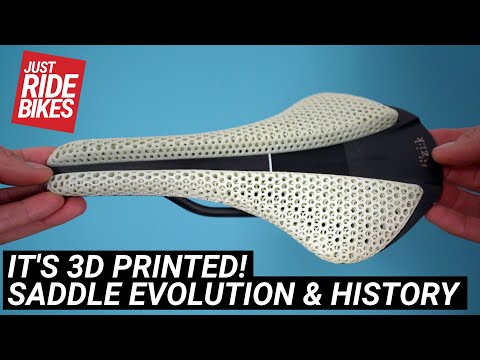

Contract 3d printing

3D printing for contract manufacturing

3D Learning Hub

See all categories

Contents:

- Introduction

- What is contract manufacturing?

- Is it possible to use 3D printing for contract manufacturing?

- What sectors are already using additive manufacturing?

- But, what are the advantages of using additive manufacturing for contract manufacturing?

- How to find the right partner for contract manufacturing

- How can we help you scale up your production?

Introduction

What is contract manufacturing?

Contract manufacturing is basically a manufacturer that contracts with a firm to produce components or finished products. Companies are choosing to outsource manufacturing to reduce cost, benefit from the expertise and advanced skills of manufacturers, and get the quality control they expect for their products. These companies will be manufacturing the product for you.

Contract manufacturing is a cost-saving technique, this way you don’t have to invest in facilities, advanced equipment, to production staff. Contract manufacturing offers the opportunity to finally access perfectly scaled production! Indeed, manufacturers are used to changing batch sizes, while maintaining high quality and efficiency. They are mastering their technologies, methodologies, and are specialists when it comes to scaling up a production! Many manufacturing companies are also using lean manufacturing.

All kinds of industries are using this process, from aerospace, food manufacturing, medical, energy, etc. Most of the time, these contract manufacturers are using traditional manufacturing methods such as CNC machining or injection molding. There are actually numerous types of manufacturing techniques: the first step is to understand the needs of your company and of your products. Maybe aa flexible and reliable technology such as 3D printing could better meet your requirements?

There are actually numerous types of manufacturing techniques: the first step is to understand the needs of your company and of your products. Maybe aa flexible and reliable technology such as 3D printing could better meet your requirements?

Is it possible to use 3D printing for contract manufacturing?

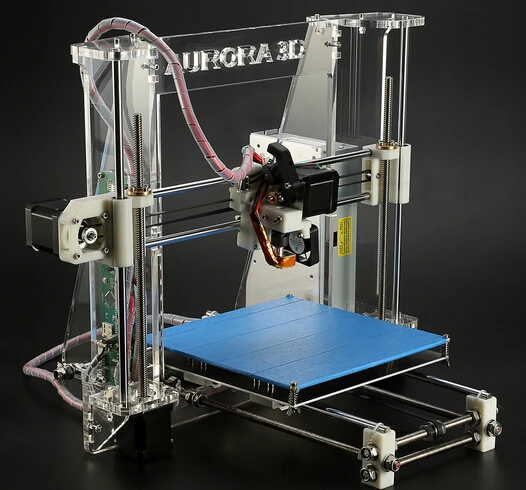

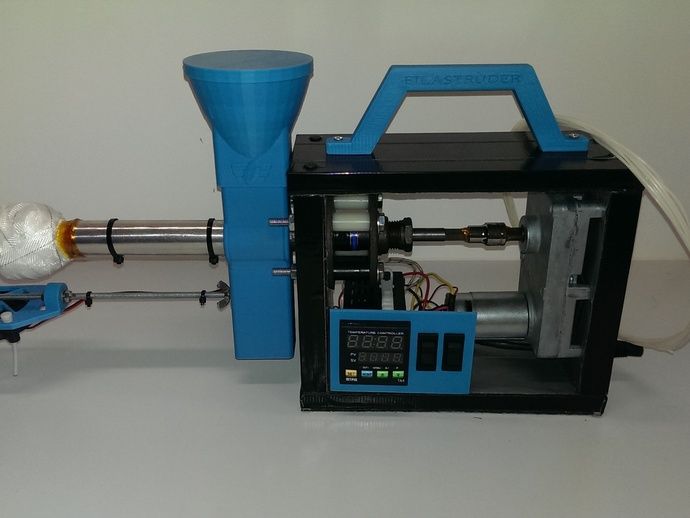

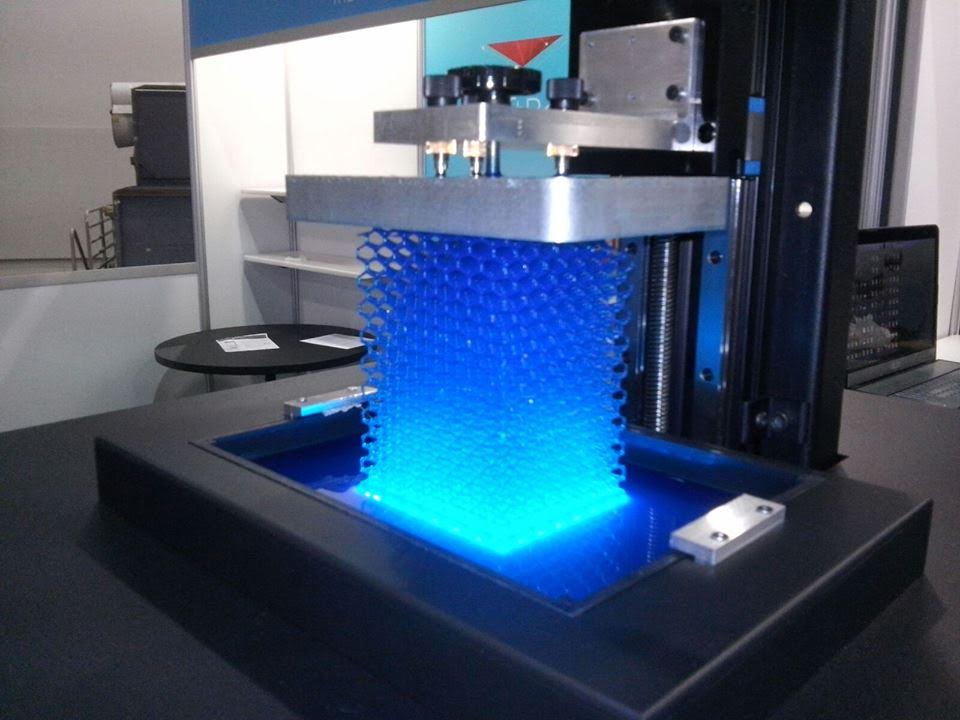

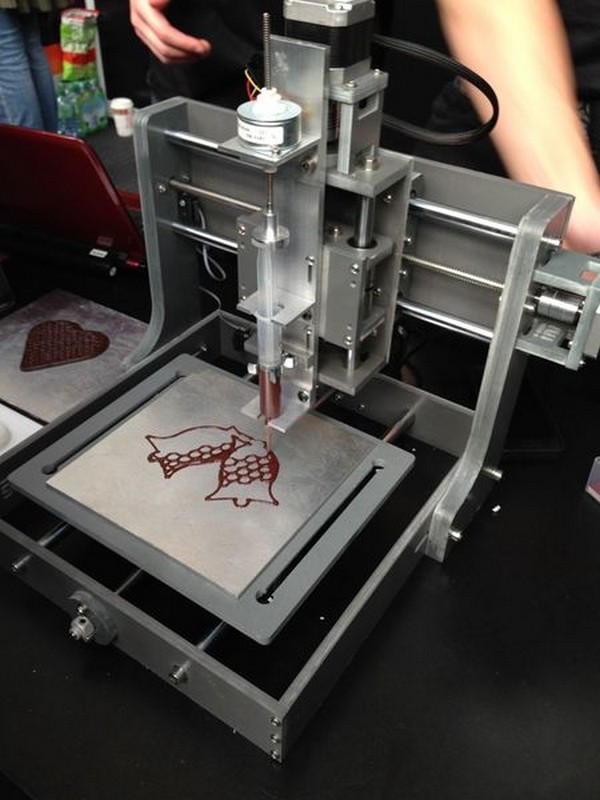

Manufacturing methods are evolving and additive manufacturing is now a real alternative to traditional methods. 3D printing is actually creating new business models, redefining the relationship between design and manufacturing, offering complete freedom from traditional constraints, and pushing the boundaries of manufacturing. Freedom of design, form, and quantity is now naturally part of the manufacturing process.

One of the main differences between additive manufacturing and traditional manufacturing techniques is that while using 3D printing, you have the opportunity to make the most of on-demand manufacturing.

If additive manufacturing is known for its great prototyping capabilities, offering great lead times, and a fully optimized process, it is now a great ally for your whole manufacturing process. With no limits for quantity, additive manufacturing offers the flexibility and the quality your business needs to manufacture your components or final product.

With no limits for quantity, additive manufacturing offers the flexibility and the quality your business needs to manufacture your components or final product.

As you can see in the table below, additive manufacturing has the capability to manufacture at a large scale, offering great product quality.

What sectors are already using additive manufacturing?

Sectors such as aeronautics, fashion, or automotive are already using 3D printing in their production process. Don’t wait for your competitors to use it first, be at the forefront of innovation and start to see how you can use Additive Manufacturing today! Let’s see a little bit more in detail what additive manufacturing can do for all of these industries.

- 3D printing for automotive

Manufacturing spare parts using 3D printing is becoming a reality in the automotive sector, especially with the development of high-performance materials for 3D printing. Improvement of the design of some parts can also improve the efficiency of a whole vehicle, by optimizing structures and weight. Mass-producing these parts is now possible with additive manufacturing!

Mass-producing these parts is now possible with additive manufacturing!

- 3D printing for eyewear

3D printing can totally be used to create finished eyewear. It even represents a great advantage for mass-customization. Thanks to the colors and finishings available, eyewear companies are using this technology to create custom eyewear, using Selective Laser Sintering, for example.

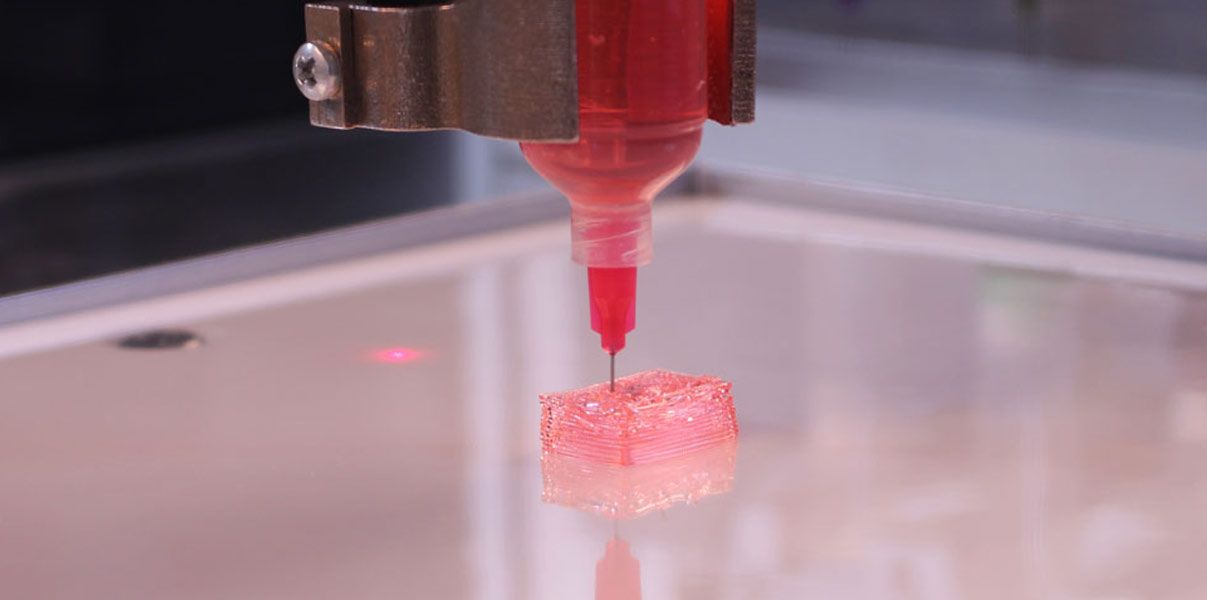

- Medical 3D printing

Additive manufacturing is more and more used in the medical sectors, and its future seems quite promising. Indeed, it can be used for the medical sector to create custom made prosthesis, but also to create adapted medical devices and tools at scale!

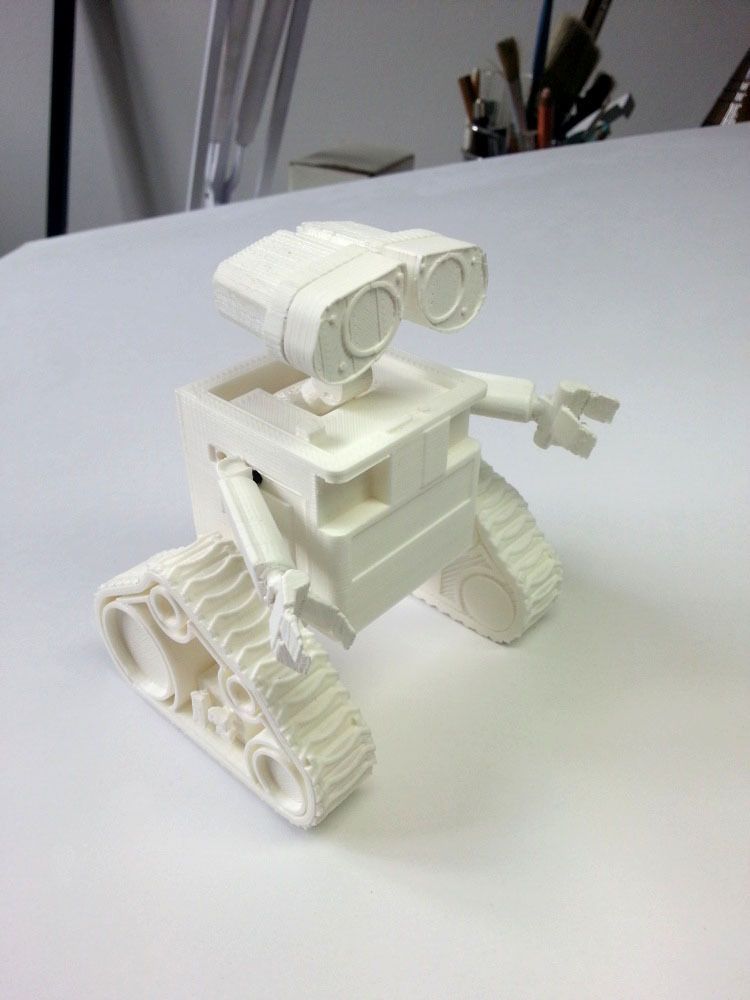

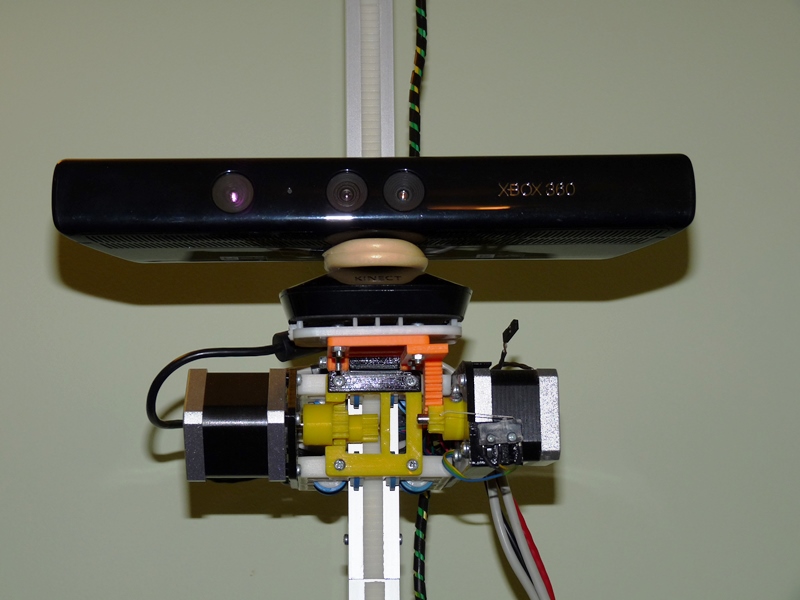

- 3D printing for electronics

3D printing can also benefit electronic products, drones, robotics, and casings. The creation of made to measure and intricate cases for electronic components, with integrated assembly, is becoming more and more common. Additive manufacturing can also be used for drones or robots also need demanding design, made-to-measure structures, etc.

Additive manufacturing can also be used for drones or robots also need demanding design, made-to-measure structures, etc.

But, what are the advantages of using additive manufacturing for contract manufacturing?

Many businesses are already using 3D printing, but how can it benefit your business? At Sculpteo, we will work with you at every stage of your project to ensure the best service and obtain the best result possible.

- Cost savings

Optimizing your processes, from prototyping to production, can help you save time and money. What if your ideas were developed faster and your iterations without design limitations? While using 3D printing you are free to print just a few parts, or only one! The exact amount of raw material needed for your project will be used, no waste, and no extra costs.

- Optimize your supply-chain

3D printing has a big role to play in the optimization of a supply chain and could push you at the forefront of innovation. Additive manufacturing is offering new opportunities, like inventory dematerialization.

Additive manufacturing is offering new opportunities, like inventory dematerialization.

You might not think about it, but 3D printing can actually change a lot of things in your supply chain management. No more busy warehouse or any risks related to inventory (shortage, inventory destruction due to accident or natural catastrophe, etc.), dematerialization could be the perfect solution to rethink your whole manufacturing process and reduce tooling investment. You could use this dematerialized inventory for your product or just for your spare-parts, depending on what is best for your business!

- Make the most of mass customization

You certainly know it, customization is an expensive process and sometimes impossible to manufacture with traditional manufacturing techniques such as injection molding or CNC machining. With 3D printing, modifying a 3D model in order to print several iterations of it is the easiest thing! You don’t have to create a mold and stick to it, you are free to adapt your parts. The flexibility offered by additive manufacturing in terms of designs and volumes is allowing easy customization.

The flexibility offered by additive manufacturing in terms of designs and volumes is allowing easy customization.

- Get a competitive advantage

Additive manufacturing is representing a real competitive advantage in a lot of sectors. This cutting-edge technology is speeding up the whole process and adding flexibility, which represents a real competitive advantage. Moreover, if your competitors are starting to use it and are ahead of your business in terms of implementation, you should start to worry about your competitiveness.

How to find the right partner for contract manufacturing

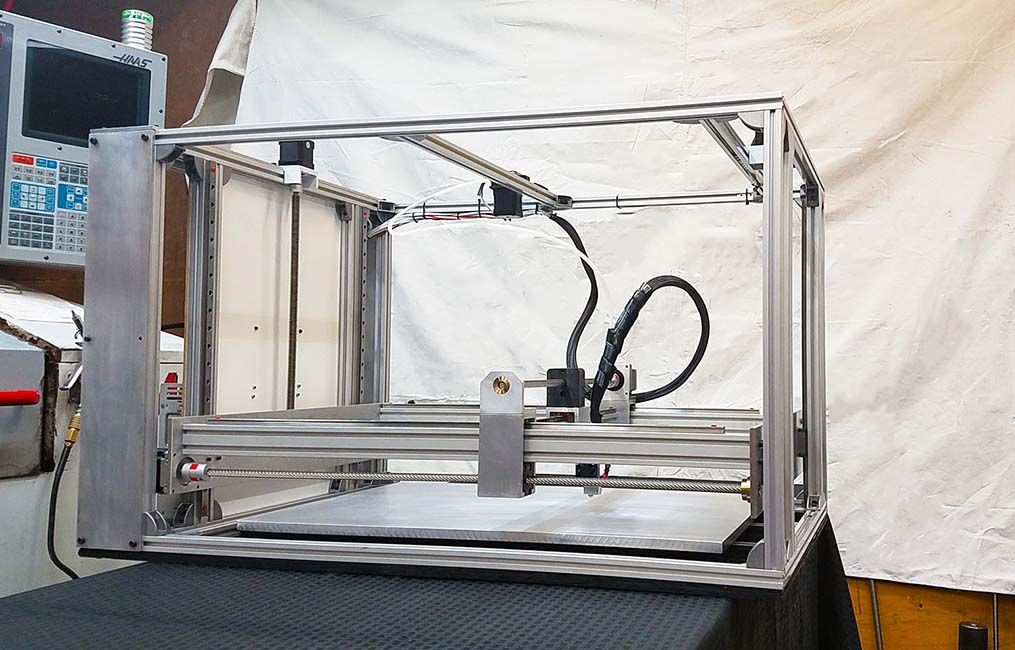

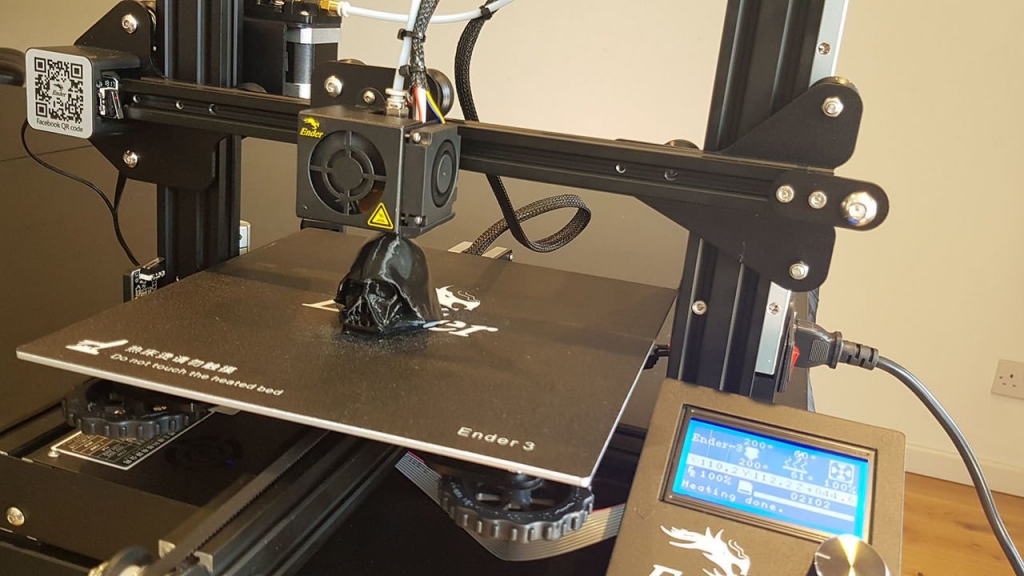

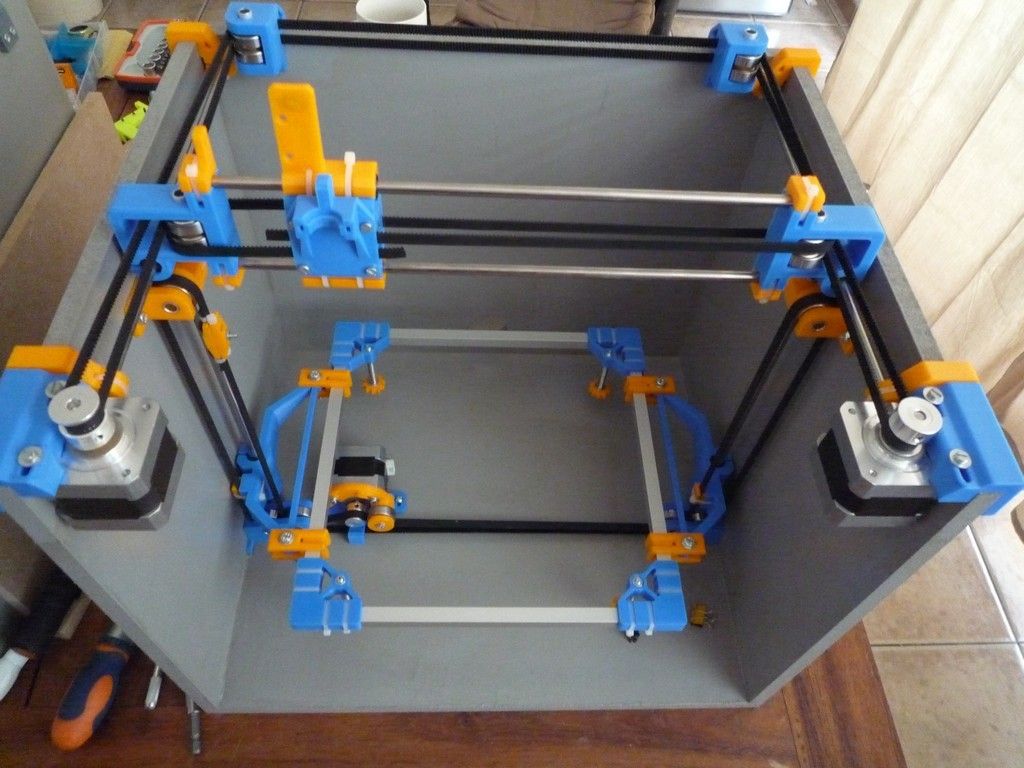

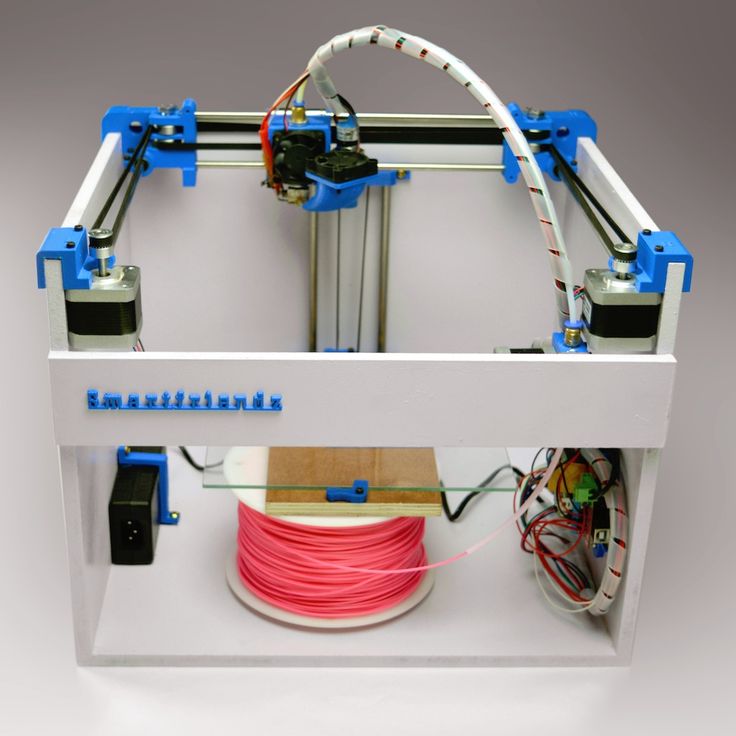

At Sculpteo, we know that implementing 3D printing in an existing process is not that easy. Moreover, industrial 3D printers are expensive and require experienced operators to get quality parts. Sculpteo’s 3D printing service specializes in industrial Additive Manufacturing to scale your production.

In just a few clicks, you can benefit from a professional service, more than 75 raw materials and finishes, professional analysis tools, and free automatic quotations to help you speed up your processes! Working with customers from all industries, Sculpteo perfectly knows how to meet industry requirements.

We are also offering consulting and design services with our 3D printing experts from Sculpteo Studio. Thanks to their advice and their expertise, implementing additive manufacturing will be easy and smart.

How can we help you scale up your production?

Do you already have your 3D file? Order your 3D printed parts in just a few clicks by uploading your 3D model on our website.

Or maybe you understand the potential of 3D printing and would like to implement this cutting-edge manufacturing technique inside your production, but you don’t know where to start? Don’t worry, our personalized consulting services will help you to figure this out, identifying all your opportunities. Our multidisciplinary team, made of both designers and engineers, will listen and support you in all of your additive manufacturing projects. Sculpteo’s expertise is at your disposal in order to help you make the most of 3D printing for contract manufacturing.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

3D Prototyping & Contract 3D Printing Services

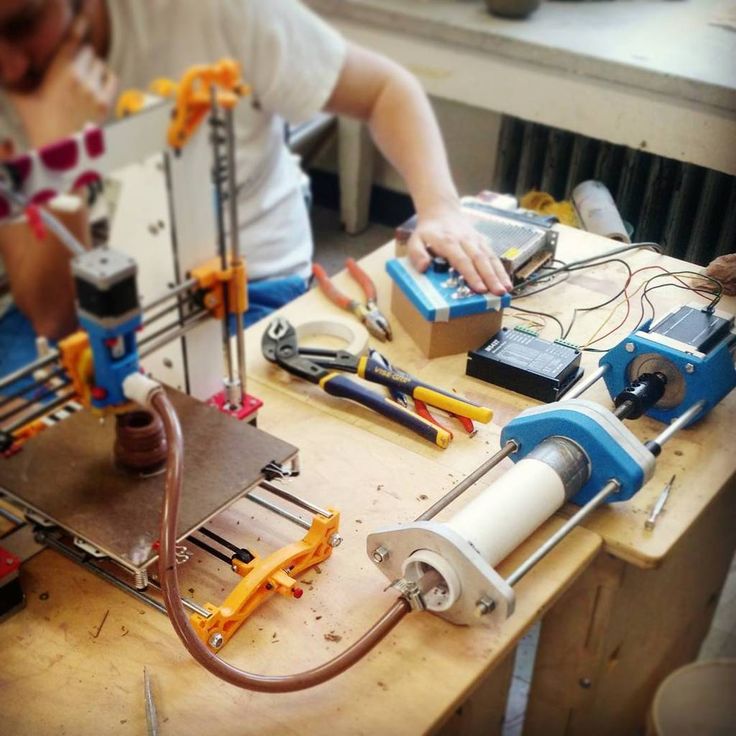

Contract 3D Printing is ideal for clients that are debating making the transition from traditional manufacturing to additive manufacturing. This technology is also great for engineers that need a prototype or a low volume production run for one specific application, but do not have a need for additive manufacturing on a regular basis.

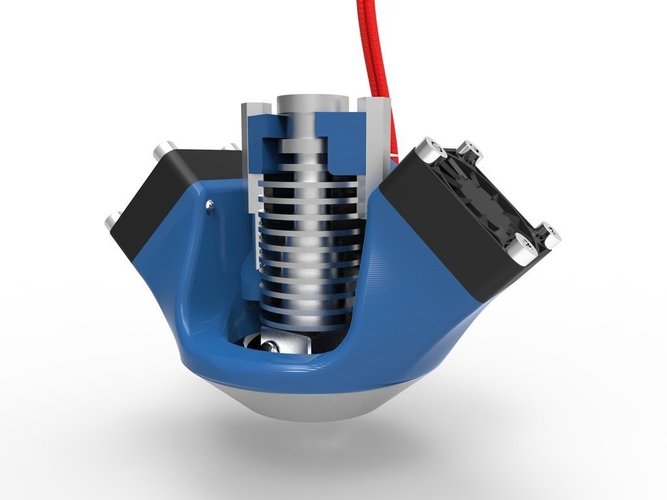

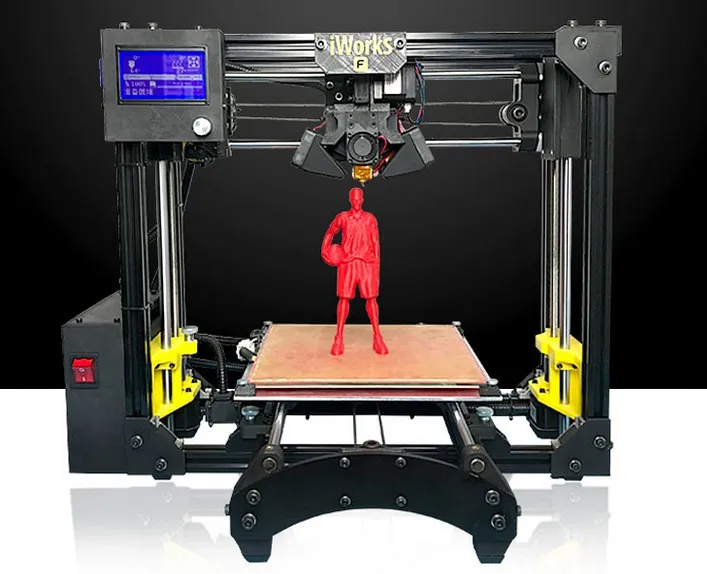

Miller 3D offers contract 3D printing services for R&D, prototyping, and low volume production parts. Our experienced additive manufacturing engineers will customize the parts according to the necessary specifications and intended use. Our 3D printing services also offers a wide variety of additive manufacturing materials, software, technology, and printers.

Once we receive the CAD design, our additive manufacturing engineers will evaluate the part, and the intended use. Next, we will create a customized 3D printing service plan for your specific application.

As a result, our client will receive custom parts that are created with less time, less material waste, and more detail than traditional manufacturing. This is the best way to see the difference that additive manufacturing can make for your business.

This is the best way to see the difference that additive manufacturing can make for your business.

When submitting CAD designs, please also include any and all intended use details. It’s also important for our team to be aware of any heat resistance, strength resistance, or biocompatibility requirements in the beginning of the contract 3D printing process.

Please note: we do not compete in contract pricing quotes with our clients.

Get a Quote for your 3D Part!

Contract 3D Printing

"*" indicates required fields

Email Address*

Project Name*

Project Details*

File

Acceptable 3D Model Filetypes: STL, OBJ, PLY, SLDPRT, CATPART, PRT, IGS, IGES, STP, STEP, XT, XB, SAT, WRL

Other uploadable filetypes: ZIP, PDF, DOC, XLS, PPT, JPG, PNG, TIF, TXT

Maximum Filesize: 20MB

Drop files here or

Accepted file types: stl, obj, ply, sldprt, catpart, prt, igs, iges, stp, step, xt, xb, sat, wrl, zip, pdf, doc, xls, ppt, jpg, png, tif, txt, Max. file size: 20 MB, Max. files: 4.

file size: 20 MB, Max. files: 4.

Miller 3D uses the latest additive manufacturing technology to transform our client’s CAD designs into parts accurately and efficiently. We also offer full transparency of the 3D Parts manufacturing process with our clients. If you have any questions about the contract 3D printing service, please do not hesitate to reach out to our team.

All file uploads are secure and confidential. If you need a non-disclosure agreement to move forward with your 3D Printing Service quote, please contact us at [email protected].

Rapid Prototyping Solutions

Save time and money with rapid prototyping solutions!

We proudly help our manufacturing clients bring their products to market faster. Additive manufacturing prototyping solutions feature low cost and quick-turn functionality so that the parts can be tested early and frequently during the process.

Prototyping parts and products using traditional methods is not always efficient on time or cost. Especially when it comes to the production of something that may or may not work for the application. Therefore, the Miller 3D printing engineers are ready to help our clients improve profitability and efficiency with our 3D prototyping printing services.

Especially when it comes to the production of something that may or may not work for the application. Therefore, the Miller 3D printing engineers are ready to help our clients improve profitability and efficiency with our 3D prototyping printing services.

Our 3D printing engineers are happy to answer any questions regarding materials capabilities that the part will need to withstand. This includes, but is not limited to heat resistance, strength resistance, and biocompatibility. From there, we can recommend the best ways to optimize the success of the prototype.

In addition, we proudly offer 3D metal printing prototyping. Now, our clients can not only assess how the part will fit, but also how it will withstand stress, and heat. Therefore, it provides a more accurate result when testing the prototype.

The 3D Printing Team Behind Your Additive Manufacturing Project

At Miller 3D, we keep an inventory of materials and printers within our manufacturing center. We proudly offer contract 3D Printing services because it provides our team with updated experience on the latest additive manufacturing innovations. Our team also trains exclusively with our partners; Markforged, 3D Systems, and Bigrep, especially when a new level of innovation is introduced. These tutorials provide us with a knowledge base and skillset for the 3D printers and materials we are using.

We proudly offer contract 3D Printing services because it provides our team with updated experience on the latest additive manufacturing innovations. Our team also trains exclusively with our partners; Markforged, 3D Systems, and Bigrep, especially when a new level of innovation is introduced. These tutorials provide us with a knowledge base and skillset for the 3D printers and materials we are using.

This experience directly benefits our 3D printing contract clients. We are eager to apply this experience to complicated designs, and intricate applications. In addition, we can consult our network of 3D printing professionals if needed. If our additive manufacturing engineers have the printers and materials available in our local manufacturing center, we will complete the application in house. However, if the technology is not available locally, we will out source the project to the applicable partner.

The Difference Between Additive and Subtractive Manufacturing

The One Miller team understands that additive and subtractive manufacturing must work in unison to be effective. When it comes to fabrication technologies, one size does not fit all because each method contains its own set of benefits and limitations.

When it comes to fabrication technologies, one size does not fit all because each method contains its own set of benefits and limitations.

Since additive manufacturing is much more versatile, the designs for the parts have almost no limitations. Here at Miller 3D, we can create parts that are much lighter, but just as strong as their machined counterparts. In addition, 3D printing is great for highly detailed, intricate designs. The engineer can also customize each part of the low volume production run as needed. Utilizing 3D part manufacturing methods for prototyping and low volume production also increases cost and time efficiency when compared to traditional manufacturing. In addition, there is very minimal material waste and the post-production inspection methods are much more advanced.

When it comes to production in large volumes, subtractive manufacturing is the favorable method. The parts come out stronger than with 3D printing because the original integrity of the material is preserved. As a result, the overall quality of the build is higher. Commonplace subtractive manufacturing methods, such as CNC machining also does not leave behind any visible layer lines. So, the parts require little to no post-processing.

As a result, the overall quality of the build is higher. Commonplace subtractive manufacturing methods, such as CNC machining also does not leave behind any visible layer lines. So, the parts require little to no post-processing.

The One Miller Team Advantage to Additive and Subtractive Manufacturing

Since the One Miller team caters to both additive and subtractive manufacturing, we have the knowledge base to help your company reach their manufacturing goals for optimal efficiency and profitability. We understand the entirety of the manufacturing industry, and everything that goes into it. This means that our clients benefit from this wide range of experience. If we see an application that could be improved with the other method, we will work with our colleagues to find the solution internally. There are also projects that benefit from a hybrid approach, combining both methods for a truly unique result.

Public offer agreement | 3D printing and scanning studio

IP NAZAROV EVGENIY VYACHESLAVOVICH

Phone: +7 (812) 649-18-29

1.

General provisions

General provisions 1.1. IE "Nazarov E.V.", hereinafter referred to as the "Seller", publishes a Public Offer for the sale of goods according to the samples presented on the Seller's official website www.3d-pechat-spb.ru/

1.2. In accordance with Article 437 of the Civil Code of the Russian Federation (CC RF), this document is a public offer, and if the conditions set out below are accepted, the individual accepting this offer pays for the Seller's Goods in accordance with the terms of this Agreement. In accordance with paragraph 3 of Article 438 of the Civil Code of the Russian Federation, payment for the Goods by the Buyer is an acceptance of the offer, which is considered equivalent to the conclusion of the Agreement on the conditions set forth in the offer.

1.3. Based on the foregoing, carefully read the text of the public offer, and if you do not agree with any clause of the offer, you are invited to refuse to purchase the Goods or use the Services provided by the Seller.

1.4. In this offer, unless the context requires otherwise, the following terms have the following meanings: • "Offer" - the Seller's public offer addressed to any individual (citizen) to conclude a sales contract with him (hereinafter referred to as the "Agreement") on the existing terms contained in the Agreement, including all its annexes. • "Buyer" - an individual who has entered into an Agreement with the Seller on the terms and conditions contained in the Agreement. • "Acceptance" - full and unconditional acceptance by the Buyer of the terms of the Agreement. • "Product" - a list of product range items presented on the official website. • "Order" - individual items from the assortment list of the Goods specified by the Buyer when placing an order on the website or through the Operator. • "Delivery" - services for the delivery of the Order.

2. Subject of the contract

2.1. The Seller sells the Goods in accordance with the current price list published on the Seller's website "www. 3d-pechat-spb.ru/", and the Buyer makes payment and accepts the Goods in accordance with the terms of this Agreement.

3d-pechat-spb.ru/", and the Buyer makes payment and accepts the Goods in accordance with the terms of this Agreement.

2.2. This Agreement and its appendices are official documents of the Seller and an integral part of the offer.

3. Ordering

3.1. The order of the Goods is carried out by the Buyer through the Internet site www.3d-pechat-spb.ru/.

3.2. When registering on the Seller's website, the Buyer undertakes to provide the following registration information about himself: • last name, first name, • actual delivery address; • E-mail address; • contact phone (mobile, landline).

3.3. When placing an Order through the Operator, the Buyer undertakes to provide the information specified in clause 3.2. actual agreement. Acceptance by the Buyer of the terms of this Agreement is carried out by entering the relevant data into the registration form on the Website or when placing an Order through the Operator. The buyer has the right to edit the registration information about himself. The Operator does not change or edit the registration information about the Buyer without the consent of the latter. The Seller undertakes not to disclose the Buyer's data specified during registration on the website www.3d-pechat-spb.ru/ and when placing an Order to persons not related to the execution of the Order. Having approved the Order of the selected Goods, the Buyer provides the Operator with the necessary information in accordance with the procedure specified in clause 3.2. actual agreement.

The Operator does not change or edit the registration information about the Buyer without the consent of the latter. The Seller undertakes not to disclose the Buyer's data specified during registration on the website www.3d-pechat-spb.ru/ and when placing an Order to persons not related to the execution of the Order. Having approved the Order of the selected Goods, the Buyer provides the Operator with the necessary information in accordance with the procedure specified in clause 3.2. actual agreement.

3.4. The Seller and the Operator are not responsible for the content and accuracy of the information provided by the Buyer when placing the Order.

3.5. The Buyer is responsible for the accuracy of the information provided when placing the Order.

3.6. Payment by the Buyer of the Order independently placed on the website means the Buyer's consent to the terms of this Agreement. The day of payment for the Order is the date of conclusion of the Purchase Agreement between the Seller and the Buyer.

3.7. All information materials presented on the website www.3d-pechat-spb.ru/ are for reference only and cannot fully convey reliable information about certain properties and characteristics of the Goods. If the Buyer has any questions regarding the properties and characteristics of the Goods, before placing the Order, he must seek advice from the Operator.

4. Order fulfillment terms

4.1. The term of execution of the Order depends on the availability of the ordered items of the Goods in the Seller's warehouse and the time required to process the Order. The deadline for the execution of the Order in exceptional cases may be agreed with the Buyer individually, depending on the characteristics and quantity of the ordered Goods. In the absence of a part of the Order in the warehouse of the Seller, including for reasons beyond the control of the latter, the Seller has the right to cancel the specified Goods from the Buyer's Order. The Seller undertakes to notify the Buyer about the change in the completeness of his Order through the Operator.

4.2. The order is considered delivered at the moment of its transfer to the Buyer. By signing on the courier's sheet, the Buyer confirms the execution of the Order.

4.3. If the Buyer provides false information about his contact details, the Seller is not responsible for the improper execution of the Order.

4.4. In case of improper execution of the delivery of the Order due to the fault of the Seller, the second delivery of the Order is free of charge.

5. Payment for the Order

5.1. Payment for the executed Order is carried out by transferring funds by the Buyer to the Delivery employee. A sales receipt is a confirmation of payment for the executed Order. Reception of funds

5.2. The prices for any items of the Goods indicated on the website "www.3d-pechat-spb.ru/" can be changed by the Seller unilaterally without notifying the Buyer. In the event of a change in the price of the ordered items of the Goods, the Operator undertakes to inform the Buyer of such a change as soon as possible. The Buyer has the right to confirm or cancel the Order. In the absence of communication with the Buyer, the Order is considered canceled within 14 calendar days from the date of registration.

The Buyer has the right to confirm or cancel the Order. In the absence of communication with the Buyer, the Order is considered canceled within 14 calendar days from the date of registration.

5.4. For all orders with delivery in Russia, the conditions are indicated on the website of IP Nazarov E.V. www.3d-pechat-spb.ru/price/ in the "Payment and Delivery" section. They must be agreed with the Operator.

5.5. Funds are accepted in two ways: cash, non-cash payment

6. Delivery of goods.

6.1 The Seller's obligation to supply the Goods with the condition of its delivery is considered fulfilled from the moment the Buyer signs the shipping documents

6.2. The ownership of the Goods and the risks of accidental damage and / or loss of the Goods are transferred to the Buyer from the moment of the actual transfer of the Goods and signing of the shipping documents upon delivery of the Goods to the Buyer.

6.3 The cost of delivery and conditions are indicated on the company's website "www. 3d-pechat-spb.ru/price/".

3d-pechat-spb.ru/price/".

7. Order return

7.1. In accordance with paragraph 4. Art. 26.1. Law of the Russian Federation No. 2300-I "On Protection of Consumer Rights" The Buyer has the right to refuse the ordered Goods at any time until the Order is executed.

7.2. The Buyer is not entitled to refuse the paid Order (or part thereof) of proper quality, having individually defined properties.

7.3. In accordance with paragraph 2 of the "List of non-food products of good quality that are not subject to return or exchange for similar goods of other sizes, shapes, dimensions, styles, colors or configurations", approved by Decree of the Government of the Russian Federation of 19.01.1998 No. 55.

7.4. In the event that the Seller delivers an Order of inadequate quality, the Buyer undertakes to provide the Goods to the Seller's office as soon as possible to check the quality of the Goods.

7.5. In accordance with Art. 22 of the Law of the Russian Federation No. 2300-I "On Protection of Consumer Rights", the amount paid by the Buyer for the Goods of inadequate quality is subject to return to the Buyer within 10 calendar days from the date of presentation of the relevant request. Refunds are made in cash at the Seller's office, in case of paid delivery, the money for it is not returned. If the Goods were paid for through the electronic payment system, then the refund is made to the Buyer's electronic account within 5 working days.

2300-I "On Protection of Consumer Rights", the amount paid by the Buyer for the Goods of inadequate quality is subject to return to the Buyer within 10 calendar days from the date of presentation of the relevant request. Refunds are made in cash at the Seller's office, in case of paid delivery, the money for it is not returned. If the Goods were paid for through the electronic payment system, then the refund is made to the Buyer's electronic account within 5 working days.

7.6 Goods of proper quality, not subject to return in accordance with Decree of the Government of the Russian Federation of 20.10.1998 N 1222, of 06.02.2002 N 81:

Products and materials in contact with food, made of polymeric materials, including for single use (tableware and tableware and kitchen utensils, containers and packaging materials for storage and transportation of food products)

Non-periodical publications (books, brochures, albums, cartographic and musical publications, sheet art publications, calendars, booklets, publications reproduced on technical media ) (clause 14 was introduced by Decree of the Government of the Russian Federation of 06. 02.2002 N 81)

02.2002 N 81)

Articles made of precious metals, with precious stones, of precious metals with inserts of semi-precious and synthetic stones, faceted precious stones.

7.7. The return of the Goods shall be made on the basis of a written request of the Buyer submitted to the sales office of the Seller.

7.8. The return of the Goods of good quality is carried out at the expense of the Buyer and is organized by him independently.

7.9. Return of the Goods is made on business days from 10-00 to 20-00 at the Seller's sales office.

7.10. When the Buyer returns the Goods of good quality, an invoice or an act on the return of the goods is drawn up, which indicates:

- the full company name of the Seller;

- last name, first name, patronymic and passport details of the Buyer;

- Product name;

- reason for returning the Goods;

- date of transfer of the Goods;

- amount to be returned;

- signatures of the Seller and the Buyer.

7.11. The cost of the Goods shall be returned no later than 10 (ten) days from the date the Buyer submits the relevant request.

7.12. To return funds to a bank card, the Customer must fill out the "Application for the return of funds", which is sent at the request of the Company to the Customer's email address, and send it along with a copy of the passport to the address: [email protected]. The refund will be made to the Customer's bank account specified in the application within 10 (Ten) working days from the date of receipt of the "Application for the return of funds" by IP Nazarov E.V.

In order to return funds credited to the settlement account of the individual entrepreneur by mistake through payment systems, the Customer must apply with a written application and attach a copy of the passport and checks / receipts confirming the erroneous crediting. This application must be sent to: [email protected]. After receiving a written application with a copy of the passport and checks / receipts attached, the Company makes a refund within 10 (ten) business days from the date of receipt of the application to the Customer's settlement account specified in the application. In this case, the refund amount will be equal to the cost of the Order.

In this case, the refund amount will be equal to the cost of the Order.

The term for consideration of the Application and return of funds to the Customer begins to be calculated from the moment the Company receives the Application and is calculated in working days, excluding holidays / weekends. If the application is received by the Company after 18:00 on a working day or on a holiday/day off, the moment the Company receives the Application is the next business day.

The Buyer must submit the request for the return of the goods to the Seller either in writing to the address 194017, St. Petersburg, Yaroslavsky pr-t, 14, apt. 1, or electronically to the email address [email protected]. The request can be made in free form with the obligatory indication of the Buyer's contact details that match those specified when ordering the Goods, the name of the returned Goods and the reasons for the return. The Buyer has the right to ask all the questions to the Seller by phone +7 (812) 649-18-29.

8. Copyright

8.1. All textual information and graphic images posted on the website www.3d-pechat-spb.ru/ are the property of the Seller and/or its suppliers and manufacturers of the Goods.

9. Rights, obligations and liability

9.1. The Seller is not responsible for the improper use of goods by the Buyer ordered on the website or through the Operator.

9.2. The Seller has the right to transfer its rights and obligations for the execution of Orders to third parties.

9.3. The Seller has the right to record telephone conversations with the Buyer. In accordance with paragraph 4 of Art. 16 of the Federal Law "On Information, Information Technologies and Information Protection" the Seller undertakes: to prevent attempts of unauthorized access to information and / or transfer of it to persons who are not directly related to the execution of Orders; timely detection and suppression of such facts. Telephone conversations are recorded in order to control the activities of the Operator and control the quality of execution of Orders.

9.4. Ownership of the Order, as well as the risk of its accidental loss or damage, passes to the Buyer from the moment the funds are transferred to the Delivery employee.

9.5. The Buyer has the right to send all claims for improper execution of the order to the e-mail address [email protected], indicated on the website www.3d-pechat-spb.ru/contact/, in the "Contacts" section. All received information is processed as soon as possible.

IP Nazarov E.V.

Achievement of metal 3D printing and contract DARPA, Sigma Labs and Honeywell Aerospace

#SIU_news 06/16/2020

Sigma Labs of Santa Fe, NM, announced their new contract with Honeywell Aerospace. The project is expanding its work with DARPA (US Defense Advanced Research Projects Agency) through the Open Manufacturing (OM) program - or Open Manufacturing. Sigma Labs was founded in 2005 by scientists from the renowned Los Alamos National Lab.

The contract, valued at $400,000, sees Sigma Labs continue to work on its PrintRite3D® technology. Mark Cola, President and CEO of Sigma Labs explains:

Mark Cola, President and CEO of Sigma Labs explains:

PrintRite3D® technology accelerates manufacturing processes such as 3D laser printing for precision metal parts. Through this, we will be in a position to demonstrate that our PrintRite3D® software can be a key enabler for the development of quality assurance standards in the processing of aerospace component metals through the use of additive manufacturing.

This news marks the third stage of the contract between Honeywell and Sigma Labs. With this, metal-based 3D printing could become a more widely used technology. In a previous interview, DARPA's Open Manufacturing Program Director explained how the agency has been evaluating the prospects for 3D printing since the late 1990s. The Pentagon Innovation Agency has two areas related to additive manufacturing: the Rapid Low Cost Additive Manufacturing (RLCAM or "fast and affordable additive manufacturing") and Titanium Fabrication (tiFAB or "titanium printing").

Metal 3D Printing Diffusion

The OM DARPA program is focused on reducing the barriers to metal 3D printing adoption by addressing three issues: speed, cost, and repeatability. While multinational companies such as General Electric are using 3D printing to make components for the aerospace industry, manufacturing filler metal is still in its early stages.

While multinational companies such as General Electric are using 3D printing to make components for the aerospace industry, manufacturing filler metal is still in its early stages.

DARPA OM Program Director Mick Maher explains how work is progressing:

We've put together a wireframe using physics-based models. A network of physics-based models model everything from a layer of powder to a molten bath with a laser. We are running a series of experiments to calibrate these models so that we understand how these parameters affect the properties and microstructure that are developed in the metal and include some of the environmental or starting conditions, such as powder particle size or its chemical composition.

Critical work and breakthroughs in understanding

Sigma Labs and its quality control software will play an important role in increasing understanding and controlling the formation of metrology departments. The high temperatures reached inside the metal powder layer in 3D printing are a particular challenge for manufacturers and are also the focus of scientists working in national laboratories such as NIST and Lawrence Livermore.