3D printing nozzle cleaning

How to Clean a 3D Printer Nozzle (5 Methods) – Clever Creations

Using a nozzle cleaning kit and a cleaning filament is the most effective way to clean your 3D printer nozzle. You can remove the nozzle and soak it in acetone to remove any traces of filament impurities. A brass wire brush with soft bristles will help eliminate any leftover filament residue.

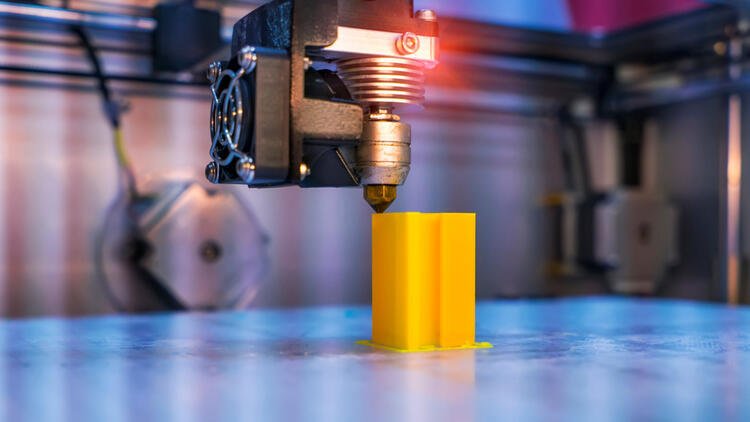

A 3D printer nozzle is a crucial element in the 3D printing process, and it is responsible for the smooth extrusion of your filament. Any clogs or blockages in the nozzles will directly affect your print quality. Clogged nozzles will lead to under extrusion, inconsistent filament flow, and uneven layers.

Even though cleaning a blocked nozzle is easy, it can be challenging to identify the clog in the first place. In this article, we’ll explain how to recognize a nozzle clog, go over the various cleaning methods and what you can do to prevent nozzle clogging in the future.

Read on to learn how to clean a 3D printer nozzle and get a smooth 3D printing experience!

How Can You Tell If a Printer Nozzle Is Clogged?

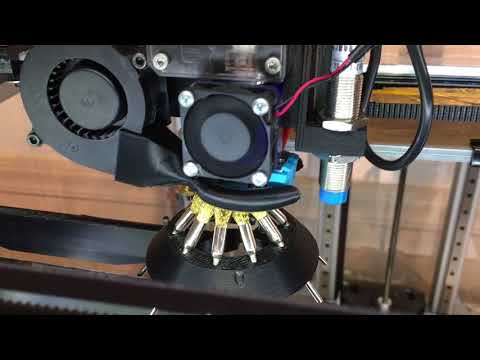

Image: squid-do via Reddit

It can be tricky to attribute print defects to clogged nozzles. However, a few notable indicators will quickly tell you whether you are dealing with nozzle clogging.

The easiest way to detect a nozzle clog is if you notice a decrease in the overall print quality. Inconsistent extrusion, missing layers, and under extrusion are a few of the side-effects of a blocked nozzle. A partial blockage in the nozzle can cause all of these problems. Similarly, a complete jam can occur due to clogged material stuck in the nozzle.

An improper first layer is another sign of nozzle clogging. If the nozzle does not extrude filament during the first layer or there’s an uneven filament flow, you might have a clog in your nozzle. However, it is helpful to eliminate any bed leveling and Z-offset issues before you check for a nozzle clog.

Additionally, filament curling right after extrusion and thinner print lines are also signs of a clogged nozzle. Recognizing these signs will help you quickly clean your nozzle and prevent further degradation of your 3D prints.

How Do You Clean a 3D Printer Nozzle?

If you start to see filament deposits on the outer surface of your nozzle, it is time to clean it. 3D printer nozzle cleaning is easy, and all you need is a brass wire brush and a wiping cloth.

The brass brush prevents damage to your brass nozzles and lets you scrub any stuck printed material from your dirty nozzle.

Before starting the cleaning process, it is helpful to first heat your 3D printer nozzle. Heating the nozzle softens any stuck filament bits and lets you wipe them off more quickly.

Once you’ve scrubbed the nozzle thoroughly, you can wipe away any leftover material from its surface. A soft microfiber cloth is our go-to equipment for this.

3D printer nozzle cleaning is now complete, and you can start printing again. Remember to always keep an eye on the state of your nozzle and clean it regularly to maintain optimal print quality.

Remember to always keep an eye on the state of your nozzle and clean it regularly to maintain optimal print quality.

Turboom Wire Brush Set Scratch Brush Set for Cleaning Welding Slag...

616 Reviews

Check PriceHow Do You Unclog a Clogged 3D Printer Nozzle?

If your nozzle is already clogged, don’t worry! Cleaning a nozzle is an easy process that can be done through a couple of different methods.

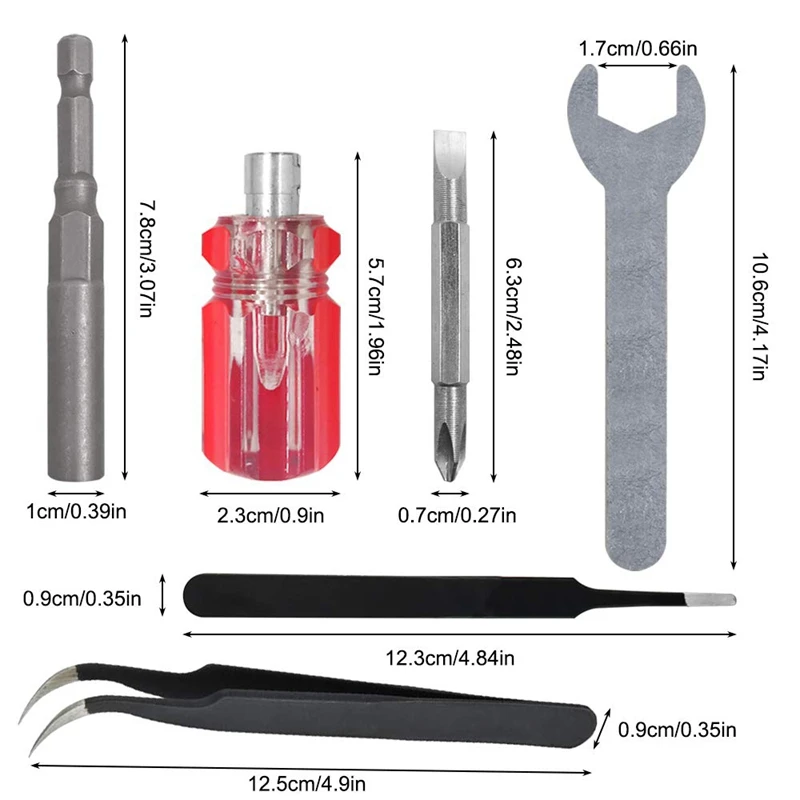

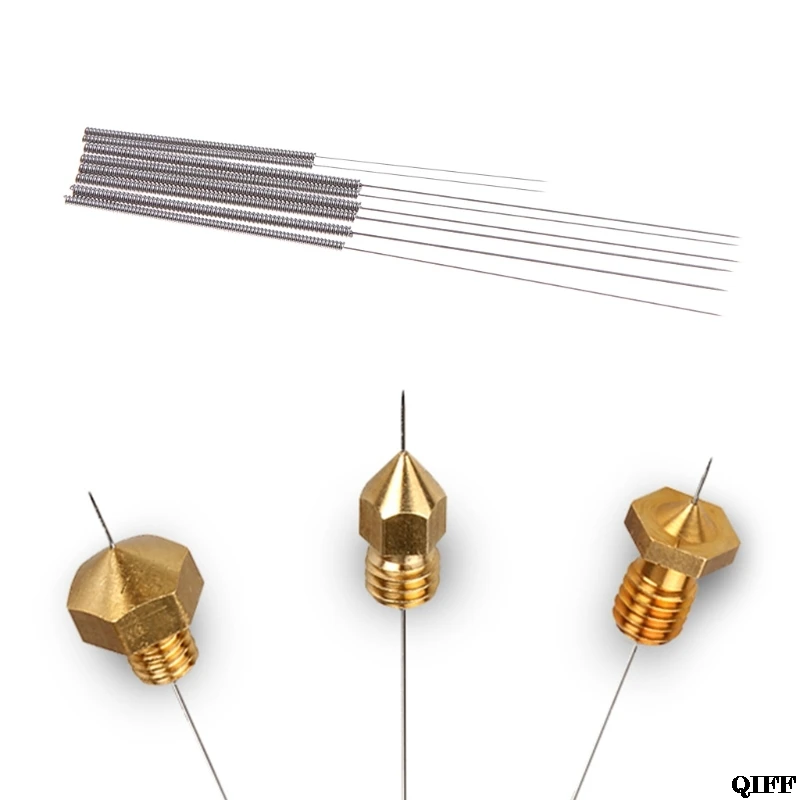

Nozzle Cleaning KitA standard nozzle cleaning kit consists of thin metal needles, tweezers, and a brush. You can use this method to clean out your nozzle by following these steps:

- Start by heating up your nozzle to right under its maximum temperature. This will help to soften any filament that is stuck inside the nozzle.

- Next, use the metal needles to pick out any larger pieces of filament that may be blocking the nozzle.

- Once the larger pieces have been removed, use the nozzle brush to clean out any smaller bits of filament.

- Finally, use the tweezers to remove any final pieces of filament or debris.

3D Printer Nozzle Cleaning Kit - 0.4mm Needles and Tweezers Toolkit...

Check PriceCold Pull

A cold pull or an atomic pull is often used to unclog the nozzle and remove any debris inside it. It is an easy technique and requires no disassembly or cleaning tools to remove the clog.

Using Nylon filament will give the best results. However, you can also use PLA, ABS, or a dedicated cleaning filament (more on this later) if Nylon is not available.

First, you need to heat the nozzle to the printing temperature of your filament. After that, you will have to manually push the filament until it extrudes out of the nozzle. You can now let your hot end cool down while pushing the filament into the nozzle.

In the final step, you need to first remove the extruded material from the nozzle tip. Then set the printer temperature to 85-90 °C. Once it reaches this temperature, slowly pull the filament out of the nozzle completely.

You might have to perform this procedure several times to remove any dirt and filament bits from the inside of your nozzle. You can stop once you notice the cold pulled filament is free from debris.

Soaking the Nozzle in Acetone

A nozzle cleaning kit and cold pull might not always be practical with filaments like ABS, and your nozzle might still be clogged. When it comes to ABS, removing the nozzle and soaking it in acetone is a good way to clear clogs.

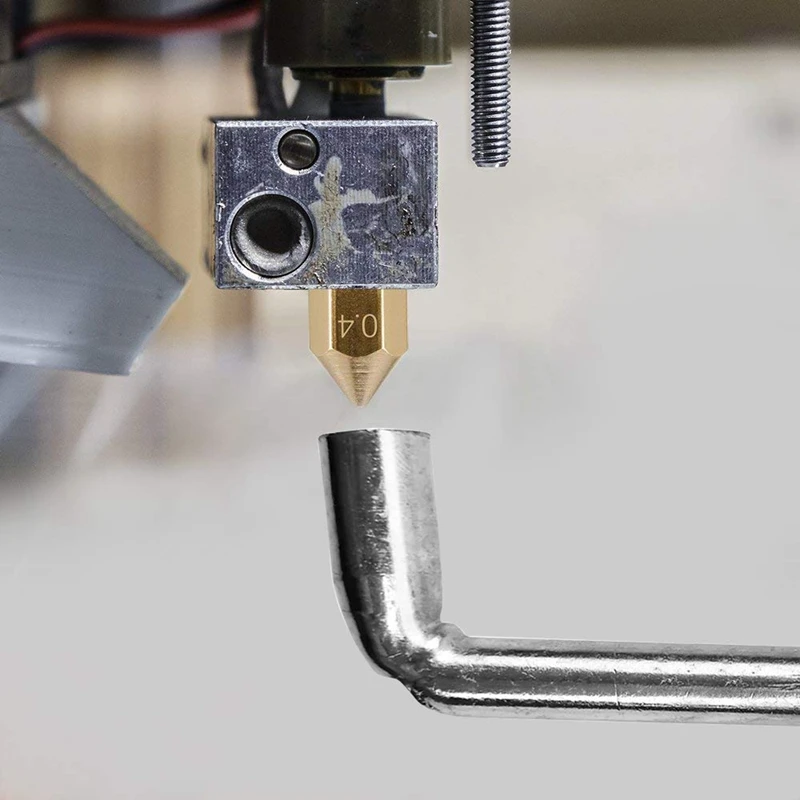

Start by heating the nozzle before removing it from the hot end. Heating the nozzle frees it up slightly from the heater block and makes it easy to unscrew. You can use a spanner or a nozzle removal tool to remove the nozzle safely and efficiently.

After you’ve removed the nozzle, soak it in a cup with a layer of acetone for around 30 minutes. The acetone will help to dissolve any ABS filament that is stuck inside the nozzle.

Recommended:

How to Melt and Dissolve PLA Filament

Once the soaking is complete, you can use a wire brush to remove any final bits of filament. Be sure to also clean the nozzle tip as this is where most of the clogs occur.

Be sure to also clean the nozzle tip as this is where most of the clogs occur.

You can now reassemble your 3D printer and start printing again. Make sure to properly dry the nozzle first. A paper towel or soft cloth is just fine for this.

Remember to always keep an eye on your nozzle and clean it regularly to maintain optimal print quality.

Using a Heat Gun

While an acetone soak is helpful for ABS filament, it is not as effective on other filament materials. Especially PETG and Nylon are fairly non-reactive to acetone.

When dealing with these filaments, a heat gun will help clear your nozzle clog.

The first step is to remove the nozzle from the 3D printer hot end or extruder assembly. This is the same as what you would do for ABS soaking.

Next, you will need to heat the nozzle with the heat gun until the filament inside melts.

Once the filament has melted, you can use a thin needle or a wire brush to remove any debris from the nozzle. Be careful, the nozzle is hot at this point.

After cleaning the nozzle, you can now reattach it to the hot end assembly and start printing again. Make sure that the nozzle is properly cooled down before reattaching it.

Wagner Spraytech 0503038 HT400 Heat Gun, Dual Temperature Hot Air Tool...

Check PriceHow Often Should You Clean a 3D Printer Nozzle?

At a minimum, you should clean your 3D printer nozzle when you change filament materials. It is easy for nozzles to clog from leftover material after a filament change.

For example, when you switch from ABS filament to PLA, some ABS material might be left in the nozzle. As PLA prints at a lower temperature than ABS, the leftover ABS will not melt and result in a nozzle clog.

Another reason for nozzle clogs is dirt and dust particles that enter along with the filament. If you continuously print with dirty filament, the debris can accumulate in the nozzle over time and clog the nozzle.

Because it can be a challenge to keep your filament free from dust and dirt, you can clean the nozzle after every 100-200 printing hours as prevention.

Generally, if you notice a decrease in print quality, that is usually a sign that your nozzle is starting to get clogged and needs cleaning. You can do this regardless of how long or with which materials you have been 3D printing.

How to Prevent 3D Printer Nozzle Clogs

Regularly Use 3D Printer Cleaning Filament

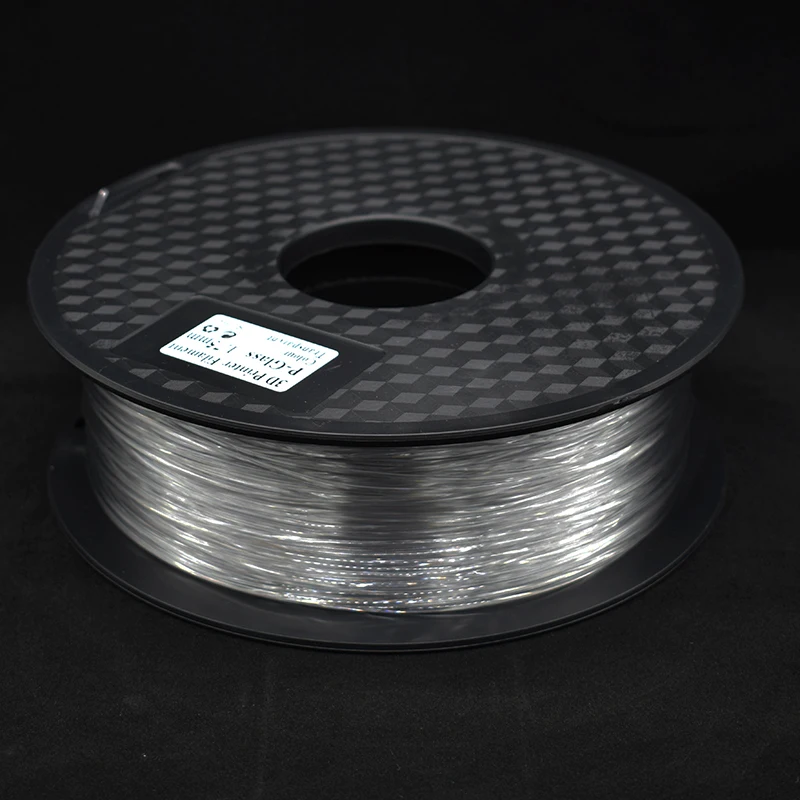

3D printing cleaning filament is the easiest way to clean your nozzles from the inside. It is made up of a material specifically used to clean and purge plastic out of injection molding machines. You need to extrude it at the printing temperature of your filament until you notice a clean white strand of material coming out of the nozzle, free of any debris or filament color.

Even though cleaning filament may seem slightly expensive, it does work effectively and clears out any partial clogs. And you only need a small amount. You can use it after every 100-200 hours of printing for effective cleaning of your nozzles and to prevent nozzle clogs.

NovaMaker 3D Printer Cleaning Filament 1. 75mm Natural,...

75mm Natural,...

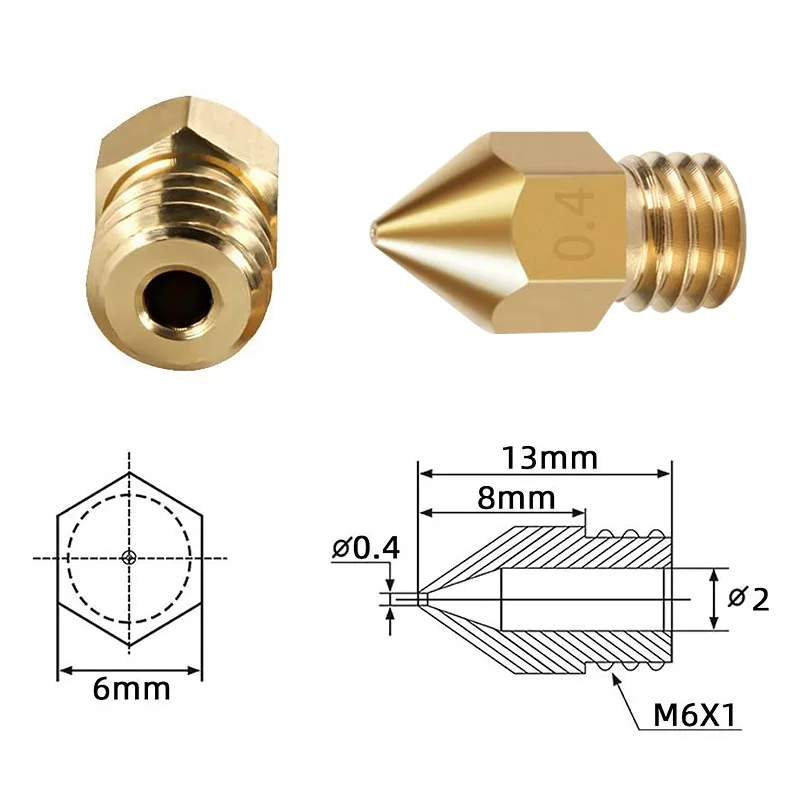

Replace Worn-out Nozzles

You want your nozzle opening to look round.This nozzle is already showing some signs of wear, but still has some print hours left in it.Brass nozzles undergo a lot of wear due to the constant friction of the filament. This wear accelerates when you use abrasive filaments like glow-in-the-dark, carbon fiber, and metal-filled filaments.

Not only do abrasive filaments wear out the nozzle opening, but the tiny metal particles of the nozzle material can start accumulating. This can block filament flow and lead to filament jams.

If you regularly use abrasive filaments or notice a lot of nozzle wear, it’s a good idea to replace your brass nozzle more often.

Alternatively, you can use stainless steel or other hardened nozzles. These are more resistant to abrasive filaments and have a higher lifespan than your typical plain brass nozzles.

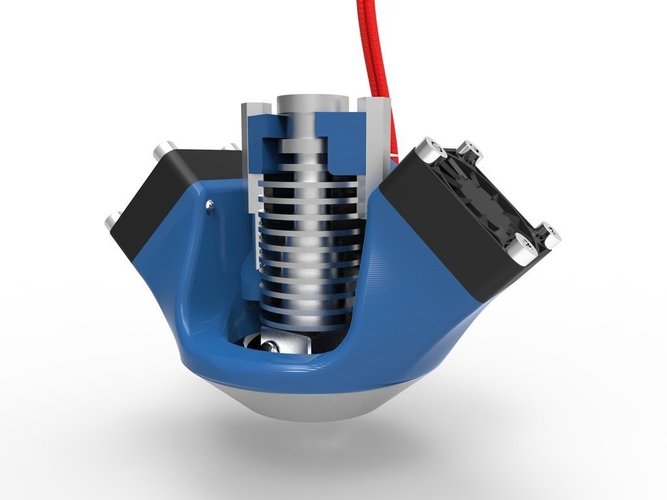

Fix the PTFE Tube Hot End Gap

In a PTFE-lined 3D printer hot end, the tube goes all the way inside and sits right on top of the nozzle. If the gap is not flush between the PTFE tube and the nozzle, the melted filament will ooze out of it. Eventually, there will be a build-up of plastic filament within the hot end, leading to filament jamming.

If the gap is not flush between the PTFE tube and the nozzle, the melted filament will ooze out of it. Eventually, there will be a build-up of plastic filament within the hot end, leading to filament jamming.

The gap is caused due to faulty PTFE tube couplings. As the couplings wear out, the PTFE tube starts sliding in and out of the hot end, creating a gap between itself and the nozzle. Extruder skipping and under extrusion are signs of a filament jam in the hot end.

You should immediately rectify the PTFE tube gap within the hot end if you notice these issues.

The first thing here is to make sure that the PTFE tube has been cut flush at a 90° angle. If it has a slope to it, it will never perfectly align with the hot end.

Secondly, it helps to use replace worn-out pneumatic couplings with new ones on both the extruder assembly and the hot end assembly. This ensures that the PTFE tube stays in place over time.

PTFE Bowden Tube (1M) 1PCS+ 6pcs KJH04-M6 Fittings + 6pcs JP4-01. ..

..

Use High-Quality Filament

A high-quality filament will reduce nozzle clogs while also giving you high print quality. Manufacturers of high-quality filament ensure that their product contains little to no impurities, is produced in a dust-free environment, has a consistent diameter, and is properly vacuum packed to reduce as many imperfections in the material as possible.

We have created an overview of the highest quality filament in our Best PLA, Best ABS, and Best PETG articles. We recommend you check these brands out if you suspect your clogged nozzles are caused by low-quality filament.

While these filaments may be more expensive than budget materials, they are often worth the extra money.

They don’t only save time, but their results are better too. If you are looking to sell your 3D prints and make money with your 3D printer, quality filaments can be a worthwhile investment.

Keep Filament Clean and Dust-Free

A clean 3D printing space contributes significantly to preventing nozzle clogs. If your plastic filament is exposed to the outside environment while printing, it will pick up dust particles that clog your nozzle. After printing with it, you need to store it away from sunlight and in a storage box to prevent the accumulation of dust on it.

If your plastic filament is exposed to the outside environment while printing, it will pick up dust particles that clog your nozzle. After printing with it, you need to store it away from sunlight and in a storage box to prevent the accumulation of dust on it.

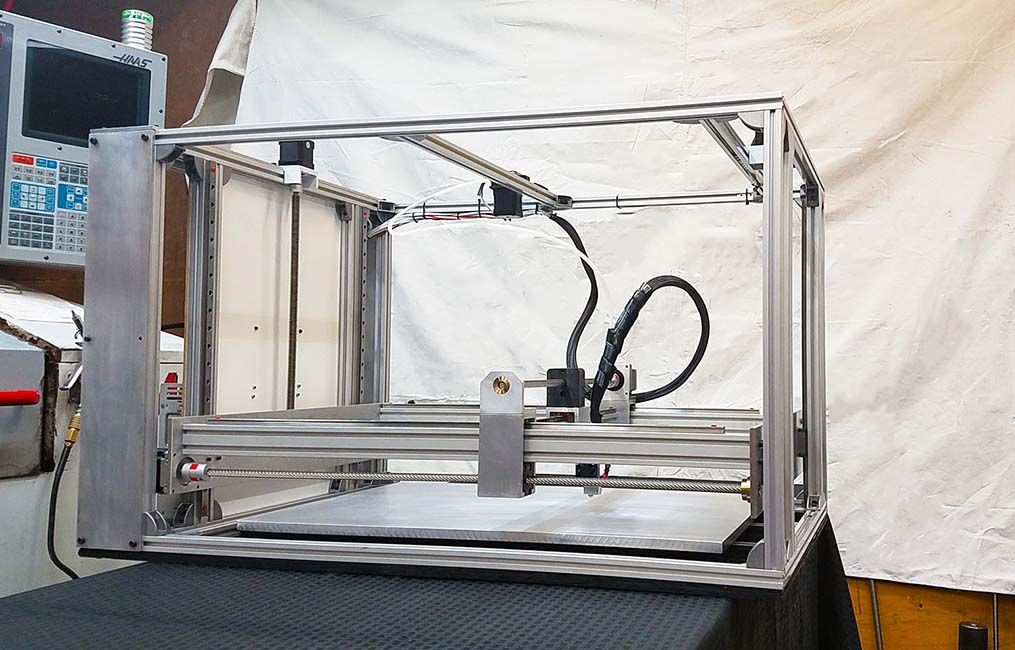

Another way you can protect your 3D printing setup from dust and dirt is by using a 3D printer enclosure. These don’t only keep the current filament in the printer clean, but also the 3D printer itself.

Frequently Asked Questions

How do you clean a clogged nozzle with PLA?

In order to clean a clogged nozzle with PLA, you will need to disassemble the printer and remove the nozzle. Once the nozzle is removed, you can use a small wire, needle, or other small pointed tool to clear any debris that may be blocking the opening. You might need to heat the nozzle up with a lighter to melt the plastic filament.

Be careful not to damage the nozzle while cleaning it.

How do you clean an Ender 3 nozzle after printing?

It’s important to clean your Ender 3 nozzle regularly to prevent clogs and ensure quality prints. After every print, it is advisable to clean the nozzle with a brass wire brush. This will remove any debris or build-up that may have occurred during the printing process.

After every print, it is advisable to clean the nozzle with a brass wire brush. This will remove any debris or build-up that may have occurred during the printing process.

A clean nozzle will ensure that your prints are of the highest quality and avoid any potential issues such as clogging or poor adhesion.

Conclusion

A clean 3D printer nozzle gives you the best print results and helps prevent damage to the 3D printer caused by clogs. Periodic cleaning of your 3D printer nozzle ensures fewer chances of sudden breakdown and prevents downtimes.

Degradation in the print quality, coupled with under extrusion and inconsistent filament extrusion are some of the indicators of a blocked nozzle. You can quickly unclog the nozzle using a nozzle cleaning kit and a wire brush and periodically use a cleaning filament. Especially the cleaning filament is useful for keeping nozzles clean.

When dealing with ABS filament, you can soak the nozzle in an acetone bath to soften the filament. This makes it a lot easier to remove.

This makes it a lot easier to remove.

Let us know your experience with 3D printer nozzle cleaning. If you find this article helpful, share it with your peers to help them prevent nozzle clogs and keep their 3D printers running smoothly.

How to Clean a Clogged 3D Printer Nozzle

- Author

- Recent Posts

Martin

Martin has a M.Sc. in physics and has gained many years of experience in industry as a lab manager and quality assurance manager. He has now tested dozens of 3D printers and is happy to share the collected experience with each new article.

Latest posts by Martin (see all)

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Whether for the hobby, in the small specialist workshop or in large-scale industrial production, 3D printing has become irreplaceable and offers almost infinite possibilities for producing large and small printable products with astonishing detail in minutes.

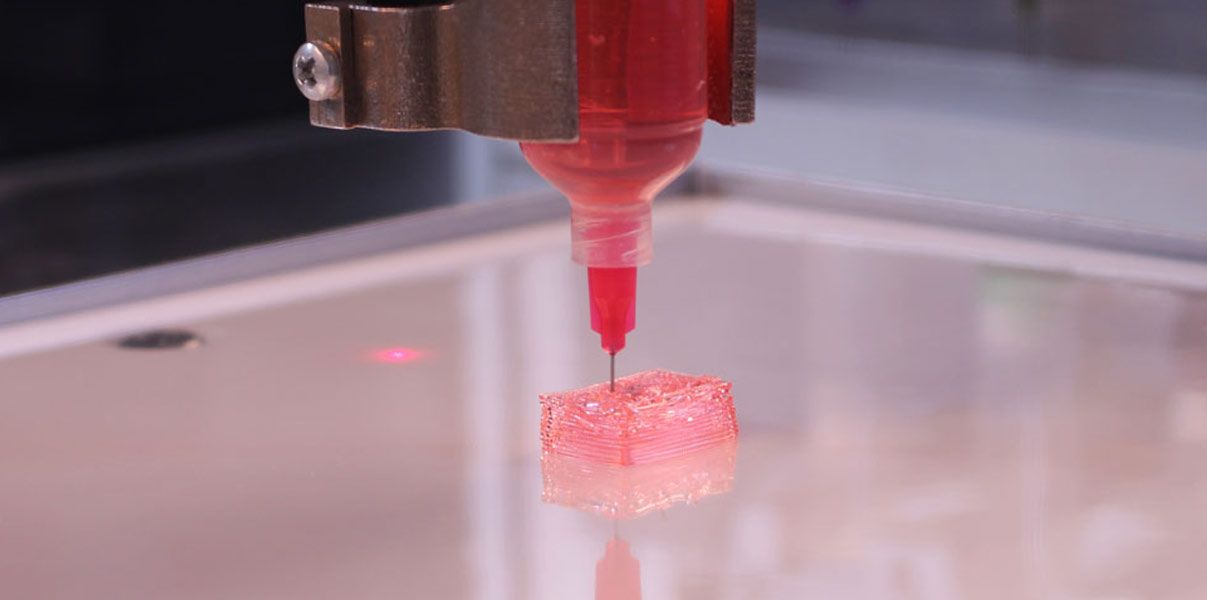

Even modern medicine makes use of this technology and is already producing prostheses or artificial organ parts using 3D printing.

As great as this printing method is, there is one problem in particular that is annoying: a clogged printer nozzle!

Light clogging of a 3D printer nozzle can be removed well with cleaning filament*. Heavy clogging with needles, acetone, various pull methods and high heat. Frequent cleaning with cleaning filament, brushes and paper towels will prevent clogging.

In this text you will learn how various types of clogging manifest themselves, what the causes are, how you clean the nozzle and how you can prevent clogging.

0.4 mm Needles and Tweezers Toolkit*0.4 mm 0.35 mm Needles Tweezers*Cleaning Filament*Table of Contents:

- 1 Symptoms

- 2 Causes

- 2.1 Wrong Nozzle Height

- 2.2 Incorrect Temperature Setting

- 2.3 Low-Quality Filaments

- 2.4 Dust & Dirt

- 2.5 Don’t Burn Anything…

- 3 Nozzle Cleaning

- 3.

1 Cleaning Filament

1 Cleaning Filament - 3.2 Push Filament Through

- 3.3 Needle

- 3.4 Acetone

- 3.5 “Atomic Pull”

- 3.6 “Cold Pull”

- 3.7 Incineration

- 3.

- 4 Replacing the Nozzle

- 5 Prevention

- 5.1 Daily

- 5.2 Weekly

- 5.3 Monthly

- 5.4 Quarterly

Symptoms

First of all, let’s clarify a very basic question: How can you tell if the printer nozzle is clogged?

The following signs indicate with high probability that your printer nozzle is clogged:

- The filament does not flow: If you have inserted a filament, your printer has been heated to the appropriate temperature and no filament is flowing or the flow is not uniform, you can be sure that the nozzle is clogged. This includes the following signs: The filament, i.e. the mass with which your object is printed, does not flow straight out of the nozzle, but curls, flows in a curve, flows in uneven quantities, the filament strand is repeatedly interrupted or no material comes out at all.

- Your printed object is faulty: especially areas that are very thin have holes, edges and borders are blurred.

- The extruder makes “click”: The extruder in your printer presses the material. If it makes a clicking sound, this indicates that it is not pressing against the material, for example, because it has hardened and the nozzle is sticking.

If you notice one or more of these symptoms, your printer nozzle is probably clogged.

Therefore we want to show you some very practical solutions how you can easily clean the printer nozzle yourself.

But first you will find out what causes a blocked nozzle in most cases. This way you will not only learn what to do once the proverbial child has fallen into the well. We also tell you how you can avoid the problem in the future.

Causes

Clogging of the 3D printer nozzle is caused by burnt-on material residues, similar to burnt-on material in a cooking pot.

For example, you have set the wrong temperature for a filament, or filament remnants from a previous print are burnt in the next print at a higher temperature. There are also filaments that are partly made of natural material, which contains coarser particles that stick more easily than synthetic material.

There are also filaments that are partly made of natural material, which contains coarser particles that stick more easily than synthetic material.

Wrong Nozzle Height

The adjustment of the nozzle height, i.e. the Z-coordinate, has a considerable influence on a clean print result. If the nozzle is set too high, the filament has a long way to the printing surface and cools down too much too fast. It is then no longer formable, does not stick and your object becomes misshapen and/or defective.

If the 3D printer nozzle is set too low, the filament will not have enough space to be extruded cleanly. The result: a totally smudged thermoplastic!

In bad cases, the material has so little space that it is pressed back into the nozzle by the print surface and there, depending on the filament, extremely stubbornly clogs the nozzle. This problem is called “retrograde extrusion“.

It is therefore important to set the printer nozzle at the correct height. As a rule of thumb, the height should be smaller or at most the same size as the diameter of the printer nozzle, it is best if it is smaller than a quarter of this diameter.

Then the extruder exerts enough pressure on the filament to make it adhere. It is lightly pressed, but not forced back.

Incorrect Temperature Setting

Setting the correct printing temperature can sometimes be an art in itself. It is important to keep the temperature suitable for your filament.

PLA is best used at 180 °C, ABS from temperatures of 225 °C. Nylon filaments tolerate much higher temperatures. There are also nozzles especially suitable for certain materials and particularly high temperatures.

If the temperature is set too low, the material does not liquefy properly and settles inside the nozzle. The pressure on the print head increases and the nozzle becomes clogged.

If, on the other hand, the temperature is too high, a so-called “heat creep” can result. The material is heated so much that it becomes liquid long before it is fed to the nozzle: So the heat travels up or back.

Liquid filament requires higher pressure. The motor is overloaded, cannot keep up, and the nozzle is blocked. In some cases, the material can also dissolve into its constituents and then crystallize in the nozzle head.

In some cases, the material can also dissolve into its constituents and then crystallize in the nozzle head.

It is therefore important that you stick to the right temperatures!

Practice also makes perfect: with a little experience, you will quickly determine which material produces the best printing results at which temperature.

When changing between different types of filaments, make sure that you always remove all residues from the nozzle, so that only the newly inserted material is heated afterward and the temperature is really adjusted to the material in the nozzle.

Also, note that a material change only works correctly under heat and that the material should not be inserted into the printer with excessive force or pressure.

Low-Quality Filaments

Particularly in various online shops, dealers are luring customers with filaments from rather unknown manufacturers at ridiculously low prices.

That’s tempting, of course. Especially if you’re new to 3D printing, you’ll probably want to try out different things and make all your ideas come true.

This can quickly become expensive because good filaments are expensive. Cheap filaments are attractive because of their price, but in most cases, they cannot keep up with the quality (exceptions confirm the rule as always).

Low-quality filaments do not have fixed tolerances, which means that the filament strand does not have a uniform diameter or varies only within certain tolerance ranges.

If the strand is of different thickness, the melting point also varies. The filament, therefore, does not flow cleanly and evenly and can lead to unclean printing and clog the nozzle. In addition, filaments are of poor quality if they are not “pure”, i.e. they tend to contain unwanted ingredients.

These “stretch” the mass in order to make it more voluminous and thus be able to sell large quantities at low prices. Or they imitate the characteristics of solid brand products with cheap but less good additives.

So before buying cheap filaments, you should do some research, read reviews and, in case of doubt, prefer proven products that can be more expensive. You can also check the quality of your filament yourself by checking the diameter of the strand at different places (best with a caliper gauge*). If the values differ greatly, it is better not to use the filament to prevent problems.

You can also check the quality of your filament yourself by checking the diameter of the strand at different places (best with a caliper gauge*). If the values differ greatly, it is better not to use the filament to prevent problems.

Dust & Dirt

Dust, dirt and other deposits on the filaments “migrate” through the extruder and the nozzle during printing. They melt and are thus carbonized and consequently extremely hardened.

A stubborn layer of dirt is formed in the nozzle, which narrows the printing opening and leads to further blockages.

You cannot completely avoid deposits. You have to reckon with and accept such pollution in large parts. However, you can reduce them by storing your filaments in clean vacuum bags or at least plastic bags after opening the package and keeping them protected from dirt. Also, check the filament for cleanliness before each use.

One cause of contamination inside the printer, in general, may not be so obvious but is often the cause: the use of spray varnish on the finished object. Many printing enthusiasts want to give their prints a colorful look right after printing and use different sprays.

Many printing enthusiasts want to give their prints a colorful look right after printing and use different sprays.

These fly around in tiny droplets and settle on and in the printer. This can also lead to permanent blockages of the nozzle and other components. If you are using ink sprays, please do so as far away from the printer as possible – preferably not in the same room!

Don’t Burn Anything…

Perhaps the following situation sounds familiar to you: Your printer is printing and you’re doing something else in the meantime. Maybe you forget the printing for a short time and only when the printer has finished its work, you return to the printer.

But to prevent filaments from drying out and burning in subsequent prints, you can enter a command to make the printer stay warm after printing is finished. This way, you keep the filament fluid or at least soft, even if you are not present.

Nozzle Cleaning

Now that you know how to recognize a blocked printer nozzle, how such blockages occur and how to avoid them, we want to equip you for the case of emergency.

The printer nozzle is clogged, nothing works. What to do?

We have put together methods for cleaning that you can try one after the other or at your own discretion. You can also repeat each method as often as you like.

When used correctly, they will not damage your printer or nozzle. Please note that the printer nozzle can be very hot. So be careful.

Depending on how badly the nozzle is clogged, different methods are used:

Partial Clog:

- Cleaning filament*

- Push filament through

Full Clog:

- Needle

- Acetone

- “Atomic Pull”

- “Cold Pull”

- Incineration

Cleaning Filament

Directly at the beginning of our cleaning methods still another piece of advice for prevention: Cleaning filaments*.

Cleaning Filament*Check Price at:

Amazon*

Cleaning filaments are made of a material especially suitable for cleaning a printer nozzle. They are inserted and then used in print passages according to the packing instructions. Dust, dirt, filament residues and other deposits adhere to them and are then mechanically removed with the print.

They are inserted and then used in print passages according to the packing instructions. Dust, dirt, filament residues and other deposits adhere to them and are then mechanically removed with the print.

We recommend that you carry out such cleaning operations regularly. Because once the nozzle is completely clogged, even the best cleaning filament will not help.

In order for this to work effectively, there must be at least a partial pressure flow. Cleaning filaments are rather expensive in the purchase price. However, you only need very little of them per cleaning cycle!

Fifty grams cost about 20 bucks, but you can do between 70 and 100 runs with it. So even if you use your printer regularly and clean it regularly, you will be able to use this amount for a long time.

Push Filament Through

Frequently, unwanted printing results do not immediately block the entire nozzle, but only slight deposits have formed at the opening and around the nozzle.

With this method you use white ABS or white nylon similar to cleaning filament – only a bit more complicated. So if you need to do it quickly and you have some left, you don’t have to wait for the cleaning filament to arrive.

So if you need to do it quickly and you have some left, you don’t have to wait for the cleaning filament to arrive.

- Step 1: Heat the nozzle to 200°C to melt the filament.

- Step 2: Remove the filament from the hotend.

- Step 3: Carefully clean the outside of the nozzle with a paper towel.

- Step 4: Manually push the filament into the nozzle as far as it will go, or until some of it is extruded.

- Step 5: Pull the filament out again.

- Step 6: Cut off the dirty/blackened end of the filament.

- Step 7: Repeat steps 4 to 6 until the filament remains white.

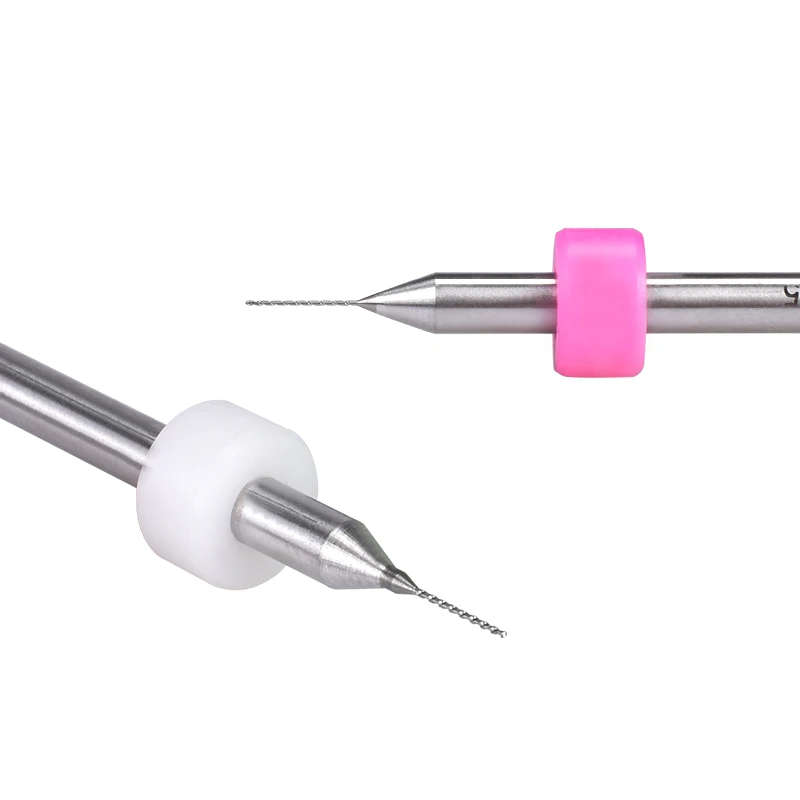

Needle

This method is based on manually unblocking the blockage with a needle. You can use this method with a cold and a hot nozzle.

Set the temperature of your printer to the temperature that suits your printed material. Now insert a very fine and pointed object into the nozzle and move it slightly until the dirt comes off. When you extrude new filament afterwards (ideally cleaning filament first), the loosened contaminants are pressed out with it.

Some manufacturers include cleaning kits made specifically for the printer when you buy it or offer them for separate purchase. Here you can have a look at these cleaning kits of the different manufacturers:

0.4 mm Needles and Tweezers Toolkit*0.4 mm 0.35 mm Needles Tweezers*48 Pieces 3D Printer Nozzle Cleaning Kit*These kits usually include needles or similar cleaning tools that you insert into the printer. If you are stuck with the above-mentioned household remedies, such a kit is highly recommended!

Of course, the needle or other cleaning tool should not be thicker in diameter than the diameter of the printing opening. In the worst case, you could damage the opening irreparably!

Acetone

If you used (at least for one of the last prints) a filament which is very easily soluble, you can also clean a clogged printer nozzle chemically.

For this, you need acetone*.

Remove the printer nozzle and place it in a container in which you cover the nozzle completely with undiluted acetone.

Allow the nozzle to soak for at least twenty-four hours and move it back and forth from time to time during this time to loosen dirt.

In between, you can remove internal dirt with a needle. Do this as often as necessary until there is no more dirt.

“Atomic Pull”

In this method, the material is fed into the printer, extruder or nozzle and then quickly pulled out again.

The steps between insertion and pull are different. Basically you can test all pulls. The “atomic pull”, which we will now explain to you, is only suitable for printers with Bowden type*.

The “atomic pull” uses the same print material for cleaning as was used for the print itself. It is heated, then cooled down and pulled out again in a jerk shortly before solidification.

And it works like this: First, remove the clamp of the Bowden hose. Set the printer temperature 30 degrees higher than specified for the filament used. Then insert about a hand length of filament (as white as possible, preferably pure white) until either an even strand of filament comes out again or you cannot push it any further in. Then adjust the temperature to the following values and wait until the extruder has reached this temperature:

- 145 °C for nylon

- 110 °C for ABS

- 90 °C for PLA

As soon as the temperature is reached, pull the filament out of the extruder again with a steady jerk. Do not use force! It should be possible to release the strand with only slight resistance.

Now, look at your extracted filament. What does the tip look like? If the front tip of the strand is dirty or discolored, the nozzle is still clogged. Repeat the process until the filament is clean.

If you can’t pull the rope out at all, repeat the whole process with slightly higher temperatures until the rope can be easily loosened. Then you can repeat the procedure until the strand is clean. Your printer should then produce perfect results again.

“Cold Pull”

This method is particularly suitable for heavy blockages and hardened deposits in the printer nozzle. It is essentially based on very high temperatures.

Heat your printer to 250 degrees Celsius for at least five minutes. Use nylon or ABS filament. These are extremely heat-resistant. Push the filament manually through the printer or extruder.

The intense heat causes deposited dirt and filament residues to loosen and melt into the nylon/ABS used. Together with nylon/ABS the blockage is then pressed out. Allow the printer to cool down until the nylon/ABS becomes solid. Then heat the printer to 120 to 130 degrees Celsius. Then pull out the filament strand with a jerk. This jerky movement of the cooled material gives the method its name.

Incineration

This method can be seen as the “emergency solution”. It combines uncontrolled heat with manual force.

Remove the nozzle from your printer. Hold the nozzle with pliers over a strong flame, such as a gas or Bunsen burner, blowtorch, or hot air dryer. Hold the nozzle over the flame with the printing opening facing down.

If material now drips out of the opening, the deposits are loosened. If you hold the printing nozzle with the opening against a light source, you can see whether it is already free and light can get through.

If this is not the case, hold the nozzle over the flame again and simultaneously pierce the nozzle opening with a pointed object to additionally loosen the blockages. You can also lightly tap the nozzle on a firm surface to loosen the deposits.

Replacing the Nozzle

Despite all prevention and all tips for cleaning the printing nozzle, it may happen that the nozzle cannot be cleaned anymore and your print will still look unsatisfactory. Then sometimes only the purchase of a new printer nozzle* will help.

Prevention

As a treat, we have put together a small checklist of cleaning tasks for you at the end and divided them according to how often they should be carried out.

So you have a simple list at hand that, along with our tips, will help you keep your printer clean and avoid problems with the printer nozzle.

If your printer is in daily and constant use, the following checks and maintenance procedures have proven to be useful:

Daily

- Remove dust, dirt and debris from the printer before use.

- If possible, have the nozzles cleaned automatically before each print.

- Check movements of the axes and all moving parts.

- Are the printing profiles ok?

- If you already know that the printer will not be used for the next few days: Remove the filaments and roughly clean the nozzle with a metal or toothbrush and needle (or guitar string or wire brush hair or paper clip or toothpick).

Weekly

- Clean the printing bed with a fine spatula and rinse under lukewarm water.

- Calibration of the printer, especially if the nozzle or other has been removed (for example to clean the nozzle with our tips).

- Rough cleaning of the nozzle with metal- or toothbrush and needle (or guitar string or wire brush hair or paper clip or toothpick)

Monthly

- Use of cleaning filaments*

- Complete (re)calibration of the printer

- Search for software updates

- Clean and oil round rods and bearings

- Remove lubricant from spindles and re-oil

Quarterly

- Complete cleaning of the extruder

- Check all cabling and the main board

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

How to clean the nozzle from deposits, plastic impurities, etc.

Technical

Subscribe to the author

Subscribe

Don't want

12

Clogged nozzles are a common occurrence. This informative guide will help you get your 3D printer back on track.

If you notice that your prints look fibrous, with skipped layers, then the nozzle is most likely clogged. Don't worry - this guide will help you solve the problem and start printing again.

What causes clogged 3D printer nozzles?

To understand what a bail is, it's best to know a few things that might be causing the problem in the first place. Maintaining the filament print and cleaning is a good practice to help avoid clogging.

- Plastic shavings on the extruder gear and filament remaining in the nozzle after printing form a plug in the thermal barrier

- Dust on the filament, foreign particles in the plastic that got into the plastic during its production form carbon deposits inside the extruder, which eventually exfoliates and cokes the nozzle

- Uncleaned nozzle after material change. For example, after printing, PLA began to be printed with hard plastics, such as hips, in which the printing temperature is much higher.

Is the printer nozzle clogged?

Release the filament pressure lever in the extruder gearbox and push the filament in by hand. If it twists, is hard to push through, or doesn't go through at all, then the nozzle is clogged. Pushing should not be tight, so do not press too hard on the plastic

Try pushing plastic by hand

Tools needed to clean the nozzle of your 3D printer

You will need the following tools for the methods below. We recommend trying them all and finding the one that works best for you.

- Piece of PLA or nylon filament.

- Brass wire brush (steel wire can damage soft material nozzle)

- Acetone

- Acupuncture needles or drills with a diameter smaller than the working diameter of the nozzle

- Half moon

- Socket wrench for unscrewing the nozzle

- Heat gun or soldering gun.

- Gas stove or burner.

And so, cleaning methods:

Method one: brass wire brush

Using a brass wire brush, clean the burnt plastic from the nozzle. Make sure you use a brass wire brush - DO NOT use a steel wire brush as this will damage the nozzle.

I recommend casting from silicone for the future or buying a cover for the extruder.

Cleaning the nozzle with a brass brush

Method two: acupuncture

Preheat the printer to the print temperature of the last material you printed.

Gently and carefully insert the acupuncture needle through the nozzle.

You don't remove dirt particles, you just mix them up so that they are squeezed out with the filament.

Drills can be used instead of needles, but they are much more expensive.

Printer Nozzle Acupuncture

Method Three: "Cold Draw" with Filament

For "Cold Draw" use the filament you normally print with, ideally nylon or pla.

- Heat the nozzle to 250°C and push the filament until you can see plastic coming out of the nozzle.

- Cool the extruder to room temperature to solidify the filament in the nozzle.

- turn on the heating of the extruder to 115 ° C

- At 90 °C, pull the thread until it comes out of the nozzle.

- Heat the nozzle again to 250°C and run the filament until it comes out smoothly without swirling.

Method Four: Heat Nozzle

- Heat the nozzle to the print temperature of the last media you used.

- replace plastic with ABS and try to push it

- use crescent wrench to hold heater block and open end wrench to unscrew nozzle.bud they are careful not to touch any hot parts.

- After removing the nozzle, use chemicals (acetone for abs) to dissolve the thread and flush out the cause of the blockage, or use a burner or hair dryer to burn it off.

If the abs fails to push through, you can use chemicals that will dissolve your plastic

but they tend to be more caustic or hard to find. In these cases, a hot air gun or soldering station (using proper precautions) can melt the remaining filament.

good luck with your printing!

Original article: https://www. matterhackers.com/news/how-to-unclog-a-3d-printer-nozzle

Subscribe to the author

Subscribe

Don't want

12

More interesting articles

Loading

11/29/2022

2353

67

Follow author

Follow

Don't want to

Greetings! The Chinese bearing crumbled in the midst of printing (8 hours of printing down the drain). K...

Read more

Picavit

Loading

03.12.2022

2140

44

Subscribe to the author

Subscribe

Don't want

Hello everyone! I want to share with you my story of creating a hand-held grinding device based on.