Largest 3d printer nozzle

Large nozzle printing - the unsung hero of functional prints : ender3

To wet your whistle, I printed this Ender 3 drawer in only 2h44m where it would have taken 12h21m with my normal profile at 0.2mm according to Cura(so probably longer... I never did manage to get it to give me an accurate estimate).

But what happens next will blow your..... ok no I can't do it. But seriously, large nozzle printing, heck yeah!

I recently decided to give large nozzle printing a shot. I had good results switching to a small nozzle for DnD minis, but the lot that I bought also contained larger nozzles. I had successfully printed Woodfill with a 0.6mm nozzle, but I had larger still!

I read an article during the research phase about how only 20% of users had switched to different nozzle sizes, and I'm here to tell you, that is a grave mistake!

I decided to give a 1mm nozzle a whirl. I have now successfully printed at a 0.8mm layer height with 1.1mm line width.

On top of the cataclysmic speed increase, the strength of large nozzle printing is. ........ impressive. I printed a bed handle out of PLA, and the strength I got from my large nozzle printing was beyond amazing. I do need the handle so I didn't try for real, but I get the impression that I could not actually break it with my hands, and that's despite accidentally having printed it at 0% infill! The articles I read suggested 5% infill and 5 top layers to make up for the bridging issue, but my gut feel says 10%. But more testing would be needed.

Because of the wide walls, I have been able to print with only 2 walls instead of 3, and that means less time spent printing walls as well as many, many, many, many fewer layers per print. On top of that, the walls are a lot thicker, so with a line width of 1.1mm, you would get what equates to 5.5 walls of 0.44mm with a 0.4mm nozzle.

The main drawback to this sort of printing is support and detail. Clearly your cooling fan gets to work extra, extra, extra hard to cool your prints, and this means overhangs are far less impressive. And you obviously are very limited at how detailed your prints can get because of how wide your lines are.

And you obviously are very limited at how detailed your prints can get because of how wide your lines are.

TL:DR: Here is a bullet point list of some things I learned researching large nozzle printing

Your filament spends a LOT less time in your nozzle. I'm not kidding, my exruder motor ran constantly and at high-ish speed. This means you will need to print a lot hotter to get the filament melted fast enough. I ended up printing PLA at 235 degrees with good results, but experiment!

Slooooow doooowwwnnnnn...... Because of the above issue, you also need to print slower. I usually print at 50mm/s, but I reduced my overall speed to 25mm/s. This means the filament spends longer in the nozzle, and this works along with the hotter printing

It was probably already clear from the two above points, but you need your cooling fan at 100% if you ever hope to cool your material fast enough. Printing with a 5015 fan duct is a great advantage.

First layer height is counter-intuitive. Usually we're told "The taller your first layer height is, the better adhesion". That's why no matter how fine I print, my first layer is always 0.2mm. This, however, only holds true to a certain point. Trying to print my first layer at 0.8mm like the rest of my print resulted in 50g of filament wasted before I noticed my print had popped off. Watching my nozzle try to lay down such a tall layer on the first layer reminded me of that scene in Rick & Morty where Morty is vomiting a space parasite slug. It was not pretty. So I ended up printing my first layer at 0.2mm even with this nozzle, and that worked really well for me

Infill overlap needs to be much higher for this kind of printing - I read to set it at 50%, and as I didn't have any problems from this, I decided to just leave it at that.

Support distance is also different. We've all heard the saying - "1-2 layer heights between support and model", and while that is fine for detailed, small nozzles, if you print with a 1mm nozzle at 0.

8mm layer height and try to set 2 layers, you are basically printing into open air. 1.6mm is a LONG way for filament to drop. I ended up at 0.8mm, and that seems to work okay. But tinker away, I haven't experimented much here.

8mm layer height and try to set 2 layers, you are basically printing into open air. 1.6mm is a LONG way for filament to drop. I ended up at 0.8mm, and that seems to work okay. But tinker away, I haven't experimented much here.Retraction speed needs to be buffed a LOT! The "golden setting" for PLA retraction on the Ender 3 is considered to be 6mm, 25mm/s. But because your filament is always moving really fast, you need to retract a lot faster. I landed at 5mm, 45mm/s. I didn't see any stringing(although at these line width I suggest we'd call that slugging :p)

My top and bottom layers were 4, that seems to work. But keep in mind, the less infill you use, the more top layers you'll want.

You will definitely want to be careful not to use too much support density or support interface density. Keep in mind, a wall at 1.1mm width is the same as 2.5 walls at 0.44, so you will want to take that into account. My first print was basically fused so I had to spend an hour removing supports with my Proxxon micro motor and a cutting disc.

Basically, I suggest experimenting - just keep in mind, because you print so fast, it is entirely possible to blow through your filament spools in pretty much no time, and that can scare and depress you. Everything in moderation!

If you typically print medium to large mechanical parts

Hey,

Posting this to ignite any latent interest in printing with larger nozzles.

The 0.4mm standard is a great general purpose nozzle. However, if you're like me, then you're typically printing medium to large mechanical pieces that don't require a LOT of surface detail.

There are some major benefits to printing with a larger nozzle size:

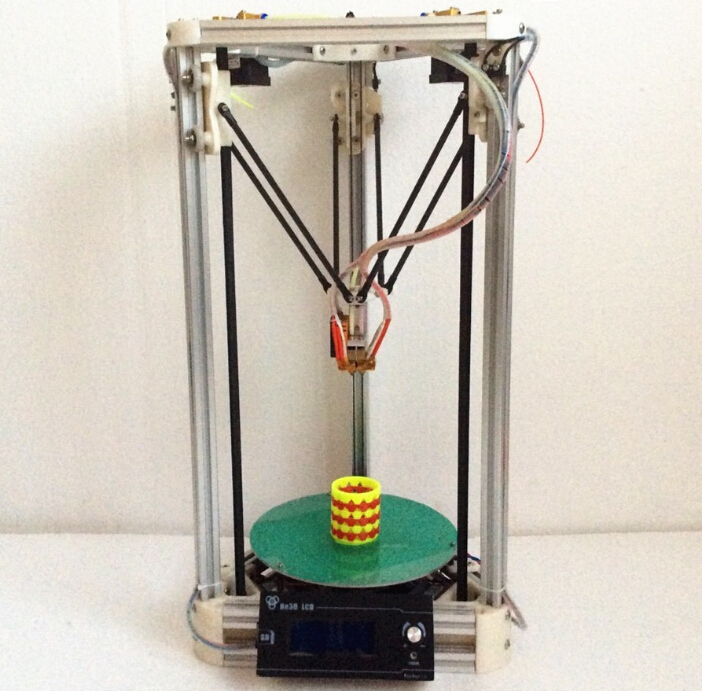

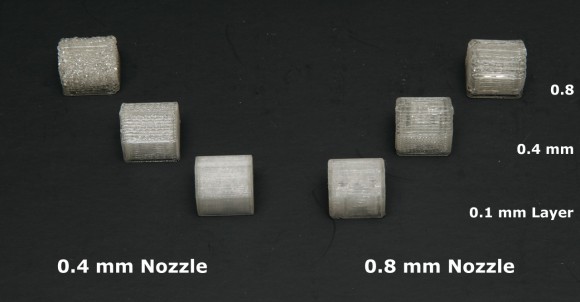

Faster prints. This goes without saying, but a 0.8mm nozzle is laying down two walls at once at potentially double the height. That's 4x faster printing.

Stronger prints. The main weakness in any FDM object is layer adhesion. Prints made with larger nozzles have fewer layers and more contact between layers.

They're STRONG.

They're STRONG.God tier vase mode. I love vase mode, but there are two main issues. One - they're flimsy. Two - they're rarely water tight. Larger nozzles solve both of these issues. A 0.8mm vase mode print is quite sturdy and holds water.

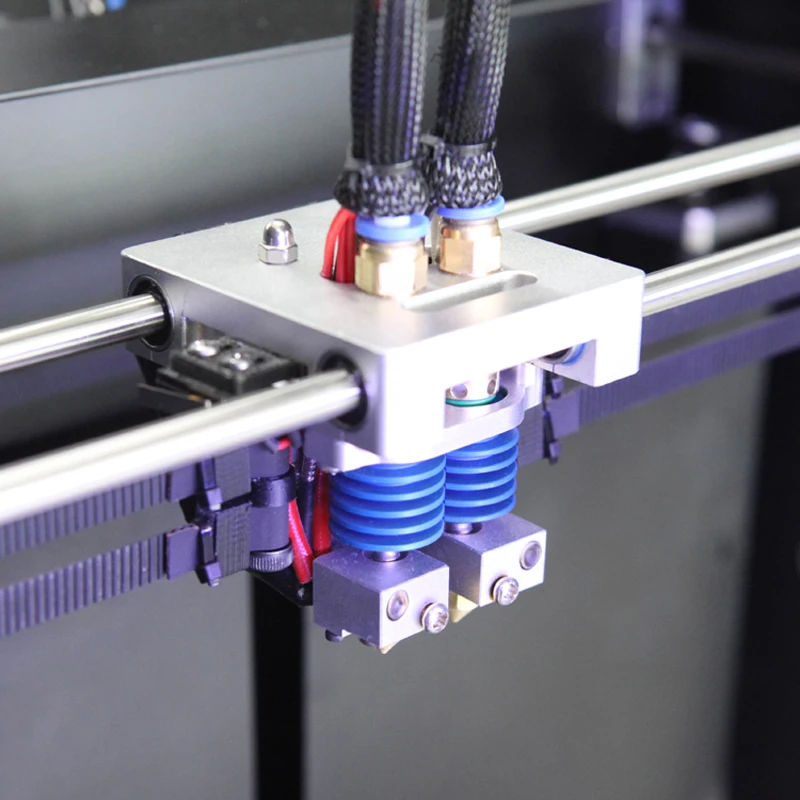

Few or no clogs. With the reduced backpressure and larger opening clogs are essentially non-existent. This also makes it easier to print with exotic filaments.

Easier on a bowden setup / easier on extruders. Again, with the reduced backpressure there is less difference between a bowden and direct drive configuration when printing with larger nozzles. Of course if you're throwing 4x more filament in there the point is moot...but you can always slow it down a bit.

Aesthetic. This might fall in the Neutral or Drawback category depending on your preferences, but the aesthetic of smooth thicc layer lines can be very nice.

Not everything comes up roses though - there are some drawbacks:

Less detail (XY). This is probably obvious but in the XY axis there will be less detail. The Z axis however can have just as much detail as you can print 0.2mm layer height with a 0.8mm nozzle. So...depending on your print orientation this may or may not matter.

More difficult to control oozing and stringing. With a wider opening it can be a little more difficult to get retraction dialed in (though to be honest, I've found it a pain to get retraction just right with any diameter / filament). That filament just wants to ooze right out. Keeping this in mind, you'll want to keep your travel speed / accel / jerk as high as possible.

Nozzle thermal limitations. Even with the stock Anet E12 or Monoprice Maker Select plus I am able to print PLA with a 0.8mm nozzle at 50mm/s, but higher temperature filaments would definitely be an issue.

If you really want to get into high speed printing you'll need a volcano or some other beefy hot-end. However, you can always reduce print speed and achieve the same results with a less powerful piece of equipment.

If you really want to get into high speed printing you'll need a volcano or some other beefy hot-end. However, you can always reduce print speed and achieve the same results with a less powerful piece of equipment.Part cooling. If you want to control the melt-factor you'll need some powerful part cooling fans. Another side effect is support adhesion - you'll have to increase support distance, especially if you can't keep up with part cooling.

Short story is - if you haven't given it a shot yet, do it! It's easier than you think to change out a nozzle and this opens up a whole new world of experimentation. You can often grab a pack of 5+ ranging from 0.1mm -> 1.2mm and even larger. I recommend 0.6mm - 0.8mm if you have a typical hotend configuration.

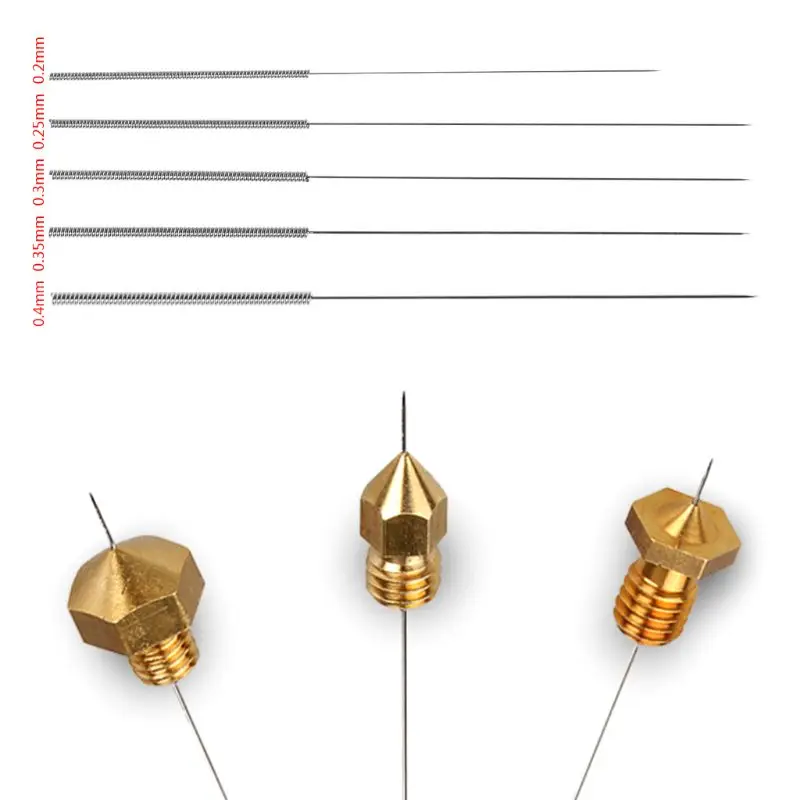

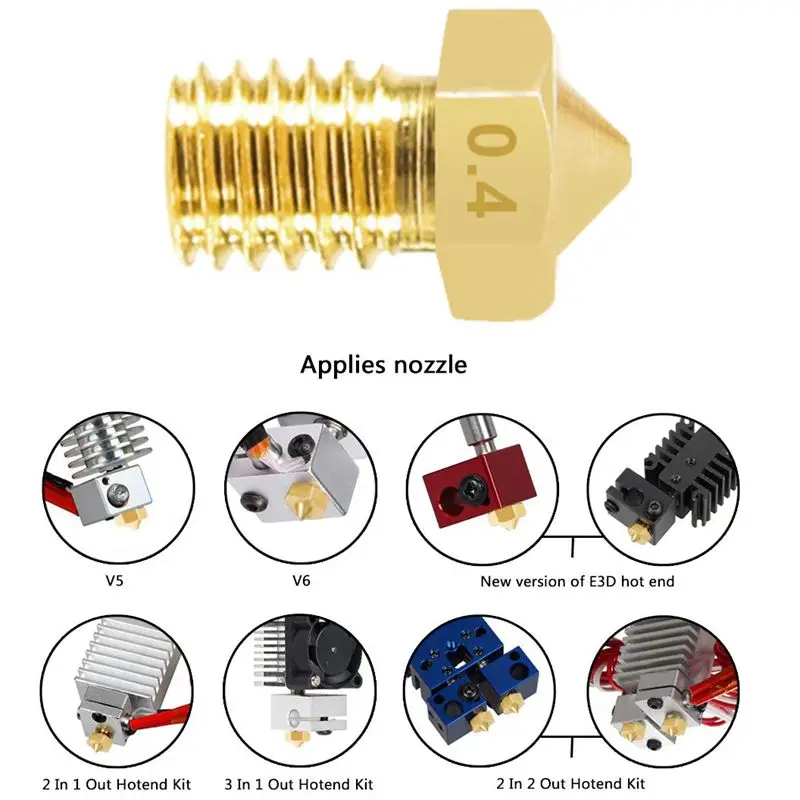

Nozzles for 3D printers - types, differences. Nozzle type

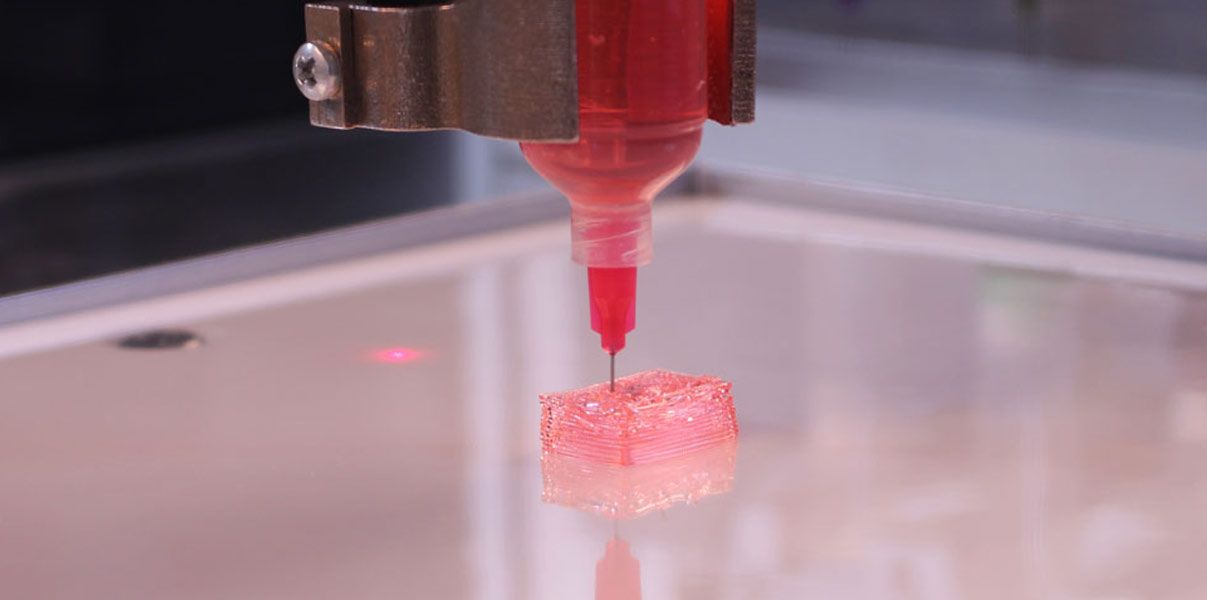

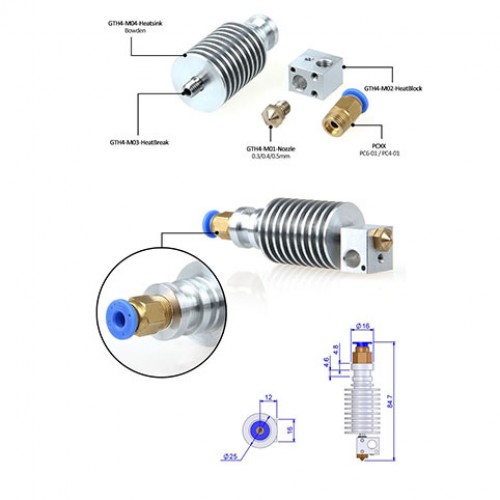

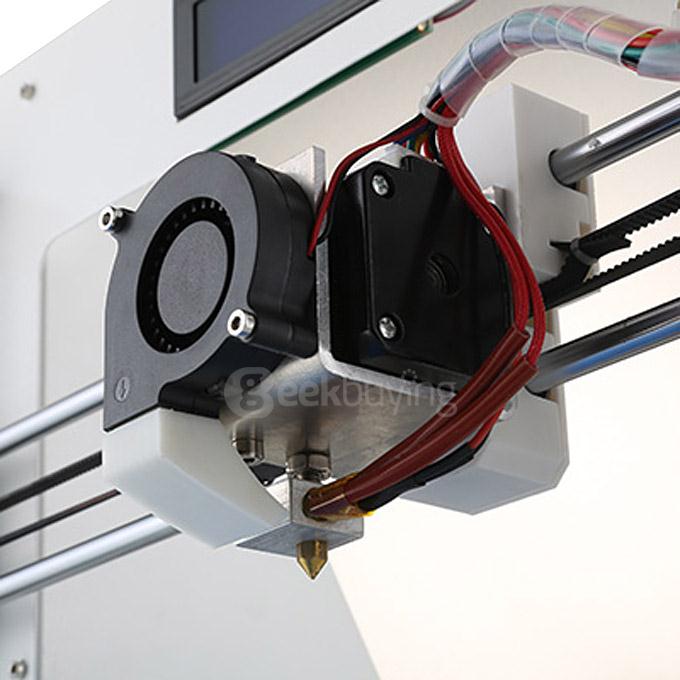

Nozzle is an integral part of any 3D printer, and there are many varieties of this part. Brass products are considered standard nozzles. This type is suitable for printing with conventional types of plastics, but for those that include an abrasive, such as NylonX, is not suitable. Printing with these materials requires higher performance nozzles made from stronger materials. There are also copper nozzles, Clean Tip nozzles - such nozzles are distinguished by the fact that the thread does not stick to them, and they remain clean.

This type is suitable for printing with conventional types of plastics, but for those that include an abrasive, such as NylonX, is not suitable. Printing with these materials requires higher performance nozzles made from stronger materials. There are also copper nozzles, Clean Tip nozzles - such nozzles are distinguished by the fact that the thread does not stick to them, and they remain clean.

3D printing allows you to replace nozzles. This allows you to achieve different results and use different materials for printing.

3D printer nozzle: what is it?

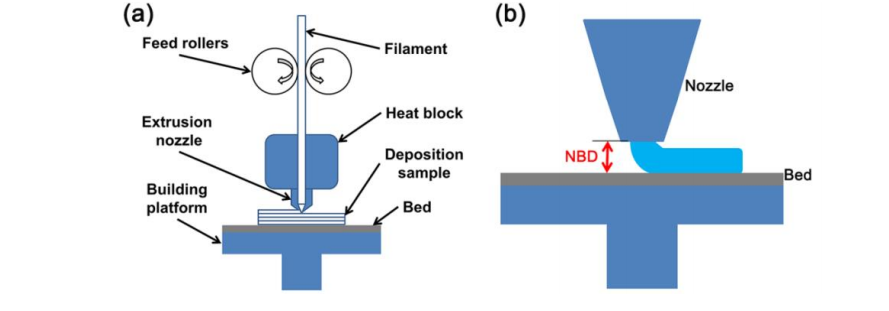

The 3D printer nozzle is a special nozzle located in the extruder heater block. It is screwed into place by means of a thread. There is a small chamber inside the nozzle where molten plastic accumulates and is squeezed out through the hole. Moreover, the key parameters of the nozzle will be: the material from which the nozzle is made and the diameter of the hole.

Nozzle material

A standard desktop 3D printer is equipped with a 0. 4mm brass nozzle. This is the best option for printing with ABS and PLA plastics. However, such nozzles are not at all suitable for printing with luminescent PLA, carbon fiber and metal enriched filaments. The fact is that plastics, which include solid particles, destroy the nozzle. The internal dimensions of the nozzle are distorted, and this affects the uniformity of the extruded material, which will inevitably affect the quality of 3D printing. For this reason, there are nozzles that are made from harder materials. Consider further the types of nozzles that can be found on the market.

4mm brass nozzle. This is the best option for printing with ABS and PLA plastics. However, such nozzles are not at all suitable for printing with luminescent PLA, carbon fiber and metal enriched filaments. The fact is that plastics, which include solid particles, destroy the nozzle. The internal dimensions of the nozzle are distorted, and this affects the uniformity of the extruded material, which will inevitably affect the quality of 3D printing. For this reason, there are nozzles that are made from harder materials. Consider further the types of nozzles that can be found on the market.

Brass 3D Printer Nozzle

Brass Nozzle is the most popular option used in most desktop 3D printers. Of all the materials used to make nozzles, this one is the softest. But brass nozzles are easy to process, cheap and affordable. Therefore, they are easy and simple to replace.

Main characteristics of brass nozzles:

- corrosion resistance;

- high thermal conductivity;

- relative softness;

- abrasion.

Application: Ideal for printing with "soft" plastics - standard ABS, PLA, PETG, and other plastic filaments that do not contain carbon fiber and metal additives.

Stainless steel or hardened steel nozzle

Steel nozzles are also used for 3D printing. They provide long-term printing with materials that contain solid particles, such as metal, carbon fiber. At the same time, such nozzles are not prone to abrasion and destruction, like softer brass nozzles. That is, you can print for a long time without reducing productivity.

But steel nozzles are not without drawbacks: lower thermal conductivity compared to brass nozzles. This can change the flow, especially when using large nozzles.

Main characteristics of steel nozzles:

- corrosion resistance;

- low thermal conductivity;

- relatively large weight;

- abrasion resistance.

Application: 3D printing with additives (carbon fiber, metal, glass, etc. )

)

Ruby nozzle

Anders Olsson developed the Olders Ruby nozzle. This is a brass nozzle equipped with a tip made of aluminum oxide, that is, an artificial ruby. This nozzle was originally created for 3D printing by the third heaviest material in the world. The nozzle was the result of an experiment conducted at Uppsala University in Sweden.

Initially standard nozzles made of steel and brass after printing 1kg of plastic wear out and are no longer usable. However, the nozzles have a number of disadvantages. Olson Ruby nozzles combine the high thermal conductivity of brass with the abrasion resistance of ruby. Of course, there are experts who say that the ruby tip has a low thermal conductivity, which negatively affects the printing result, but there is no evidence for this. At least for now.

The main characteristics of Olsson Ruby nozzles are:

- corrosion resistance;

- low thermal conductivity;

- abrasion resistance.

Application: Can be used for highly abrasive threads.

Tungsten Carbide Nozzles

Dyze Design Tungsten Carbide Nozzles are something of a newcomer to the market as they only started production at the end of 2018. Tungsten carbide is hard and wear resistant. It is used for drilling, cutting ceramics and metals. Such nozzles also have disadvantages, but it is too early to talk about them.

Main characteristics of tungsten carbide nozzles:

- abrasion resistance, very high;

- hardness;

- high thermal conductivity;

- corrosion resistance.

Application: This is a universal nozzle that can be added to your nozzle set, and the nozzle is also suitable for printing with highly abrasive filaments.

Nozzle sizes for 3D printer

Nozzles are characterized by the hole diameter. This characteristic will affect the degree of print detail. In this case, the influence will be exerted not only on the width of the lines, but also on the height of the layer.

Beginners are advised to use a nozzle with a diameter of 0.15mm. Compared to a standard 0.4mm nozzle, this nozzle allows you to get a higher resolution in the OX and OY axes. Thanks to thin lines, sharper corners can be obtained, but this will only be possible in that case. If your 3D printer is well set up and serviced regularly.

The choice of nozzle diameter should be determined by the layer height you require. It is necessary to choose a nozzle so that the size of the layer during printing is 25-50% of the nozzle size.

If the device is calibrated correctly, optimum adhesion can be achieved between coats. For example, a standard 0.4mm nozzle allows you to print layers of 0.1-0.2mm. If you want to successfully print ultra-thin layers that are less than 0.05mm high, we recommend using the 0.2mm nozzle.

Small nozzles have one significant disadvantage. They are more prone to clogging and therefore need to be cleaned regularly. In addition, smaller nozzles significantly increase print time as the print head requires more passes to coat. the larger the nozzle, the less time it will take to print, and the time will be reduced exponentially. For example, a 0.8mm wall will take half as long to print as a 0.4mm wall. Also, large extrusion lines have greater adhesion, and therefore the finished prints have greater strength. If you are not printing fine details, then you are better off using large nozzles, which will allow you to print faster.

the larger the nozzle, the less time it will take to print, and the time will be reduced exponentially. For example, a 0.8mm wall will take half as long to print as a 0.4mm wall. Also, large extrusion lines have greater adhesion, and therefore the finished prints have greater strength. If you are not printing fine details, then you are better off using large nozzles, which will allow you to print faster.

Smaller nozzles are more commonly used for hobby, precision models with fine details, such as jewelry.

And in order to have your own opinion on this matter, it is best to experiment!

How to choose nozzle size for 3D printer? Pros and cons

3DPrintStory 3D printing process How to choose nozzle size for 3D printer? Pros and cons

When choosing your 3D printer, the nozzle size of your 3D printer may have been the last thing on your mind. This is a detail that is often overlooked. But depending on what you need to print, the wrong nozzle diameter can get in the way.

This is a detail that is often overlooked. But depending on what you need to print, the wrong nozzle diameter can get in the way.

In this article, we'll take a look at the different 3D printer nozzle sizes and why you should consider this assembly, what materials it's made of, understand the relationship between nozzle size and layer height, and how to measure the actual nozzle diameter.

How does nozzle size affect 3D printing?

Nozzle diameter affects the extrusion width of the 3D printer line. This affects some elements of your model. If you are 3D printing for business (make a lot of orders), you need to make sure your extruder is feeding the right amount of material. If too much material is fed, then more filament is used than is actually required for successful 3D printing. Well, a smaller number can simply lead to marriage.

Or maybe you're printing different models, some of them very detailed and intricate, and some more practical (like a replacement doorknob) that just needs to be printed quickly and with maximum durability.

In any case, you will need the correct setting to save time, material and ensure the normal quality of the 3D model.

There is no easy answer to what is the best nozzle size for a 3D printer. You need to weigh what you want to achieve and what elements of the 3D model are most important to you.

Depending on your 3D printer, the nozzle can be quite easily replaced (most of them are mounted on screws), and buying a package with different sizes will cost you a lot.

Most common 3D printer nozzle options

The most common standard nozzle size is the 0.4mm (or 0.35mm) nozzle used by most modern 3D printer manufacturers. The reason for this is that it is a rather large and yet versatile nozzle size. This means that you can print with exceptional detail in no time.

With the 0.4 mm 3D printing nozzle you can print up to a layer thickness of only 0.1 mm or up to 0.3 mm. The lower the layer height, the better the detail (on the Z axis) and the larger the layer height, the faster your 3D print will be, but with worse detail quality.

A common misconception is that if someone doesn't get good enough 3D print quality on their printer with a 0.4mm nozzle, they immediately think they need a smaller 3D print nozzle.

Another common smaller size is 0.25 mm. Some 3D printers offer 0.2mm, 0.15mm, and Mass Portal is even experimenting with 0.1mm 3D printer nozzles. And the experiments are really interesting. Thanks to this miniature nozzle, they were able to print the clock mechanism with excellent detail.

How is nozzle diameter related to 3D printer resolution?

Theoretically, smaller 3D printer nozzles allow for greater precision. But for many 3D printers, especially cheaper or older models, a smaller extruder nozzle won't necessarily make a difference if your printer doesn't support the higher resolution you need. It's like putting low-profile, high-performance tires on an old classic car - it doesn't make it go faster, and it doesn't necessarily make it better cornering.

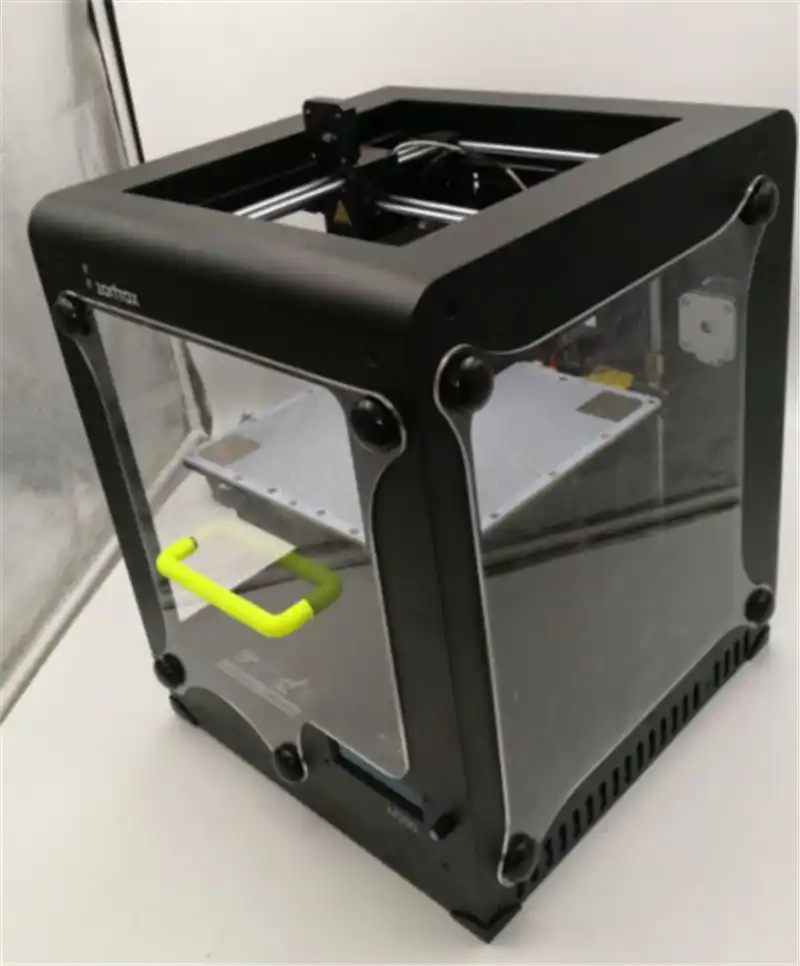

This is also similar to how the specifications of a 3D printer on paper (eg claimed resolution) do not always result in the best print quality of the finished product. Just like Ultimaker and Zortrax have very similar resolutions on paper, but in many actual tests Zortrax produces better models than Ultimaker 2.

Just like Ultimaker and Zortrax have very similar resolutions on paper, but in many actual tests Zortrax produces better models than Ultimaker 2.

smaller nozzles as resolution across the board is getting better every day.

Let's look at the pros and cons of 3D printing with smaller nozzles. Some are less obvious than others. Next, we'll look at the larger, underpriced nozzles available. I hope after reading this article you will be able to answer the question: "What nozzle size should I print?".

You probably already guessed that the smaller the size of the nozzle in the extruder, the more detailed model you can get as a result of 3D printing. The thin nozzle is great for complex figures, or if you need to print very thin walls for aircraft skins, or high transparency models, etc.

The photo below shows the printed skin of a model aircraft that was made with a standard 0.4mm nozzle. If the same skin is printed with a nozzle with a diameter of 0.2 mm, then the weight (and strength) would be halved.

It is worth noting that a 3D printer with a 0.2 mm nozzle feeds half as much material as a 0.4 mm nozzle. And this actually leads to an increase in print time by the same two times. It should be noted that strength and detail are reciprocals of time. So to get high-quality 3D models using a thin nozzle and high resolution, you will have to be patient (2 times more than when printing with a standard 0.4 extruder :)). In some cases this is justified, in others it is a waste of time...

As a general rule, the smaller the nozzle size, the higher the chance of problems with the 3D printer. Especially if you are using cheap materials - they can work well with low models and thicker nozzles, but if you need detailed models that are printed using a thin nozzle, then you should also be puzzled by buying quality filaments for 3D printing.

Other factors are less obvious when 3D printing with a thin diameter nozzle - for example, protrusions can be a problem. This is because each layer has a smaller width for the next layer. Crossing bridges can also be difficult.

Crossing bridges can also be difficult.

But there is good news too! Where overhangs form, the caliper material will be much easier to remove if printed with a thin nozzle. Due to the increased accuracy, your slicer can use a minimum amount of material between your model and supports, so they will break off more easily and have fewer damaged pads that need to be sanded.

And finally, the most annoying thing about a thin nozzle is the ease with which it clogs. If you downsize to 0.2mm or even 0.1mm, you'll need a small particle to clog the hotend. You need to be very careful about the cleanliness of your 3D printing material and regularly clean the nozzle of your 3D printer. Otherwise, you will not end up with additional unnecessary problems.

It is also worth taking the time to understand the relationship between nozzle size and layer thickness. In short, the first parameter determines the horizontal detail (along the x and y axes), and the second adjusts the resolution along the vertical or z axis.

How to measure the nozzle size of a 3D printer?

Although the actual nozzle diameter should be engraved on the side of the nozzle, it is not always possible to read this value if it is already installed in the extruder or if you have been printing with it for some time. After all, there is the concept of wear and you may not be sure that the nozzle is the same size as before.

To determine what size your nozzle really is, very slowly extrude some material into the air (high speed may change shape or size) at the lowest setting you can feed material at (approximately 1 mm/s). Once cool, use a micrometer if you have one. They are generally more accurate than digital calipers. Keep in mind that the filament will probably expand after being extruded. Poor quality material or an extruder that is too hot (especially if you extrude at 1mm/s) will cause the material to expand more, resulting in inaccurate readings.

It is also useful to know the size to which your material expands after extrusion if you are working on getting a really nice and accurate model. So feel free to experiment with higher speeds that are a bit more like your actual 3D printing.

So feel free to experiment with higher speeds that are a bit more like your actual 3D printing.

How is 3D printing layer height and nozzle diameter related?

In simple terms, this is the thickness of each line of extruded material that makes up each layer of your model. The thinner the layer height (or layer thickness), the finer the print detail in the Z-axis (the vertical dimension of your model), but the more layers will be required. Increases print time.

These characteristics are related, but not completely. For example, you can print using a thinner, thicker nozzle if vertical resolution is less important to you. Or you can use a thicker nozzle with a very small layer height. Although in this case, do not get too carried away. To maintain adequate pressure, your layer height should be at least 20% less than your nozzle width - and in most cases, for best 3D printing results, it should be around 50%.

How to determine the correct distance from the nozzle to the desktop of a 3D printer?

With the correct setting of the distance between the table and the nozzle, the base of the finished model should have an almost perfectly smooth, glassy surface. Many people assume that you need to use a stylus to properly set the distance between the nozzle and the 3D printer bed, but in fact, even that can be too thick. So it's worth thinking in the direction of the already proven table calibration with a piece of paper. You should use thin paper. For example, check paper is a great choice. Place the receipt paper under the nozzle and gradually lower the nozzle down until the receipt paper resists a little when you try to push it out. 3D printing at this height will give the bottom of the model a great look, and in the case of tall models, the print will definitely not go astray.

Many people assume that you need to use a stylus to properly set the distance between the nozzle and the 3D printer bed, but in fact, even that can be too thick. So it's worth thinking in the direction of the already proven table calibration with a piece of paper. You should use thin paper. For example, check paper is a great choice. Place the receipt paper under the nozzle and gradually lower the nozzle down until the receipt paper resists a little when you try to push it out. 3D printing at this height will give the bottom of the model a great look, and in the case of tall models, the print will definitely not go astray.

What is the maximum 3D print layer height compared to the nozzle size?

You don't necessarily need a layer height calculator on your 3D printer, but typically the maximum layer height is 50% of the nozzle width. In some cases, you can go higher (perhaps 75%), but in this case, you must be aware that you can sacrifice reliability.

It's best to experiment with the parameters of your model if you understand the relationship between the 3D printer's nozzle size and the layer height you'll be using to print. So for a 0.4mm nozzle, you will need to print with a layer height of 0.2mm, or up to 0.3mm. Your minimum should be around 0.1mm. If less, then in fact you just increase the waiting time without much benefit (on the same 0.4 mm nozzle).

So for a 0.4mm nozzle, you will need to print with a layer height of 0.2mm, or up to 0.3mm. Your minimum should be around 0.1mm. If less, then in fact you just increase the waiting time without much benefit (on the same 0.4 mm nozzle).

In most cases, it is worth printing thinner layers with smaller nozzle diameters and generally thicker layers with thicker nozzles. Just note that if you are printing with a thicker nozzle diameter and very thin layer height, you will need to lower the extrusion settings in your slicer to prevent overfeeding.

It's also worth noting that regardless of size, you should always make sure you always have a clean nozzle. One of the easiest ways to do this is to use a high quality cleaning floss. You only need to use a few grams of it each time you brush, but this will prevent carbon buildup over time.

So why should I use a 0.8mm nozzle or thicker?

Similar nozzle sizes were more common on older 3D printers but are making a comeback. It's all about using what you need and nothing more. For a large number of models, the 0.4mm headroom that your 3D printer probably comes with may be overkill in terms of detail.

It's all about using what you need and nothing more. For a large number of models, the 0.4mm headroom that your 3D printer probably comes with may be overkill in terms of detail.

If you're looking for strength and speed, but detail is less important, a 0.8mm or even 1.0mm nozzle is worth it. And don't forget that models printed with a 0.8mm nozzle can be very detailed, as a lot depends on your 3D printer as well.

The only slight disadvantage may be that you use more material, but with thicker part walls you can probably compensate with less infill.

There is no single optimal nozzle size for all models, you just need to take all factors into account and decide which nozzle size is best for you.

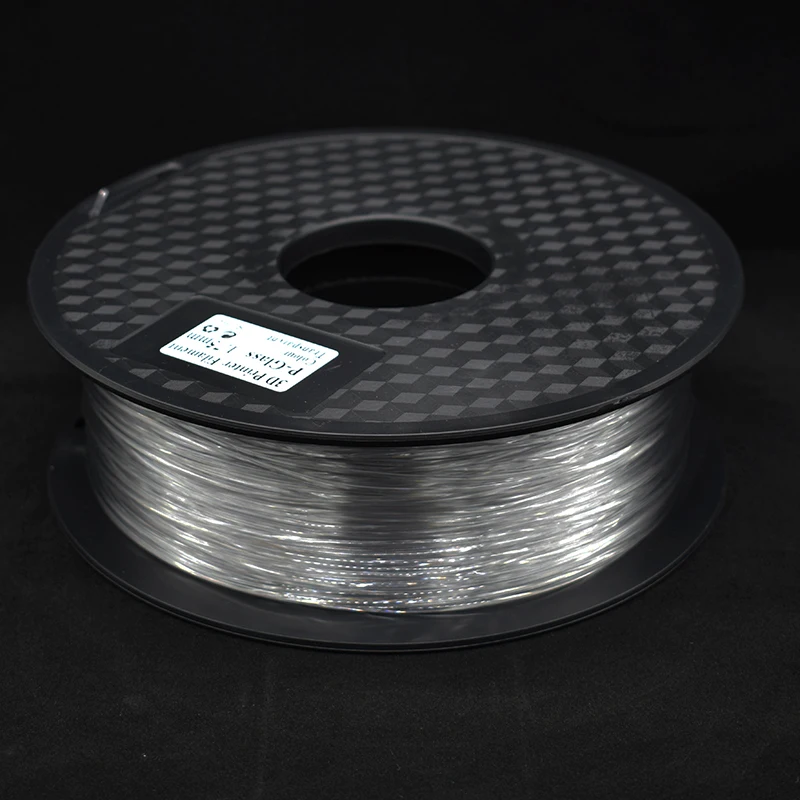

What nozzle size should I use for composite materials?

It is worth noting that composite materials (any particulate filament such as wood filler, copper filler, carbon fiber nylon or glass reinforced nylon) will cause extrusion problems when using a thinner nozzle.