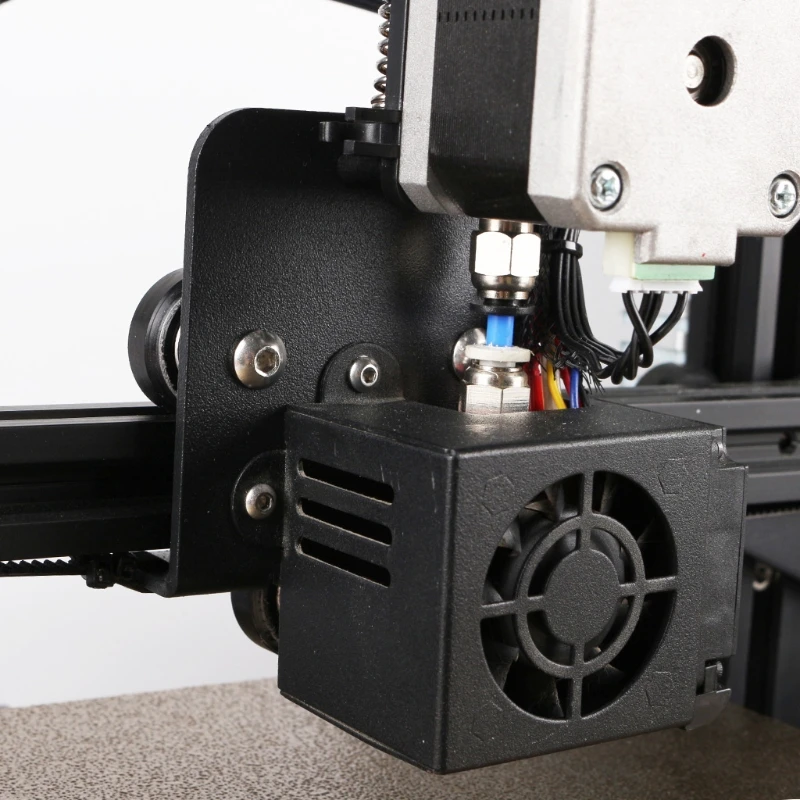

3D Systems created its first commercial SLA-1 rapid prototyping system in 1987 and after extensive testing sold it in 1988. However, despite the fact that SLA technology may claim the first place in the history of 3D printing, it was not the only rapid prototyping technology at this time. At 19In 1987, Carl Deckard, who worked at the University of Texas, applied for a US patent for selective laser sintering (SLS-Selective Laser Sintering). This patent was issued in 1989 and SLS was later licensed from DTM Inc. and subsequently acquired by 3D Systems. Also in 1989, Scott Crump, co-founder of Stratasys Inc., applied for a patent for FDM-Fused Deposition Modeling technology, which the company still owns today, the technology used today by many entry-level printers. open source level RepRap (Replicating Rapid Prototyper). The FDM patent was issued to Stratasys in 1992 in Europe.

However, despite the fact that SLA technology may claim the first place in the history of 3D printing, it was not the only rapid prototyping technology at this time. At 19In 1987, Carl Deckard, who worked at the University of Texas, applied for a US patent for selective laser sintering (SLS-Selective Laser Sintering). This patent was issued in 1989 and SLS was later licensed from DTM Inc. and subsequently acquired by 3D Systems. Also in 1989, Scott Crump, co-founder of Stratasys Inc., applied for a patent for FDM-Fused Deposition Modeling technology, which the company still owns today, the technology used today by many entry-level printers. open source level RepRap (Replicating Rapid Prototyper). The FDM patent was issued to Stratasys in 1992 in Europe.

Scott Crump Co-founder of Stratasys

In 1989, Hans Langer founded EOS GmbH in Germany. After playing around with SL technology, EOS shifted its focus to SLS technology. Today, EOS is recognized worldwide for the quality of its products for industrial prototyping. In 1990, EOS sold its first Direct Metal Laser Sintering (DMLS) stereo system in cooperation with Electrolux Finland, which was later acquired by EOS. nine0005

In 1990, EOS sold its first Direct Metal Laser Sintering (DMLS) stereo system in cooperation with Electrolux Finland, which was later acquired by EOS. nine0005

Other 3D printing technologies emerging in these years include Ballistic Particle Manufacturing (BPM) originally patented by William Masters, Laminated Object Manufacturing (LOM) patented by Mikhail Feigin, mask stereolithography ( SGS - Solid Ground Curing), patented by Itzhak Pomeranz and three-dimensional printing (3DP), patented by Emanuel Sachs. So in the early nineties, there was an increase in the number of competing companies in the rapid prototyping market, but only three of them have survived to this day - 3D Systems, EOS and Stratasys. nine0005

Development of various 3D printing technologies. 1990-2000

Throughout the 1990s and into the early 2000s, many new technologies continued to be introduced, but they all remained exclusively focused on industrial production. Through research and development (R&D), more advanced technology has been introduced for specific casting tools. This marked the beginning of a new terminology, namely high-speed machining (RT-Rapid Tooling), rapid casting (Rapid Casting) and rapid production (RM-Rapid Manufacturing). nine0005

This marked the beginning of a new terminology, namely high-speed machining (RT-Rapid Tooling), rapid casting (Rapid Casting) and rapid production (RM-Rapid Manufacturing). nine0005

So in 1996 SandersPrototype (later Solidscape) and ZCorporation were created, in 1997 - Arcam, Objet Geometries - in 1998, in 2000 MCP Technologies introduced the technology of selective laser melting (SLM), in 2002 EnvisionTec was founded, In 2005, ExOne was established as a subsidiary of Extrude Hone Corporation and SciakyInc. introduced its pioneering additive process based on patented electron beam welding technology.

All these organizations joined the ranks of Western companies operating in the world market. Terminology has also evolved with the spread of manufacturing applications, and a common term for all technologies has been adopted - additive manufacturing (AM - Additive Manufacturing). It is noteworthy that at the same time there were many parallel processes in the Eastern Hemisphere, but in the end, all of them did not have a significant impact on the world market. nine0005

nine0005

The mid-2000s began to show signs of diversification in two specific areas of focus that are much more clearly defined today.

First of all, these are high-end 3D systems, still very expensive equipment, which was aimed at producing high-quality, high-tech complex parts. The growth of this field continues to this day, but only now, after years of research and development, the results are becoming more visible when using technologies in the aerospace, automotive, medical and jewelry sectors. Much still remains behind closed doors and/or under non-disclosure agreements. nine0005

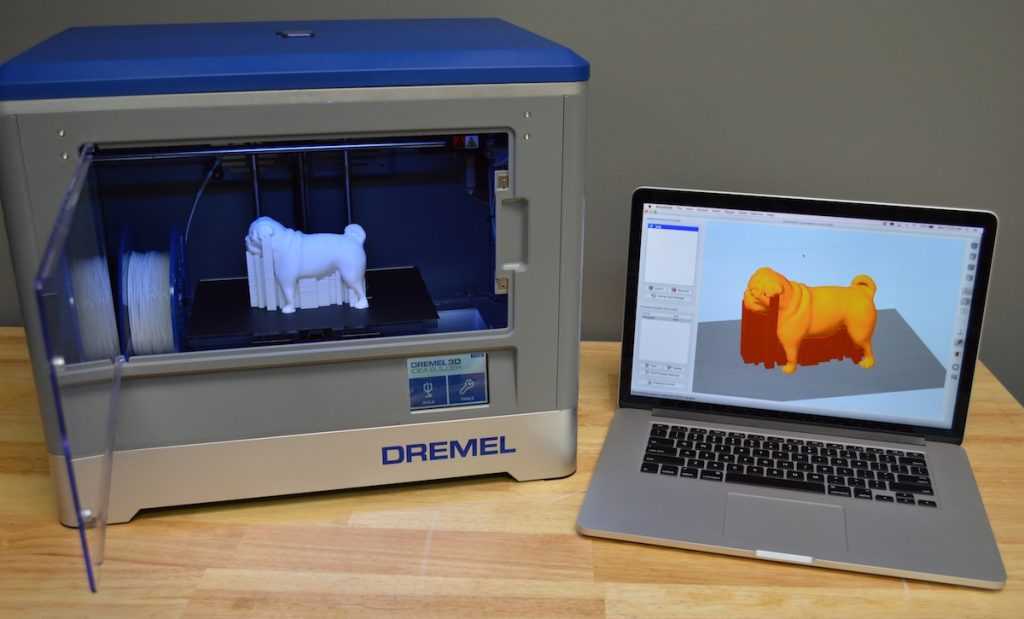

On the other hand, some manufacturers of 3D printing systems are directing their efforts towards the development and promotion of the concept of modelers, as they were called at the time. In particular, these were 3D printers that kept the focus on improving functional prototyping, which were designed specifically as office-friendly, cost-effective systems. This was the prelude to today's desktop printers. However, most of these systems were still being developed for industrial prototyping. nine0005

However, most of these systems were still being developed for industrial prototyping. nine0005

In hindsight, this was indeed the calm before the storm.

Opening 3D printing to the general public 2007 - ...

In the low-price segment, 3D printers are in the middle of the price range today, as price struggles have come along with incremental improvements in materials used, as well as printing speed and accuracy.

In 2007, the market saw the first $10,000 printers from 3D Systems, but they failed to achieve their intended goal. This was partly due to the system itself, partly to market influences. According to many industry insiders, users, and commentators, the holy grail at the time was getting a $5,000 3D printer as the key to opening up 3D printing technology to a wider audience. nine0005

For most of the year, the world was looking forward to the arrival of the long-awaited Desktop Factory, as many predicted that they would find the Holy Grail. However, the expectations were in vain, as production faltered in anticipation of the release. Desktop Factory, led by Cathy Lewis, was acquired by 3D Sysytems in 2008, and that was it. As it turned out later, 2007 did become a turning point for the opening of 3D printing technology to a wide audience, although at that moment no one realized that the RepRap phenomenon had already taken root. Dr Bowyer conceived the concept of an open source, self-replicating RepRap 3D printer back in 2004. In the years that followed, the seeds gradually germinated, with major contributions from members of his Bath team, especially Vic Oliver and Rhys Jones, who developed the concept of working prototype 3D printers based on deposition modeling technology. In 2007, shoots began to appear, and the promotion of 3D printing to the masses began to gain momentum. nine0005

Desktop Factory, led by Cathy Lewis, was acquired by 3D Sysytems in 2008, and that was it. As it turned out later, 2007 did become a turning point for the opening of 3D printing technology to a wide audience, although at that moment no one realized that the RepRap phenomenon had already taken root. Dr Bowyer conceived the concept of an open source, self-replicating RepRap 3D printer back in 2004. In the years that followed, the seeds gradually germinated, with major contributions from members of his Bath team, especially Vic Oliver and Rhys Jones, who developed the concept of working prototype 3D printers based on deposition modeling technology. In 2007, shoots began to appear, and the promotion of 3D printing to the masses began to gain momentum. nine0005

Adriano Bowyer (left) and Vik Olliver (right)

However, the first commercially available disassembled 3D printer based on the RepRap concept was only put up for sale in January 2009. It was a BfB RapMan 3D printer. MakerBot Industries closely followed this technology, the founders were actively involved in the development of the RepRap printer, until, due to extensive investments, they moved away from the philosophy of open source printers. In 2009, a lot of similar printers appeared, sold in various parts of the world, and this continues to this day. The RepRap phenomenon has spawned a new sector of entry-level commercial 3D printers. nine0005

MakerBot Industries closely followed this technology, the founders were actively involved in the development of the RepRap printer, until, due to extensive investments, they moved away from the philosophy of open source printers. In 2009, a lot of similar printers appeared, sold in various parts of the world, and this continues to this day. The RepRap phenomenon has spawned a new sector of entry-level commercial 3D printers. nine0005

2012 was the year of introducing alternative printing technologies to the entry level market. B9Creator with color LED projection technology (DLP-Digital Light Processing) appeared in June, and Form 1 in December. Both projects were launched with Kickstarter funding and both have been huge successes.

As a result of market divergence, significant shifts at the industry level, and a sharp increase in awareness, 2012 was also the year of the emergence of various media channels. 2013 was a year of significant growth and consolidation in 3D printing technology.